Rotary wheel of rotary wheel type dehumidifier

A rotary wheel dehumidifier and rotary wheel technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of difficult repair, increased energy consumption, low actual efficiency, etc., and achieve long service life, rotation Good sealing and good purging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

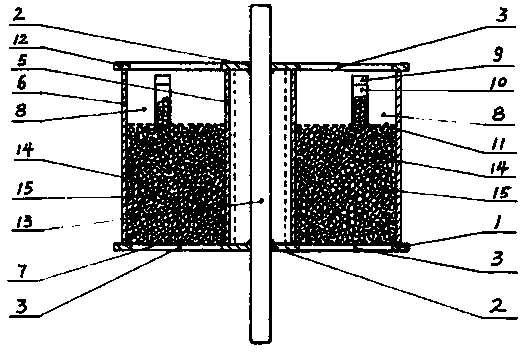

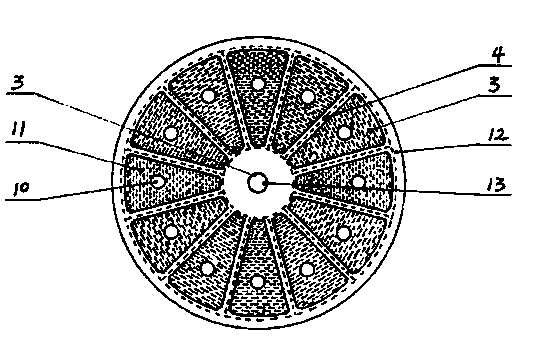

[0014] See figure 1 with figure 2 , in the runner of the runner dehumidifier of the present embodiment, a central circular hole 2 is provided in the middle of the circular lower supporting plate 1, and 12 equal holes are arranged on an annular plane close to the edge at an appropriate distance from the central circular hole 2. The fan-shaped ventilation openings 3 of the cloth and the spacer strips 4 that are radial to each other; the positioning sleeves 5 and the peripheral cylinders 6 of the same height are respectively provided on the inner side and the outer side near the fan-shaped ventilation openings 3; The upper surface of the air vent 3 is also provided with a material support mesh plate 7 connected to its edge, and a material partition plate 8 with the same height as it and connected with it is arranged between the positioning sleeve 5 and the peripheral cylinder 6. On each spacer slat 4, the middle part is provided with the cover material mesh plate 11 of the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com