Heat exchanger structure

A technology of heat exchangers and heat exchange tubes, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc. The heat exchange efficiency of the heat exchanger and other issues can be improved to improve the heat exchange effect, reduce the possibility of equipment blockage and failure, and achieve good purging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

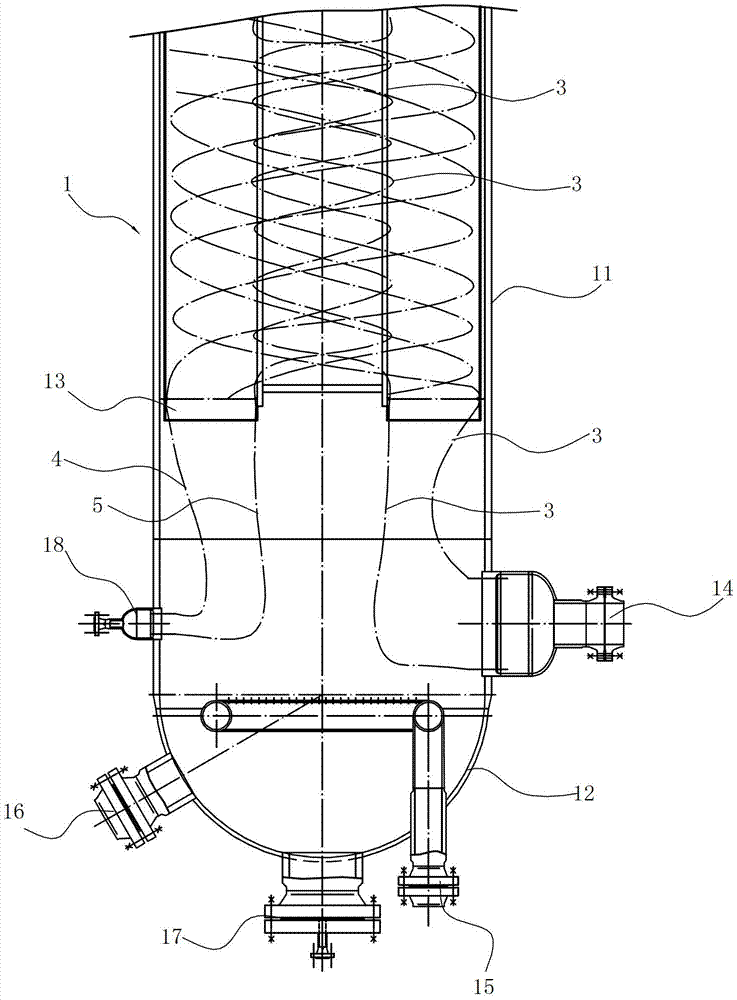

[0016] Such as figure 1 with figure 2 As shown, this embodiment takes a vertical heat exchanger as an example for description, and the technology of the present invention is also applicable to a horizontal heat exchanger. The heat exchanger structure includes:

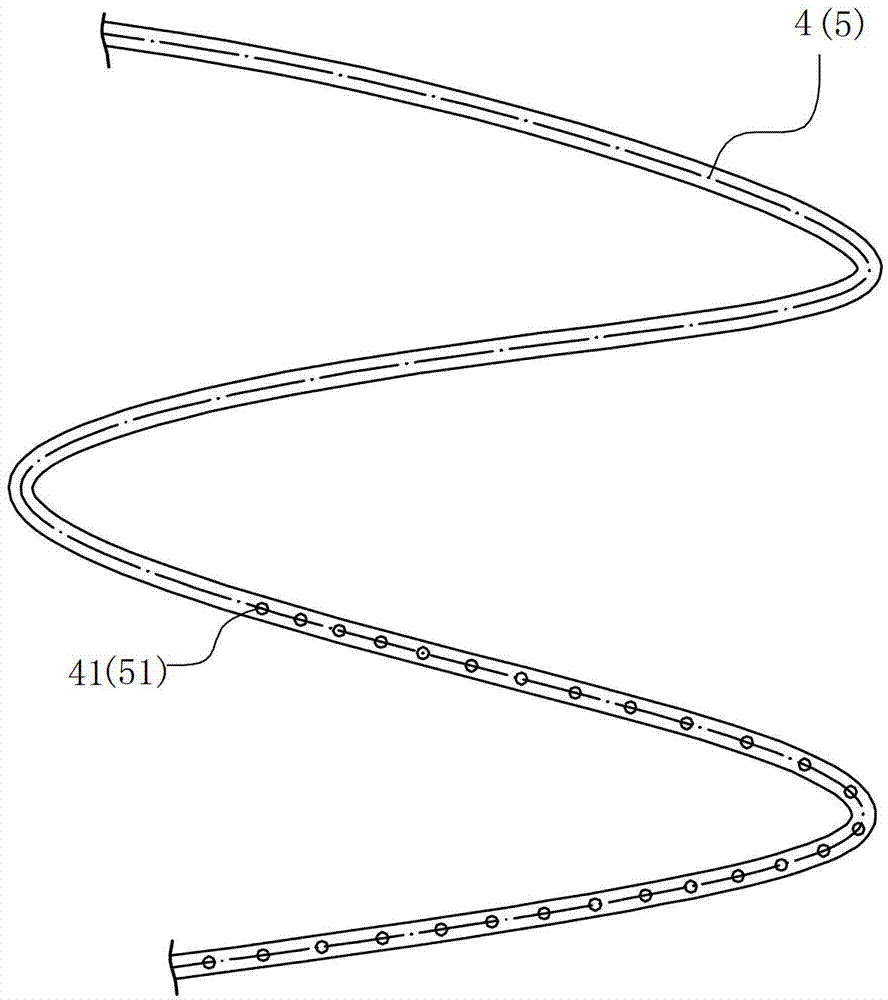

[0017] The casing 1 is a closed structure, including an upright cylinder 11, an upper head (not shown in the figure) and a lower head 12 arranged at both ends of the cylinder, and the two ends of the cylinder inside the casing are also provided with parallel The first tube sheet (not shown in the figure) and the second tube sheet 13, the shell is provided with a tube side inlet (not shown in the figure), a tube side outlet 14, a shell side gas phase inlet 15, a shell side liquid phase Inlet 16, shell side outlet (not shown in the figure) and condensate discharge port 17, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com