Drying stirrer and treatment system and method for silicon tetrachloride slag slurry in cold hydrogenation technology

A technology of silicon tetrachloride and agitator, which is applied in the direction of drying solid materials, drying gas arrangement, non-progressive dryers, etc., can solve problems such as uneven heating, blind areas, and no circulating flow of slurry, so as to reduce leakage The effect of risk, stirring and heating evenly, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

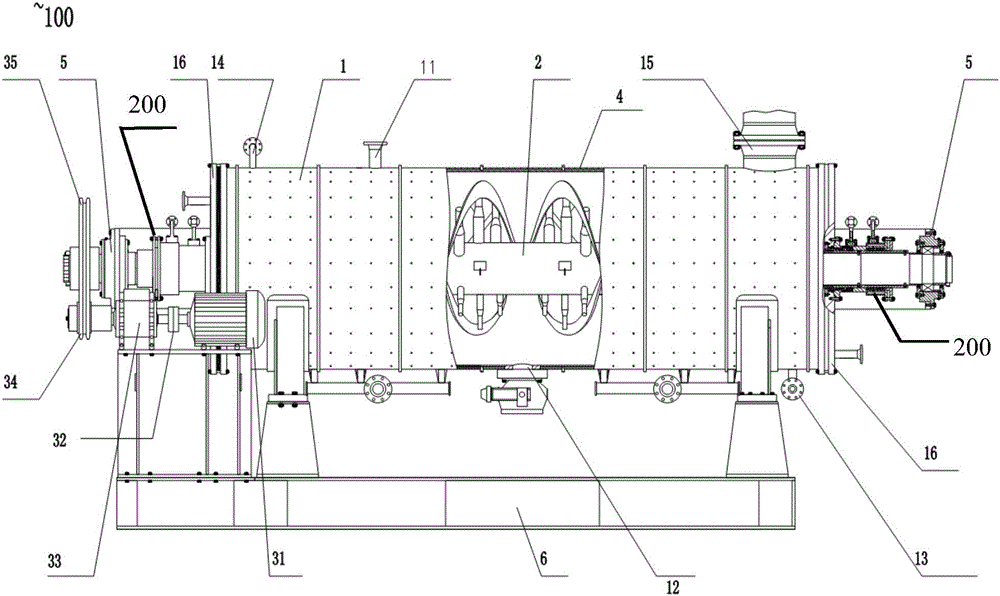

[0097] Please also refer to Figure 1-Figure 11 , is a schematic structural diagram of a dry mixer 100 for silicon tetrachloride slurry in a cold hydrogenation process provided by a preferred embodiment of the present invention.

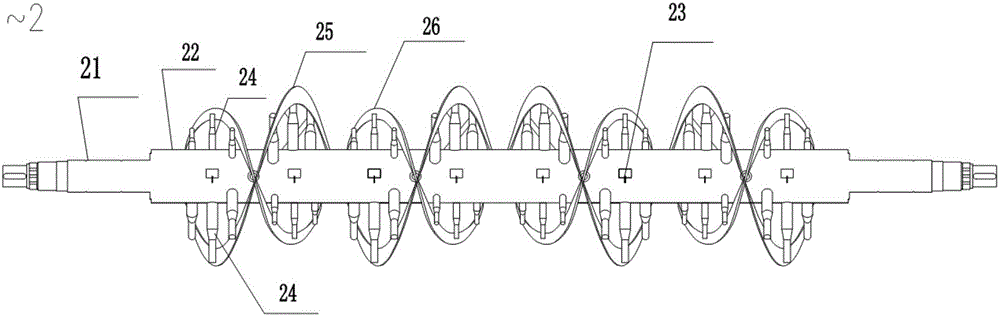

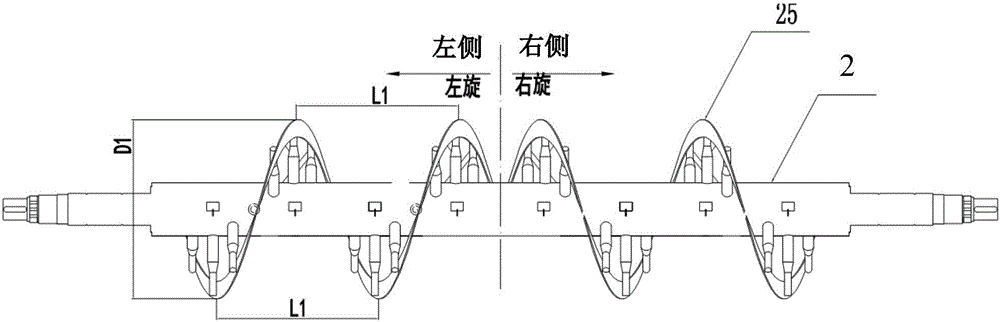

[0098] The dry mixer 100 includes a housing 1, a stirring shaft 2, a transmission device 3 ( figure 1 The label is not shown in), the housing 1 is surrounded to form a drying chamber, the top and bottom of the housing 1 are respectively provided with a feed port 11 and a discharge port 12, as preferably, the discharge port 12 is located at The center of the bottom of the housing 1. The stirring shaft 2 is placed horizontally in the drying chamber for stirring the slurry in the drying chamber driven by the transmission device 3 . Both left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com