Vacuum high-pressure casting method

A high-pressure casting and vacuum technology, which is applied in the field of vacuum high-pressure casting technology, can solve the problems of reducing the process quality and mechanical properties of castings, and achieve the effects of eliminating solidification shrinkage defects, shrinkage cavity and loose defects, and good feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment do further description:

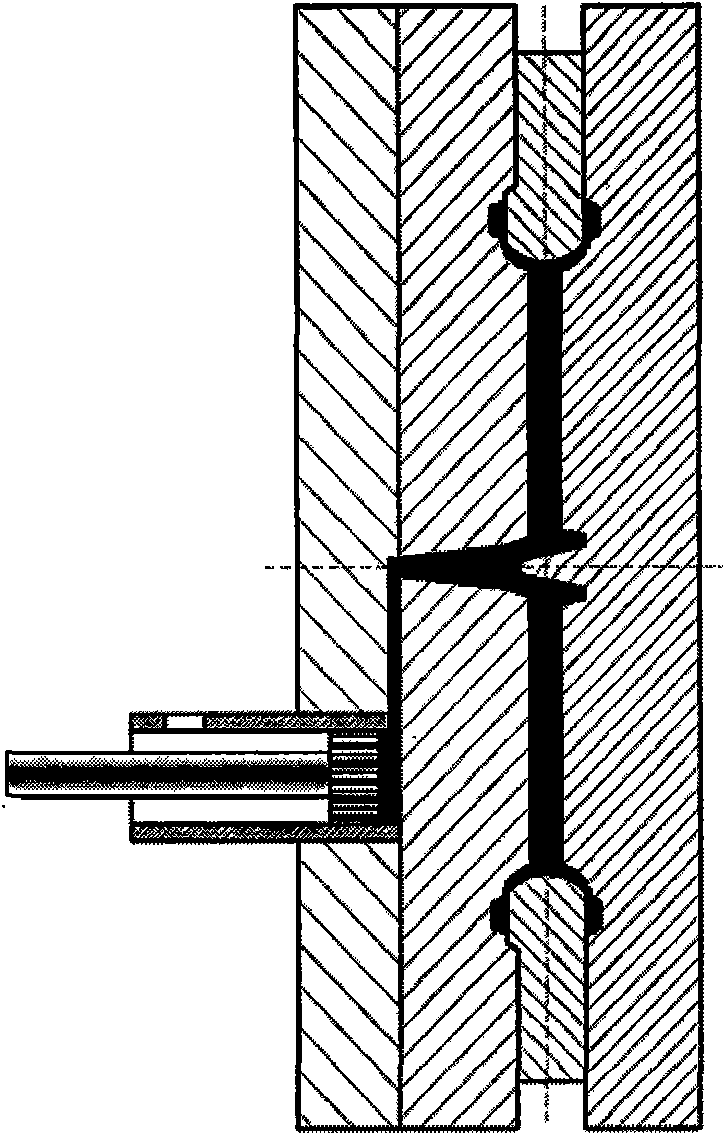

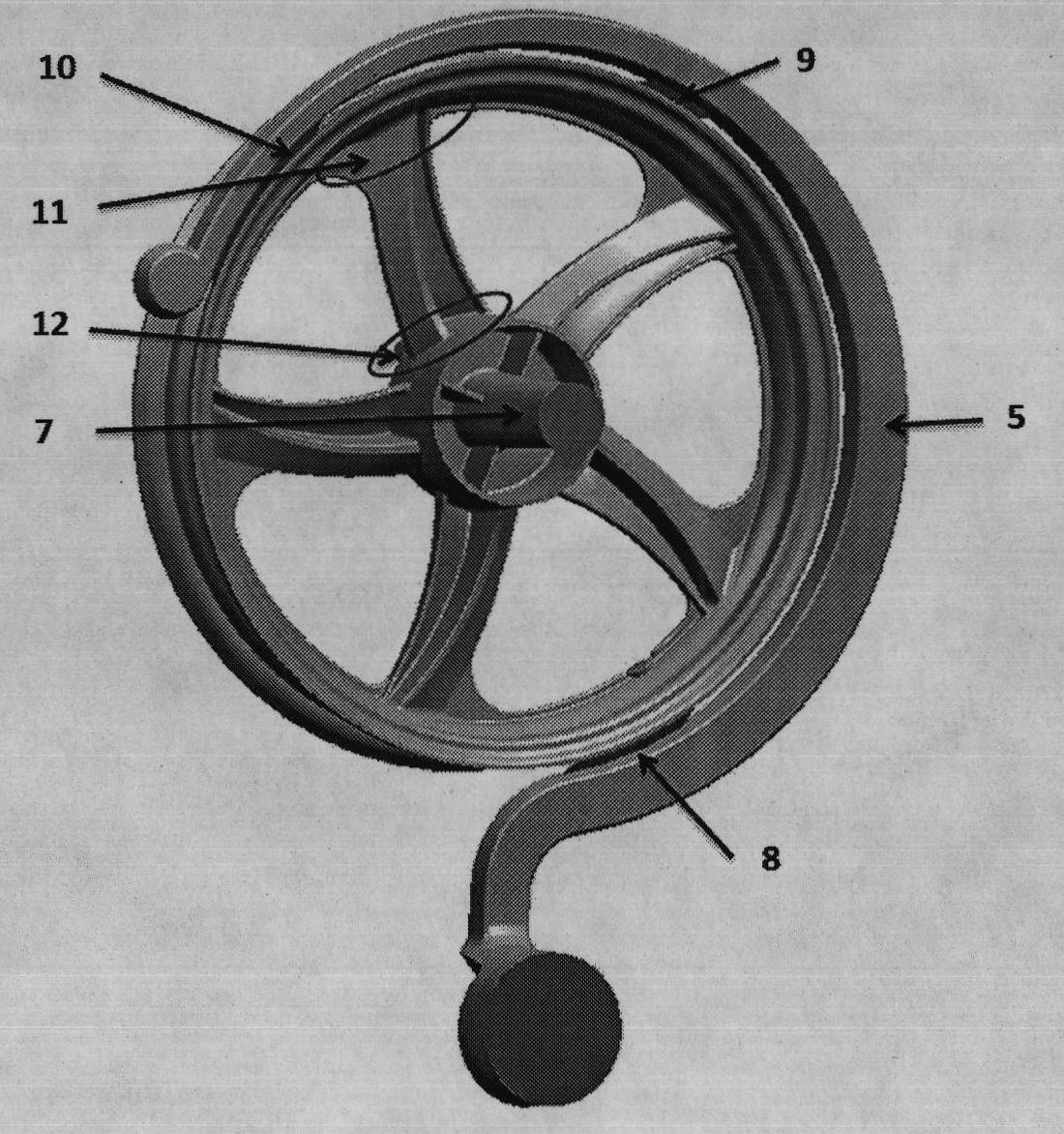

[0023] The embodiment takes the vacuum die-casting process of a motorcycle hub as an example. The process adopts vertical parting, annular tangential vacuum filling, and central pressure supplementation. The process is as follows:

[0024] 1. Vacuum high-pressure filling: the alloy melt (4) is quantitatively injected into the pressure chamber (2) through the sprue (1), and the extrusion head (3) moves forward to close the sprue (1) to form a closed cavity and then vacuumize; The head (3) continues to move forward to complete the filling of the rim, spokes and wheel center in sequence, and completes the vacuuming before the filling is completed; see the filling process Figure 4 .

[0025] 2. Pressurized solidification: After the mold filling is completed, the pressure head (3) and the pressure filling head (6) are pressurized and maintained together, so that the alloy melt (4) in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com