Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Consistent workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

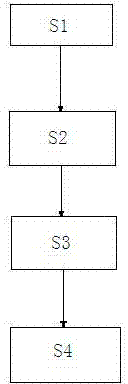

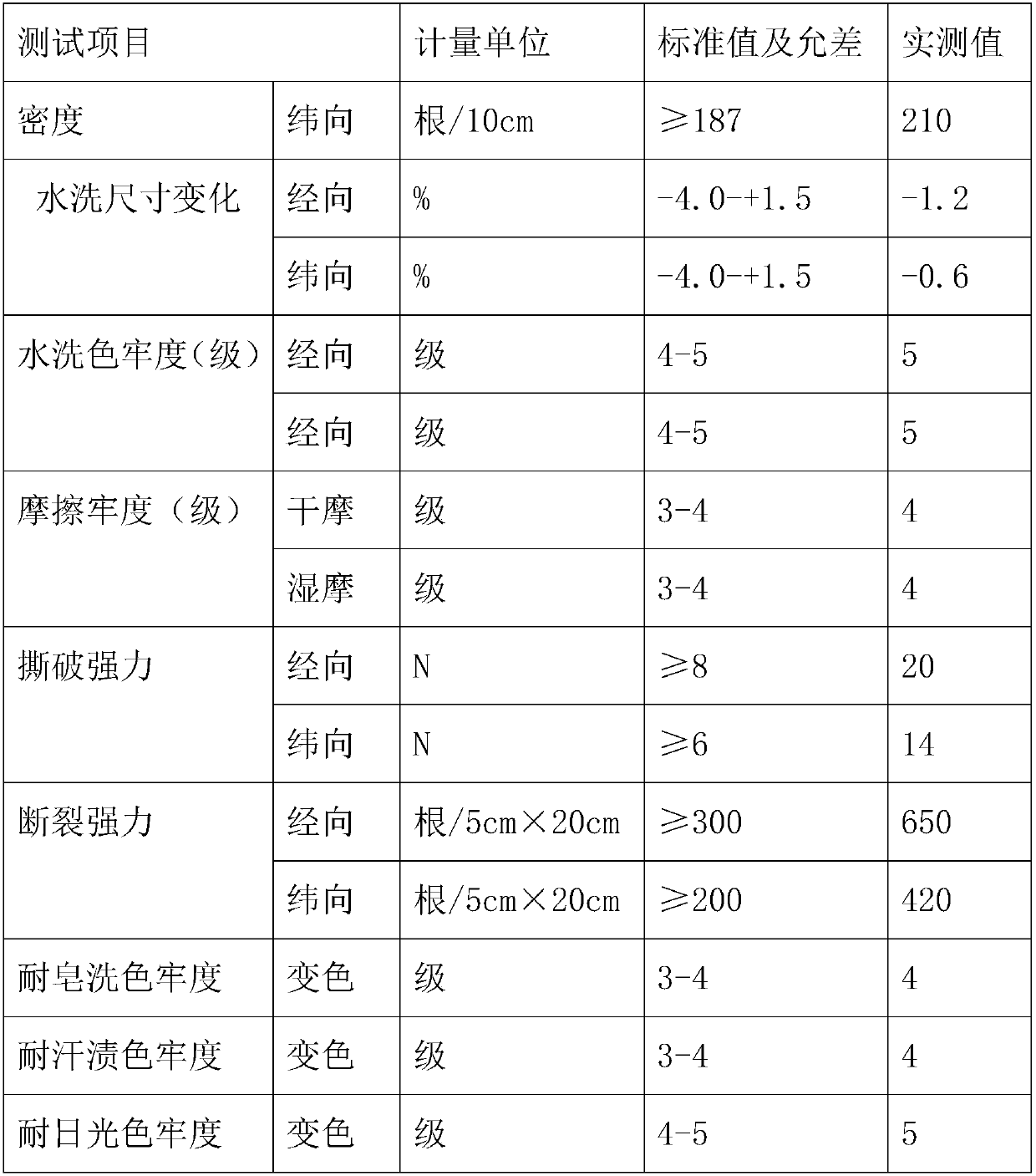

Dyeing and printing technology of camouflage fabric

InactiveCN105040490AImprove tensile propertiesImprove printing and dyeing adsorption functionDyeing processWoven fabricsCamouflagePolyester

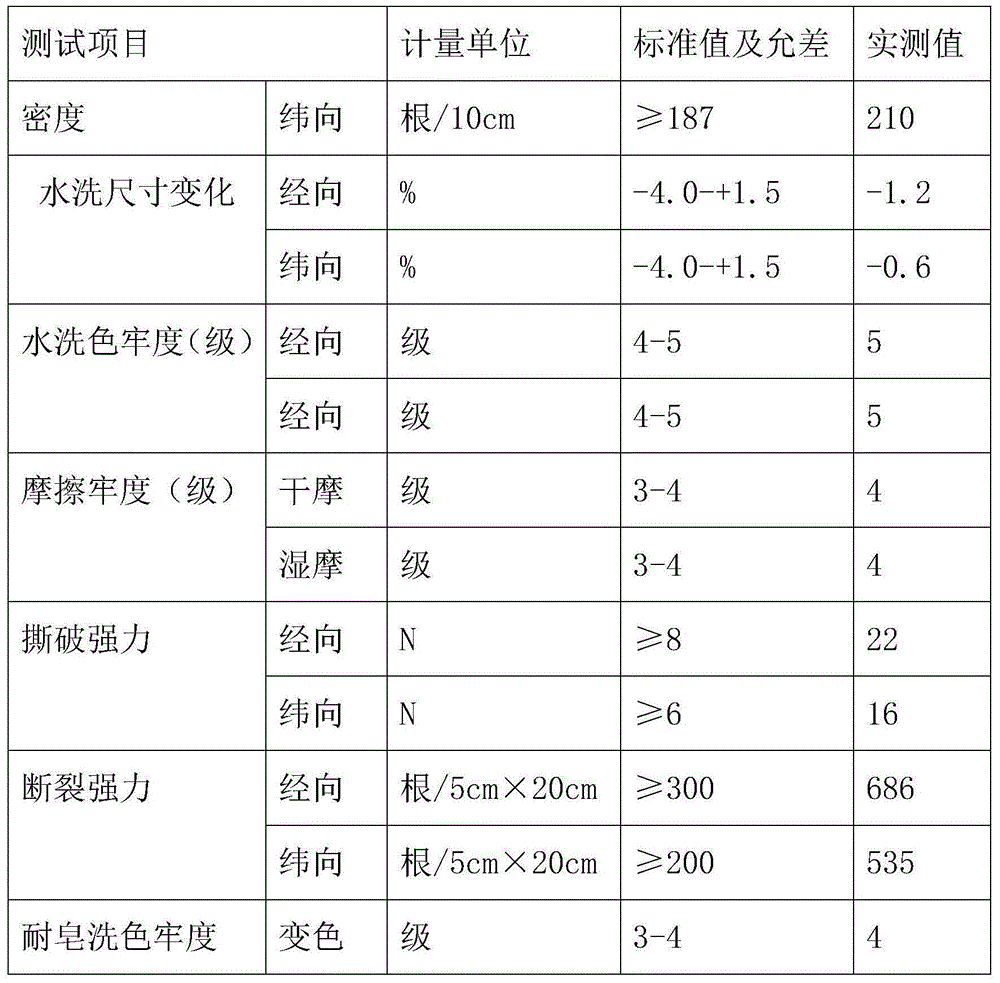

The invention discloses a dyeing and printing technology of a camouflage fabric. The camouflage fabric is prepared by blending and interweaving the following raw materials in percentage by weight: 30%-50% of cotton fiber, 30%-50% of polyester fiber, 10%-30% of spandex fiber and 10%-20% of spun silk fiber. The dyeing and printing technology comprises the following steps: S1 singeing; S2 cold heaping; S3 alkaline washing; S4 mercerizing; S5 ground dyeing; S6 printing; S7 waterproof and flame-proof treatment; and S8 stentering pre-shrinking. According to the dyeing and printing technology of the camouflage fabric, the high color fastness of the dyed ground color and the front and rear stability of the color of the camouflage fabric can be ensured; the camouflage printing requirements can be met; the quality repeatability is good; and the quality index of the finished product can meet the customer requirements.

Owner:芜湖市瑞都服装贸易有限公司

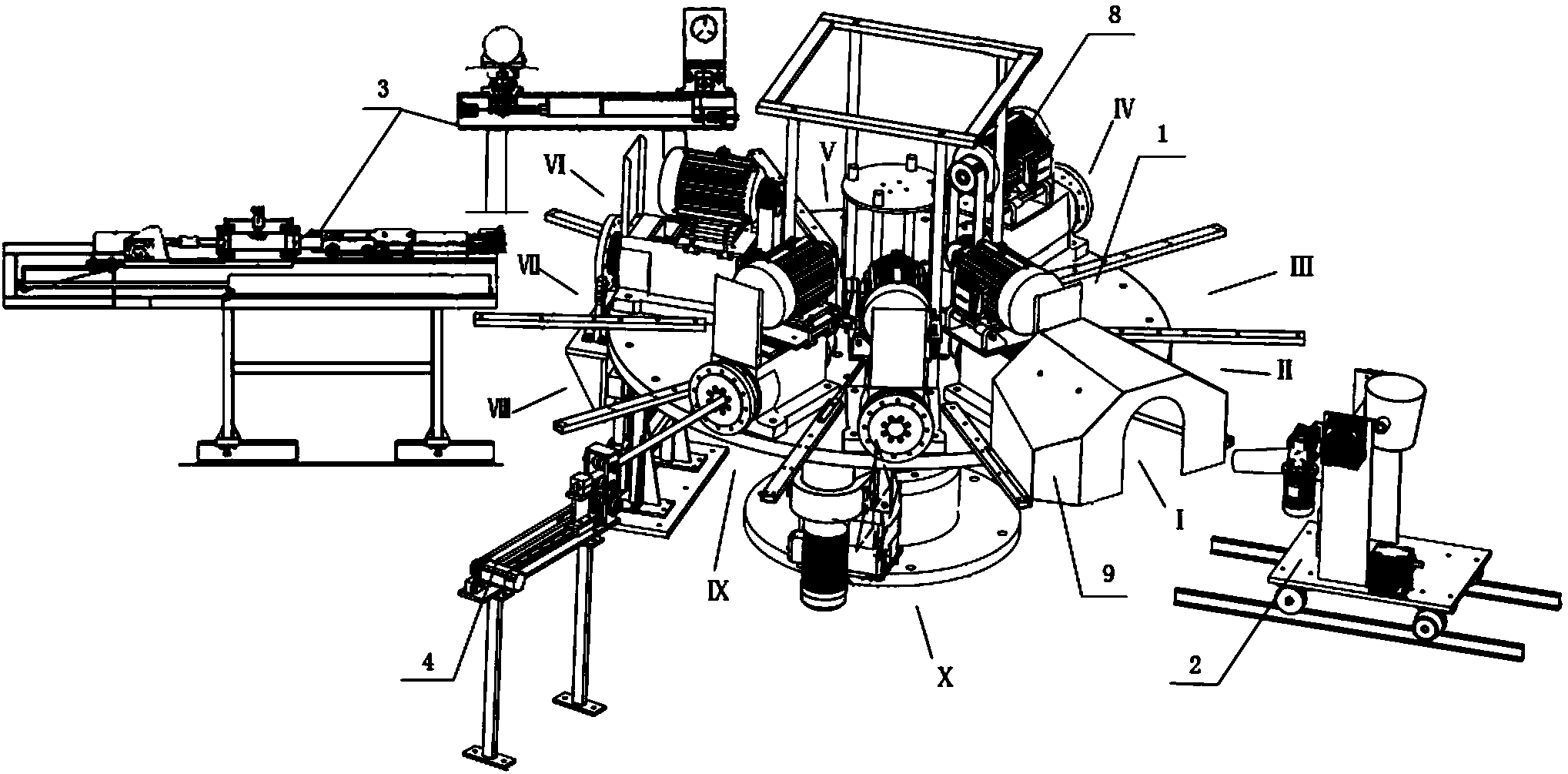

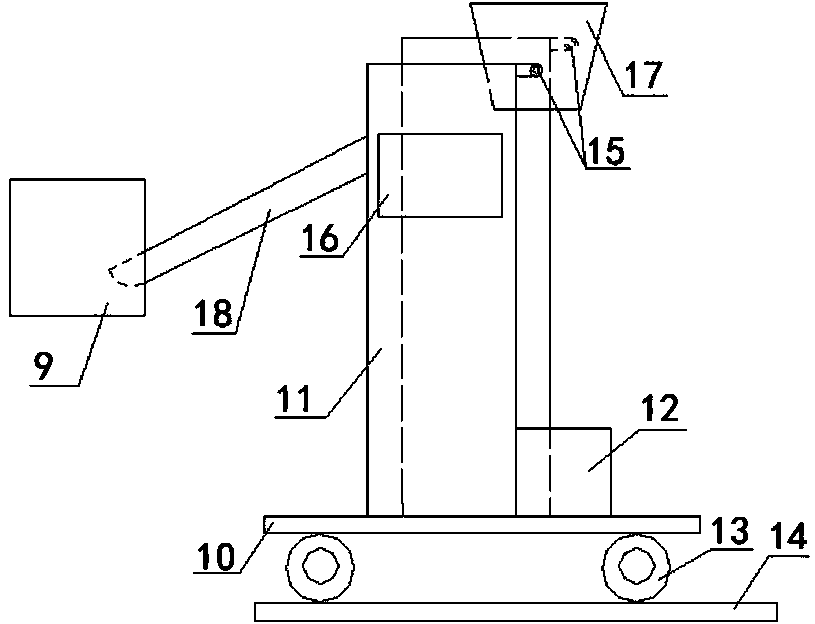

Intelligent multi-station cylinder sleeve centrifugal casting machine

The invention discloses an intelligent multi-station cylinder sleeve centrifugal casting machine and belongs to the technical field of machine casting. The multi-station cylinder sleeve centrifugal casting machine comprises a turntable mechanism, a casting mechanism, an automatic cylinder sleeve taking mechanism and an automatic paint spraying mechanism, and is provided with ten stations of a casting station, a cooling station a, a cooling station b, a cooling station c, an ageing station, a door sheet taking station, a material taking station, a cleaning station, a painting station and a drying station; the casting mechanism, the automatic cylinder sleeve taking mechanism and the automatic paint spraying mechanism respectively correspond to the casting station, the door sheet taking station and the material taking station, and the painting station and are positioned outside the turntable mechanism. The intelligent multi-station cylinder sleeve centrifugal casting machine is high in automation degree and realizes full automation in operating links such as automatic casting, automatic cooling, automatic door ring taking, automatic cylinder sleeve taking and automatic paint spraying in cylinder sleeve production, technologies are consistent, the quality is stable, the labor cost is reduced, and the production efficiency is improved.

Owner:江苏奥凯自动化设备技术有限公司

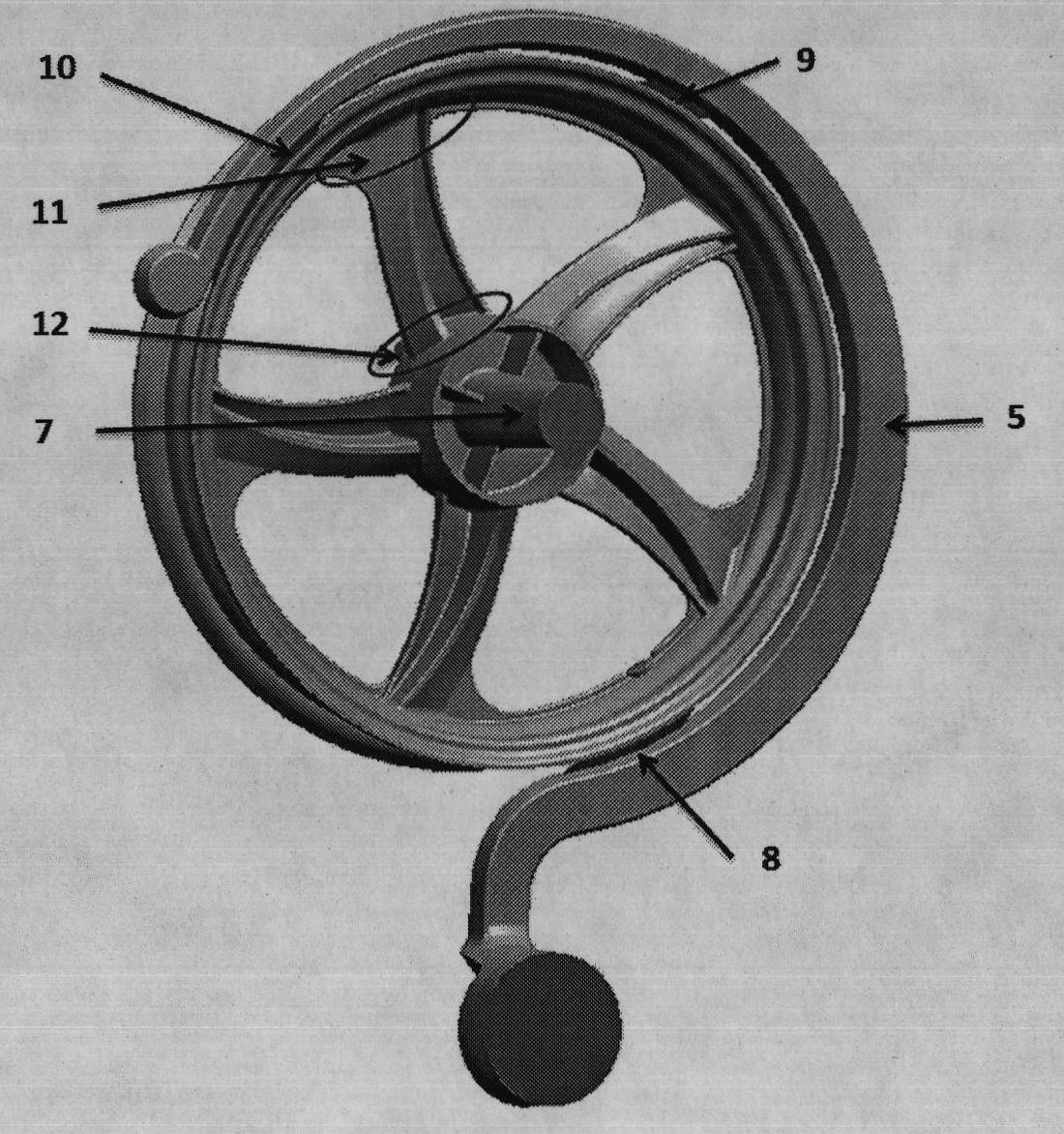

Vacuum high-pressure casting method

The invention relates to a vacuum high-pressure casting process method for a wheel disc casting. The method comprises the following steps of: after melt casting is finished, sequentially and centripetally filling a model from a wheel flange to a wheel center through a broken ring-shaped runner and a tangential ingate with the assistance of vacuum; and after model filling is finished, jointly pressurizing by a pressure head and a pressure filling head which is positioned on an epitaxial slag ladle of the wheel center and maintaining the pressure till a casting is fully solidified to obtain a high-quality wheel disc casting which has the advantages of high-quality wheel flange model filling and no solidification contraction and blowhole defect on a wheel flange hot spot and a wheel center hot spot.

Owner:重庆硕龙科技有限公司

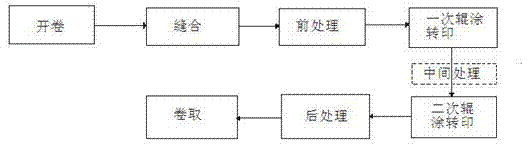

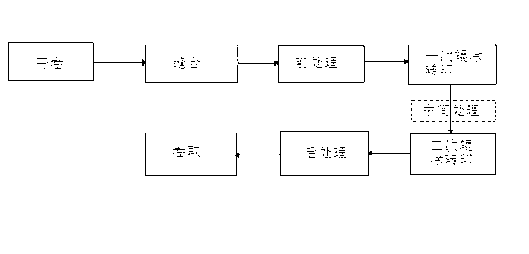

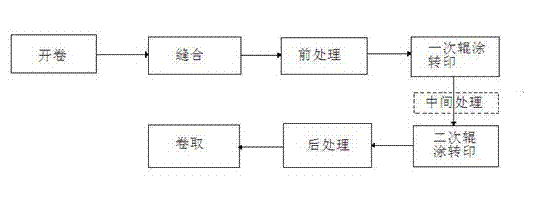

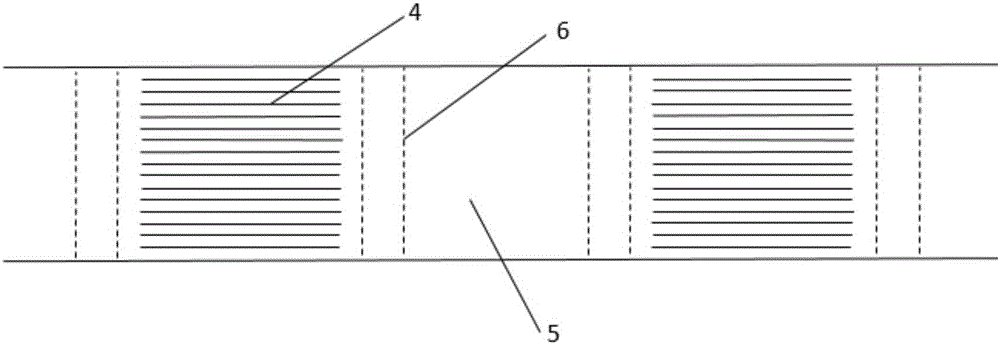

Production method of multicolor pattern color steel plate

InactiveCN103029502AConsistent speedConsistent workmanshipDecorative surface effectsRotary pressesProduction lineProgrammable logic controller

The invention provides a production method of a multicolor pattern color steel plate. For the once transfer printing, on one hand, a PLC (programmable logic controller) control module in a servo control system is used for computing the theoretical roller surface linear velocity of each roller in a roll coater set by acquiring the technical velocity and the rotation velocity of each roller in the roll coater set, and enables the theoretical roll surface linear velocity to be accordant with the technical rotation velocity; and on the other hand, a servo control module with a coder acquires the practical roller surface linear velocity of each roller in the roll coater set, and inputs the practical roller surface linear velocity into the PLC control module, so that a PLC control system can be used for comparing the practical roller surface linear velocity with the theoretical roller surface linear velocity, and adjusting the current frequency till the practical roller surface linear velocity is accordant with the theoretical roller surface linear velocity. According to the control method, the practical roller surface linear velocity is adjusted to be accordant with the theoretical roller surface linear velocity, and the theoretical roller surface linear velocity is adjusted to be accordant with the technical velocity, so that the practical roller surface linear velocity is adjusted to be accordant with the technical velocity, and furthermore, the adjustment by stopping a production line does not need in the process of production, so that the production efficiency can be improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

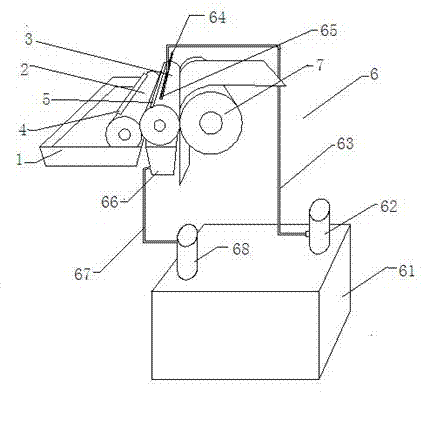

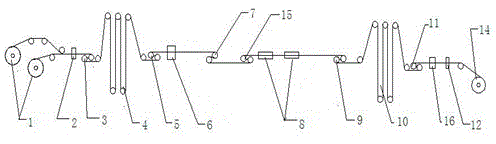

Production line of multi-color patterned roller-coated steel plate

InactiveCN102990360AConsistent speedConsistent workmanshipOther manufacturing equipments/toolsRotary pressesProduction lineProgrammable logic controller

The invention provides a production line of a multi-color patterned steel plate. On one hand, a PLC (programmable logic controller) control module in a servo control system is used for collecting the process speed and the rotating speed of every roller of a roller coating unit, calculating the theoretical linear speed of the surface of every roller in the roller coating unit and making the theoretical linear speed of the roller surfaces identical to the process speed; on the other hand, the actual linear speed of the surface of every roller in the rolling coating unit is collected by a servo control module with an encoder, the signal of the actual linear speed of the surface of every roller is input into the PLC control system, the actual linear speed of the surface of every roller is compared with the theoretical linear speed of the surface of every roller through the PLC control system, and the current frequency is adjusted until the actual linear speed of the surface of every roller is identical to the theoretical linear speed of the surface of every roller. By adopting the control method, the actual linear speed of the surface of every roller can be ensured to be identical to the process speed, stoppage is not needed in the production process for adjustment, and the production efficiency is improved. Moreover, a steel strip is subject to pre-transfer treatment in the production method in order to improve the adhesion between a coating and the surface of the steel strip and the moldability of the steel strip after printing.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Improved production method of multi-color patterned roller-coated steel plate

InactiveCN103158415AConsistent speedConsistent workmanshipLiquid surface applicatorsRotary intaglio printing pressProgrammable logic controllerControl system

The invention provides an improved production method of a multi-color patterned steel plate. On one hand, a PLC (programmable logic controller) control module in a servo control system is used for collecting the process speed and the rotating speed of every roller of a roller coating unit, calculating the theoretical linear speed of the surface of every roller in the roller coating unit and enabling the theoretical linear speeds of the roller surfaces to be identical to the process speed; and on the other hand, the actual linear speed of the surface of every roller in the rolling coating unit is collected by a servo control module with an encoder, a signal of the actual linear speed of the surface of every roller is input into the PLC control system, the actual linear speed of the surface of every roller is compared with the theoretical linear speed of the surface of every roller through the PLC control system, and the current frequency is adjusted until the actual linear speed of the surface of every roller is identical to the theoretical linear speed of the surface of every roller. By adopting the control method, the actual linear speed of the surface of every roller can be identical to the process speed, the stoppage is not needed in the production process for adjustment, and the production efficiency is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

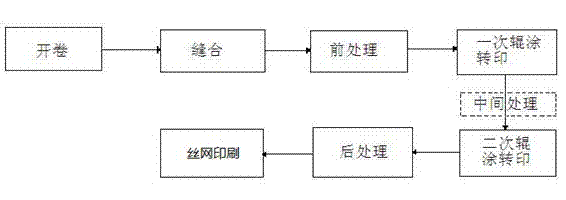

Production method of graph code steel plate integrating roller painting printing and silk-screen printing into whole

InactiveCN103158381AStrong three-dimensional senseConsistent speedLiquid surface applicatorsRotary intaglio printing pressScreen printingStart time

The invention provides a production method of a graph code steel plate integrating roller painting printing and silk-screen printing into a whole. The silk-screen printing and the roller painting printing are combined. Not only can an accurate grounding decorative pattern be obtained, but also a printing layer which is thick, solid and strong in third dimension can be obtained. Simultaneously, a servo control system which controls the rotating speed of rollers in a roller painting equipment assembly and controls the starting time is additionally arranged in a roller painting segment, and thereby the actual roller surface linear speed is guaranteed to be consistent with the technology rotating speed. Then line-stop adjustment is not needed in the production process, and the production efficiency is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

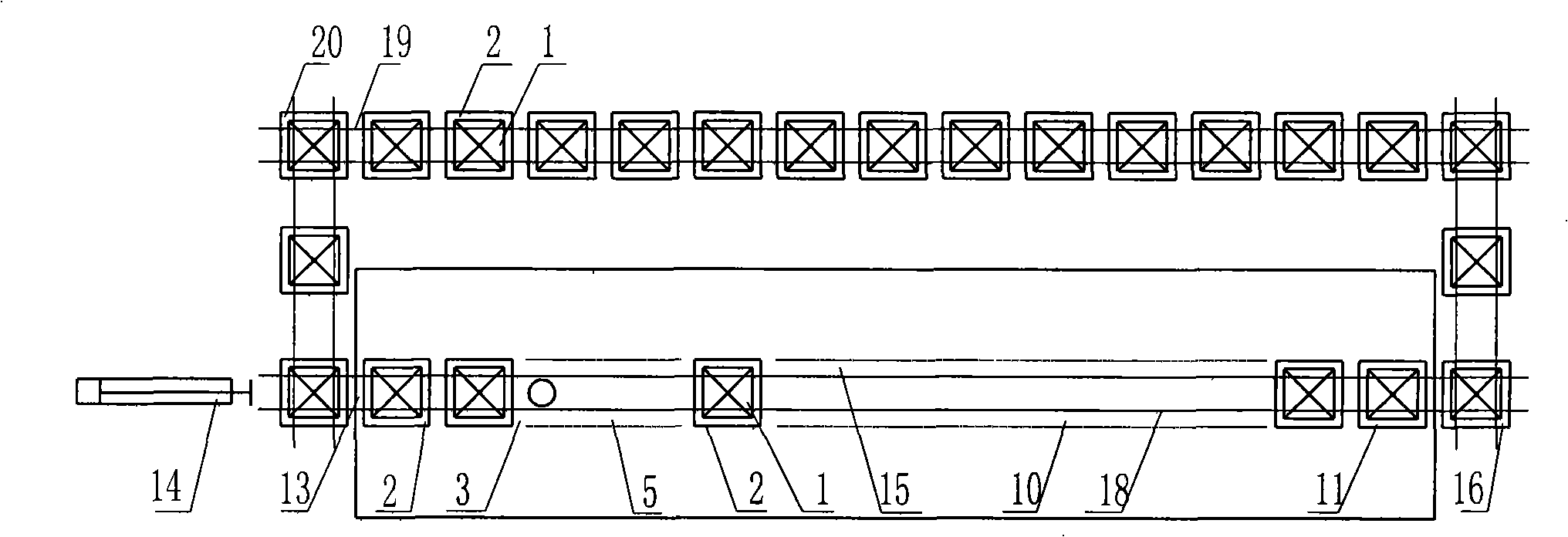

Directional solidification method and its device for continuous production for polycrystalline silicon ingot

InactiveCN101307487AEasy to replaceRealize job productionPolycrystalline material growthFrom frozen solutionsHearthPolycrystalline silicon

The invention provides a directional freezing method for continuously producing polysilicon ingots, relating to an uniform polycrystal material which takes material or shape as characteristics and possesses of a certain structure. The invention provides a directional freezing method for continuously mass production of polysilicon ingots in the process of producing solar energy-level polysilicon by metal silicon in the metallurgy process and a device adopting the method. Empty graphite molds are arranged according to the axial space order and driven to move forward by a furnace vehicle, and the empty graphite molds are preheated in the preheating area; liquid silicon undergoing melt refining is put in the empty graphite molds after preheating; the liquid silicon is kept warm in a high-temperature area of a hearth and enters an intermediate-temperature area; from the high-temperature area to the intermediate-temperature area, the liquid silicon are gradually directionally frozen in graphite molds; frozen silicon is cooled down to room temperature below a revolving track protective cover in the graphite molds to obtain directionally frozen polysilicon ingots. The directional freezing continuous track furnace for continuously producing polysilicon ingots is provided with a furnace body, a furnace hearth, a furnace vehicle track, a furnace vehicle, a front auxiliary cart, a back auxiliary cart, a revolving track, a propelling device and a power supply and temperature control system.

Owner:JACO SOLAR SILICON LONGYAN CO LTD +1

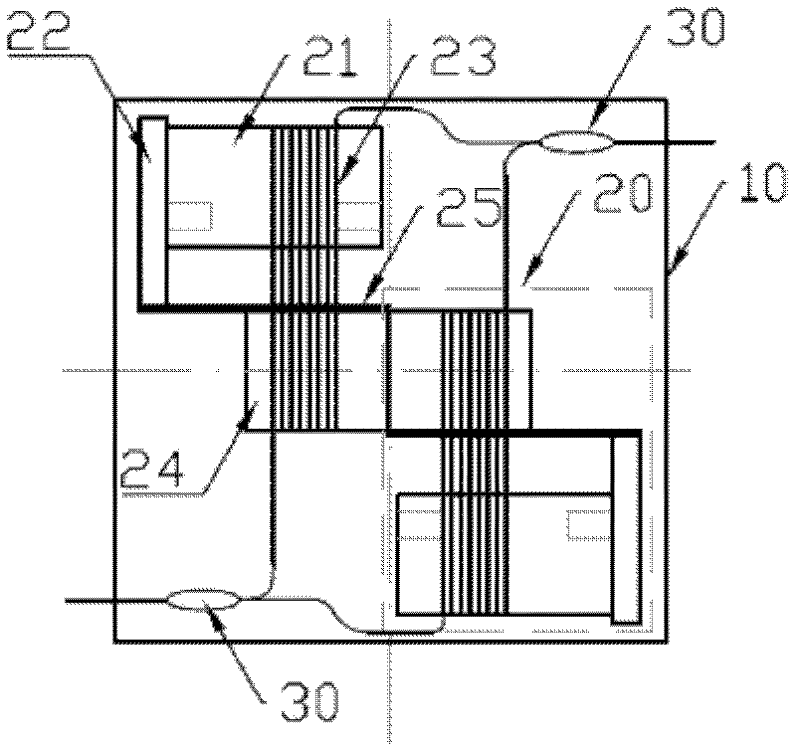

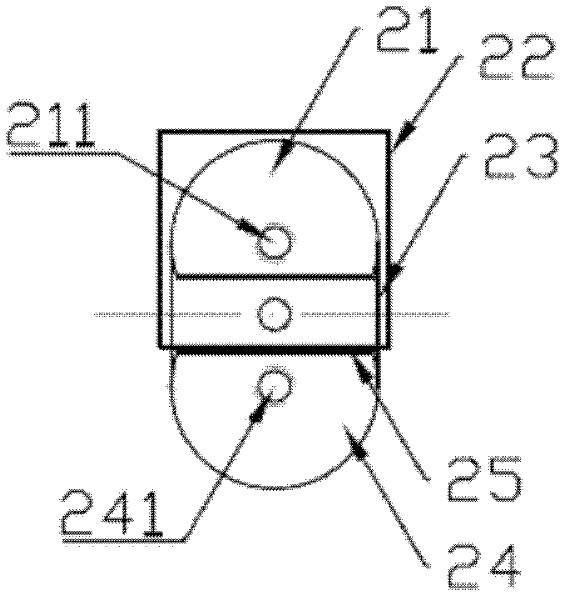

Push-pull fiber detector

The invention discloses a push-pull fiber detector which comprises that: a pedestal used for installing a sensing arm; two sensing arms which are installed on the pedestal in a central symmetry mode and are used for sensing a vibration signal; a fiber coupler used for enabling light in sensing fibers of the two sensing arms to interfere, wherein two ends of a same side of the fiber coupler connect with one end of the sensing fibers of the two sensing arms respectively. According to the invention, through winding fibers around a support beam and a mass block, utilizing a diaphragm as an elastic element, a volume of the push-pull fiber detector is effectively reduced; through limiting a vibration mode of the mass block through the diaphragm, transverse sensitivity is effectively reduced; through employing a method of winding fibers around the support beam and the mass block, structures of each sensing arm are same, technology is consistent, composition design is simplified, technology difficulty of the fiber detector is effectively reduced, and consistency of the detector is raised.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for packaging double-faced crystalline silicon heterojunction main-grid-free solar cell piece

InactiveCN106847968ANo secondary printing requiredReduce silver usagePhotovoltaic energy generationSemiconductor devicesHeterojunctionSilver paste

The invention relates to a packaging method for a double-sided HIT busbar-free battery sheet, which mainly includes: laying a 10-80 μm-diameter plated battery on a self-made or outsourced busbar-free HIT battery sheet with once-printed thin grid lines. Copper wire with metal anti-oxidation layer; when the height of the thin grid wire is greater than the diameter of the copper wire, first lay the copper wire in the direction perpendicular to the thin grid wire, and the contact point between the copper wire and the grid wire is a node, and the heat and pressure sensitive After the glue or photosensitive glue is covered on the copper wire and the battery sheet along the direction of the copper wire, the colloid is cured; when the height of the thin grid line is less than or equal to the diameter of the copper wire, a circular pattern is pre-dotted at the junction of the copper wire and the grid line The cured conductive paste or conductive tape is pasted, copper wire is laid, and hot-pressed and cured below 200°C; then the copper wire and the cell are hot-pressed to complete the packaging of the double-sided busbar-free HIT cell. The invention greatly reduces the amount of silver paste used, reduces production costs, and solves the problem of poor weldability of batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

Control method and system for roller painting and printing production line

InactiveCN102991123AConsistent speedConsistent workmanshipCylinder pressesLiquid surface applicatorsProduction lineColor printing

The invention provides a control method for a roller painting production line. According to the control method, the rotating speed of each roller and the process speed are enabled to be uniform by calculating and controlling the theoretic roller surface linear speed and the actual roller surface linear speed of each roller in a roller coating unit, and therefore the production efficiency is improved; and meanwhile, dislocation distances of patterns in multiple printing are calculated by using a secret identification technology so as to adjust the rotating speed of each roller, so that the patterns in multi-color printing are vivid and complete, and the printing length of the patterns is prolonged.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

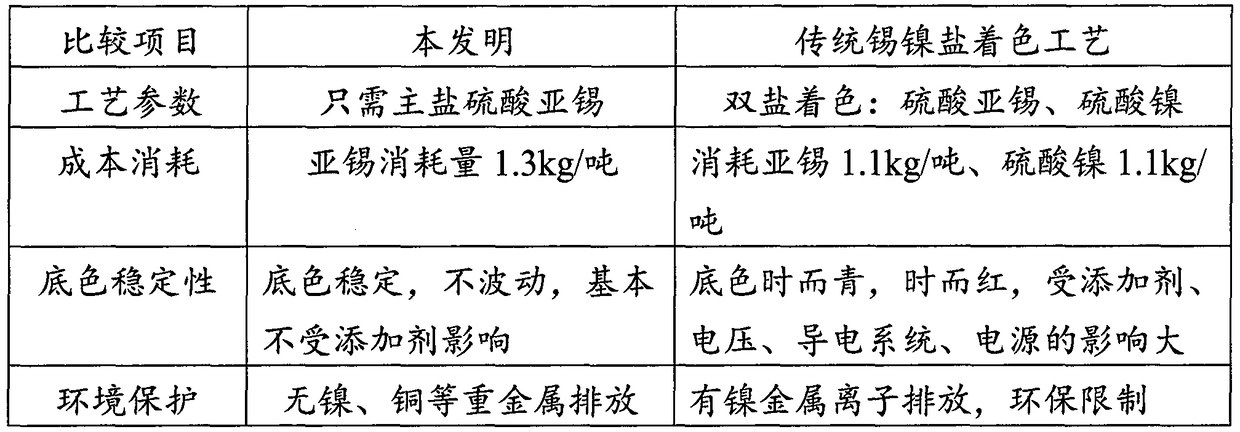

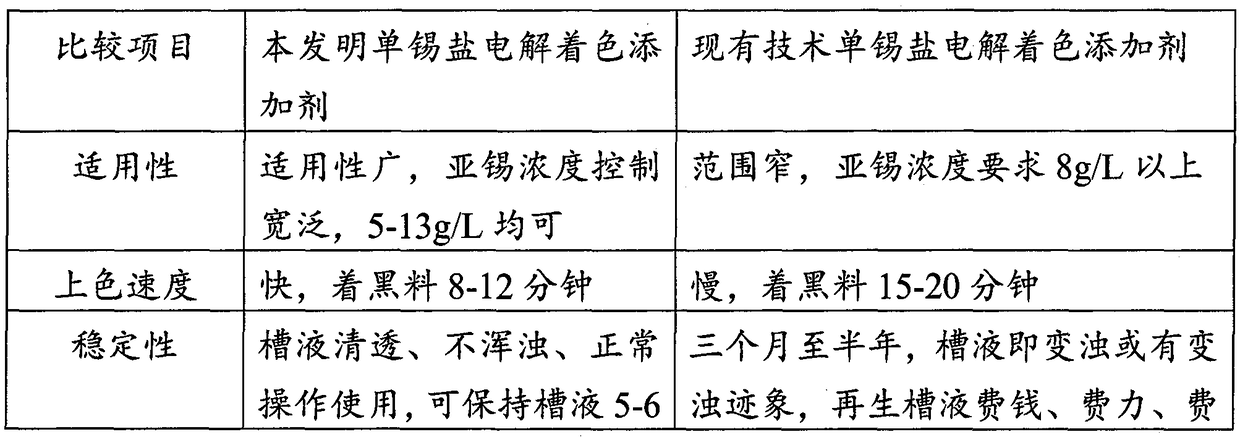

Single tin salt electrolytic coloring additive and application thereof

InactiveCN108342763AAntioxidantProtection stabilitySurface reaction electrolytic coatingZinc phosphateElectrolysis

The invention discloses a single tin salt electrolytic coloring additive. The single tin salt electrolytic coloring additive comprises a complexing agent, a buffer agent, an antioxidant and a surfactant, wherein the antioxidant comprises ferrous sulfate; the single tin salt electrolytic coloring additive also comprises an auxiliary agent containing ferrous sulfate; the auxiliary agent comprises modified amino amide zinc phosphate. The single tin salt electrolytic coloring additive disclosed by the invention has good comprehensive performances, solves the problem that nickel must take part in the reaction in an electrolytic coloring process, and is stable in groove liquid and quick and uniform to color, and the cost can be lowered effectively. Moreover, the single tin salt electrolytic coloring additive is low-carbon, energy-saving and green and environment-friendly, and process and product quality consistent to those of a double salt system can be obtained.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

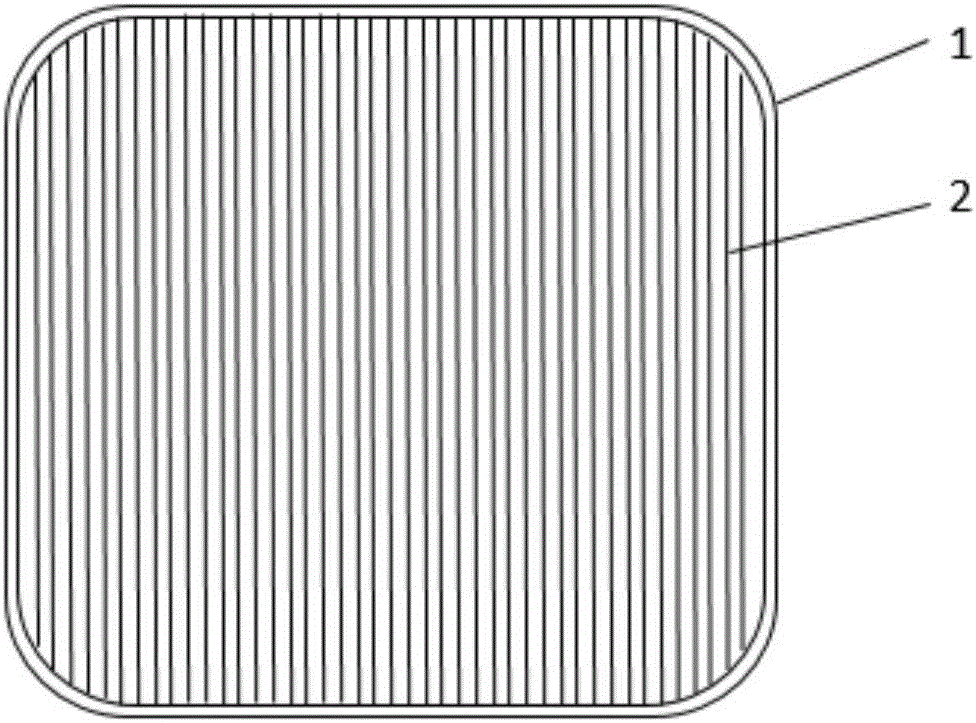

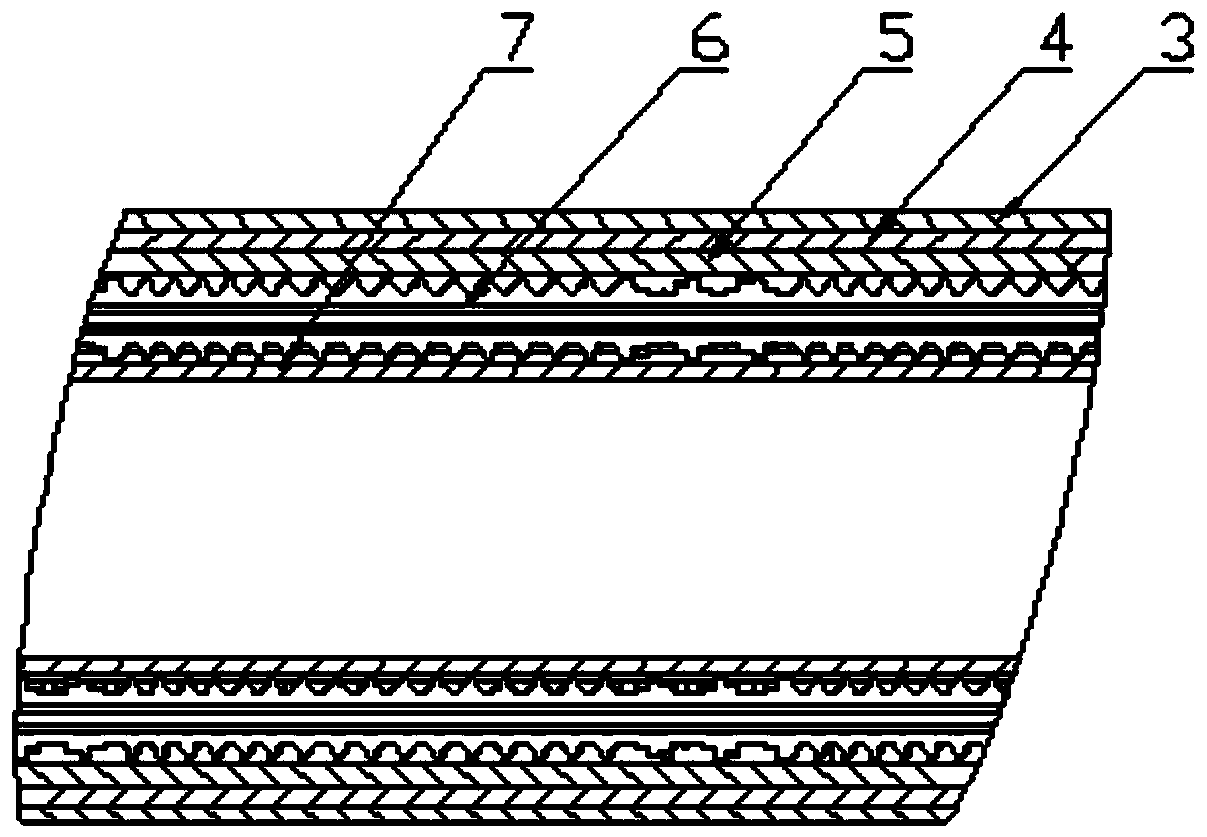

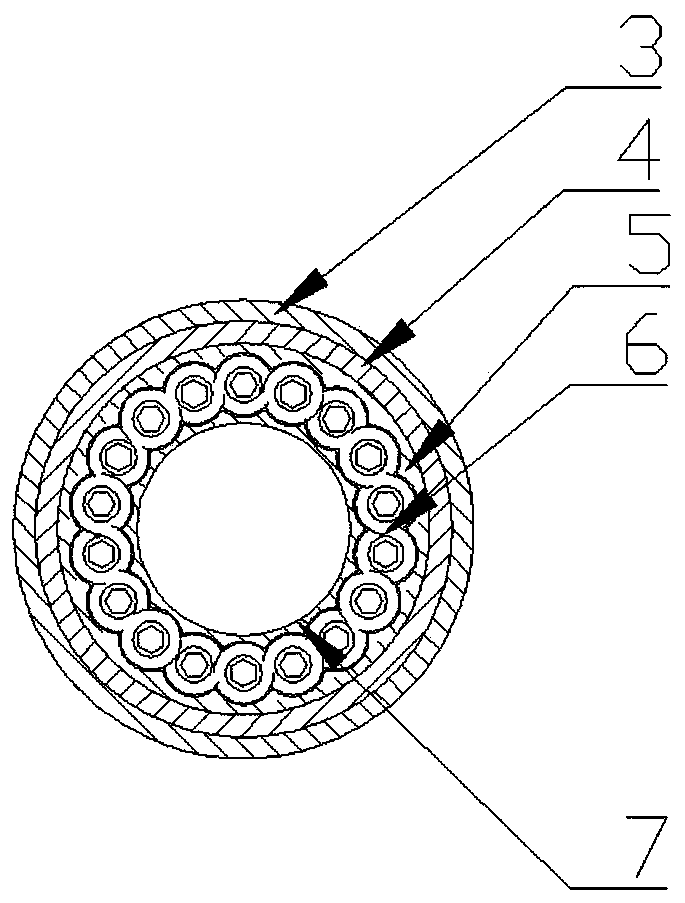

Composite film for interconnection of main-grid-free heterojunction solar cell modules, and preparation method thereof

ActiveCN112786727AThe production process is simpleHigh photoelectric conversion powerFinal product manufacturePhotovoltaic energy generationHeterojunctionComposite film

The invention discloses a composite film for interconnection of main-grid-free heterojunction solar cell modules. The composite film comprises composite film bodies and copper wires, each composite film body comprises a base material layer and an adhesive film layer, the adhesive film layer is arranged on the base material layer, and the copper wires are embedded in the adhesive film layer in parallel along the adhesive film layer. A preparation method of the composite film comprises the following steps: arranging and straightening the copper wires, putting a whole piece of one composite film body or cutting the whole piece of the composite film body into a slice film, putting the slice film on a pressing tool heating platform with the adhesive surface facing upwards, pressing the composite film body or the slice film with half of the copper wires, placing another whole piece of the composite film body or cutting the other whole piece of composite film body into a slice film with the adhesive surface facing downwards on the other half of the copper wire, closing the pressing tool, adjusting the pressing pressure and the pressing time, pressing the copper wires and the composite film bodies together to manufacture the required composite film, taking out the composite film, and cooling the composite film. The composite film is simple in manufacturing process, low in cost, diversified in structure and better in use effect, and the production efficiency can be improved.

Owner:无锡市联鹏新能源装备有限公司

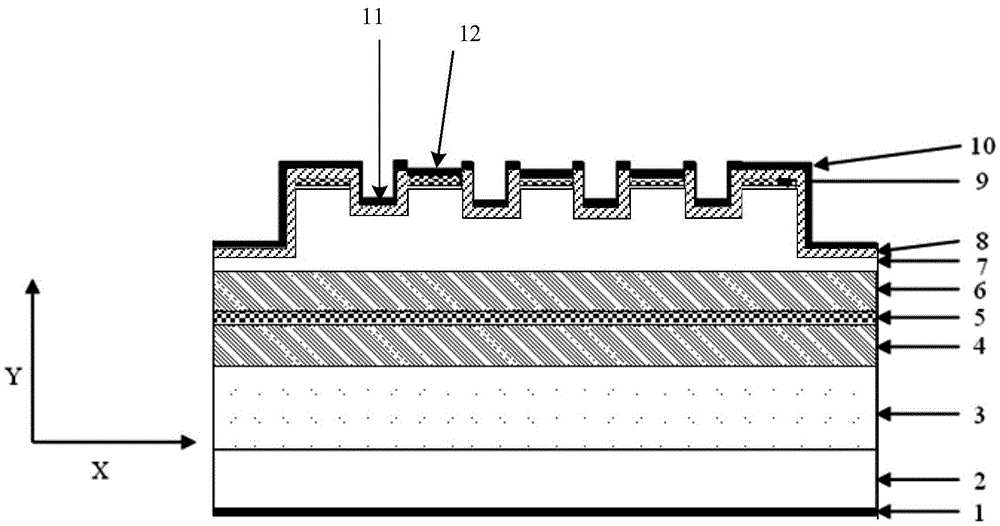

Semiconductor laser and fabrication method thereof

ActiveCN105529615AConsistent production processThe preparation process is matureOptical wave guidanceLaser detailsElectricityPower flow

The invention discloses a semiconductor laser and a fabrication method thereof. The semiconductor laser comprises an N-type electrode, a P-type electrode and a functional layer, wherein the N-type electrode and the P-type electrode are oppositely arranged; the functional layer is arranged between the N-type electrode and the P-type electrode; the functional layer comprises a substrate, an N-type cladding, an N-type optical limiting layer, an active region, a P-type optical limiting layer, a P-type cladding, an insulating layer and a P-type ohmic contact layer, which are sequentially arranged, in the first direction; the first direction is the direction that the N-type electrode points to the P-type electrode; the P-type electrode comprises a current injection region and a non-current injection region; and a hollow-out pattern is arranged at the position, opposite to the current injection region, of the insulating layer in the first direction, so that the P-type electrode and the P-type ohmic contact layer are electrically connected in the current injection region; and the semiconductor laser has the characteristics of a lateral divergence angle.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Production line for roller-coated color steel plate

InactiveCN102975019AGuaranteed uptimeGood molding effectOther manufacturing equipments/toolsRotary pressesProduction lineSurface roughness

The invention provides a production line for roller-coated color steel plates. Steel bands at all process sections are flattened through a plurality of tension rollers and stable and constant tension is particularly provided for a roller coating section. Moreover, since corona treatment is conducted to the surfaces of the steel bands before the steel bands enter the roller coating section to form a plurality of pits on the surfaces of the steel bands, the surface roughness of the steel bands is improved, the adhering force between the surfaces of the steel bands and color pattern layers is improved, the color pattern layers are not apt to peel off and the formability of the steel bands is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

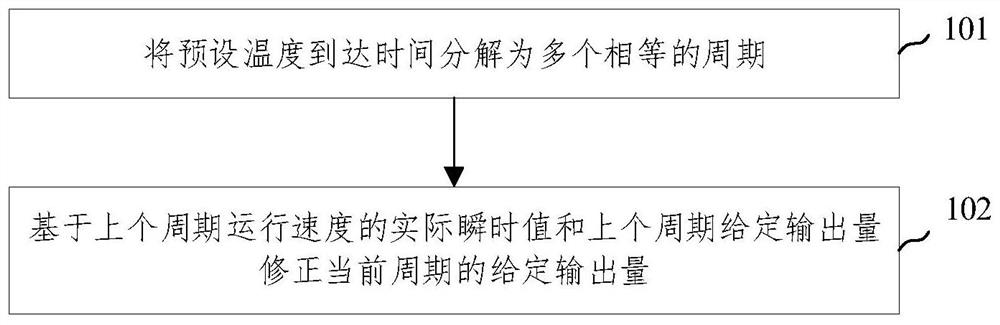

Method and device for controlling output quantity of semiconductor temperature control device

ActiveCN112596557AConsistent cooling effectConsistent workmanshipTemperatue controlTemperature controlProcess equipment

The invention provides a method and a device for controlling the output quantity of a semiconductor temperature control device. The method comprises the following steps of: decomposing preset temperature arrival time into a plurality of equal periods; and correcting the given output quantity of the current period based on the actual instantaneous value of the running speed of a previous period andthe given output quantity of the previous period. According to the method and device for controlling the output quantity of the semiconductor temperature control device, the output quantity of the system is controlled according to the temperature rising and falling time, different system characteristics are adapted, the temperature rising and falling time of a heating system and a refrigerating system meets the requirements, and different needed temperature rising and falling time is set corresponding to different temperature intervals; the temperature rising and falling curve of the whole equipment is consistent with the calibration curve of main process equipment.

Owner:BEIJING JINGYI AUTOMATION EQUIP CO LTD

PVDF fluorocarbon powder coating and preparation method thereof

The invention discloses a PVDF fluorocarbon powder coating and a preparation method thereof. The PVDF fluorocarbon powder coating comprises the following materials: ultra-fine PVDF resin, auxiliary solid resin, a pigment and an auxiliary agent; the PVDF fluorocarbon powder coating is characterized in that the weight ratio of the ultra-fine PVDF resin to the auxiliary solid resin is 70:30, the auxiliary solid resin comprises acrylic resin and alicyclic epoxy resin, wherein the weight ratio of the acrylic resin to the alicyclic epoxy resin in the auxiliary solid resin is (5:25)-(25:5); and the preparation method comprises the following steps: (1) dispersing and mixing the auxiliary solid resin and the pigment at a high speed and performing rubbing to generate heat; (2) adding the ultra-finePVDF resin, performing high-speed dispersion and mixing continuously, and performing rubbing to generate heat; (3) performing melt extrusion, performing cooling, performing drying, and performing pressure-roller cutting; (4) spraying liquid nitrogen and performing freezing; (5) performing crushing, and in the crushing process, performing freezing by using liquid nitrogen; (6) classifying powder; (7) collecting qualified powder, adding an adhesion accelerator and a nano modifier auxiliary agent, and performing spheroidization and loosening treatment; and (8) screening powder which meets a standard. According to the technical scheme, a problem that the PVDF resin is plasticized is avoided, and therefore the PVDF resin and the acrylic resin are mixed uniformly.

Owner:广东依斯特新材料有限公司

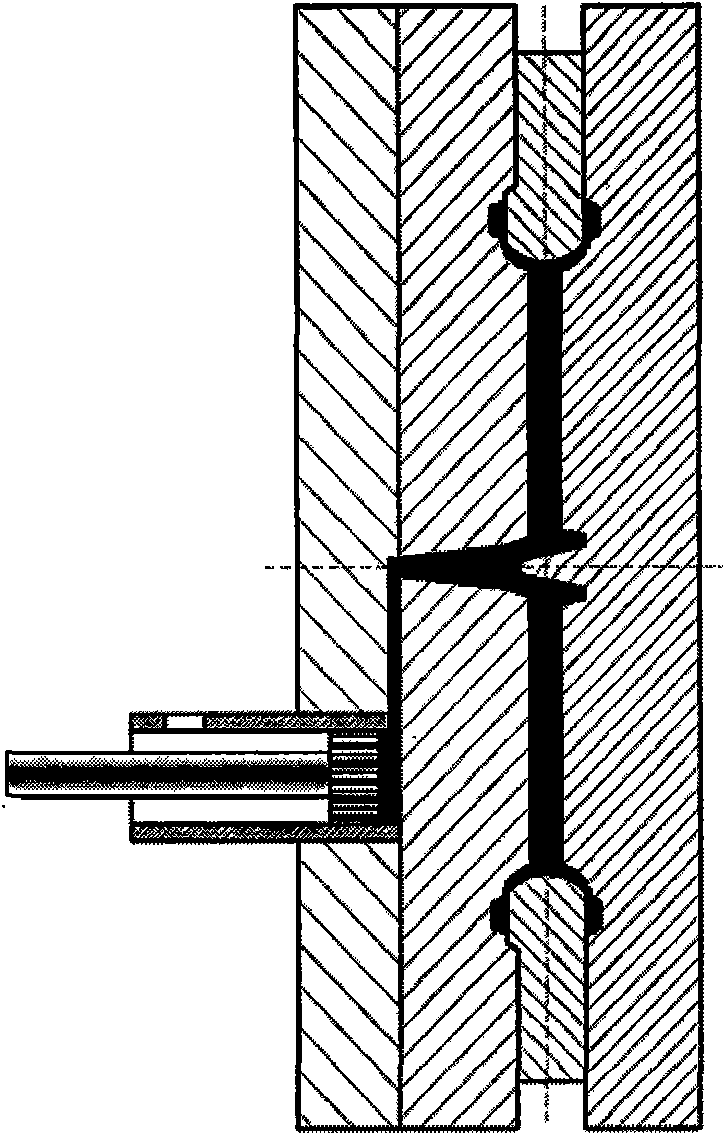

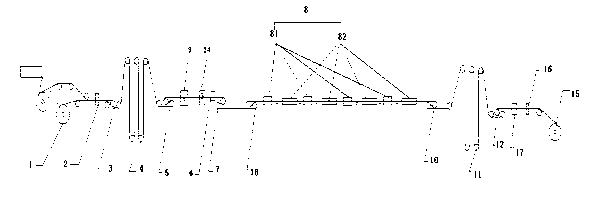

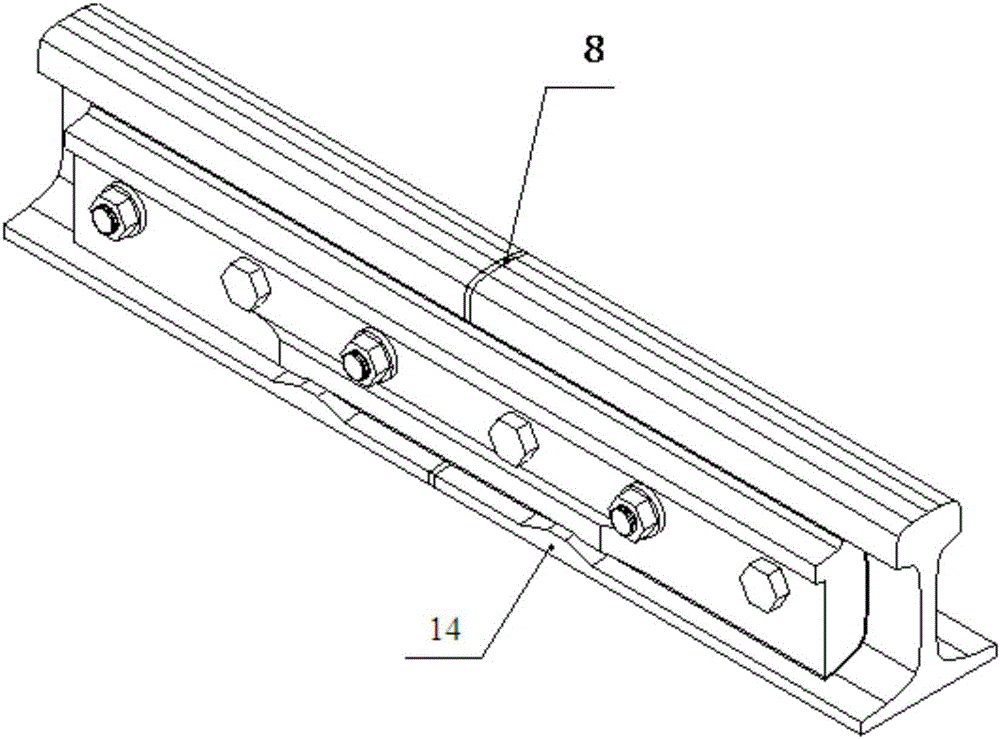

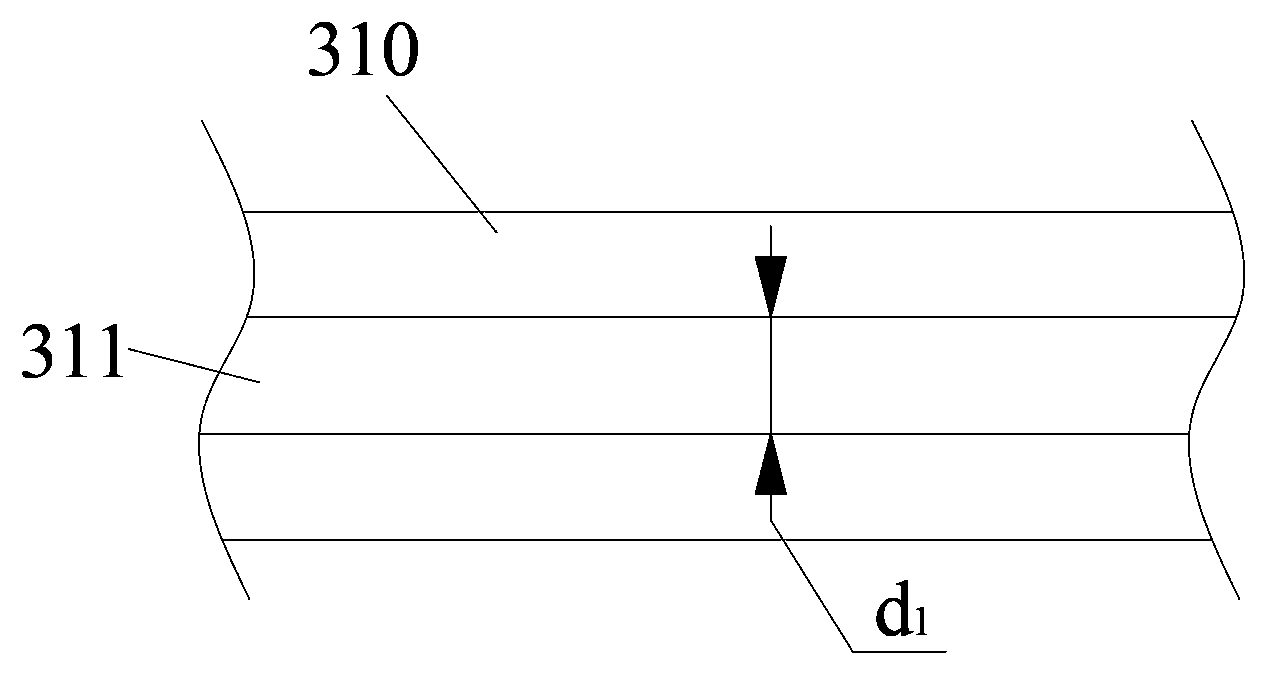

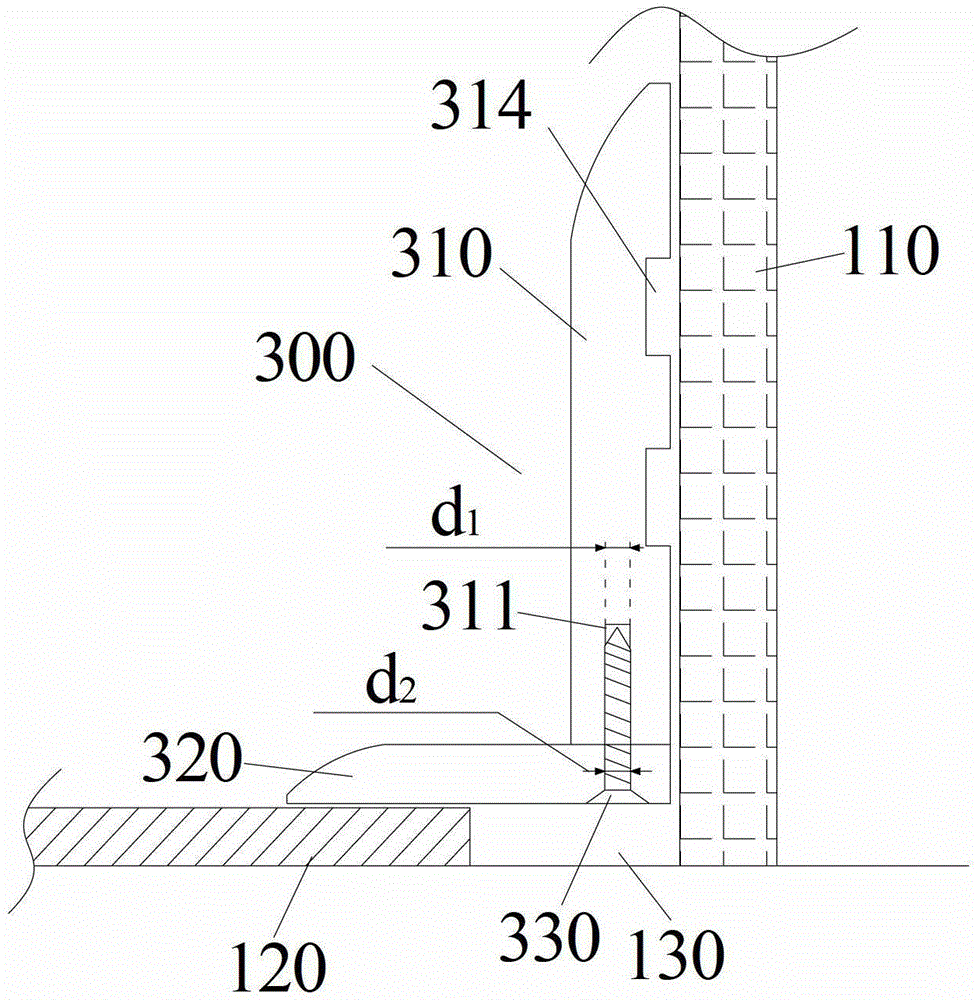

Special-shaped steel rail and steel rail glue joint insulating joint

ActiveCN105064141AConsistent structureConsistent workmanshipRailsRail jointsAbnormal shapedEngineering

The invention provides a special-shaped steel rail which comprises a rail head 11, a rail waist 12 and a rail bottom 13. The steel rail further comprises an arch slope 14 protruding out of the surface of the steel rail. The invention further provides a steel rail glue joint insulating joint. The insulating joint comprises two special-shaped steel rails connected in series. By means of the glue joint insulating joint, a large rail seam does not occur on the connection portion of the two steel rails connected in series. Besides, the probability that the steel rail glue joint insulating joint is damaged by temperature stress and train impact and accordingly fails can be substantially reduced. The steel rail glue joint insulating joint can fully resist temperature stress changes of a seamless line and impact force generated during running of a train, and development requirements of the trans-section seamless line are met.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Improved screen print production line of figure-number steel plates

InactiveCN103287064AStrong three-dimensional senseConsistent speedScreen printersPrinting press partsProduction lineScreen printing

The invention provides an improved screen print production line of figure-number steel plates. The improved screen print production line combines the screen print and the roller coating print, and therefore not only can acquire comparatively accurate underpainting patterns but also can acquire comparatively massive and highly three-dimensional printing layers; and meanwhile a servo control system, which is used for controlling the rotational speed and starting time of the material adsorbing roller and the coating roller of a roller equipment component, is added to a roller painting section, so that the consistency of linear velocity of a practical roller face and the rotational speed of the technology is ensured. Thus, the production line does not need to be stopped for an adjustment in the production process and the production efficiency is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Intelligent dyeing system and method

InactiveCN113514306ASame conditionsConsistent workmanshipPreparing sample for investigationControl engineeringProcess engineering

The invention belongs to the technical field of cell observation, and particularly relates to an intelligent dyeing system and method. The system comprises a transmission part which comprises a motion transmission mechanism, a first mechanical arm and a sensor and is used for automatically putting a smear into a dyeing area and taking the smear out of the dyeing area after dyeing, a liquid dripping part which comprises a second mechanical arm, a dyeing liquid dripping pipeline, a cleaning liquid flushing pipeline and a waste liquid collecting pipeline, and is used for dripping dyeing liquid and buffer liquid to the smear and flushing redundant dyeing liquid after dyeing, a mixing part which is used for uniformly mixing the dyeing liquid and the buffer liquid on the smear, a gland part which is used for fixing and sealing the smear, a drying part which is used for drying the smear which is dyed and washed, and a control part which is used for controlling the transmission part, the liquid dripping part, the mixing part, the gland part and the drying part according to preset operation steps. The observation liquid prepared by using the system not only has a better observation effect, but also enables the observation to be more efficient.

Owner:重庆德方信息技术有限公司

Steel rail cementing insulating joint

ActiveCN105064145AConsistent structureConsistent workmanshipRail jointsTemperature stressEngineering

The invention provides a steel rail cementing insulating joint. The steel rail cementing insulating joint comprises two steel rails connected in series, insulating end plates arranged at the joint of the two steel rails, insulating trough plates tightly attached to the two sides of the steel rails, clamping plates arranged on the outer sides of the insulating trough plates, and screw joint insulating assemblies used for fastening the clamping plates and the insulating trough plates to the steel rails. The screw joint insulating assemblies comprise bolts, nuts, gaskets and insulating casing pipes arranged on the outer circular faces of the bolts in a sleeving mode. The steel rails further comprise arch slopes protruding out of the surfaces of the steel rails, convex layers matched with the arch slopes are correspondingly arranged on the insulating trough plates, and concave openings matched with the arch slopes and convex layers are correspondingly formed in the clamping plates. The cementing insulating joint can sufficiently resist the temperature stress changes of seamless tracks and the impact force generated in the running process of trains, and the development demands of trans-regional seamless tracks are met.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Combined skirting line

ActiveCN103912110APrevent archingSimple structureBuilding constructionsEngineeringMechanical engineering

The invention provides a combined skirting line which comprises a strip-type skirting line plate and a batten plate. The skirting line plate is attached to a wall and fixedly connected with the wall, and the batten plate is fixedly connected with the skirting line plate, attached to a floor but not fixedly connected with the floor. The batten plate can effectively cover the gap between the floor and the wall and combine the floor with the wall, the floor can freely expand and contract in the direction parallel to a floor plane without limitation of the batten plate of the skirting line when changing in volume due to deformation caused by wet swelling and dry shrinkage as the batten plate is not fixedly connected with the floor, the floor can be effectively prevented from locally arching or breaking away from coverage of the skirting line, and damage to the floor or the skirting line and the like caused by relative stress generated between the floor and the skirting line can be effectively avoided.

Owner:ZHEJIANG LINGGE WOOD

A special-shaped rail and rail glued insulation joint

ActiveCN105064141BConsistent structureConsistent workmanshipRailsRail jointsEngineeringStress variation

The present invention firstly provides a special-shaped rail, which includes a rail head 11 , a rail waist 12 and a rail bottom 13 , and the rail also includes an arch 14 protruding from the surface of the rail. The present invention also correspondingly provides a rail glued insulated joint, the insulated joint comprising two series-connected special-shaped steel rails as described above. The glued insulated joint provided by the present invention can prevent large rail gaps from appearing at the junction of two steel rails in series, and can greatly reduce the possibility of failure of the glued insulated joint of the rails due to temperature stress and impact force of the train. Small. The glued insulated joint provided by the invention can fully resist the temperature stress change of the seamless line and the impact force generated during the operation of the train, and meets the development requirement of the cross-interval seamless line.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Bottle blowing machine installing rack

The invention discloses a bottle blowing machine installing rack used for installing main motion components of a bottle blowing machine. The installing rack comprises an upper panel, a lower panel, aplurality of middle rib plates and ground foot supports, wherein a plurality of installing faces are machined on the surface of the upper panel, the middle rib plates are connected between the upper panel and the lower panel, and the ground foot supports are arranged below the lower panel. A box-shaped laminated board structure is integrally formed by the upper panel, the lower panel and the middle rib plates. According to the bottle blowing machine installing rack, the specific rigidity of the rack is high, machining and installing datum planes are consistent, and the phenomena such as motioncomponent matching precision lowering, machine dynamic property worsening and even structure damage caused by deformation or other factors during installing and transporting can be prevented; meanwhile, according to the installing rack, the component machining number and machining faces are reduced, and the machining cost can be reduced; main components are directly arranged on the rack, design,technology and assembling datum is consistent, machining and assembling precision is high, the machine running speed is high, vibration and noise are low, and replacement and maintenance of formworksand other components are convenient.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

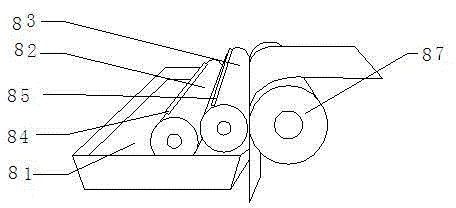

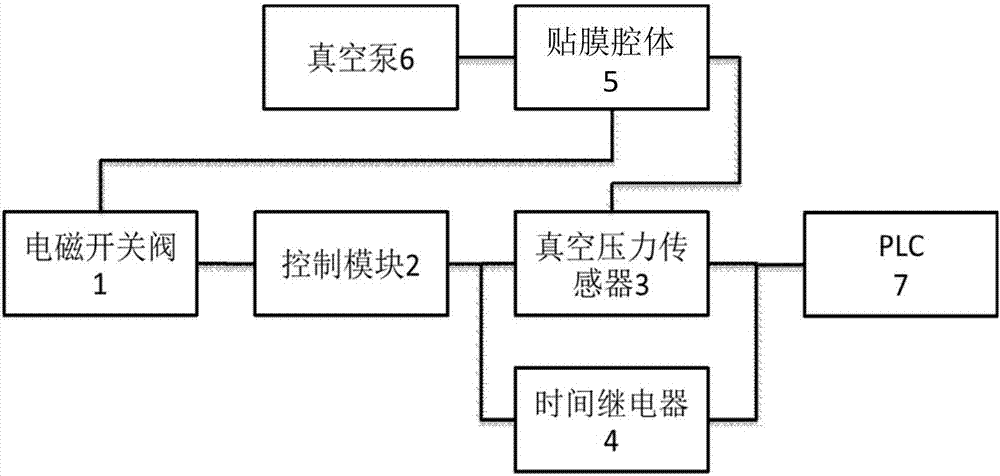

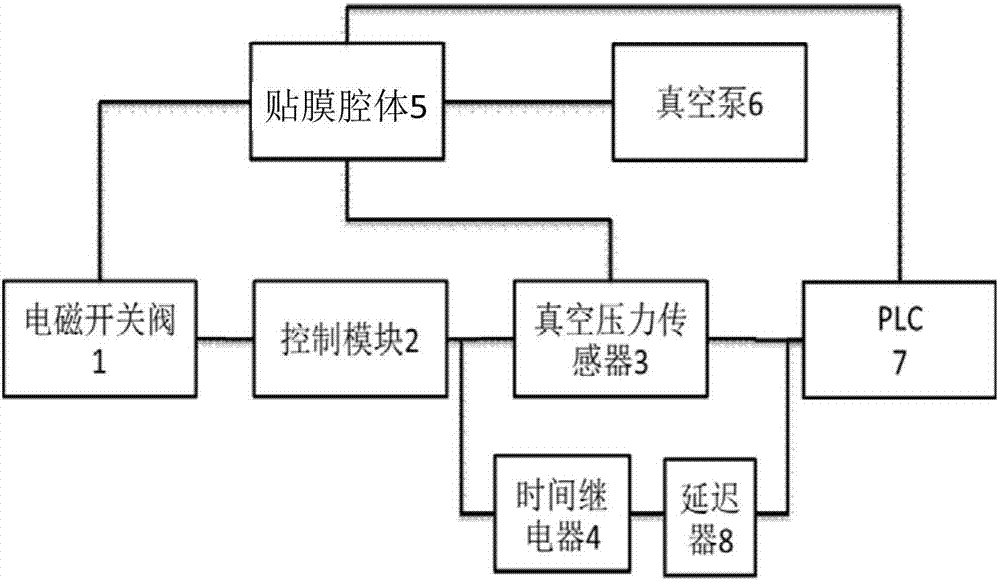

A dry film sticking machine and a dry film sticking method

ActiveCN104465416BConsistent workmanshipReduce labor costsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

The invention provides a dry film sticking machine and a film sticking method thereof. The dry film sticking machine includes a vacuum pressure sensor (3), a time relay (4), and a PLC (7). When the vacuum degree in the film cavity (5) reaches a specific value SP1, the vacuum pressure sensor (3) transmits the vacuum degree signal SP1 to the PLC (7) and the time relay (4), and triggers the time relay (4) to start counting down, PLC (7) controls the film sticking device to start film sticking; the time relay (4) transmits a signal T to PLC (7) when the countdown ends; when PLC (7) receives the signal T, it controls the film sticking device to finish sticking the film and opens the film sticking cavity (5) . By using the time relay in the dry film sticking machine and dry film sticking work instead of manual timing to directly control the film sticking process time of the machine, the labor cost can be greatly reduced. At the same time, using the time relay to control the time can avoid errors and make the control more accurate than manually pinching the watch. Higher precision ensures that the process of the film laminating machine is consistent, and different process time settings can be made according to the characteristics of different materials.

Owner:NANTONG FUJITSU MICROELECTRONICS

A kind of anti-infrared military camouflage fabric and its printing and dyeing process

ActiveCN106049092BGood hair effectExcellent adsorption uniformityMercerising of indefinite length fabricsSingeingDisperse dyeTextile printer

The invention discloses an anti-infrared military camouflage fabric and its printing and dyeing process. The warp and weft yarns of the camouflage fabric are all made of cotton-polyester blended yarn, and the cotton-polyester blended yarn is composed of 40-60wt% cotton fiber, 30-50wt% Polyester fiber, 5‑10wt% nylon fiber and 5‑10wt% spun silk fiber are blended, and the printing and dyeing process includes the following steps: S1, pretreatment process, S2, dyeing process, S3, printing process, S4, tenter finishing; Wherein, the dyeing process adopts the disperse bath dyeing of vat dyes and disperse dyes; the printing process adopts the same paste printing of vat dyes and disperse dyes. The anti-infrared military camouflage fabric and its printing and dyeing process of the present invention, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness, full color and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

A combined skirting line

The invention provides a combined skirting line which comprises a strip-type skirting line plate and a batten plate. The skirting line plate is attached to a wall and fixedly connected with the wall, and the batten plate is fixedly connected with the skirting line plate, attached to a floor but not fixedly connected with the floor. The batten plate can effectively cover the gap between the floor and the wall and combine the floor with the wall, the floor can freely expand and contract in the direction parallel to a floor plane without limitation of the batten plate of the skirting line when changing in volume due to deformation caused by wet swelling and dry shrinkage as the batten plate is not fixedly connected with the floor, the floor can be effectively prevented from locally arching or breaking away from coverage of the skirting line, and damage to the floor or the skirting line and the like caused by relative stress generated between the floor and the skirting line can be effectively avoided.

Owner:ZHEJIANG LINGGE WOOD

A kind of PVDF fluorocarbon powder coating and preparation method thereof

ActiveCN107603362BImprove adhesionImprove boiling resistanceEpoxy resin coatingsEpoxyPolymer science

Owner:广东依斯特新材料有限公司

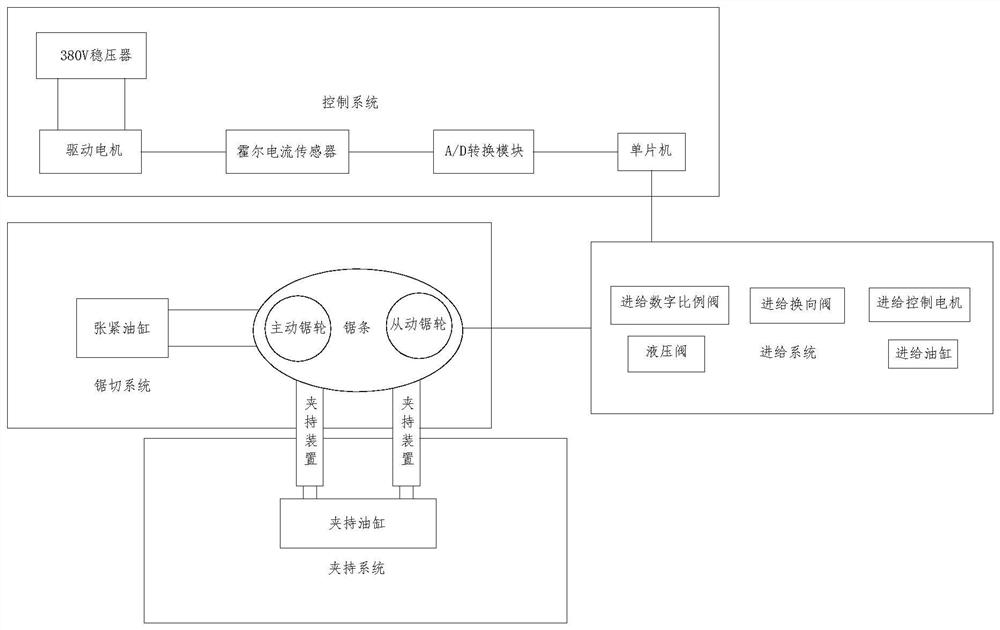

Variable-speed sawing control system of sawing machine

PendingCN114433941AEasy to adjust the positionEasy to collectMetal sawing devicesMetal sawing accessoriesControl systemStructural engineering

The invention discloses a sawing machine variable-speed sawing control system which comprises a workbench, first sliding grooves are formed in the two sides of the workbench, first sliding blocks are movably installed in the first sliding grooves, first telescopic rod pieces are fixedly installed at the tops of the first sliding blocks, and fixed rod pieces are fixedly installed at the tops of the first telescopic rod pieces; and a second sliding groove is formed in the fixing rod piece, a second sliding block is movably installed outside the second sliding groove, an adjusting fixing rotary knob is movably installed at the top of the second sliding block, and a first connecting plate piece is fixedly installed at the bottom of the second sliding block. According to the plate cutting device, the height of the related fixing mechanism and the height of the related cutting mechanism are conveniently adjusted through the arrangement of the related telescopic rod pieces, so that different cutting modes can be conducted on different plates during related cutting operation, and overall cutting is finer by adjusting the related cutting height.

Owner:缙云县澳美逊计算机系统工程有限公司

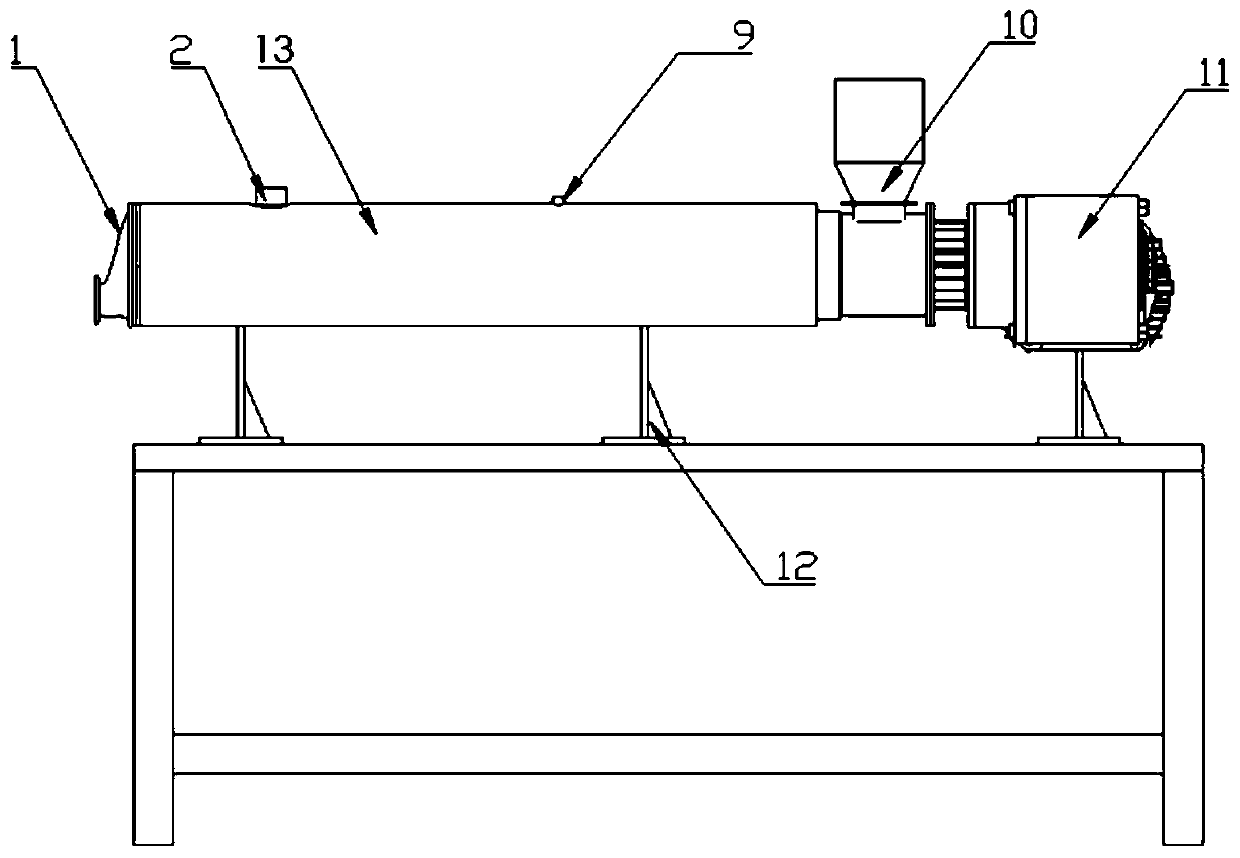

Multi-screw material dissolving machine

PendingCN109833787AWell mixedImprove quality and efficiencyRotary stirring mixersTransportation and packagingMechanical engineering

The invention discloses a multi-screw material dissolving machine which comprises a machine body, a feeding port and a discharging port, the feeding port and the discharging port are arranged on the machine body; the machine body is of a cylindrical shape and comprises, from outside to inside in sequence, a shell, an outer sleeve and an inner sleeve; an annular cavity is formed between the outer sleeve and the inner sleeve; a plurality of screw rods are uniformly distributed in the annular cavity along the circumferential direction; and the annular cavity is communicated with the feeding portand the discharging port respectively. The moving process of all the materials in a machine barrel is the same, under the action of high shearing force and meshing force, the material mixing is sufficient, and the mixing quality and the production efficiency of the product are greatly improved. The whole process is simple, coherent and efficient.

Owner:PHARM TECH TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com