Composite film for interconnection of main-grid-free heterojunction solar cell modules, and preparation method thereof

A technology of solar cells and composite films, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of low production efficiency, unsatisfactory use effect, and complicated production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

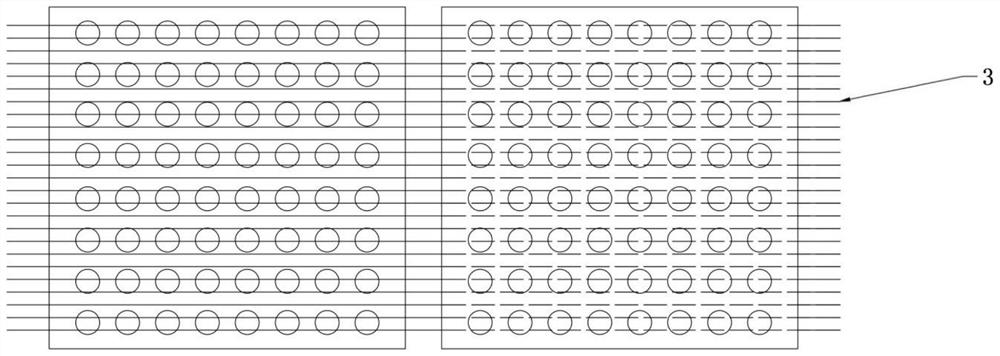

[0036] combine figure 1 , figure 2 Shown is the first embodiment of a composite film for interconnection of busbar-free heterojunction solar cell modules and its preparation method according to the present invention. The composite film includes a composite film body and copper wires 3, and the composite film body includes a base A material layer 1 and an adhesive film layer 2, the adhesive film layer 2 is arranged on the base material layer 1, and several copper wires 3 are embedded in the adhesive film layer 2 along the adhesive film layer 2 in parallel.

[0037] In this embodiment, the substrate layer 1 is a PVDF film with a thickness of 0.01-0.2 mm. PVDF film contains related additives, such as light stabilizers, anti-ultraviolet agents, etc.

[0038] In this embodiment, the adhesive film layer 2 is a PUR adhesive film with a thickness of 0.01-0.2 mm. The PUR film also contains triacryl isocyanate, dibenzoyl peroxide, 2-hydroxy-4-n-octyloxybenzophenone and UV stabilizer...

Embodiment 2

[0046] The difference between the composite film of this embodiment and the first embodiment is that the substrate layer 1 is a circular hollow PVF film with a hollow structure with a thickness of 0.01-0.2 mm, and the PVF film contains related additives, such as light stabilizers , anti-ultraviolet agent, etc. The film layer 2 is an EVA film with a thickness of 0.01 to 0.2mm, and the EVA film also contains triacrylisocyanurate, dibenzoyl peroxide, and 2-hydroxy-4-n-octyloxydibenzoyl Ketone and UV light stabilizers.

[0047] combine image 3As shown, the preparation method of the composite membrane of the present embodiment comprises the following steps:

[0048] Step 1), use the winding tool to arrange the copper wires 3 whose length is longer than twice the width of the cell evenly and horizontally on the tooling and stretch them straight. The parallel distance between two adjacent copper wires 3 ranges from 2 to 20 mm. The overall width of the 3 rows is smaller than the c...

Embodiment 3

[0053] The difference between the composite film of this embodiment and the first embodiment is that the substrate layer 1 is a PET film with a thickness of 0.01-0.2 mm, and the PET film contains related additives, such as a light stabilizer, an anti-ultraviolet agent, and the like. The film layer 2 is a TPU film with a thickness of 0.01 to 0.2 mm, and the TPU film also contains triacrylisocyanate, dibenzoyl peroxide, and 2-hydroxy-4-n-octyloxybenzoyl Ketone and UV light stabilizers.

[0054] combine Figure 4 As shown, the preparation method of the composite membrane of the present embodiment comprises the following steps:

[0055] Step 1), use the winding tool to arrange the copper wires 3 whose length is longer than twice the width of the cell evenly and horizontally on the tooling and stretch them straight. The parallel distance between two adjacent copper wires 3 ranges from 2 to 20 mm. The overall width of the 3 rows is smaller than the cell width;

[0056] Step 2), o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com