Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Consistent material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

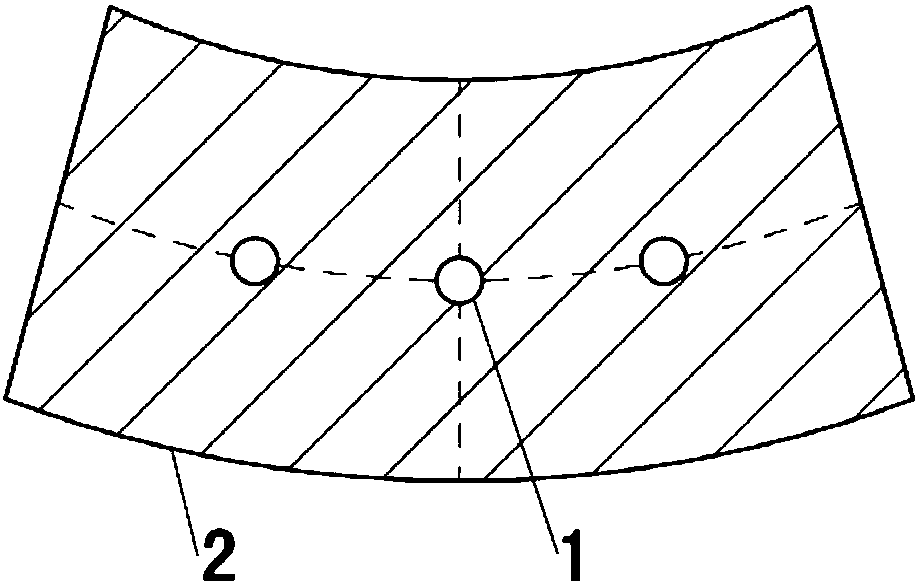

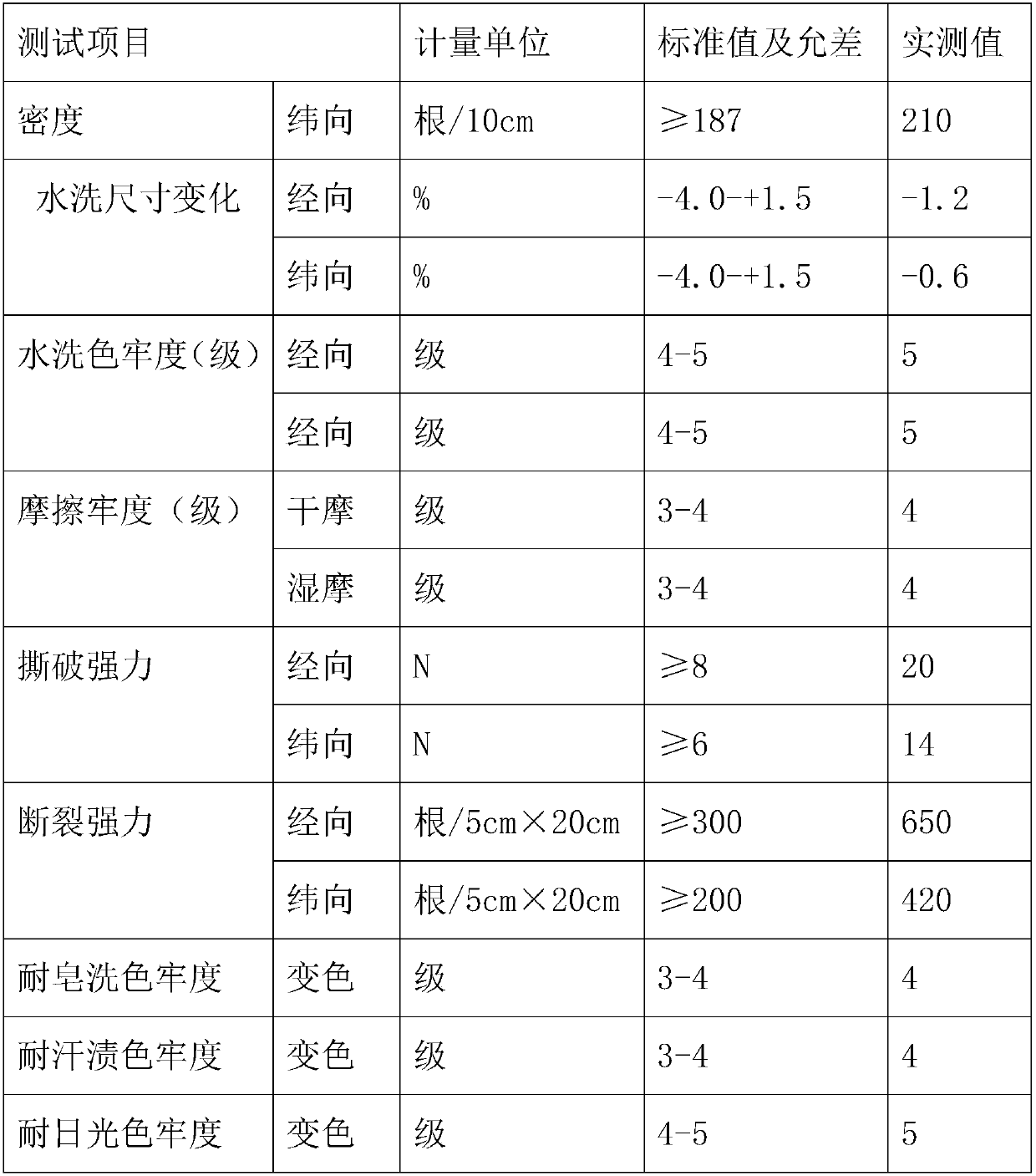

Dyeing and printing technology of camouflage fabric

InactiveCN105040490AImprove tensile propertiesImprove printing and dyeing adsorption functionDyeing processWoven fabricsCamouflagePolyester

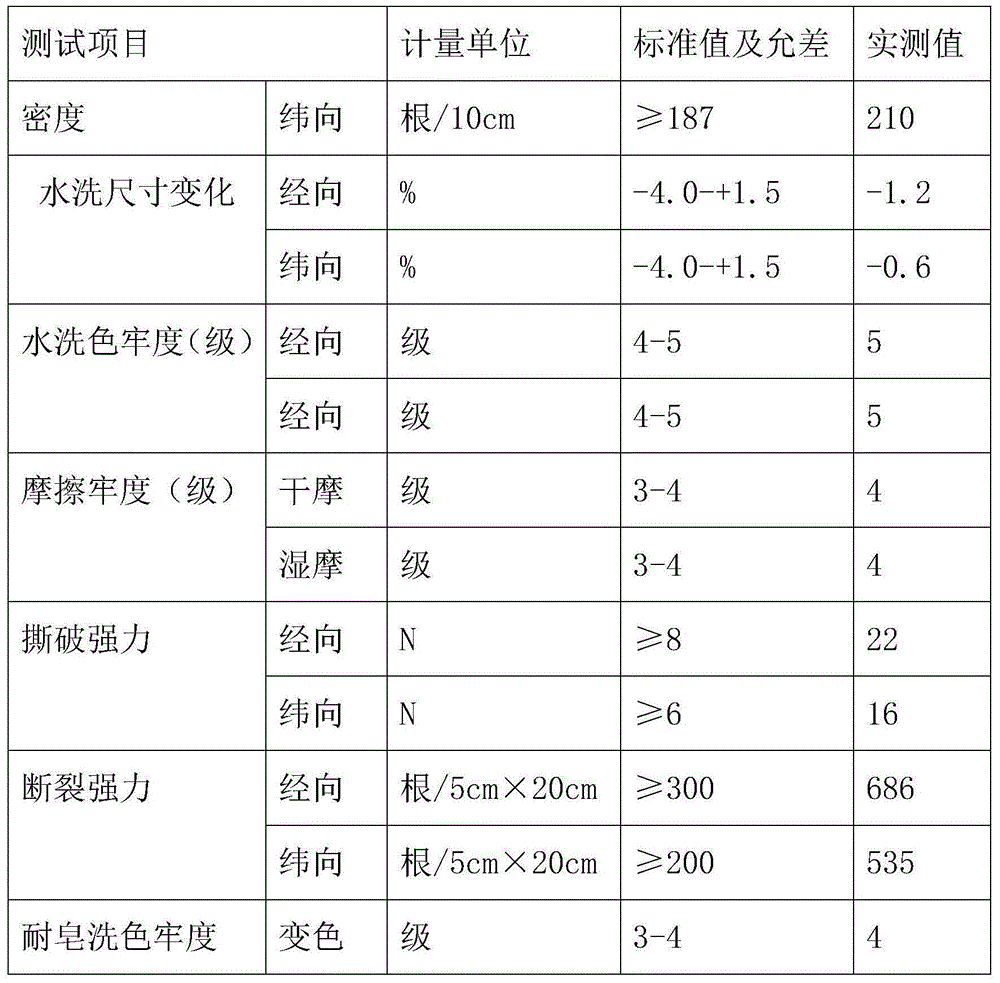

The invention discloses a dyeing and printing technology of a camouflage fabric. The camouflage fabric is prepared by blending and interweaving the following raw materials in percentage by weight: 30%-50% of cotton fiber, 30%-50% of polyester fiber, 10%-30% of spandex fiber and 10%-20% of spun silk fiber. The dyeing and printing technology comprises the following steps: S1 singeing; S2 cold heaping; S3 alkaline washing; S4 mercerizing; S5 ground dyeing; S6 printing; S7 waterproof and flame-proof treatment; and S8 stentering pre-shrinking. According to the dyeing and printing technology of the camouflage fabric, the high color fastness of the dyed ground color and the front and rear stability of the color of the camouflage fabric can be ensured; the camouflage printing requirements can be met; the quality repeatability is good; and the quality index of the finished product can meet the customer requirements.

Owner:芜湖市瑞都服装贸易有限公司

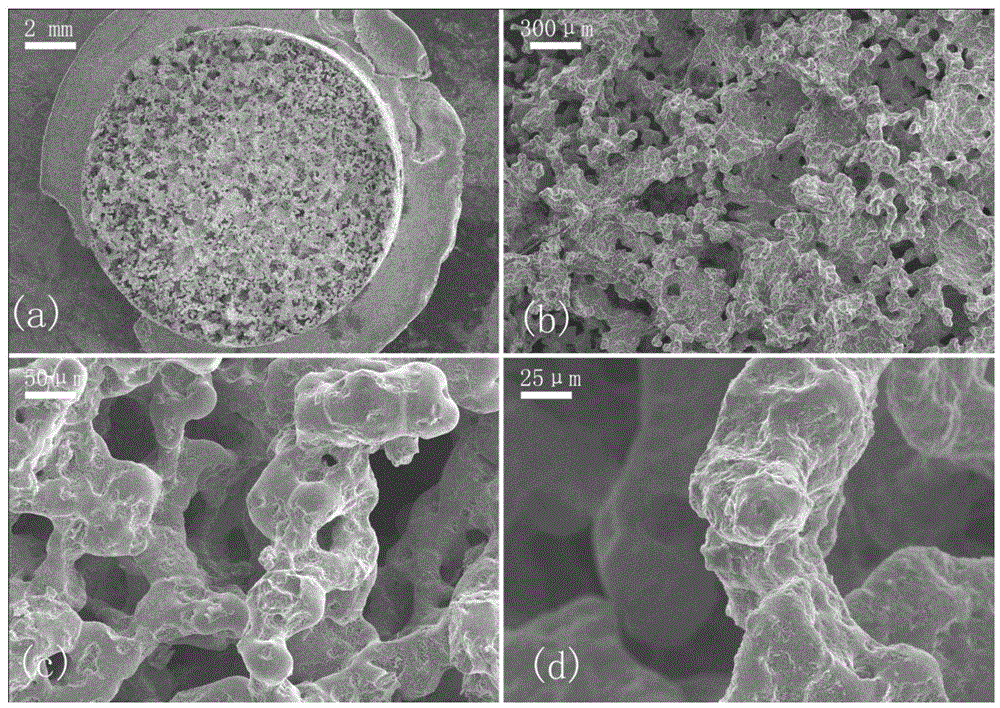

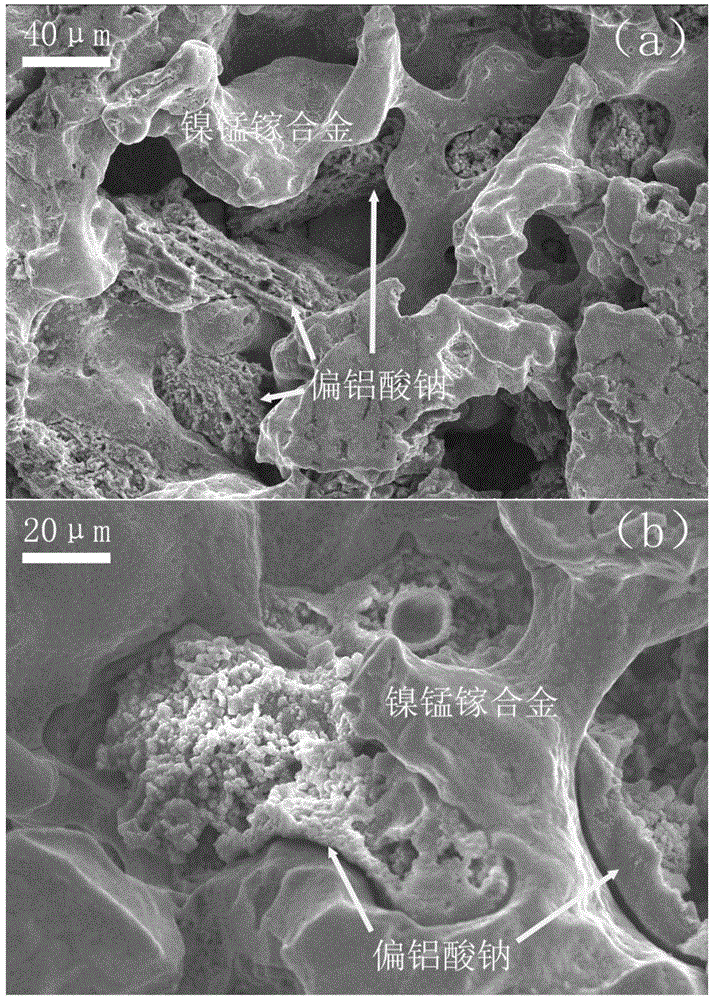

Method of preparing porous foam alloy and removing pore forming material sodium metaaluminate

The invention relates to a method of preparing a porous foam alloy and removing a pore forming material sodium metaaluminate. A metal or alloy composite material is prepared by adopting a pressure casting or sintering method and the pore forming material sodium metaaluminate. After the pore forming material sodium metaaluminate is removed, the porous foam metal or alloy is obtained. The method comprises the following steps: 1) excising an outer coating for the composite material to expose part of or all sodium metaaluminate particles; 2) putting the composite material into a reaction kettle; and 3) dissolving a sodium hydroxide solution with the concentration range of 80-300g / L and immersing the metal or alloy material; heating to 150-350 DEG C and insulating for 0.5-5 hours; then, cooling to room temperature, and obtaining the obtained porous structure material; soaking and washing by tap water or distilled water or ultrasonically cleaning within a short time and removing residual alkali liquor attached to the surfaces of porous metal and alloy to obtain the porous structure metal or alloy material.

Owner:NANJING UNIV

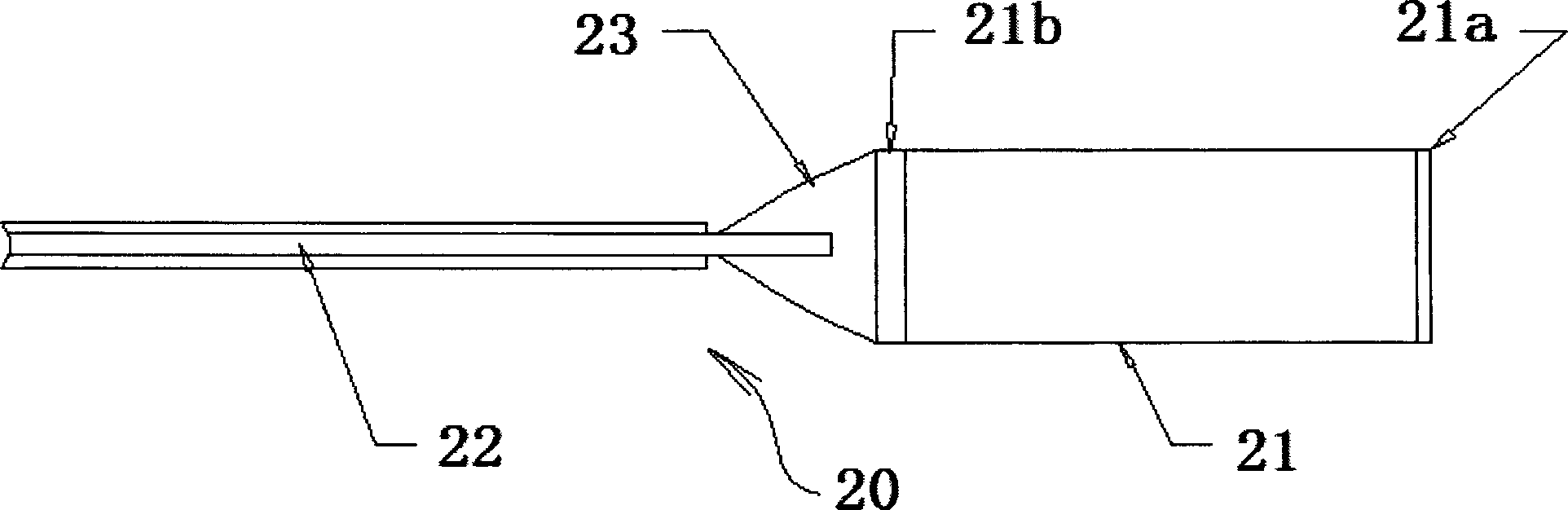

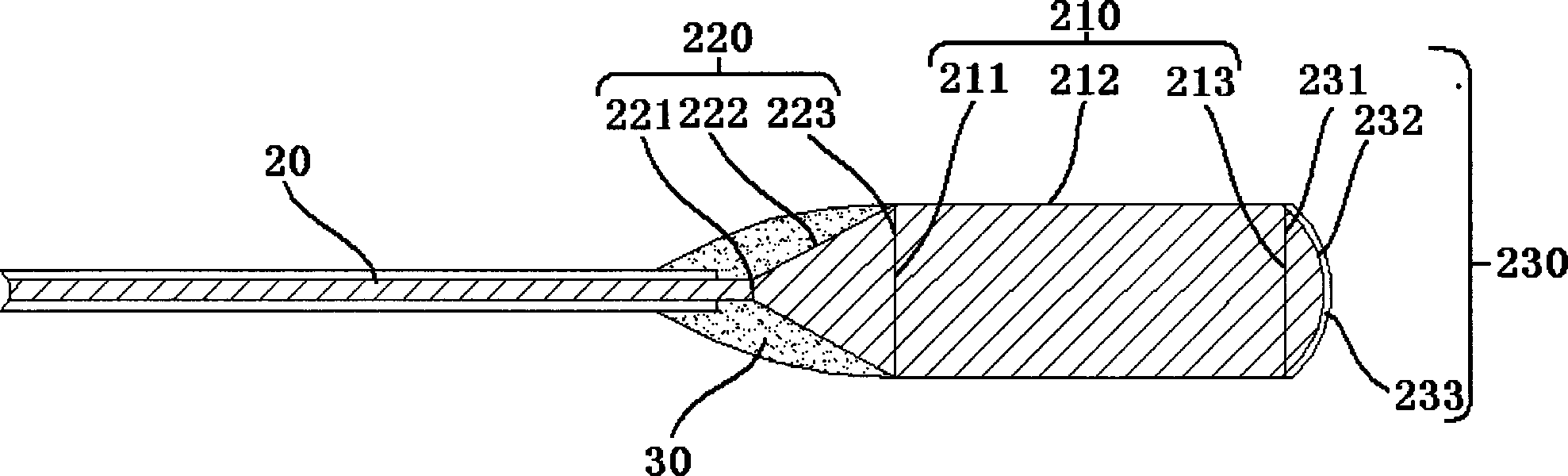

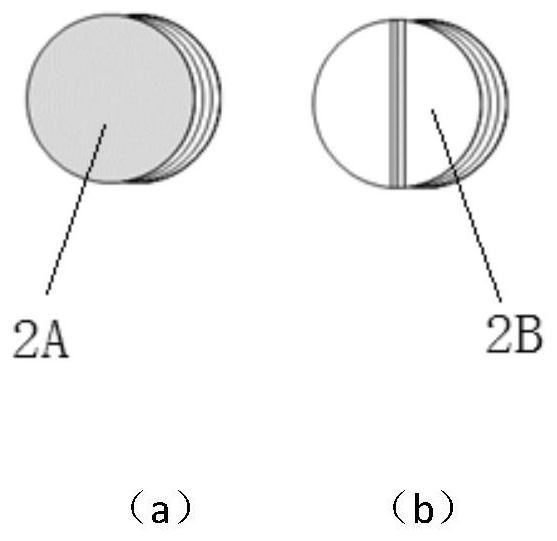

Optical fiber collimator and production method thereof

ActiveCN103246020AConsistent materialNo cumbersome adjustmentsCoupling light guidesCompression moldingHigh volume manufacturing

The invention relates to an optical fiber collimator. The optical fiber collimator comprises a special lens, an optical fiber and optical structural adhesive, wherein the special lens and the optical fiber are in fusion welding connection with each other, and the optical structural adhesive is bonded on the periphery of a welding point of the optical fiber and the special lens; and the optical fiber and the special lens are made of the same material. The junction between the optical fiber and the lens is unnecessary to polish and coat; by adopting the compression molding technology, the mass production of the lens can be realized; the overall size can be miniaturized to be consistent with the diameter of the optical fiber, so that the optical fiber collimator can be maximally miniaturized and integrated; and fewer components are needed, the optical fiber and the lens can be welded simply by centering, the complicated adjustment of a light path is not needed, the assembling process is simpler, and the cost is lower. The optical fiber and the lens are made of the same material, so that the light passes through the fewest medium layers, and the return loss can be minimized.

Owner:深圳市天阳谷科技发展有限公司

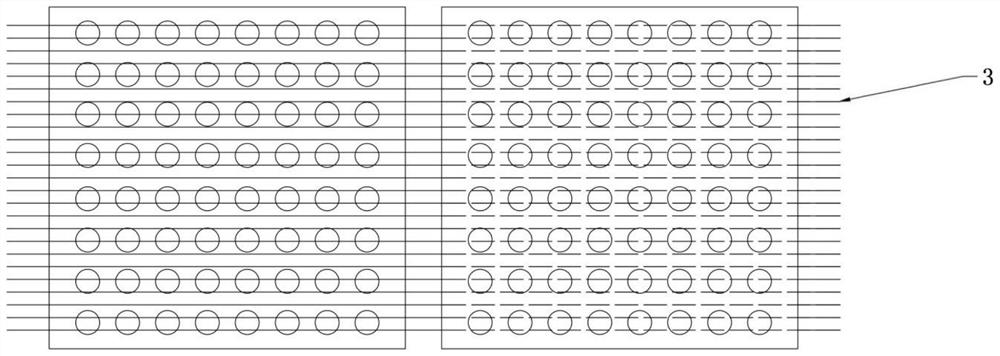

Method for packaging double-faced crystalline silicon heterojunction main-grid-free solar cell piece

InactiveCN106847968ANo secondary printing requiredReduce silver usagePhotovoltaic energy generationSemiconductor devicesHeterojunctionSilver paste

The invention relates to a packaging method for a double-sided HIT busbar-free battery sheet, which mainly includes: laying a 10-80 μm-diameter plated battery on a self-made or outsourced busbar-free HIT battery sheet with once-printed thin grid lines. Copper wire with metal anti-oxidation layer; when the height of the thin grid wire is greater than the diameter of the copper wire, first lay the copper wire in the direction perpendicular to the thin grid wire, and the contact point between the copper wire and the grid wire is a node, and the heat and pressure sensitive After the glue or photosensitive glue is covered on the copper wire and the battery sheet along the direction of the copper wire, the colloid is cured; when the height of the thin grid line is less than or equal to the diameter of the copper wire, a circular pattern is pre-dotted at the junction of the copper wire and the grid line The cured conductive paste or conductive tape is pasted, copper wire is laid, and hot-pressed and cured below 200°C; then the copper wire and the cell are hot-pressed to complete the packaging of the double-sided busbar-free HIT cell. The invention greatly reduces the amount of silver paste used, reduces production costs, and solves the problem of poor weldability of batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

Composite film for interconnection of main-grid-free heterojunction solar cell modules, and preparation method thereof

ActiveCN112786727AThe production process is simpleHigh photoelectric conversion powerFinal product manufacturePhotovoltaic energy generationHeterojunctionComposite film

The invention discloses a composite film for interconnection of main-grid-free heterojunction solar cell modules. The composite film comprises composite film bodies and copper wires, each composite film body comprises a base material layer and an adhesive film layer, the adhesive film layer is arranged on the base material layer, and the copper wires are embedded in the adhesive film layer in parallel along the adhesive film layer. A preparation method of the composite film comprises the following steps: arranging and straightening the copper wires, putting a whole piece of one composite film body or cutting the whole piece of the composite film body into a slice film, putting the slice film on a pressing tool heating platform with the adhesive surface facing upwards, pressing the composite film body or the slice film with half of the copper wires, placing another whole piece of the composite film body or cutting the other whole piece of composite film body into a slice film with the adhesive surface facing downwards on the other half of the copper wire, closing the pressing tool, adjusting the pressing pressure and the pressing time, pressing the copper wires and the composite film bodies together to manufacture the required composite film, taking out the composite film, and cooling the composite film. The composite film is simple in manufacturing process, low in cost, diversified in structure and better in use effect, and the production efficiency can be improved.

Owner:无锡市联鹏新能源装备有限公司

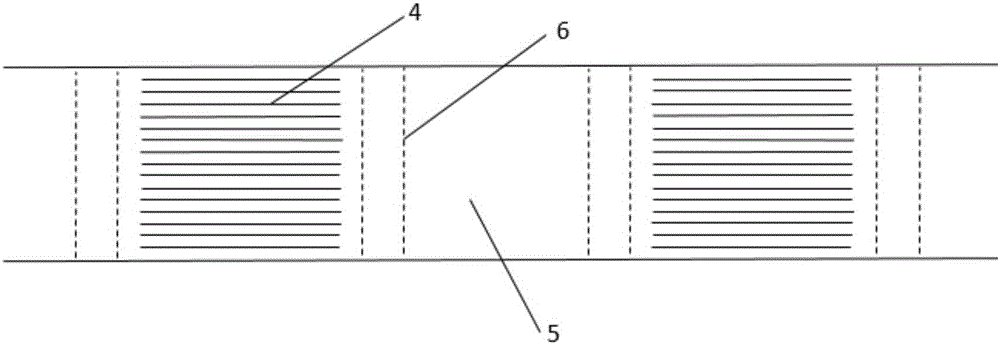

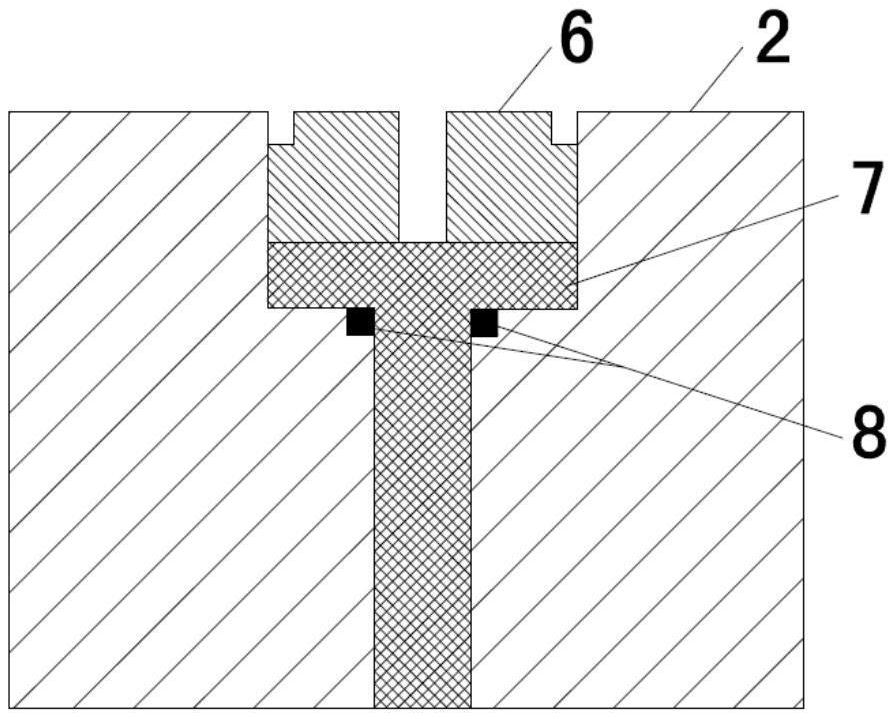

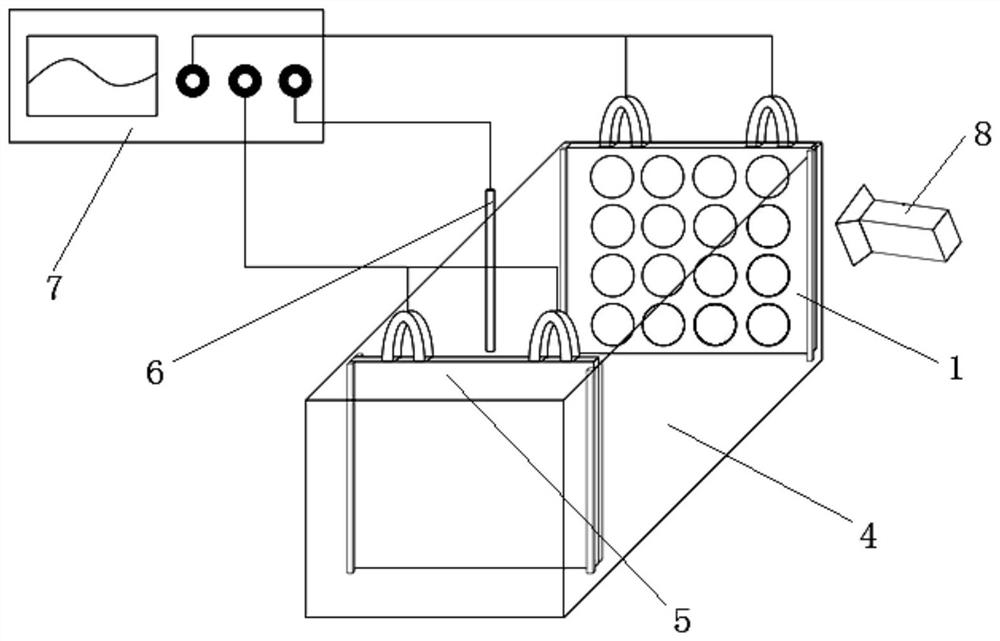

Exhaust method for buffer material building block preparation

The invention belongs to the technical field of buffer material building block preparation, and particularly relates to an exhaust method used for buffer material building block preparation and capable of ensuring the building block pressing quality. An exhaust device for buffer material building block preparation comprises exhaust holes (1), a male die (2), a female die (3), bentonite powder (4),a press machine pressure-bearing plate (5), a screw rod (6), a filter rod (7) and a sealing ring (8). The exhaust method comprises the following steps: 1, exhaust hole forming; 2, exhaust device machining; 3, exhaust hole mounting; and 4, exhaust and maintenance. The exhaust method for buffer material building block preparation has the beneficial effects that (1) discharge of the bentonite powdercan be effectively blocked while the exhaust function is achieved, and the pressing quality and efficiency are improved; and (2) the exhaust device is consistent with the pressing dies in material, potential corrosion of metal is effectively prevented, and the service life is prolonged.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

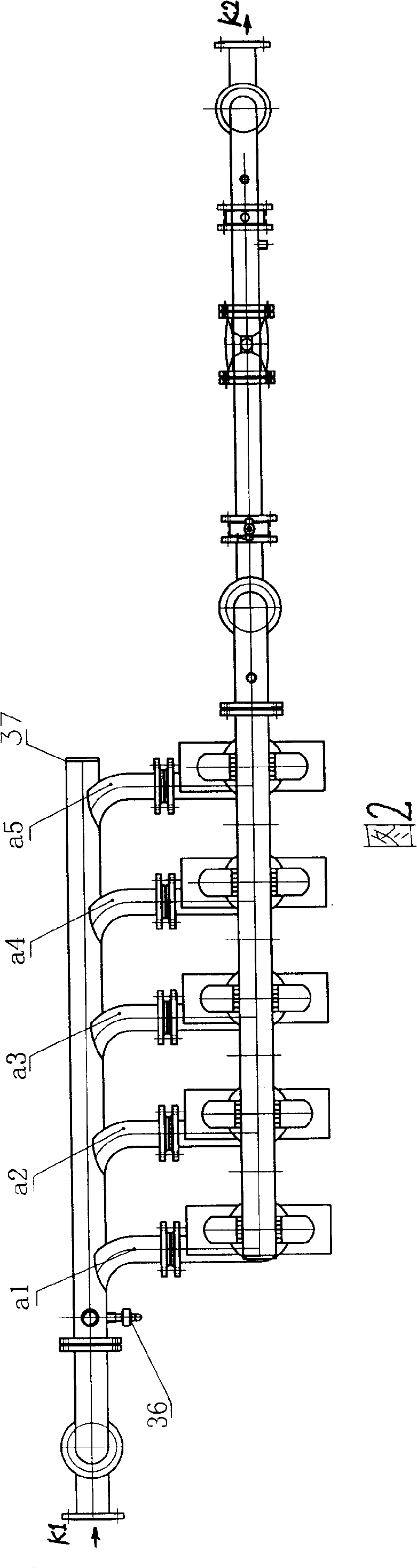

Drip-irrigation water-current mud-sand separation system

InactiveCN101069793AEasy to separateExtended service lifeReversed direction vortexCentrifugal force sediment separationDrip irrigationWater flow

The present invention relates to a dip irrigation water flow sediment separation system. Said system mainly includes the following several portions: water inlet pipe, several water-dividing pipes, several flow-dividing pipes, cyclone centrifugal separators, sand-collecting tank, sediment outlet, filters, flow-collecting pipe, water outlet pipe and dip irrigation system. Besides, said invention also provides the concrete operation method of said system.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

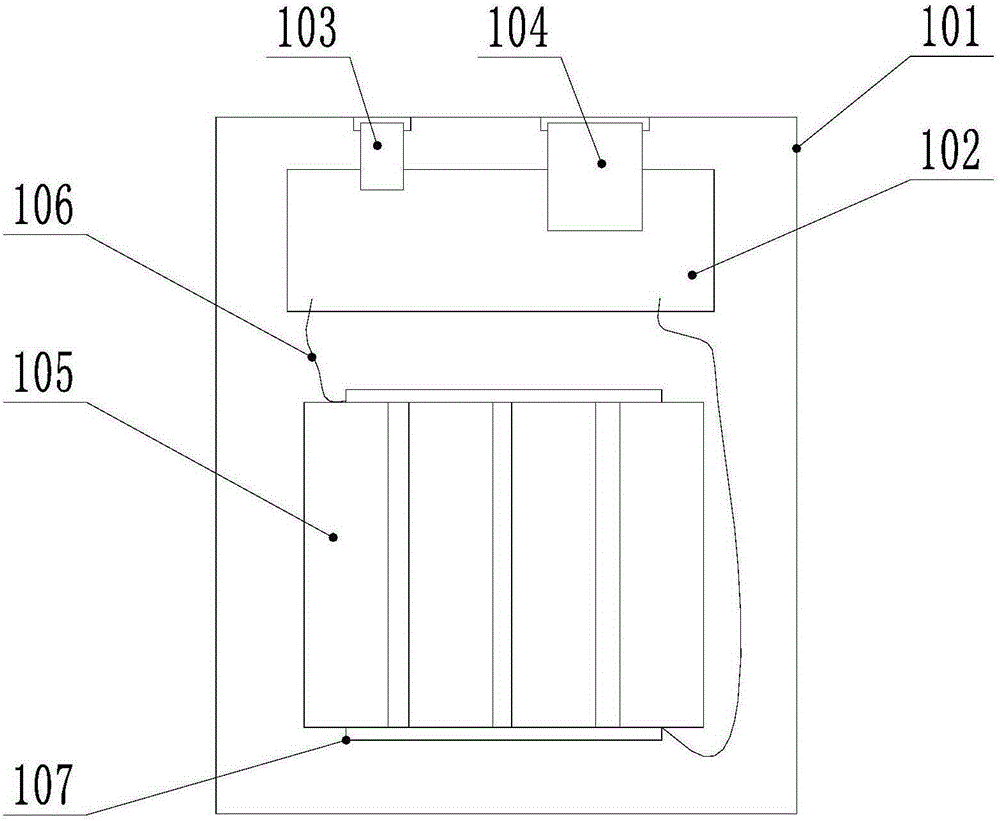

Mobile power supply

InactiveCN105244977AConsistent materialLess types of consumablesBatteries circuit arrangementsElectric powerEngineeringWater layer

The invention provides a mobile power supply, which belongs to the field of electronic accessories. The mobile power supply comprises an input interface, an output interface, a circuit board, a wire, an electric core and a shell, wherein the shell is provided with two openings, and the two openings are respectively corresponding to the input interface and the output interface; the outer side wall of the input interface and the output interface is provided with an anti-water layer made of an elastic material; the anti-water layer is used for filling gaps between the input interface and the output interface and the openings, and areas where the anti-water layer and the openings are contacted are in a compression state. The anti-water layer made of the elastic material is arranged on the outer side wall of the input interface and the output interface, the areas where the anti-water layer and the openings are contacted are in a compression state, the gaps between the openings and the two interfaces are filled, and anti-water performance of the mobile power supply is improved; and in addition, through filling the gaps, the interfaces have less shaking during a plug-pull process.

Owner:张晓君

Preparation method of ultra-thin automobile radiating circular pipe and automobile radiator

PendingCN109158845AImprove uniformityNo disconnectionStationary conduit assembliesVehicle componentsPower flowSlag

The invention discloses a preparation method of an ultra-thin automobile radiating circular pipe. The method comprises the following steps that a solid-state high-frequency welding power source is used for welding a pipe barrel into a circular pipe with the outer diameter of 7.0-7.3 mm, the thickness of a wall is 0.20-0.25 mm, and cooling, slag scraping and cutting off are carried out to obtain the ultra-thin automobile cooling circular pipe; and the invention further provides an automobile radiator, the heat radiator is composed of the ultra-thin automobile heat dissipation circular pipe, turbulent flow fins, a reinforcing plate, a mounting plate, an upper water chamber, a lower water chamber and an aluminum comb plate. According to the method, a single-layer aluminum alloy material is adopted to prepare the automobile heat dissipation circular pipe, the material uniformity is good, a high-frequency current with a high-current and large-frequency is adopted for welding, so that the welding speed is high, the welding efficiency is high, a melting point of a welding position is consistent, and the anti-corrosion performance is good; and the wall thickness of the circular pipe is very thin, not exceed 0.25 mm, the heat exchange efficiency is high, the weight is light, a consumable material is saved, and the cost is low.

Owner:NANNING ANHE MECHANICAL EQUIP CO LTD

Combined loudspeaker device and method thereof

ActiveCN105848042AProduce combined sound effectsEnhance listening experienceFrequency/directions obtaining arrangementsLoudspeaker spatial/constructional arrangementsEngineeringLoudspeaker

The invention discloses a combined loudspeaker device and method thereof. The combined loudspeaker device comprises at least two frequency band loudspeakers, wherein the high frequency band loudspeaker is arranged in the middle, and the rest frequency band loudspeakers are arranged at the periphery of the high frequency band loudspeaker in array, thereby enabling the combined loudspeaker to produce excellent sound effect.

Owner:NINGBO SHENGYA ELECTRONICS

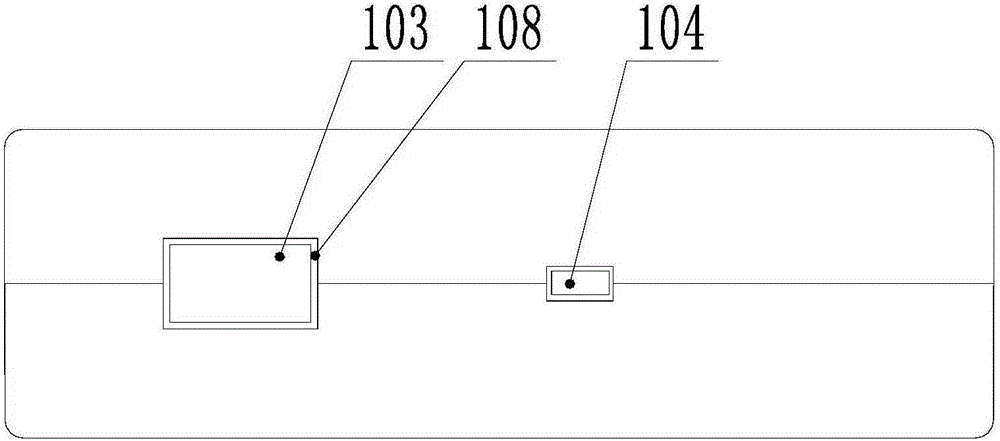

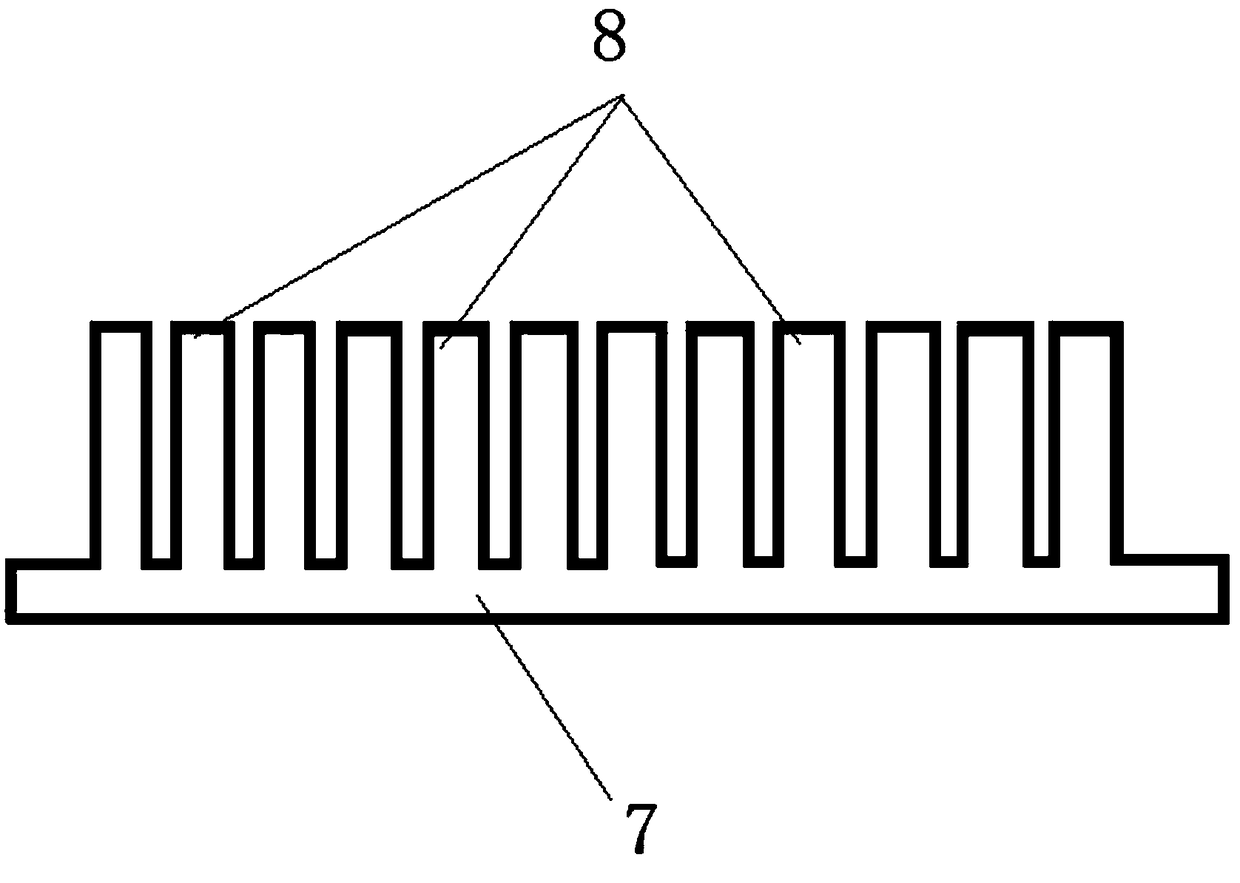

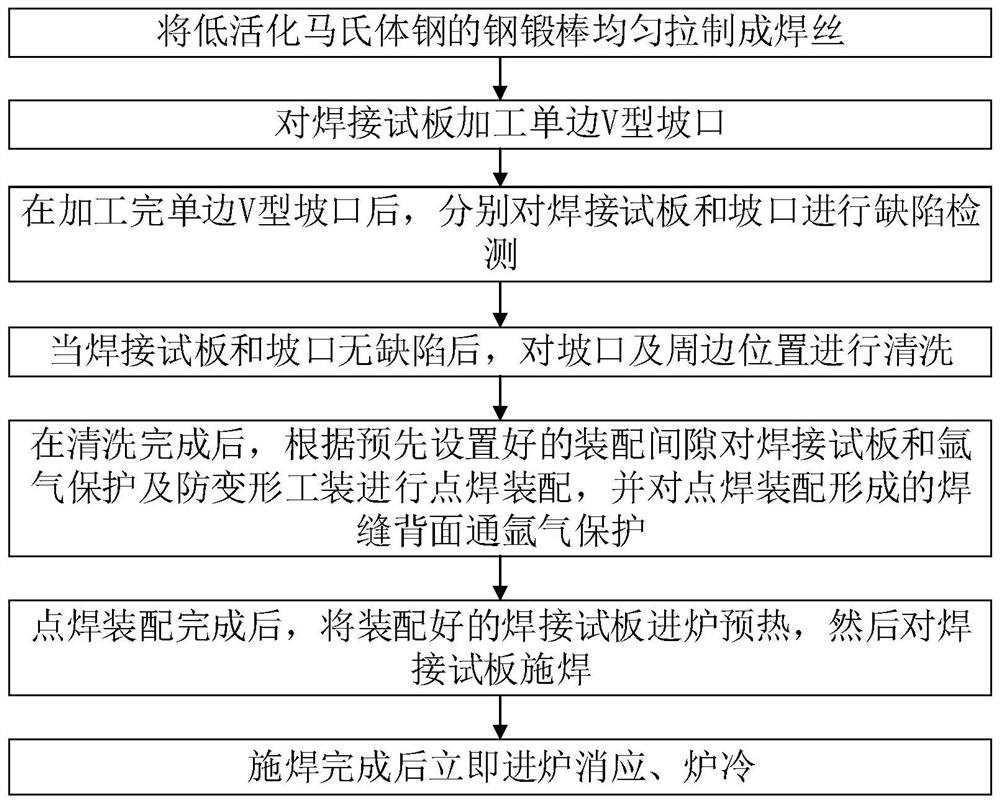

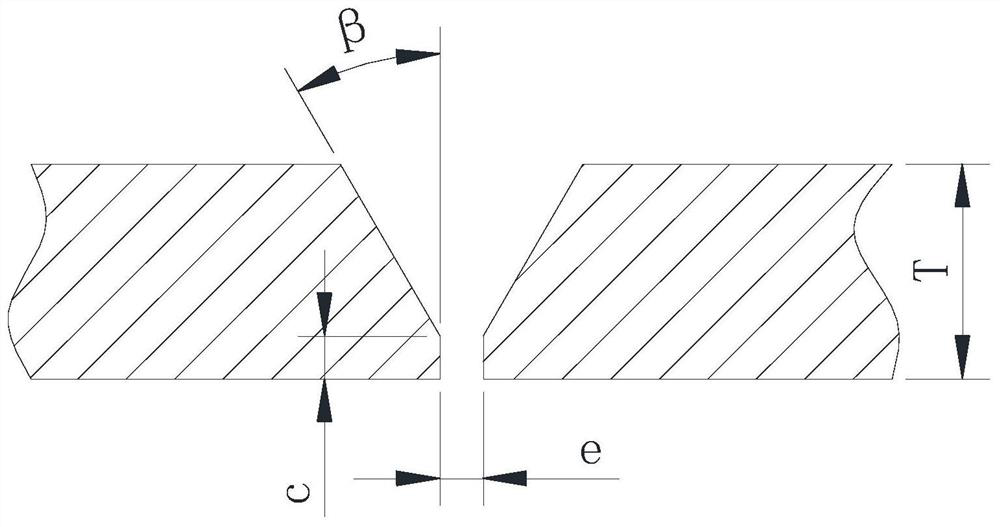

TIG welding method for low-activation martensitic steel

ActiveCN112091380AConsistent materialImprove welding compatibilityWelding accessoriesBase metalMaterials science

The invention discloses a TIG welding method for low-activation martensitic steel. According to the method, a welding wire made of low-activation martensitic steel base metal is used, so that the welding wire and a welding test plate are made of the same material, and the welding matching performance is improved; the diameter of the welding wire is set to be phi 1.6-2.4mm, and the welding test plate is subjected to single-face welding and double-face forming through a TIG welding process; and by controlling process parameters corresponding to welding and heat treatment, a welding joint of thelow-activation martensitic steel is flat, attractive and free of cracks and air holes, and the good performance of the welding joint is guaranteed.

Owner:SOUTHWESTERN INST OF PHYSICS

Making method of improved filter bag mouth

InactiveCN101920145AConsistent materialNot easy to softenDispersed particle filtrationEngineeringSpring steel

The invention relates to a making method of an improved filter bag mouth. The method comprises the following steps of: making a concave pad by using cloth for making a filter bag; attaching the concave pad to a spring steel sheet to make a synthetic piece; fording filter bag material cloth to wrap the synthetic piece; and stacking the skirts of two layers of filter bag material cloth at one end of the synthetic piece outside the filter bag mouth to be sewed together. By improving the concave pad material and the sewing method of the filter bag mouth, the filter bag mouth can resist aging, softening and dust, and has lower and stable dust discharge amount of tail gas dust; and the filter bag hardly falls in use and has long service life and decreased making cost.

Owner:宜兴市泰清环保设备有限公司

Wall bricking finishing lightweight slurry

InactiveCN101215128AHigh bond strengthConsistent heat and cold coefficientSolid waste managementEmulsionCoal

The invention discloses a lightening paste for masonry and plaster of wall, which is characterized in that the invention is produced by the following weight percentage materials: coal ash 70-80%, cement 10-18%, cellulose ether powder 0.1-0.4%, redispersible emulsion powder 1-5%, dehydrated early-strength admixture 2-6% and thickening agent 1-4%. The invention is used the masonry and plaster of wall of the vapor tension aerated concrete blocks, which causes the wall to have good overall effect, strong stability, strong capacity of anti-knock and compressive resistance and be difficult to crack.

Owner:苏兰元 +1

Large-specification salix psammophila building material and production method thereof

ActiveCN104390122AConsistent materialQuality is easy to controlStrutsElongated constructional elementsEcological environmentEngineering

The invention relates to a large-specification salix psammophila building material and a production method thereof. The production method is characterized by comprising the following steps: salix psammophila growing in the same period serves as a raw material; the peeling and the degreasing are performed for salix psammophila strips by methods of heating cooking and water pressure blasting; the procedures of drying, dyeing and assembly are synchronously finished once for the gummed salix psammophila strips; and the large-specification salix psammophila building material of 12000-30000 mm*400 mm*300 mm is produced by pressing, gluing and curing. The production method has the following beneficial effects: the salix psammophila planted and cultivated in the same period in the desert is adopted as the raw material, and is processed to produce the large-specification salix psammophila building material; the material properties are accordant; the mechanical performance is excellent; the quality is controllable; an engineering structure material with environmental protection and energy conservation is provided to a building industry, so that a natural forest resource is facilitated to be saved, and the consumption of a fossil resource is reduced; and in particular, a sustainable industrial desertification prevention and control method is provided, so that an active effect on the repairing and the protection of human ecological environment is achieved.

Owner:ERDOS CITY HUALIN SALIX TECH CO LTD

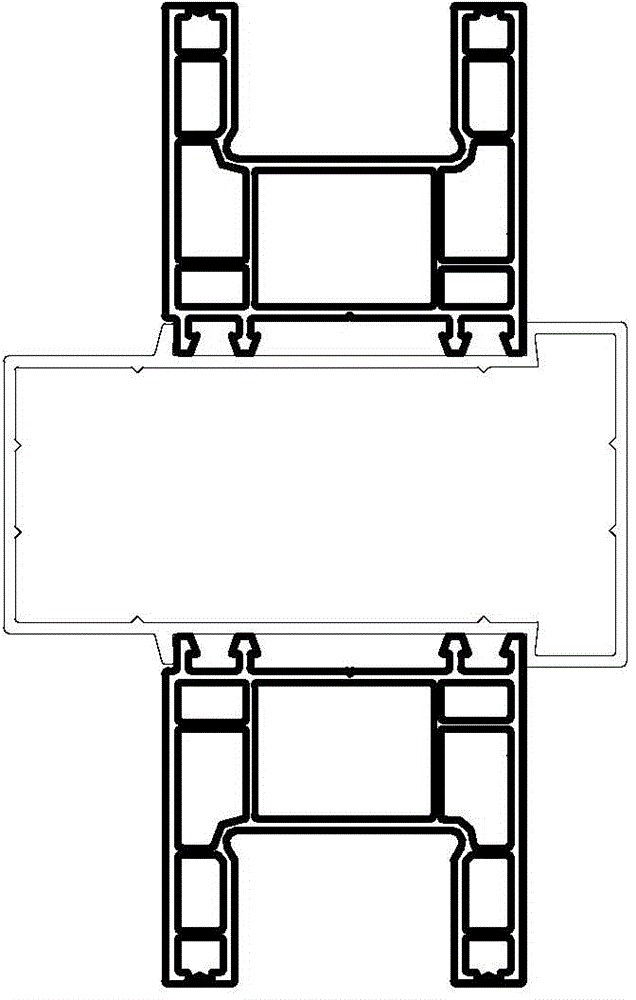

Universal spliced tube for plastics doors and windows and profiles using spliced tube

The invention discloses a universal spliced tube for plastics doors and windows and profiles using the spliced tube. The spliced tube comprises a plastic frame and a steel liner positioned in the plastic frame, wherein the section of the plastic frame comprises a spliced claw and a frame body which are integrally shaped; the spliced claw is higher than the frame body; the section of the plastic frame is integrally T-shaped; raised fixture blocks are respectively arranged at two sides of the frame body. The plastic frame and the profiles are consistent in material, large in pressure bearing, and difficult to deform. The inner chamber steel liner adopts the common square tubes on the market; the steel liner does not need special customization and processing. The spliced claw and fixture blocks of the spliced tube can be excellently matched with 60 side hung, 60 push-and-pull, 80 push-and-pull and 90 push-and-pull door and window series.

Owner:安徽科苑门窗工程有限公司

Mold for preparing variable diameter glass fibre reinforced plastic pipeline

InactiveCN101391486AIncrease profitReduce manufacturing costTubular articlesEngineeringFibre-reinforced plastic

The invention belongs to the field of die technique, and particularly discloses a die used for preparing variable-diameter FRP pipe. The main technical proposal is as follows: a long rotation shaft is started by a power mechanism; the rotation shaft is sleeved by at least two cylindrical dies; the cylindrical die consists of a cylinder part and a structure with the end in cone shape, wherein, the cone mouth of the cylindrical die is sleeved on the rotation shaft; the cone mouths of other cylindrical die are respectively sleeved on the cylinder part of the cylindrical die; and the other end of the cylindrical die is respectively and oppositely fixed with the rotation shaft. The die used for preparing the variable-diameter FRP pipe can directly produce the die which can directly produce the variable-diameter FRP pipeline which is integrated into a whole and has no joint seam, and overcomes the defects that the variable-diameter FRP pipeline which is prepared by manual pasting has non-uniform bearing performance and is easy to seep. The die can prepare variable-diameter FRP pipes of different specifications, greatly improves the utilization ratio of the die and reduces the production cost.

Owner:徐长太 +1

Refractory mortar powder

InactiveCN109776072AImprove medium and high temperature bond strengthMaximize utilizationCeramic materials productionClaywaresBrickRefractory

The invention discloses a refractory mortar powder which is prepared from the following raw materials in percentage by weight: 46-48% of silica of which the SiO2 content is not less than 96%, 46-48% of residual silica bricks of which the SiO2 content is not less than 92%, 3-8% of refractory brick clay of which the Al2O3 content is not less than 25%, 0.05-0.09% of graphite and 0.03-0.05% of a phenolic resin powder, wherein the residual silica bricks are made of a material of silica bricks constructed by the refractory mortar powder. Due to the adoption of the phenolic resin powder, the adhesionstrength of refractory mortar can be kept at a high temperature, and the medium / high temperature adhesion strength of the mortar can be improved; due to the adoption of the residual waste bricks, themaximal utilization of wastes can be achieved, the service lives of a steel ladle and a furnace can be prolonged, and the refractory mortar powder is applicable to high-temperature furnaces and steelladles.

Owner:JIANGSU YUEZHAN NEW MATERIALS

Water flow mud-sand separating system for drip irrigation

InactiveCN101259343AEasy to separateExtended service lifeReversed direction vortexWatering devicesDrip irrigationWater flow

A flow sediment separation system for dripping irritation aims at improving the sediment separation efficiency of large river flows with greater sediment content. An inlet pipe is connected with distributed pipes which are respectively provided with five water shunts for dividing discharge of stream, The inlet of each water shunt is respectively installed on the distributed water pipes obliquely and accordingly to the direction flow of inlet water, and from the one nearest to the inlet pipe, the cross- sectional areas of the water shunts are 1 / 5, 2 / 5, 3 / 5, 4 / 5 and 5 / 5 that of the distributed water pipe. The outlet of each water shunt is respectively arranged at a cylinder of a rotary flow centrifugal separator, at the lower part of which a sediment outlet is respectively connected with a sand collecting pot. The outlet at the upper part of each rotary flow centrifugal separator is respectively connected with an inlet of a lamination type filter, and the outlet of the lamination type filter is respectively connected with an inlet of a flow collecting pipe. The outlet of each flow collecting pipe is respectively installed on the water collecting pipe which is connected with the dripping irrigation system by the water outlet pipe.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Drip-irrigation water-current mud-sand separation system

InactiveCN100551485CEasy to separateExtended service lifeReversed direction vortexCentrifugal force sediment separationCycloneDecomposition

The purpose of the drip irrigation water flow sediment separation system is to improve the efficiency of sediment separation for rivers with a large amount of sediment. The water inlet of the shunt pipe is installed on the water shunt pipe obliquely relative to the water inlet flow direction respectively, and from the shunt pipe closest to the water inlet pipe, the cross-sectional area of the water inlet is 1 / 4 of the cross-sectional area of the water shunt pipe (35), The cross-sectional area of the second branch pipe (a2) water inlet is 2 / 4 of the cross-sectional area of the water pipe (35), and the cross-sectional area of the third branch pipe (a3) water inlet is 2 / 4 of the cross-sectional area of the water pipe (35). 3 / 4, the cross-sectional area of the water inlet of the fourth shunt pipe (a4) is 4 / 4 of the cross-sectional area of the water shunt pipe (35), and the water outlet of each shunt pipe is respectively installed in a cyclone centrifugal separator (32, 30, 26, 24) on the cylinder, the silt outlet at the bottom of each cyclone centrifugal separator (32, 30, 26, 24) is respectively connected with a sand collection tank (31, 29, 27, 25), The outlet on the top of each cyclone centrifugal separator (32, 30, 26, 24) is connected with the inlet of a laminated filter (4, 7, 8, 9) respectively, and each laminated filter (4, The outlets of 7, 8, and 9) are respectively connected to the inlets of a collecting pipe (b1, b2, b3, b4), and the outlets of each collecting pipe (b1, b2, b3, b4) are respectively installed in the water collecting pipe ( 5) On, connected to the drip irrigation system via the outlet pipe.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

A method of degassing for the preparation of buffer material blocks

ActiveCN109719837BBlocking dischargeRealize exhaust functionCeramic shaping apparatusPhysical chemistryEngineering

The invention belongs to the technical field of buffer material block preparation, and in particular relates to an exhaust method for buffer material block preparation that ensures the pressing quality of the block; the exhaust device for buffer material block preparation includes an air vent (1), a punch (2), die (3), bentonite powder (4), press bearing plate (5); screw rod (6), filter rod (7) and sealing ring (8), wherein, described method comprises the following steps Step 1, exhaust hole layout; Step 2, exhaust device processing; Step 3, exhaust hole installation; Step 4, exhaust and maintenance; the beneficial effects of the present invention are: (1) a buffer provided by the present invention The exhaust method for the preparation of material blocks can effectively block the discharge of bentonite powder while realizing the exhaust function, and improve the pressing quality and efficiency; (2) the exhaust method for the preparation of a buffer material block provided by the invention, which The material of the exhaust device is the same as that of the pressing mold, which can effectively prevent the potential corrosion of the metal and increase the service life.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

A method for preparing porous foam alloy and removing pore-forming agent sodium metaaluminate

The invention relates to a method of preparing a porous foam alloy and removing a pore forming material sodium metaaluminate. A metal or alloy composite material is prepared by adopting a pressure casting or sintering method and the pore forming material sodium metaaluminate. After the pore forming material sodium metaaluminate is removed, the porous foam metal or alloy is obtained. The method comprises the following steps: 1) excising an outer coating for the composite material to expose part of or all sodium metaaluminate particles; 2) putting the composite material into a reaction kettle; and 3) dissolving a sodium hydroxide solution with the concentration range of 80-300g / L and immersing the metal or alloy material; heating to 150-350 DEG C and insulating for 0.5-5 hours; then, cooling to room temperature, and obtaining the obtained porous structure material; soaking and washing by tap water or distilled water or ultrasonically cleaning within a short time and removing residual alkali liquor attached to the surfaces of porous metal and alloy to obtain the porous structure metal or alloy material.

Owner:NANJING UNIV

Electronic detection system test platform for indoor monitoring of different depths of outdoor real material

ActiveCN109916446AConsistent materialEasy to testMeasurement devicesEnvironment effectSystem testing

The invention discloses an electronic detection system test platform for indoor monitoring of different depths of an outdoor real material. By utilizing the horizontal box body and various undergrounddetection materials, an outdoor underground deep-digging multi-scale detection system test environment which is easily influenced by the environment and has potential safety hazards of collapse is changed into an indoor underground electronic detection system test platform. The box bodies are all made of moisture-resistant bamboo boards, the detected materials are actual asphalt, backfill soil, surface soil, deep graphs, moist gravel soil and other materials, and the system can be divided into a working mode and a low-power-consumption mode. Under the working mode, the current of the system is 10mA, and under the low-power-consumption mode, the current is smaller than 1mA, the system can be powered by a battery, and on the premise that the data of the system and the environment are correct, the detector and the identifier detect different materials and depths according to requirements and display the materials and depths by using related instruments.

Owner:BEIJING UNIV OF TECH

Under-seed device for crystal growth

ActiveCN110904501BEasy to manufactureEasy to joinPolycrystalline material growthFrom condensed vaporsWaferingThermal insulation

The invention provides a seed crystal down-mounted device for crystal growth, which includes a cylindrical down-mounted crucible and a cylindrical heat-preservation structure, the heat-preservation structure is tightly wrapped around the under-mounted crucible; the heat-preservation structure includes: Cylinder; the upper sealing cover of the thermal insulation structure arranged above the middle cylinder of the thermal insulation structure; the lower bottom support of the thermal insulation structure arranged under the middle cylinder of the thermal insulation structure, and a hole is formed in the lower bottom cover support of the thermal insulation structure; the insulation for sealing the hole Gasket at the bottom of the structure; the lower crucible includes: a cylinder in the middle of the crucible; a top cover on the crucible arranged above the cylinder in the middle of the crucible; a groove; a crucible bottom cover set under the cylinder in the middle of the crucible; and a funnel-shaped wafer support frame set on the crucible bottom cover for placing seed crystals. The invention can realize the application requirements of sublimation-desublimation crystals with high crystal quality, specific doping and large anchor size.

Owner:安徽微芯长江半导体材料有限公司

Embossed ladder step tile pressed with gold

InactiveCN111673889AMeet the high-volume and efficient production requirementsConvenient and beautiful pavingTreadsMouldsPolishingCoating

The invention discloses an embossed ladder step tile pressed with gold. The surface of a tile body is grooved, open grooves and the tile body are simultaneously pressed to be formed, and the interiorsof the grooves and the tile surface are the same in texture; the surface is plated with the gold through a vacuum magnetron sputtering coating process, and beauty and practicability are achieved; anda new gold-plated embossed pattern can be derived after coating and polishing, and the effects of skid resistance, warning, safety and the like can be achieved during using, and a product is beautiful and practical. Anti-skid groove lines of the ladder step tile pressed with the gold is designed on a tile die and prepared through a production process with blank pressing, glazing and sintering being the same as those of the tile body, the inner walls of the groove lines are consistent with the tile surface in texture, and fouling prevention and abrasion resistance are achieved. The embossed tile surface can be matched with a pattern of any texture, and the large-batch efficient production requirement can be met; and during using of the finished tile product, light-emitting devices can be arranged in the embossed grooves, and the great decoration effect can be achieved.

Owner:江安宇铄陶瓷有限公司

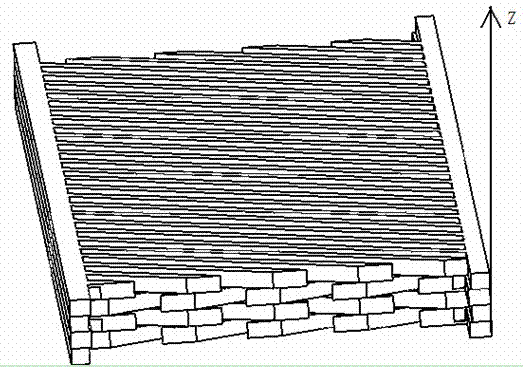

Manufacturing method of aluminium alloy workpiece with complex inner cavity body

ActiveCN102059512BGuaranteed machining accuracyIncrease productivitySoldering apparatusSpecial data processing applicationsMetallurgyBrazing

The invention relates to a manufacturing method of an aluminium alloy workpiece with a complex inner cavity body, comprising the following steps of: firstly analyzing a real object or design diagram of the to-be-manufactured aluminium alloy workpiece with the complex inner cavity body, then drawing a three-dimensional diagram of the aluminium alloy workpiece, carrying out equidistant or non-equidistant virtual segmentation on the aluminium alloy workpiece along the direction of the height axis of the aluminium alloy workpiece so as to obtain continuous virtual slices, numbering the virtual slices according to the sequence, carrying out facsimile reproduction respectively on the virtual slices on prepared processing plates according to the numbers, then assembling the processing plates after being processed according to the numbers of the corresponding virtual slices, then conveying the processing plates which are assembled and firmly pressed into a vacuum brazing furnace for vacuum brazing, finally carrying out finishing and clearing on assembled bodies after vacuum brazing, passing the qualification inspection, and then obtaining the to-be-manufactured aluminium alloy workpiece. The design not only is suitable for manufacturing the aluminium alloy workpiece with the complex inner cavity body, and has lower manufacturing difficulty, but also has higher accuracy and higher production efficiency and can ensure consistency of materials.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

A kind of anti-infrared military camouflage fabric and its printing and dyeing process

ActiveCN106049092BGood hair effectExcellent adsorption uniformityMercerising of indefinite length fabricsSingeingDisperse dyeTextile printer

The invention discloses an anti-infrared military camouflage fabric and its printing and dyeing process. The warp and weft yarns of the camouflage fabric are all made of cotton-polyester blended yarn, and the cotton-polyester blended yarn is composed of 40-60wt% cotton fiber, 30-50wt% Polyester fiber, 5‑10wt% nylon fiber and 5‑10wt% spun silk fiber are blended, and the printing and dyeing process includes the following steps: S1, pretreatment process, S2, dyeing process, S3, printing process, S4, tenter finishing; Wherein, the dyeing process adopts the disperse bath dyeing of vat dyes and disperse dyes; the printing process adopts the same paste printing of vat dyes and disperse dyes. The anti-infrared military camouflage fabric and its printing and dyeing process of the present invention, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness, full color and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

A method for connecting railway through ground wire

ActiveCN112490811BTensile strength up toGuaranteed reliabilityLine/current collector detailsCable/conductor manufactureButt weldingElectric cables

The invention discloses a connection method for railway through-earth wires. The porcelain sleeve is placed on the cable core from which the sheath has been removed, and the cable core is welded by a butt welding machine; after welding, the porcelain sleeve is smashed; the cable core is welded Grind the joint part; cut off the brass sleeve of appropriate length, put on the brass sleeve; use a vise, clamp the brass sleeve, and tightly fit it on the cable core; line the brass sleeve and the circumference of both ends Weld with the sheath; grind the welding scars of the brass casing. Beneficial effects of the present invention: different welding methods for the cable core and the sheath are used for welding recovery, which can not only ensure the reliability of the use of the spliced cable, make it maintain good grounding conductivity and corrosion resistance, but also digest the short section cable.

Owner:TIANSHUI RAILWAY CABLE

A method of repairing resin products

The invention discloses a method for repairing a resin product, which includes the following steps: step a, smoothing the defect of the resin product to facilitate bonding, placing the defective plane upwards and horizontally, using the same formula as that used for the production of the resin product The repair material fills the defect; the defect is in a planar structure or planar shape; step b, take a piece of polyurethane film with an electric heating film on the surface, and coat or print electrodes on the electric heating film; step c, then the polyurethane film The smooth surface of the film is attached to the defect of the resin product filled with the repair material, and the electrode of the electric heating film is heated to keep the repair material at a temperature range of 80-100°C for 2-4 hours, so that the repair material is cured and formed ; Step d, disconnect the power supply of the electric heating film, and tear the polyurethane film from the resin product. Through the above method, the repairing method of the present invention can well repair the defect of the resin product, and the repaired part has good gloss and consistent color.

Owner:GUANGDONG SIHUI INSTR TRANSFORMER WORKS

Working electrode with multiple electrodes, combined parallel test system and use method of combined parallel test system

PendingCN113092551AAchieve one-offImplement batch filteringMaterial analysis by optical meansMaterial electrochemical variablesPtru catalystElectrolysed water

The invention belongs to the technical field of water electrolysis, and discloses a working electrode with multiple electrodes, the working electrode comprises a conductor and a plurality of same sheet electrodes, the conductor is provided with a plurality of through holes, and the sheet electrodes are installed in the through holes; and one surface of the sheet electrode is coated with an electrocatalyst layer. The invention also discloses a combined parallel test system comprising the working electrode, the working electrode, the reference electrode and the counter electrode are arranged in a constant-temperature electrolytic bath, and one surface, coated with the electrocatalyst layer, of the sheet electrode is arranged opposite to the counter electrode; the electrochemical workstation is respectively connected with wiring terminals of the working electrode, the counter electrode and the reference electrode; the surface change condition of each sheet electrode on the working electrode is shot by using a camera, the reaction characteristics of a plurality of electrodes can be simultaneously measured on the same conductive body in the same test environment, one-time measurement of a large number of different electrode properties is realized, and by designing the parameter difference of the catalyst layer on each electrode, batch screening of various electrochemical catalysts is realized.

Owner:HUANENG CLEAN ENERGY RES INST +9

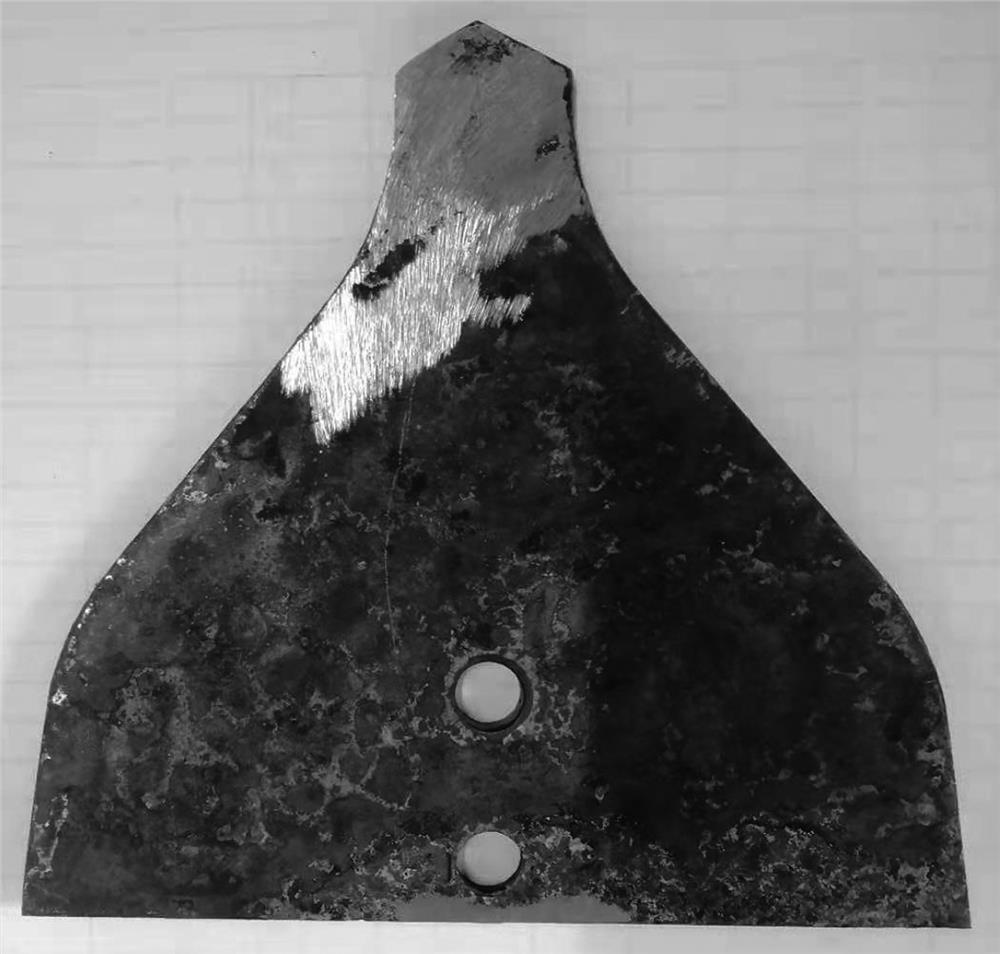

Manufacturing method of green sand casting sprue cup milling cutter

PendingCN113369612AEasy accessSimple processFurnace typesHeat treatment furnacesSaline waterMilling cutter

The invention provides a manufacturing method of a green sand casting sprue cup milling cutter. The manufacturing method comprises the following steps of (1) material selection, wherein a common carbon steel plate is selected as a base material; (2) linear cutting, wherein the carbon steel plate is machined into the outline of the milling cutter through the linear cutting technology; (3) blade machining, wherein the working area of the milling cutter is machined through a machining center, and a blade is machined out; and (4) local quenching of the working area, wherein the working area is quenched, the working area is heated to 800-1000 DEG C, after heat preservation is conducted for a certain time, the working area is taken out and put into saline water to be soaked for 3-10 min, and the area except the working area is not subjected to quenching treatment. According to the milling cutter manufactured through the method, the hardness of the working area reaches the standard, a mounting area has good toughness, the structural consistency is good, transition is smooth without concave-convex steps, cost is low, and performance is excellent.

Owner:ZHUMADIAN ZHONGJI HUAJUN CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com