A method of degassing for the preparation of buffer material blocks

A technology of buffer material and exhaust method, which is applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of high pressure, affecting the development of buffer materials, and difficult to discharge powder gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is further introduced:

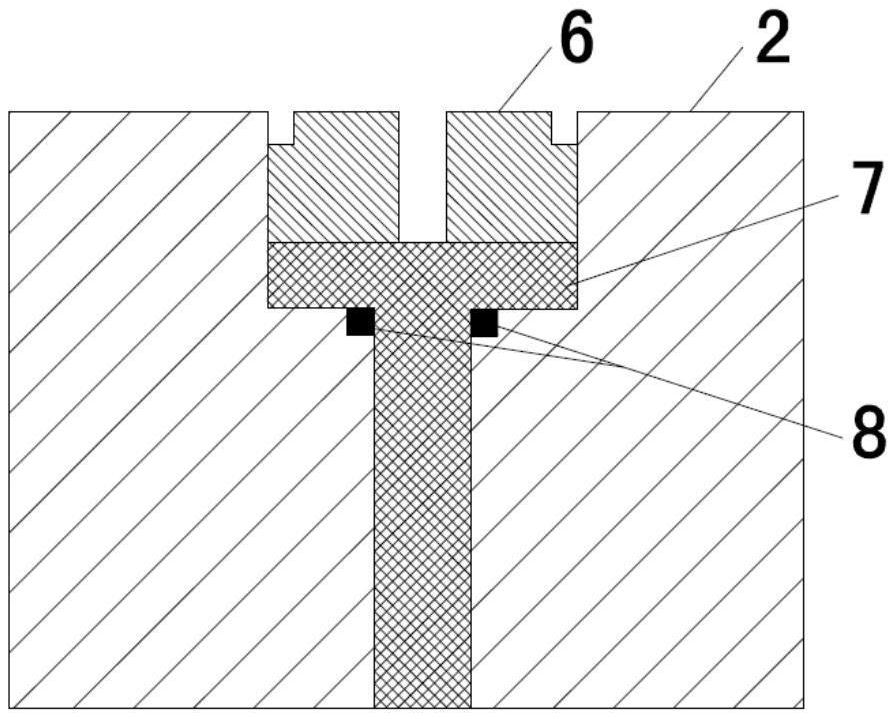

[0033] A venting method for preparing a cushioning material block. The venting device for preparing a cushioning material block includes a venting hole 1, a punch 2, a die 3, bentonite powder 4, a press plate 5, a screw 6, a filter Rod 7 and sealing ring 8, described method comprises the following steps:

[0034] Step 1, layout of vent holes;

[0035] Step 2, exhaust device processing;

[0036] Step 3. Vent installation;

[0037] Step 4, exhaust and maintenance.

[0038] Described step 1 comprises the following steps:

[0039] Step 1.1, according to the shape and size of the punch 2, considering the side seam effect, a vent hole 1 is arranged in the center of the mold;

[0040] Step 1.2, taking the center of the short side as the axis symmetry, in consideration of the range and effect of the exhaust, arrange an exhaust hole 1 in the center of each part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com