Preparation method of ultra-thin automobile radiating circular pipe and automobile radiator

A technology for radiators and round tubes, which is applied in the direction of indirect heat exchangers, heat exchange equipment, heat exchanger types, etc., and can solve the problem of increasing the size of the radiator core in the width direction, inconvenient addition of turbulence devices, and low production efficiency, etc. problems, to achieve the effect of high overall stability, simple process and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

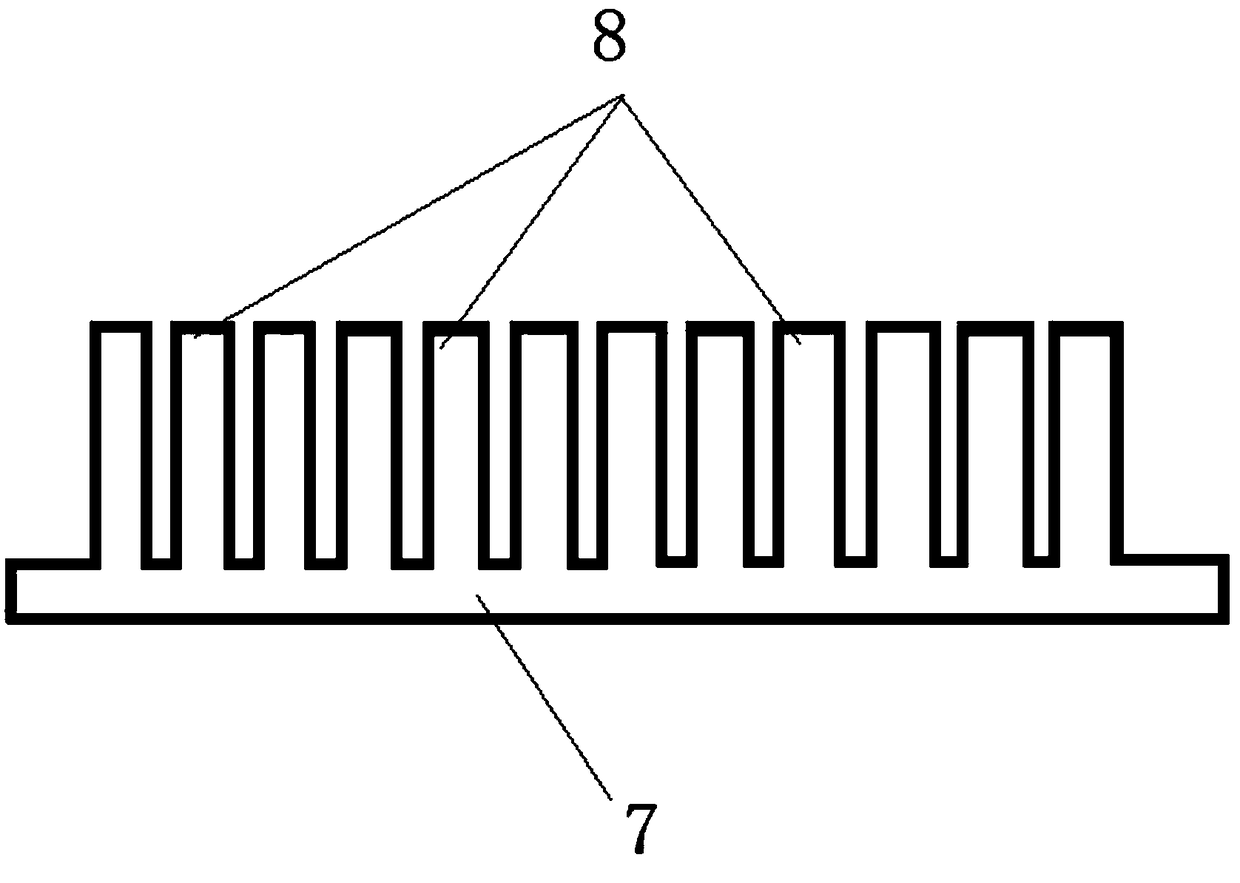

Image

Examples

Embodiment 1

[0051] Aluminum alloy is used as the material of the welded pipe, rolled into a tube shape with an outer diameter of 7.0mm through a mold, and a welding allowance of 0.2mm is left, and the welding allowance of the tube is removed under certain welding conditions by using a solid-state high-frequency welding power source. Weld the tube joints into a circular tube with an outer diameter of 7.0mm and a wall thickness of 0.20mm, and pass the circular tube directly through the cooling pool, and the cooling pump in the cooling pool continuously circulates the cooling liquid into the pool to realize the online circulation of the circular tube Cooling, the water flow rate of the cooling pump is 180L / min, and the frequency is 30Hz; scrape off the welding slag on the surface of the round pipe, cut off the pipe body with a length of 200mm, and obtain the ultra-thin automobile heat dissipation round pipe 1;

[0052] The inner high-frequency welding seam height of the ultra-thin automobile ...

Embodiment 2

[0056] Aluminum alloy is used as the material of the welded pipe, rolled into a tube shape with an outer diameter of 7.1mm through a mold, and a welding allowance of 0.25mm is left, and a solid-state high-frequency welding power source is used to remove the welding allowance of the tube under certain welding conditions. A round tube with an outer diameter of 7.1 mm and a wall thickness of 0.22 mm is welded at the joint of the tube tube, and the round tube is passed directly through the cooling pool. Cooling, the water flow rate of the cooling pump is 187L / min, and the frequency is 30Hz; scrape off the welding slag on the surface of the round pipe, cut off the pipe body with a length of 400mm, and obtain the ultra-thin automobile heat dissipation round pipe 1;

[0057] The inner high-frequency welding seam height of the ultra-thin automobile heat dissipation circular pipe 1 is 0.07mm, the line profile tolerance is 0.04, and the arch curvature is 0.18mm / 500mm;

[0058] The weldi...

Embodiment 3

[0061] Aluminum alloy is used as the welded pipe material, rolled into a tube shape with an outer diameter of 7.2mm through a mold, and a welding allowance of 0.3mm is left, and a solid-state high-frequency welding power source is used to remove the welding allowance of the tube under certain welding conditions. A round tube with an outer diameter of 7.2mm and a wall thickness of 0.23mm is welded at the joint of the tube tube, and the round tube is passed directly through the cooling pool, and the cooling pump in the cooling pool continuously circulates the cooling liquid into the pool to realize the online of the round tube Cooling, the water flow rate of the cooling pump is 194L / min, and the frequency is 30Hz; scrape off the welding slag on the surface of the round pipe, cut off the pipe body with a length of 500mm, and obtain the ultra-thin automobile heat dissipation round pipe 1;

[0062] The inner high-frequency welding seam height of the ultra-thin automobile heat dissip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com