Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Good hair effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Short-flow pre-treatment process for pure cotton woven fabric

InactiveCN102486003AAchieve the goal of energy saving and emission reductionGood desizing rateDry-cleaning apparatus for textilesBleaching apparatusRoom temperatureSlurry

The invention provides a short-flow pre-treatment process for a pure cotton woven fabric, which belongs to the technology of printing and dyeing pre-treatment of textiles. The short-flow pre-treatment process provided in the invention simplifies the conventional three-step method of desizing, scouring and bleaching into a two-step method, wherein the first step is cold pad batching and the second step is high temperature steaming; the procedures of scouring and bleaching in a conventional processing method for a pure cotton woven fabric are integrated in the short-flow pre-treatment process, no caustic soda is used in the process, and flow of the process comprises singeing, desizing (rolling a gray fabric and stacking the fabric at room temperature), open washing (with 7 open-washing boxes), scouring and bleaching (100 DEG C, 40 to 60 min), open washing (with 5 open-washing boxes) and drying. The invention provides a formula for desizing slurry and a formula for scouring and bleaching liquid to cooperate with the flow; the formula for the desizing slurry comprises 15 to 30 g / l of caustic soda (100%), 3 to 6 g / l of a penetrating agent and 2 to 5 g / l of a scouring agent; the formula for the scouring and bleaching liquid comprises 4 to 10 g / l of hydrogen peroxide (35%), 20 to 30 g / l of solid scouring enzyme, 5 to 8 g / l of water glass 40 degrees Be, 2 to 3 g / l of a scouring agent and 2 to 4 g / l of a complexing agent, and the pH value of the scouring and bleaching liquid is 10.5.

Owner:上海王港华纶印染有限公司

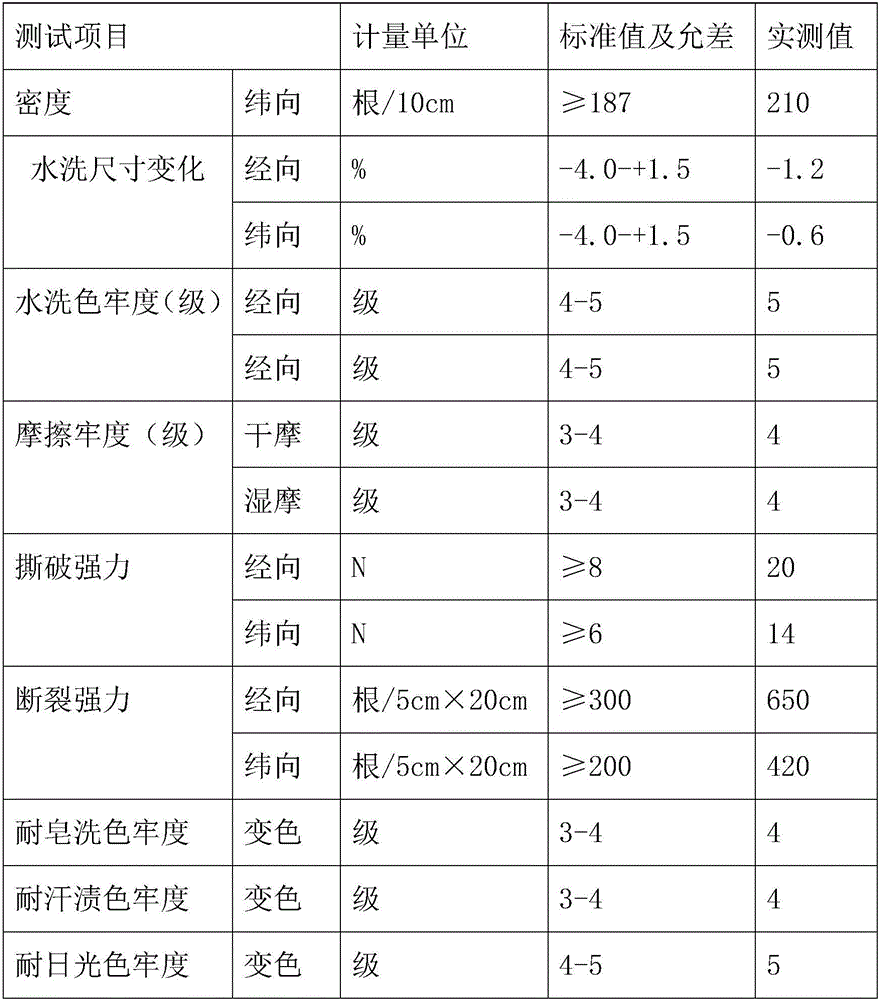

Anti-infrared military camouflage fabric and printing and dyeing process thereof

ActiveCN106049092AImprove friction resistanceImprove tensile strength at breakMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

The invention discloses anti-infrared military camouflage fabric and a printing and dyeing process thereof. Warp and weft yarns of the camouflage fabric use cotton polyester blended yarns; the cotton polyester blended yarns are formed by blending 40 to 60 weight percent of cotton fiber, 30 to 50 weight percent of polyester fiber, 5 to 10 weight percent of polyamide fiber and 5 to 10 weight percent of spun silk fiber. The printing and dyeing process of the anti-infrared military camouflage fabric comprises the following steps of S1, a pretreatment process; S2, a dyeing process; S3, a printing process; S4, tentering sorting, wherein the dyeing process uses disperse bath process dyeing of reduced dye and disperse dye; the printing process uses printing of reduced dye and disperse dye in one paste. According to the anti-infrared military camouflage fabric and the printing and dyeing process of the anti-infrared military camouflage fabric, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness of all items, full color and luster and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Seaweed sesame paste

InactiveCN103519142AImprove anti-agingGood hair effectFood ingredient functionsFood preparationLigusticum chuanxiongJasminum nudiflorum

The invention discloses seaweed sesame paste consisting of the following raw materials in parts by weight: 45-55 parts of tomato paste, 58-65 parts of soybean paste, 20-30 parts of glutinous rice, 20-30 parts of chicken, 8-10 parts of black sesame, 15-20 parts of seaweed, 2-3 parts of scouring rush, 2-3 parts of prepared rehmannia root, 2-3 parts of ligusticum wallichii, 1-2 parts of jasminum nudiflorum, flos farfarae and the like. The seaweed sesame paste takes the seaweed and the black sesame as main ingredients, thus increasing content of iodine; the black sesame can play a role in resisting aging and blacking hair; meanwhile, the paste is added with extracts such as the prepared rehmannia root, the ligusticum wallichii and the like to enhance special healthcare effect; therefore, the paste has excellent functions of nourishing yin and supplementing blood.

Owner:HEFEI KANGLING HEALTH TECH

Process for dyeing and finishing by using bamboo vinegar

InactiveCN102061619AGood antibacterial effectIncrease productivityBleaching apparatusDyeing processFiberGram

The invention relates to a process for dyeing and finishing by using bamboo vinegar, belonging to the technical field of textile dyeing and finishing. The process for dyeing and finishing by using bamboo vinegar comprises the following steps of: (1) boiling and blenching; (2) dyeing; and (3) after finishing. The after finishing specifically comprises the steps of: adding 18-22 grams of bamboo vinegar in each liter of water to make finishing liquor; carrying out after finishing on a bamboo fiber fabric by using the finishing liquor; and controlling the liquid entrainment rate of the bamboo fiber within 68-80%, the pre-drying temperature within 75-85DEG C and the curing temperature within 115-130DEG C during the after finishing. Compared with the prior art, the process of the invention is more suitable for dyeing and finishing the bamboo fiber; the bamboo fiber fabric dyed and finished by the process of the invention has favorable bacteriostasis rate and bacteriostasis value; and the physical properties such as air permeability, diffusivity, capillary effect and the like, which have larger influences on the bamboo fiber fabric, are improved obviously.

Owner:ANJI TANZHUZHUANG BAMBOO FIBER

Method for preparing silk quilt by using plate cocoons

ActiveCN104352121AHigh strengthGood hair effectBed-coversAnimal fibresAgricultural engineeringSpin density

The invention discloses a method for preparing a silk quilt by using plate cocoons. Particularly, the method comprises the following steps: 1) breeding silkworms; 2) controlling a plate cocoon production device; 3) regulating the plate cocoon production environment; 4) controlling the spinning density; 5) producing the plate cocoons; 6) harvesting the plate cocoons; 7) puffing silk; 8) refining with a special refining agent; 9) rinsing and dehydrating; 10) drying and regaining moisture; 12) making the quilt. The special refining agent is added in the refining process, the refining effect is improved, meanwhile, the refined silk has the characteristics of high strength, soft hand feel, excellent whiteness, and low cost, and the quality of the silk quilt is ensured.

Owner:NANTONG LOVER APPL

Low-temperature deoiling scouring agent and preparation method thereof

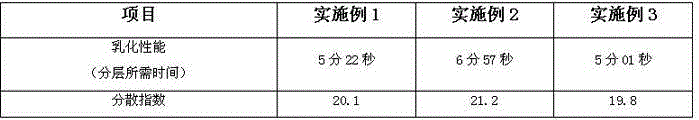

InactiveCN105002022AGood degreasing effectGood emulsification and dispersionSurface-active non-soap compounds and soap mixture detergentsAlcoholSolvent

The invention discloses a low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent comprises, by weight friction, 10-20% of fatty alcohol-polyoxyethylene ether (EO9), 10-20% of fatty amine alcohol-polyoxyethylene ether (EO15), 5-10% of Isomeric ten alcohol-polyoxyethylene ether (EO5), 5-15% of secondary alcohol-polyoxyethylene ether (EO9), 3-6% of solubilizer, and the allowance is deionized water. The invention further discloses a preparation method for the low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent is applied to the pretreatment processes of refining, deoiling, detergent washing and the like, the deoiling problem of fabric (especially the fabric containing spandex) in the process of pretreatment is solved, and oil stain and impurities in the fabric are guaranteed to be removed effectively. The functions of dispersing, emulsifying and wetting are achieved, the permeability is good, the form is little, and detergency is strong.

Owner:BONUS FUJIAN TEXTILE IND CO LTD

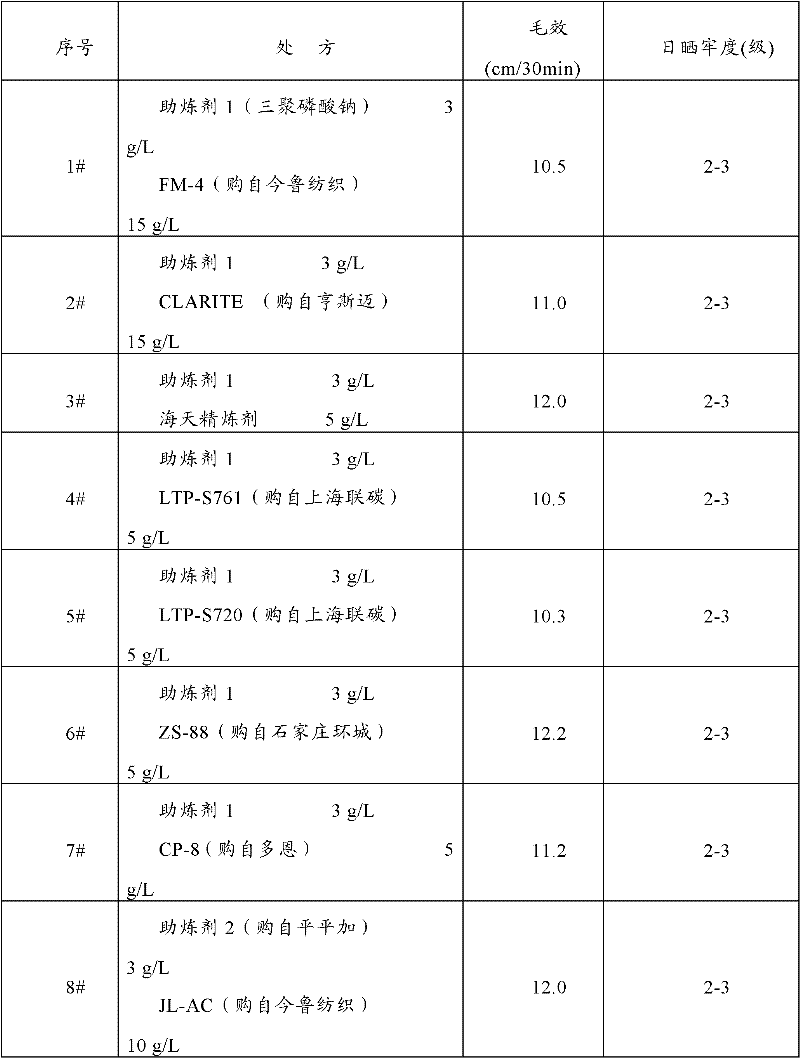

Method for improving light fastness of natural green colored cotton

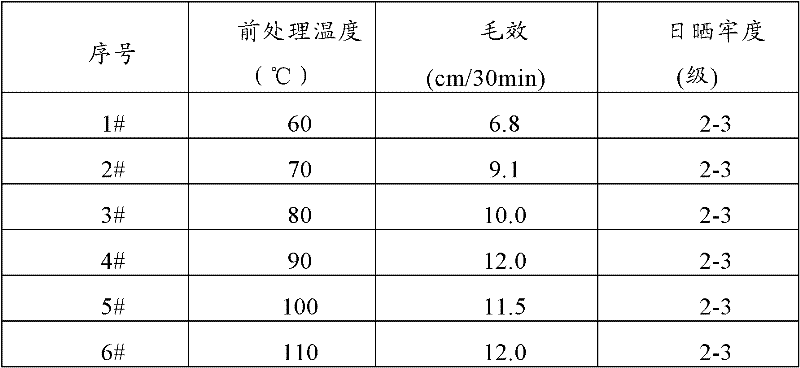

InactiveCN102561009AImprove antistatic performanceGood moisture permeabilityVegetal fibresNational standardMaterials science

The invention provides a method for improving the light fastness of natural green colored cotton. The method comprises the steps as follows: green colored cotton grey cloth is pre-processed through preprocessing addition agents; metal complexation and softening treatment are carried out after the capillary effect of the grey cloth reaches 10 to 12 cm / 30min; and then the light fastness of the grey cloth is enabled to reach 4 level, so that green colored cotton with beautiful color and stable performance is obtained. The sample production can be carried out by adopting the prescription and the technology of the processing method, so that the technology achieves good reproducibility, the light fastness of natural green colored cotton reaches 4 level, and good capillary effect and hand feeling can be achieved. Fabrics that are obtained by processing 75 percent of green colored cotton by adopting the method achieve beautiful colors and stable performances, and all the indexes of the fabrics can meet the requirements (National Standard 18401).

Owner:BEIJING GUANGHUA TEXTILE GRP

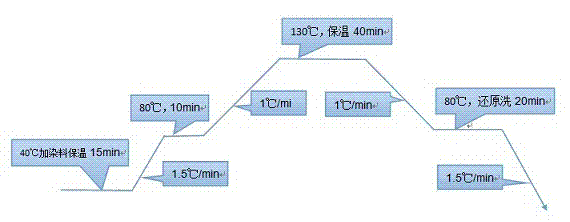

Polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process

InactiveCN104762837AFully absorbedGuaranteed fastnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterPulp and paper industry

The invention discloses a polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process. The production process includes: cold stacking, open-width desizing, in-cylinder finishing scouring, overflow dyeing, reducing cleaning, finishing, cylinder discharge, dehydration width opening, and shaping. Specifically, the finishing adopts moisture absorbing and sweat releasing, overflow washing is conducted after reducing cleaning, and a moisture absorbing and sweat releasing assistant is added after washing the fabric surface clean to carry out finishing. The process ensures sufficient textile desizing, makes the capillary effect of the taslan fabric reach the best state, so that the textile can fully absorb the moisture absorbing and sweat releasing assistant to enhance the moisture absorbing and sweat releasing effect, and the fabric can be resistant to washing. The process avoids or reduces the generation of watermark problem, and has very good practical effect.

Owner:WUJIANG FUHUA WEAVING

Enzyme scouring agent for linen fibers

ActiveCN103469600AImprove the effect of impurity removalReduce usageBiochemical fibre treatmentVegetal fibresFiberPectinase

The invention discloses an enzyme scouring agent for linen fibers. The enzyme scouring agent contains 2%-3% by volume of pectinase, 2%-4% by volume of glucanase, 2%-3% by volume of cellulose, as well as a 4-5g / L surfactant scouring agent and a 2-3g / L chelating agent, wherein a bath ratio is 1:30. The linen fibers are scoured by compound enzyme, so that the effect of removing impurities of pectin and lignin is very good; besides, the surfactant scouring agent and the chelating agent are added, thereby further reinforcing the impurity removing effect of the compound enzyme and effectively reducing the use amount of the compound enzyme; in addition, the scoured linen fibers achieve a degumming degree of 20%-23% and have a good handfeel, excellent whiteness and a fine capillary effect.

Owner:山东信开源科技创新发展有限责任公司

Rehydration method for sea cucumber

The invention discloses a rehydration method for sea cucumber, which comprises the following steps: placing dry sea cucumber into clear water and washing surface dust and salinity; placing sea cucumber in clean water, heating to 30-60 DEG C. by micro wave, keeping the temperature for 20-90 min, and cooling naturally; cleaning the sea cucumber internal organ and impurity, placing sea cucumber into purified water, heating to 60-95 DEG C. by microwave, and keeping the temperature for 20-40 min, cooling naturally, heating to 60-95 DEG C again, keeping the temperature for 10-30 min; finally placing sea cucumber into purified water after cooling, placing in an enclosed container for vacuum-pumping, keeping the degree of vacuum at 0.02-0.09 MP, placing the sea cucumber into -4-4 DEG C. for rehydration about 6-10 hours, and obtaining the finished product, and the invention has the advantages of short time, low temperature, less nutrition loss, large rehydration multiple, plump and complete shape and glistened color.

Owner:DALIAN XIAOQIN FOOD

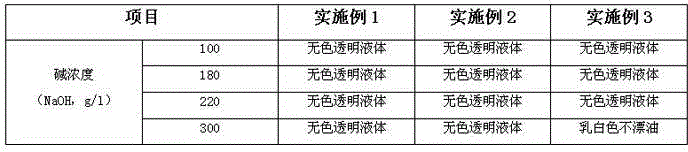

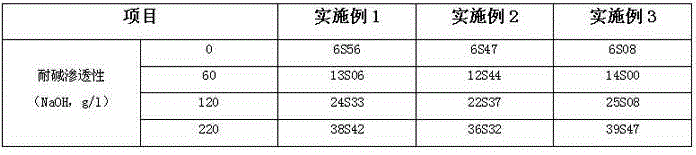

High-alkali-resistance type textile scouring agent and preparation method thereof

InactiveCN104532556AExcellent decontaminationGood hair effectFibre treatmentPolymer scienceActive agent

The invention provides a high-alkali-resistance mild-performance safe and environment-friendly textile scouring agent. The textile scouring agent is prepared from the following components in percentage by weight: 20 to 25% of alcohol alkoxylate, 15 to 25% of alkyl glycoside, 10 to 15% of ethoxy alkyl sodium sulfate, 5% of ethylene glycol monobutyl ether, 2 to 4% of organic solvents, 0.2 to 0.8% of edetic acid, 0.5 to 1.0% of defoaming agents, and 20 to 45% of water. According to the textile scouring agent, the alcohol alkoxylate with high penetration, the alkyl glycoside with a mild performance, and the ethoxy alkyl sodium sulfate which serves as an anionic surfactant are used as active matter raw materials which almost do not irritate the skin and damage cotton, hemp, silk, leather and other high-level fabrics; the formula is basically free of harmful substance residue, high in penetration, high in cleaning capacity, and outstanding in detergency capacity, and the hand feel of a processed fabric is good.

Owner:YANSHI RANHE BIOMATERIAL

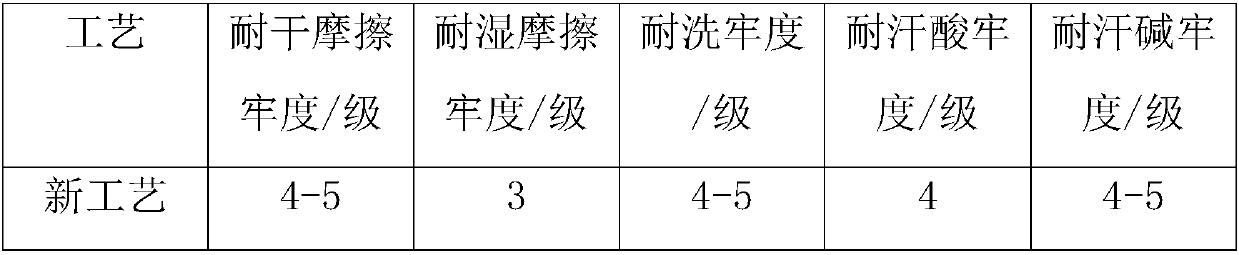

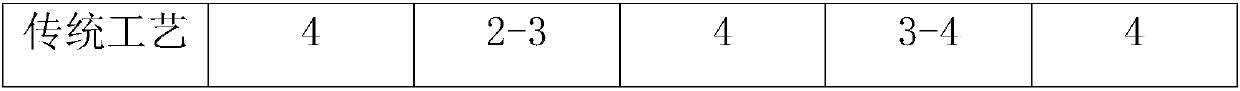

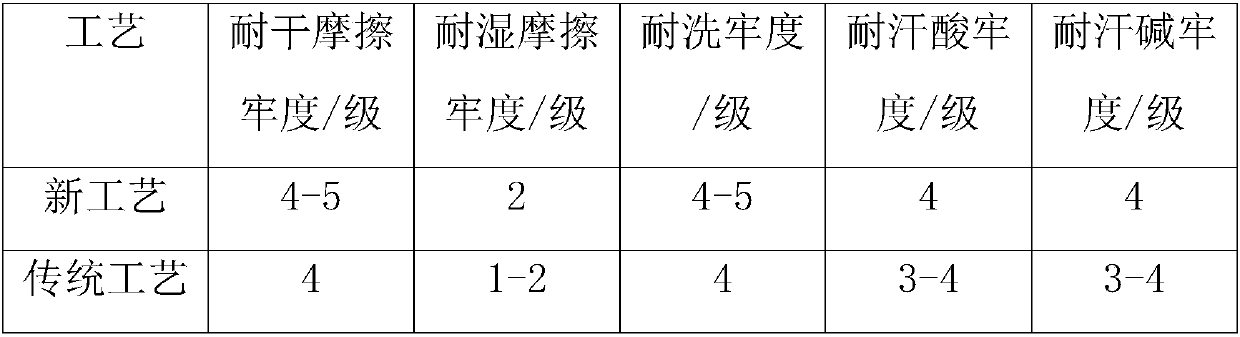

Process method for improving woven dark cloth wet rubbing fastness

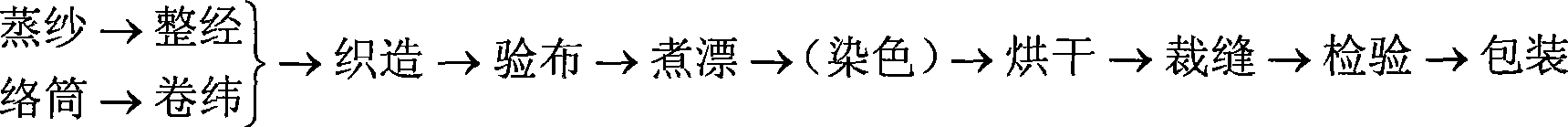

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

High performance cold rolling stack scouring agent and preparation method

InactiveCN101338514AAdsorptiveHas the ability to solubilizeFibre treatmentHigh concentrationOrganic acid

The invention provides a high-performance cold pad-batch scouring agent and its preparation method, which is characterized in that its structure molecular formula is CH-O(EO)n(PO)m-H, and it has the following formulation: 1mol of R(R')CH-O(EO)n(PO)m-H, 1-1.2mol of maleic anhydride, 0.05-1% of catalyst-composite organic acid by weight, 1-1.2mol of anhydrous sodium sulfite; the preparation method comprises an esterification reaction comprising adding low carbon alcohol EO / PO polyether, maleic anhydride and catalyst into a reactor, stirring and heating in nitrogen, timely sampling and measuring acid value until reaction termination; and a sulphonation reaction comprising reacting the resultant of the esterification reaction with sodium sulfite solution, adding nitrogen, stirring and heating to temperature of 40-85 DEG C until reaction termination when sulphonation rate variation is less than 0.5% per hour. The scouring agent of the invention can be resistant to high-concentration alkali liquor, make scouring and bleaching liquor permeate quickly, has good emulsification and dispersion ability, and good ability to adsorb or solubilize decomposed reaction product, thereby the scoured and bleached cloth acquires good capillary effect and whiteness.

Owner:金东辉

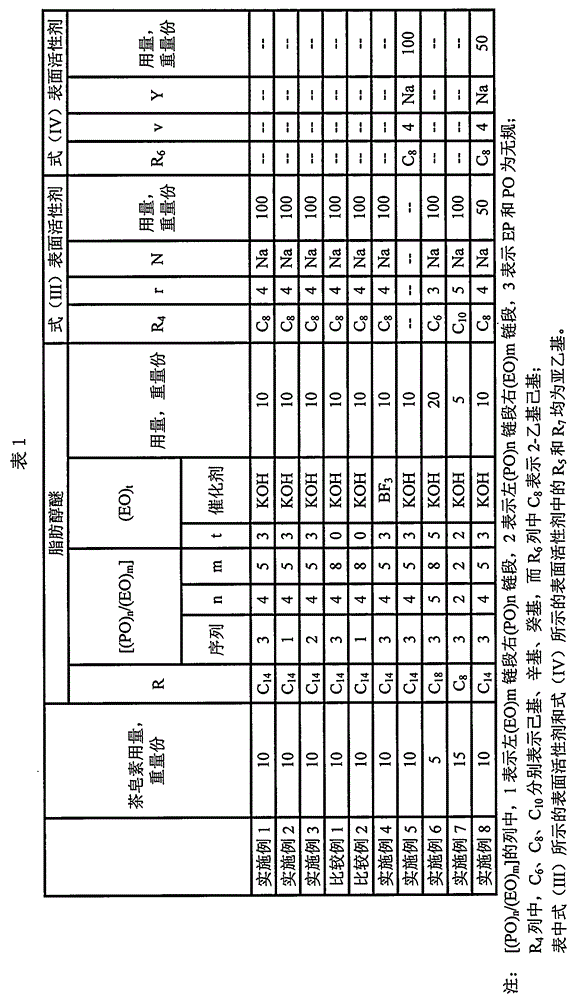

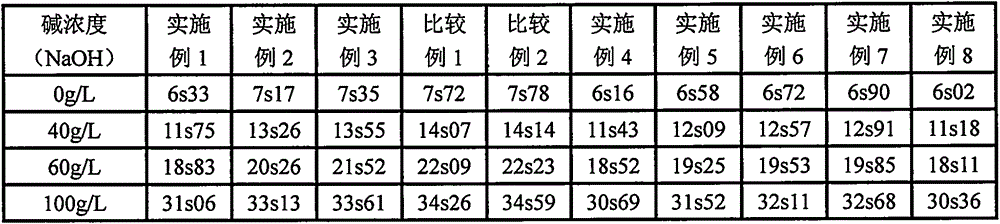

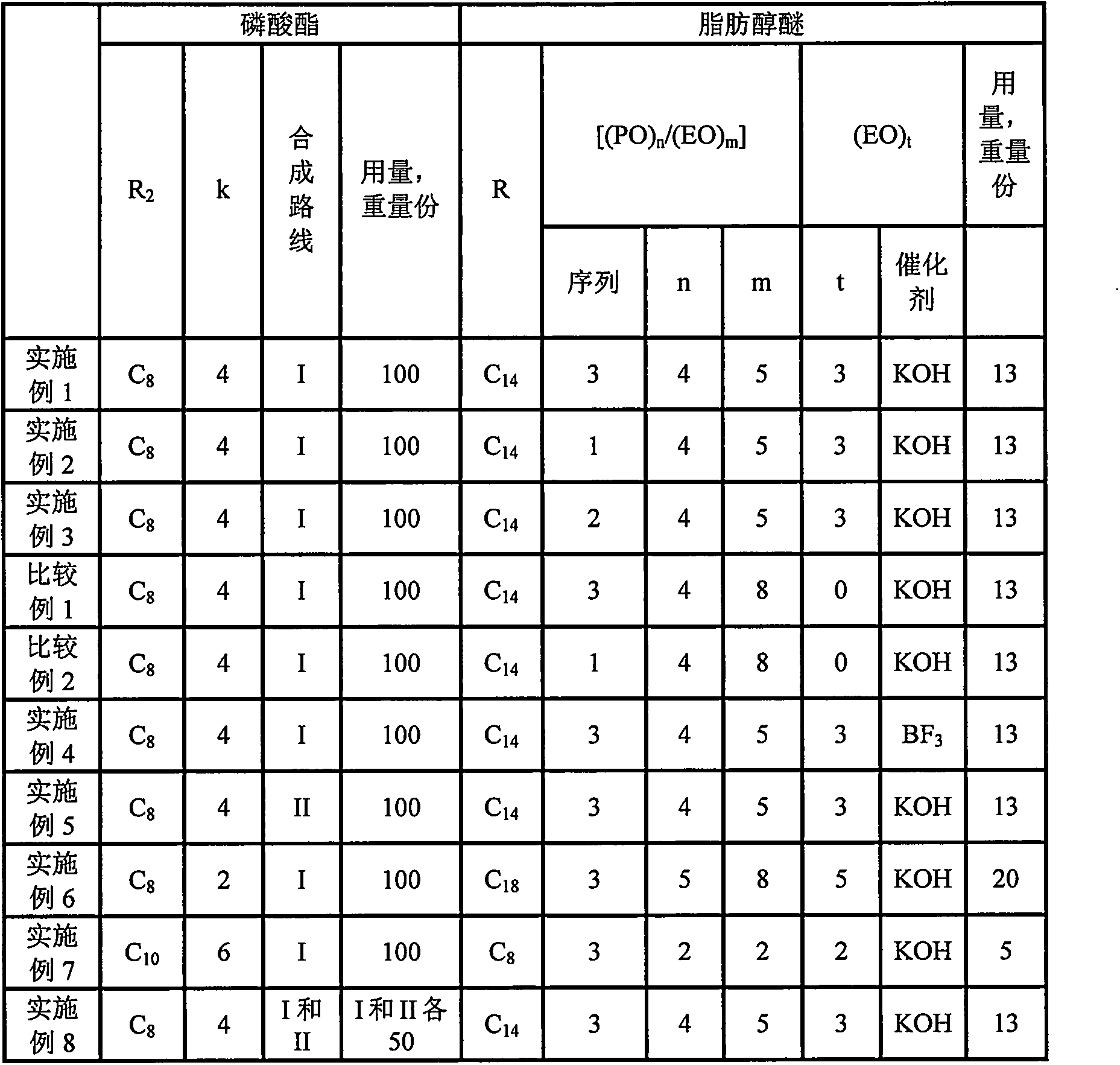

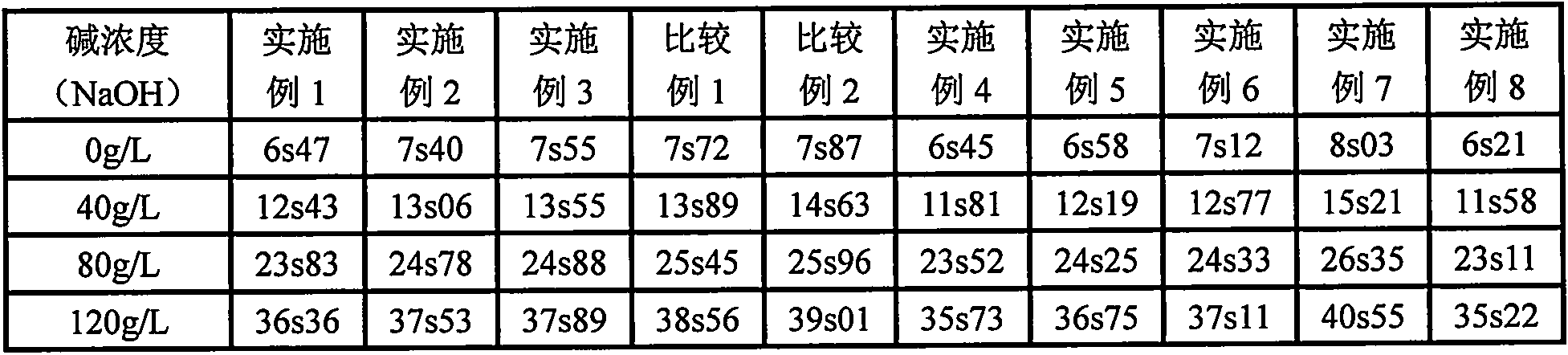

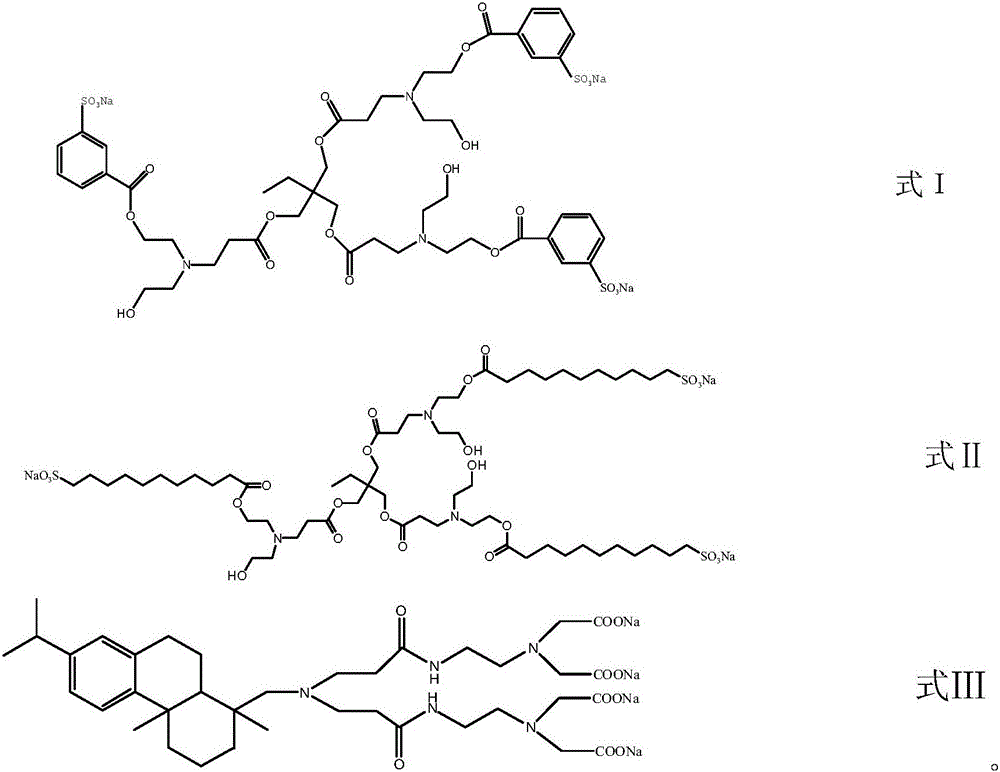

Phosphorus-free textile scouring agent

The invention relates to a phosphorus-free textile scouring agent, and solves the problem that the conventional phosphorus-free textile scouring agent has poor permeability and wettability. The novel phosphorus-free textile scouring agent comprises components in parts by weight as follows: 5-20 parts of saponin, 5-20 parts of fatty alcohol ether and 100 parts of an anionic surfactant, wherein the fatty alcohol ether has the general formula shown as the following formula (I): R-O-[(PO)n / (EO)m]-(EO)t-H, wherein R is C8-C18 alkyl; [(PO)n / (EO)m] is a copolymerized chain segment formed by PO and EO, the number n of PO units in the copolymerized chain segment ranges from 2 to 5, and the number m of EO units in the copolymerized chain segment ranges from 2 to 8, and the number t of EO structural units at the tail end of the molecule in the general molecular formula ranges from 2 to 5. With adoption of the technical scheme, the technical problem is better solved, and the phosphorus-free textile scouring agent can be applied to dyeing pretreatment processes for various textile fabric such as cotton, wool, linen, silk, synthetic fiber and the like.

Owner:SHANGHAI DUOLUN CHEM

Spinning scouring agent

The invention relates to a spinning scouring agent. The spinning scouring agent can be used for solving the problem that permeability and wettability of a spinning and scouring agent with a phosphate ester and fatty alcohol polyether system are poor. According to the technical scheme, the spinning scouring agent comprises the following components in parts by weight: 100 parts of phosphate ester and 5-20 parts of fatty alcohol ether, wherein the fatty alcohol ether has the general molecular formula, R-O-[(PO)n / (EO)m]-(EO)t-H, wherein R is C8-18 alkyl, [(PO)n / (EO)m] is a copolymerization chain segment composed of PO and EO, the number n of PO units in the copolymerization chain segment is 2-5, the number m of EO units in the copolymerization chain segment is 2-8, and the number t of EO structural units at a molecular tail end of the general molecular formula is 2-5. The technical problem is solved, and the spinning scouring agent can be used in a printing and dyeing pre-treatment process of various textile fabrics of cotton, fur, fibre, natural silk, synthetic fibers and the like.

Owner:SHANGHAI DUOLUN CHEM

Method for intertexture production of high-moisture absorption ultra-soft towel with Modal and cotton

The invention relates to a method for the preparation of a high moisture absorption ultra-soft towel by weaving Modal and cottons, comprising the steps of: (1) via the treatment of a yarn steaming machine, selecting 16-25 texX2 of Modal fiber as upper warp of the towel; selecting 24-32 texX2 of cotton fiber yarn as lower yarn; and selecting 24-32tex cotton fiber as weft; (2) at room temperature, adding a penetrating agent JFC to regulate pH value to 7, immersing the towel to heat up to the temperature ranging from 50-60 DEG C, adding complex enzyme for heat preservation, heating up to the temperature ranging from 95-100 DEG C, and adding H2O2, Na2SiO3 for heat preservation; and (3) then drying, tailoring, checking and packing. The invention saves cost, reduces pollution, and has excellent towel effect and less damage on the fibers; the prepared Modal / cotton-weaved towel has much softer and more comfortable hand feeling, more gorgeous color and better moisture absorption performance as well as is free from compacting, hardening and stickiness after long-term usage and washing.

Owner:DONGHUA UNIV +1

Low-temperature pre-treatment technology of cotton fabric

InactiveCN103469535AShort processMild reaction conditionsBiochemical fibre treatmentDry-cleaning apparatus for textilesDyeingHydrogen peroxide

The invention relates to a low-temperature pre-treatment technology of a cotton fabric. The low-temperature pre-treatment technology is characterized in that the cotton fabric is sequentially subjected to work procedures of hot water pre-treatment, biological enzyme treatment, hot water washing, enzyme inactivation and water washing, and then the cotton fabric is treated in a treating bath by a low-temperature scouring-bleaching agent, a low-temperature scouring-bleaching accelerant, a low-temperature hydrogen peroxide activator, and hydrogen peroxide. The low-temperature pre-treatment technology has a short process and moderate reaction conditions, adopts the raw materials with low cost, and has an environment-friendly effect due to low values of COD (Chemical Oxygen Demand) and AOX (Adsorbable Organic Halides) in waste water; besides, the treated cotton fabric is good in whiteness, capillary effect and breaking strength and symbionts in the cotton fabric can be effectively removed. The low-temperature pre-treatment technology only has little damage to fibers and the treated cotton fabric has a good scouring effect, and is high in quality and soft in handfeel; the energy consumption of printing and dyeing is lowered greatly and the energy consumption of water, electricity and gas is far lower than that of a traditional technology, so that the low-temperature pre-treatment technology is very beneficial to protection of biological environment and greatly reduces pressure of environment protection, energy conservation and emission reduction.

Owner:HUZHOU JINTADI TEXTILE MILL

Low-temperature plasma pre-treatment process

InactiveCN104674577AGood hair effectGood moisture absorptionSucessive textile treatmentsDyeing processCamel hairPolymer science

The invention relates to a low-temperature plasma pre-treatment process which is characterized by comprising the following steps: sorting wool; washing wool; drying; carrying out low-temperature plasma treatment; sizing and the like. The invention is the low-temperature plasma pre-treatment process which is clean and uniform to treat and has water-saving and energy-saving effects, and the surface hydrophilic performance of spinnable blanket wool (yak hair, wool, camel hair and the like) is effectively improved, so that the dyeing property of the wool is improved, and the dyeing, coating and bonding performances are improved.

Owner:青海大自然地毯纱有限公司

Dried konjac and manufacturing method therefor as well as processed foods using said dried konjac

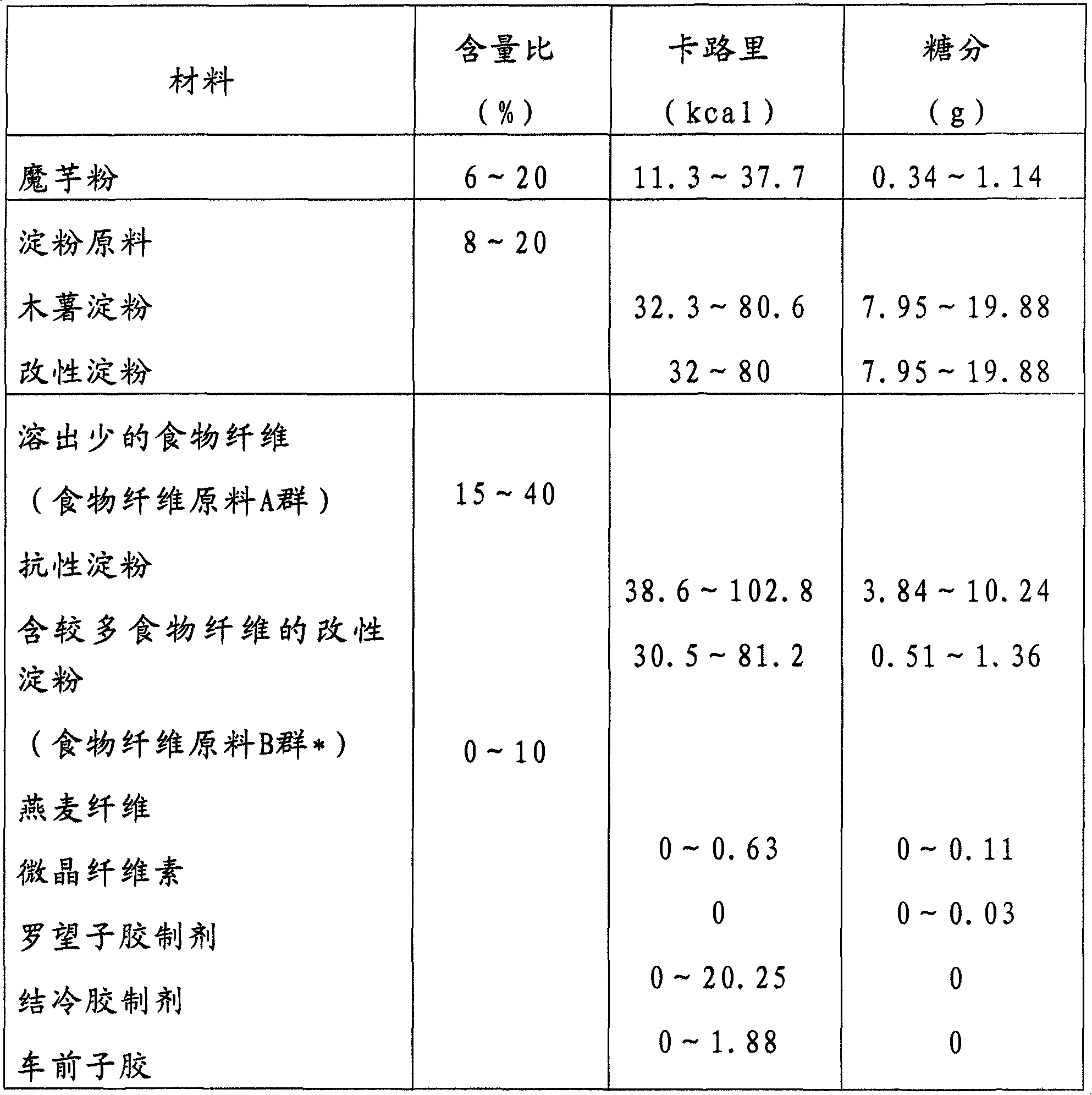

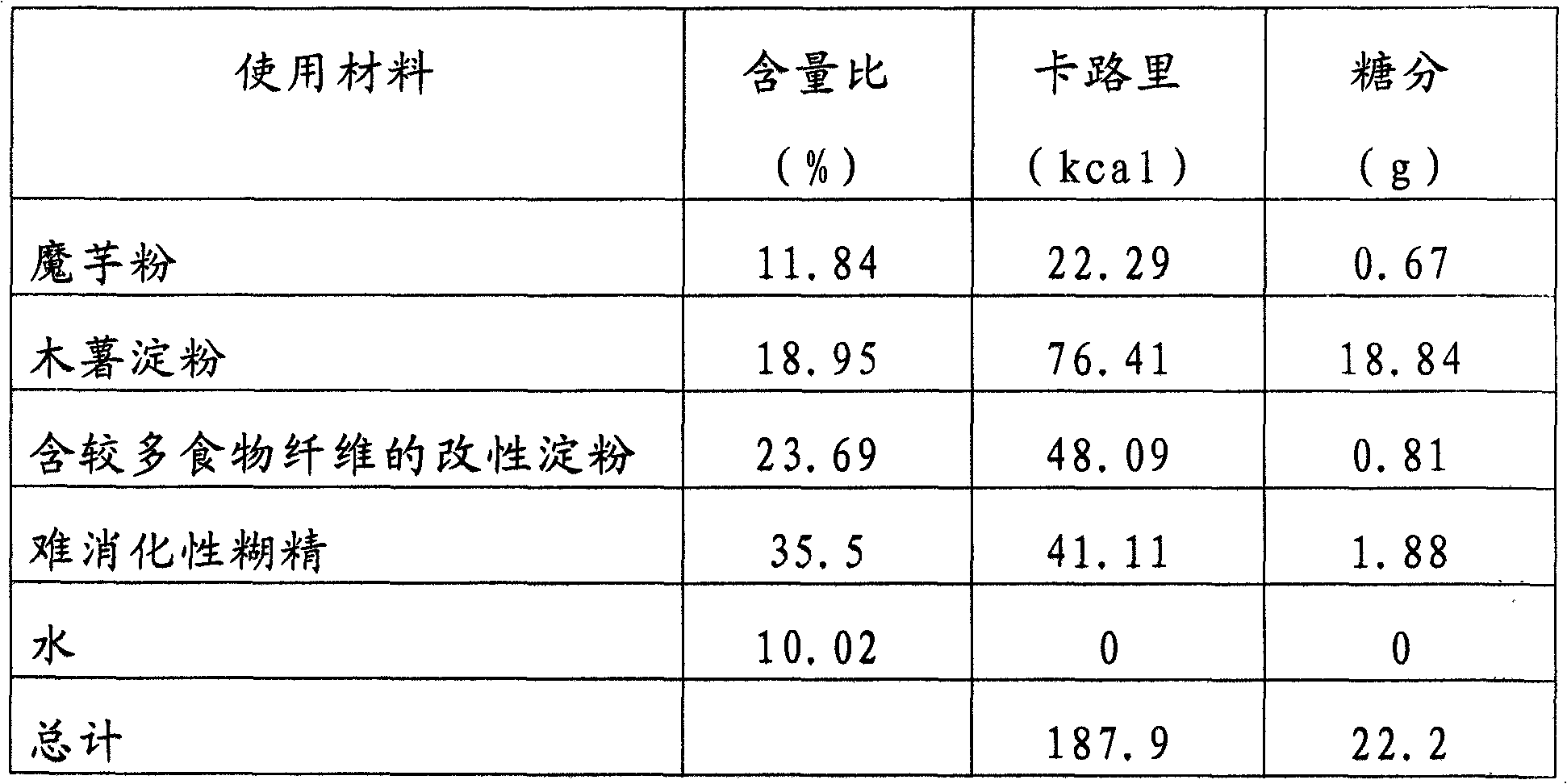

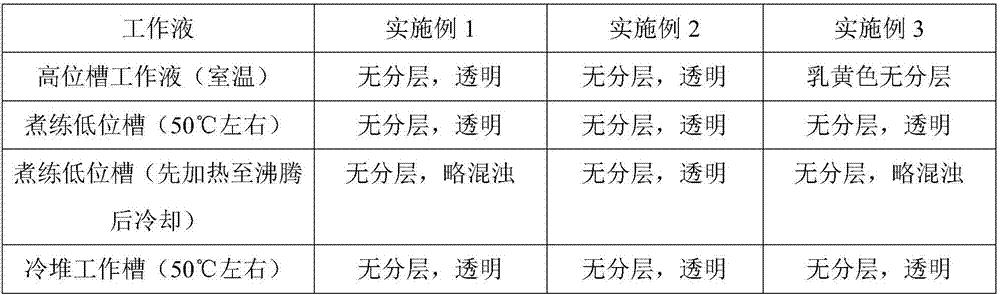

ActiveCN102123612ABlood sugar controlGood hair effectFood ingredient functionsFood preparationCelluloseFiber

Provided are dried konjac having the contradictory elements of improved water-reconstitution properties and an effect to prevent degeneration when dried along with reduced calories and sugars and which can be anticipated to have blood sugar-suppressing effects, a manufacturing method therefor, and processed foods using said dried konjac. The dried konjac is characterized in that it comprises, by weight ratio, 8 to 20% of one or more kinds of starch material selected from tapioca, potato, cornstarch and processed starch, 6 to 20% konjac powder, 15 to 40% of one or more kinds of dietary fiber material selected from a dietary fiber material A group including digestion-resistant starch and processed starch comprising a large quantity of dietary fiber, 0 to 10% of one or more kinds of dietary fiber materials selected from a dietary fiber material B group comprising oat fiber, wheat fiber, potato fiber, sugar cane fiber, crystalline cellulose, sodium alginate, carrageenan, guar gum, hydrolyzed guar gum, psyllium seed gum, xanthan gum, tamarind gum, tragacanth gum, and jeran gum, and 30 to 50% of digestion-resistant dextrin.

Owner:ABS

Pretreatment working fluid of cotton fabrics

InactiveCN103643530ALittle power lossGood cloth finishBiochemical fibre treatmentVegetal fibresAmylaseSurface finish

The invention discloses pretreatment working fluid of cotton fabrics. The pretreatment working fluid per liter is formed by mixing the following raw materials: 1-2 g of oleoyl amino acid sodium, 5-6 g of cellulase, 2-4 mL of 25%-28% ammonia water, 1-2 g of sodium polyacrylate, 6-8 g of alkaline amylase, 5-6 g of emulsifier, 3-4 g of scouring enzyme, 1-2 g of chelating dispersant, 7-8 g of 30% hydrogen peroxide, 6-7 g of fatty alcohol-polyoxyethylene ether and 2-3 g of brightening agent. Strength loss of a cotton fabric treated by the pretreatment working fluid disclosed by the invention is low, and the cotton fabric has good surface finish, desizing rate, whiteness and capillary effect.

Owner:常熟市洁韵巾被有限公司

Spinning and dyeing pretreatment auxiliary agent and preparation method and application thereof

The invention relates to a spinning and dyeing pretreatment auxiliary agent, which is prepared by adopting the following raw material components: 30 to 50 parts by weight of desizing agent, 5 to 20 parts by weight of alkali-resisting penetrant, and 4 to 10 parts by weight of complexing agent; the desizing agent is multi-alkyl amine salt; the alkali-resisting penetrant is an alkali-resisting nonionic surfactant; the complexing agent is hydroxy carboxylate. Further, the adopted raw material components also include 1 to 10 parts by weight of hydrogen peroxide stabilizer; the hydrogen peroxide stabilizer is organic phosphonate. The spinning and dyeing pretreatment auxiliary agent can be obtained through the preparation of successively mixing the raw material components, and the spinning and dyeing pretreatment auxiliary agent can be applied to a cold-batch method or open-width scouring-bleaching method spinning and dyeing pretreatment process. The spinning and dyeing pretreatment auxiliary agent can shorten the flow of the conventional spinning and dyeing pretreatment process, can reduce the energy consumption and material consumption in the pretreatment process, and can reduce the effluent volume; an obtained intermediate product of textile fabrics has good whiteness, capillary effect and desizing percentage.

Owner:青岛先达精细化工有限公司

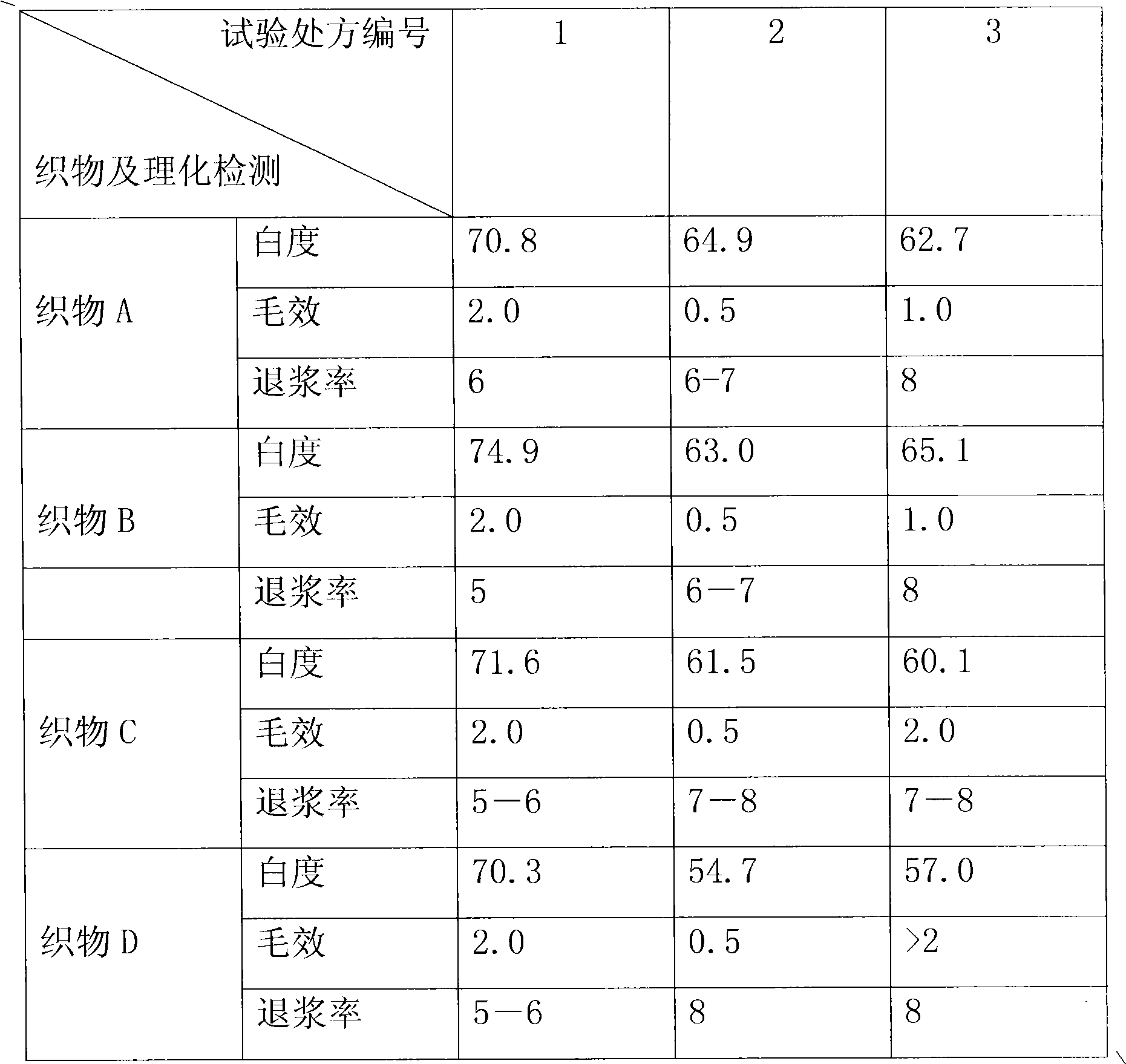

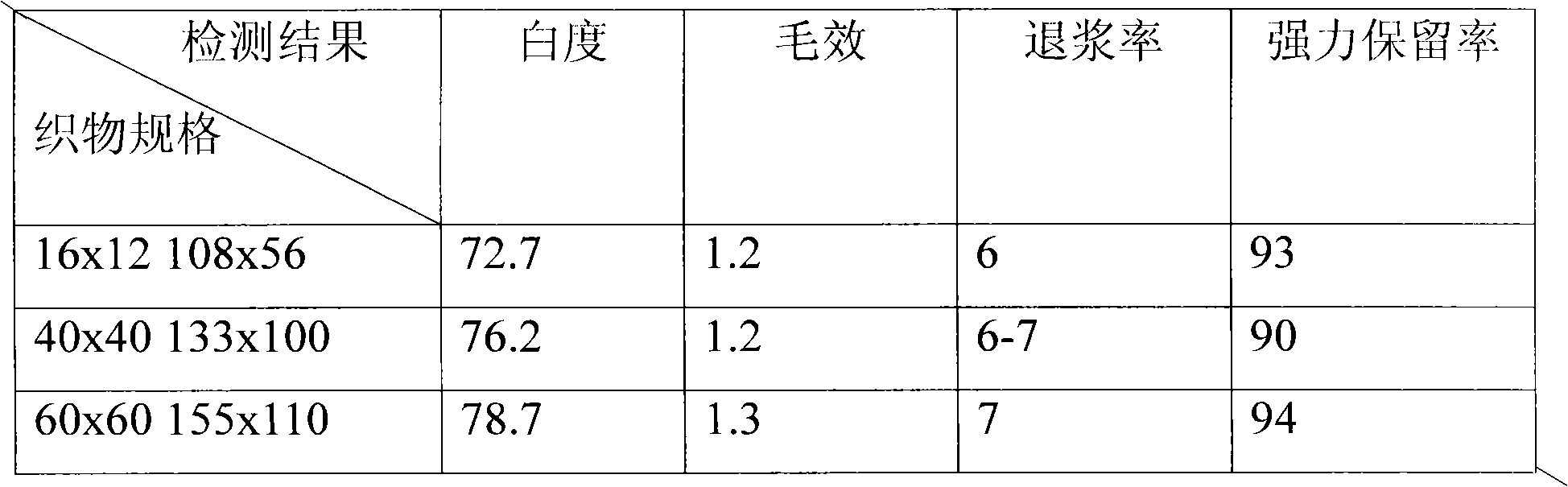

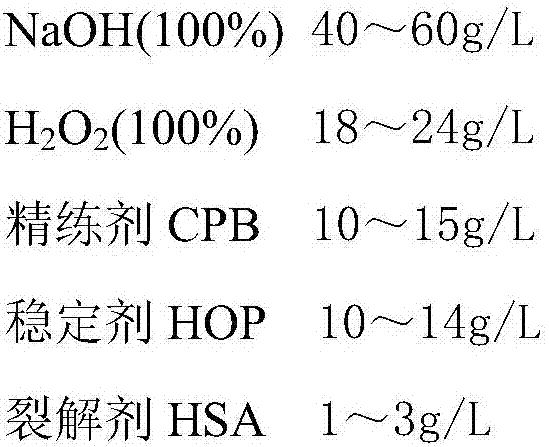

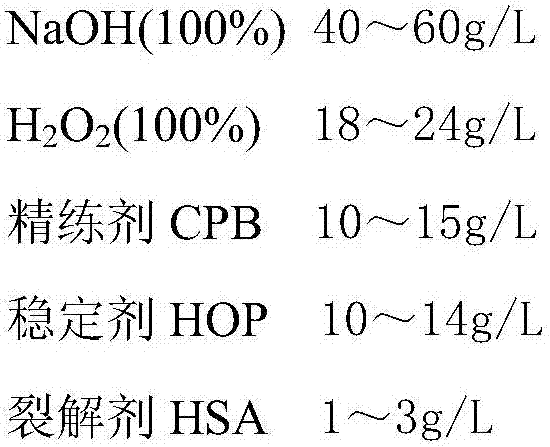

Pretreatment method for all-cotton high-density poplin

InactiveCN105568497AGood hair effectGood desizing rateMercerising of indefinite length fabricsSolvent-treatmentHigh densityPretreatment method

The invention relates to a pretreatment method for all-cotton high-density poplin. The method comprises the steps of (1) singeing; (2) padding, rolling and cold-batching; (3) tight continuous padding alkali-oxygen liquid short steaming; (4) mercerizing; and (5) drying. The all-cotton high-density poplin is treated with the method, so that the efficiency can be improved and the pollution can be alleviated.

Owner:SUNTEX

Acid dye continuous pad dyeing method for polyamide woven tapes

The invention discloses an acid dye continuous pad dyeing method for polyamide woven tapes. The acid dye continuous pad dyeing method sequentially includes steps of 1, pretreating the polyamide woventapes; 2, drying the polyamide woven tapes by infrared rays or hot air; 3, simultaneously carrying out pad dyeing by acid dye liquor and color fixing agents; 4, carrying out steaming dyeing and primary color fixing treatment; 5, carrying out hot washing; 6, carrying out secondary color fixing treatment; 7, carrying out hot washing; 8 carrying out drying; 9, dropping tapes. The acid dye continuouspad dyeing method has the advantages that the polyamide woven tapes have bright colors by the aid of acid dye steaming processes and color fixing one-bath dyeing schemes, the dye depths of the polyamide woven tapes can be effectively increased, the acid dye continuous pad dyeing method is good in deep dyeing property in polyamide woven tape dyeing procedures, and the polyamide woven tapes can be dyed with rich dark colors by the aid of the acid dye continuous pad dyeing method; pad dyeing is carried out on the polyamide woven tapes by acid dye, combined effects can be realized by an early color fixing scheme and a late color fixing scheme, the dye and the woven tapes are firmly combined with one another by chemical bonds, and the problem of poor color fastness of existing polyamide woven tapes after burning-preventive finishing is carried out on the existing polyamide woven tapes can be effectively solved by the aid of the acid dye continuous pad dyeing method.

Owner:CHENGDU HAIRONG TECHNICAL TEXTILES CO LTD

Efficient low-foam refining agent and preparation method thereof

The invention provides an efficient low-foam refining agent, which is prepared from the following ingredients including alkyl polyglucoside, branched chain fatty alcohol polyoxypropylene polyethenoxy ether, sodium polyacrylate, alkyl diphenyl ether disulfonate and water. According to a preparation method of the efficient low-foam refining agent, firstly, the alkyl polyglucoside is added into the water; stirring is performed; after the complete dissolution, the temperature of the solution is raised to 40 to 60 DEG C; then, the branched chain fatty alcohol polyoxypropylene polyethenoxy ether is added; stirring is performed for 30 to 40 min; finally, the sodium polyacrylate and the alkyl diphenyl ether disulfonate are added; uniform stirring is performed; then, cooling is performed. The refining agent has good seepage, emulsification and dispersion effects. The efficient low-foam refining agent is applicable to high-temperature boiling and scold rolling piling process; whiteness and the hairy effect of the treated fabric are high; the subsequent processing requirements are met.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Dyeing and finishing method for textile material and textile product

ActiveCN107558267ALow viscositySmall molecular weightDyeing processVegetal fibresCopolymerPolymer chemistry

The invention relates to a dyeing and finishing method for a textile material and a textile product. The dyeing and finishing method comprises the following steps: mixing dimethyl diallyl ammonium chloride-diallyl amine copolymer with water, thereby acquiring a color fixing solution; soaking the textile material into the color fixing solution and treating for 10-40min while keeping the temperatureat 45-70 DEG C, wherein the mass percent of the dimethyl diallyl ammonium chloride-diallyl amine copolymer in the color fixing solution is 0.1%-6%; and mixing poly siloxane quaternary ammonium with water, thereby acquiring a softening solution, soaking the textile material treated with the color fixing solution into the softening solution and treating for 5-35min while keeping the temperature at40-65 DEG C, wherein the mass percent of poly siloxane quaternary ammonium in the softening solution is 0.1%-5%. According to the dyeing and finishing method, the hydrophily of the textile material isnot influenced, so that the acquired textile product is difficult to have cross strip defects after the subsequent singeing or water washing, the textile material can be uniformly treated in a mercerizing process, the finally acquired textile product has better appearance, the enterprise loss is reduced and the cost is lowered.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Cold batch pretreatment technology of cotton and blended or interlaced fabric thereof

The invention relates to the technical field of textile printing and dyeing, in particular to the pretreatment process of fabrics, in particular to a cold stack pretreatment process of cotton and its blended or interwoven fabrics. The cold stack pretreatment process includes the following steps: immersing the cotton to be treated and its blended or interwoven fabric in the treatment solution for padding treatment; rolling the padded cotton and its blended or interwoven fabric, and stacking for 18- 24 hours; efficient washing of the piled cotton and its blended or interwoven fabrics; drying of the efficiently washed cotton and its blended or interwoven fabrics. The present invention can achieve the cloth surface effect of the traditional one-cooking-bleaching process, with good whiteness, good capillary effect, clean cloth surface slurry, and clean cloth surface cottonseed husks; the treated fabric has little damage to the strength; the process safety factor is high, The risk of processing fabric holes is low; the consumption of steam and water is saved, and the cost of pretreatment is greatly reduced; the discharge of production sewage is reduced; the range of fabric types applicable to the process becomes wider.

Owner:多恩生物科技有限公司

Low-temperature pretreatment technology of cotton and cotton blended fabrics

InactiveCN102978895AHigh whitenessGood hair effectDry-cleaning apparatus for textilesBleaching apparatusBreaking strengthWastewater

The invention provides a low-temperature pretreatment technology of cotton and cotton blended fabrics. A low-temperature scouring and bleaching agent, a low-temperature scouring and bleaching promoter, a low-temperature hydrogen peroxide activator and hydrogen peroxide are adopted to treat cotton and the cotton blended fabrics in a treatment bath. The technology has the advantages of short flow, mild reaction condition, low raw material costs, low COD and AOX values in wastewater, environmental protection, realization of good whiteness, capillary effect and breaking strength of the treated fabrics, and effective removal of symbionts in the cotton fabrics.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

Continuous oxygen bleaching refining agent and preparation method thereof

The invention relates to a continuous oxygen bleaching refining agent and a preparation method thereof. The continuous oxygen bleaching refining agent comprises a rare-earth catalyst, a hydrogen peroxide stabilizer, biodegradable surfactant, Gemini surfactant, hyperbranched surfactant and water. Compared with a conventional refining agent, the continuous oxygen bleaching refining agent has the advantages that the continuous oxygen bleaching refining agent is efficient and environmental friendly and wide in process applicability, the NaOH use amount is lowered by about 40%, the COD value of discharged wastewater is lowered by more than 40%, and the whiteness, capillary effect and breaking strength of fabric treated by the continuous oxygen bleaching refining agent are evidently better.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Cold pad-batch pre-treatment method for cotton textile

InactiveCN103556449AImprove wettabilityAccelerated alkaline hydrolysisBleaching apparatusVegetal fibresWater useBatch processing

The invention relates to a cold pad-batch pre-treatment method for a cotton textile and belongs to a spinning and printing pre-treatment process technology. According to the cold pad-batch pre-treatment method, a method for changing a cold pad-batch process path of the cotton textile and preparing alkali liquid and bleaching liquid in the cold pad-batch process of the cotton textile is adopted; the cotton textile is sequentially padded by the alkali liquid formed by mixing a high-ratio alcohol organic solvent with sodium hydroxide, and the bleaching liquid formed by mixing the high-ratio alcohol organic solvent with hydrogen peroxide, and then the cotton textile is subjected to pad-batch pre-treatment so as to reduce the water use amount to the greatest extent and improve a treatment effect. The method is simple in process and good in treatment effect and has the characteristics of good capillary effect, high whiteness, good quality, high softness and good glossiness; favorable conditions are created for subsequent dyeing processing and the use amount of water and chemical reagents is reduced; the alcohol organic solvent is recycled so that the burden of sewage treatment of enterprises is reduced greatly; the cold pad-batch pre-treatment method for the cotton textile is a clean production process meeting the environmental requirements and has very high social and economic benefits.

Owner:WUHAN TEXTILE UNIV

Pretreatment method for all-cotton single-yarn drill

The invention relates to a pretreatment method for all-cotton single-yarn drill. The method includes the steps of singeing; padding, rolling and cold batching; compact continuous padding alkali oxygen liquid short steaming; mercerizing; drying. The method is adopted to treat the all-cotton single-yarn drill, efficiency can be improved, and pollution can be reduced.

Owner:SUNTEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com