Process method for improving woven dark cloth wet rubbing fastness

A technology of wet rubbing fastness and process method, which is applied in the field of technology, can solve the problems affecting the color fastness to wet rubbing of fabrics, fiber bonding, etc., and achieve the effect of deepening softness, improving wet rubbing fastness, and good penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

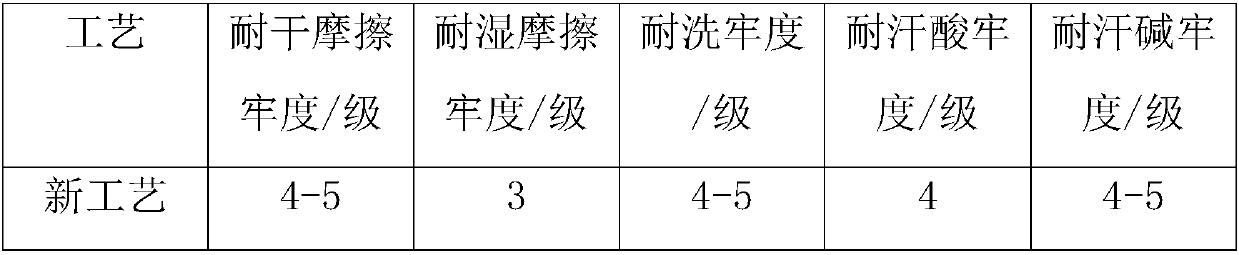

Examples

Embodiment 1

[0079] Embodiment 1: a kind of processing method of promoting the wet rubbing fastness of woven dark-colored cloth, carry out according to the following steps: (1), distributing cloth

[0080] According to the "production notice" to get the gray cloth, check whether the cloth is consistent with the production process card before distributing the cloth. According to the number of meters of each order, select an appropriate number of gray cloth bags for distribution, so that the number of meters for distribution is consistent with the number of meters required by the production process card. When distributing, implement one truck and one truck, and do not place more indiscriminately. Make a detailed record of the order quantity on the production process card. Production order number: 713149, gray fabric: 70"20*16+70D Zhigong cloth, finished product width: 57-58", composition: cotton, color: dark blue, order quantity: 18847M.

[0081] (2), Singeing cold pile desizing

[0082] ...

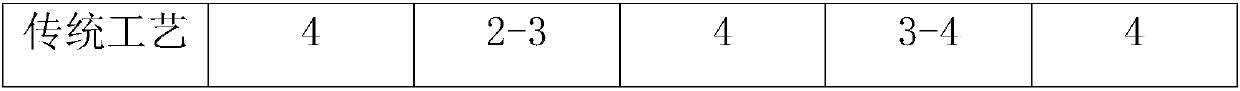

Embodiment 2

[0127] A process for improving the wet rubbing fastness of woven dark-colored cloth is carried out in the following steps:

[0128] (1), Distribution:

[0129] According to the "production notice" to get the gray cloth, check whether the cloth is consistent with the production process card before distributing the cloth. According to the number of meters of each order, select an appropriate number of gray cloth bags for distribution, so that the number of meters for distribution is consistent with the number of meters required by the production process card. When distributing, implement one truck and one truck, and do not place more indiscriminately. Make a detailed record of the order quantity on the production process card. Production order number: 710913, gray fabric: 72"88*42 / 10+10*10+70D elastic fabric, composition: cotton, finished product width: 49-50", color: bright red, order quantity: 18062M.

[0130] (2), Singeing cold pile desizing:

[0131] Singeing and desizin...

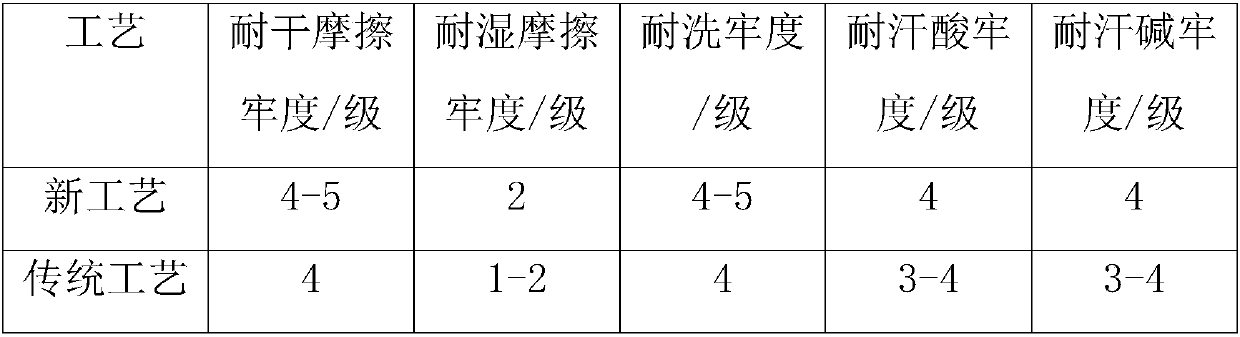

Embodiment 3

[0176] A process for improving the wet rubbing fastness of woven dark-colored cloth is carried out in the following steps:

[0177] (1), Distribution:

[0178] According to the "production notice" to get the gray cloth, check whether the cloth is consistent with the production process card before distributing the cloth. According to the number of meters of each order, select an appropriate number of gray cloth bags for distribution, so that the number of meters for distribution is consistent with the number of meters required by the production process card. When distributing, implement one truck and one truck, and do not place more indiscriminately. Make a detailed record of the order quantity on the production process card. Production order number: 712002, gray fabric: 70"10*16 bamboo + 70D elastic slub fabric, composition: cotton, finished product 53-54", color: gram color, order quantity 3804M.

[0179] (2), Singeing cold pile desizing:

[0180] Singeing and desizing we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com