Cold batch pretreatment technology of cotton and blended or interlaced fabric thereof

A technology for pre-processing and interweaving fabrics for cold stacking, which is applied in the fields of fiber treatment, textiles and papermaking, plant fibers, etc., can solve the problems of large consumption of water, electricity and steam, poor cloth surface treatment effect, and narrow scope of application of the process. Steam and water savings, clean removal, process for a wide range of fabric types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

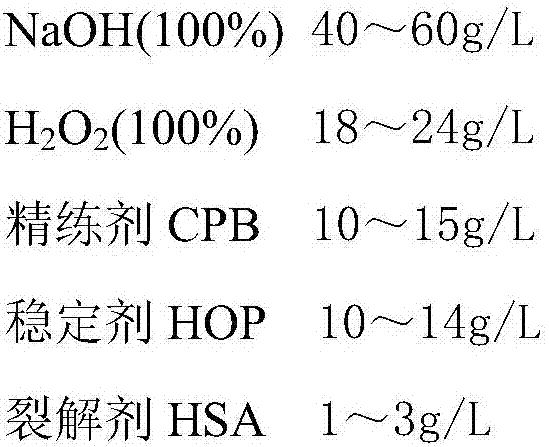

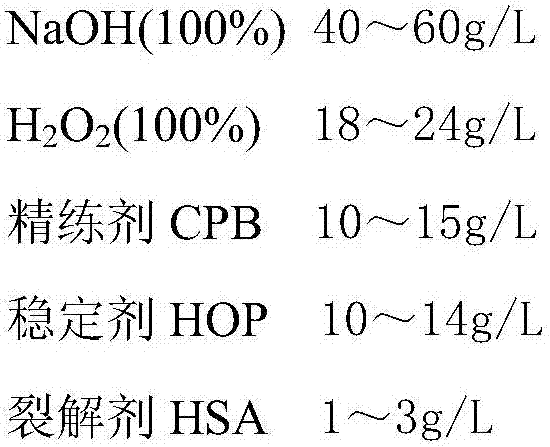

Method used

Image

Examples

Embodiment 1

[0032] The present invention prepares 50×50 / 154×80 cotton fabrics (high-count and high-density specifications), and prepares gray fabric according to the above steps → singeing and dry fire extinguishing → padding treatment liquid → stacking for 24 hours → high-efficiency water washing (including short steaming steps ) → drying, etc., and the treated cotton and its blended or interwoven fabrics are tested, and the test results are shown in Table 1.

[0033] Table 1: Quality index of 50×50 / 154×80 cotton fabric (high count and high density specification) after treatment

[0034]

[0035] From the analysis of the above-mentioned test results, it is concluded that Embodiment 1 adopts the above-mentioned specific cold stack pretreatment process, and compared with the traditional pretreatment process, the treated 50 × 50 / 154 × 80 cotton fabric (high count and high density specification) has a fabric Good surface whiteness, good wool effect, clean cloth surface slurry, clean cloth...

Embodiment 2

[0037] The present invention prepares 20×16 / 128×60 cotton fabrics (conventional specifications), and performs gray cloth preparation according to the above steps → singeing and dry fire extinguishing → padding treatment liquid → stacking for 24 hours → high-efficiency water washing → drying, etc. The treated cotton and its blended or interwoven fabrics were tested, and the test results are shown in Table 2.

[0038] Table 2: Quality index of 20×16 / 128×60 cotton fabric (conventional specifications) after treatment

[0039]

[0040]

[0041] From the analysis of the above-mentioned test results, the embodiment 2 adopts the above-mentioned specific cold stack pretreatment process, and compared with the traditional pretreatment process, the treated 20 × 16 / 128 × 60 cotton fabric (conventional specification) has a cloth surface whiteness Good, good capillary effect, clean cloth surface slurry, clean cloth surface cottonseed husks, small cloth surface strength damage and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com