Manufacturing method of green sand casting sprue cup milling cutter

A manufacturing method and sprue cup technology, applied in furnace types, manufacturing tools, furnaces, etc., can solve problems such as low yield rate, difficult quality control, and large influence of human factors, and achieve high hardness and wear resistance, raw materials Get the effect that is easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

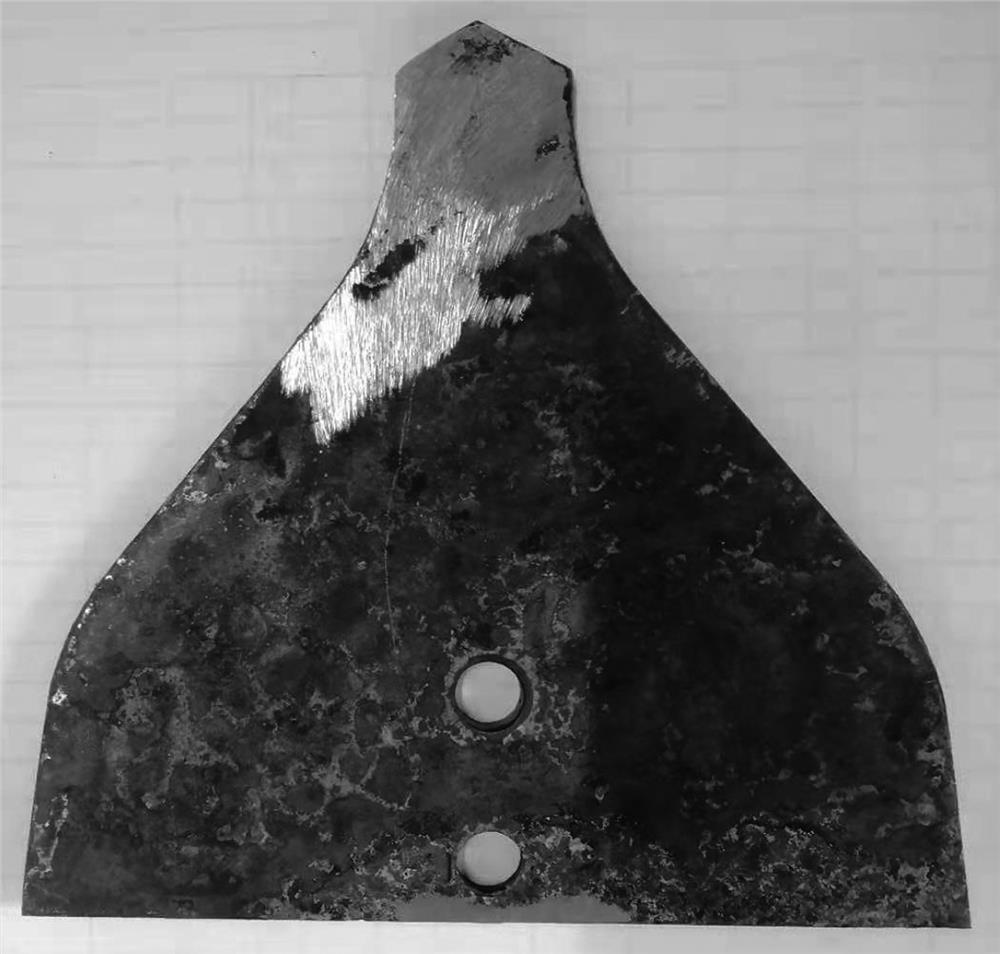

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0027] A method for making a sprue cup milling cutter for green sand casting, comprising the following steps:

[0028] Step 1) Material selection, choose ordinary carbon steel plate as the base material, and the size of the selected steel plate is controlled at a thickness of 12±2mm. Since ordinary carbon steel plate has good toughness and is freely available in the workshop, it can be obtained from scraps of other workpieces The utilization rate of waste materials is improved.

[0029] Step 2) Wire cutting, use the wire cutting technology to process the carbon steel plate into the outline of the milling cutter, specifically, use the wire cutting machine tool to divide the steel plate into plates with similar shapes, and then clamp its two ends on the machine tool On the rotating shaft, the shape is processed.

[0030] In this step, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com