Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Increase axial load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

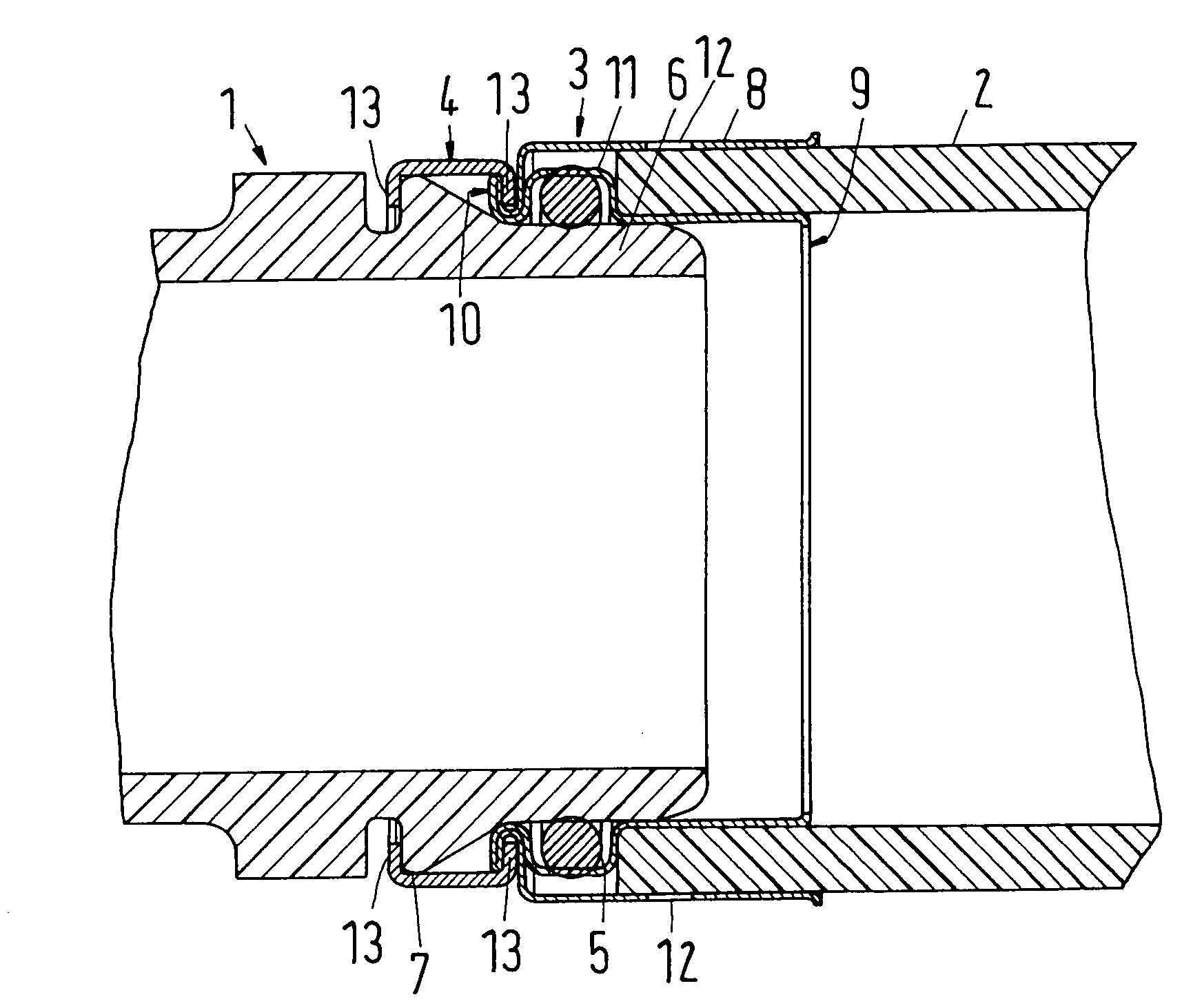

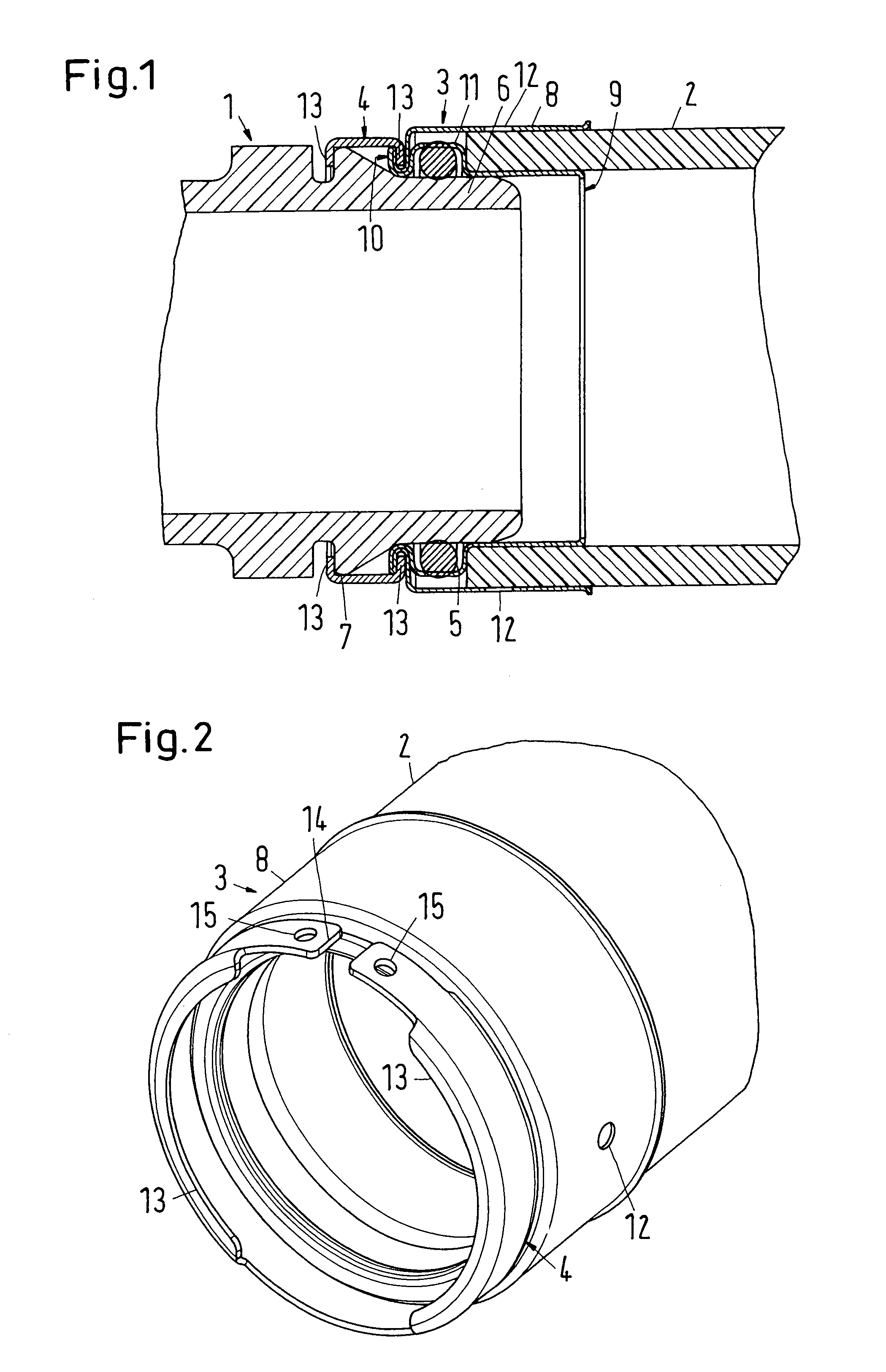

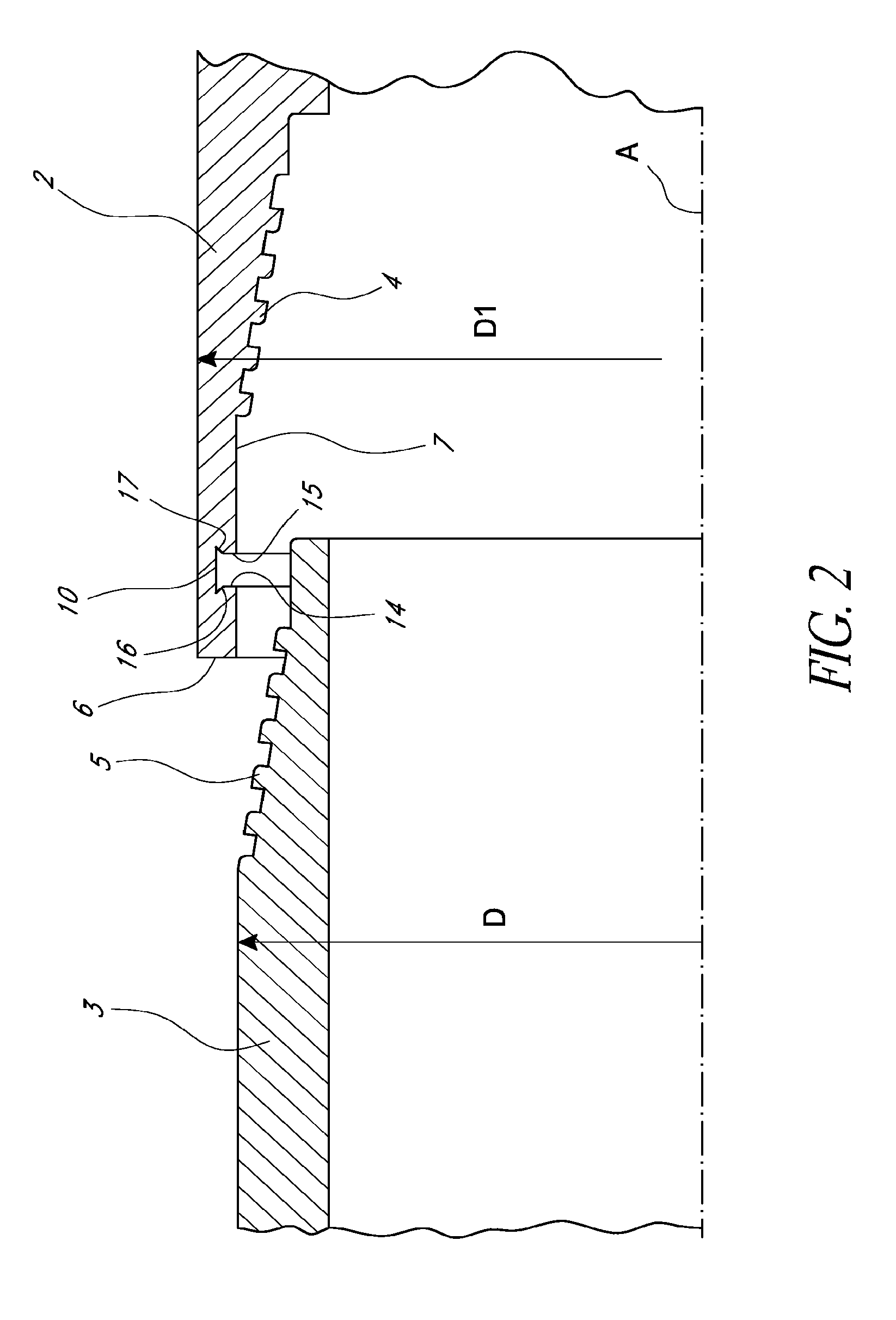

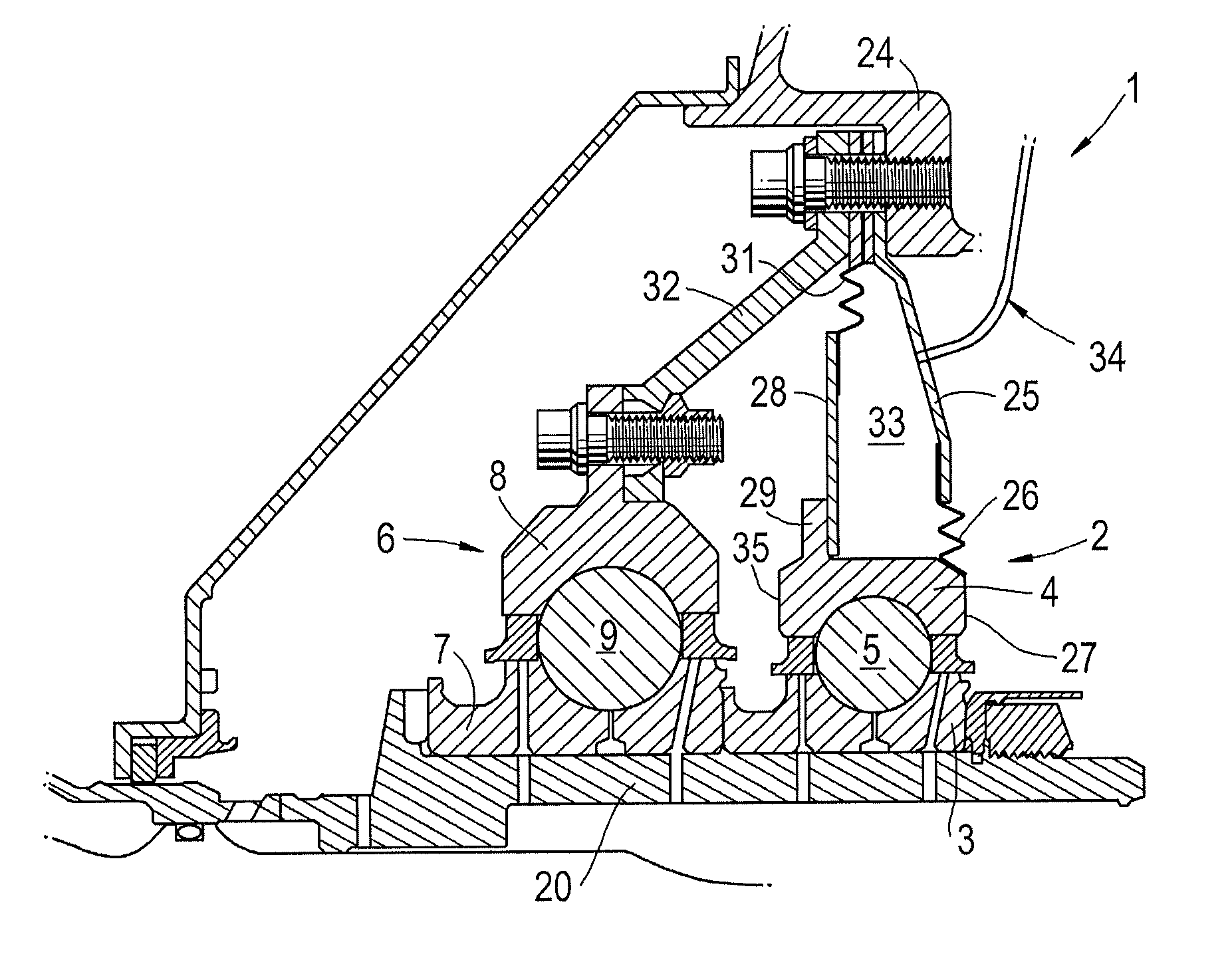

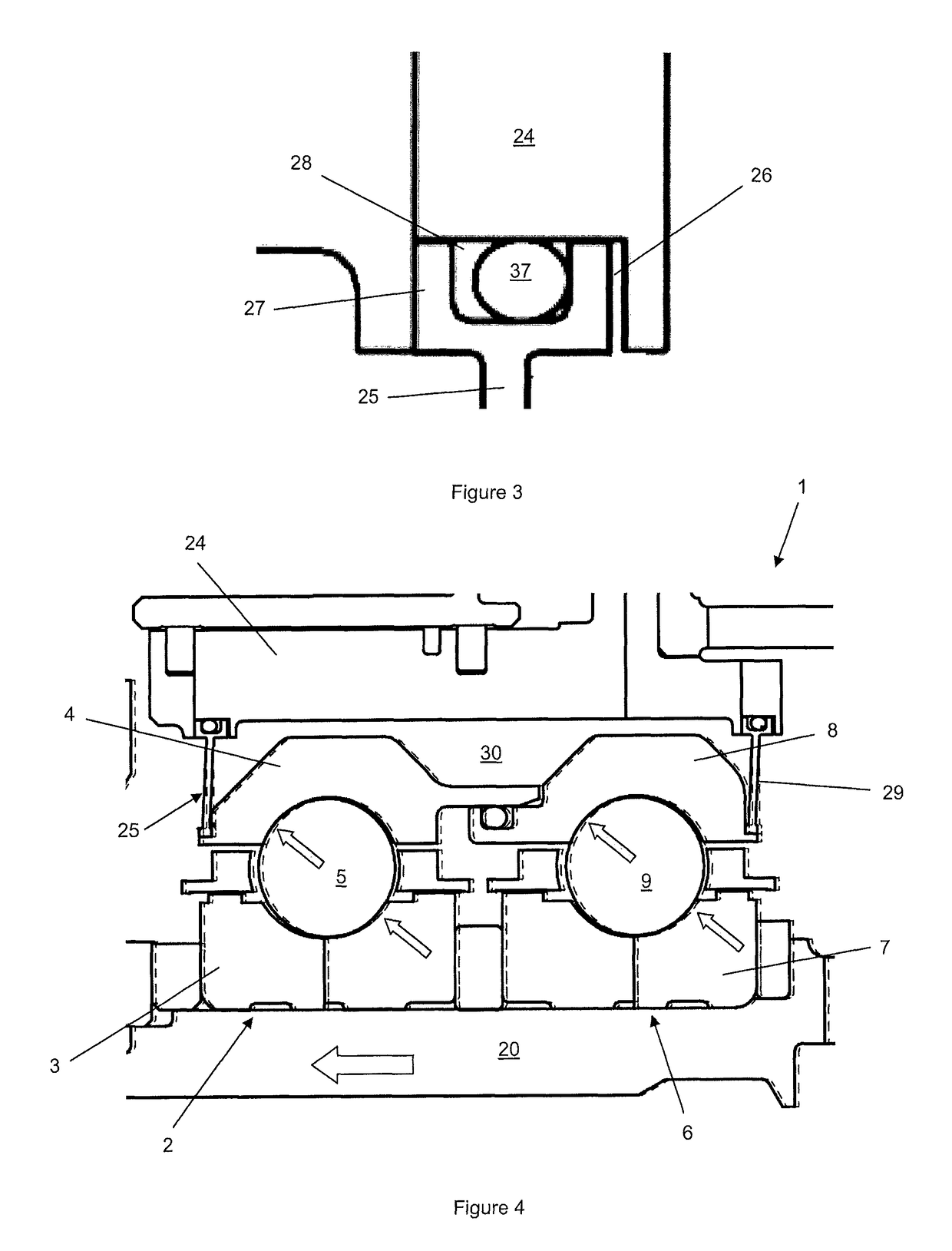

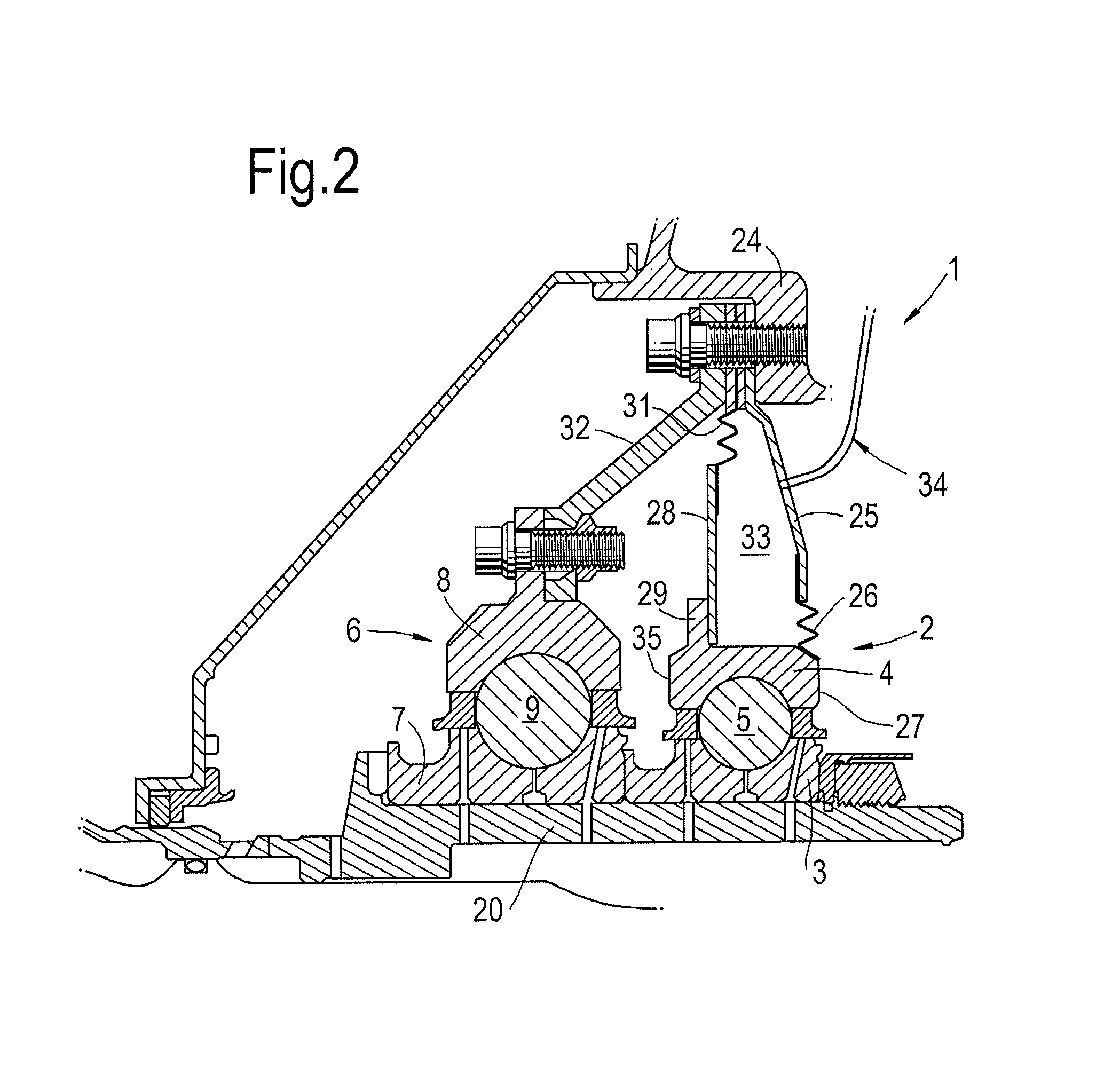

Plug-type connection arrangement for a hose and a pipe

InactiveUS7562910B2More compact constructionIncrease axial loadEngine sealsPipe elementsEngineeringFlange

A plug-type connection arrangement for a hose and a pipe, the connection arrangement comprising a sleeve having an outer wall and an inner wall, wherein the hose is insertable from an end of the sleeve and is clampable in the sleeve, wherein the sleeve has at another end thereof a first annular groove with an open resilient connecting ring which extends over more than 180° and is lockable to the sleeve and the pipe, and a sealing ring for sealing the sleeve relative to the pipe in a connected state of the pipe and the hose, the connecting ring being comprised of a plate spring ring with inwardly directed flanges at both circumferential edges thereof, wherein the flanges of one circumferential edge are engageble in the first annular groove and the flanges of the other circumferential edge are engageable behind a holding rib on the pipe, wherein the sealing ring is mounted in a second annular groove formed by the inner wall of the sleeve and the axially inner wall of the first annular groove, and wherein an end portion of the pipe is insertable into the sleeve.

Owner:NORMA GERMANY GMBH

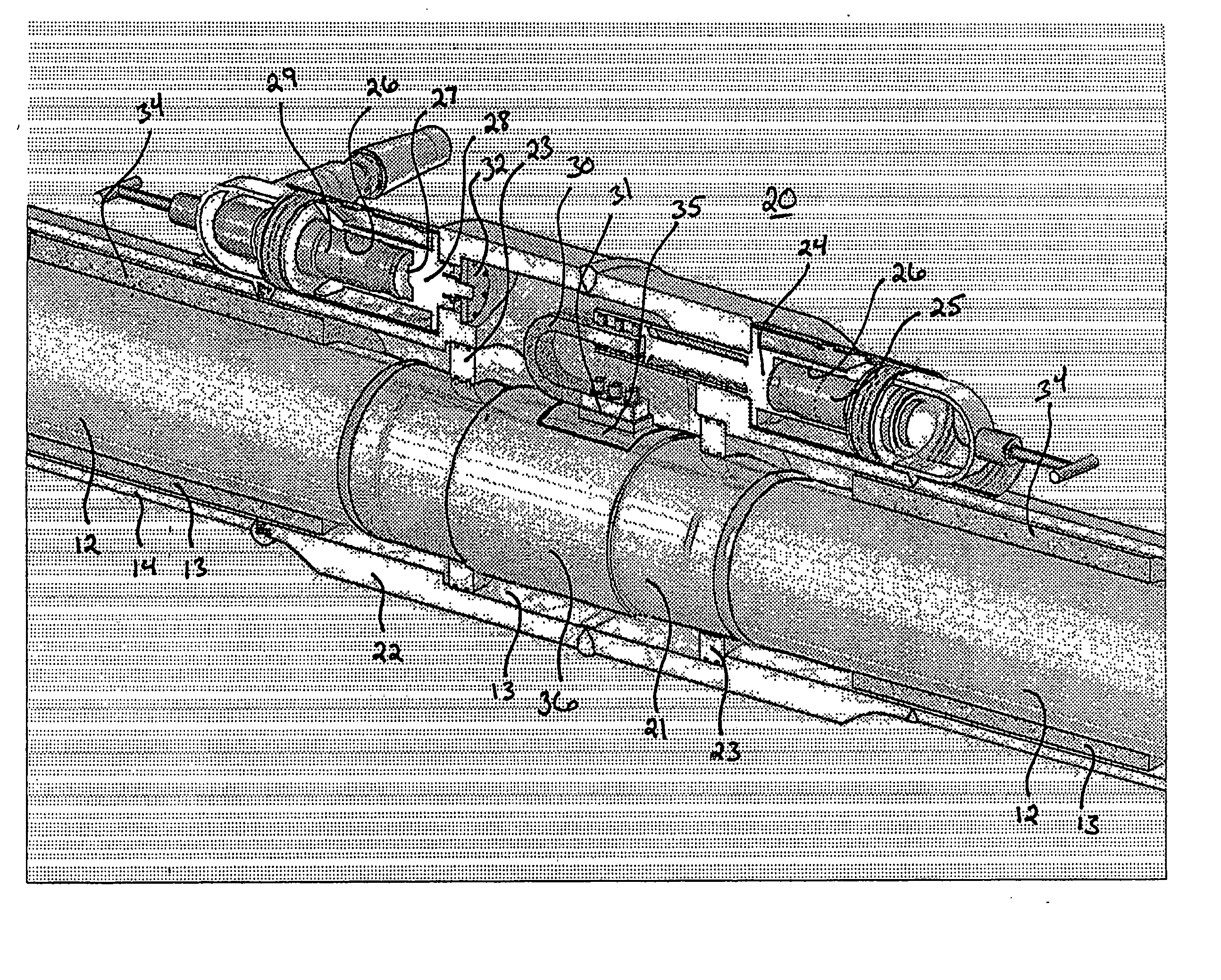

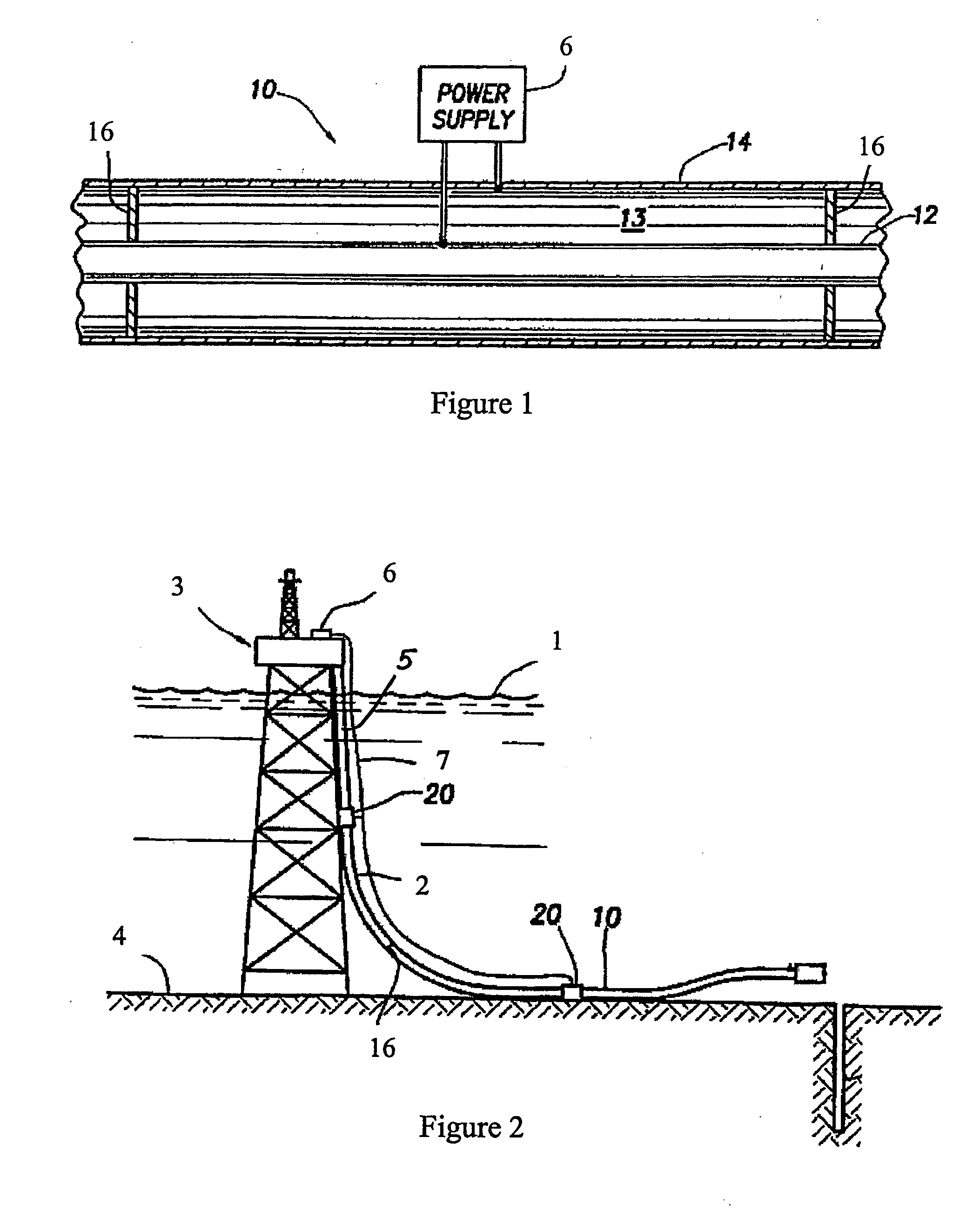

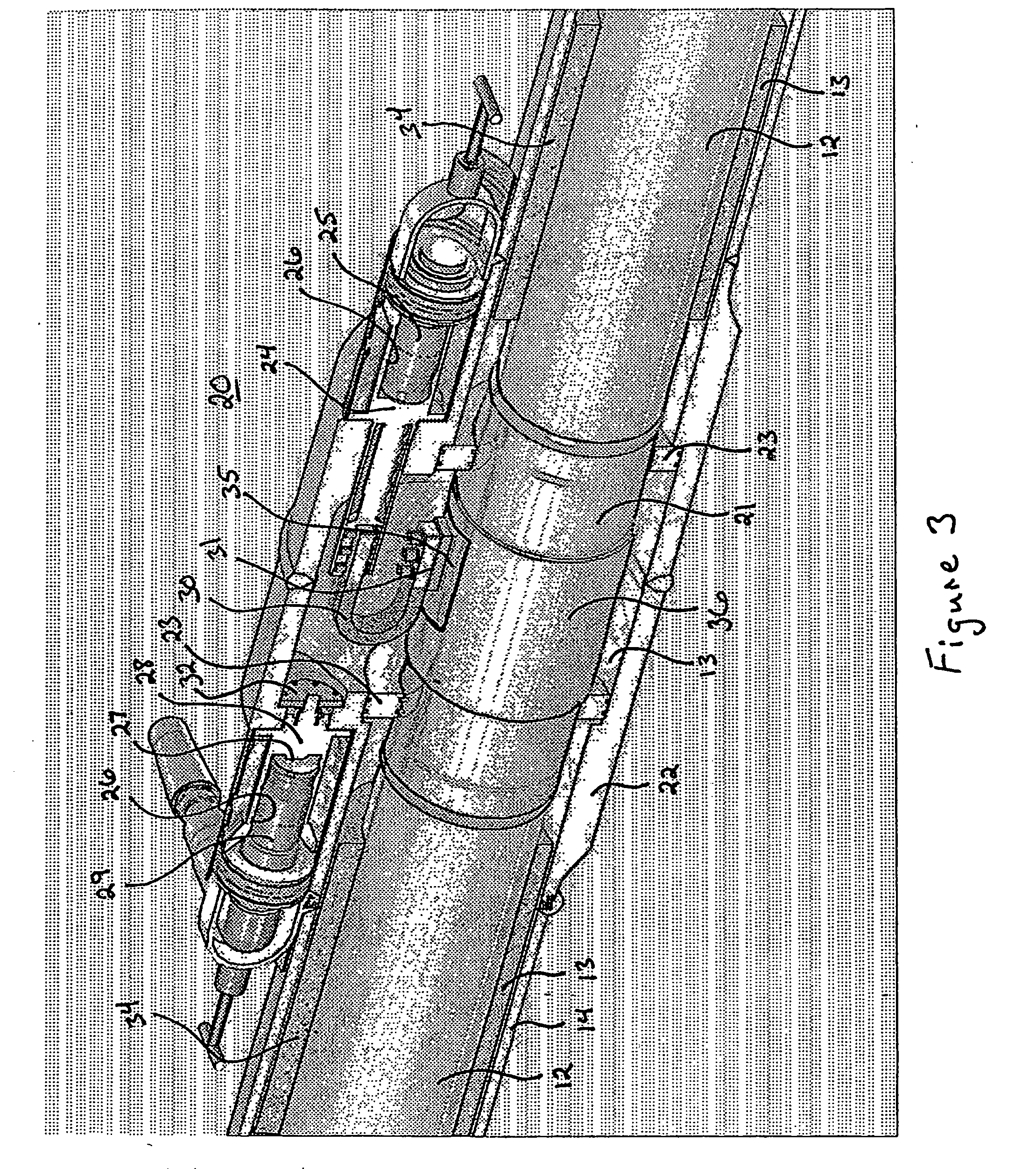

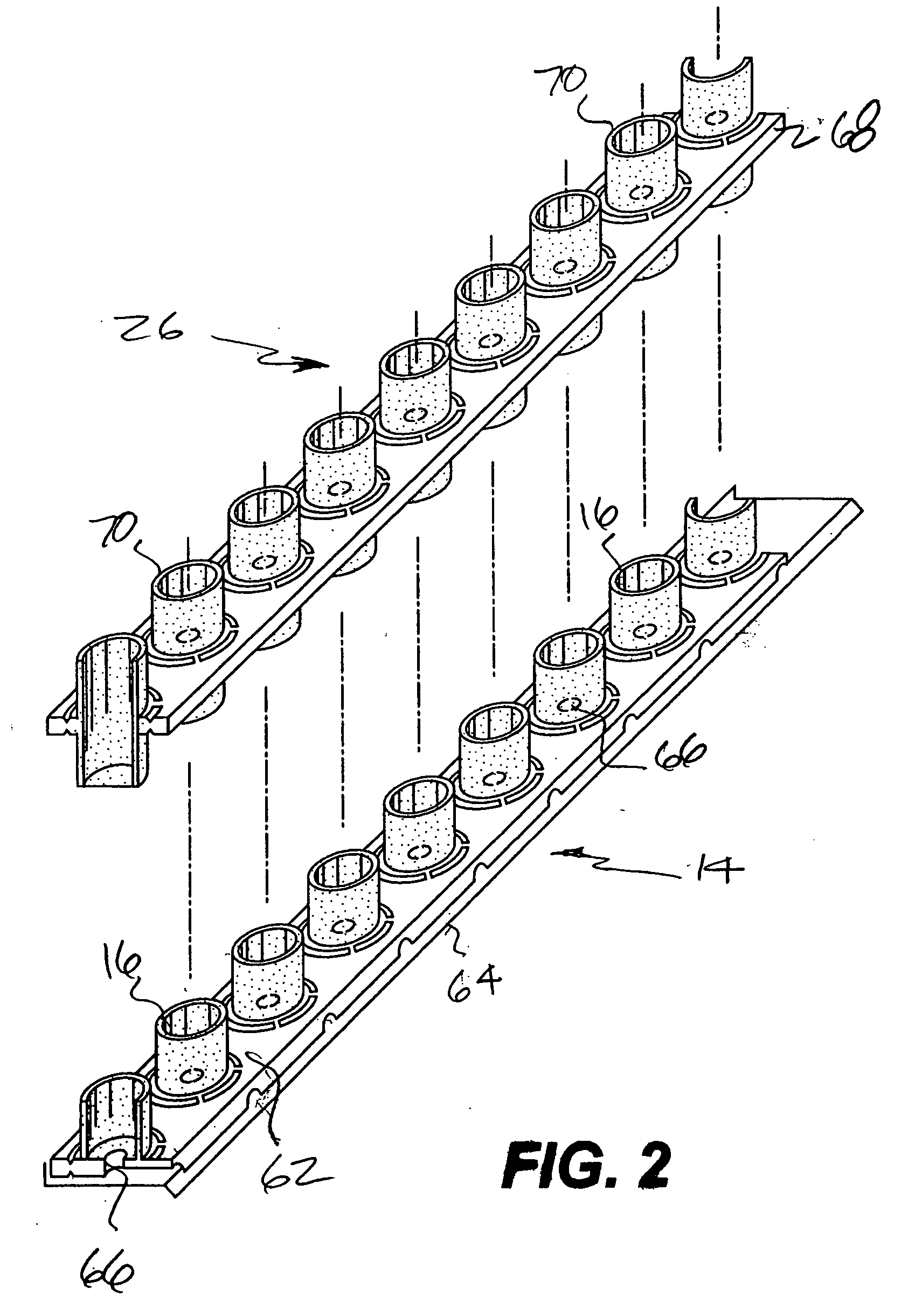

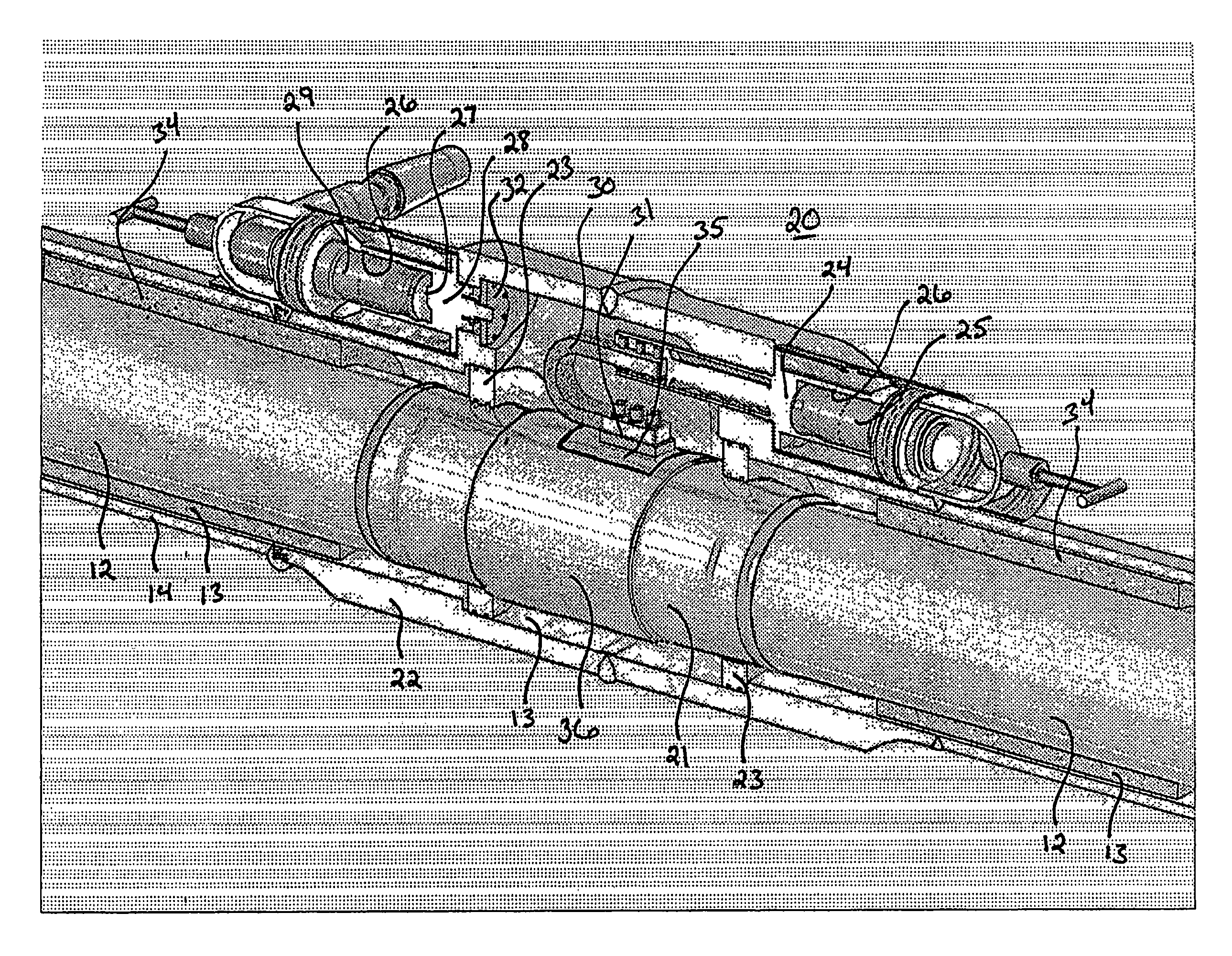

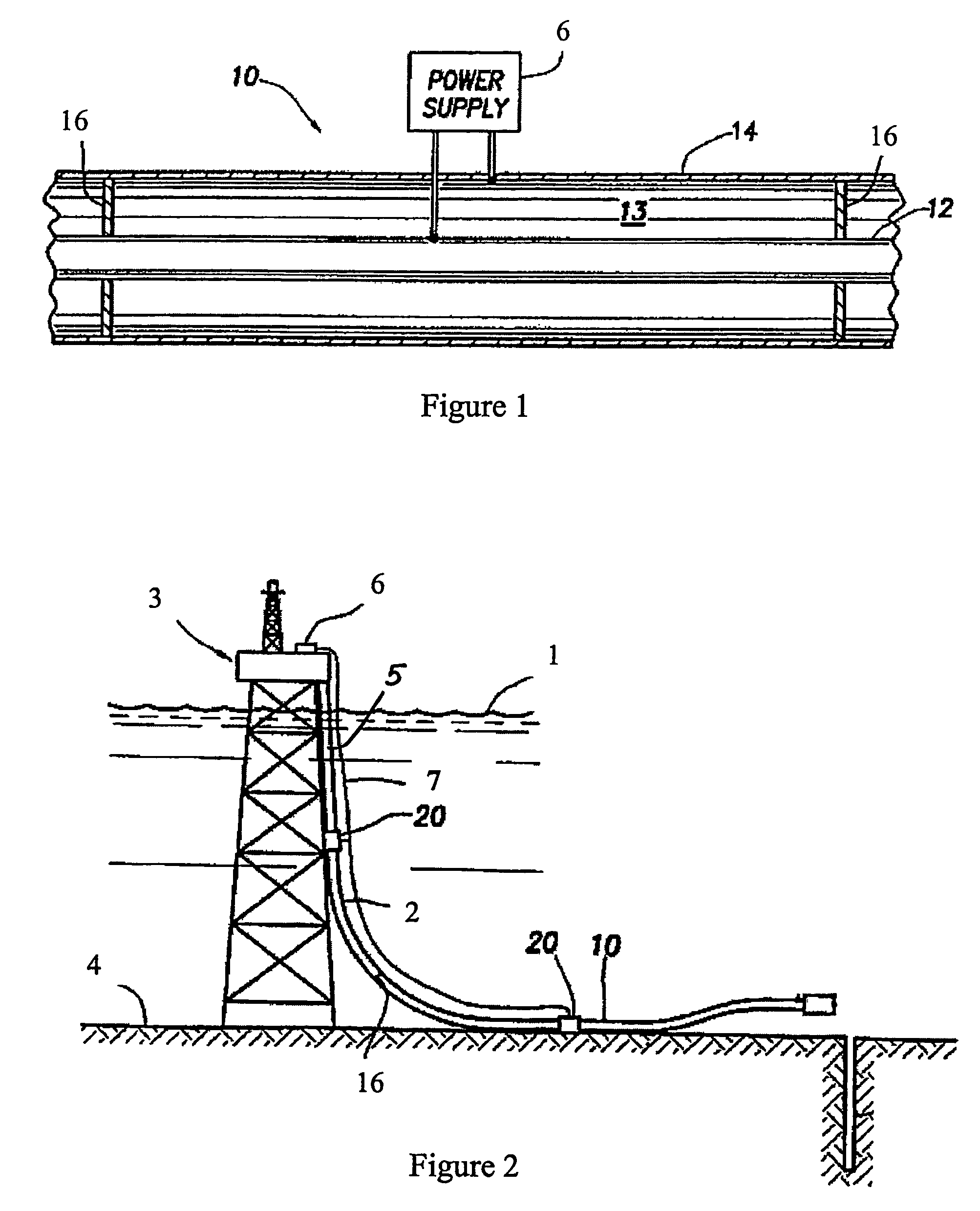

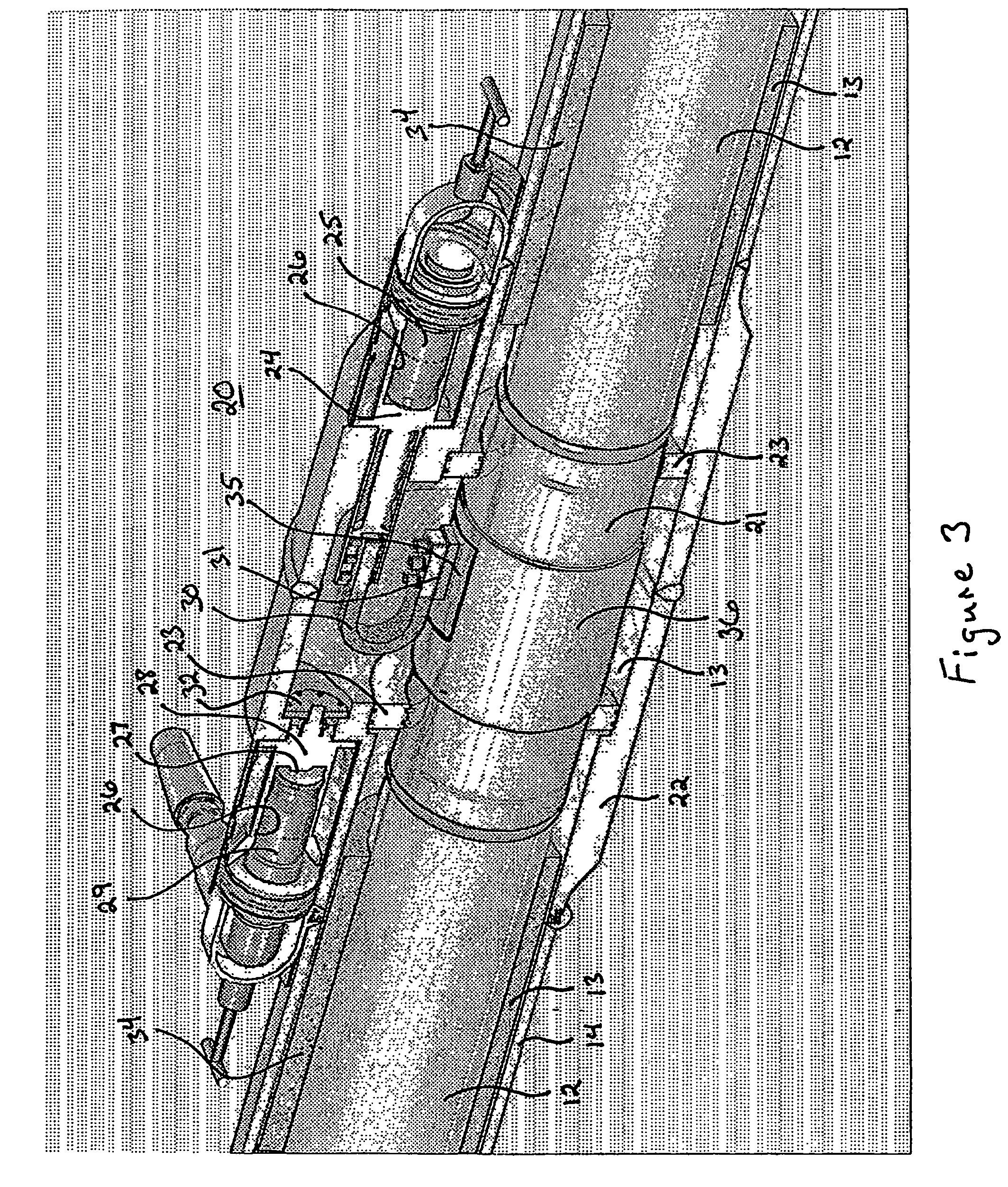

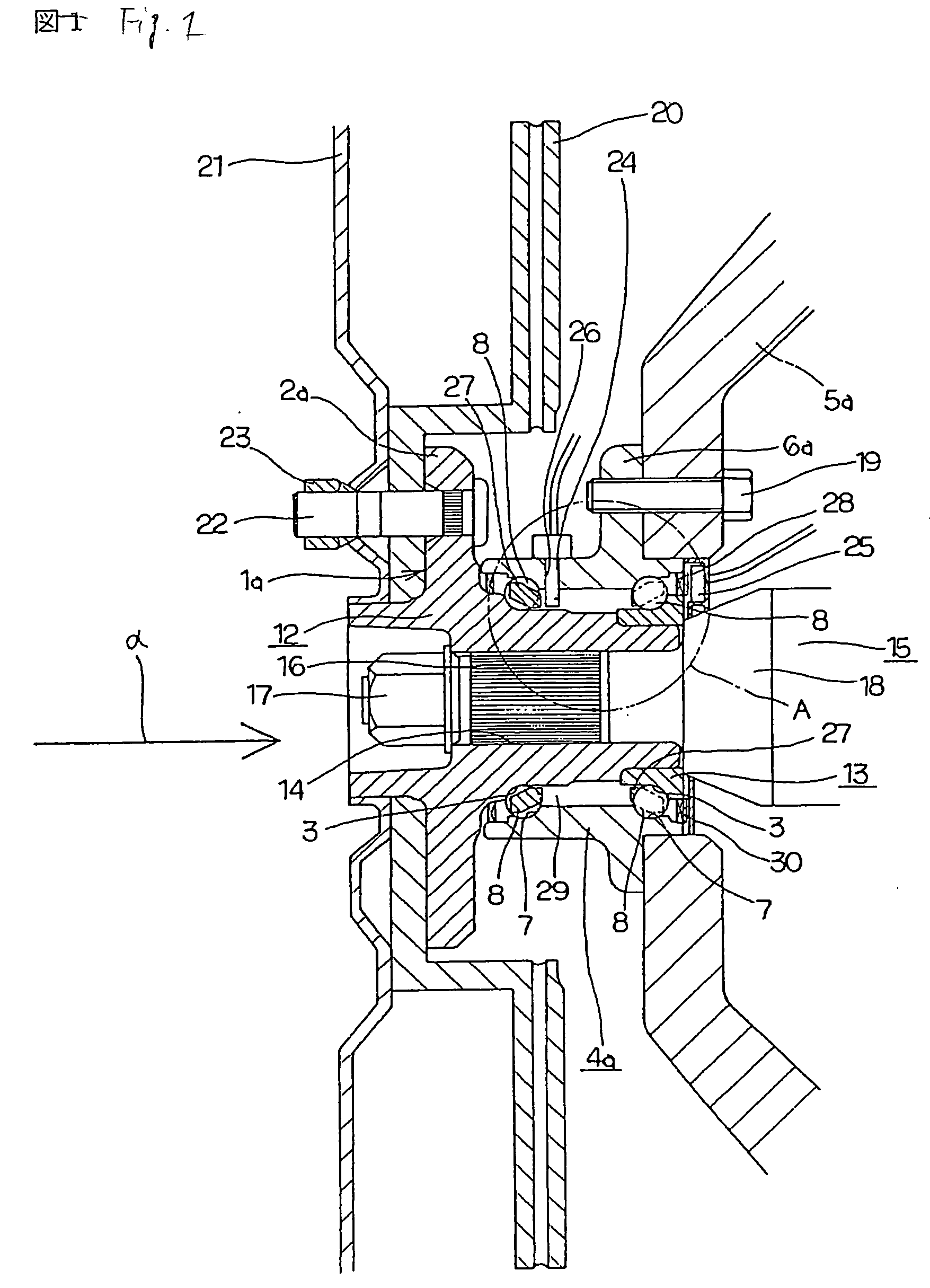

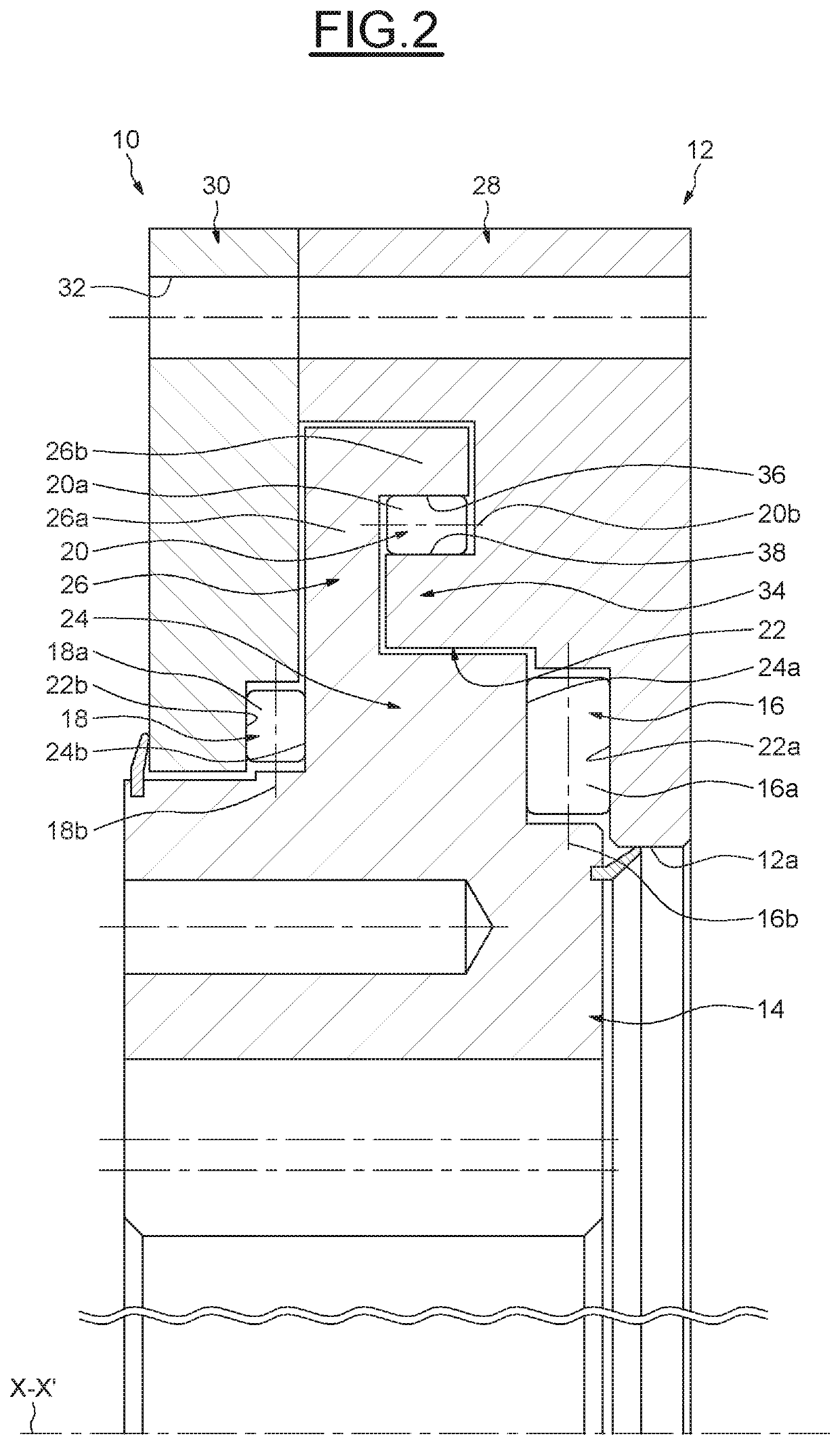

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS20050054228A1Increase axial loadAvoid local accumulationPipe heating/coolingPipe-jointsElectricityElectrical conductor

For heating a pipe-in-pipe pipeline with power provided through an electric cable, mid-line connector is provided including: a connector housing joinable to the outer pipe of the pipeline; a blank pipe positioned within the connector housing and joinable to the inner pipe of the pipeline; at least one pocket mounted in the connector housing, wherein the cable is mateable with the at least one pocket; a blank pipe conductor electrically coupled between the at least one pocket and the blank pipe; and an outer pipe conductor electrically coupled between the at least one pocket and the outer pipe.

Owner:SHELL OIL CO

Threaded joint with pressurizable seal

ActiveUS8333409B2Simple and reliable processEasy to operateDrilling rodsFluid pressure sealed jointsEngineeringScrew thread

Owner:TENARIS CONNECTIONS

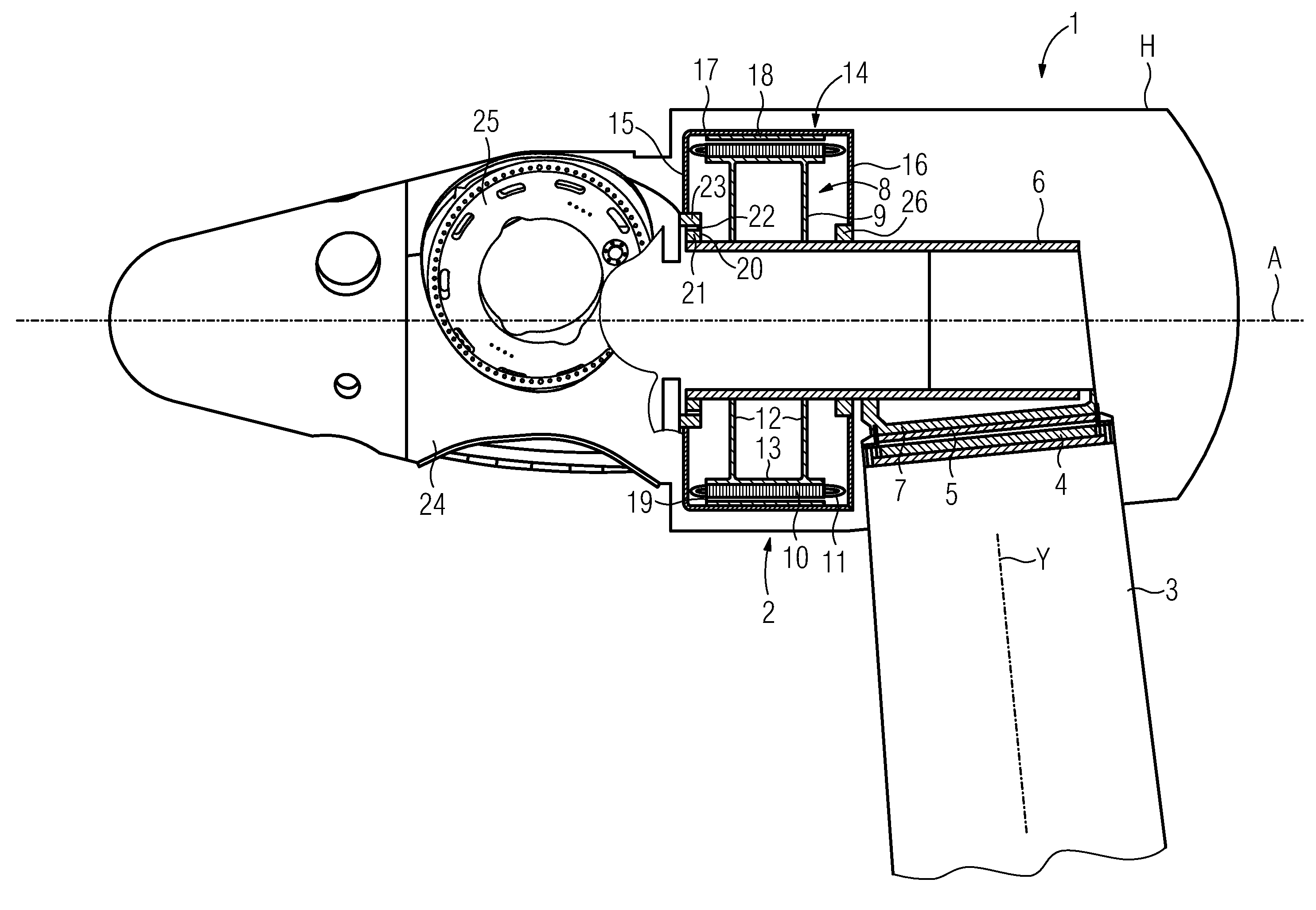

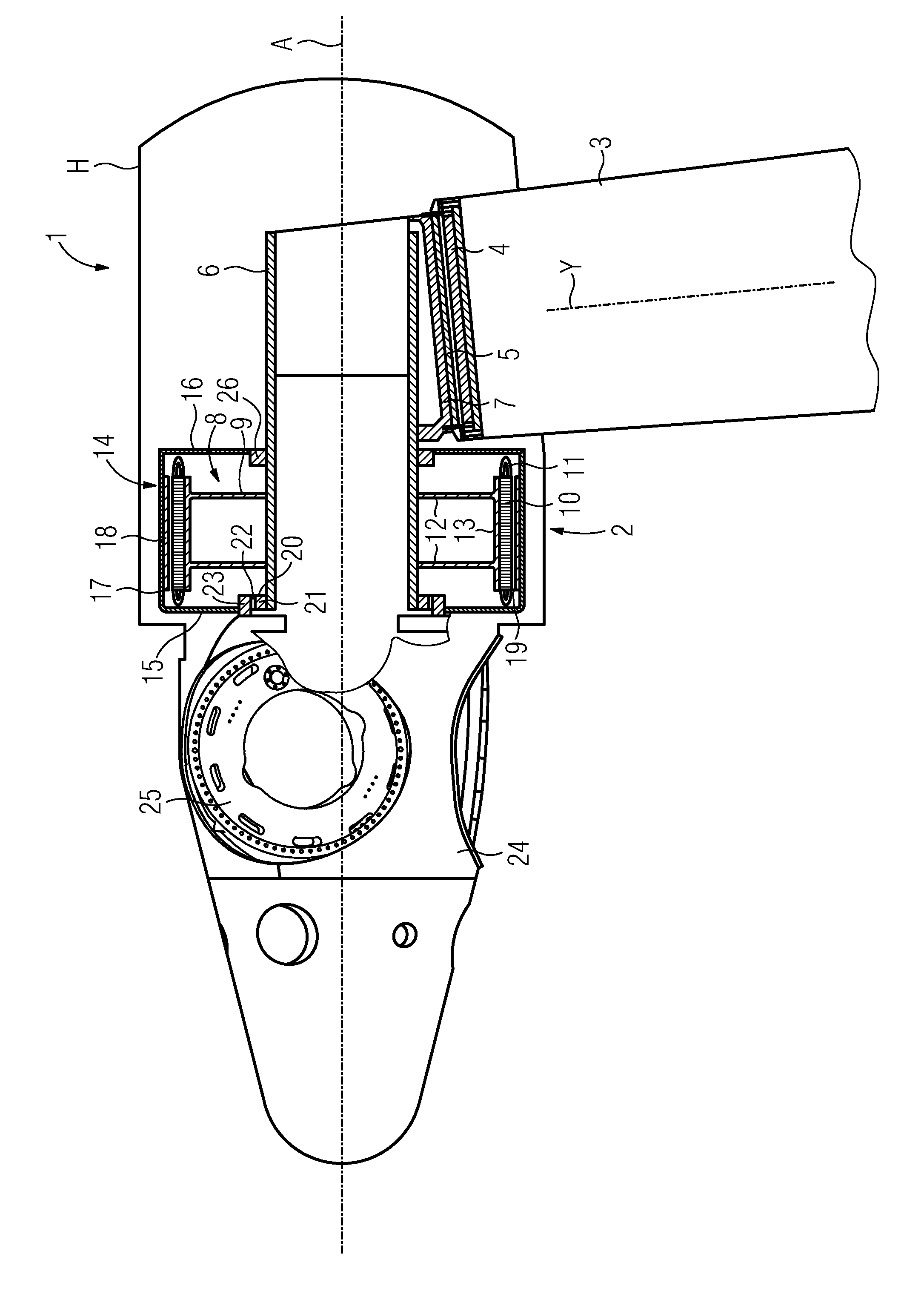

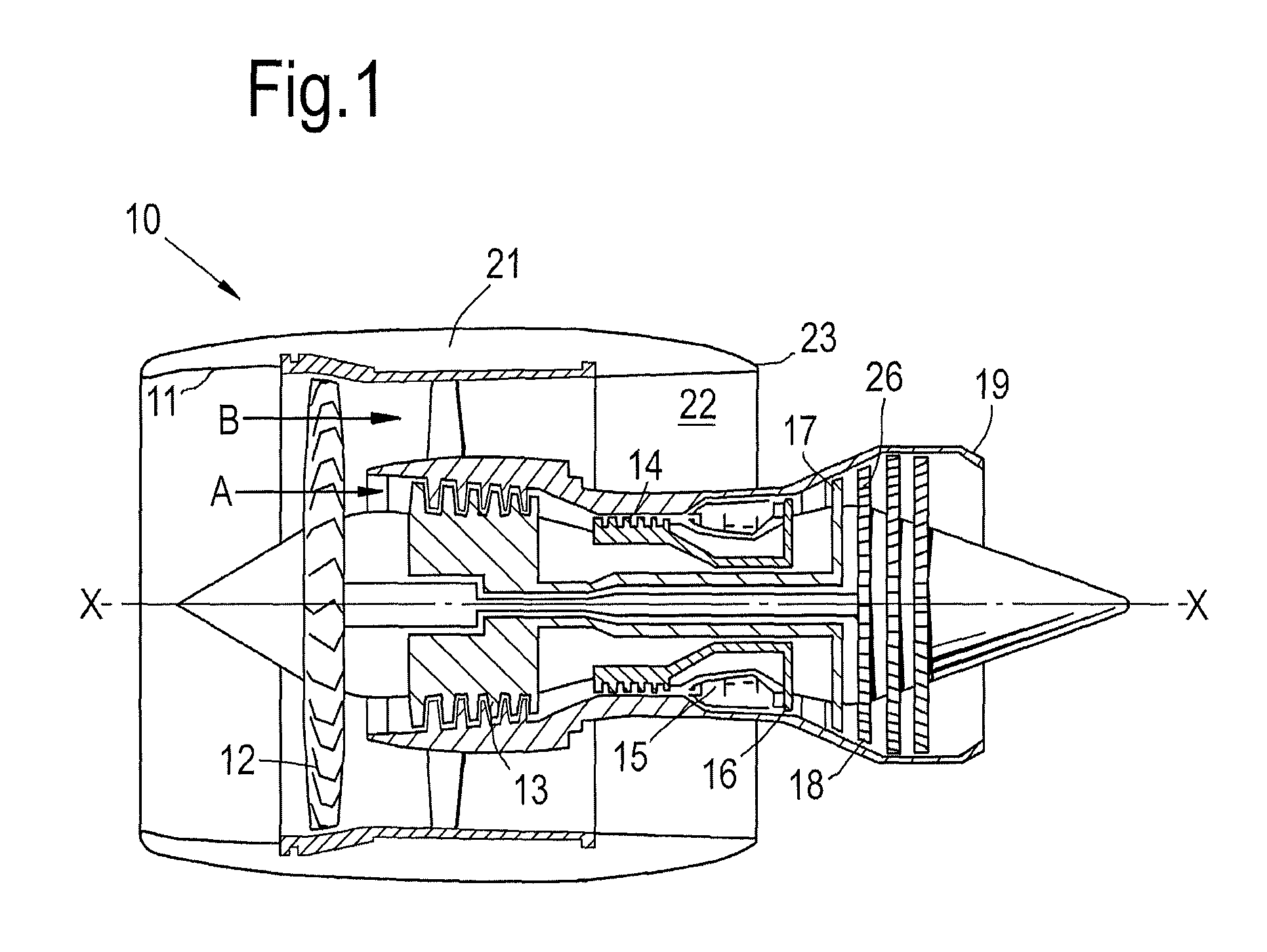

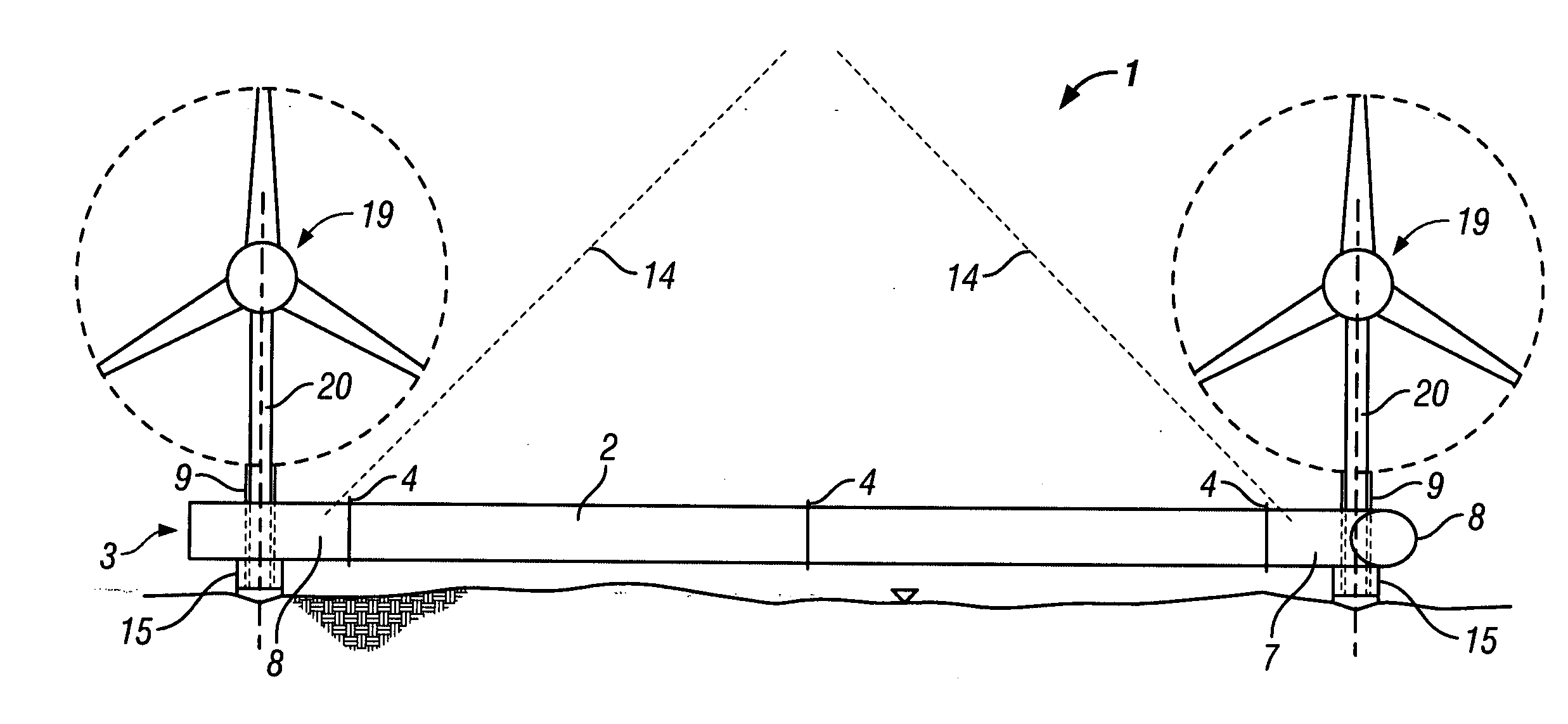

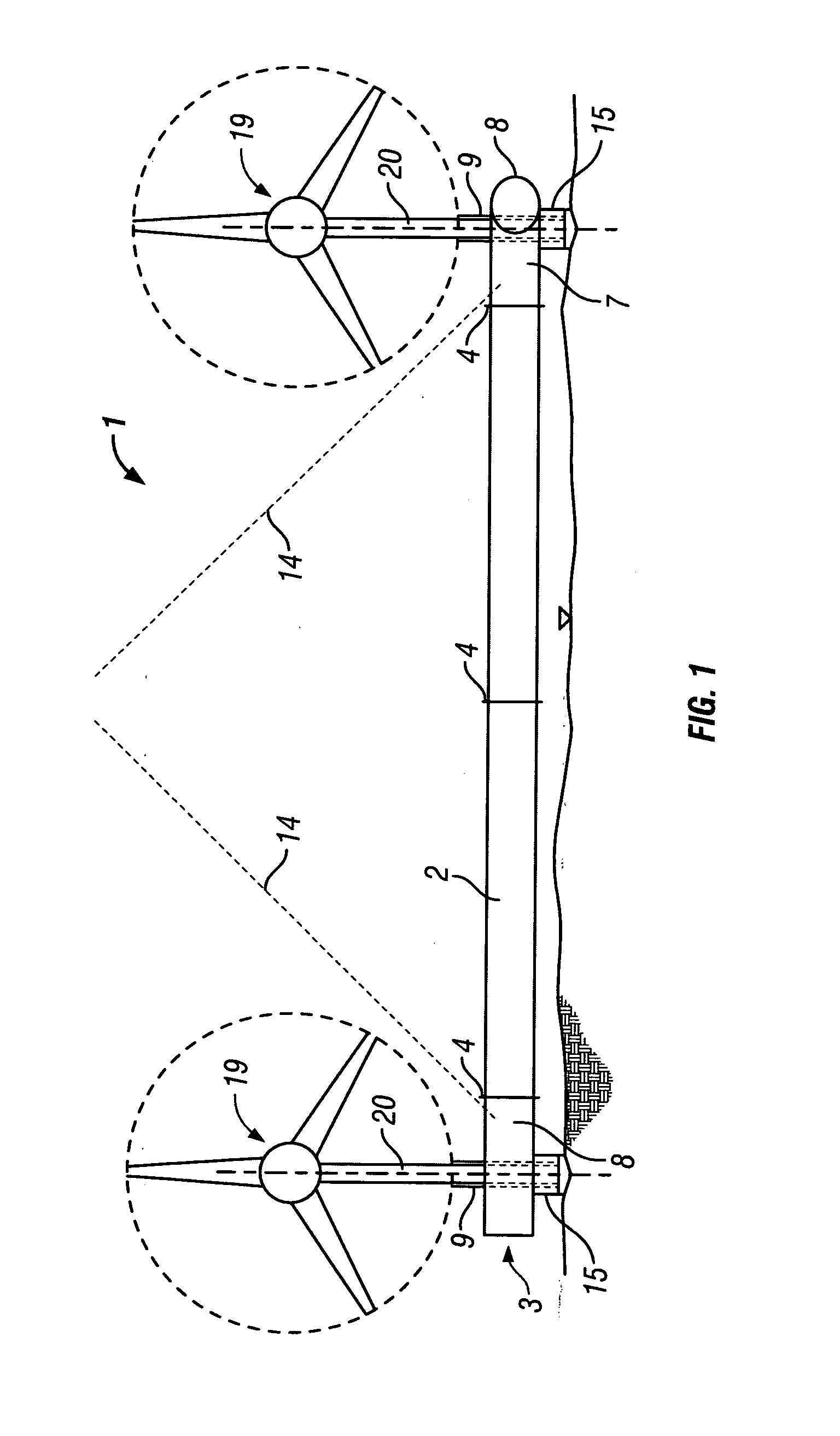

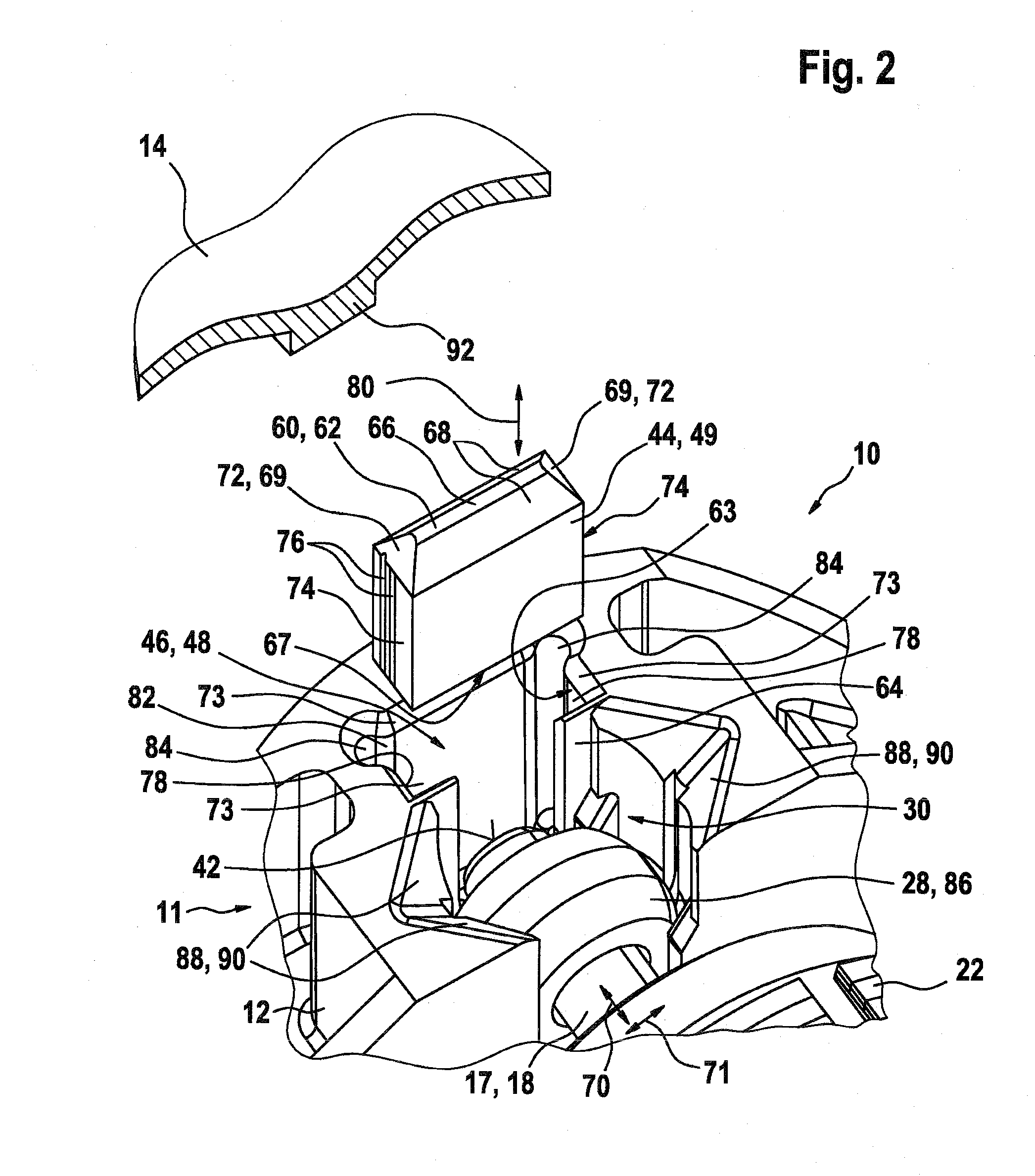

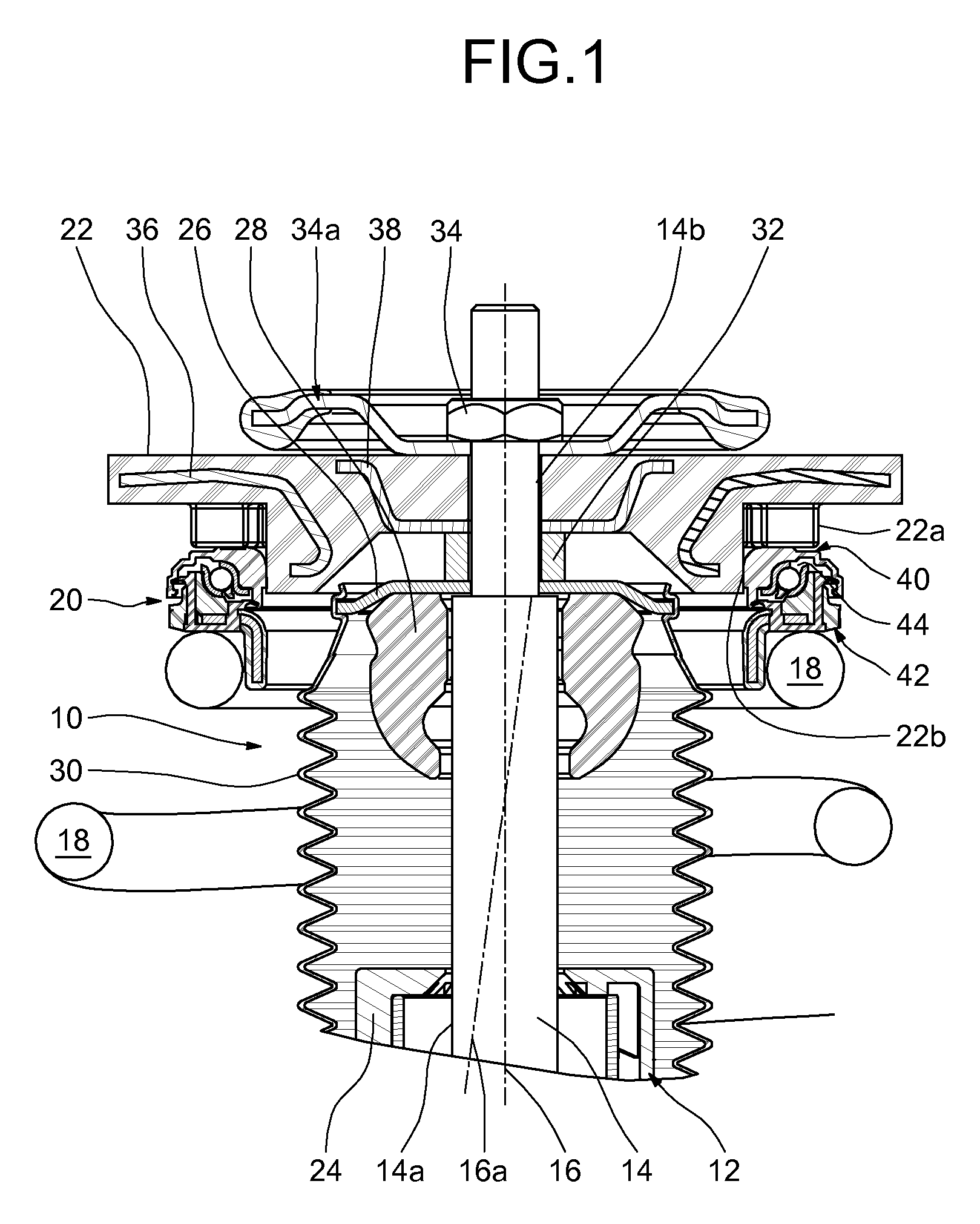

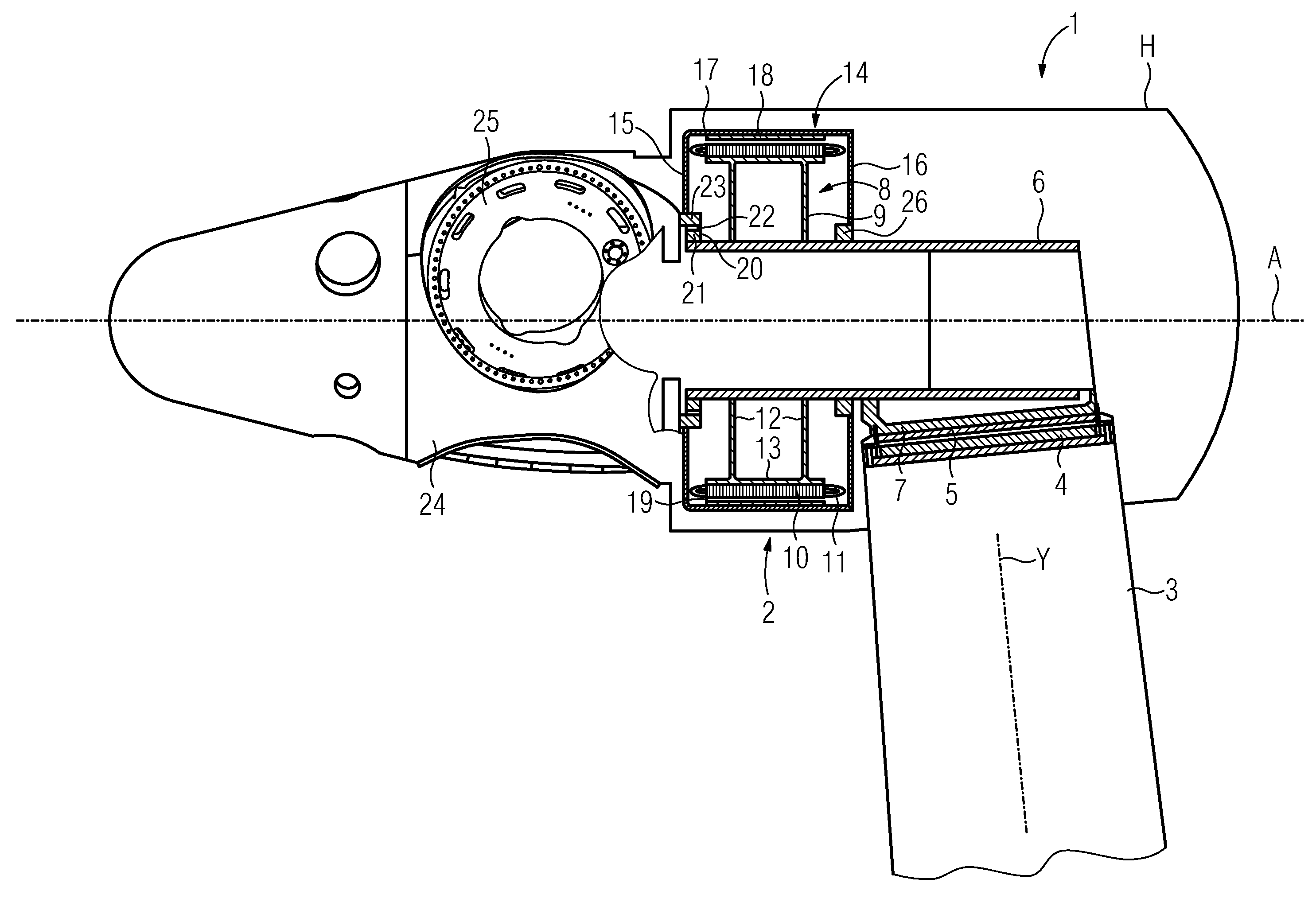

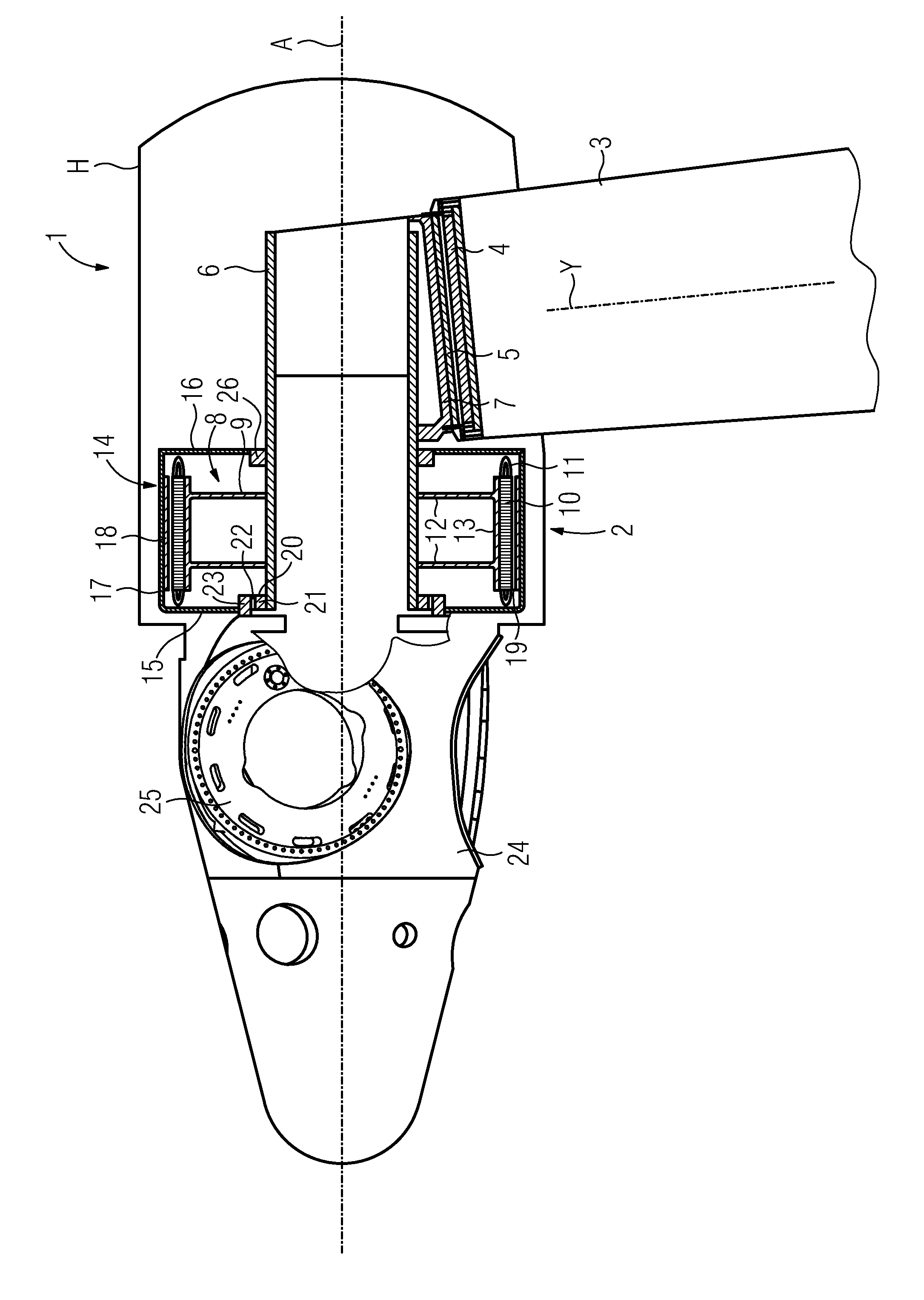

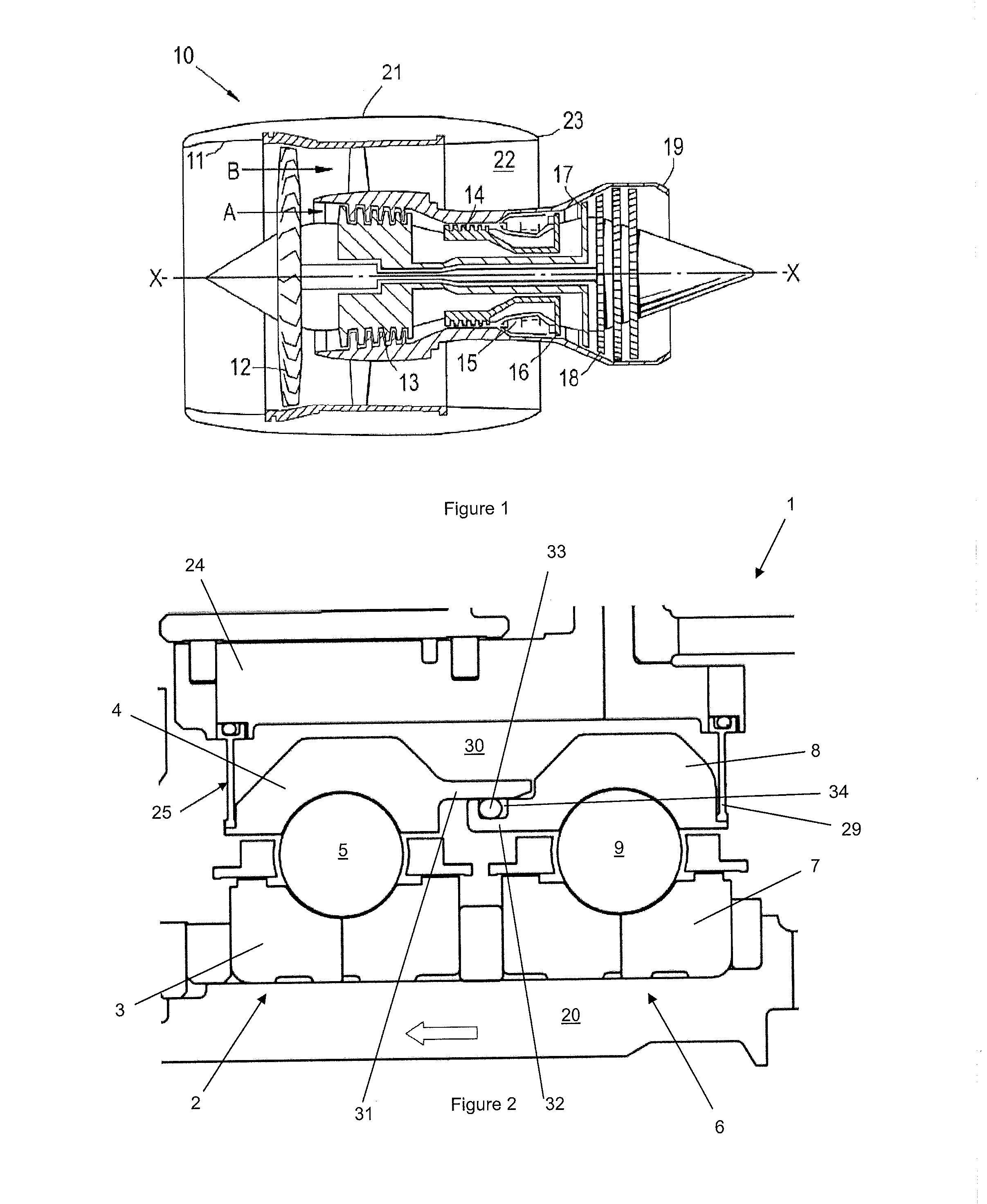

Wind Turbine

A wind turbine which includes a direct drive generator is disclosed. The direct drive generator includes an inner stator arrangement and an outer rotor arrangement and a stationary shaft with a centre axis. The stator arrangement is arranged on the outside of the stationary shaft, the rotor arrangement is substantially arranged around the stator arrangement, on the front side at least indirectly supported or arranged on the stationary shaft by a main bearing and on the rear side at least indirectly supported or arranged on the stationary shaft by a support bearing. The main bearing and / or the support bearing is a four-point bearing.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

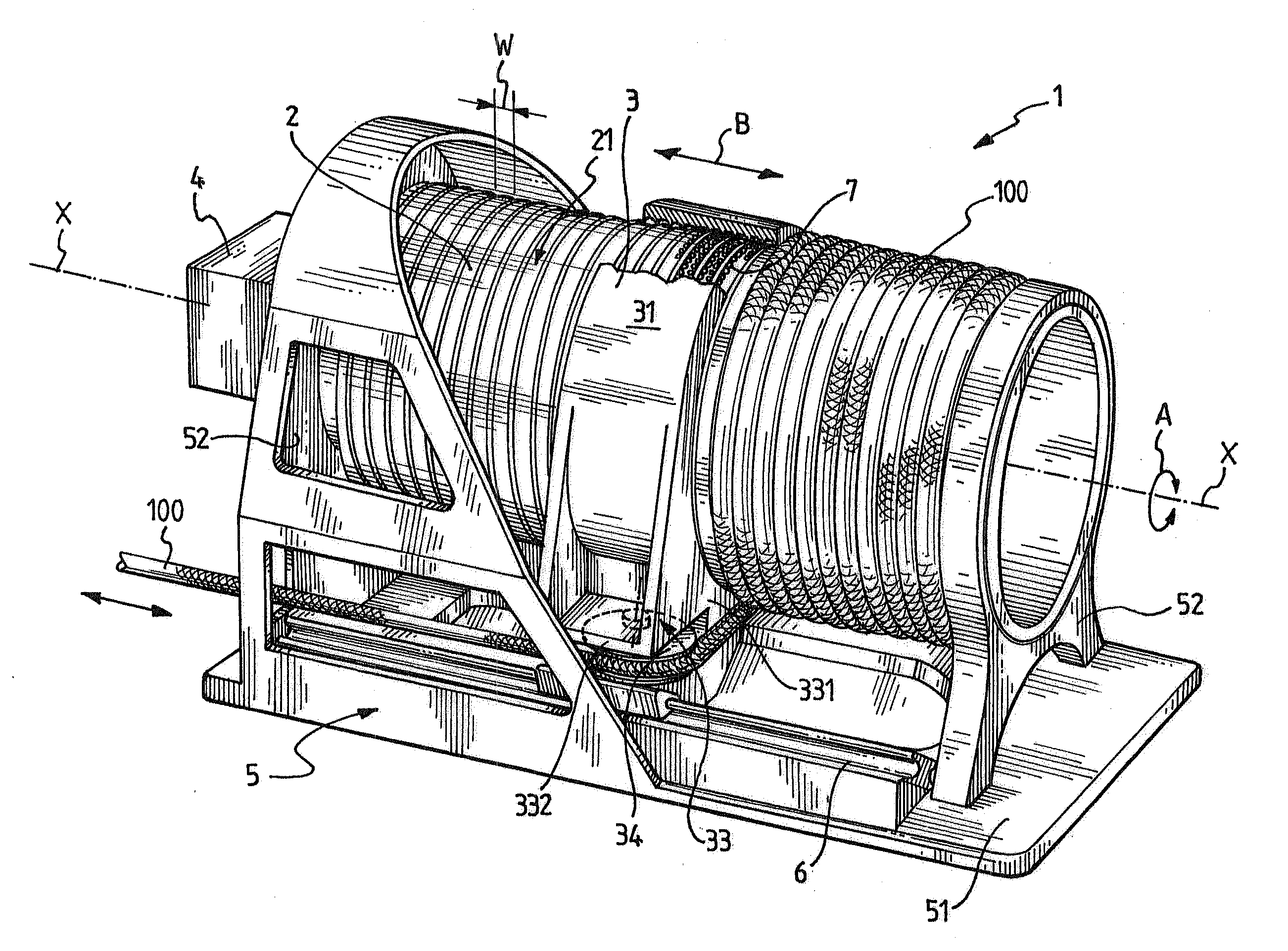

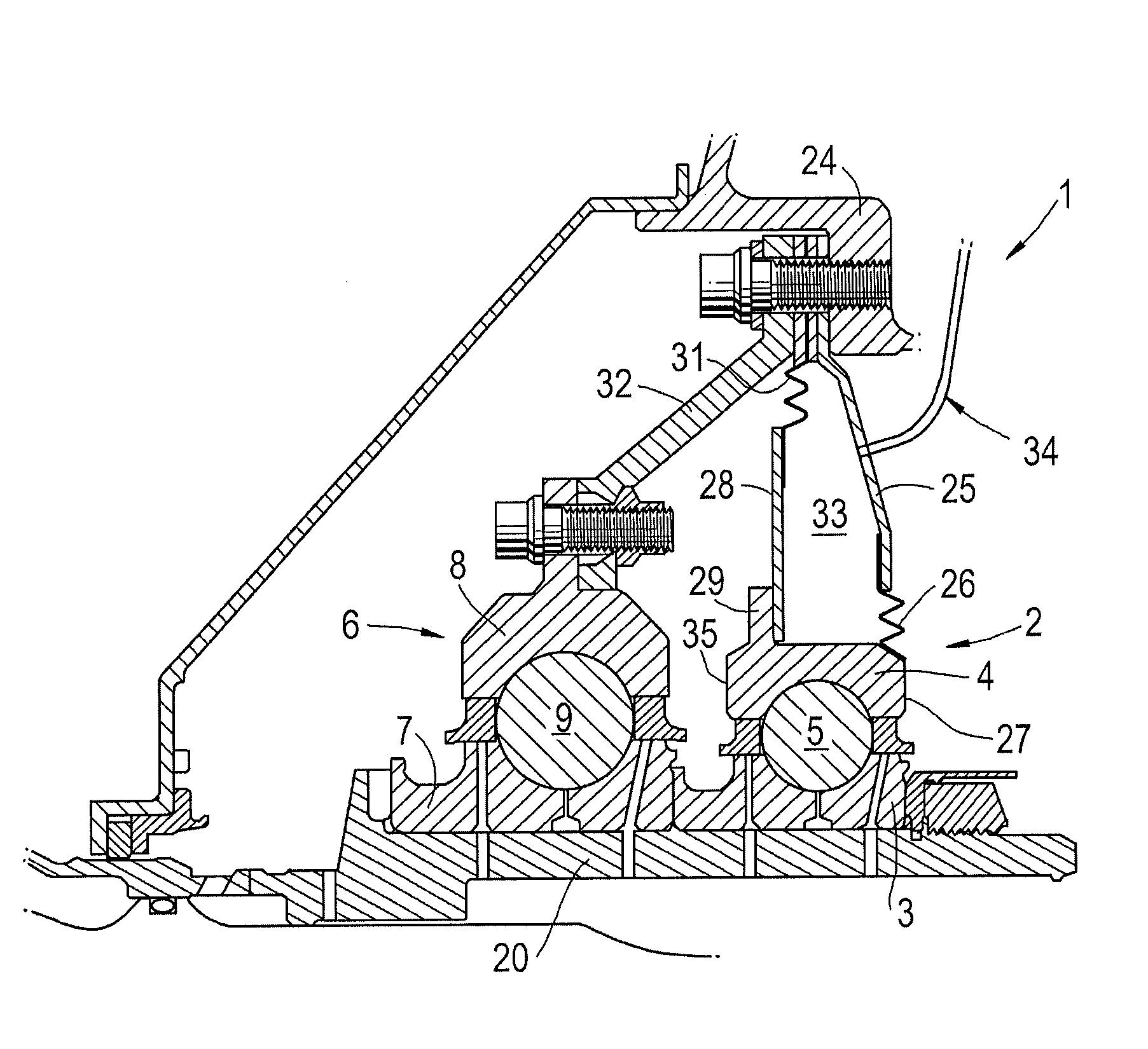

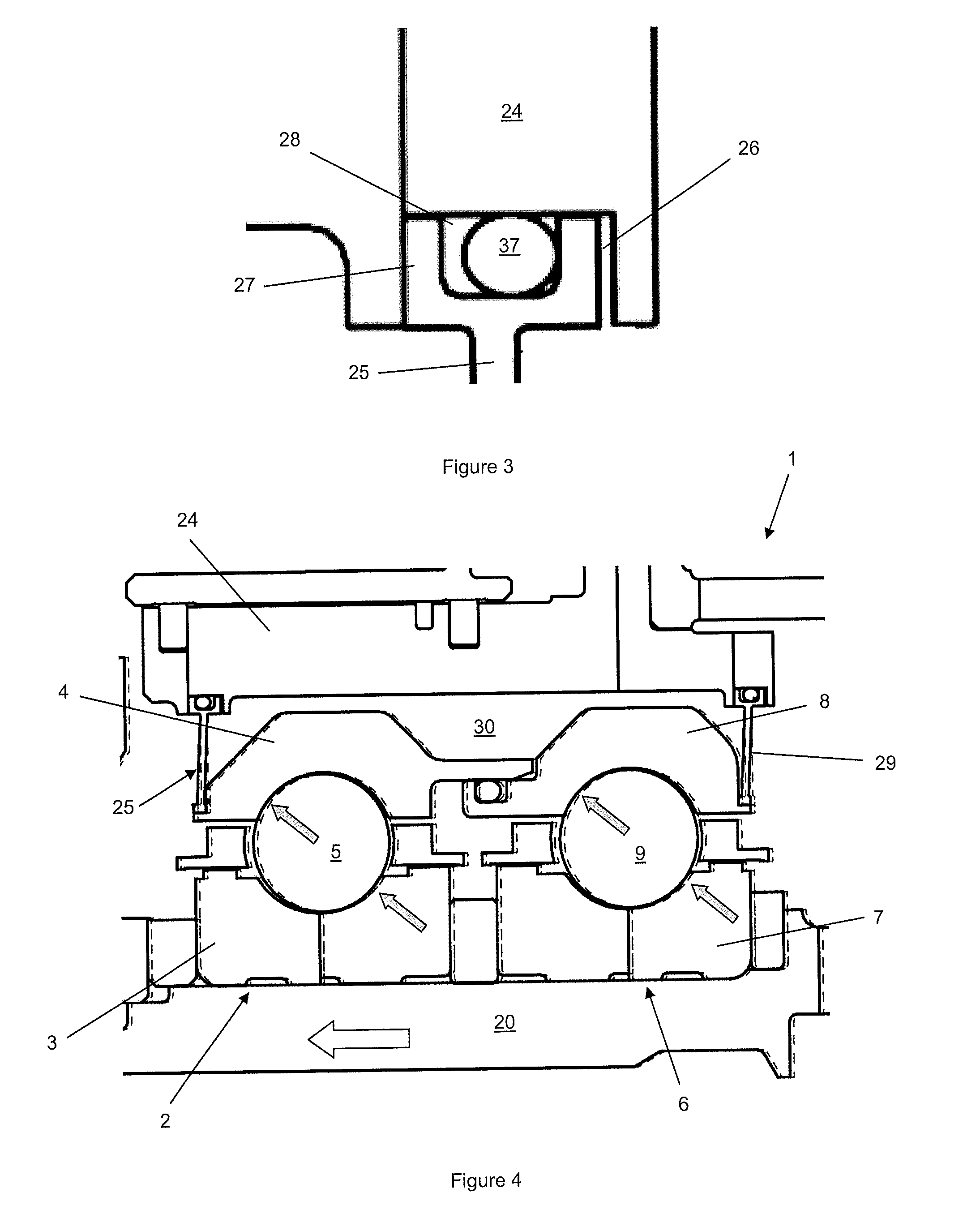

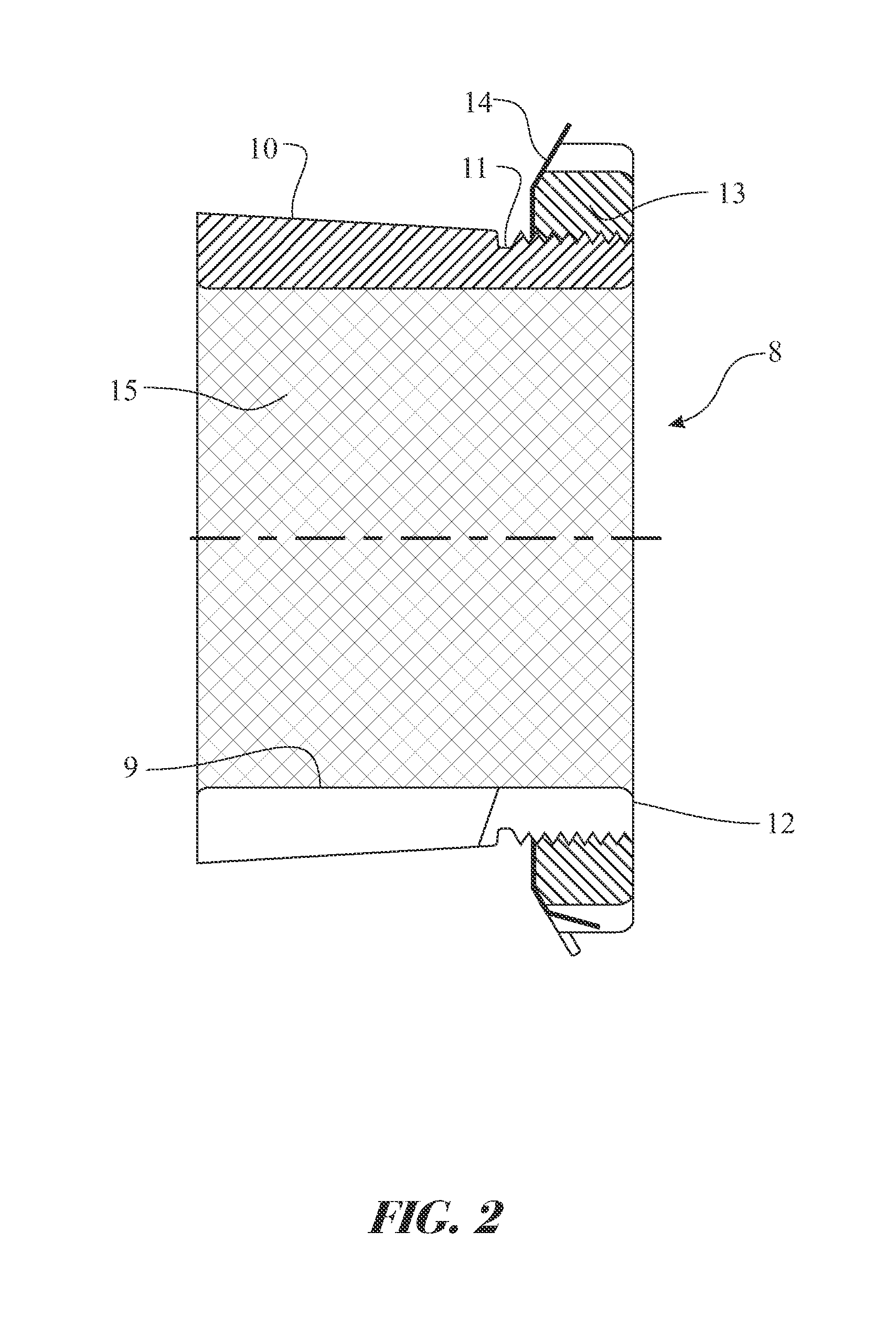

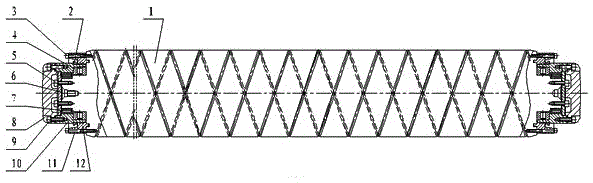

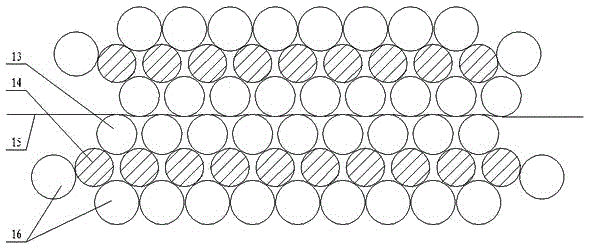

Cable collecting winch

InactiveUS20100032509A1Reduced dimensionIncrease axial loadFilament handlingWinding mechanismsEngineeringWinch

A cable collecting winch (1) comprises a collecting drum (2) rotatably actuatable about a respective longitudinal axis (X-X) to wind / unwind a cable (100), and a cable guide device (3) kinematically connected with the collecting drum (2) and adapted to translate along a direction parallel to said longitudinal axis (X-X) upon rotation of the collecting drum (2) to guide the winding / unwinding of the cable (100). The collecting drum (2) and the cable guide device (3) form a nut and screw assembly wherein such components are respectively the screw and the nut of said nut and screw assembly.

Owner:HARKEN ITAL

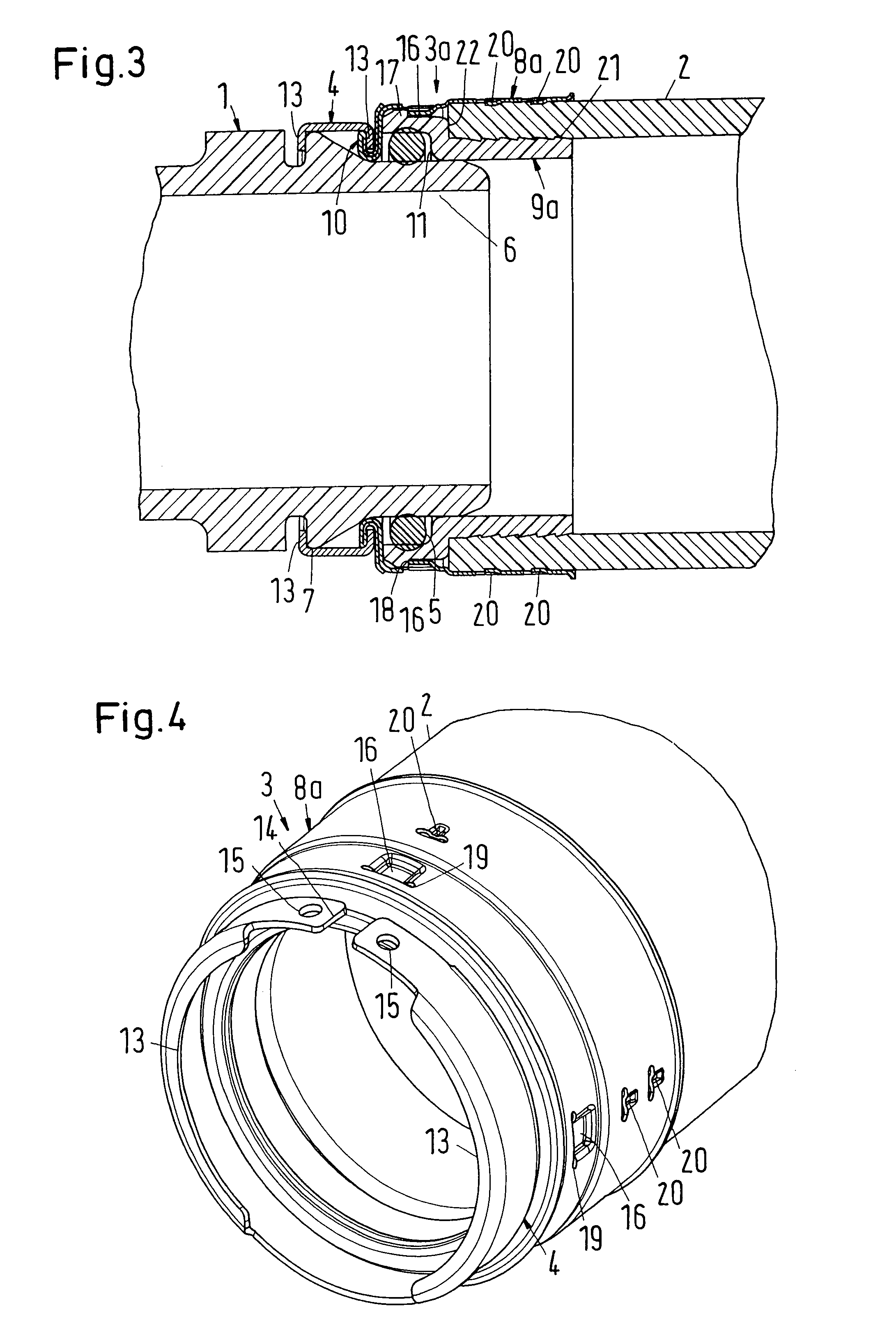

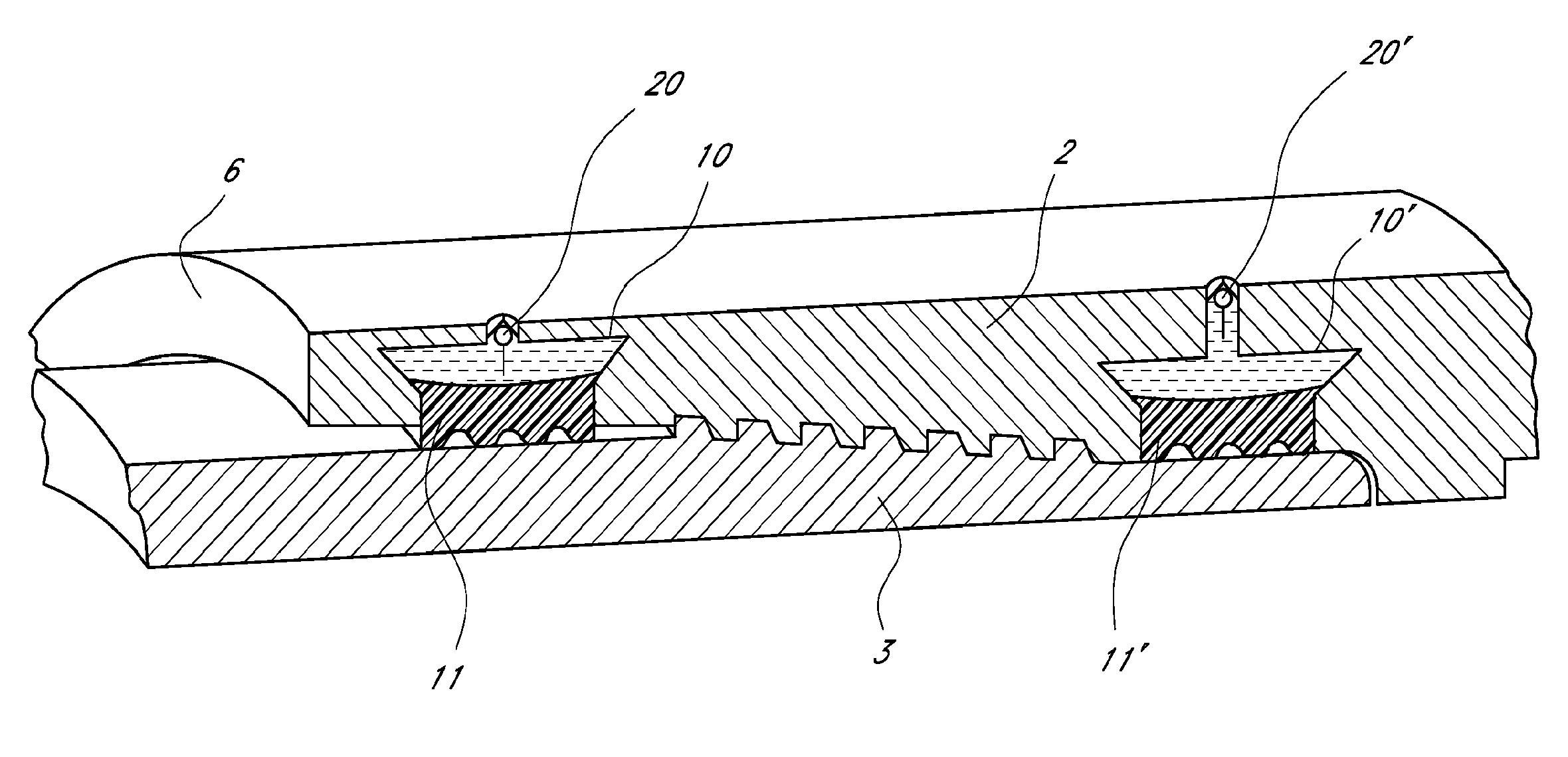

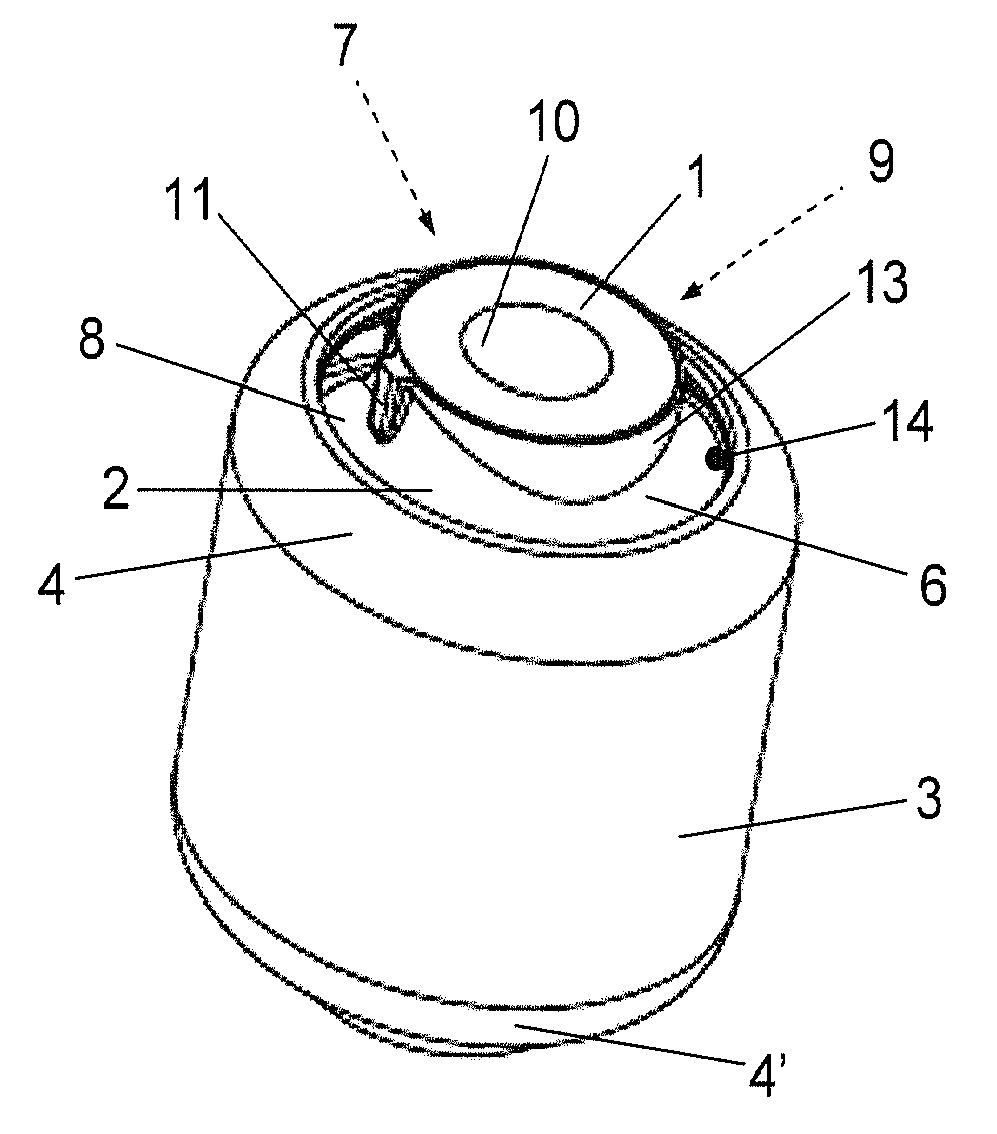

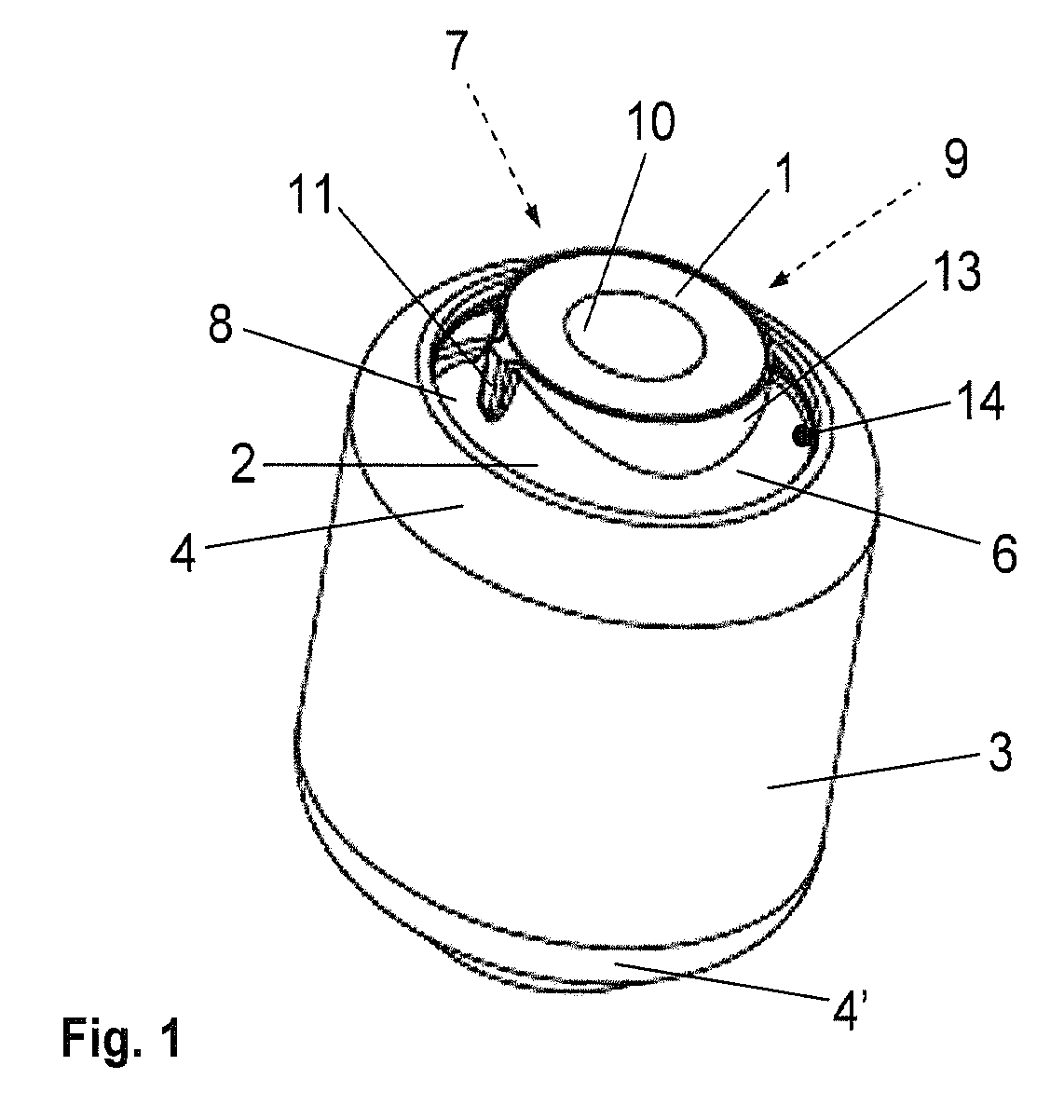

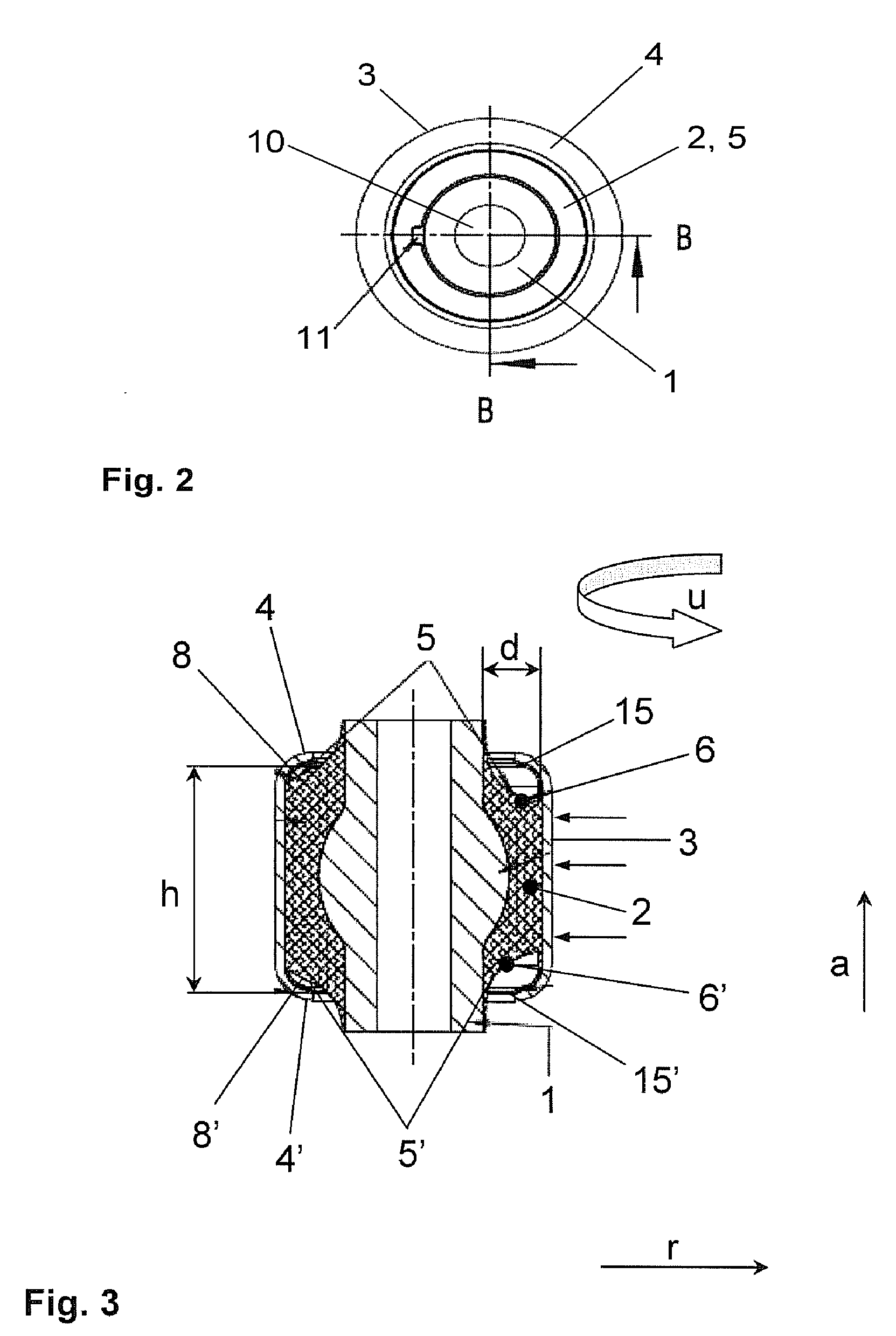

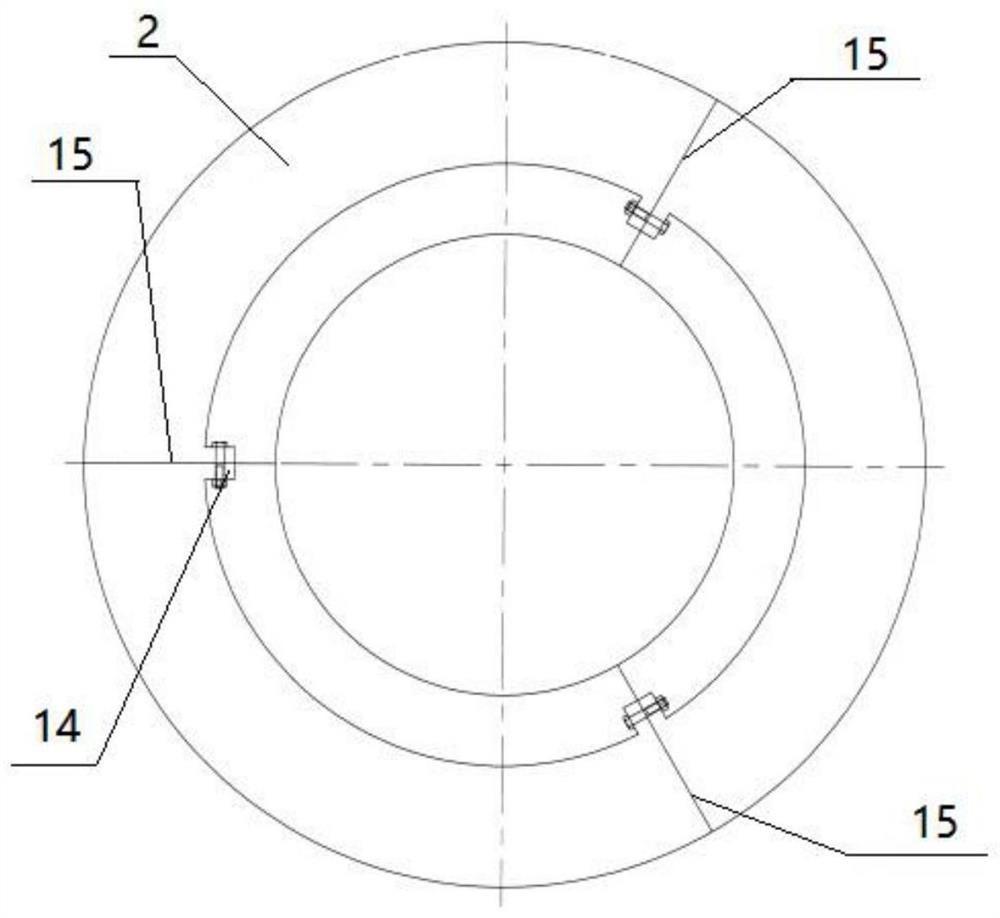

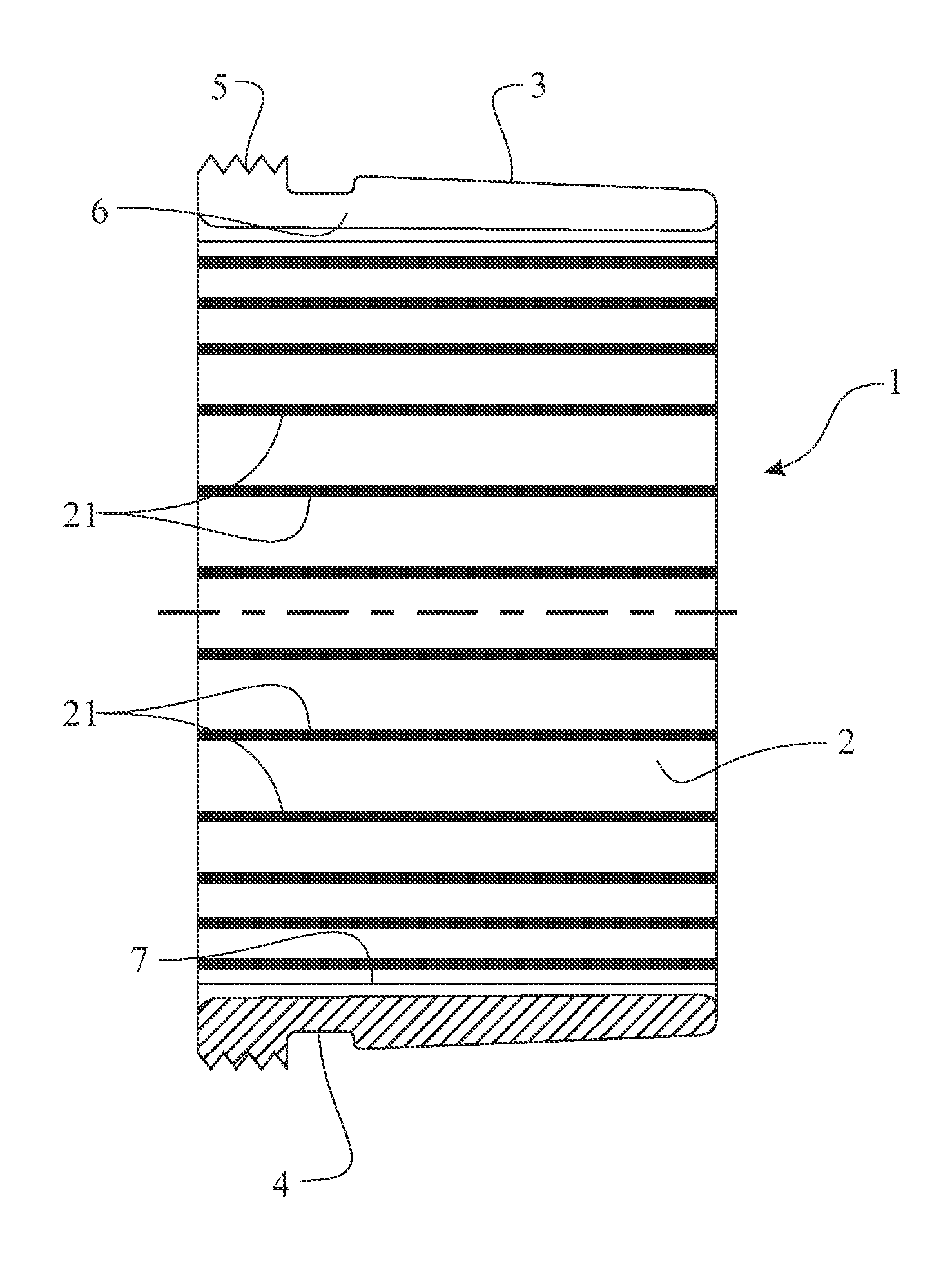

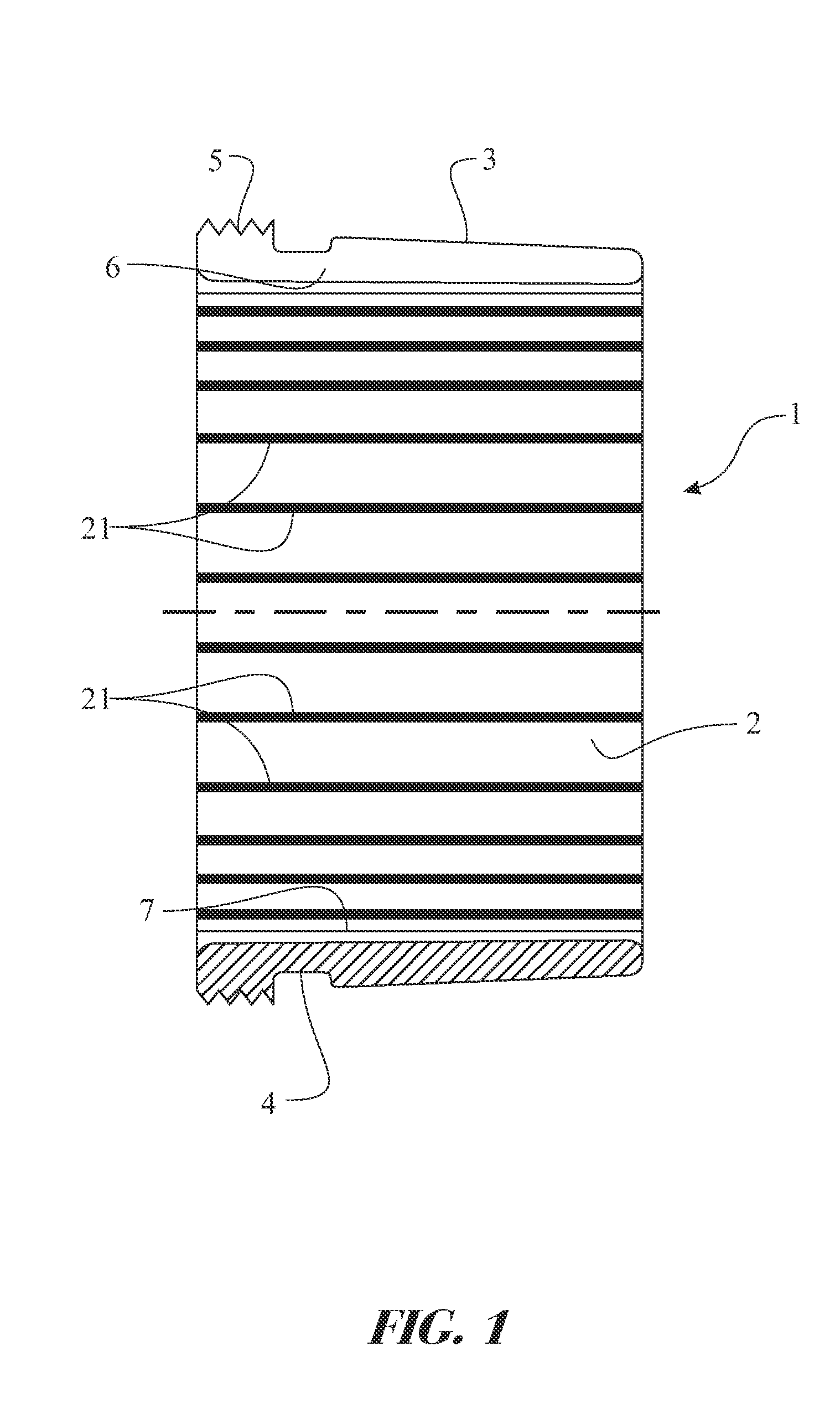

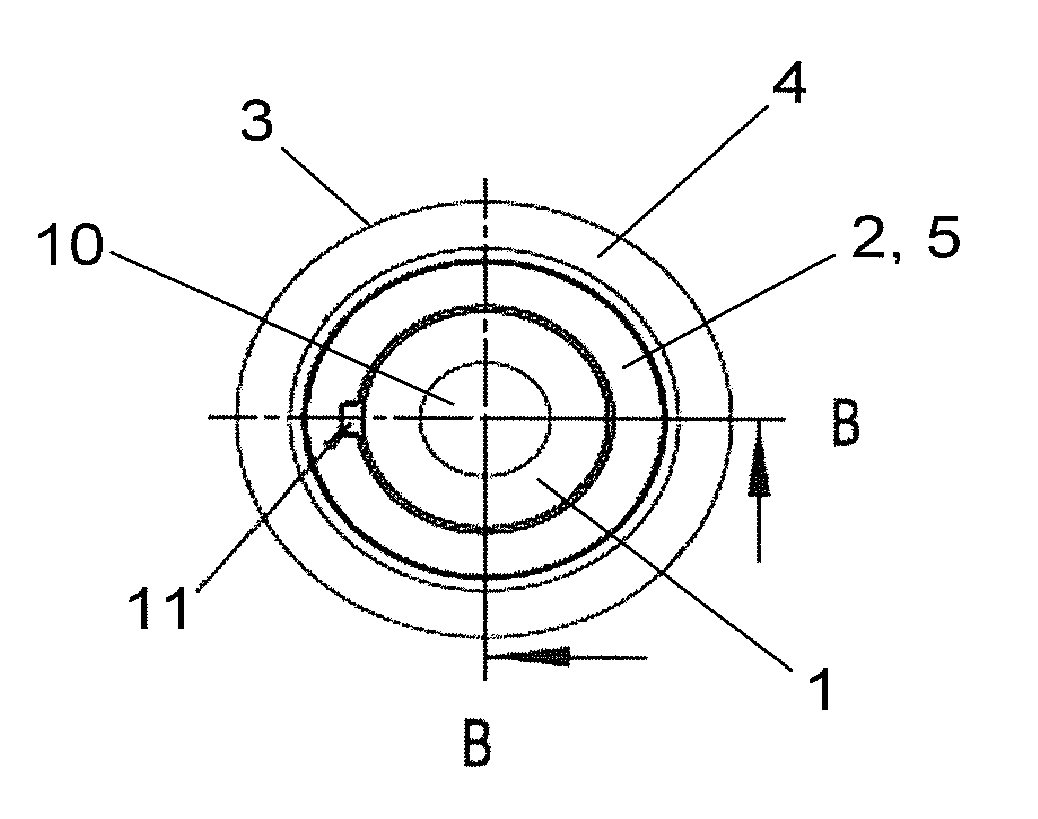

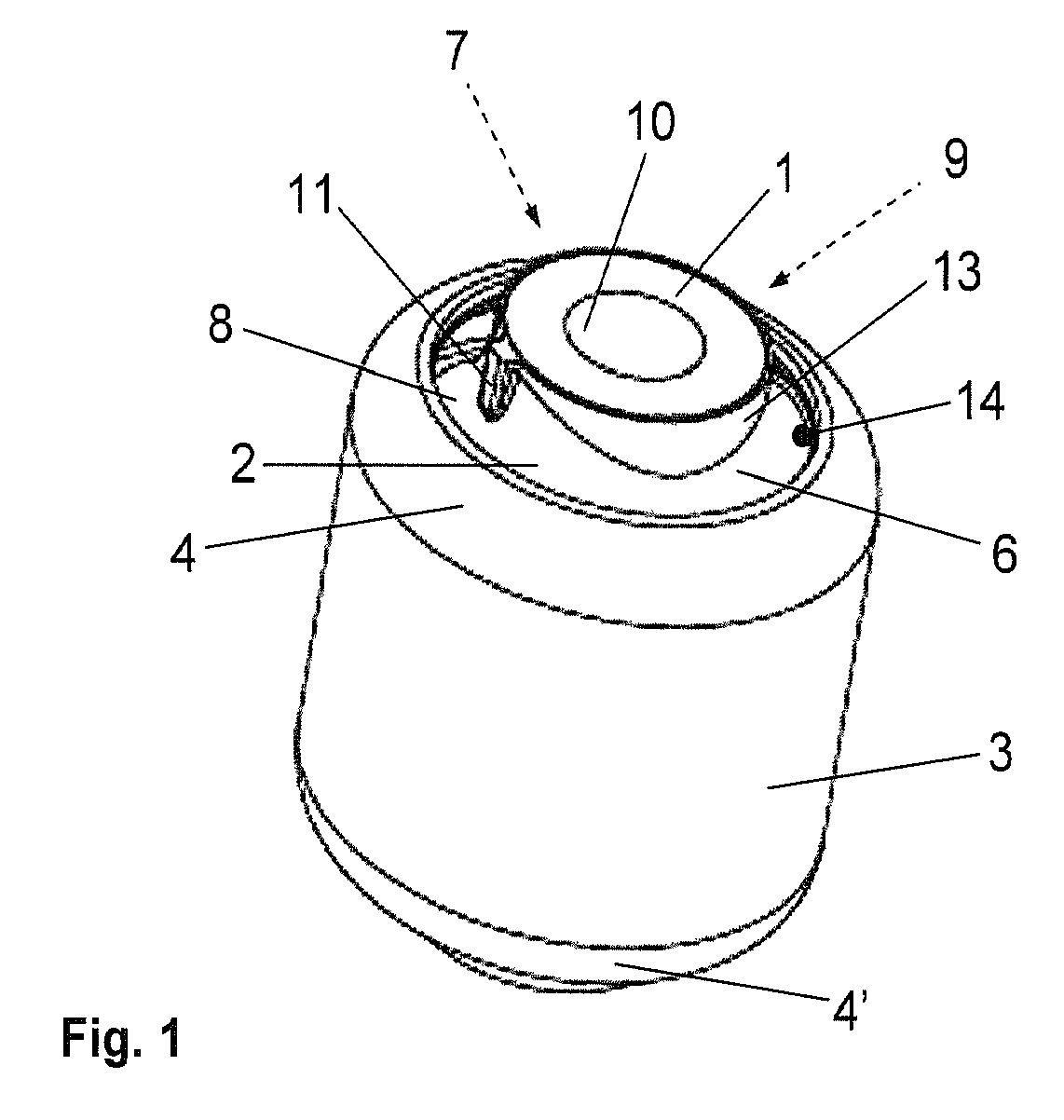

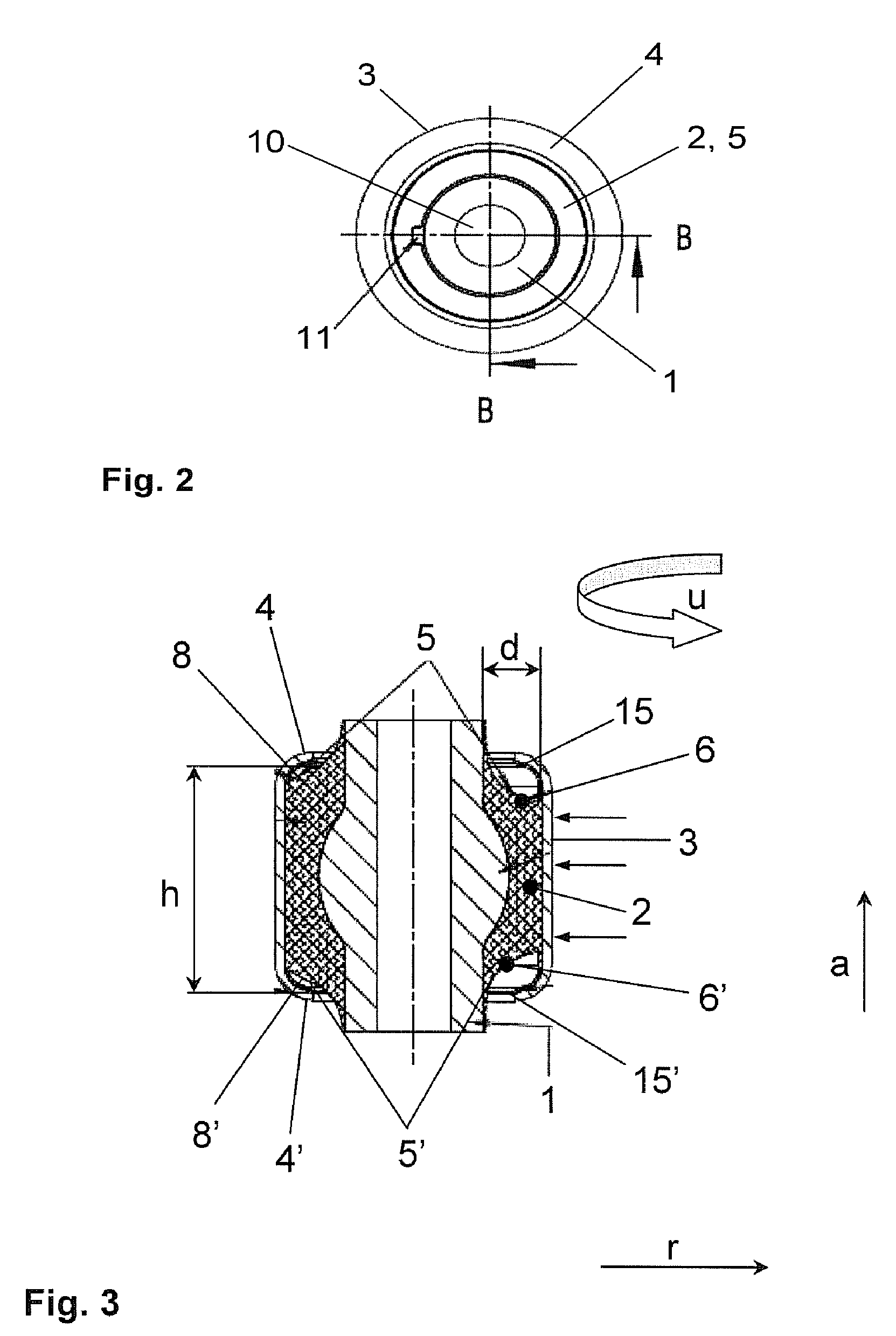

Bush bearing with bearing body having an axial profile

InactiveUS20070258671A1Lift radial loadAffecting service lifeResilient suspensionsRubber-like material springsElastomerEngineering

An elastomer bush bearing, wherein the bearing body (2) is encapsulated through axial flanges (4, 4′) of the outer bearing sleeve (3), with the bush bearing having an elastomer bearing body (2) with a special profile in the axial direction. The bearing body (2) is employed in constructing the bush bearing of the invention, which is capable of supporting high radial loads even with low radial stiffness and without adversely affecting its stability and service life. The two axial end faces (5, 5′) of the bearing body (1) each have undulated contours which extend in the circumferential direction (u) in the same direction, both with respect to one another and also over the entire region of the material thickness (d) of the bearing body (2). The end faces (5, 5′) of the bearing body (2) thus have wave troughs (6, 6′, 7, 7′) and wave crests (8, 8′, 9, 9′), whereby the corresponding wave troughs (6, 6′, 7, 7′) of both end faces (5, 5′) and their wave crests (8, 8′, 9, 9′) are formed so as to face one another, and each extend radially over the entire material thickness (d) of the bearing body (2) in the respective circumferential segment.

Owner:ZF FRIEDRICHSHAFEN AG

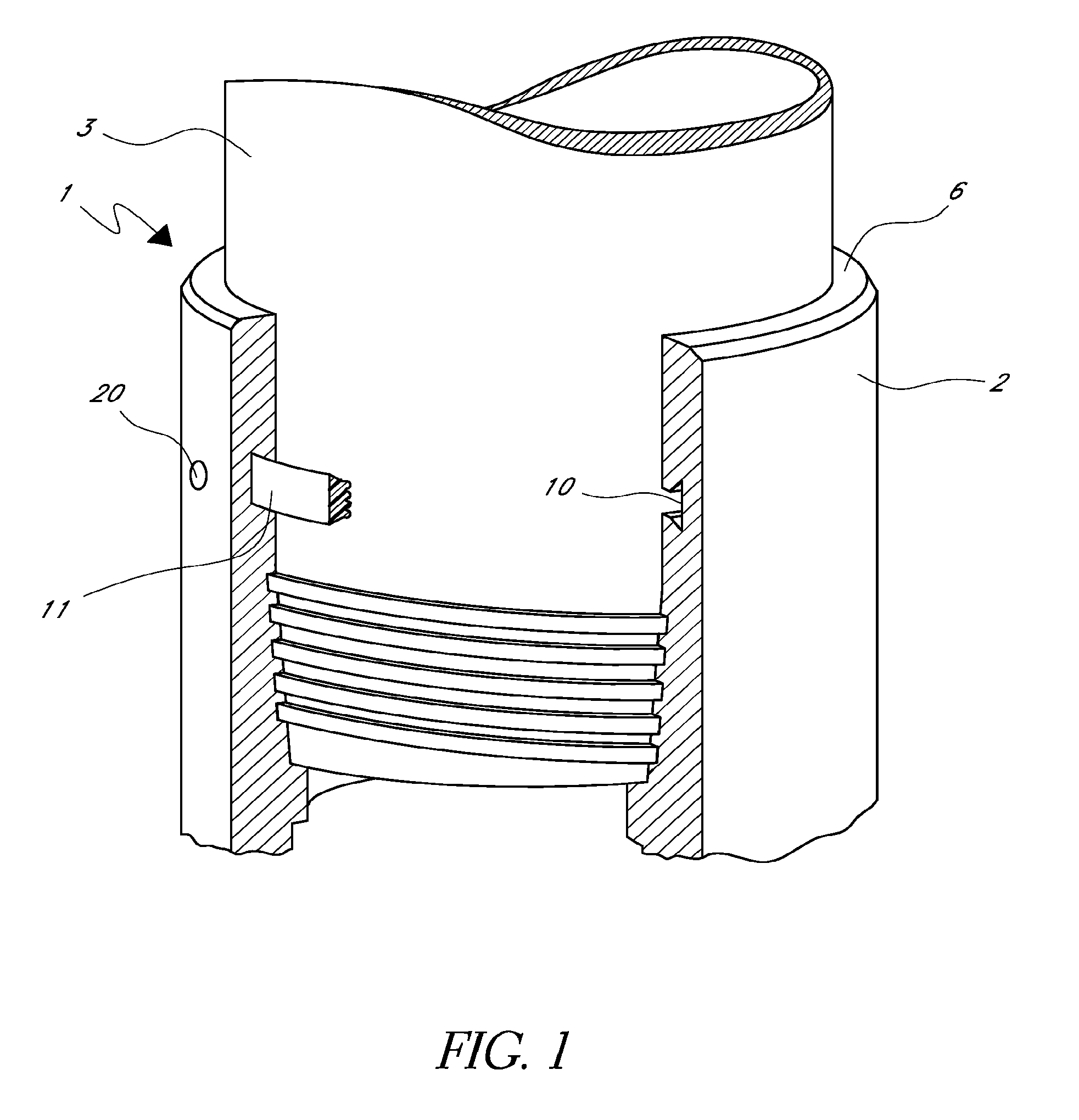

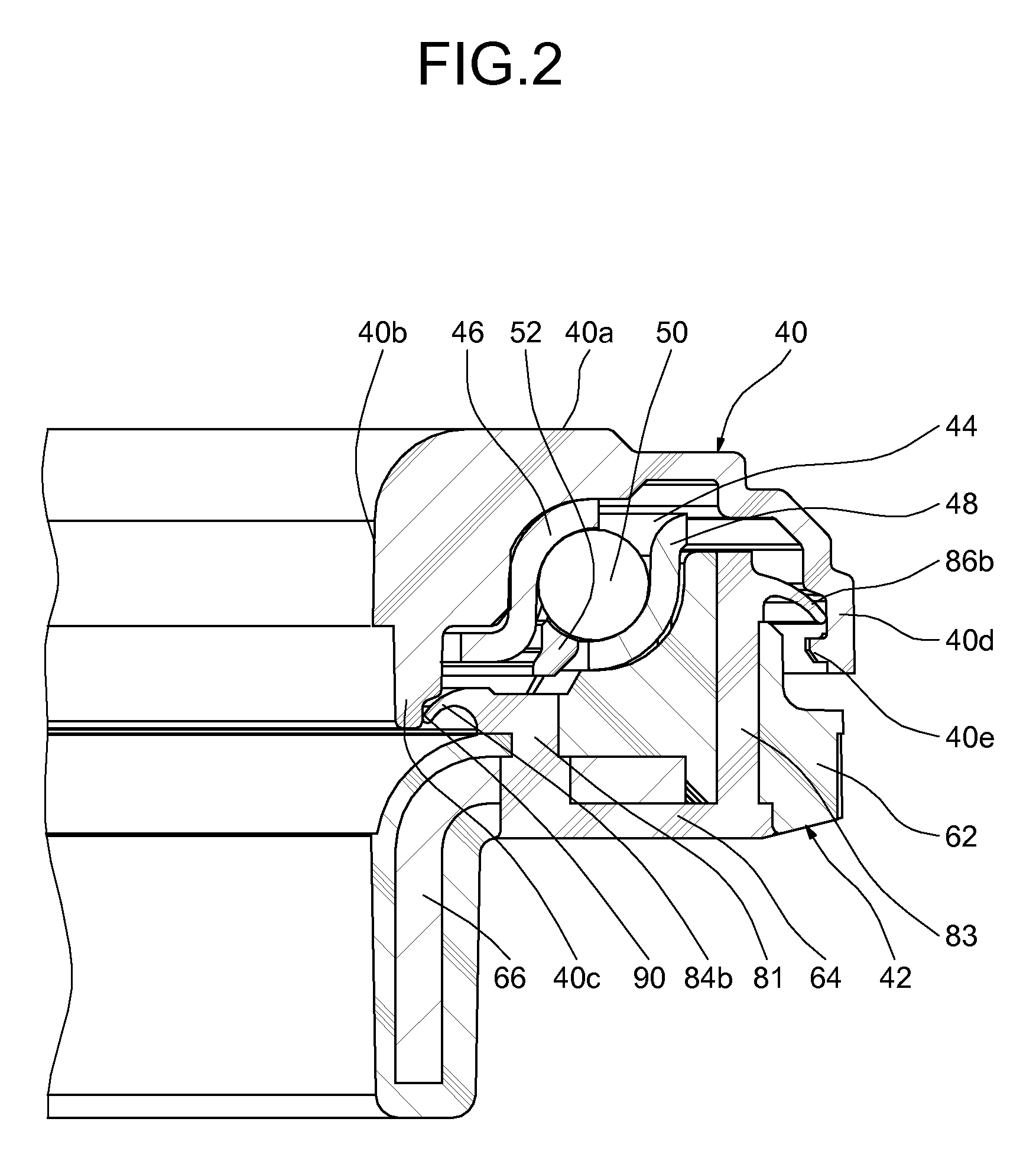

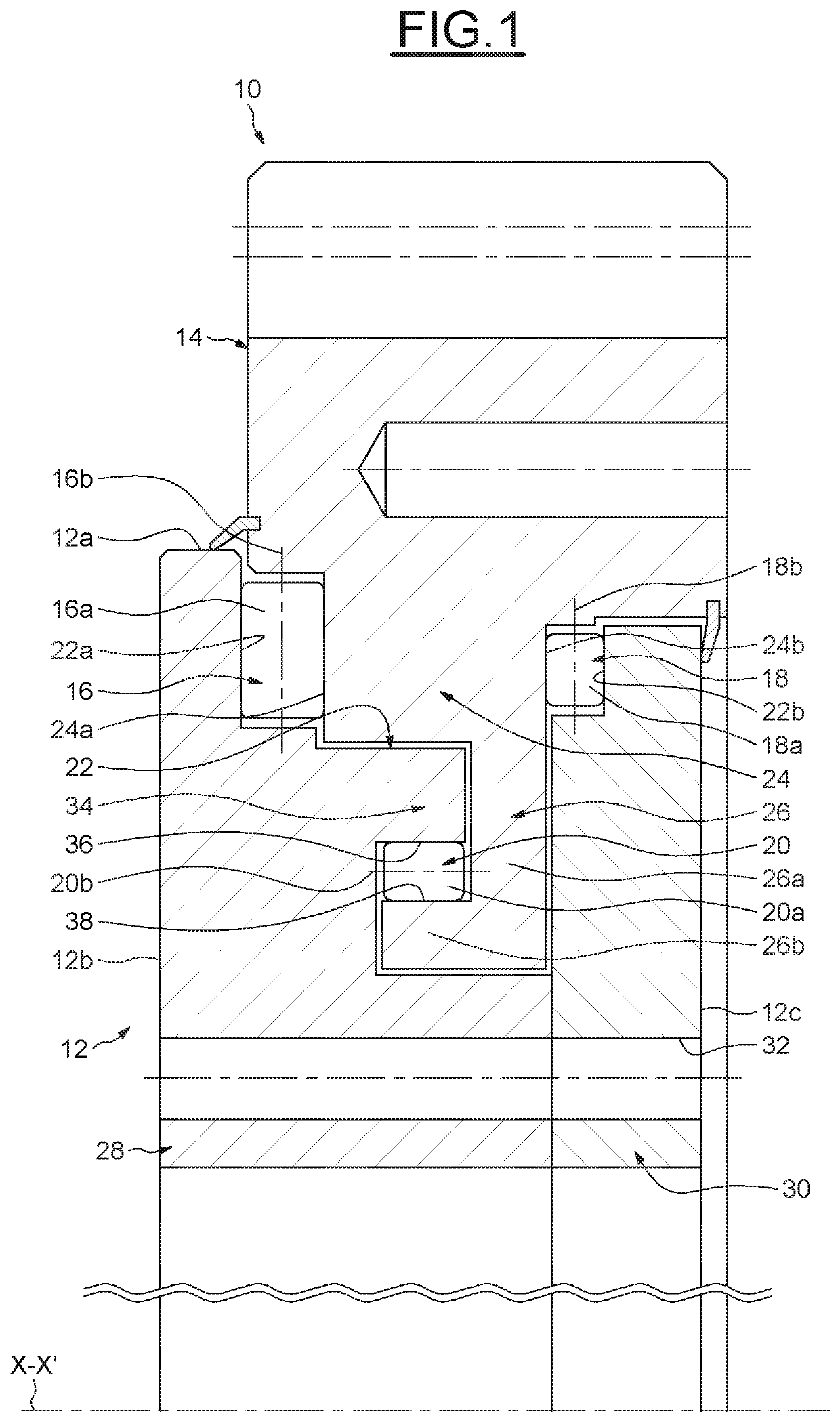

Bearing structure

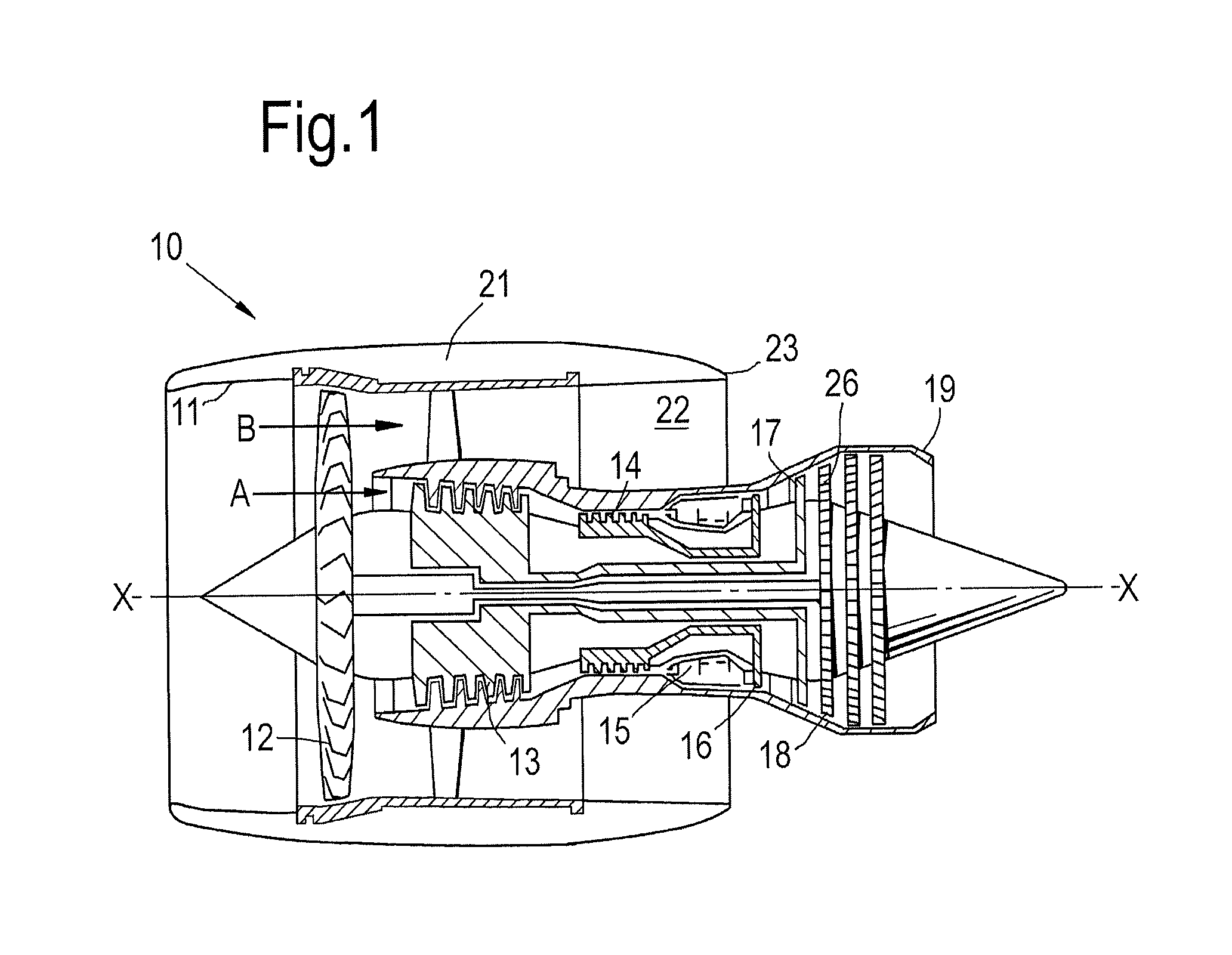

ActiveUS9447817B2Increase axial loadMinimize impactBearing assemblyEngine fuctionsEngineeringMechanical engineering

Bearing structure including a first bearing, surrounded by a housing, having a first inner and outer race and first set of rolling elements between the inner and outer races and a second bearing having a second inner and outer race and second set of rolling elements between the second inner and outer races. A first compliant element is connected to the first outer race. A rigid diaphragm is connected to the first outer race between the compliant element and outer race, and is connected to the housing at its outer end. The first compliant element, outer race and rigid diaphragm at least partly define a pressure chamber. The first outer race is axially slidable relative to the second such that a pressure increase in the chamber changes the axial spacing between the first and second outer races, inducing additional axial load on the bearings which helps balance thrust load sharing.

Owner:ROLLS ROYCE PLC

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS7033113B2Increase axial loadAvoid local accumulationPipe laying and repairWaterborne vesselsElectricityElectrical conductor

Owner:SHELL OIL CO

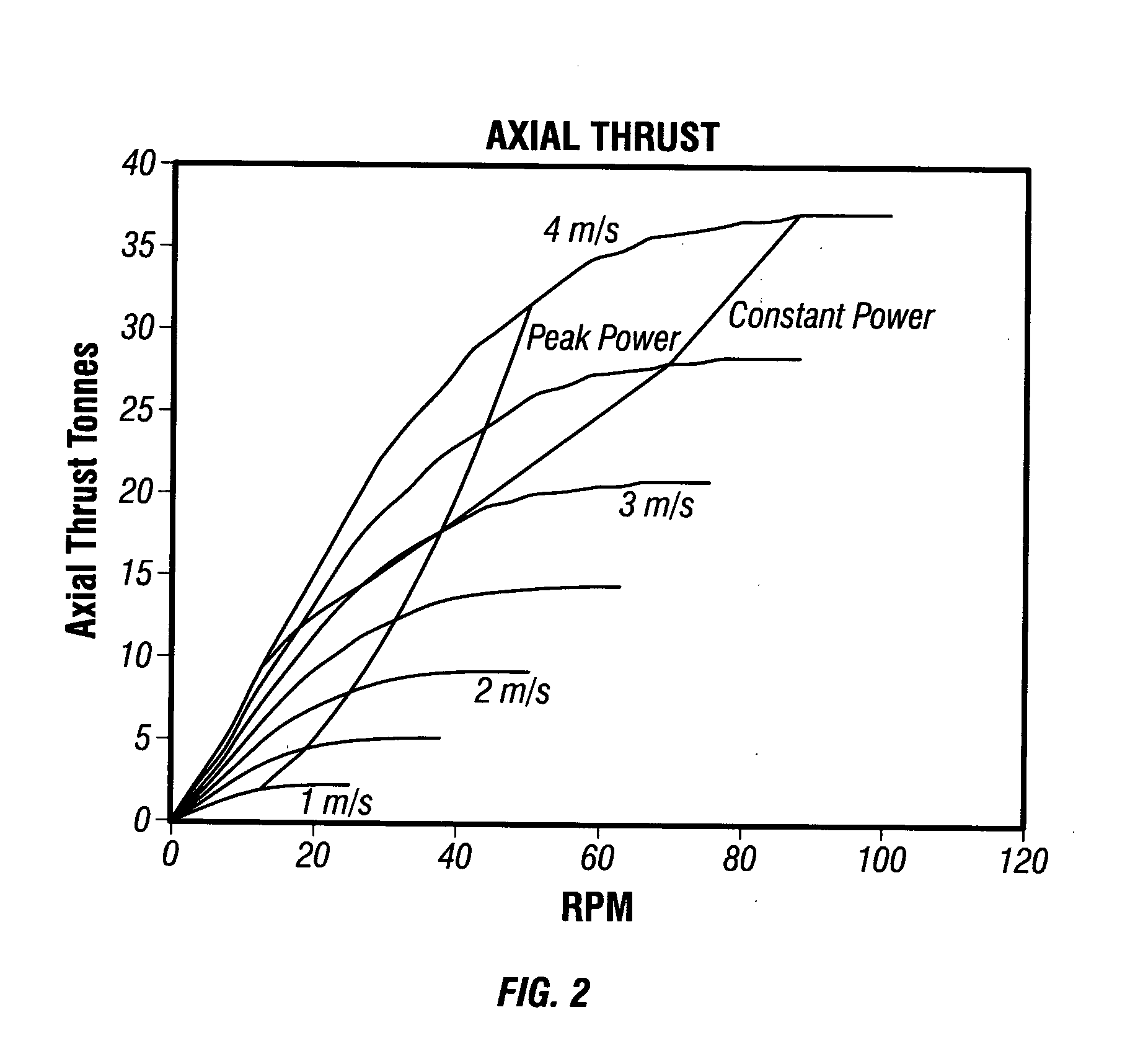

Tidal Turbine System

InactiveUS20110254271A1Increase speedIncrease axial loadReaction enginesSafety/regulatory devicesAxial LoadingsTurbine blade

A tidal flow turbine system has a rotor and turbine blades attached at a fixed attitude with respect to the rotor and extending outwardly from the rotor. The stagger angle of the blades, tip speed ratio, or other blade parameters is such that over the in-service operational speed range of the turbine, over a lower range of rotational or tidal flow speeds, increased speed results in increased axial loading on the turbine, but at higher speed range above a predetermined threshold, axial loading on the turbine does not increase.

Owner:TIDAL ENERGY

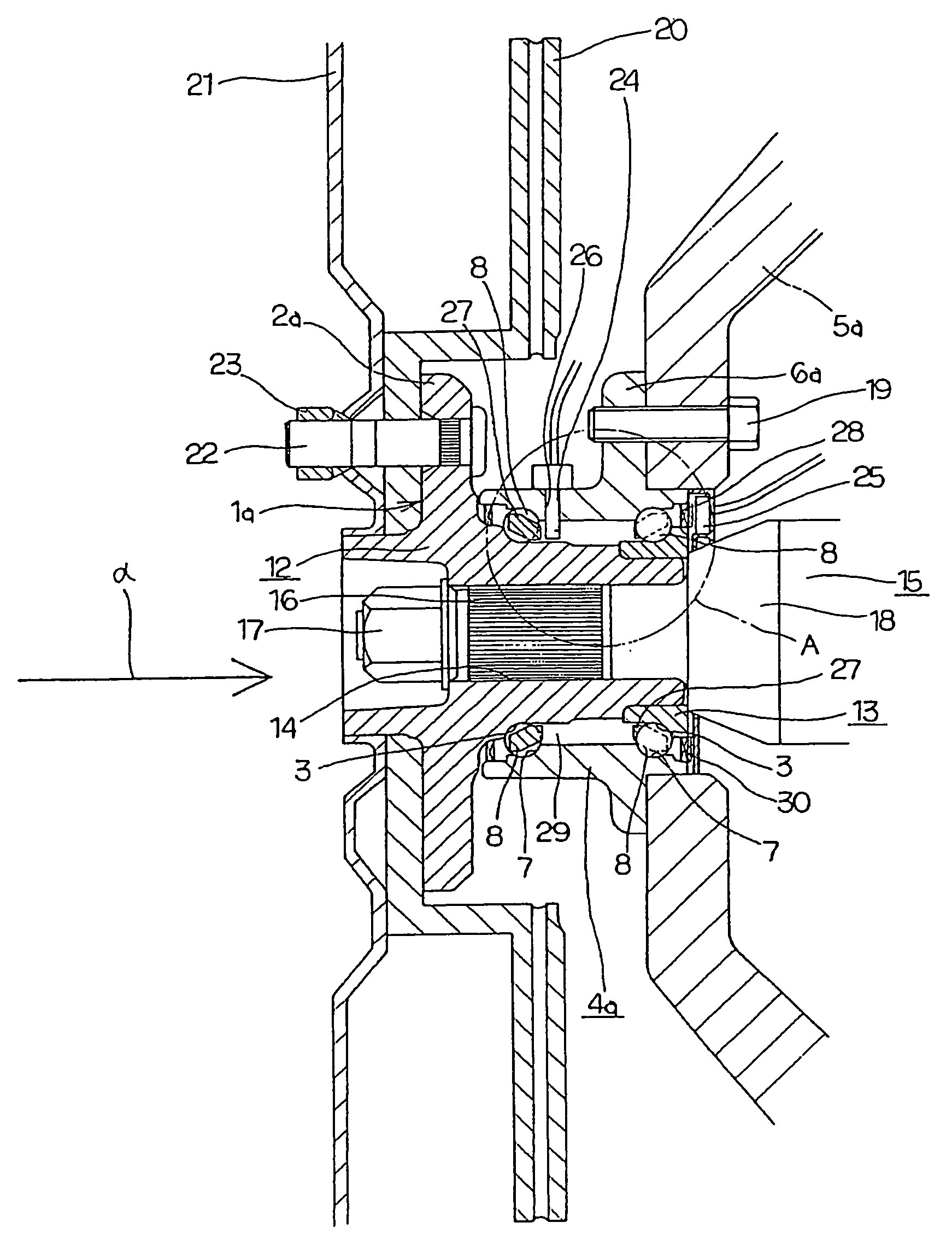

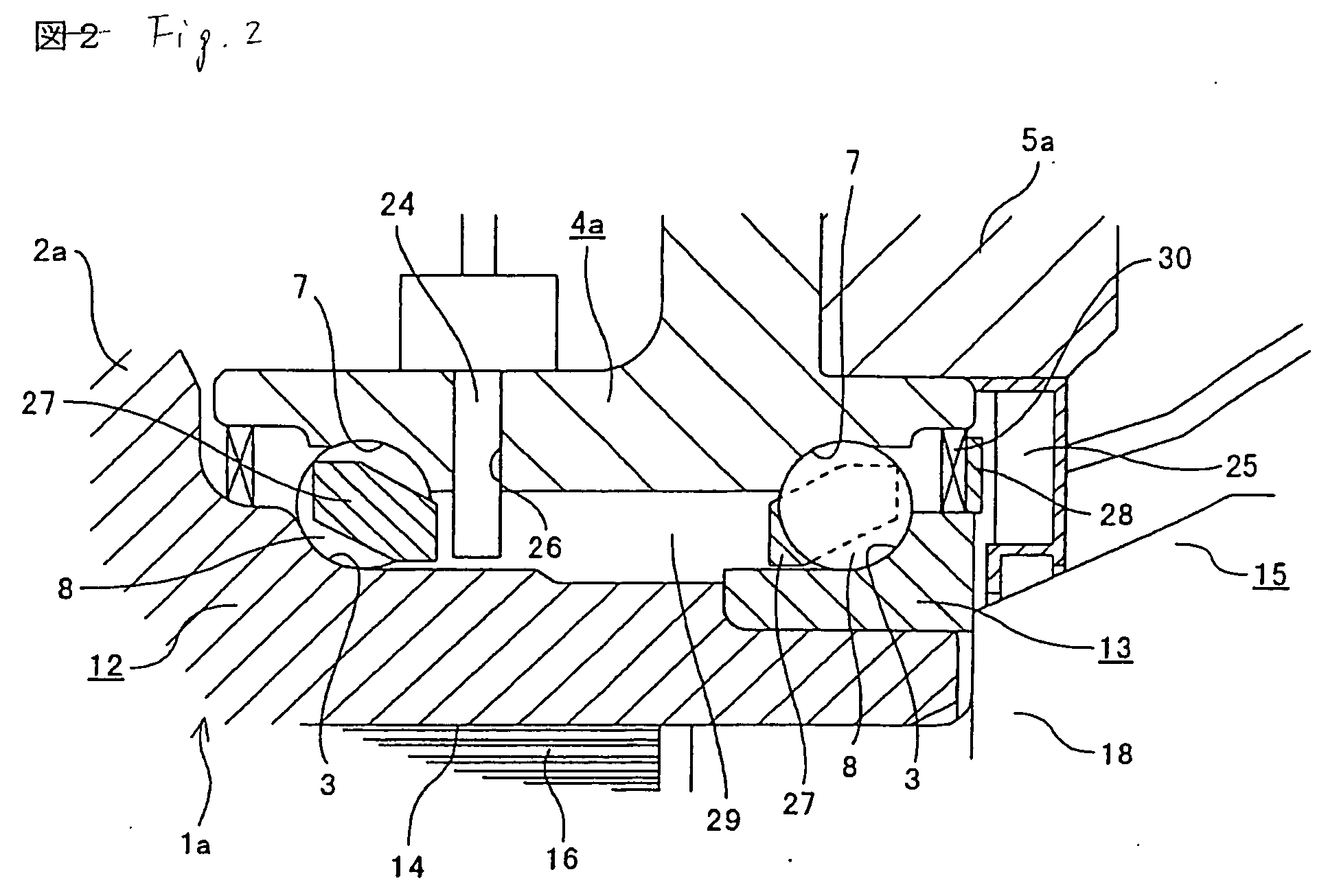

Load-measuring device for rolling bearing unit and rolling bearing unit for load measurement

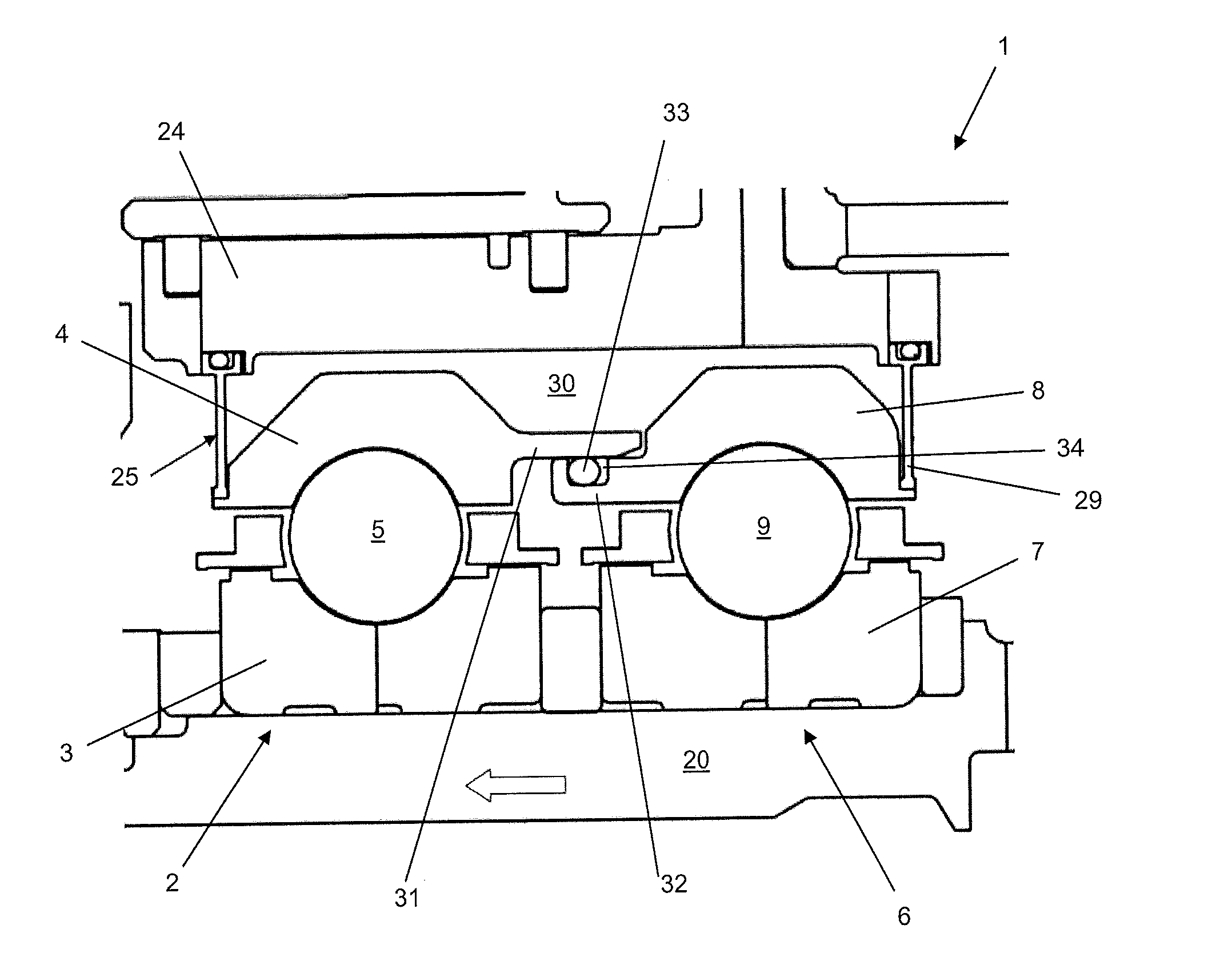

ActiveUS20060155507A1Reduce manufacturing costIncrease axial loadRolling contact bearingsBearing assemblyRolling-element bearingControl theory

A revolution speed of balls 8, 8 constituting the outer side row is sensed by a revolution speed sensor 24. Also, a rotation speed of a hub 1a is sensed by a rotation speed sensor 25. A speed ratio as a ratio between a revolution speed and the rotation speed is calculated based on a sensed signal of both sensors 24, 25. When the axial load is changed and then the contact angles of the balls 8, 8 are changed, the revolution speed is changed and in turn the speed ratio is changed. Therefore, the axial load is calculated based on a change of the speed ratio. Accordingly, the configurations that can be manufactured at a low cost and is able to sense the axial load applied between the hub 1a and the outer ring 4a can be realized.

Owner:NSK LTD

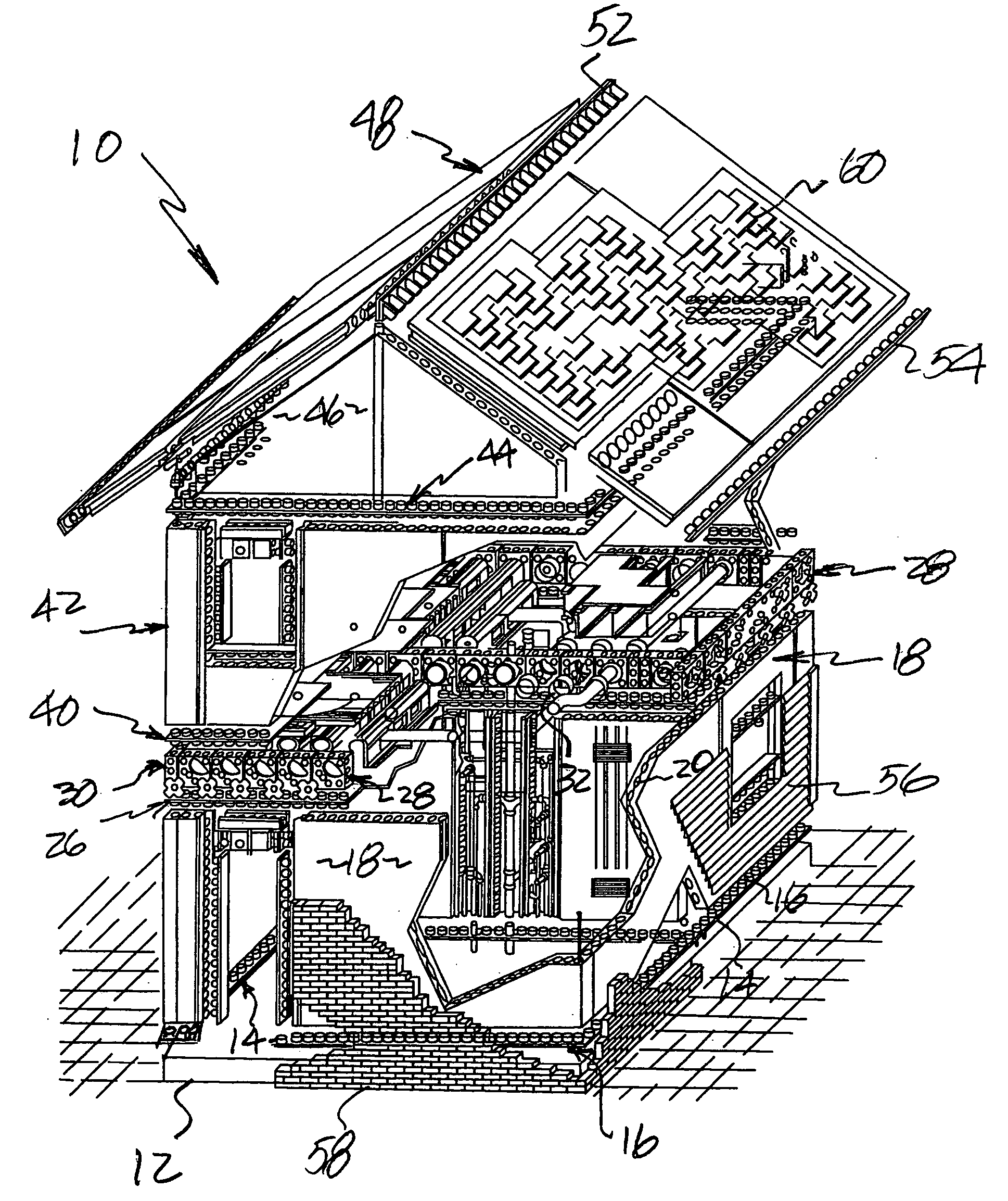

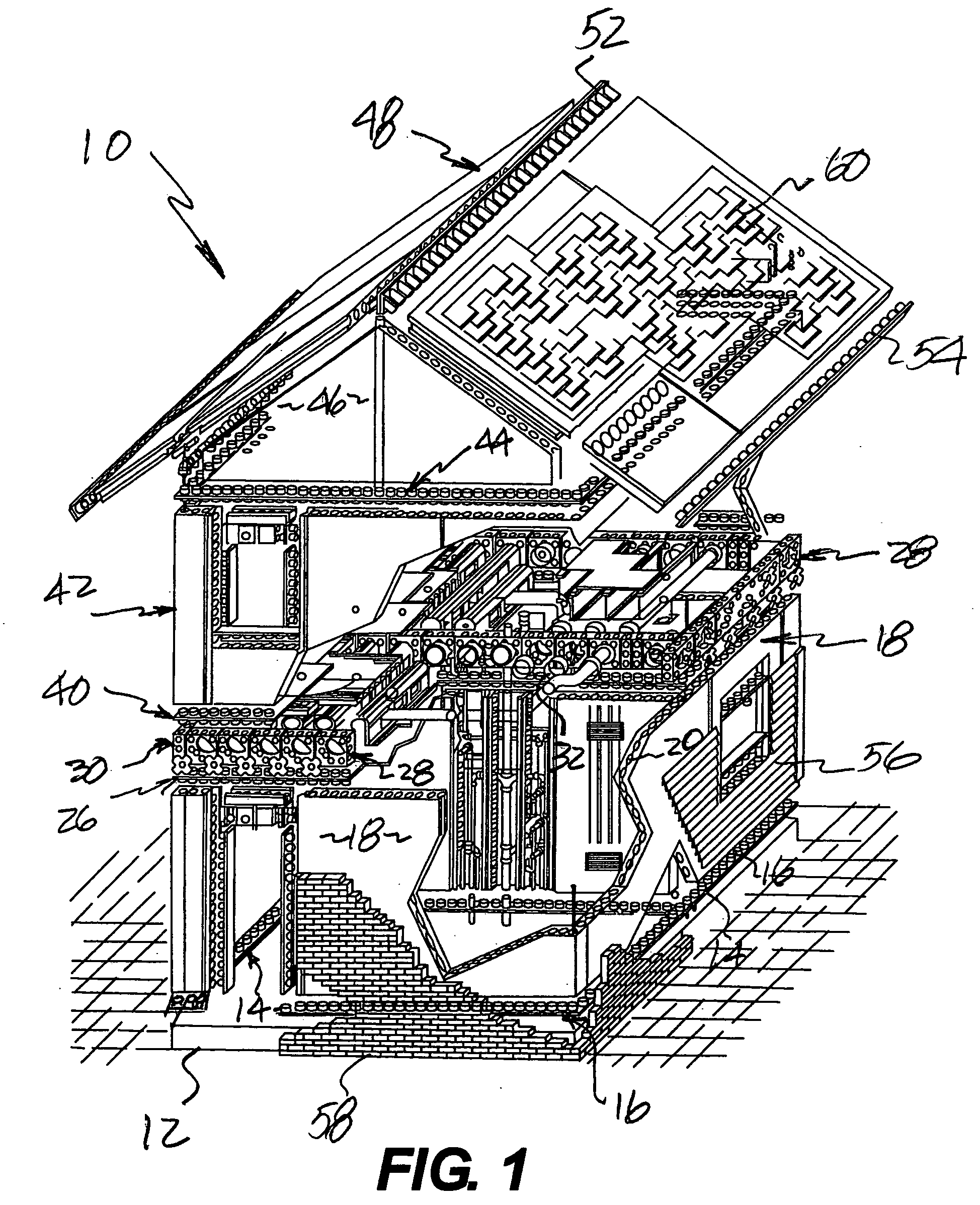

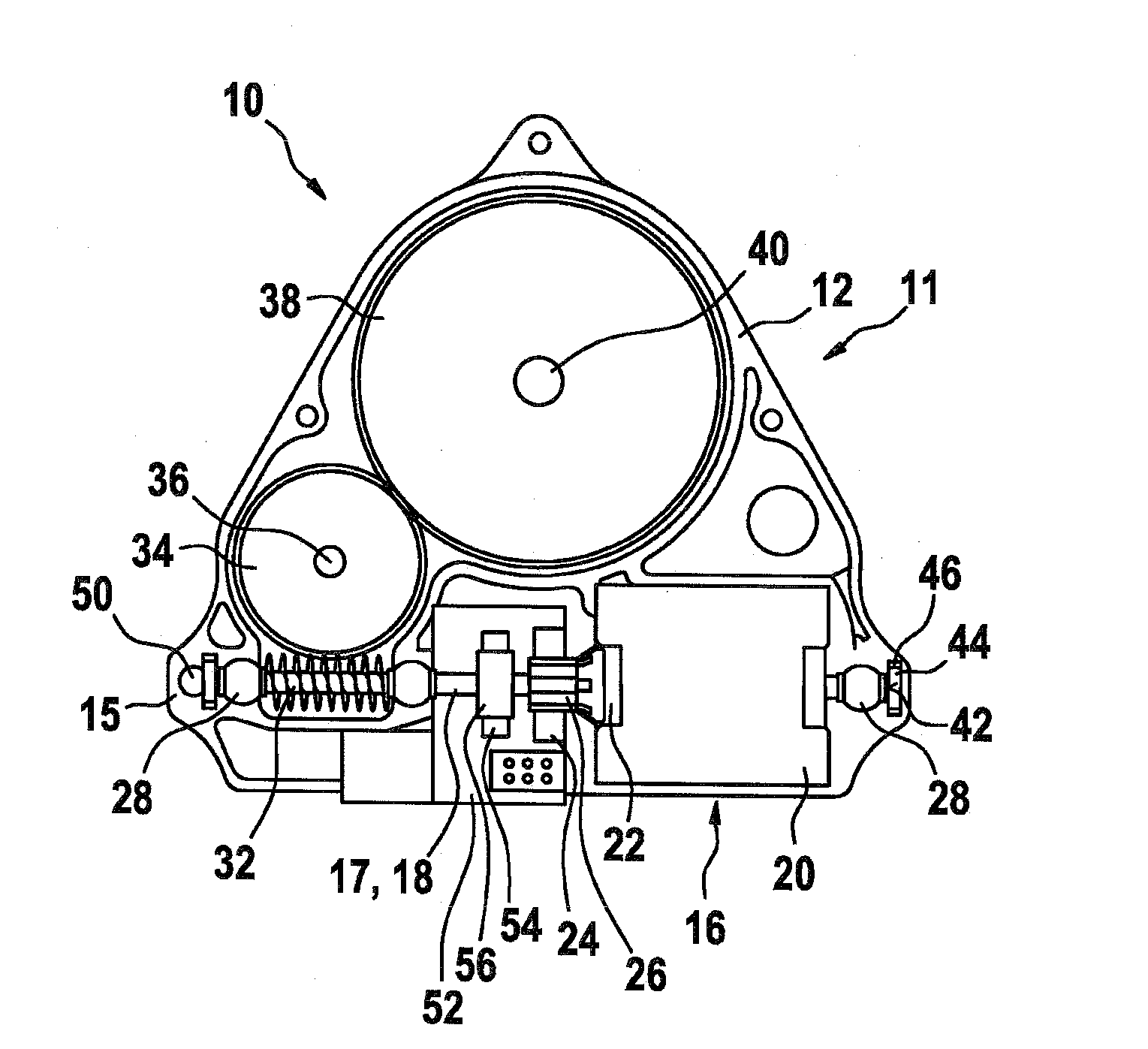

Driver unit with a thrust washer and method for manufacturing the same

InactiveUS20100224019A1Increase axial loadImprove the lubrication effectGearboxesShaftsEngineeringLubricant

The invention relates to a drive unit (10) and to a method for producing the same, in particular for adjusting moveable parts in a motor vehicle, having a metal driveshaft (17) which is mounted in a housing (11) by means of at least one radial bearing element (28), wherein the driveshaft (17) has two end sides (42), at least one of which, as an axial stop, is supported on the housing (11) by means of a stop disk (44), wherein the stop disk (44) is produced from a self-lubricating material (49) which lubricates the axial stop over the entire service life of the drive unit (10) without the use of additional, separate lubricants.

Owner:ROBERT BOSCH GMBH

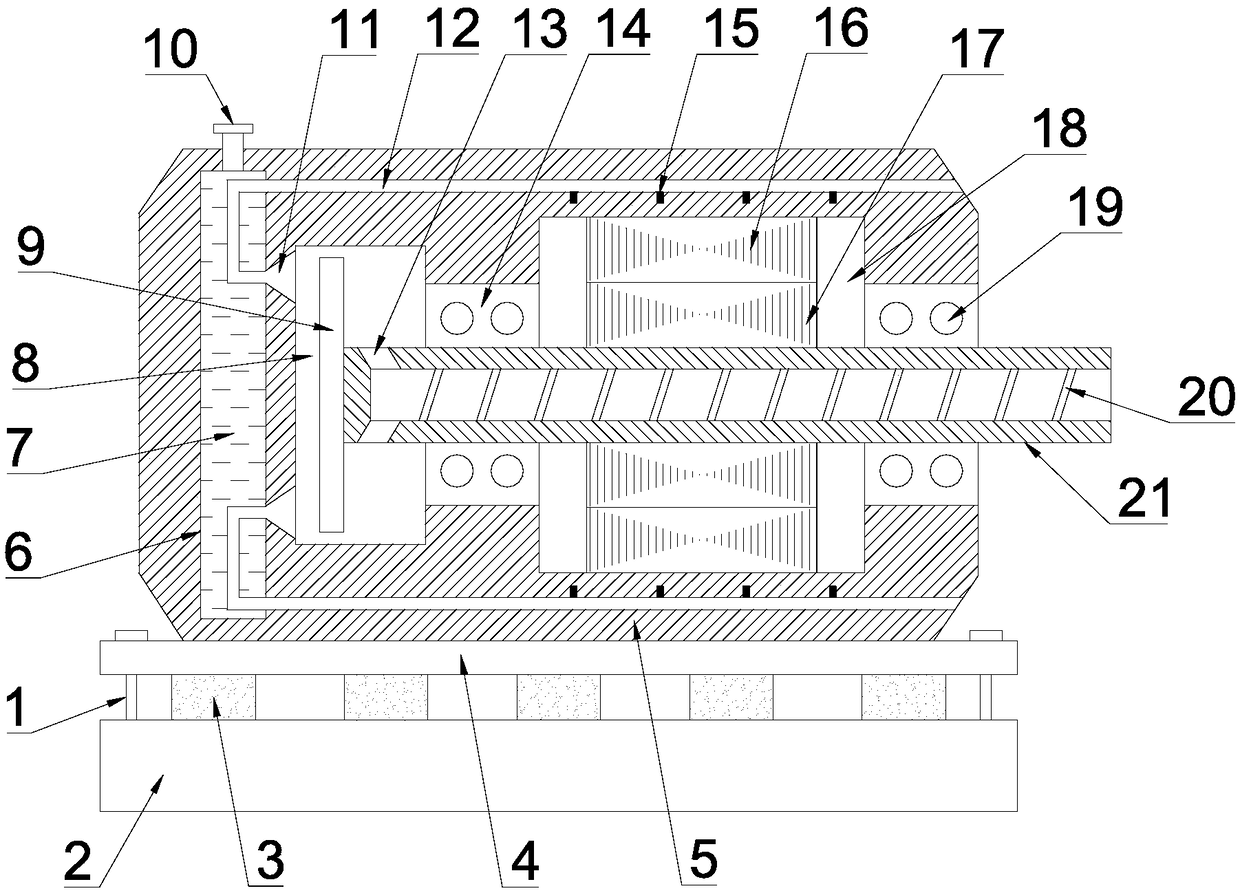

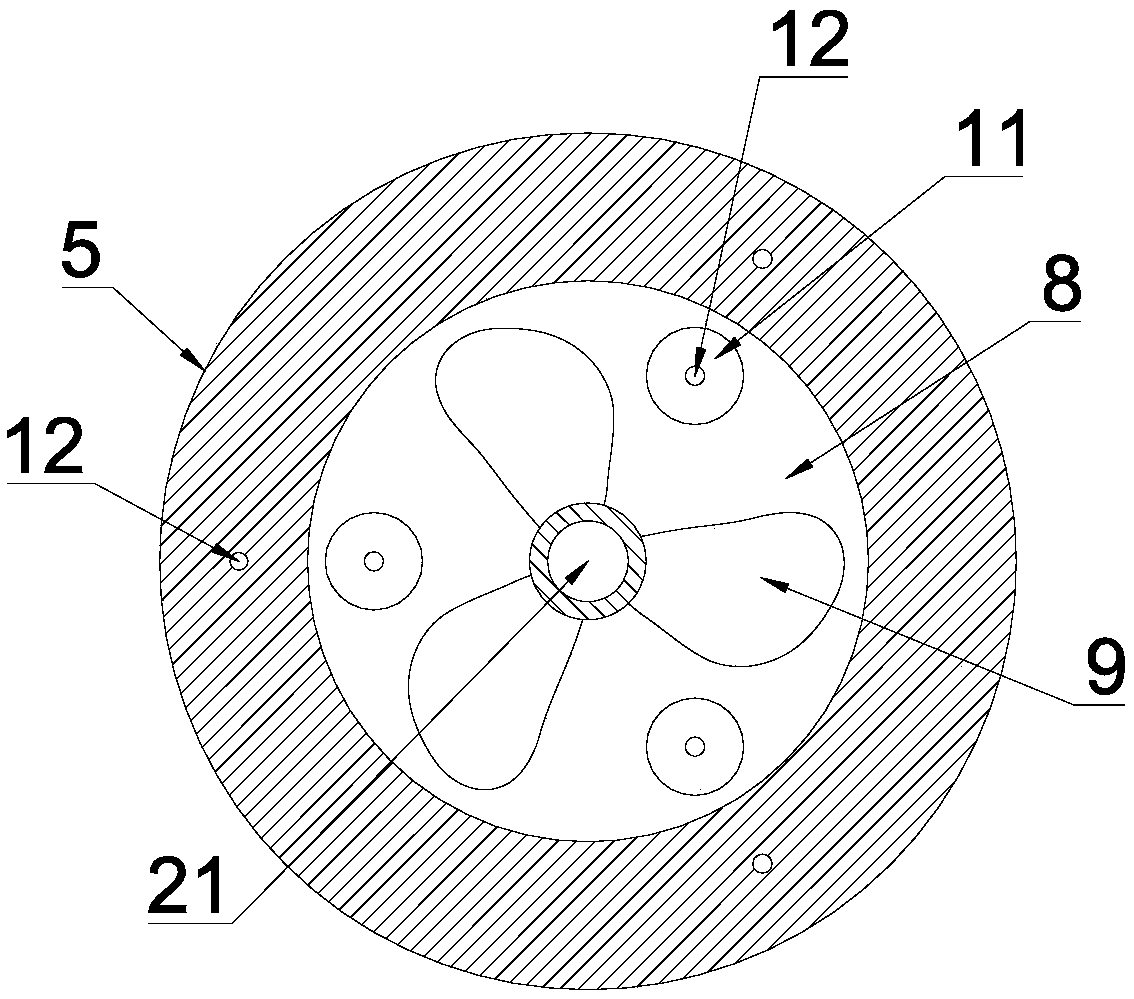

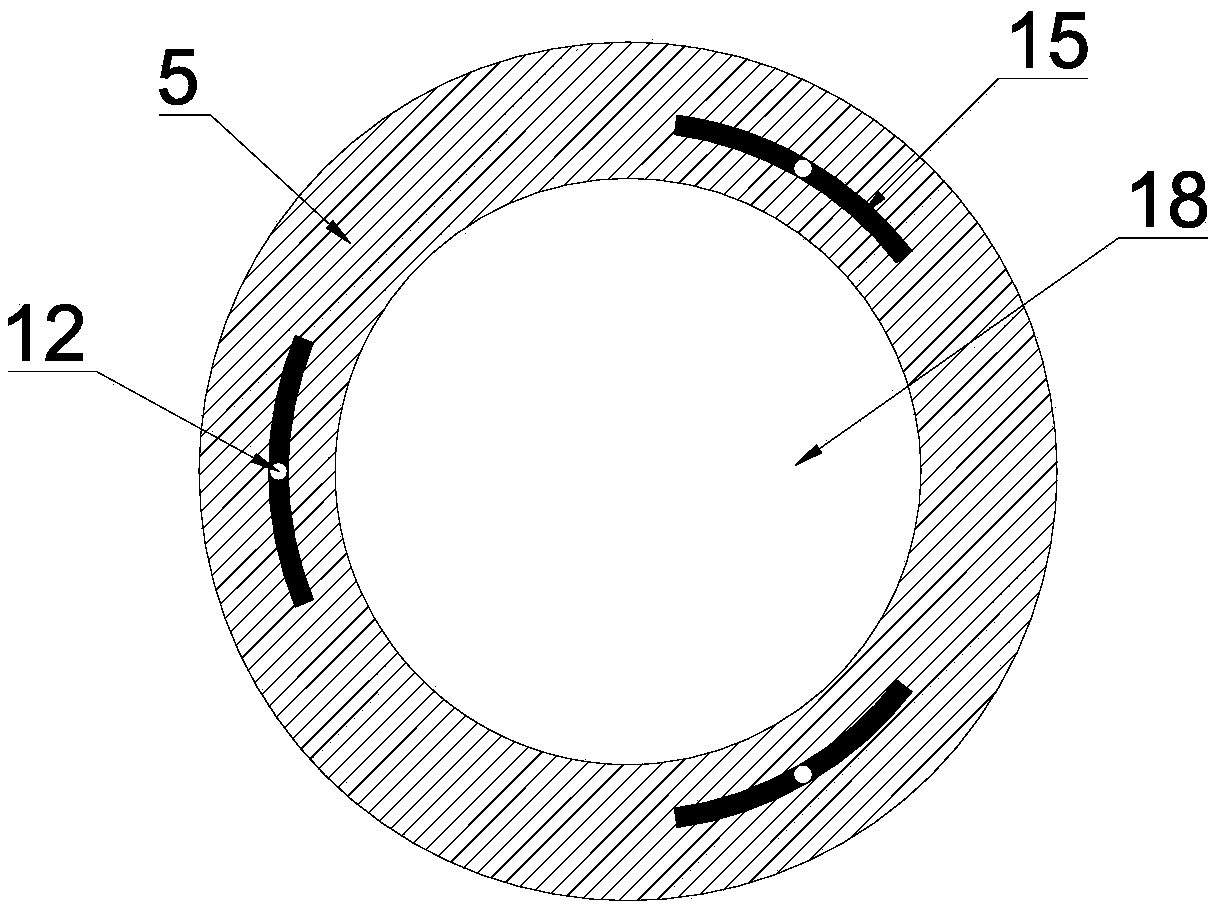

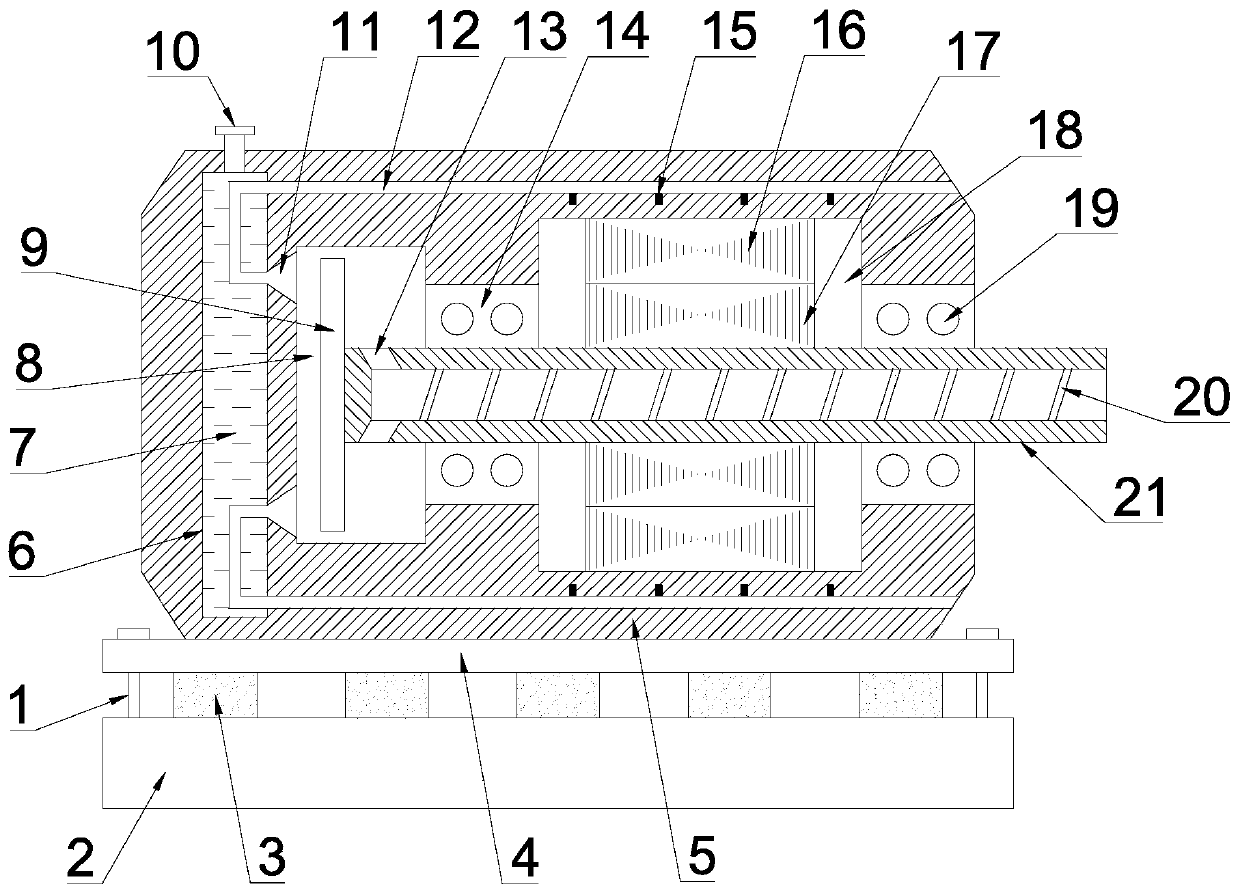

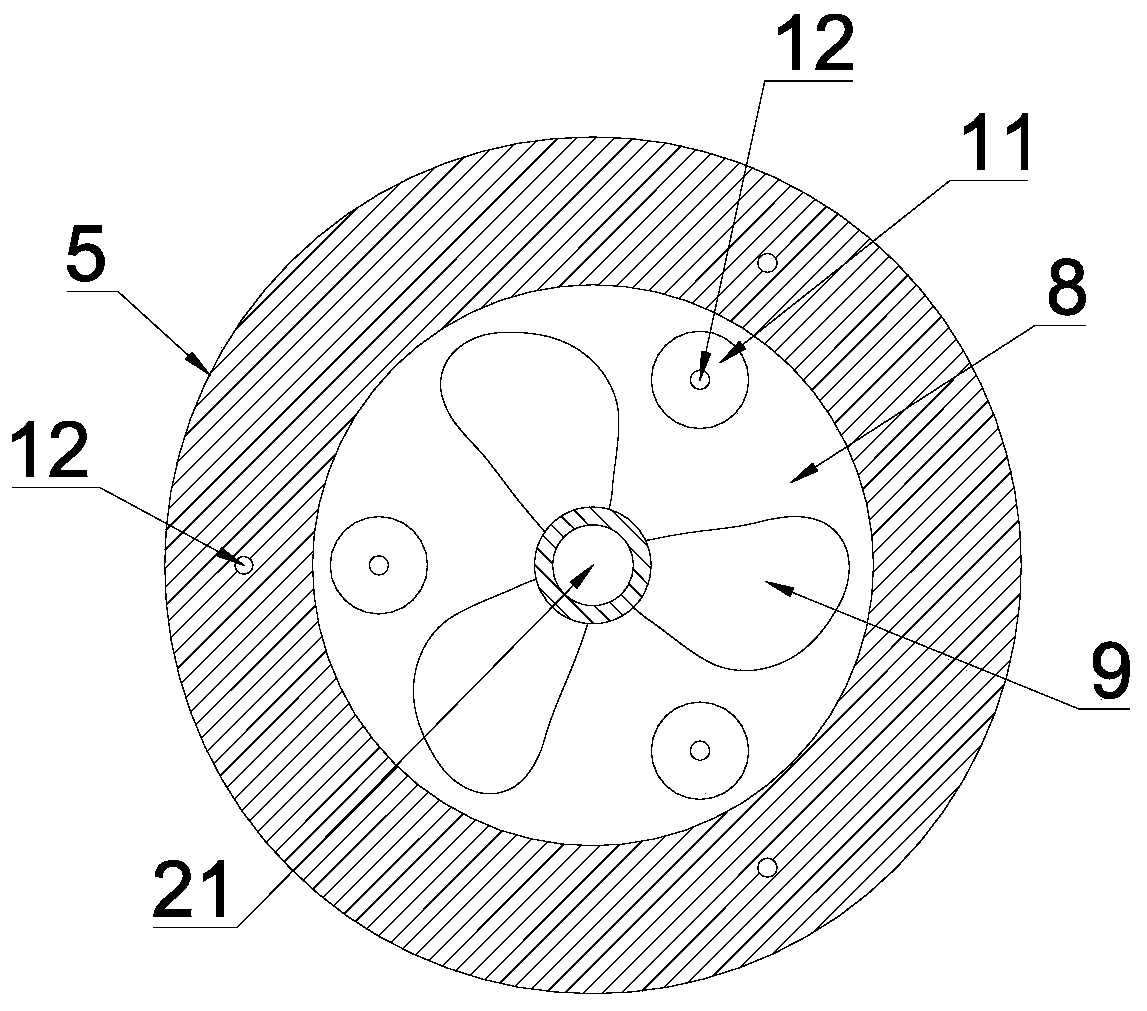

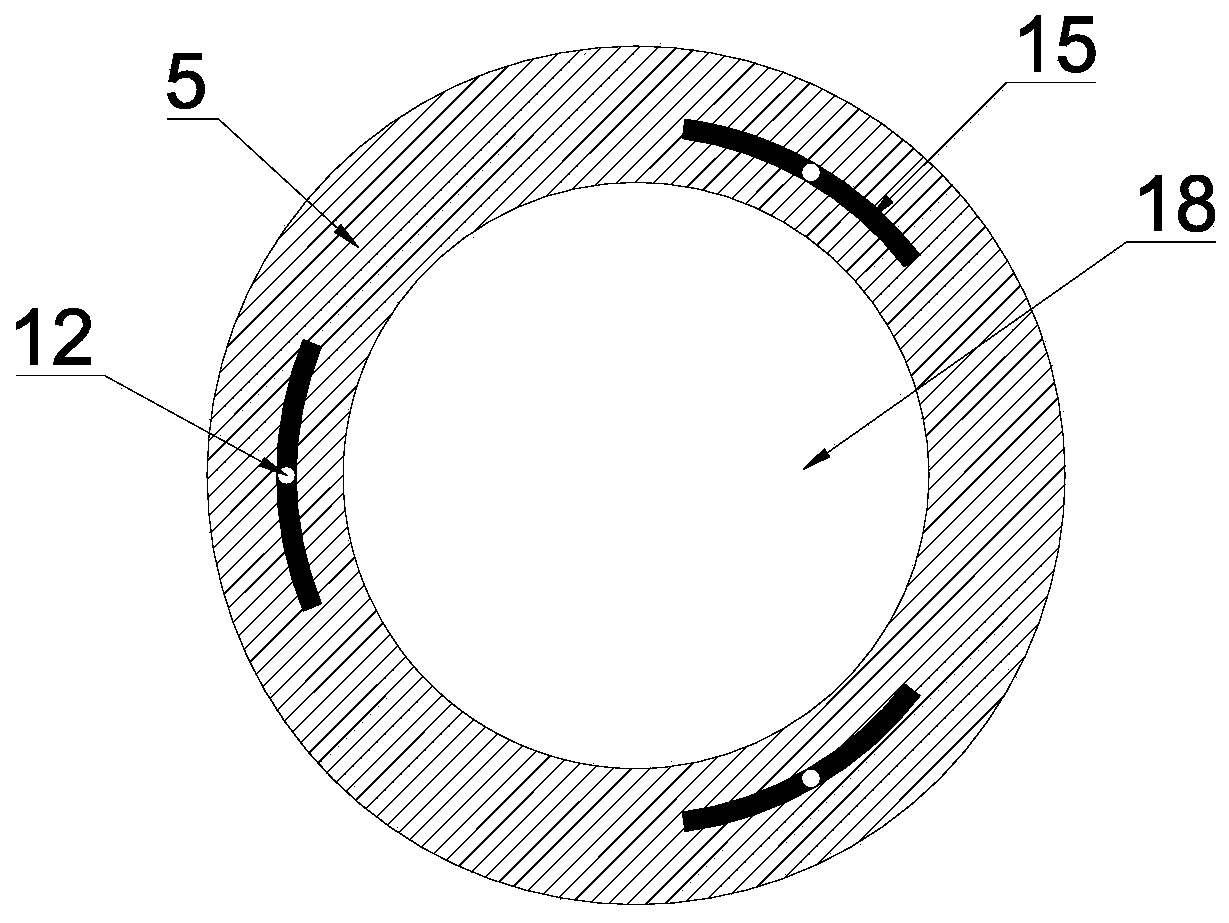

Servo heat dissipation and damping motor

ActiveCN108667213AStable supportSmall working vibrationMechanical energy handlingCooling/ventillation arrangementThrust bearingEngineering

The invention discloses a servo heat dissipation and damping motor. The motor comprises a motor body, a cooling cavity, a ventilation cavity and a motor cavity are formed in the motor body from left to right respectively, and a motor shaft is arranged in the middle of the motor body and rotatably connected with the motor body through first ball thrust bearings and second ball thrust bearings separately; blades are installed on the portion, located at the left end of the motor shaft, in the ventilation cavity, multiple vent holes communicated with an inner cavity of the motor shaft are furtherformed in the side surface of the left end of the motor shaft, and multiple exhaust covers are arranged on the left side wall of the ventilation cavity in the circumference direction; ventilation pipes are connected to the left ends of the exhaust covers, the vertical parts of the ventilation pipes are located in the cooling cavity, and the upper horizontal parts of the ventilation pipes extend out of the right end of the motor body. The servo heat dissipation and damping motor is high in stability, can conduct heat dissipation by itself during operation, and has a good heat dissipation effect, the motor works for a long time conveniently, and the service life of the motor is prolonged.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

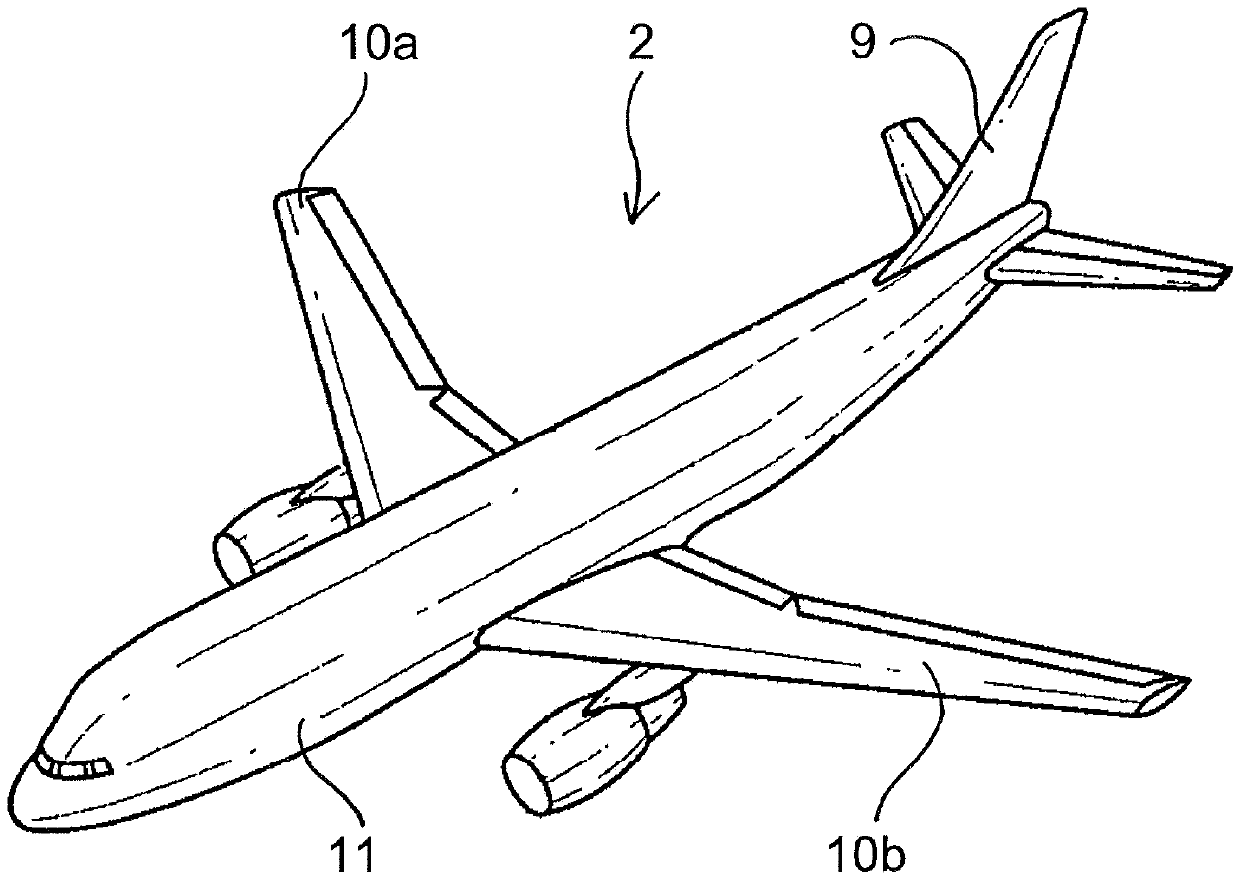

Passive load alleviation for a fiber reinforced wing box of an aircraft with a stiffened shell structure

ActiveCN103625630AImprove axial stiffnessReduce intensityFuselage framesSpars/stringersFlight vehicleClassical mechanics

The invention relates to a wing box (1) of an aircraft (2) with a stiffened shell structure (3), consisting of fiber reinforced material comprising a skin (4) for absorbing shear loads, and several stringers (5) arranged on the inner side of the wing box (1) for absorbing axial loads, in which at least 60% of the mass of the stiffened shell structure (3) is concentrated in the stringers (5), wherein the stringers (5) provide at least 80% of the axial stiffness of the stiffened shell structure (3). In the specific case of wing structure, this embodiment allows the use of unbalanced laminates for the skin (4) to induce higher nose-down twist of the wing box (1) without any loss in bending stiffness and so envisaging higher weight saving capability.

Owner:AIRBUS OPERATIONS GMBH

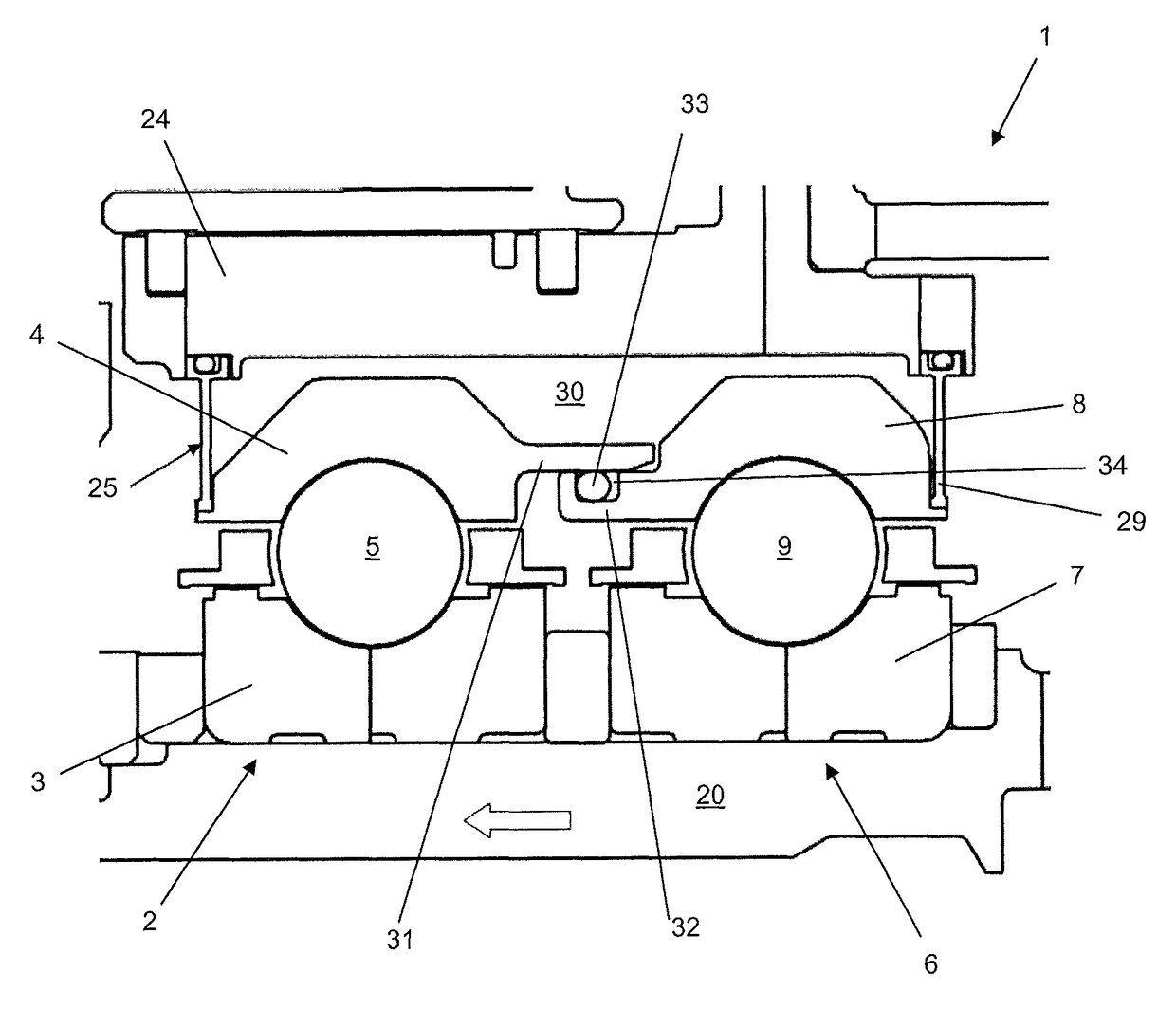

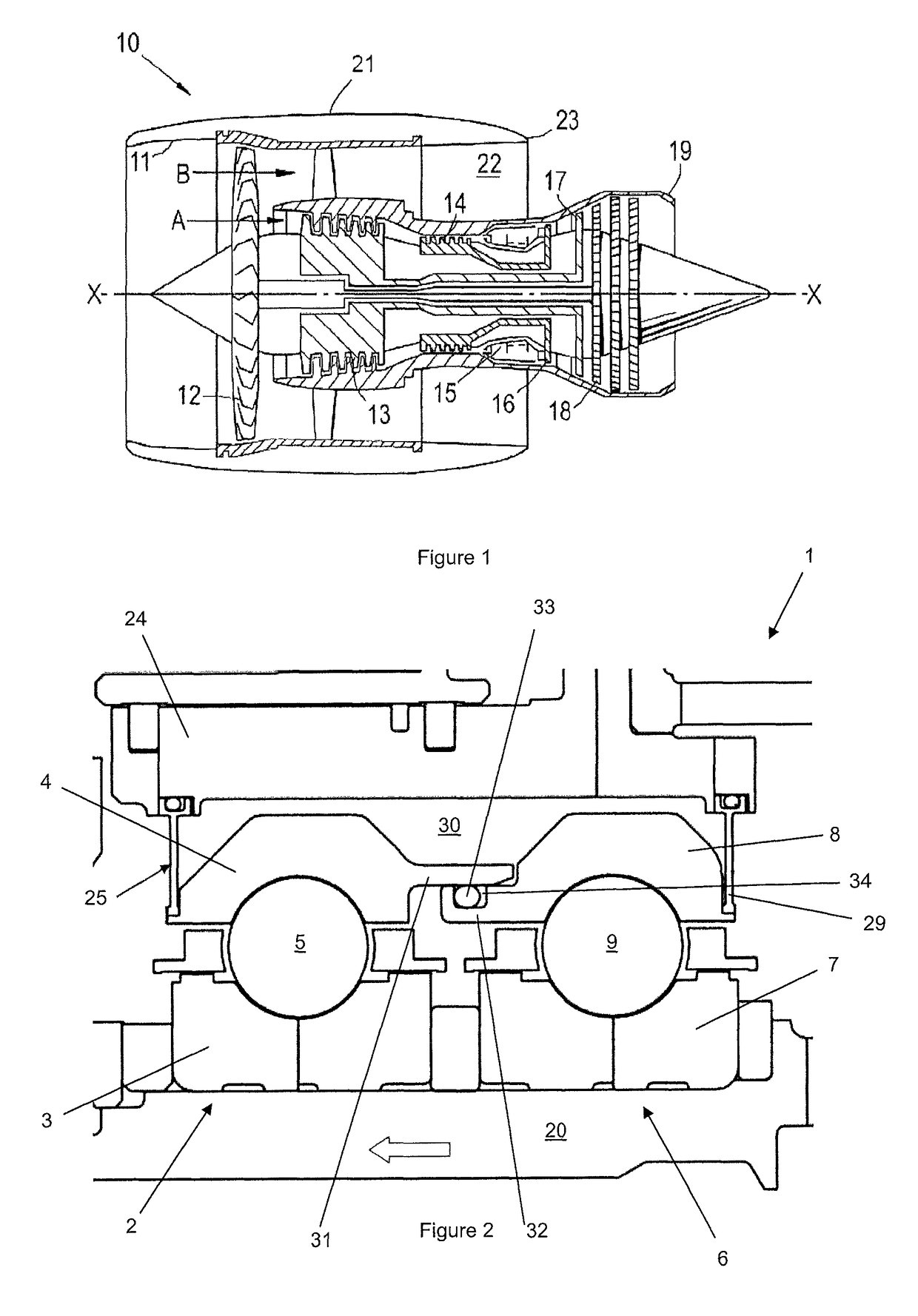

Bearing structure

ActiveUS9829037B2Increase axial loadBearing assemblyEngine fuctionsEngineeringMechanical engineering

Load sharing stacked bearing structure including first bearing having a first inner race, first outer race and first set of roller elements housed between first inner race and first outer race and a second bearing having a second inner race, second outer race and second set of roller elements housed between second inner race and the second outer race. A housing surrounds the first and second bearings. First compliant element is provided with the first compliant element connected between the housing and the first outer race. The first compliant element, first outer race and housing define at a pressure chamber. The first outer race axially slidable relative to the second outer race such that an increase in pressure in pressure chamber causes a change in axial spacing between the outer races. This induces an additional axial load on the bearings which helps balance thrust load sharing.

Owner:ROLLS ROYCE PLC

Suspension bump stop and strut device

InactiveUS9010741B2Increase friction torqueImprove sealing propertiesSpringsBall bearingsRolling-element bearingStops device

The suspension bump stop device comprises a rolling bearing (44) that forms an axial bump stop, equipped with an upper ring (46), with a lower ring (48) and with a plurality of rolling elements positioned between the rings, the upper and lower rings being supported respectively by an upper cup (40) and a lower cup (42), the lower cup forming a bearing means for a suspension spring (18), at least one sealing lip being provided on one of the cups so that it bears against a bearing surface portion of the other cup. The bearing surface portion is substantially cylindrical, the sealing lip being directed downwards away from the rolling bearing and bearing with radial interference against the said surface portion, the said substantially cylindrical surface portion being connected towards the top to a shoulder against which the lip can bear if the two cups become radially eccentric relative to one another.

Owner:AB SKF

Bearing structure

ActiveUS20160160910A1Minimize impactIncrease axial loadBearing assemblyEngine fuctionsEngineeringMechanical engineering

Bearing structure including a first bearing, surrounded by a housing, having a first inner and outer race and first set of rolling elements between the inner and outer races and a second bearing having a second inner and outer race and second set of rolling elements between the second inner and outer races. A first compliant element is connected to the first outer race. A rigid diaphragm is connected to the first outer race between the compliant element and outer race, and is connected to the housing at its outer end. The first compliant element, outer race and rigid diaphragm at least partly define a pressure chamber. The first outer race is axially slidable relative to the second such that a pressure increase in the chamber changes the axial spacing between the first and second outer races, inducing additional axial load on the bearings which helps balance thrust load sharing.

Owner:ROLLS ROYCE PLC

Wind turbine

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

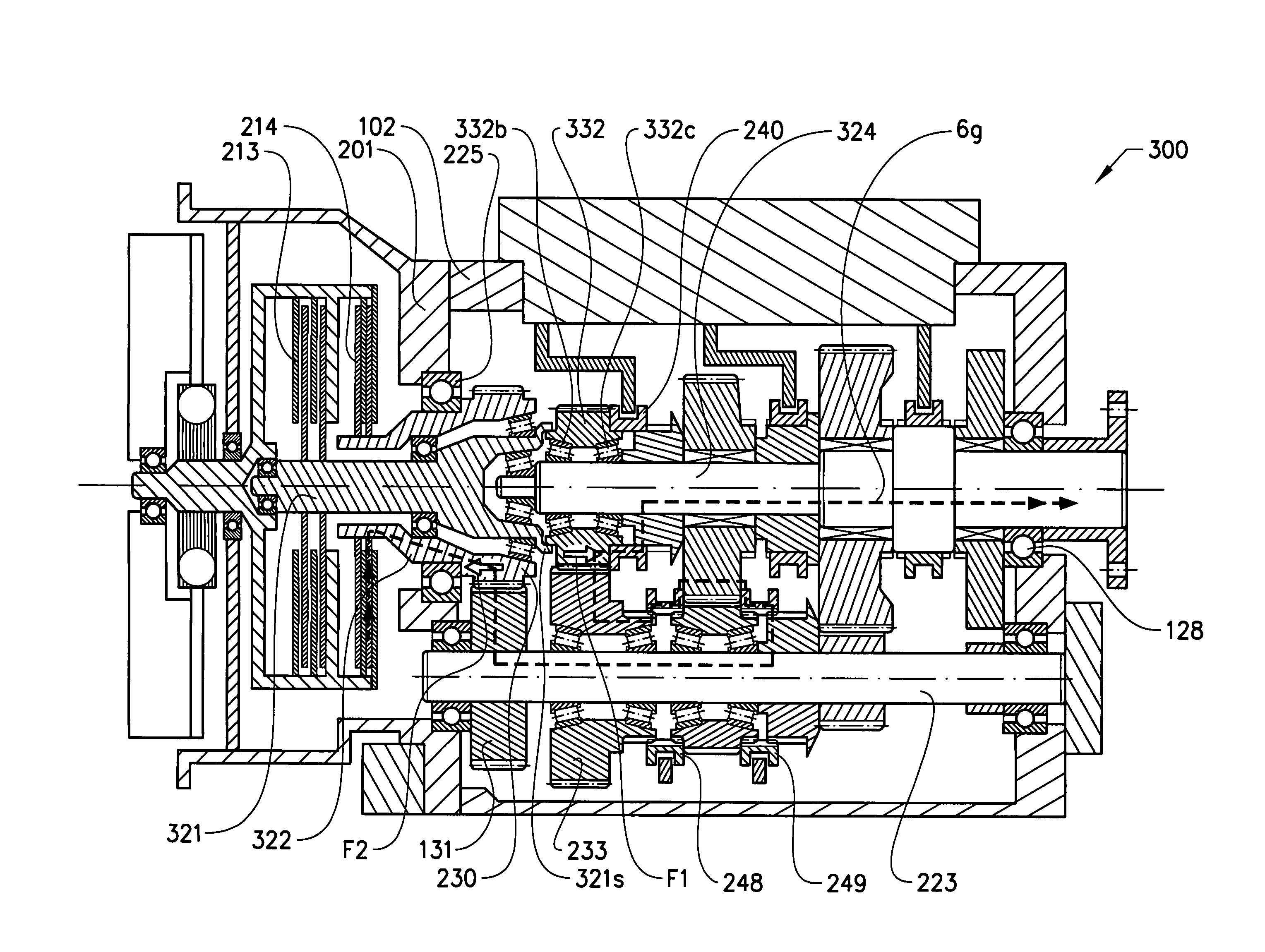

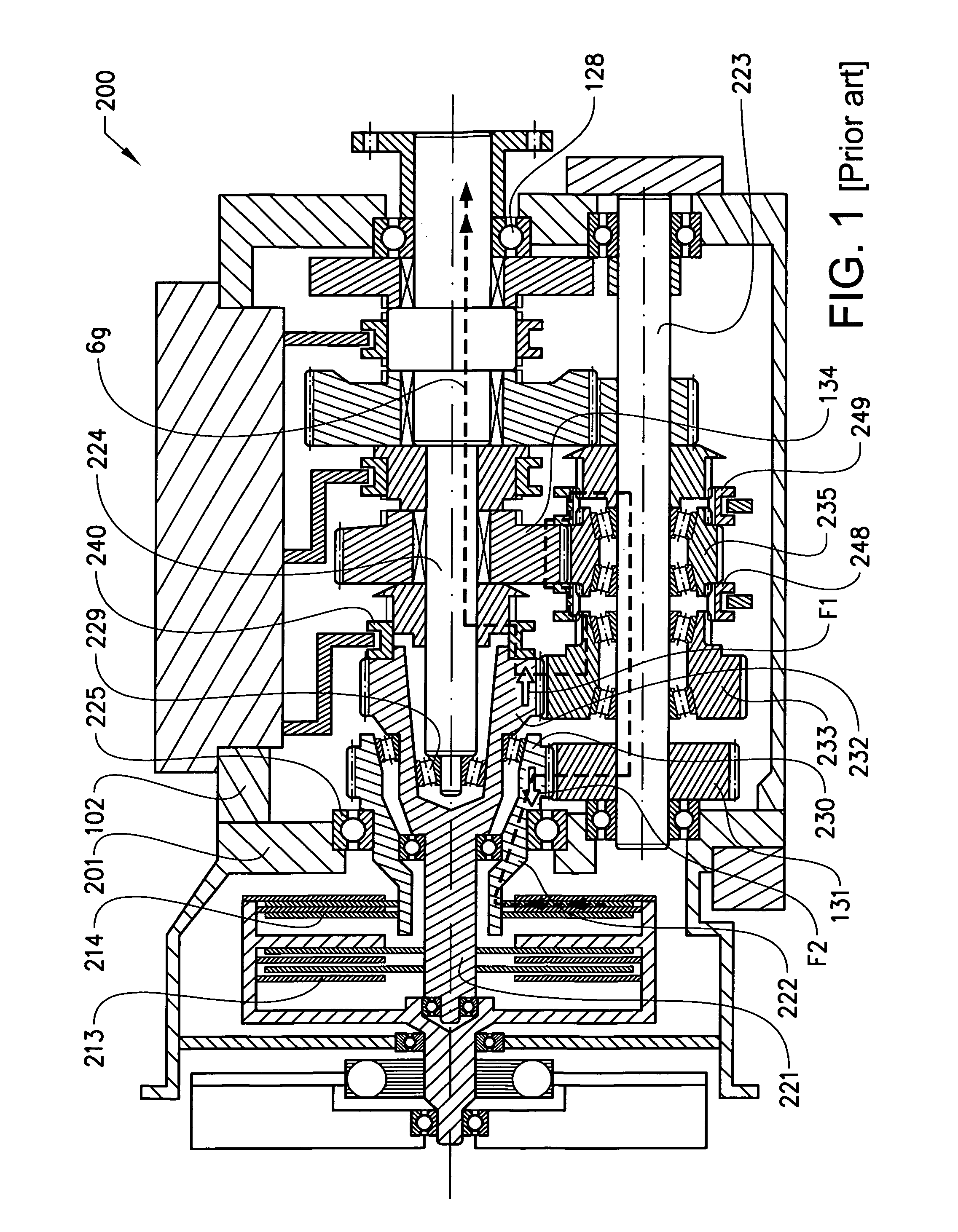

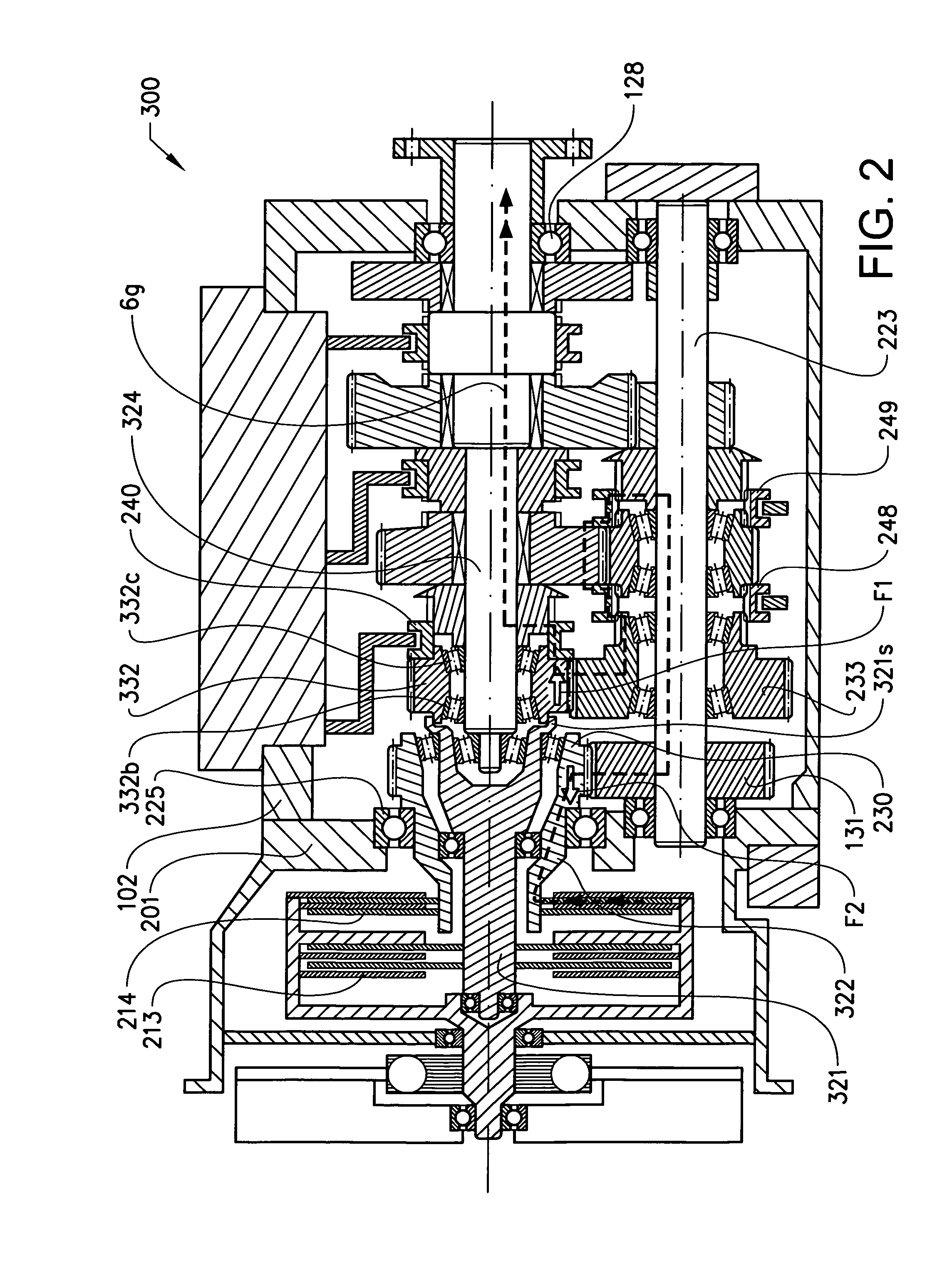

Dual clutch transmission

ActiveUS20150128736A1Reduce loadIncrease axial loadToothed gearingsGearing detailsClutchElectrical and Electronics engineering

A dual clutch transmission includes a first and a second input shaft provided with a first and second input arrangement, respectively, a centre shaft, a countershaft, and a first and a second primary gear step. The first and second input shaft are coaxially arranged with the centre shaft and can transfer torque from the first and second input means to the countershaft via the first and the second primary gear step. The first primary gear step including a first input gearwheel and a first driven gearwheel. The first input gearwheel is rotationally fixed with the first input shaft. The first input gearwheel is arranged upon the centre shaft.

Owner:VOLVO LASTVAGNAR AB

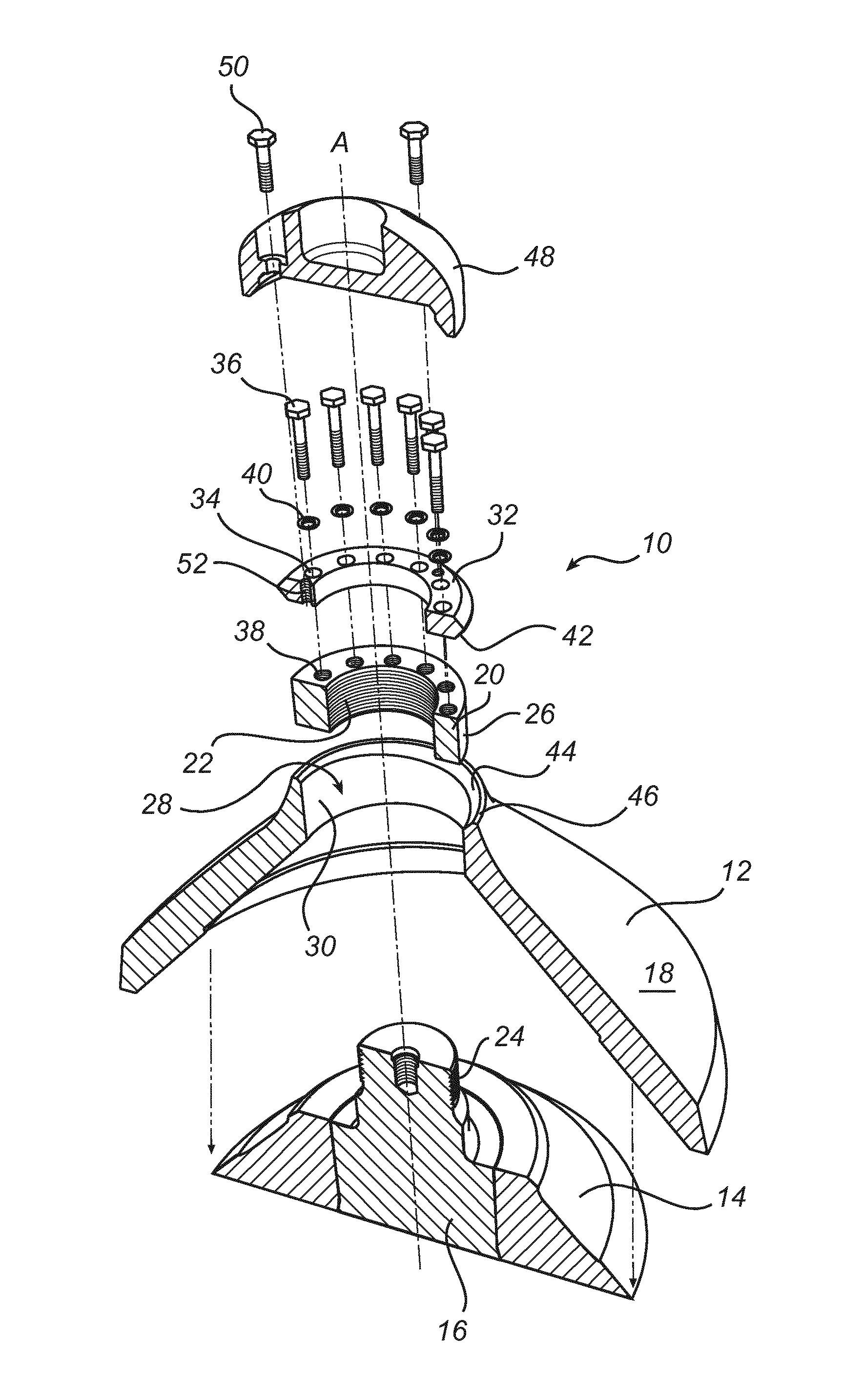

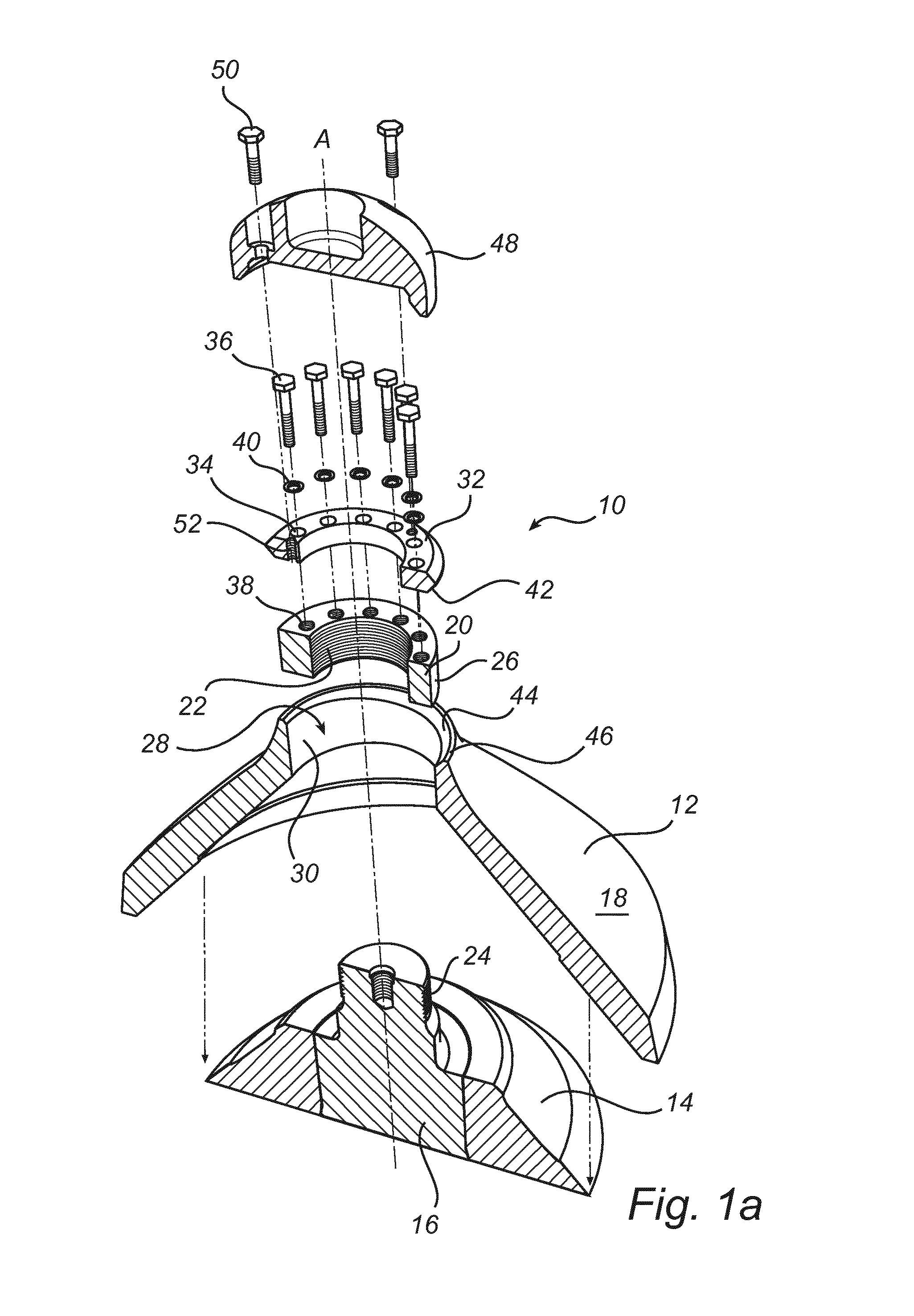

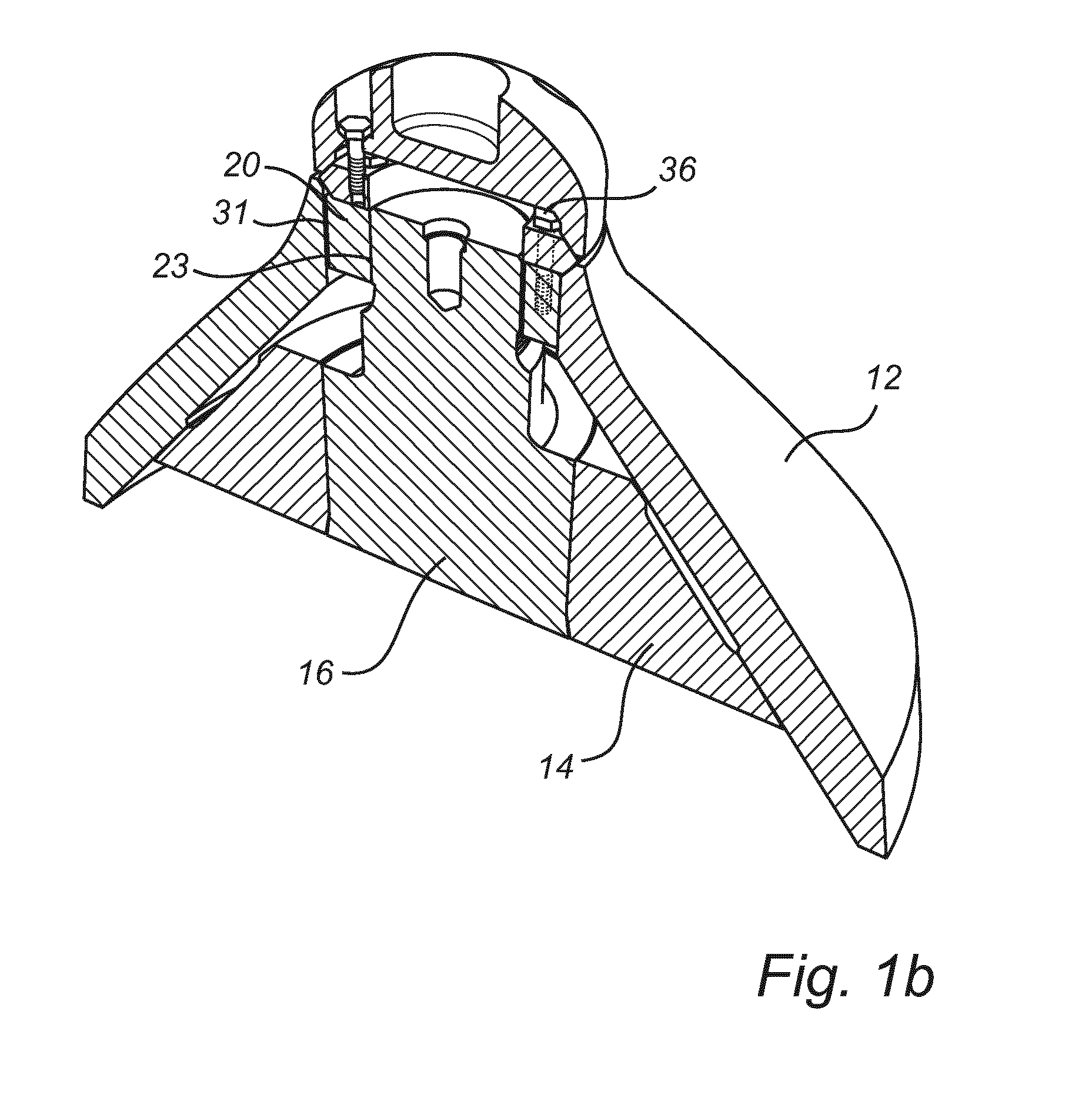

Crusher, crushing shell, and method of attaching crushing shell

A cone crusher includes an inner crushing shell supported on a crushing head and clamped thereon by a retaining arrangement, the crushing head being arranged for rotating about a crushing head axis. The retaining arrangement includes a first portion of a threaded joint for self-tightening the retaining arrangement. The first portion is concentric with the crushing head axis and rigidly joined with the crushing head. A first portion of a form-fitting engagement arrangement is rigidly joined with the inner crushing shell. A crushing shell tightener is provided with a second portion of the threaded joint and a second portion of the form-fitting engagement arrangement. The form-fitting engagement arrangement rotationally locks the crushing shell tightener to the inner crushing shell.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Bearing structure

ActiveUS20160160911A1Increase axial loadBearing assemblyEngine fuctionsEngineeringMechanical engineering

Load sharing stacked bearing structure including first bearing having a first inner race, first outer race and first set of roller elements housed between first inner race and first outer race and a second bearing having a second inner race, second outer race and second set of roller elements housed between second inner race and the second outer race. A housing surrounds the first and second bearings. First compliant element is provided with the first compliant element connected between the housing and the first outer race. The first compliant element, first outer race and housing define at a pressure chamber. The first outer race axially slidable relative to the second outer race such that an increase in pressure in pressure chamber causes a change in axial spacing between the outer races. This induces an additional axial load on the bearings which helps balance thrust load sharing.

Owner:ROLLS ROYCE PLC

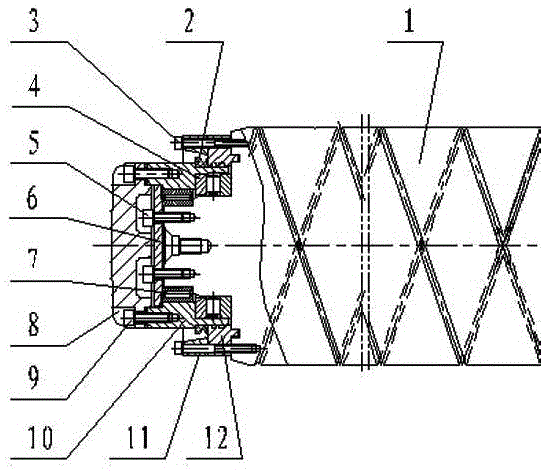

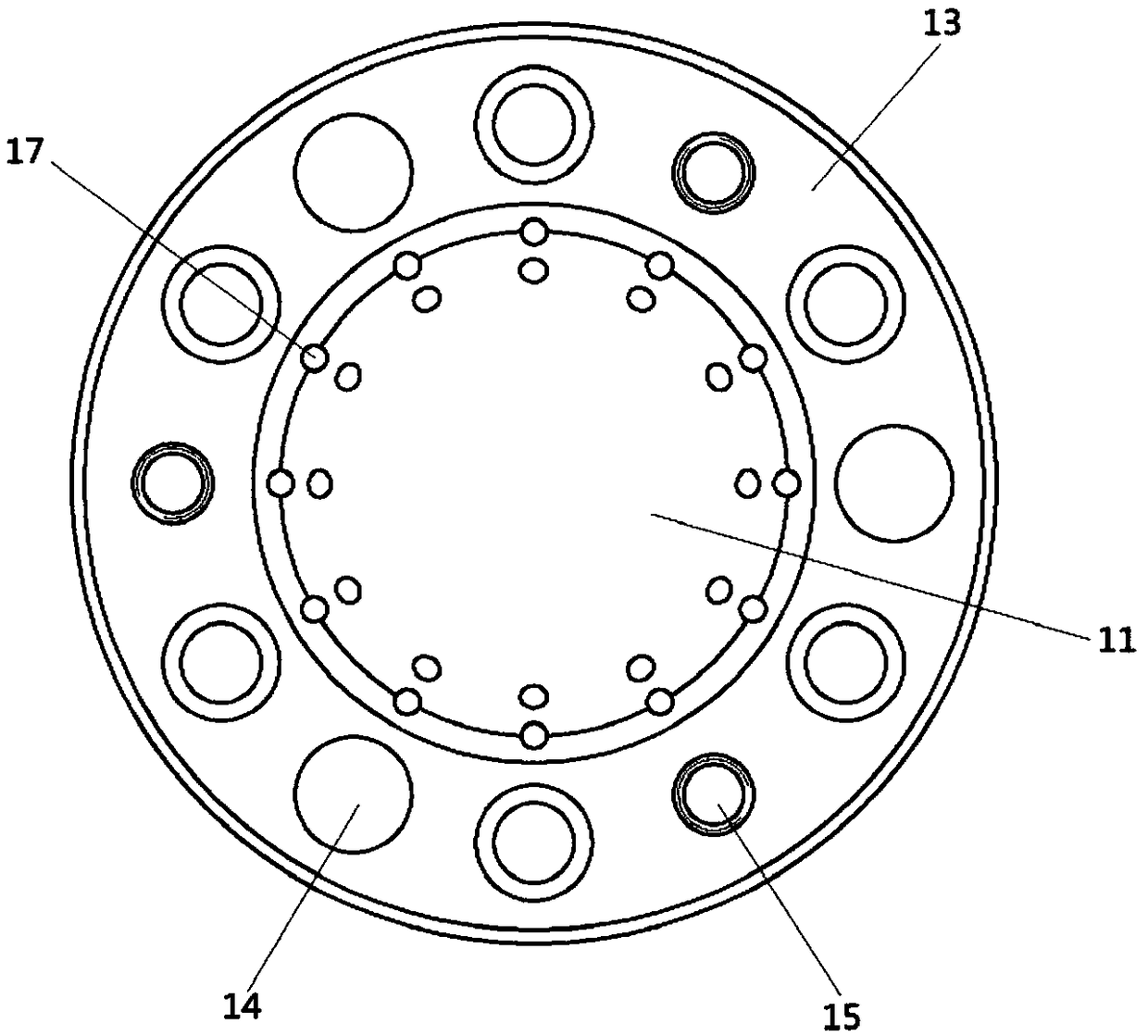

Block type heading machine cutterhead driving structure

The invention provides a block type heading machine cutterhead driving structure which comprises a cutterhead, a gearbox, a main bearing, a flange, a large gear ring, a small gear and a plurality of driving single pieces. Each driving single piece comprises a speed reducer, a driving motor and a torque limiter; the multiple driving single pieces jointly drive the cutterhead to excavate a tunnel, and the cutterhead, the main bearing, the gearbox, the flange and other parts of the cutterhead driving structure are blocked in the radial direction, so that the size and weight of the single parts inthe cutterhead driving structure are reduced, the requirement for blocking disassembly and underground assembly of the parts of the cutterhead driving structure is met, the problems that in the special tunnel construction environment, the transportation space is limited, and the lifting capacity is insufficient are solved, and the problem that an integral cutter head driving structure cannot be disassembled and recycled in the tunnel is solved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Rolling bearing, notably large-diameter rolling bearing

ActiveUS20200340524A1Increase axial loadHigh tilting momentRoller bearingsDrilling accessoriesRotational axisRolling-element bearing

Owner:AB SKF

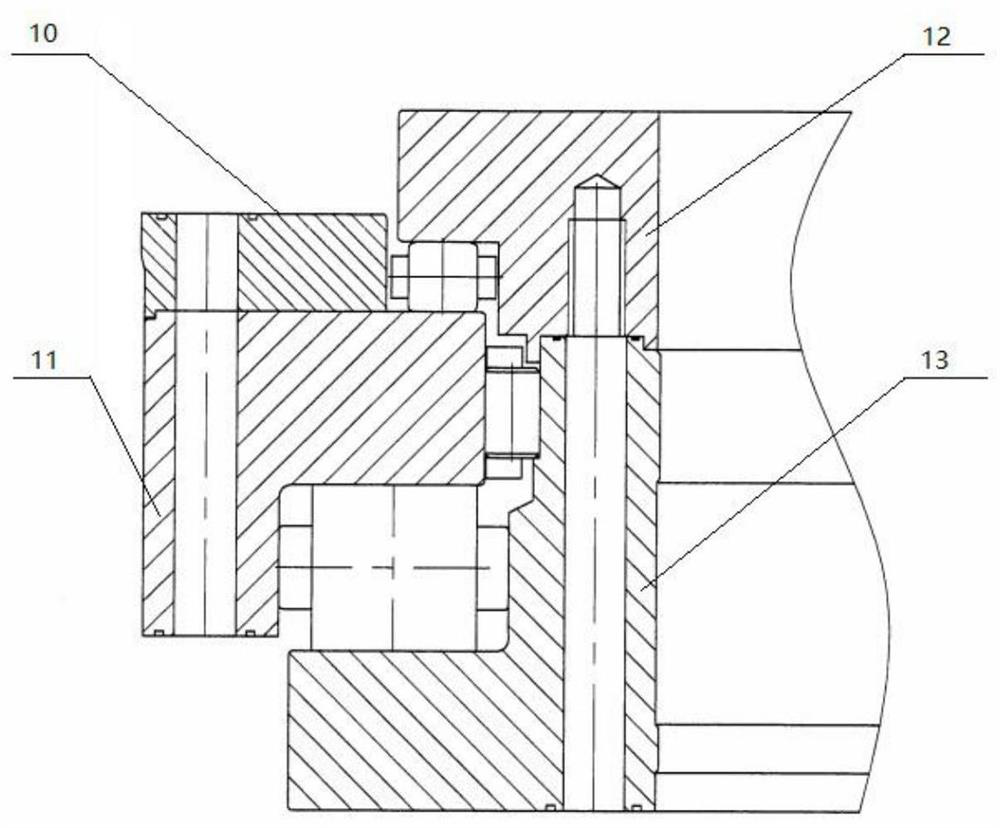

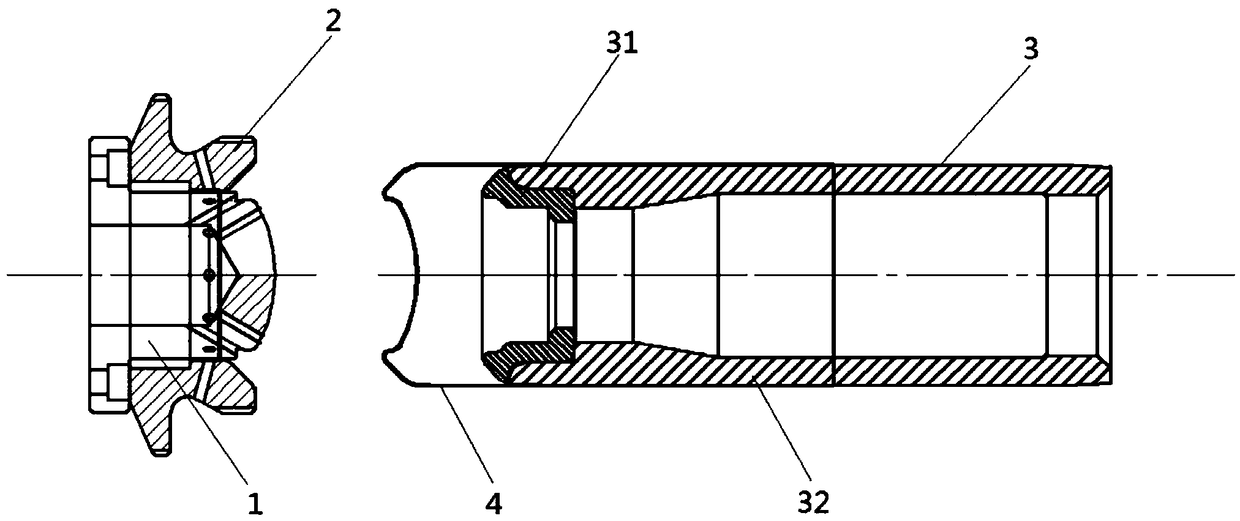

Mounting sleeve for mounting a ring member on a shaft and a bearing assembly incorporating such a mounting sleeve

ActiveUS8801293B2Improve accommodationRaise transfer toRoller bearingsBearing assemblyMechanical engineeringAxial load

The present invention refers to a mounting sleeve (1) for mounting a ring having a tapering inner bore on a cylindrical shaft, wherein the mounting sleeve has a cylindrical inner envelope surface, wherein the inner surface of the mounting sleeve has an increased friction coefficient, for giving an increased ability to the mounting sleeve to transfer axial load, without sliding along the surface of the shaft.

Owner:AB SKF

Bush bearing with bearing body having an axial profile

InactiveUS7909313B2Lift radial loadAffecting service lifeResilient suspensionsRubber-like material springsElastomerEngineering

An elastomer bush bearing, wherein the bearing body (2) is encapsulated through axial flanges (4, 4′) of the outer bearing sleeve (3), with the bush bearing having an elastomer bearing body (2) with a special profile in the axial direction. The bearing body (2) is employed in constructing the bush bearing of the invention, which is capable of supporting high radial loads even with low radial stiffness and without adversely affecting its stability and service life. The two axial end faces (5, 5′) of the bearing body (1) each have undulated contours which extend in the circumferential direction (u) in the same direction, both with respect to one another and also over the entire region of the material thickness (d) of the bearing body (2). The end faces (5, 5′) of the bearing body (2) thus have wave troughs (6, 6′, 7, 7′) and wave crests (8, 8′, 9, 9′), whereby the corresponding wave troughs (6, 6′, 7, 7′) of both end faces (5, 5′) and their wave crests (8, 8′, 9, 9′) are formed so as to face one another, and each extend radially over the entire material thickness (d) of the bearing body (2) in the respective circumferential segment.

Owner:ZF FRIEDRICHSHAFEN AG

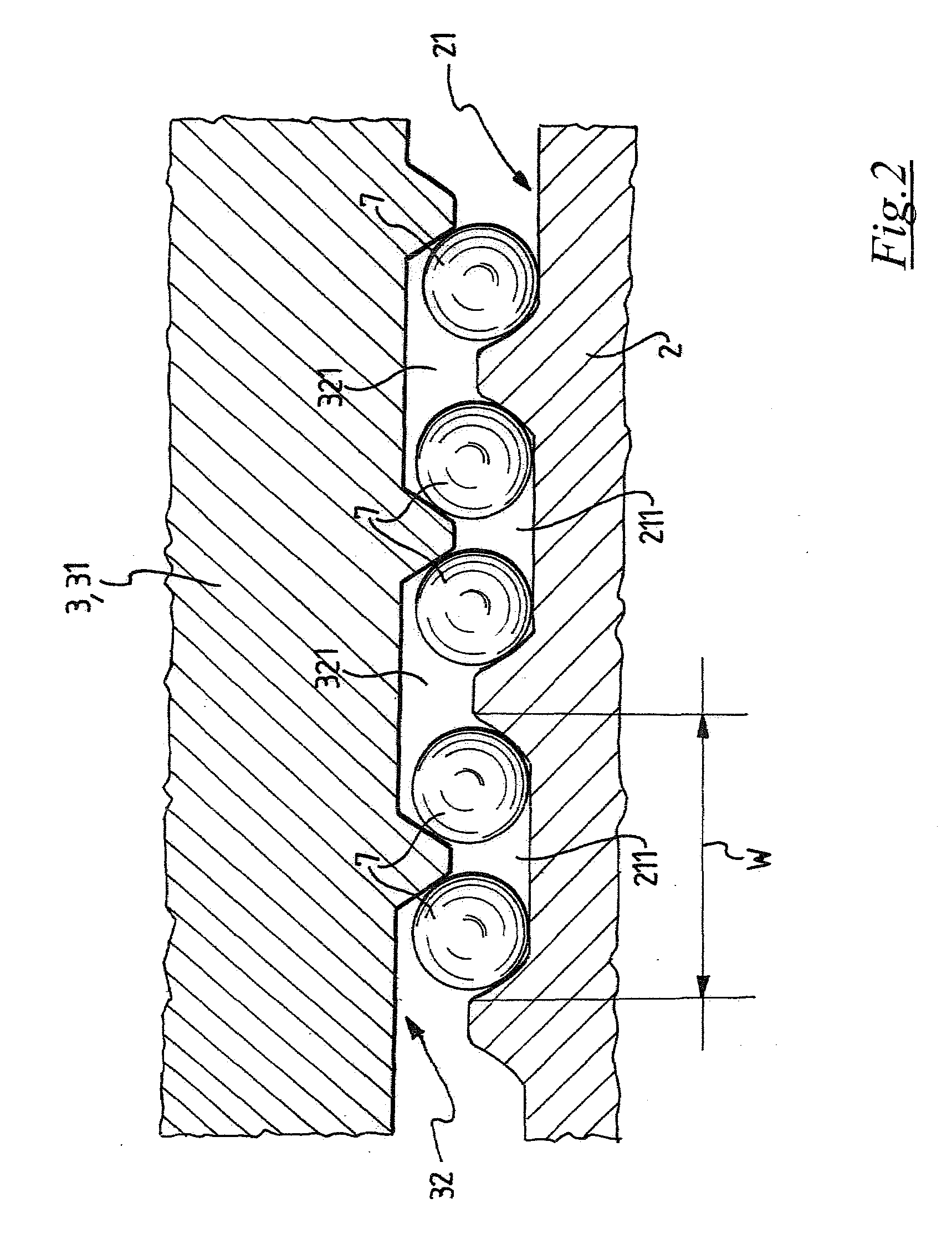

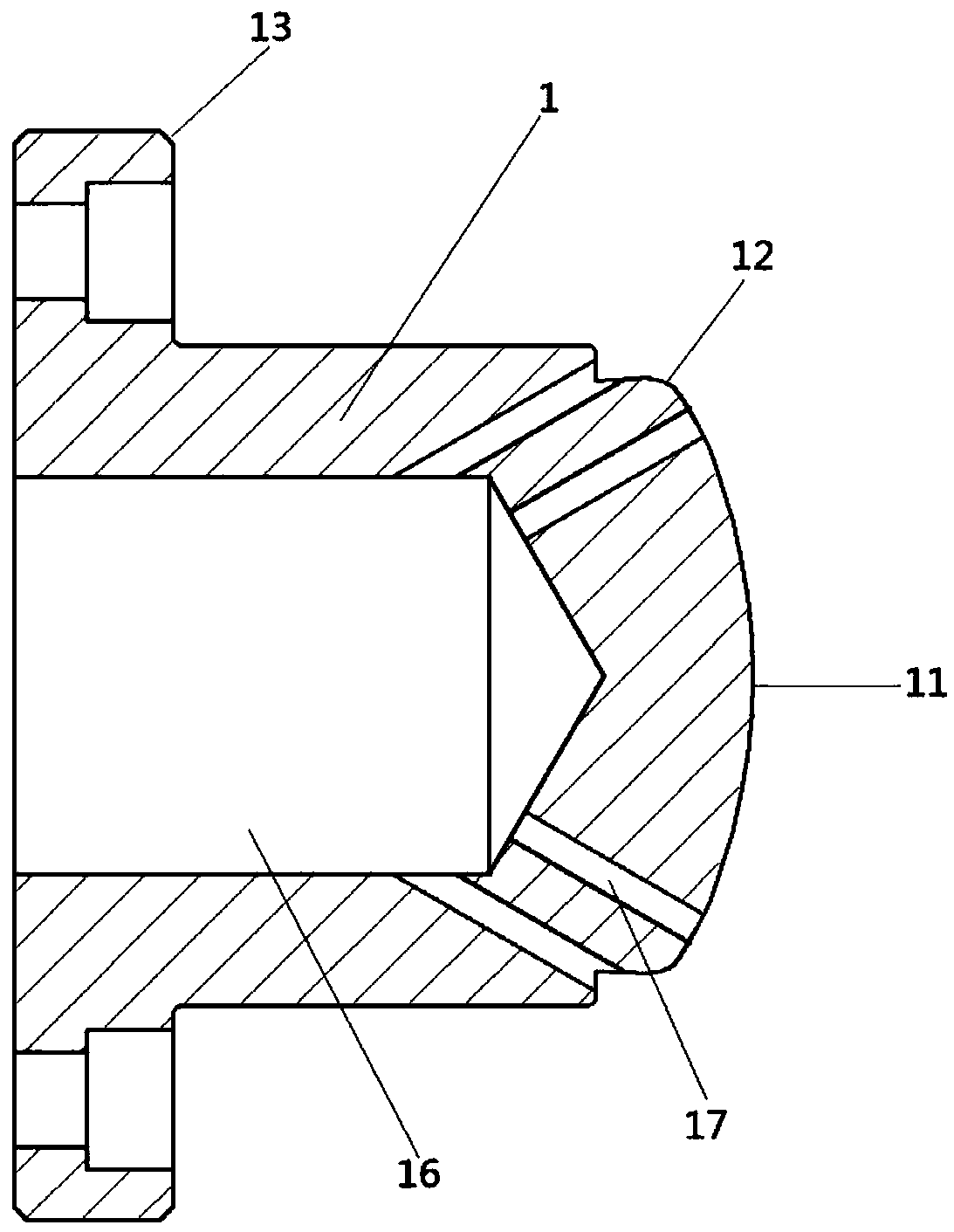

Medium and thick plate straightening machine intermediate roll assembly

An intermediate roller assembly for a straightening machine for medium and thick plates is used for a sixfold type medium and thick plate straightening machine roller box in steel and nonferrous industries. An intermediate roller is provided with a spiral groove, two ends of the intermediate roller are provided with a thrust cylindrical roller bearing and a needle bearing, an end cover is arranged on the end face of the intermediate roller, the needle bearing and the thrust cylindrical roller bearing are arranged in a bearing casing, and the thrust cylindrical roller bearing is located axially. A lip opening of a sealing ring is attached to a sealing loop, the sealing ring is arranged on the bearing casing, an inner hole of the sealing loop is provided with an annular groove, a dustproof cover fastens the sealing loop on the intermediate roller through a screw, an inner conical face of the dustproof cover enables metal foreign matters to be thrown out in a centrifugal mode or fall freely, a top cover is connected with the bearing casing through a screw, the outer end face of the top cover is a spherical face, and the bearing casing is located axially through the end cover. The intermediate roller assembly has good sealing performance, can effectively prevent the foreign matters from entering the bearings, is high in bearing capacity, can reduce fault hidden danger and avoids tremendous economical loss caused by unexpected halt and overhauling.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

High-strength thick-wall bottle and can die

The invention provides a high-strength thick-wall bottle and can die. The high-strength thick-wall bottle and can die is characterized in that one end, facing a punch, of an inner bottom die is equipped with an arc-shaped protruded surface, wherein R angle of the arc-shaped protruded surface is 45-46mm; the side edge of the arc-shaped protruded surface is in smooth transition with the outer wall of the inner bottom die through a circular arc section, and the R angle of the circular arc section is 24.5-25.5mm; an outer bottom die sleeves the inner bottom die; one side, facing the punch, of theouter bottom die is provided with a concave chamber; an inclination angle between the inner wall surface of the concave chamber and an axis of the outer bottom die is 45 degrees; the arc-shaped protruded surface is arranged in the concave chamber; a clearance for forming an inclination angle of the bottom part of the bottle or can is arranged between the inner wall surface of the concave chamber and the outer wall of the inner bottom die; one side, facing the outer bottom die, of a punching nose is provided with an inclined surface which is matched with the concave chamber; an included angle between the inclined surface and an axis of the punching nose is 45 degrees; and a step surface for controlling the wall thickness of the bottle or can is arranged at the outer wall of a punch body. The high-strength thick-wall bottle and can die solves the problem that the pressure resistance of the bottom of the bottle or the can manufactured through an existing die is low, and a can body is easily wrinkled, and the wall of a can body is thin, and the can is easily broken.

Owner:GUANGZHOU RONGXIN CONTAINER

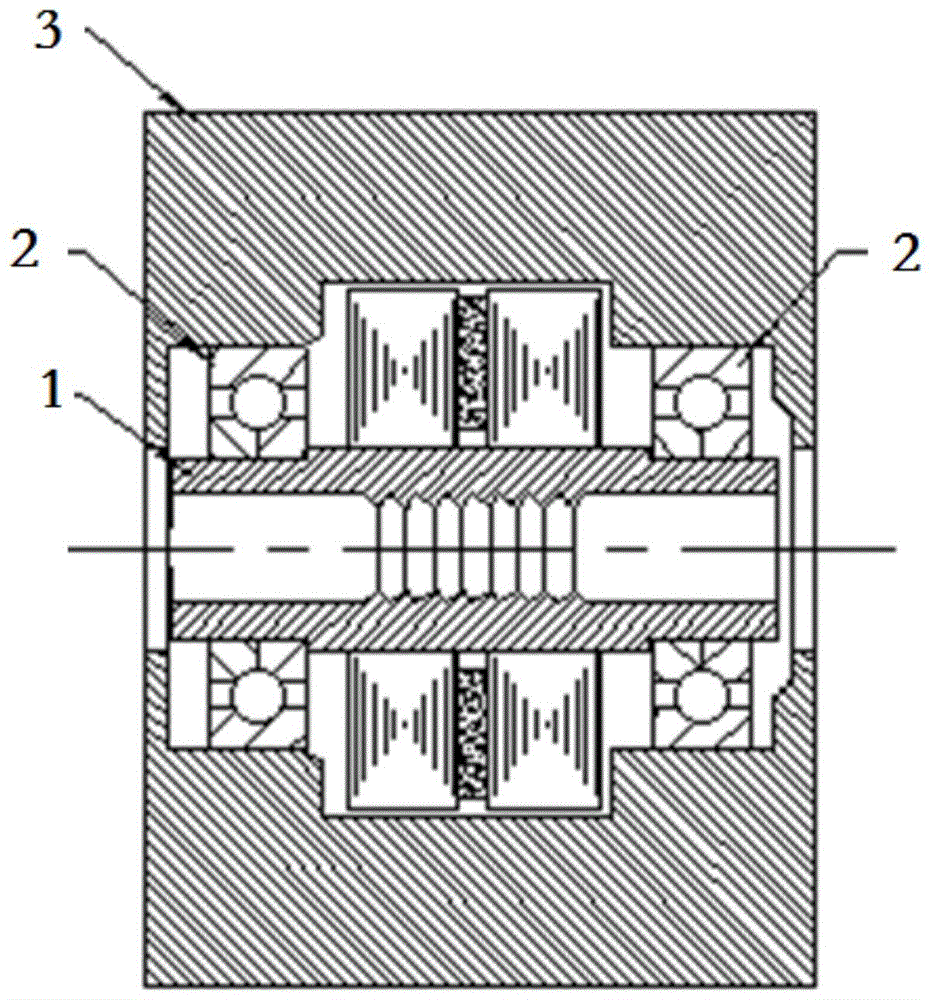

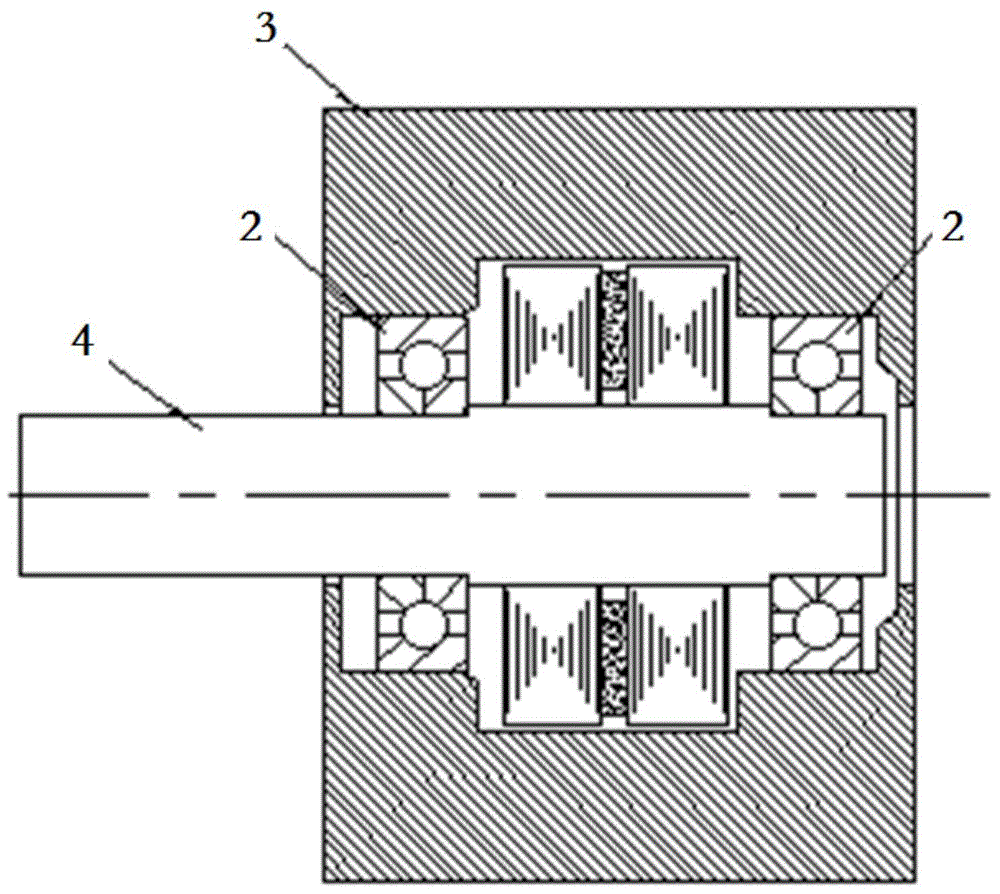

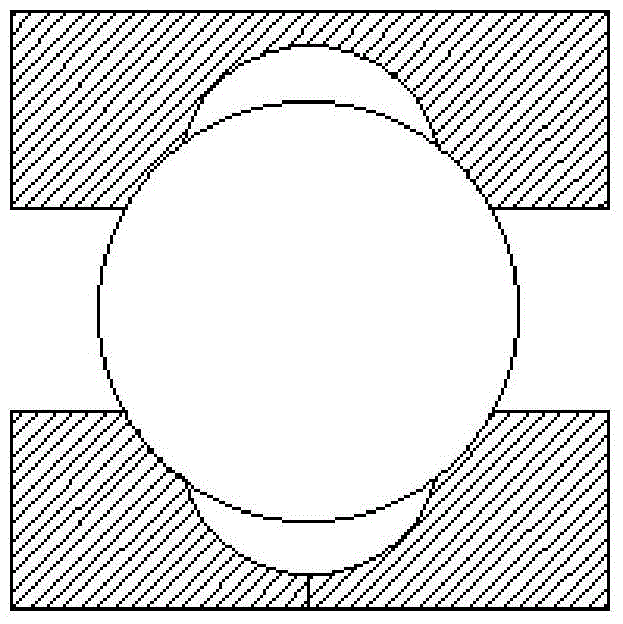

High axial bearing stepping linear motor

The present invention relates to a high axial bearing stepping linear motor. The motor comprises a rotor, a four-point angular contact bearing that is mounted on both ends of the rotor, and a stator disposed opposite to the rotor. Compared with the prior art, the invention has the advantages of high axial load and long service life.

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

A kind of follow-up heat dissipation shock absorption motor

ActiveCN108667213BStable supportSmall working vibrationMechanical energy handlingCooling/ventillation arrangementVentilation tubeThrust bearing

The invention discloses a servo heat dissipation and damping motor. The motor comprises a motor body, a cooling cavity, a ventilation cavity and a motor cavity are formed in the motor body from left to right respectively, and a motor shaft is arranged in the middle of the motor body and rotatably connected with the motor body through first ball thrust bearings and second ball thrust bearings separately; blades are installed on the portion, located at the left end of the motor shaft, in the ventilation cavity, multiple vent holes communicated with an inner cavity of the motor shaft are furtherformed in the side surface of the left end of the motor shaft, and multiple exhaust covers are arranged on the left side wall of the ventilation cavity in the circumference direction; ventilation pipes are connected to the left ends of the exhaust covers, the vertical parts of the ventilation pipes are located in the cooling cavity, and the upper horizontal parts of the ventilation pipes extend out of the right end of the motor body. The servo heat dissipation and damping motor is high in stability, can conduct heat dissipation by itself during operation, and has a good heat dissipation effect, the motor works for a long time conveniently, and the service life of the motor is prolonged.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

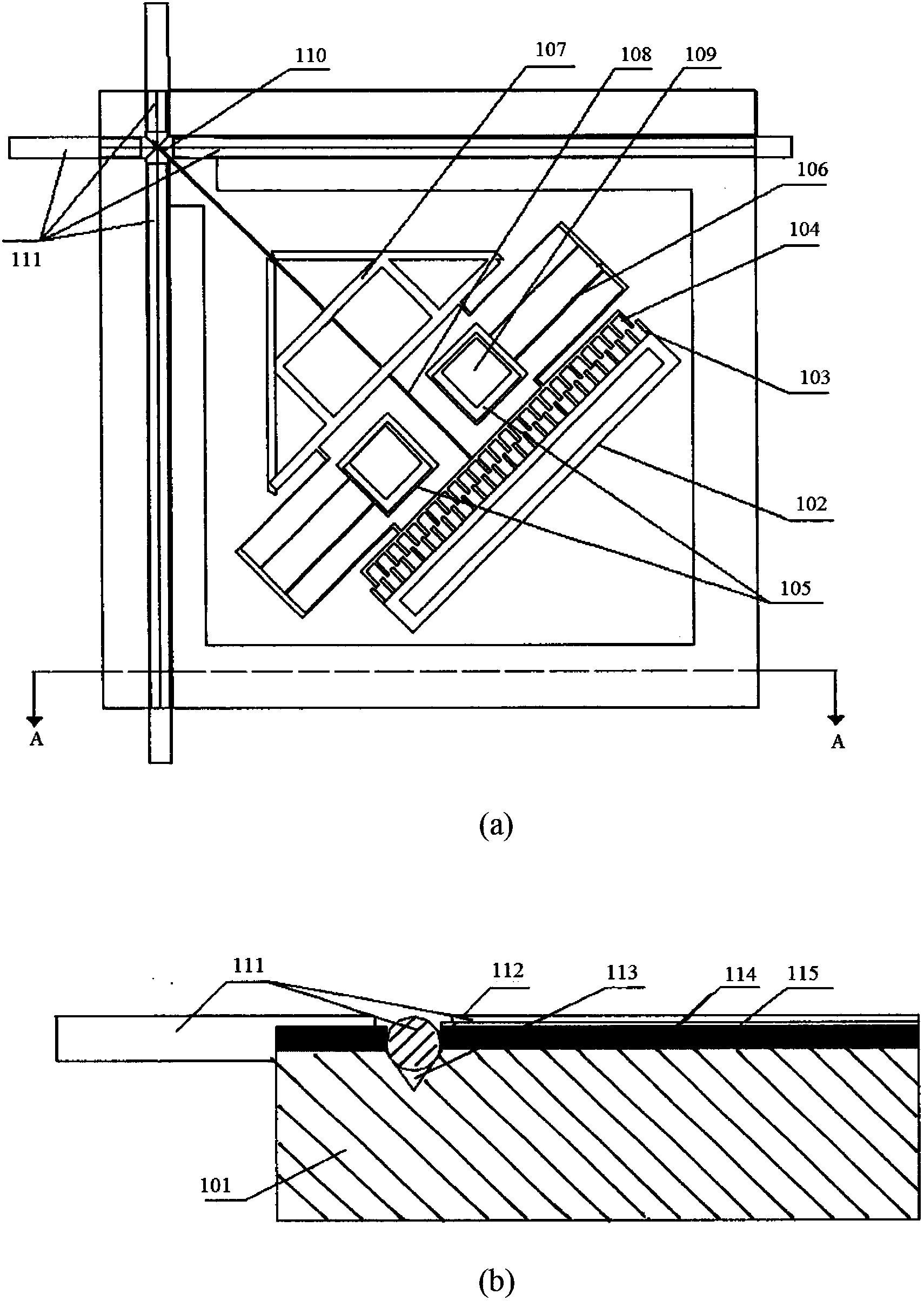

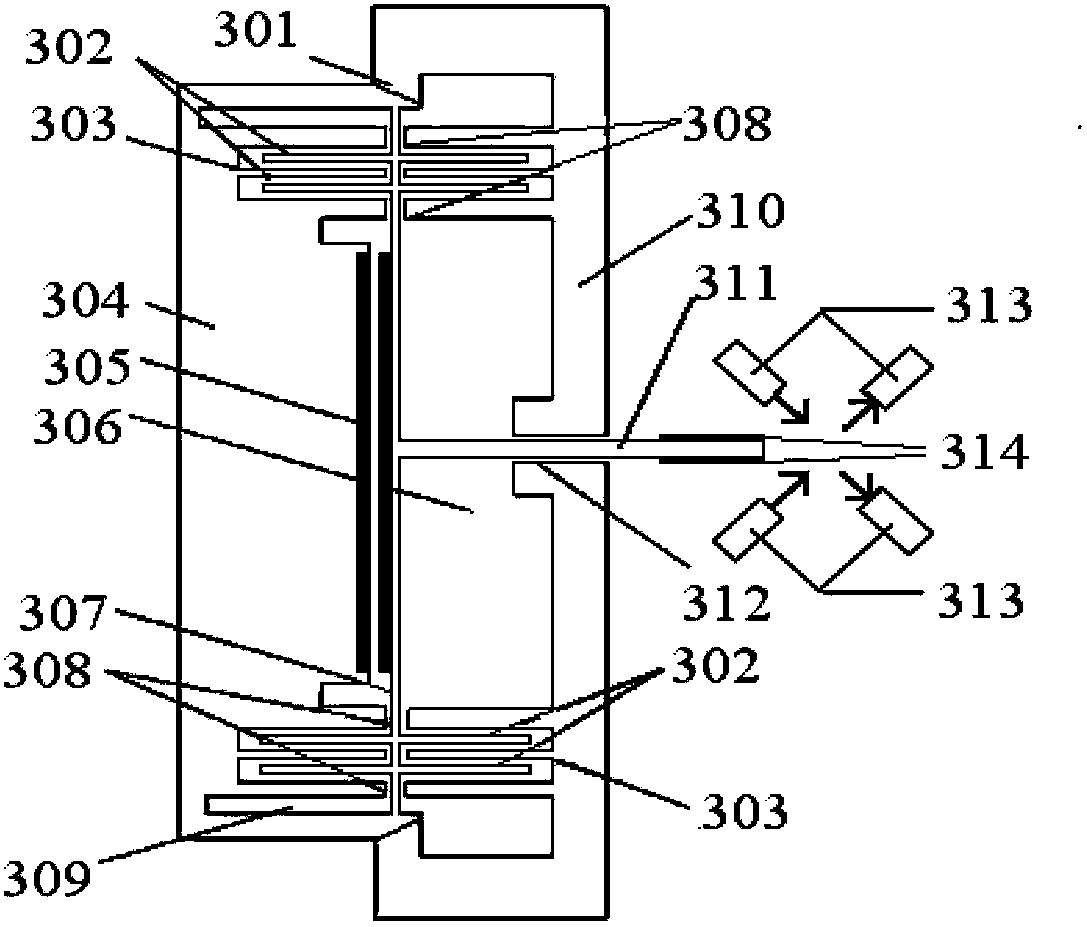

Straight beam buckling electrostatic type micro mechanical optical switch

InactiveCN103033885BIncrease the bearing areaLarge driving displacementCoupling light guidesEngineeringElectrode pair

The invention discloses a straight beam buckling electrostatic type micro mechanical optical switch which mainly solves the problem that the existing switch is high in driving voltage, long in switching time, high in energy consumption and the like. The straight beam buckling electrostatic type micro mechanical optical switch comprises a micro beam (307) with a diamond-shaped structure in the middle position, a fixed base (304), an outer framework (310), driving electrode pairs (305 and 306), adjusting electrode pairs (302 and 303), a micro reflecting mirror (314) and optical fibers (313), wherein the micro beam (307) is connected with the fixed base (304) together, and a span supporting structure (309) is adopted at the junction of the micro beam (307) and the fixed base (304); the fixed base (304) is fixed with the outer framework (310) through a wedge-shaped extrusion structure (301), and guide mechanisms (308) are arranged at the two ends of the fixed base (304); the adjusting electrode pairs (302 and 303) adopt comb tooth-shaped structures and are symmetrical to each other up and down; a guide groove (312) is formed in the middle position of the outer framework (310); the optical fibers (131) are perpendicularly placed in a crossed manner; and the micro reflecting mirror (314) is fixed at the front end of a micro mirror bracket (311). The straight beam buckling electrostatic type micro mechanical optical switch has the advantages of low driving voltage, short switching time, low energy consumption and expandable switch array and can be used for key optical devices of optical communication network equipment.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com