Ultra-lite building system

a building system and ultra-light technology, applied in building components, walls, ceilings, etc., can solve the problems of affecting the final product results, affecting the quality of the end product, so as to improve the structural integrity of the structure, improve the structural integrity, and be suitable for modular construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

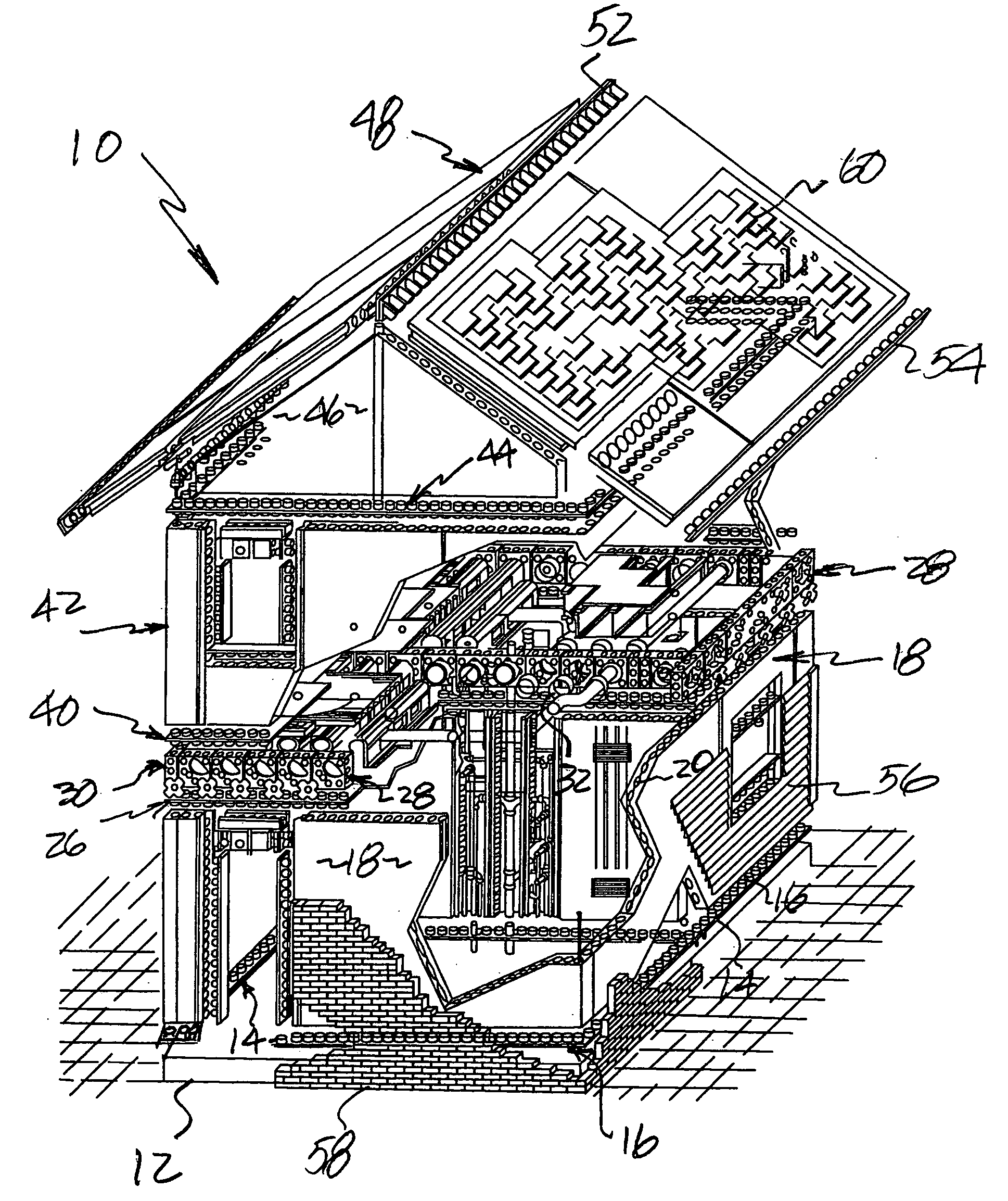

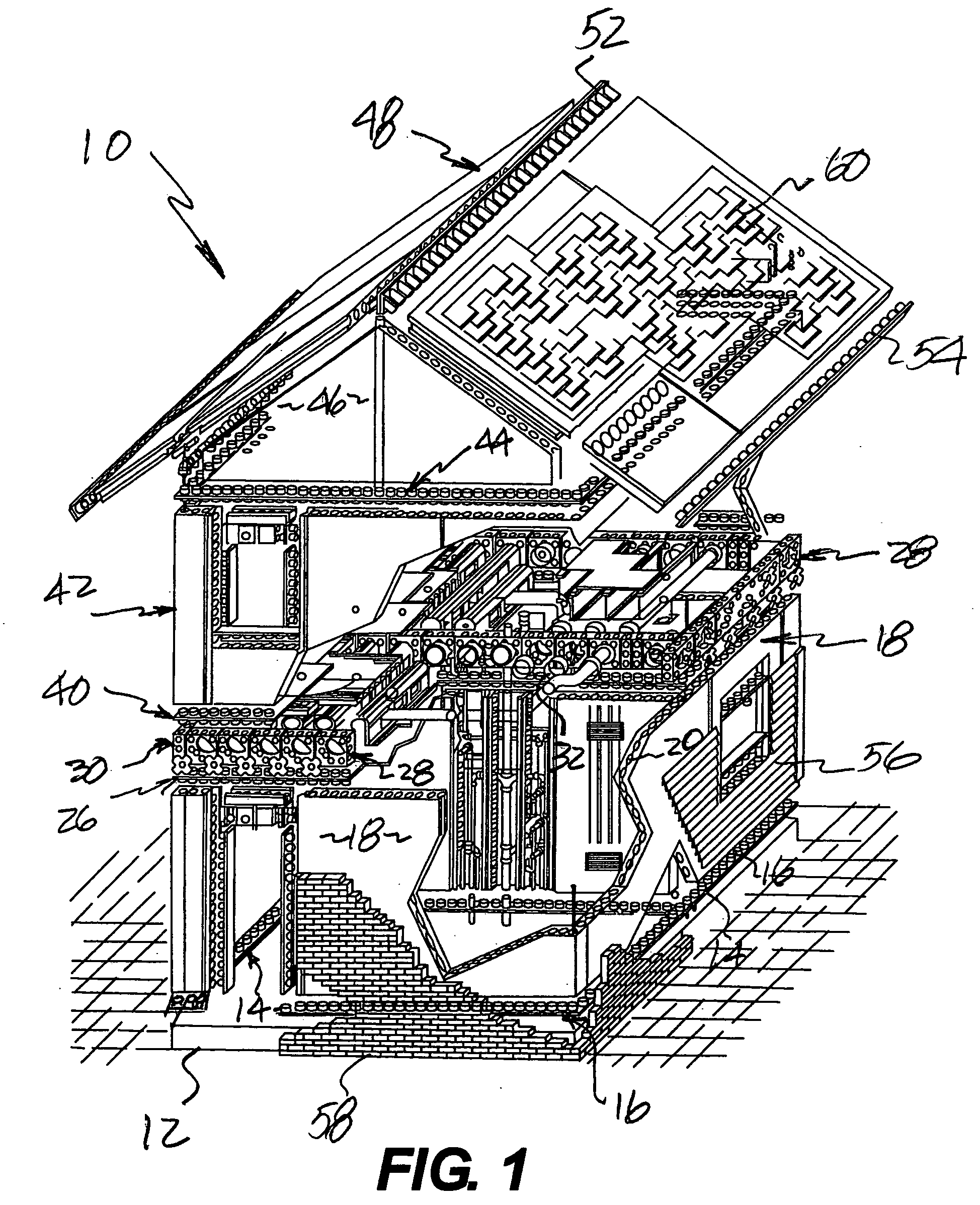

[0044] Turning now to the drawings wherein like references refer to like parts, FIG. 1 discloses an axonometric view (partially broken away to disclose internal detail) of a building structure 10 fabricated in accordance with the ultra-lite building system.

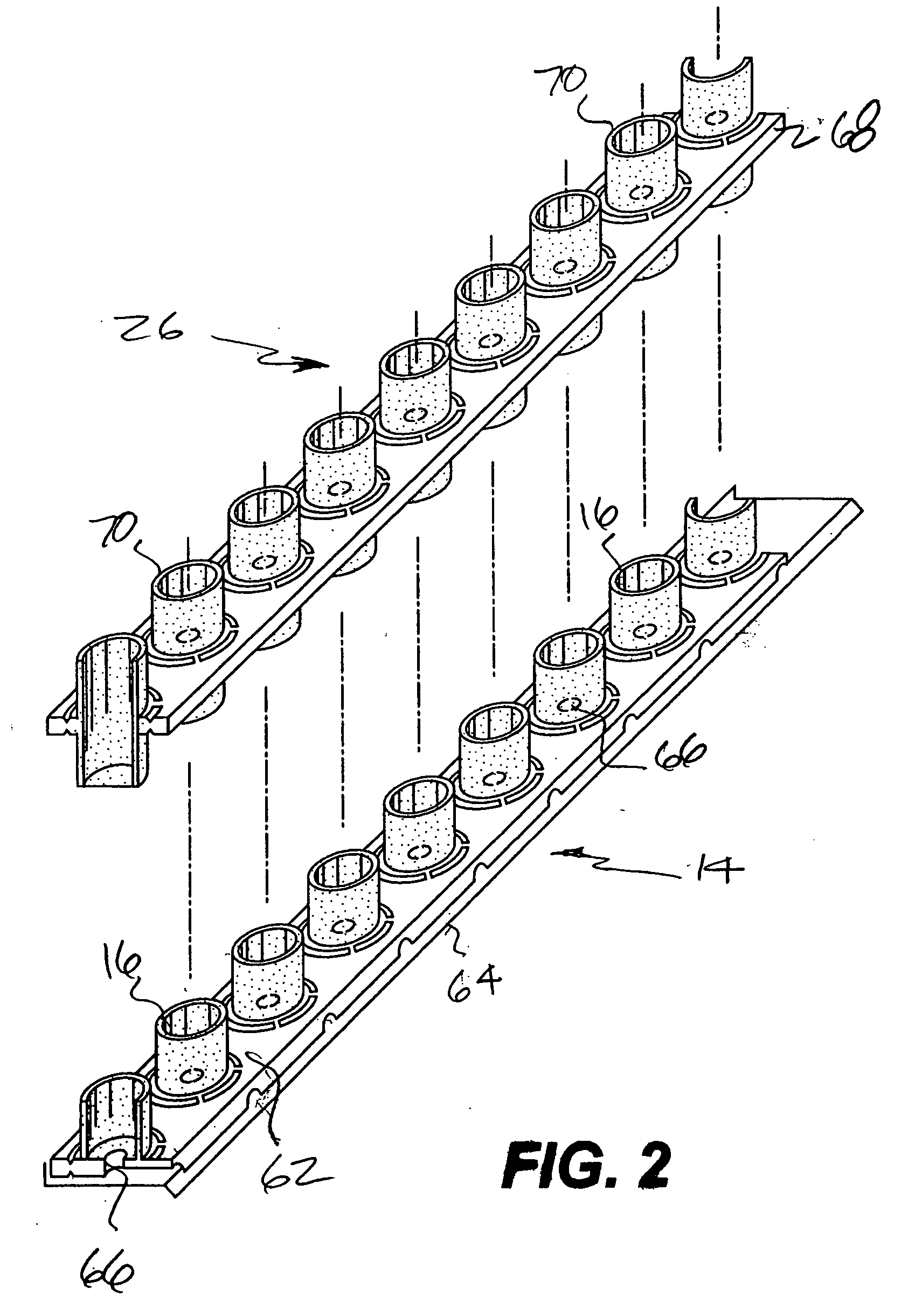

[0045] In a preferred embodiment the building structure 10 is constructed upon conventional foundation of concrete pad 12. First a perimeter course of base plates 14 are positioned about the perimeter of the concrete pad. These base plates can be bolted to the concrete pad in a conventional manner. Each of the base plates 14 includes a plurality of upstanding stub columns 16 which are preferably circular in cross section but may be manufactured with other geometrical configurations such as elliptical, square, triangular, etc. as desired.

[0046] Mounted above the base plates are a plurality of wall panels 18. these wall panels 18 are generally composed from plastic columns 20 which are interconnected by spacer plates 22 as will be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com