Medium and thick plate straightening machine intermediate roll assembly

An intermediate roller and straightening machine technology, applied in the field of intermediate roller assembly, can solve the problems of flying metal powder and metal debris, small bearing capacity, easy to cause heat, etc., to prevent foreign matter from intruding into the bearing, seal Reliable performance and the effect of avoiding early failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

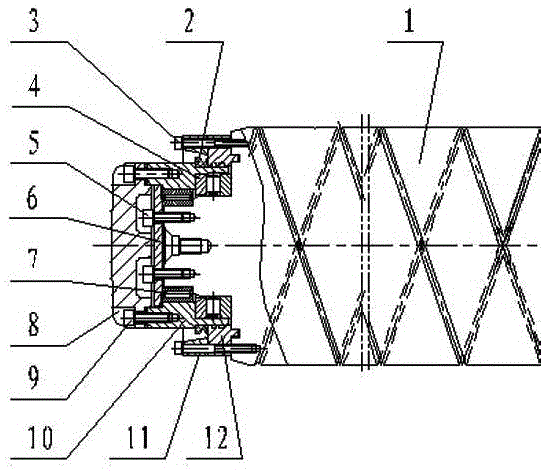

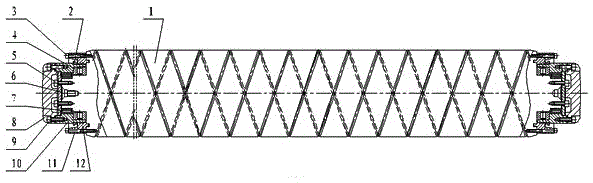

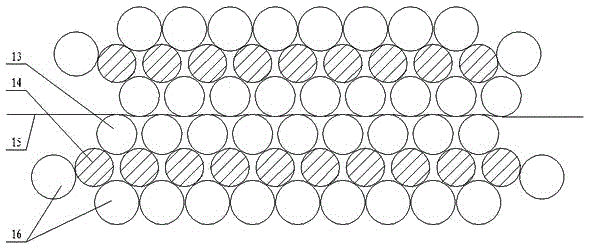

[0022] Such as figure 1 , figure 2 As shown, the thrust cylindrical roller bearing 4 and the needle roller bearing 7 are installed on the stepped cylindrical surface at both ends of the middle roller 1. End discharge, the two ends of the intermediate roller 1 have steps for axial positioning of the bearing and screw holes for assembling the dust cover 11, and a stop for positioning the sealing ring 12 on the end face of the roll body; The end cover 6 is mounted on the end face of the intermediate roller 1 with screws 5 to axially position the needle roller bearing 7 and the bearing shell 10. There are steps on the inner side of the end cover 6; the needle roller bearing 7 and the thrust cylinder are installed in the bearing shell 10 roller bearing 4, and axially locate the thrust cylindrical roller bearing 4; the lip of the seal ring 2 is attached to the seal ring 12, which acts as a first-stage seal for the bearing, and the inner hole of the seal ring 12 has an annular groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com