Directional solidification method and its device for continuous production for polycrystalline silicon ingot

A technology of directional solidification and polycrystalline silicon ingots, which is applied in the direction of self-solidification, polycrystalline material growth, chemical instruments and methods, etc., can solve the problems of long production cycle, high production cost, complicated equipment, etc., and achieve low equipment cost and high yield High, process-consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

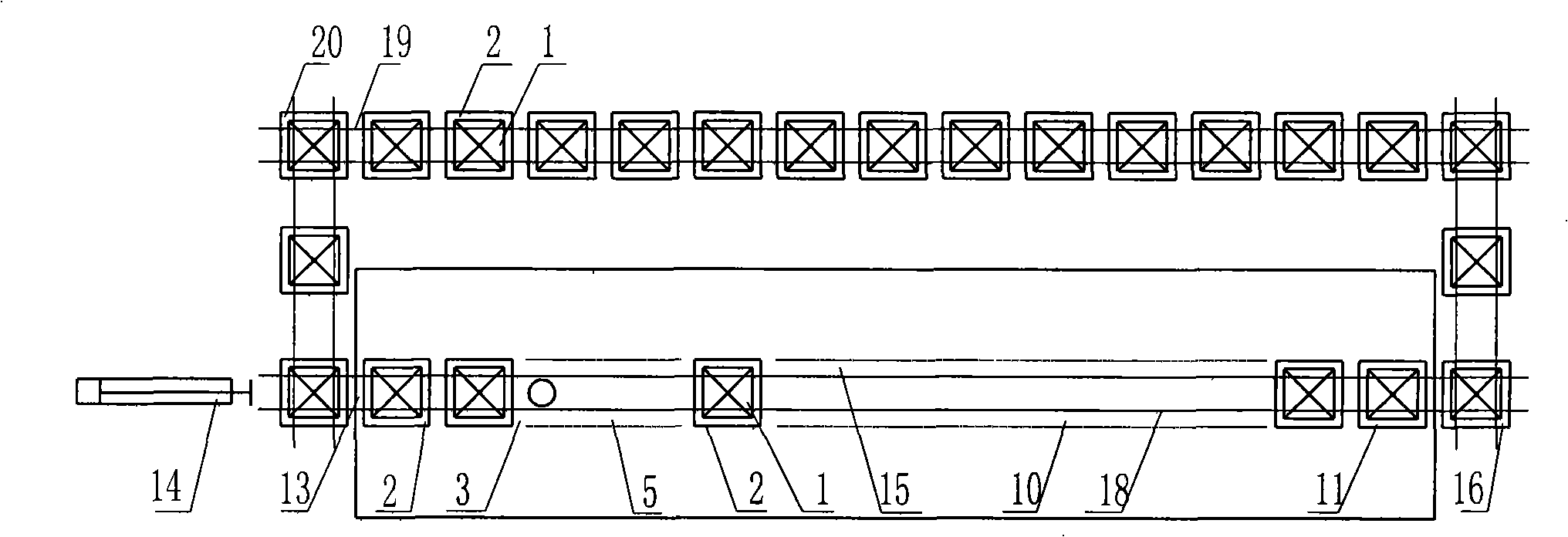

[0029] see figure 1 , the operation process of the directional solidification method for continuous production of polycrystalline silicon ingots according to the present invention is as follows.

[0030] A series of empty graphite molds 1 are arranged in an axial spatial sequence, and are respectively driven by a series of furnace cars 2 to move synchronously to the right. The empty graphite mold 1 that has undergone anti-oxidation treatment is gradually preheated in the preheating zone 3 for 2-6 hours, and the temperature is raised to 1200-1600°C. Quantitative liquid silicon 4 melted and refined is poured into the preheated empty graphite mold 1 from the furnace top feeding port 6 in the high temperature zone 5 of the furnace. The high-temperature zone 5 of the furnace is fed into the argon atmosphere 8 through the observation hole bypass 7 . The liquid silicon 9 is kept in the high temperature zone for 2-8 hours (at a temperature of 1400-1600°C) and then enters the medium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com