Single tin salt electrolytic coloring additive and application thereof

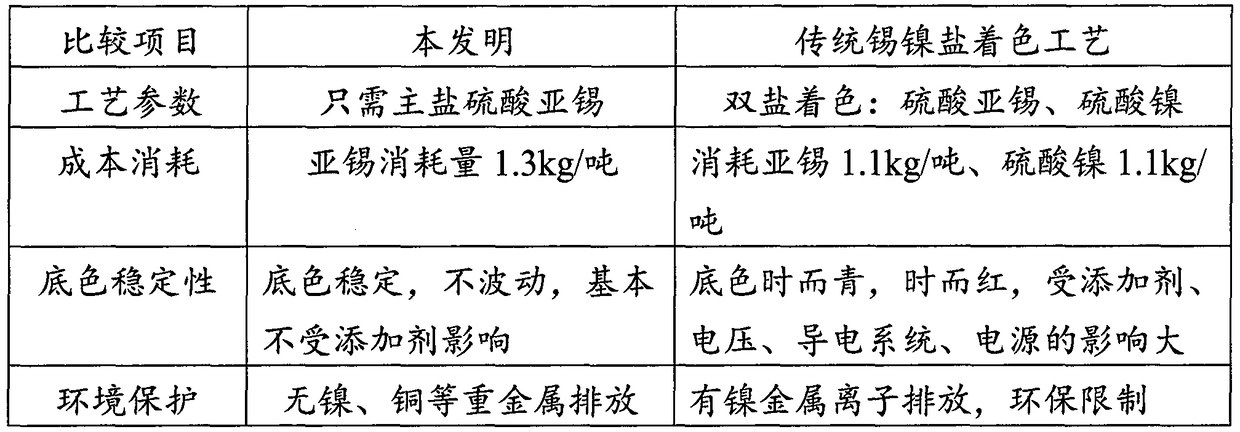

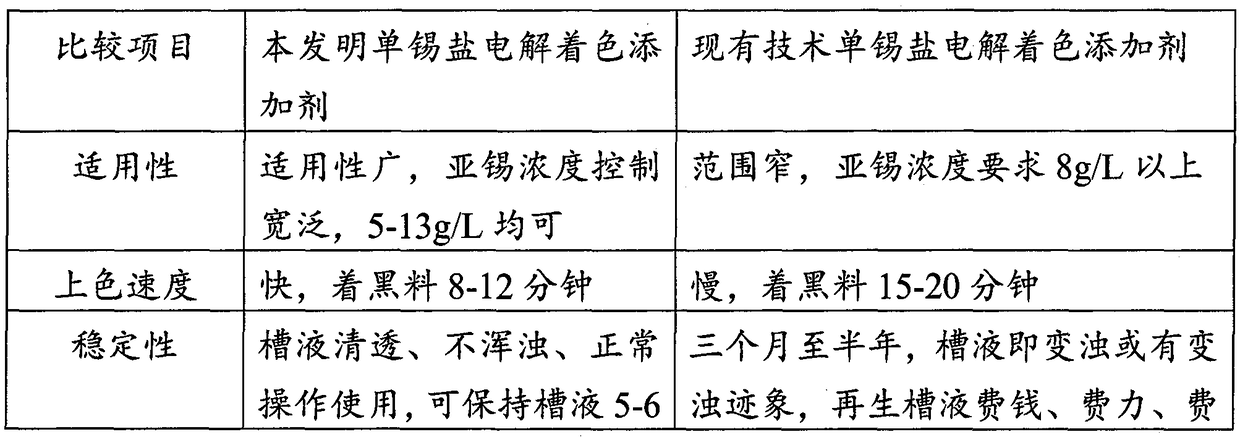

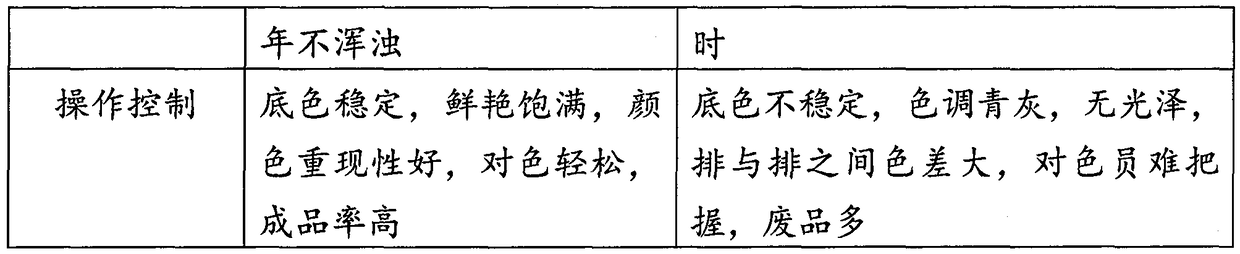

A technology of electrolytic coloring and additives, applied in the direction of electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as difficult to put into use, unstable production, unstable quality, etc., to achieve weakened edge effects, full and bright background color , the effect of stable and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A monotin salt electrolytic coloring additive comprises 30 parts of tartaric acid, 10 parts of boric acid, 25 parts of ferrous sulfate, 10 parts of hydrazine sulfate, 5 parts of thiourea and 1 part of modified aminoamide zinc phosphate in parts by mass.

[0036] Among them, tartaric acid is used to prevent the hydrolysis of stannous sulfate in the tank matching process. Boric acid is used to keep the conductive bath from becoming less acidic. Hydrazine sulfuric acid complexes stannous ions, making stannous ions more stable and difficult to hydrolyze into tetravalent tin. Thiourea is used to improve the dispersibility of the monostannic salt electrolytic coloring additive of the present invention. Ferrous sulfate can ensure the stability of the coloring solution.

[0037] Each component of the monotin salt electrolytic coloring additive of the present invention is indispensable, and cooperates with each other to bring out the best in each other.

[0038] The mono-tin s...

Embodiment 2

[0040] A monotin salt electrolytic coloring additive comprises 35 parts of tartaric acid, 15 parts of boric acid, 35 parts of ferrous sulfate, 17 parts of hydrazine sulfate, 7 parts of thiourea and 1 part of modified aminoamide zinc phosphate in parts by mass.

[0041] In this embodiment, the single tin salt electrolytic coloring additive tank and its coloring process are the same as in Embodiment 1.

Embodiment 3

[0043] A monotin salt electrolytic coloring additive, comprising 40 parts of tartaric acid, 20 parts of boric acid, 45 parts of ferrous sulfate, 25 parts of hydrazine sulfate, 10 parts of thiourea and 1 part of modified aminoamide zinc phosphate in parts by mass.

[0044] In this embodiment, the single-tin salt electrolytic coloring additive tank and its coloring process are also the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com