Steel rail cementing insulating joint

A technology for insulating joints and rails, which is applied to the joints of rails, tracks, roads, etc., and can solve problems such as failure of glued insulating joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

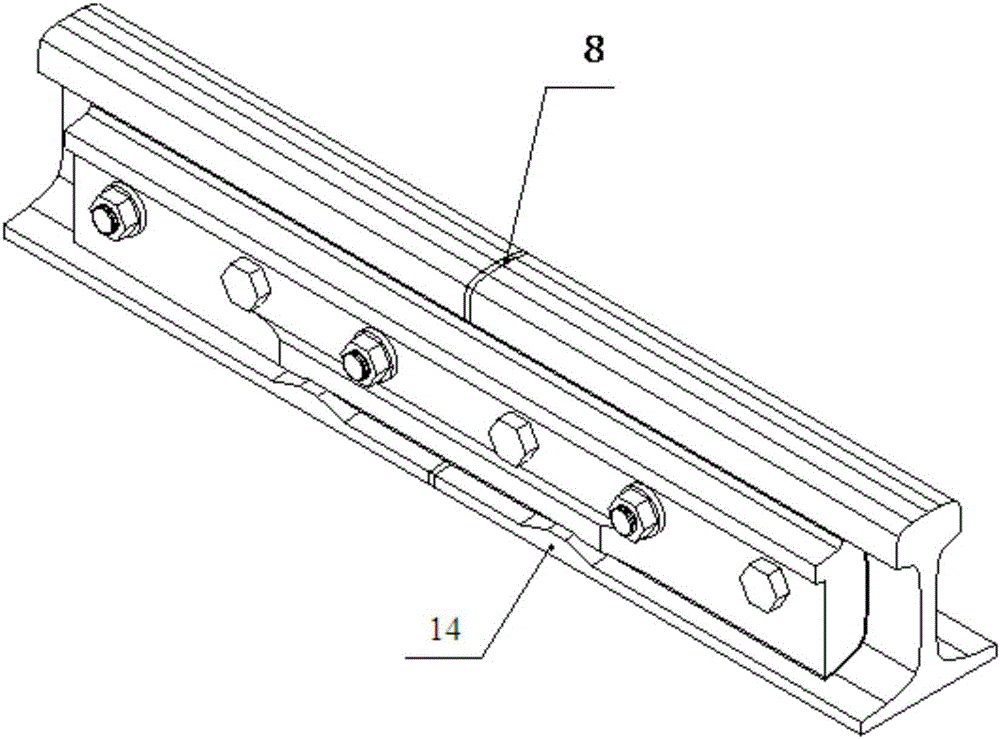

[0024] The present invention firstly provides a rail glued insulating joint, comprising two rails 1 connected in series, an insulating end plate 8 arranged at the joint of the two rails, an insulating groove plate 2 arranged closely on both sides of the rail, and an insulating groove plate arranged in the insulating groove The splint 3 on the outside of the plate and the screwed insulation assembly used to fasten the splint and the insulating slot plate on the rail, the screwed insulation assembly includes bolts 4, nuts 5, washers 6 and sleeved on the outer circle of the bolts The insulating sleeve 7 on the surface, the rail also includes an arch 14 protruding from the surface of the rail, the insulating slot plate is correspondingly provided with a convex layer 21 matching the arch slope, and the splint is correspondingly provided with Recesses 31 matching said arches and elevations.

[0025] Those skilled in the art can understand that the arch slope can be arranged on the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com