Novel double-wheel type flat ground rammer compactor

A tamping machine and two-wheel technology, applied in soil protection, roads, road repair and other directions, can solve problems such as troublesome, troublesome, small tamping area, and achieve the effect of simple structure, saving time and improving tamping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

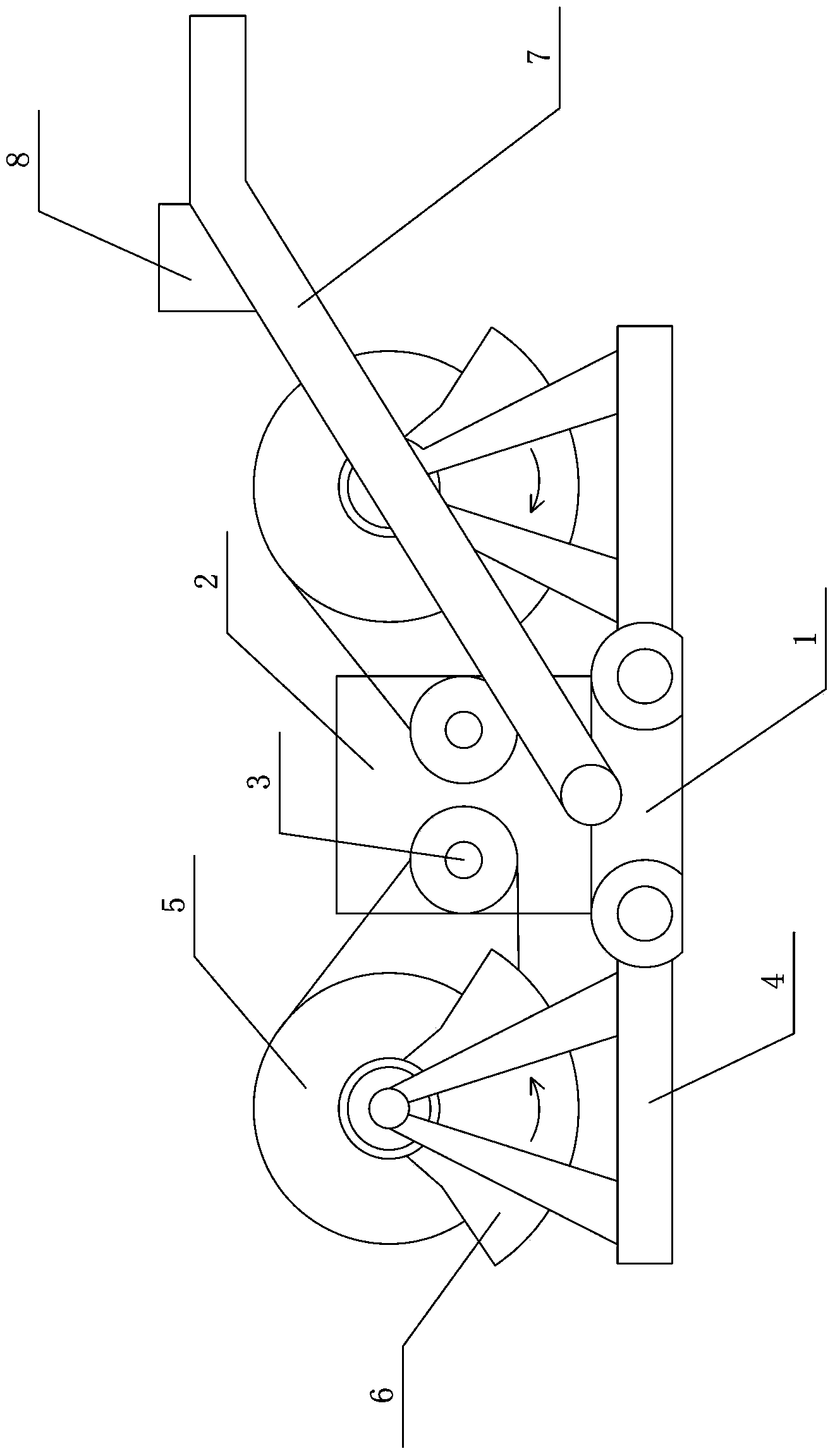

[0009] see figure 1 , the specific embodiment adopts the following technical solutions: it includes a chassis base 1, a motor case 2, a motor unit 3, a compacted steel plate 4, a circular runner 5, an eccentric arc wheel 6, a handle 7, and a control switch 8. The chassis base 1 is provided with a motor case 2, and the inside of the motor case 2 is provided with a motor unit 3. Both sides of the chassis base 1 are connected with a compacted steel plate 4 through movable bearings, and a circular runner 5 is arranged on the compacted steel plate 4. The outer side of the circular runner 5 is provided with an eccentric arc wheel 6, the circular runner 5 is connected with the motor unit 3 through a belt pulley, the middle of the chassis base 1 is connected with a handle 7, and the handle 7 is provided with a control switch 8.

[0010] The working principle of this specific embodiment: after starting the switch of the motor unit, the motor unit drives the eccentric wheel to rotate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com