Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237 results about "Sintering shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

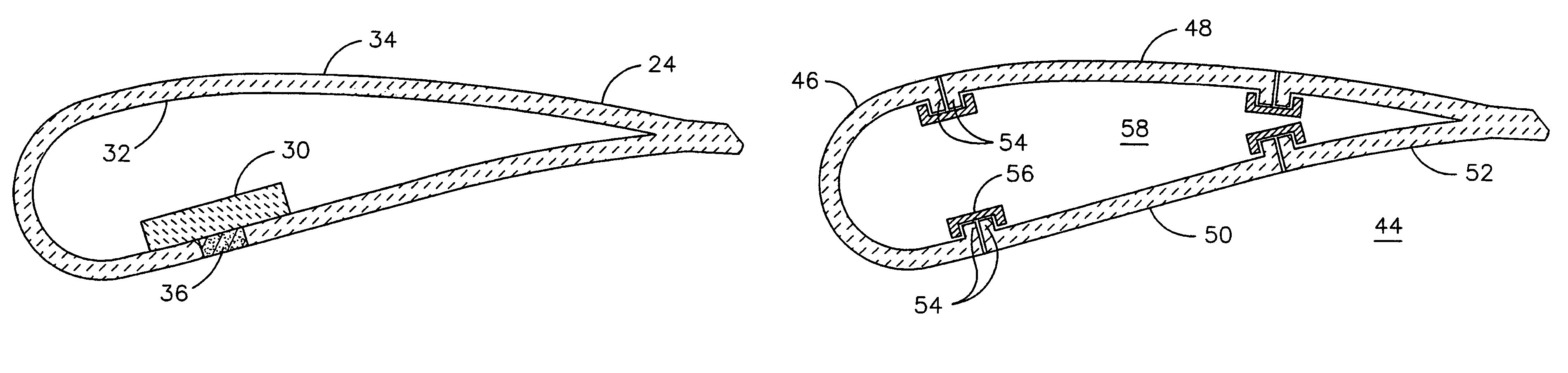

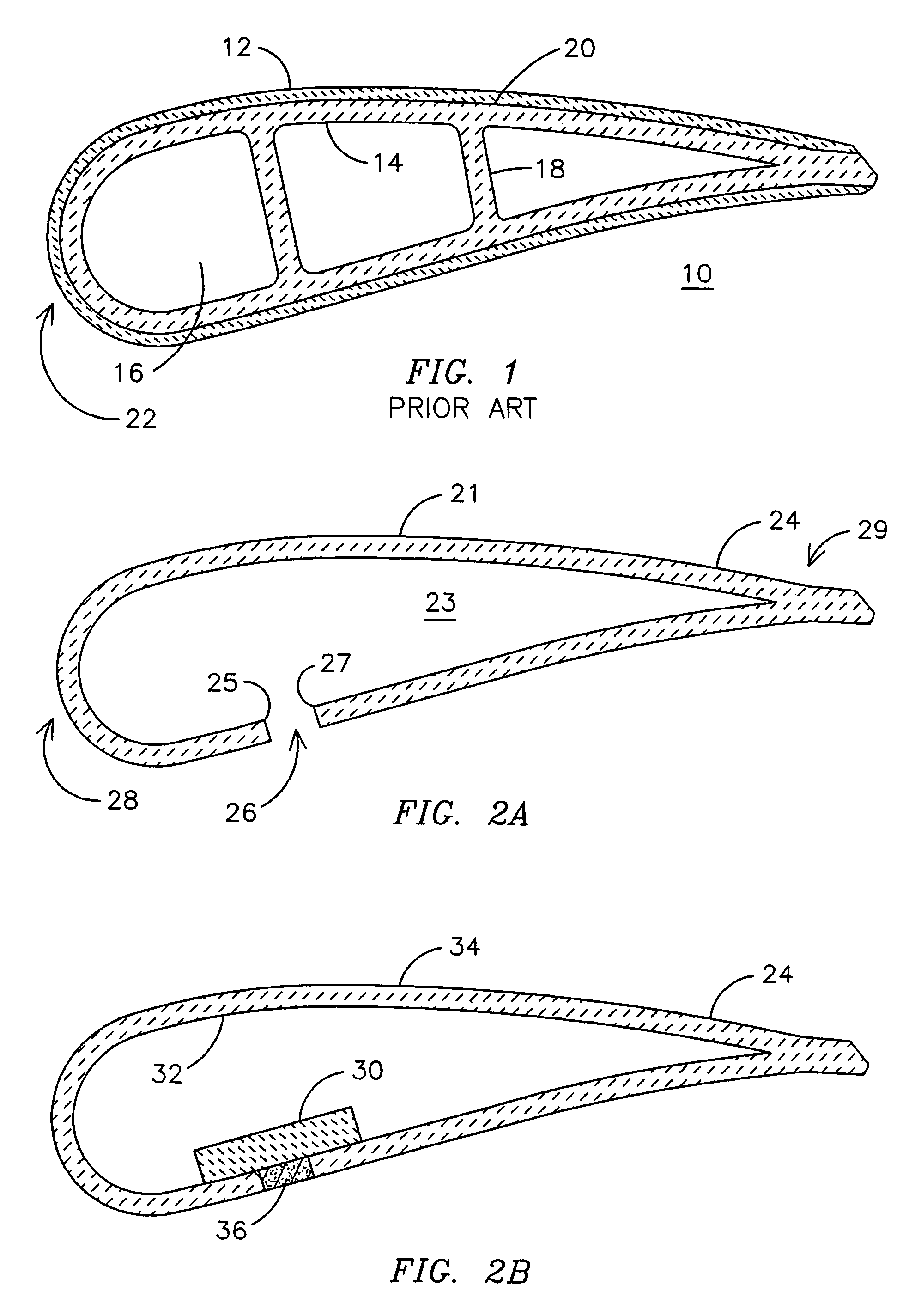

CMC component and method of fabrication

An airfoil (44) formed of a plurality of pre-fired structural CMC panels (46, 48, 50, 52). Each panel is formed to have an open shape having opposed ends (54) that are free to move during the drying, curing and / or firing of the CMC material in order to minimize interlaminar stresses caused by anisotropic sintering shrinkage. The panels are at least partially pre-shrunk prior to being joined together to form the desired structure, such as an airfoil (42) for a gas turbine engine. The panels may be joined together using a backing member (30), using flanged ends (54) and a clamp (56), and / or with a bond material (36), for example.

Owner:SIEMENS ENERGY INC

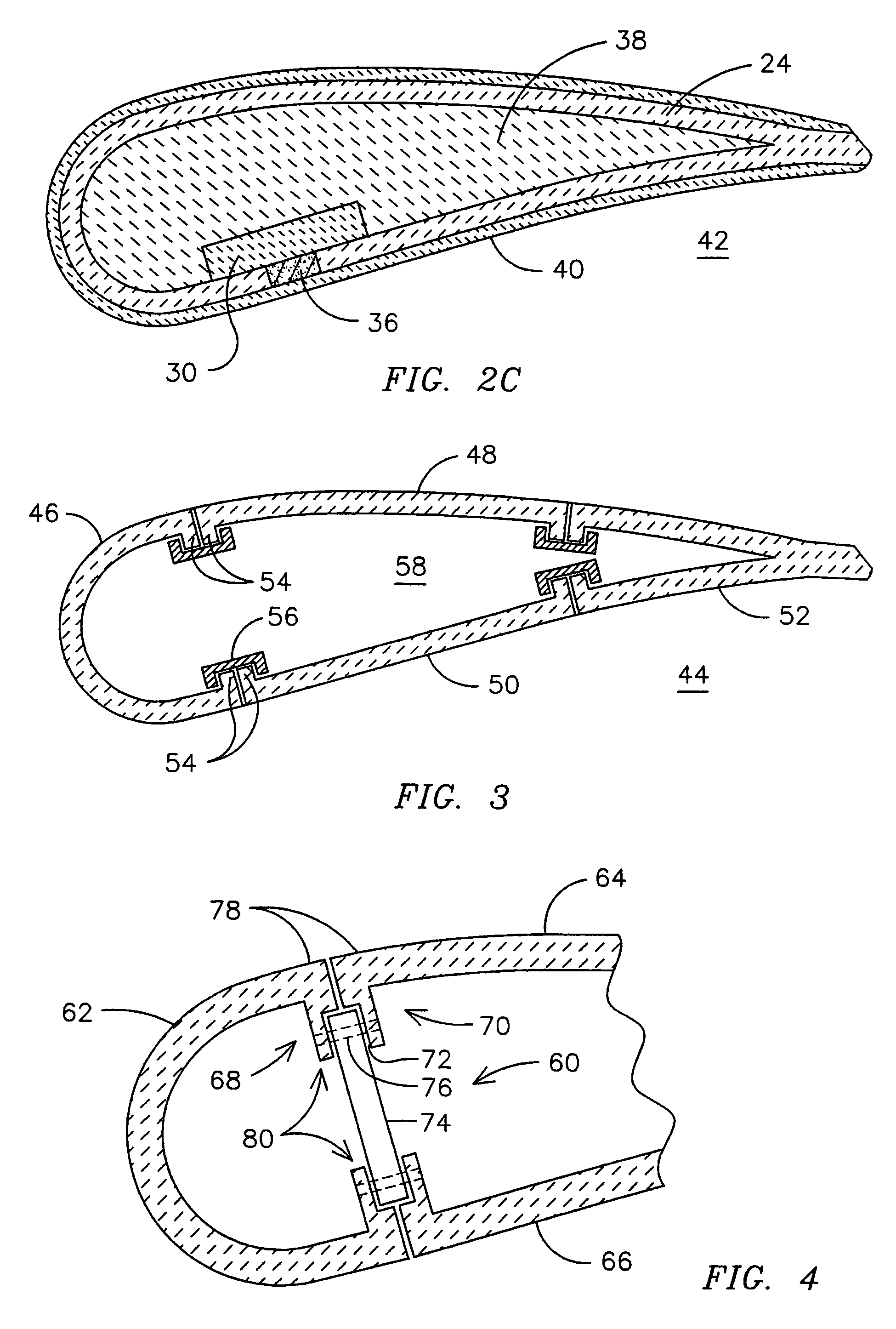

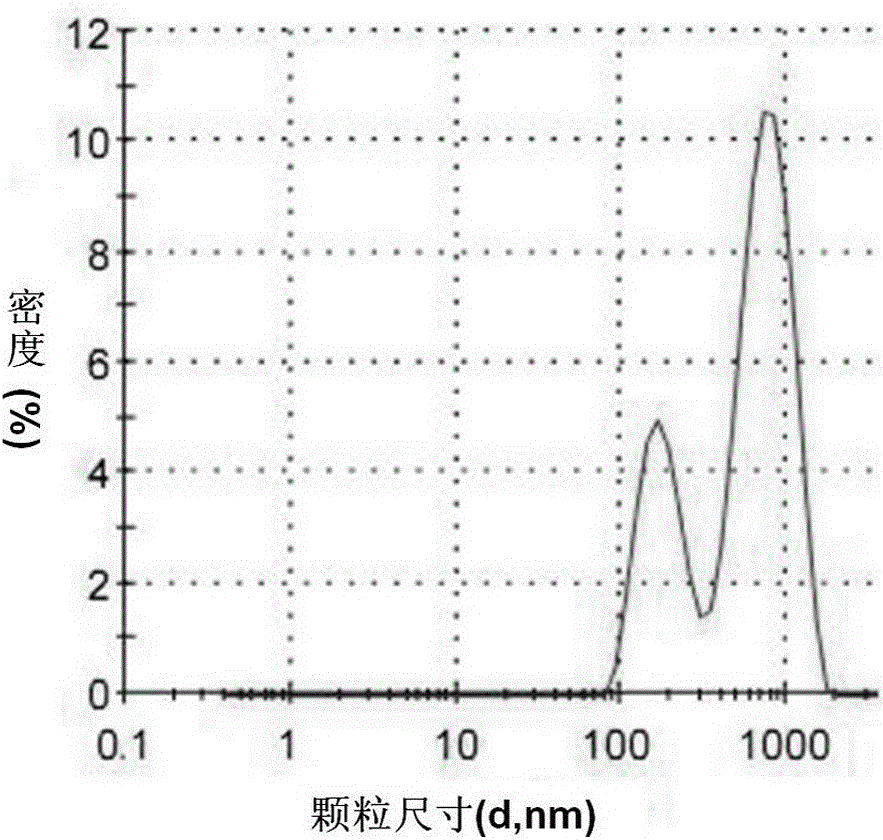

Translucent zirconia sintered body, process for producing the same, and use of the same

InactiveUS20110027742A1High densityGood light transmissionMaterial nanotechnologyDental implantsTransmittanceBody density

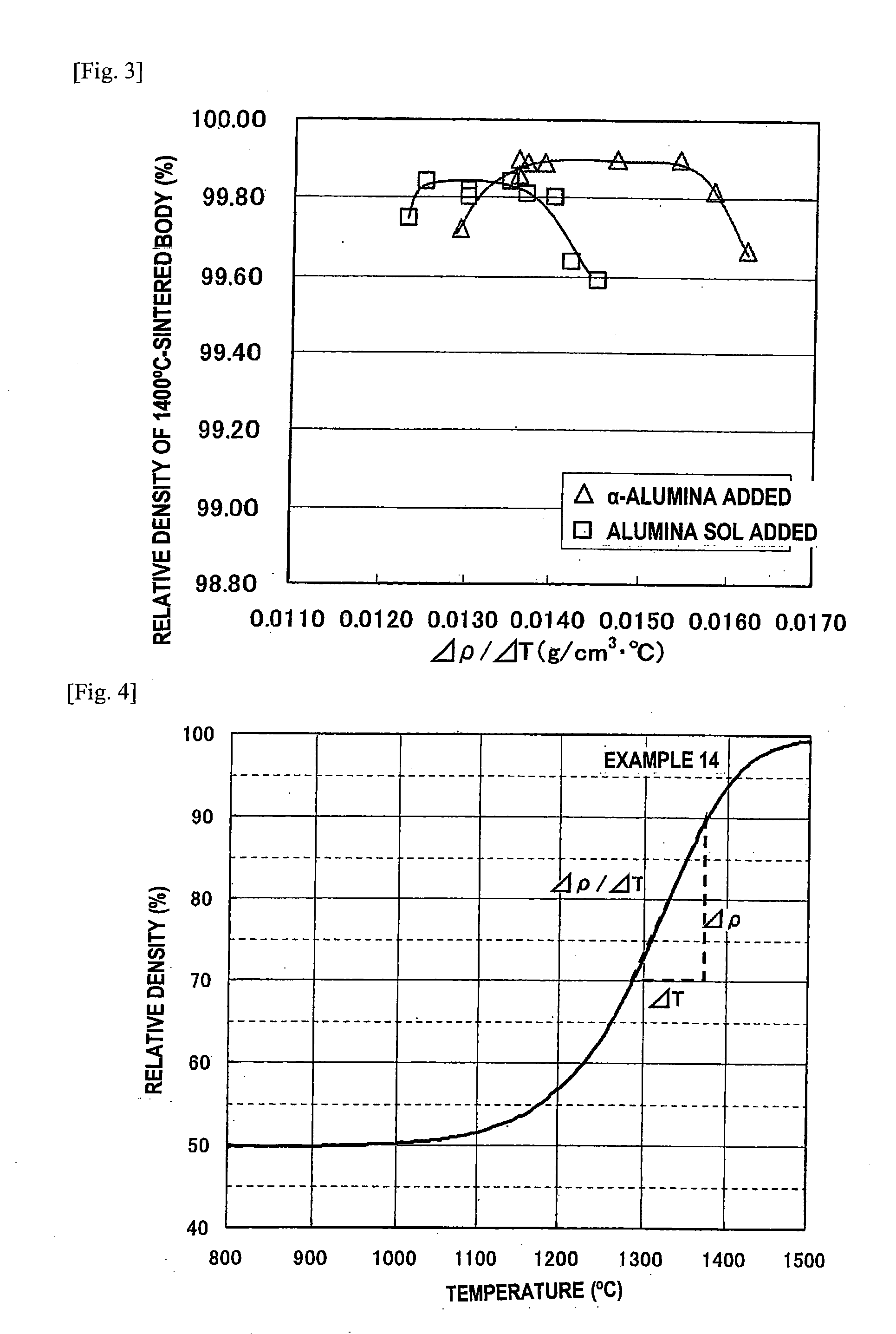

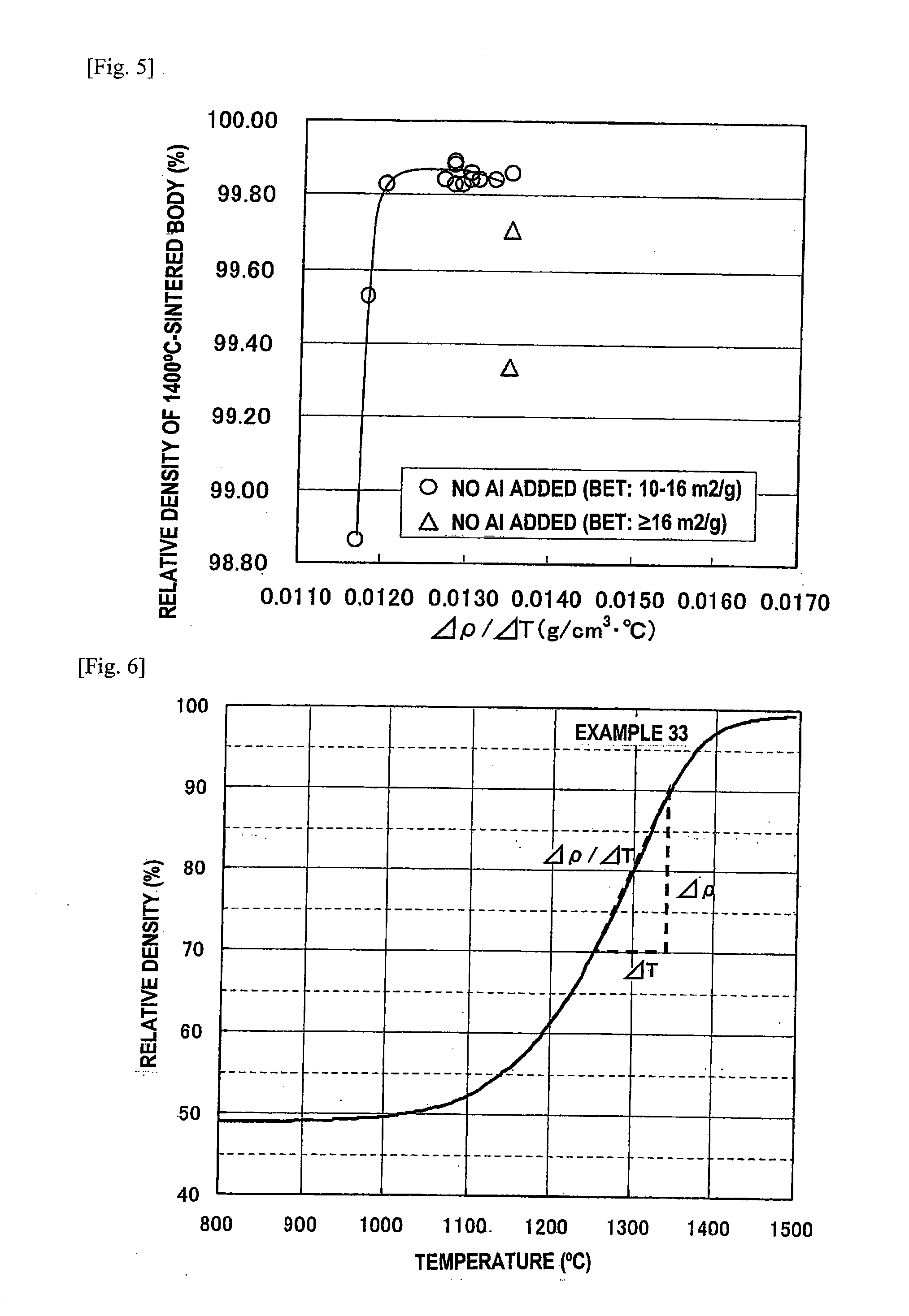

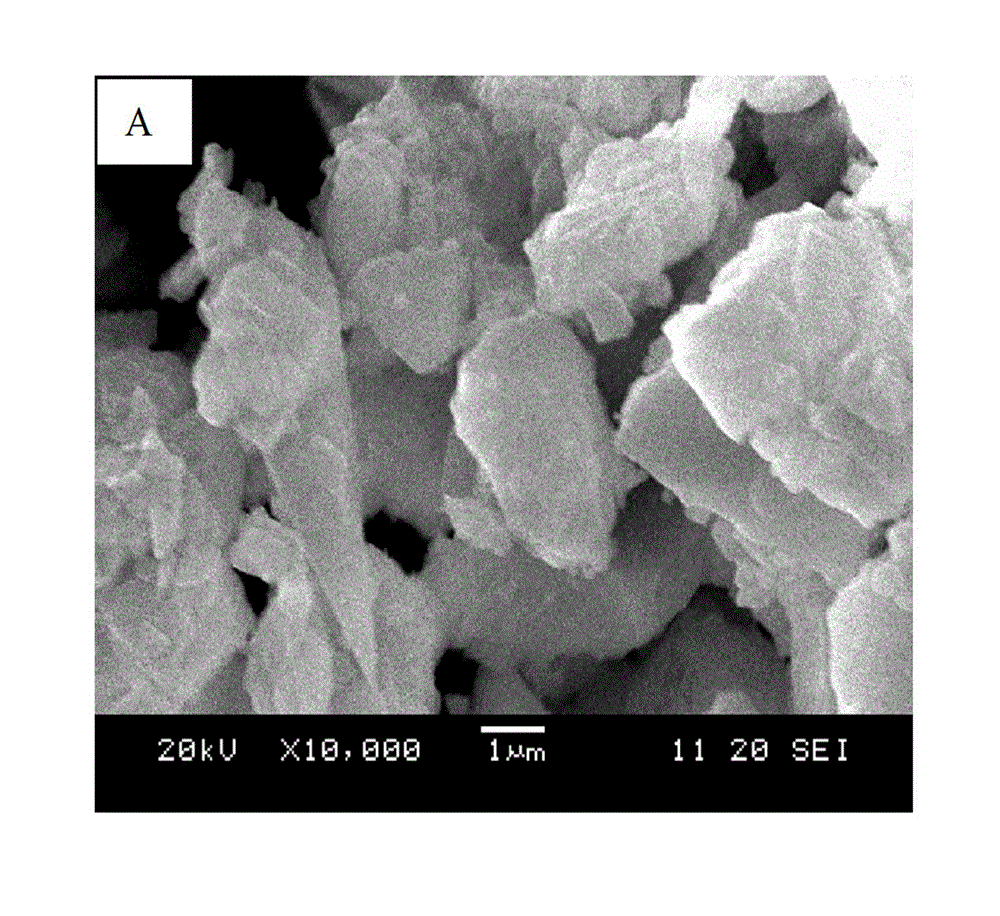

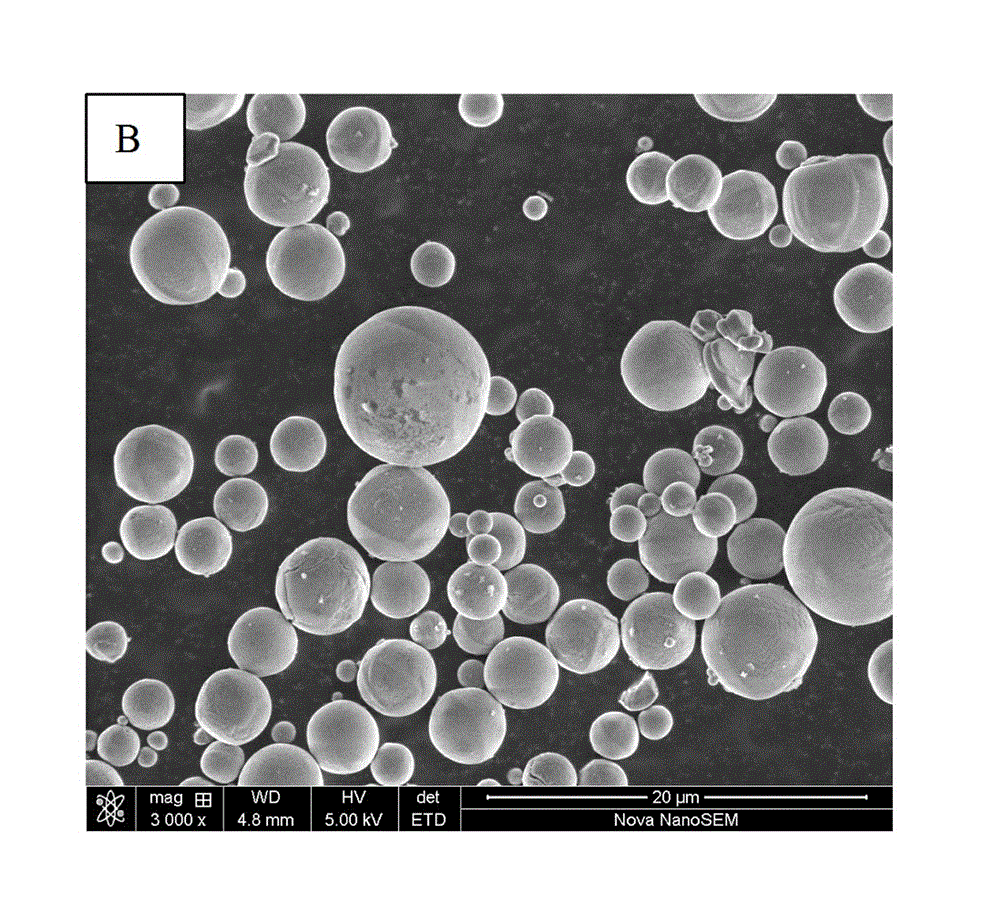

A subject of the invention relates to providing a powder for a translucent zirconia sintered body which is necessary for the production of a zirconia sintered body having a high sintered-body density and high strength and giving an excellent sense of translucency, without conducting any special sintering, such as HIP sintering. The invention relates to a technique for obtaining, through normal-pressure sintering, a translucent zirconia sintered body characterized by comprising zirconia which contains 2-4 mol % yttria as a stabilizer and has an alumina content of 0.2 wt % or lower, and by having a relative density of 99.8% or higher and a total light transmittance, as measured at a thickness of 1.0 mm, of 35% or higher. It is preferred that a powder containing 0-0.2 wt % alumina with a particle diameter of 0.01-0.5 μm, having a BET specific surface area of 5-16 m2 / g and an average particle diameter of 0.3-0.7 μm, and having a rate of sintering shrinkage in normal-pressure sintering (Δρ / ΔT; g / cm3·° C.) of 0.0125 or higher but 0.0160 or lower should be subjected to normal-pressure sintering in the atmosphere.

Owner:TOSOH CORP

Preparation method of corundum/mullite light-weight heat insulating material

ActiveCN103011884ARapid in situ solidificationThe process is easy to controlCeramicwareMaterials preparationFoaming agent

The invention belongs to the technical field of heat insulating material preparation, and particularly relates to a preparation method of a corundum / mullite light-weight heat insulating material, which comprises the following steps: by using ceramic powder, silica sol, deionized water, ammonia water and dryness-control chemical additive as initial raw materials, carrying out ball milling to prepare a ceramic slurry; adding a foaming agent into the ceramic slurry, and foaming in a mechanical stirring mode to obtain a foam slurry; adding an NH4Cl solution into the foam slurry while stirring, injecting the uniformly stirred foam slurry into a mold, and quickly curing to form the foam slurry; and drying the demolded blank, and firing to obtain the corundum / mullite light-weight heat insulating material. The invention is characterized in that the gelation reaction of the silica sol is utilized to implement curing and formation of the foam slurry; meanwhile, the volume expansion generated by mullitization in the firing process is utilized to avoid sample cracking due to excessive sintering shrinkage; and in addition, the raw materials are nontoxic and cheap, and the preparation process is simple to control and suitable for industrial production.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

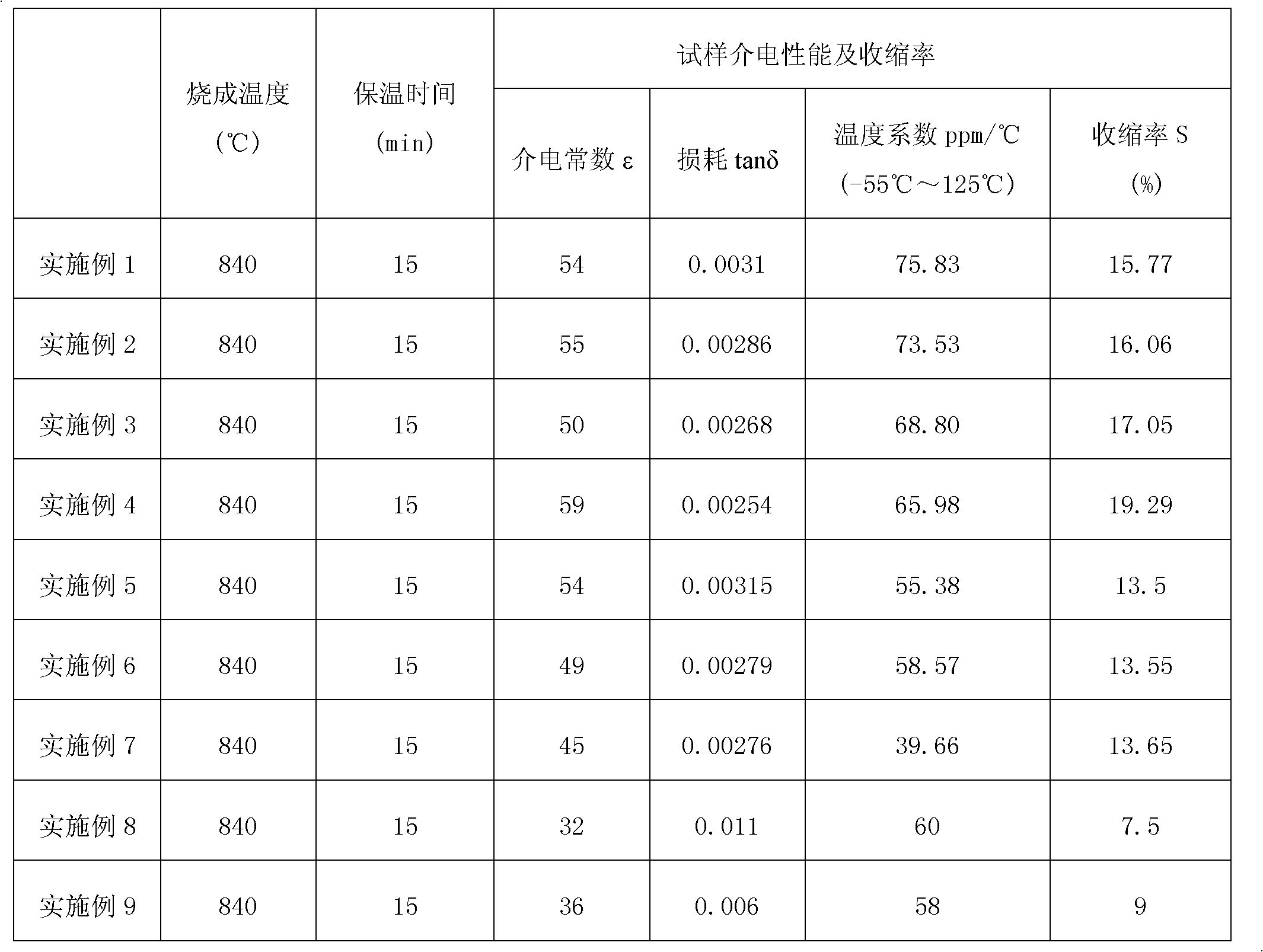

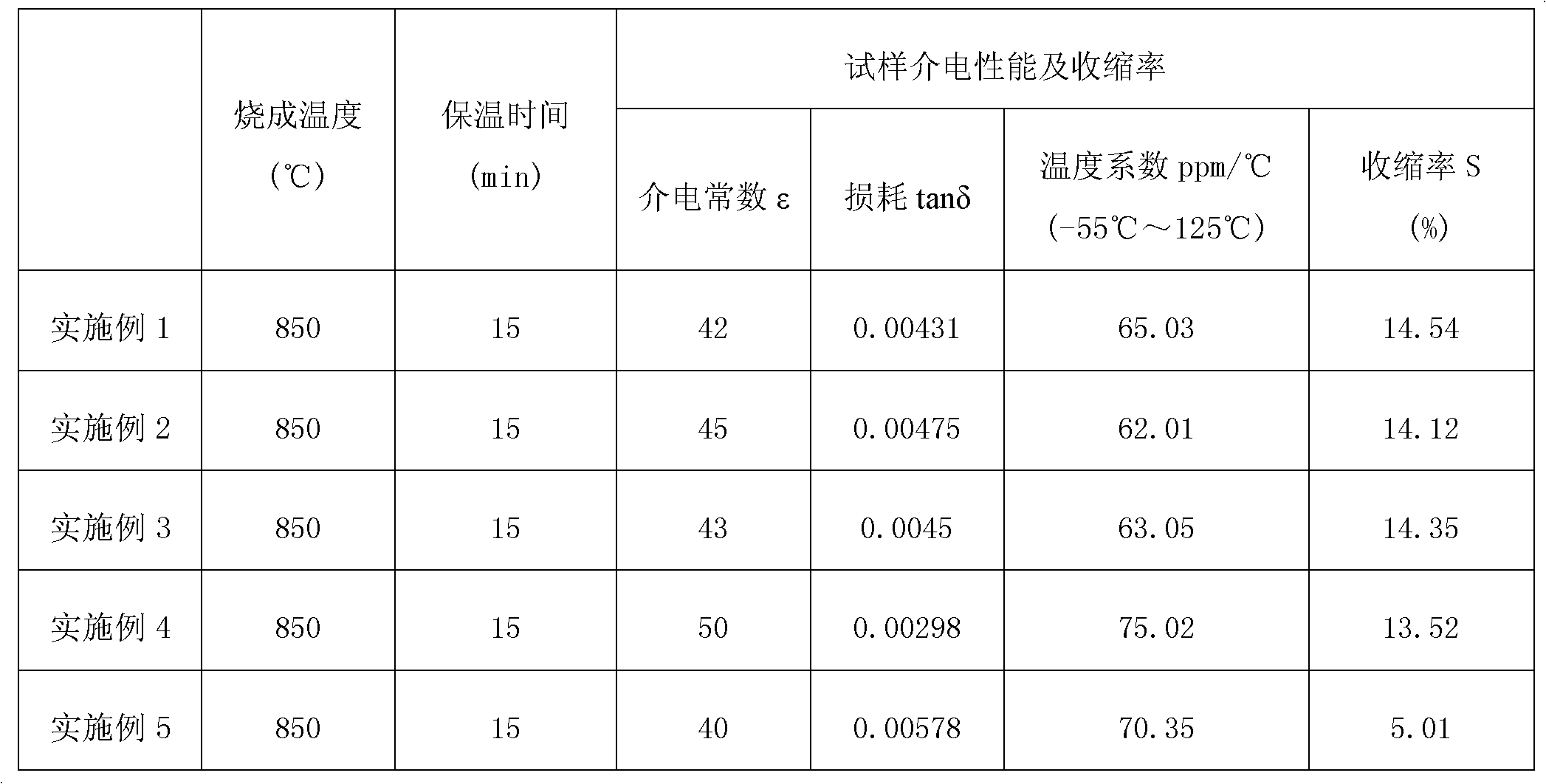

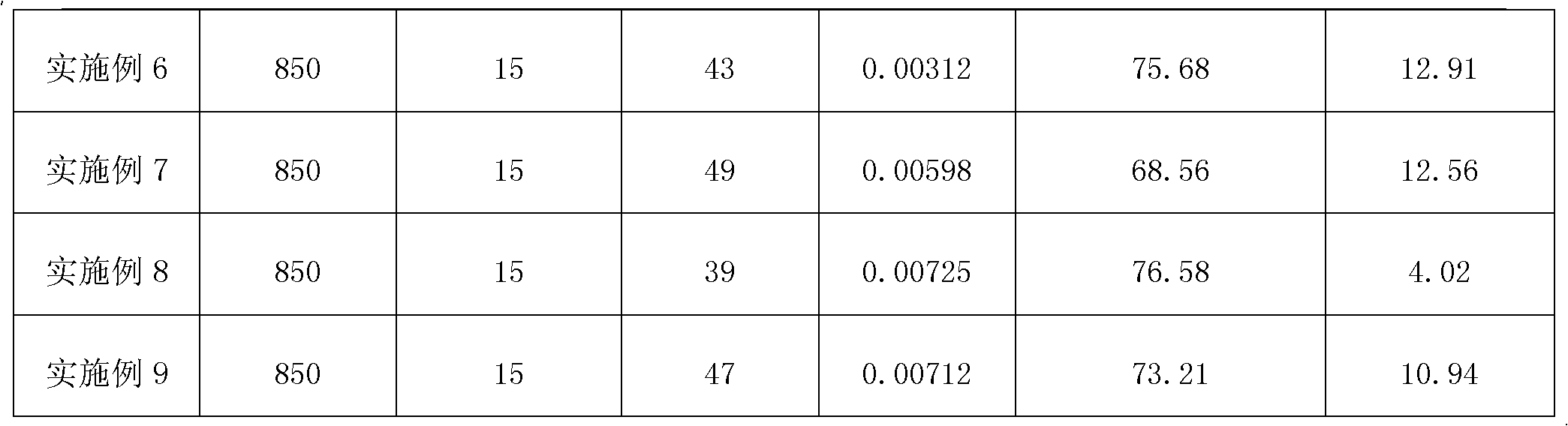

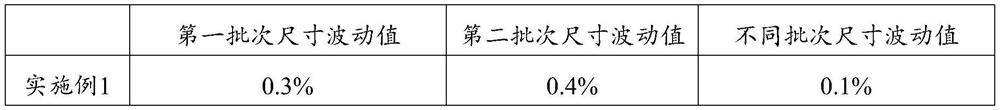

Borosilicate glass-spherical alumina low temperature co-fired ceramic green tape and preparation method thereof

The invention discloses a borosilicate glass-spherical alumina low temperature co-fired ceramic (LTCC) green tape and its preparation method. The green tape is composed of a glass-ceramic composite material and a casting medium. Specifically, the glass-ceramic composite material consists of borosilicate glass and spherical alumina. The casting medium consists of a mixed solvent, a monomer binder, a plasticizer and a dispersing agent. The low temperature co-fired ceramic green tape prepared in the invention has a level and smooth surface, a solid content up to 88-92wt%, and a firing shrinkage rate of 9-11%. The difference between the sintering shrinkage rate of each direction is small. And the green tape can achieve wiring co-firing with Au, Ag and other low melting point metals at 850DEG C. The raw material tape sintered ceramic body provided in the invention has excellent dielectric properties. Under the condition of less than 10GHz, the dielectric constant (epsilon r) of 7-8, the dielectric loss (Tan delta) is less than 2*10<-3>, and effectively solves the anisotropy problem of traditional LTCC green tape sintering shrinkage.

Owner:凤阳凯盛硅材料有限公司

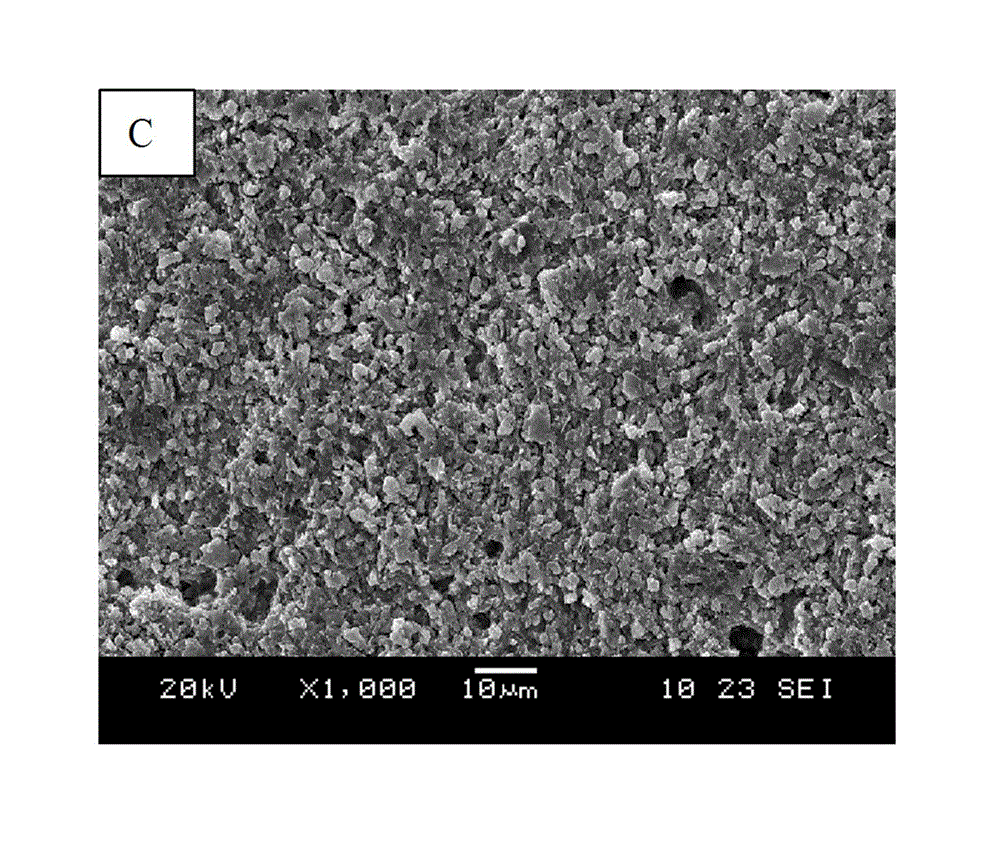

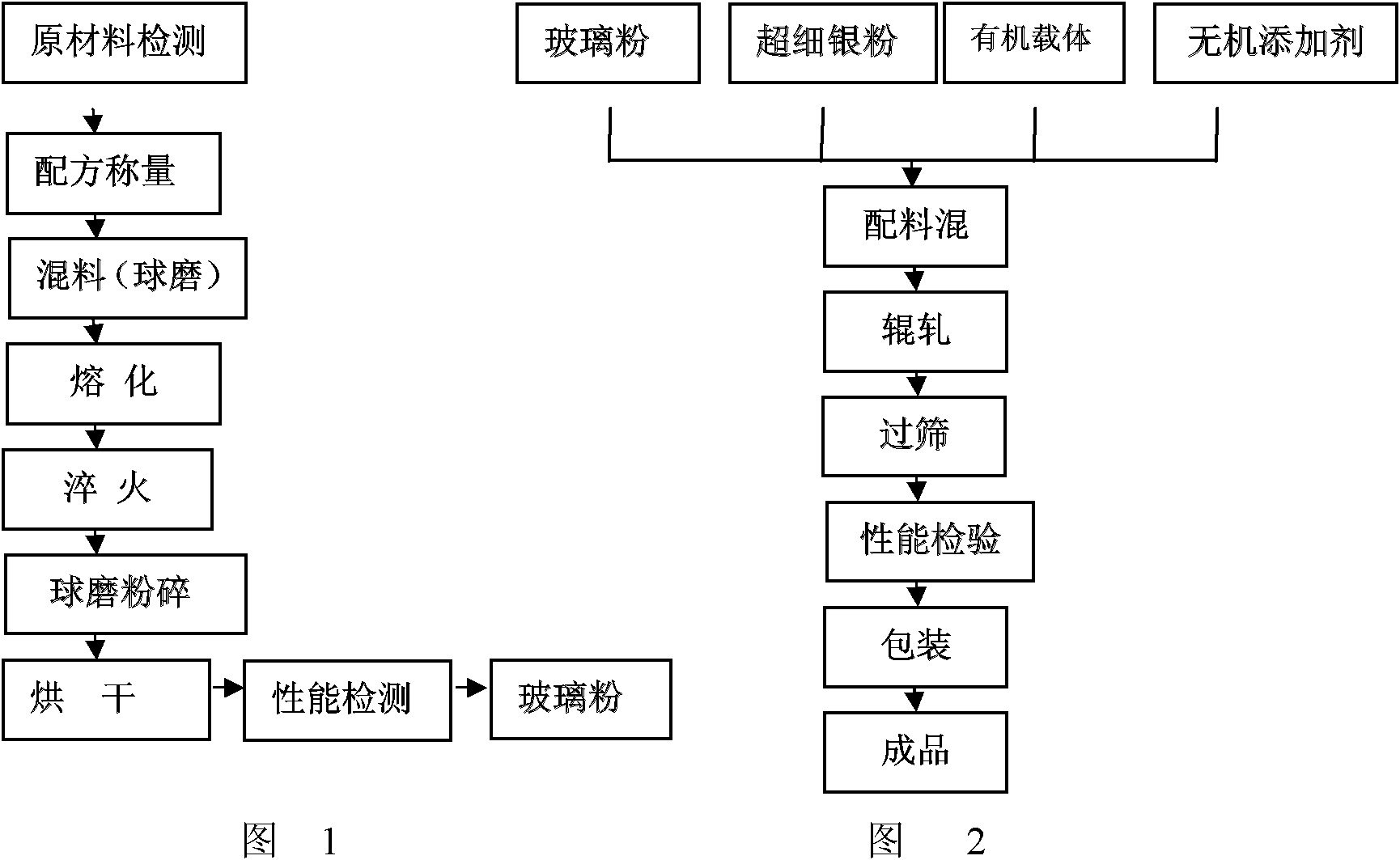

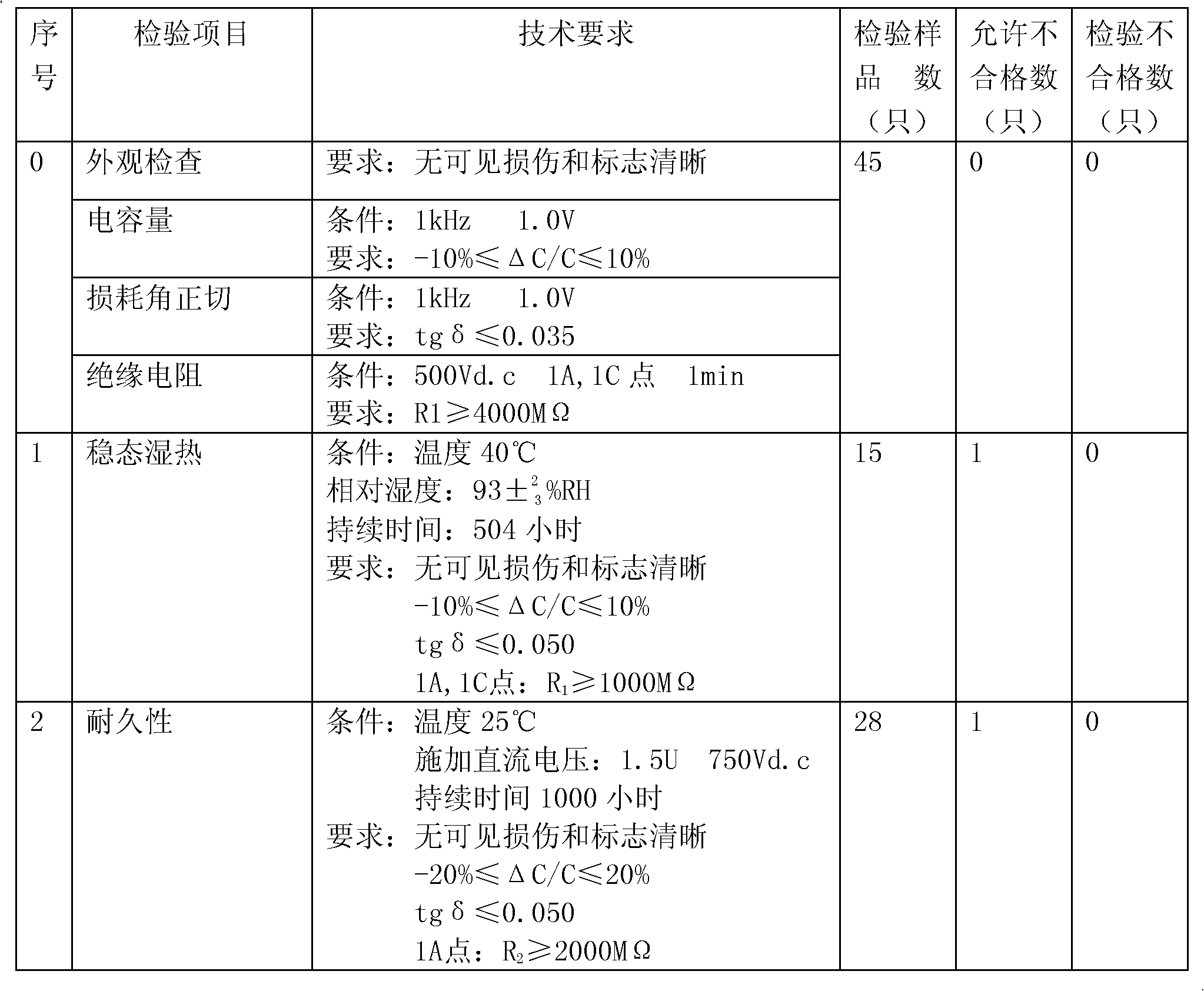

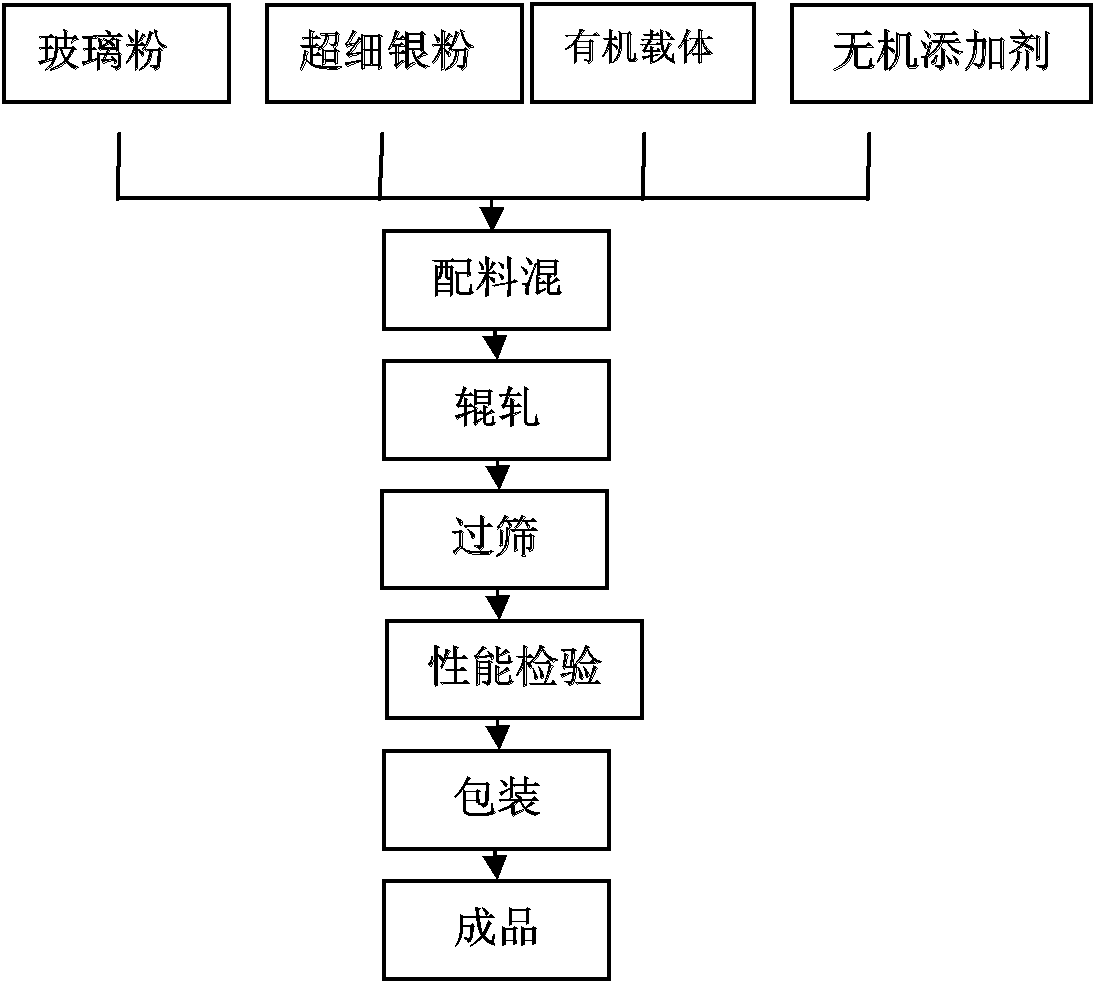

Silver paste for disk capacitor electrode

ActiveCN101986390AImprove adhesionExcellent electrical performanceFixed capacitor electrodesNon-conductive material with dispersed conductive materialCapacitanceScreen printing

The invention discloses silver paste for a disk capacitor electrode. The silver paste comprises the following components by weight percent: 50-80% of ultrafine silver powder with the particle size of less than 2mu m, 2-15% of lead-free glass powder, 0.1-10% of inorganic additive, 5-25% of polymer resin, 10-40% of solvent and 0-10% of organic additive, wherein the sum of the weight percentages of the components is 100%. The silver paste has good dispersivity, narrow particle size distribution, low sintering shrinkage rate and good conductivity, the screen printing patterns are smooth and flat,the silver surface is continuous and bright, the silver paste has high adhesive force and good electrical performance; and the glass powder does not contain lead, cadmium and the compounds of lead and cadmium, thus the environmental requirements of the European Union RoHS can be met.

Owner:广东羚光新材料股份有限公司

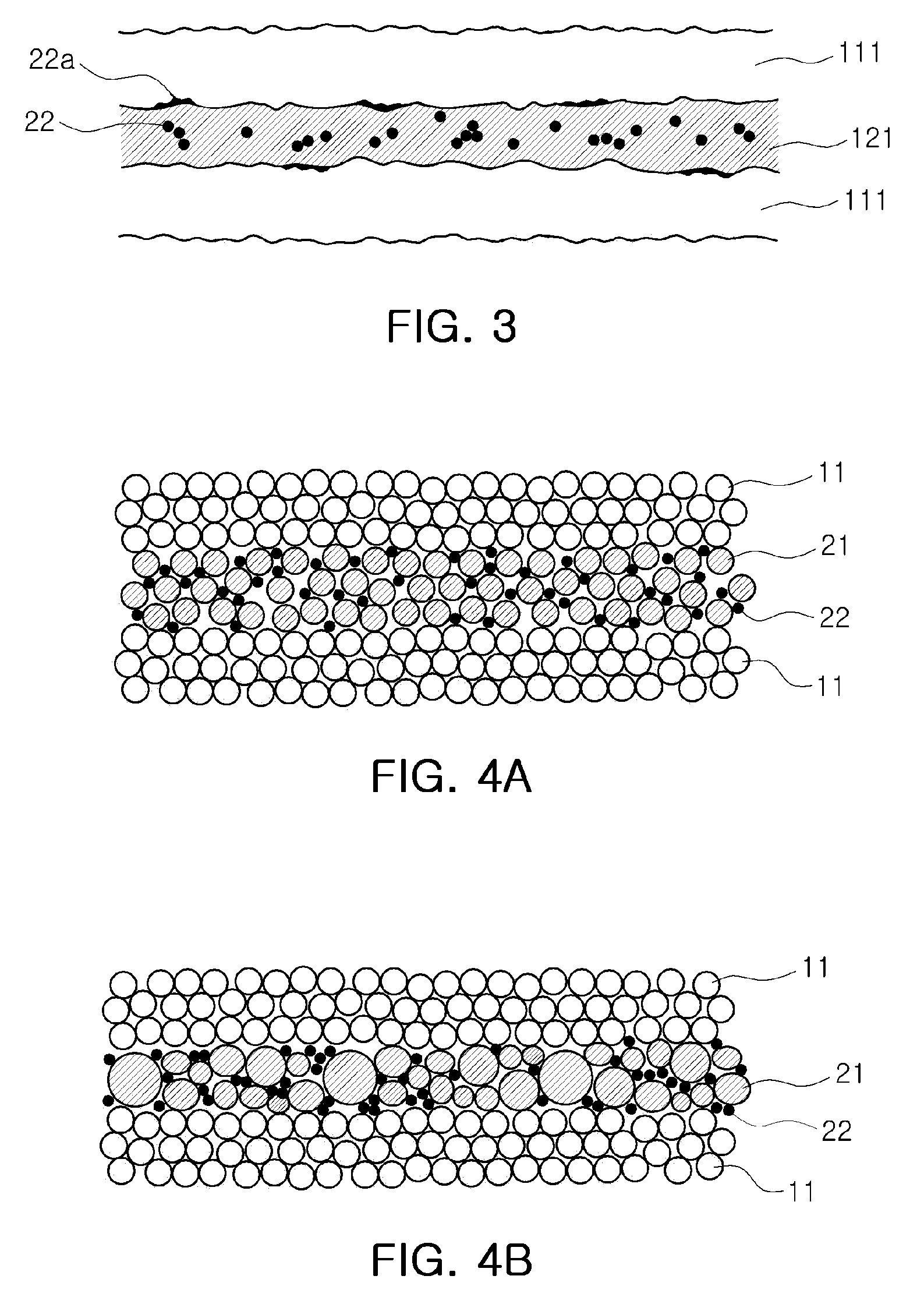

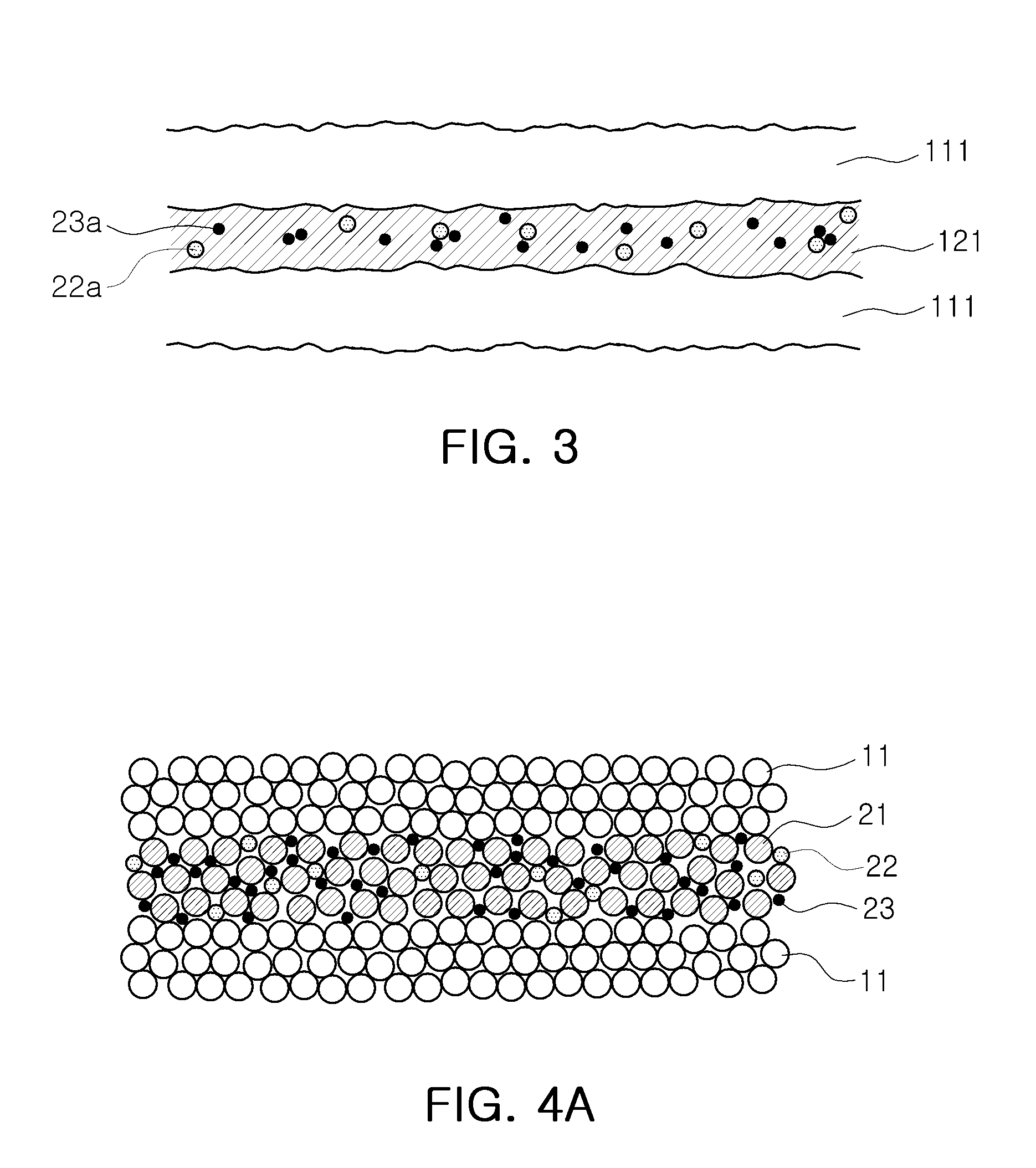

Powder-based material system with stable porosity

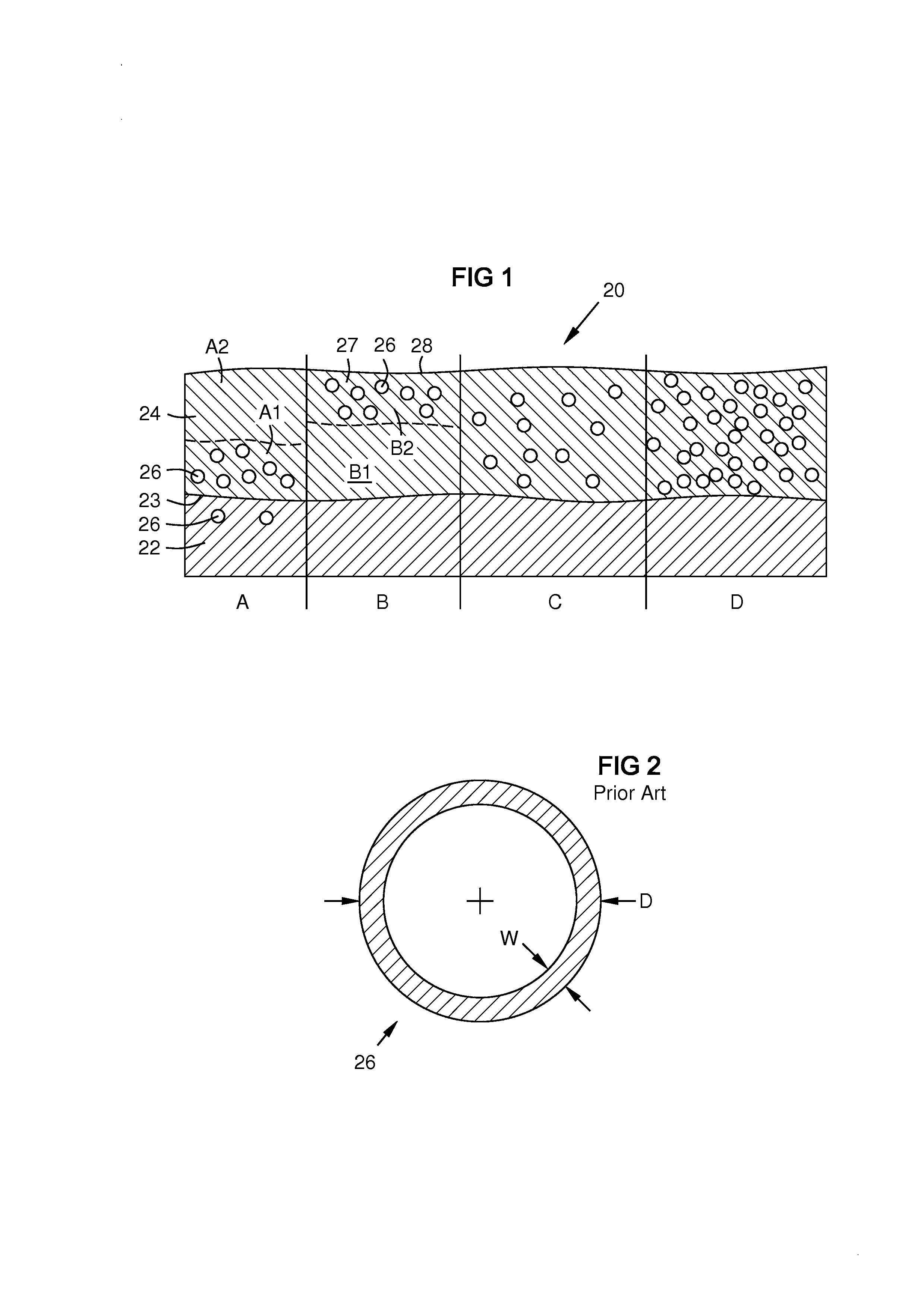

A powder-based material system having an intrinsic and stable degree of porosity provided by hollow ceramic spheres (26) in a fully dense matrix (27). A substrate (22) is formed from a metal powder (70), and may be partially sintered (60). A layer (24) of ceramic powder is arranged on the substrate including the pre-sintered hollow ceramic spheres plus a proportion of nano-sized ceramic particles effective to reduce the layer sintering temperature and to increase the sintering shrinkage of the layer to approximate that of the metal substrate during subsequent co-sintering. The substrate and layer are then co-sintered (61), such as with spark plasma sintering (32, 34, 36), at a temperature and for a duration to fully densify the ceramic powder matrix around the hollow spheres, thereby producing a metal / ceramic material system with low interface stress and with stable porosity during operational temperatures in a gas turbine engine.

Owner:SIEMENS AG

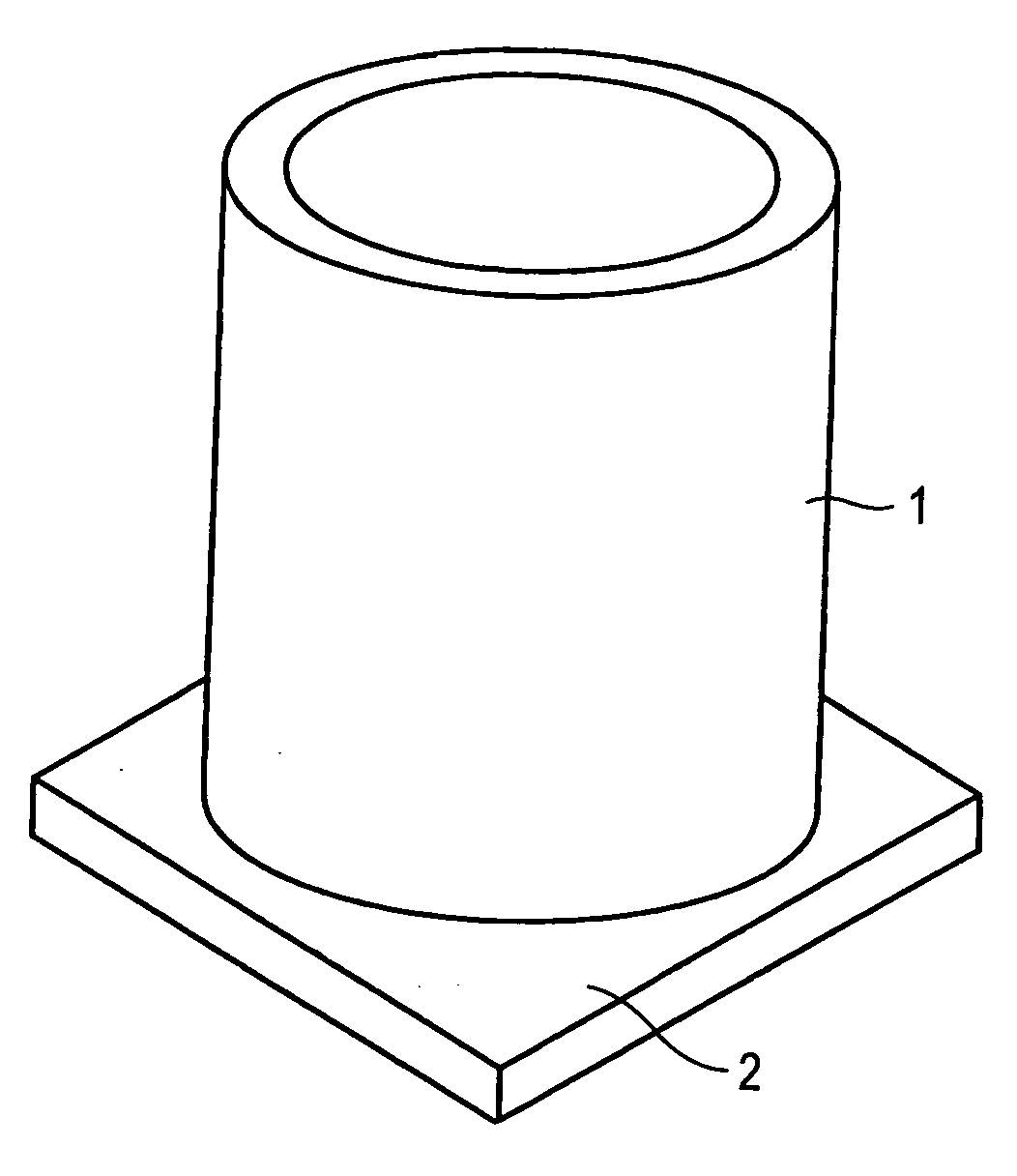

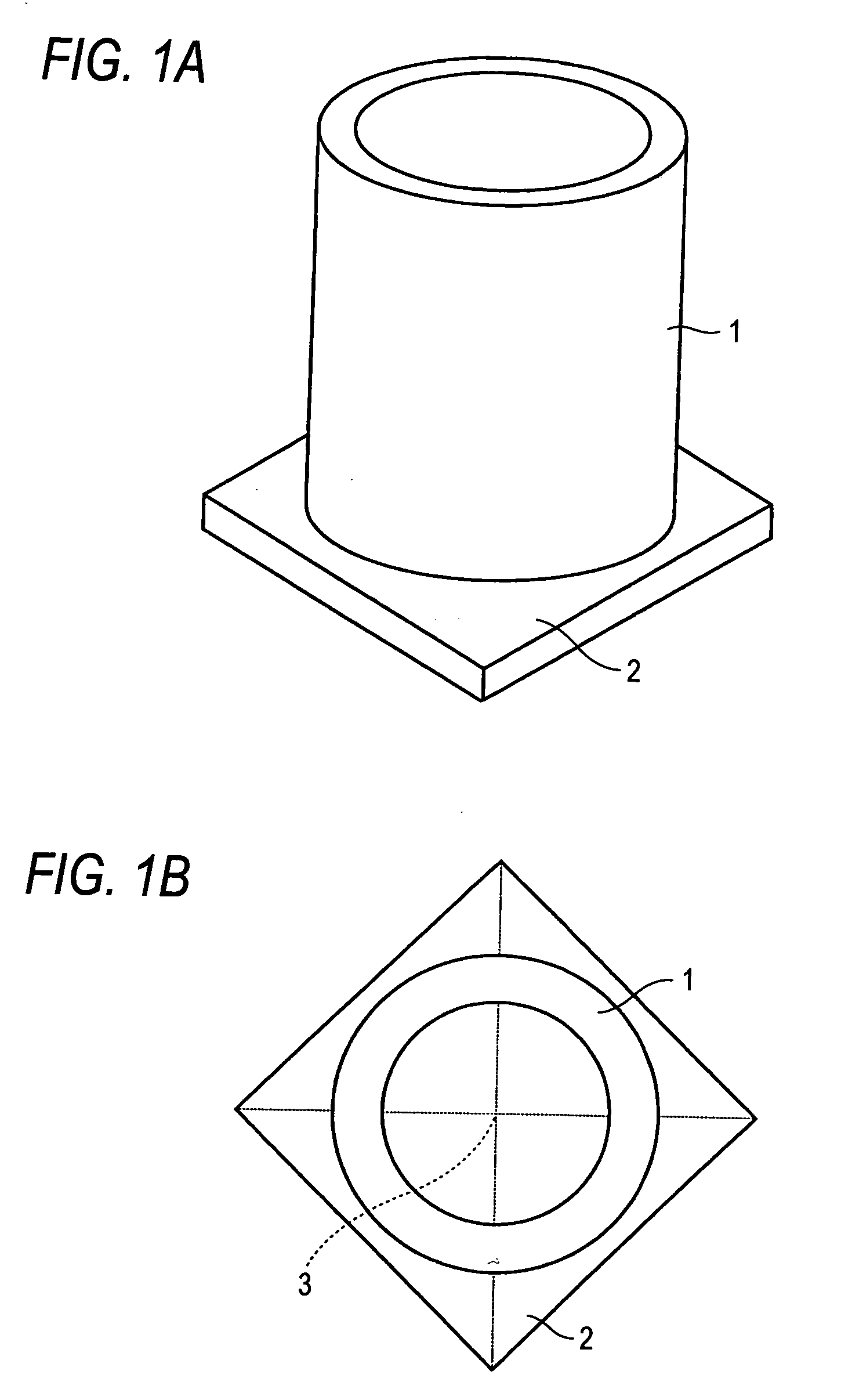

Cylindrical sputtering target, ceramic sintered body, and process for producing sintered body

ActiveUS20060151321A1High densityQuality improvementCellsVacuum evaporation coatingCeramic sinteringHigh density

A hollow cylindrical ceramic sintered body having high density, a process for producing the sintered boy, and a cylindrical ceramic sputtering target having high quality without cracks or breakage, are disclosed. The hollow cylindrical ceramic sintered body is obtained by placing a cylindrical ceramic molding to be sintered on a plate-like ceramic molding having a coefficient of sintering shrinkage similar to that of the cylindrical ceramic molding, and then sintering the resulting assembly, thereby obtaining a hollow cylindrical ceramic sintered body having a relative density of 95% or higher. The cylindrical ceramic sputtering target is prepared using the hollow cylindrical ceramic sintered body.

Owner:TOSOH CORP

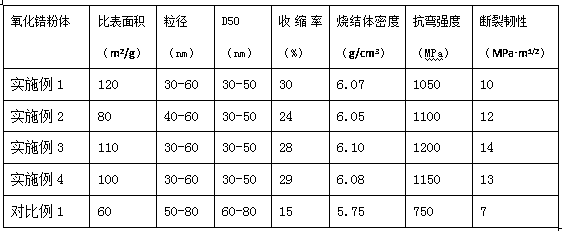

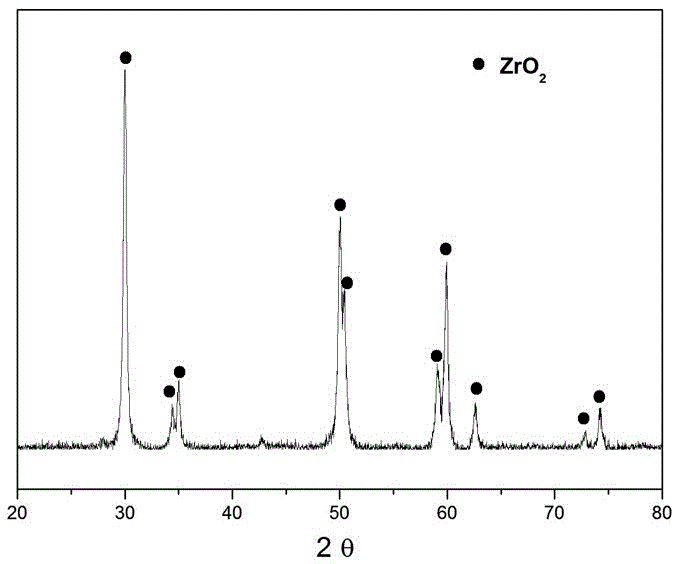

Preparation method of nanometer yttrium stabilized zirconia powder

ActiveCN107628643AHigh sintering shrinkageHigh sintered body densityNanotechnologyZirconium oxidesEthylenediamineMass ratio

The invention discloses a preparation method of nanometer yttrium stabilized zirconia powder. The preparation method comprises mixing zirconium oxychloride, yttrium oxide and deionized water accordingto a mass ratio of (50-60): (0.8-1): (10-12), heating the mixture to 90-110 DEG C, carrying out heat preservation for 1-3h, adding plant gum into the mixture, then adding at least one of ethylenediaminetetraacetic acid or citric acid into the mixture, carrying out stirring for 3-5h to obtain a colloidal solution, adding an ammonia solution into the colloidal solution along with stirring for 8-10huntil pH of 10.0-11.0 so that white precipitates are produced, standing the white precipitates for aging for 24-48h, washing and filtering the precipitates, carrying out spray drying and fluid energymilling to obtain precursor powder, and calcining the precursor powder at 450-600 DEG C for 5-7h to obtain the nanometer yttrium stabilized zirconia powder. The zirconia powder has a high sintering shrinkage rate, high sintering density, good strength, good performances, small particle size and narrow distribution.

Owner:汉中市恒宝锆业科技有限责任公司

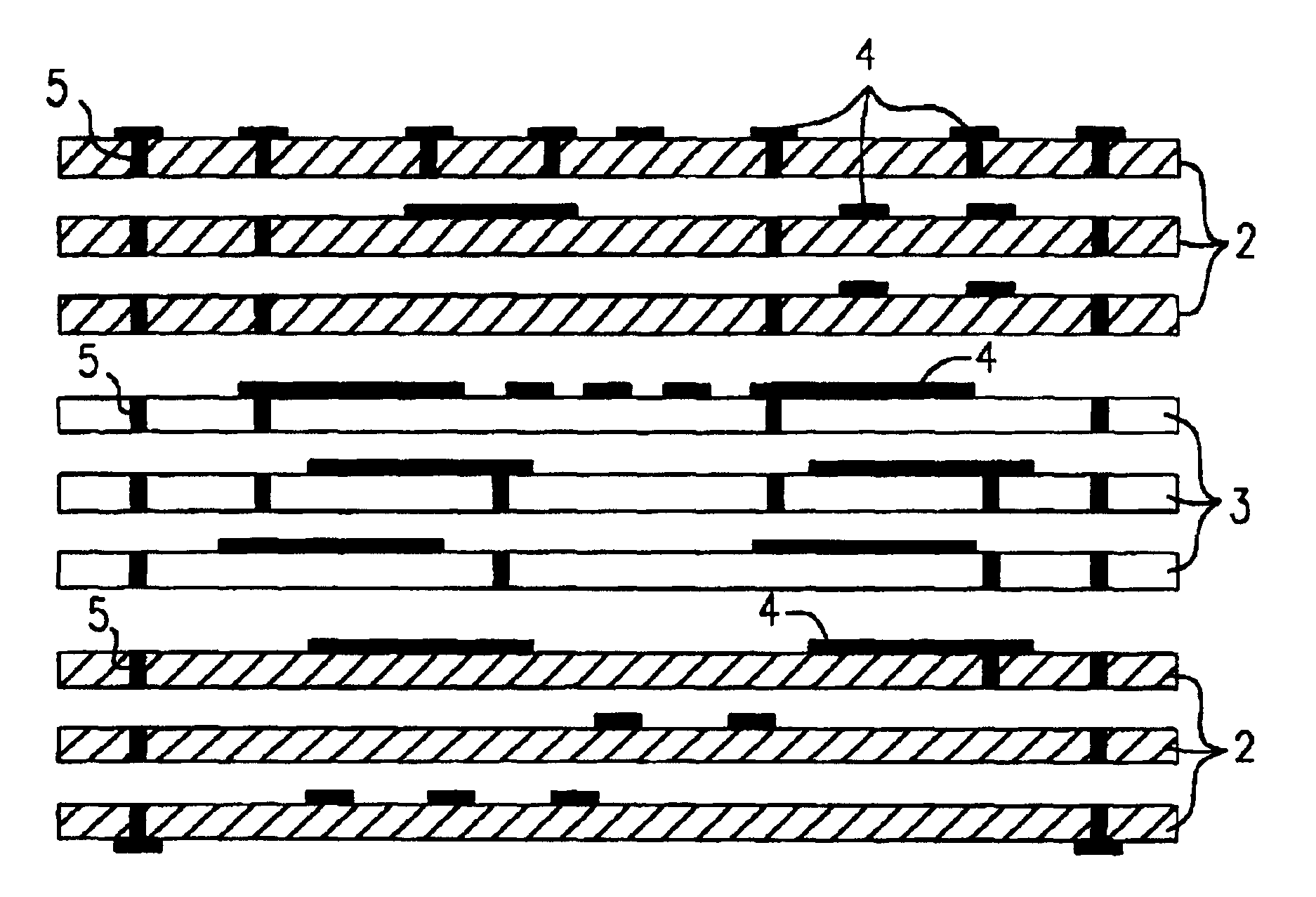

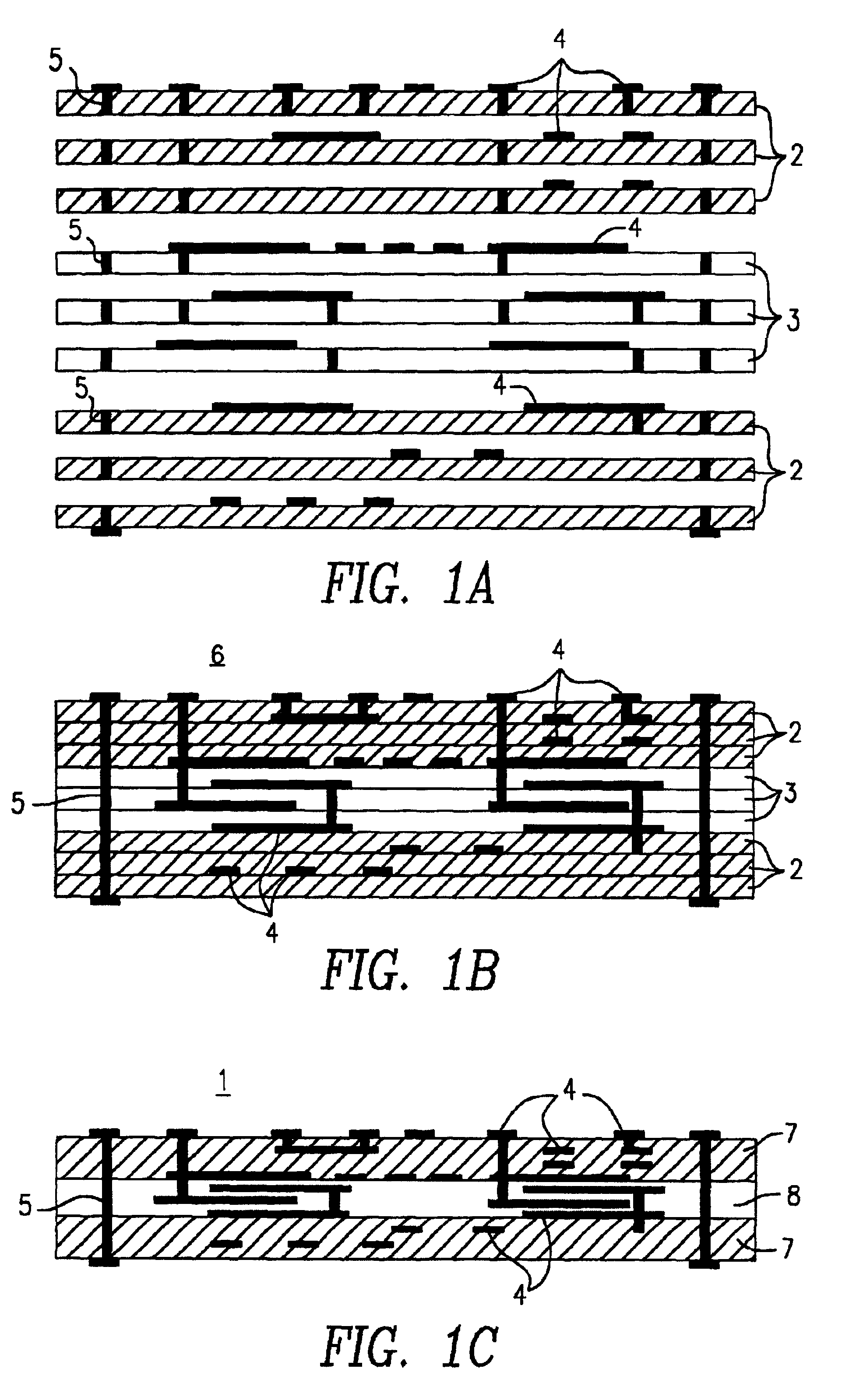

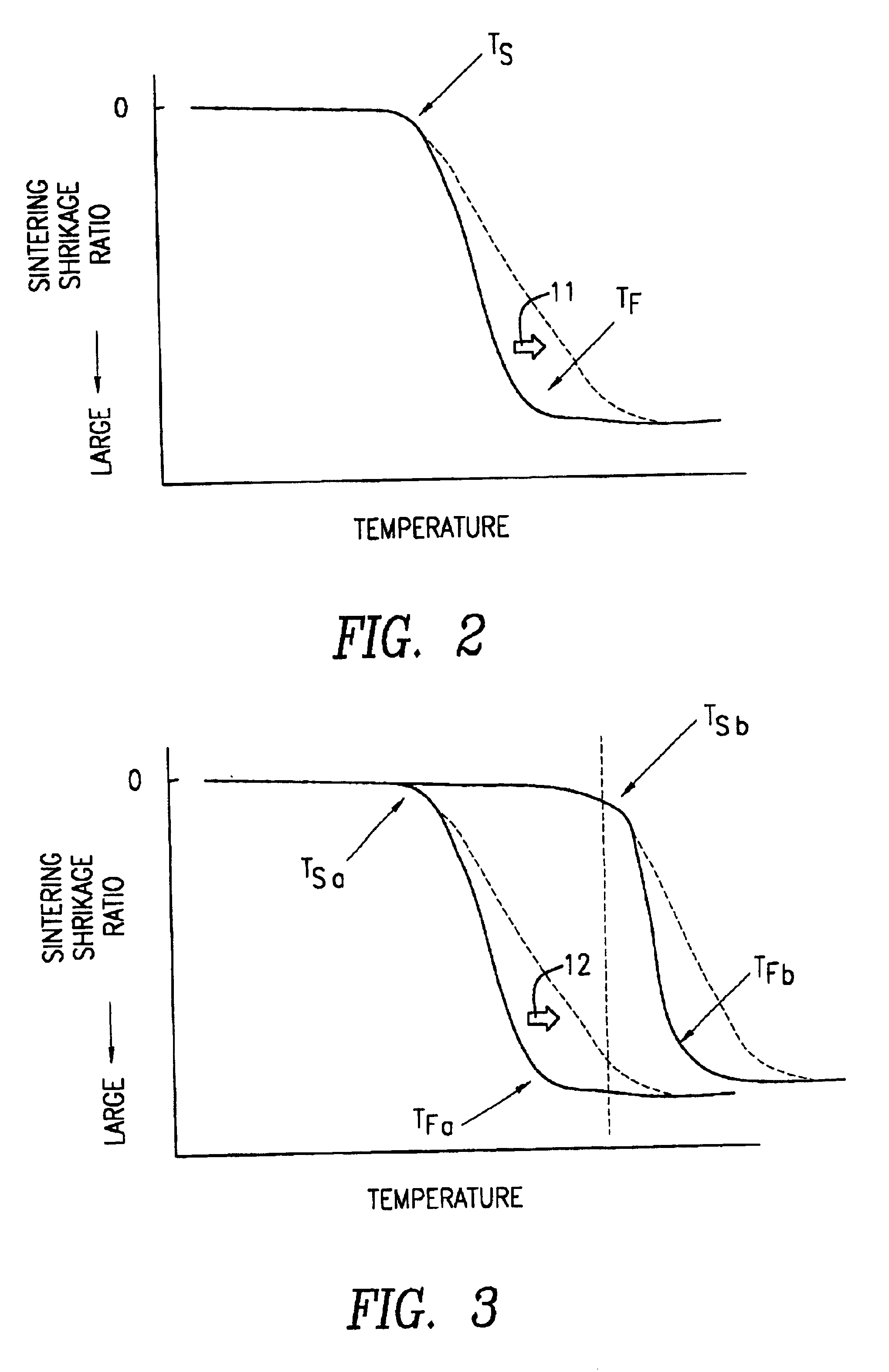

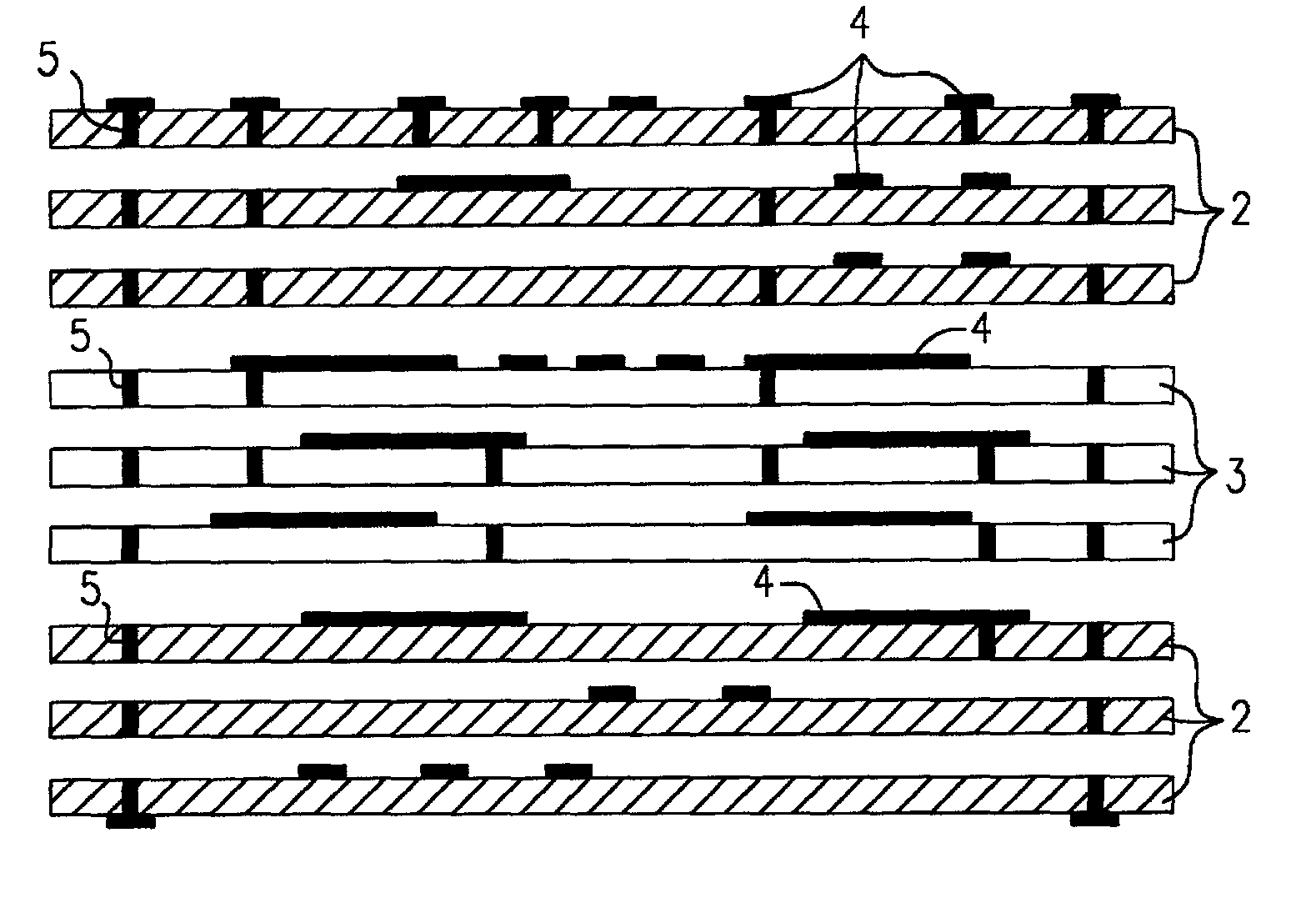

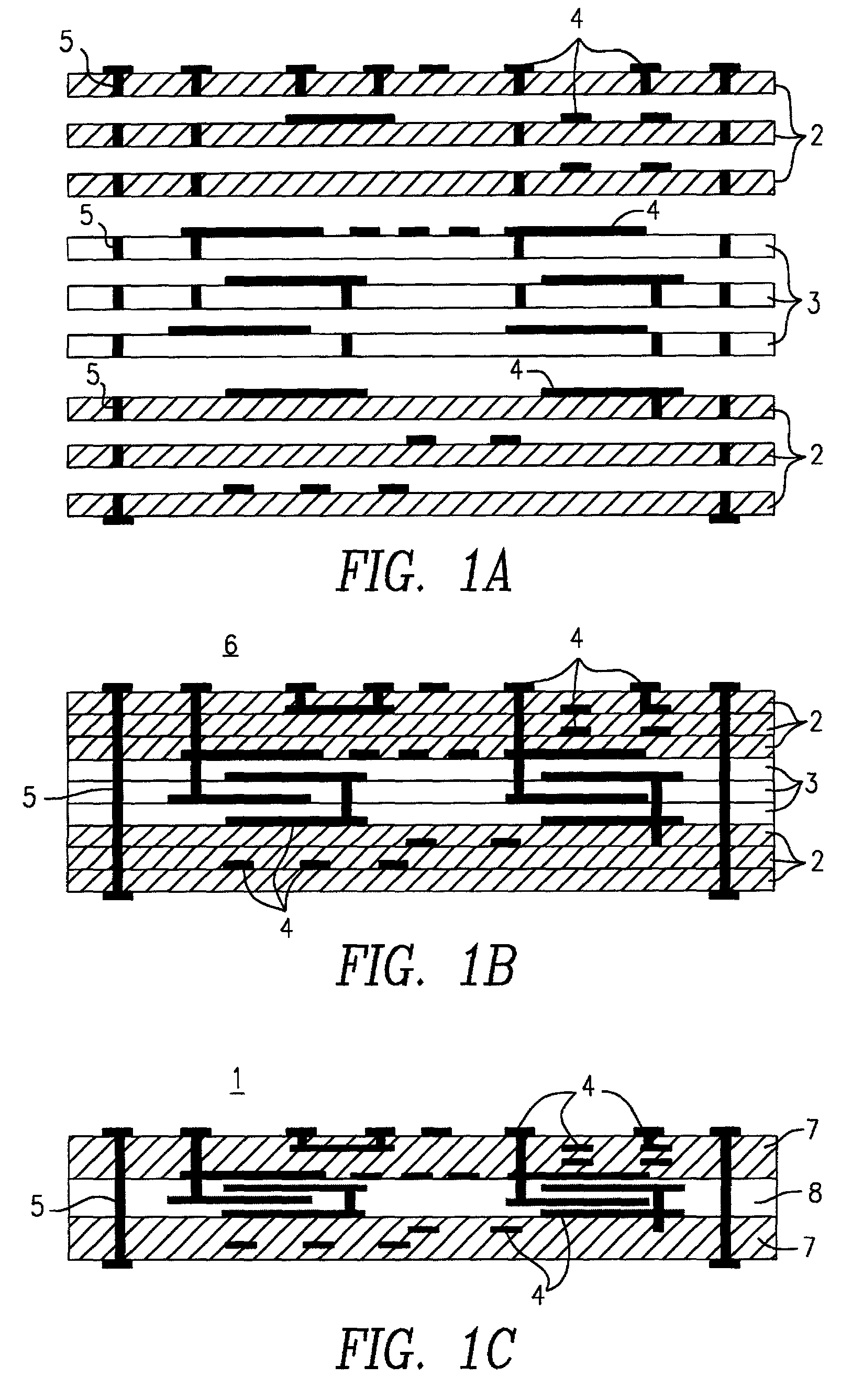

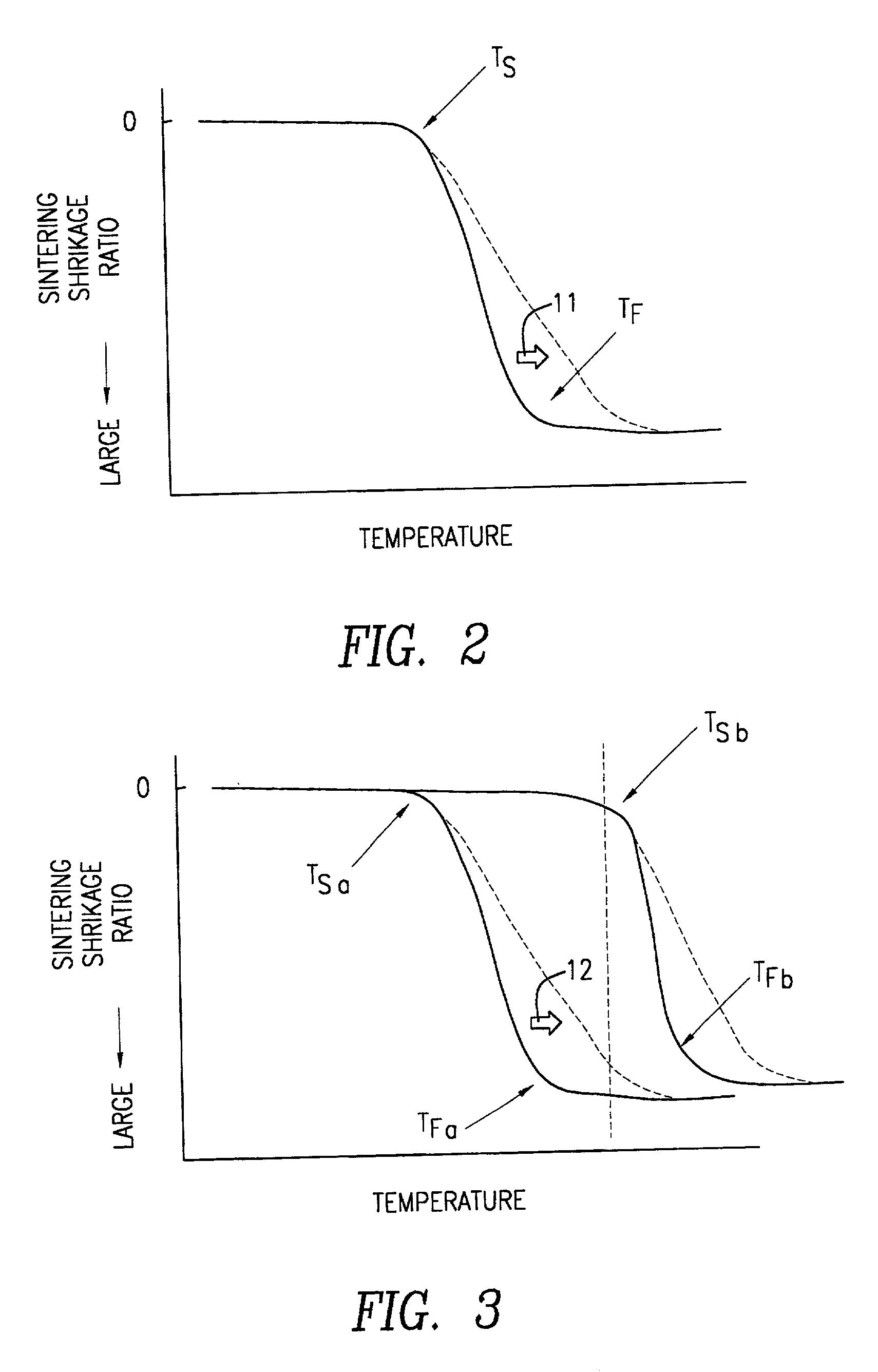

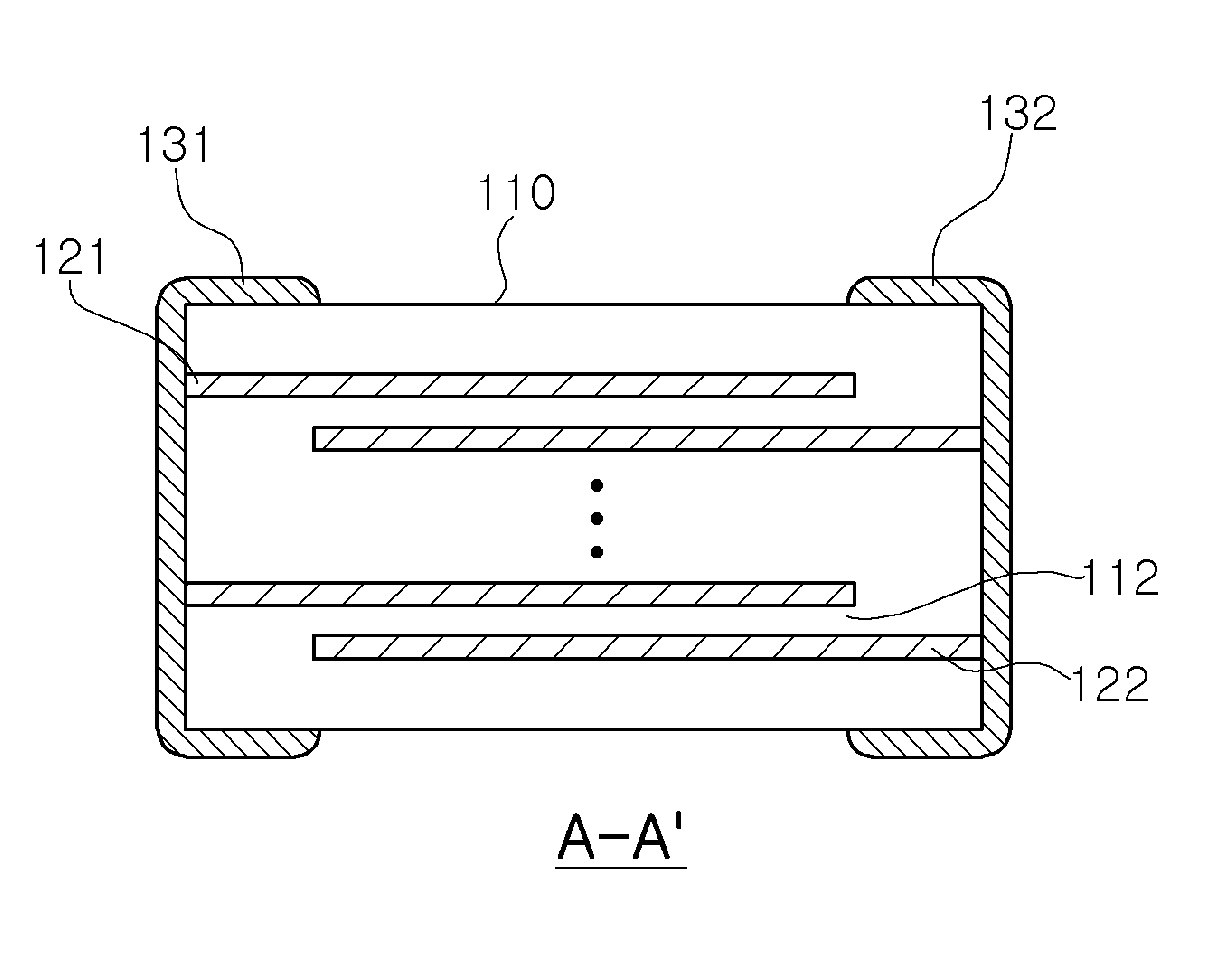

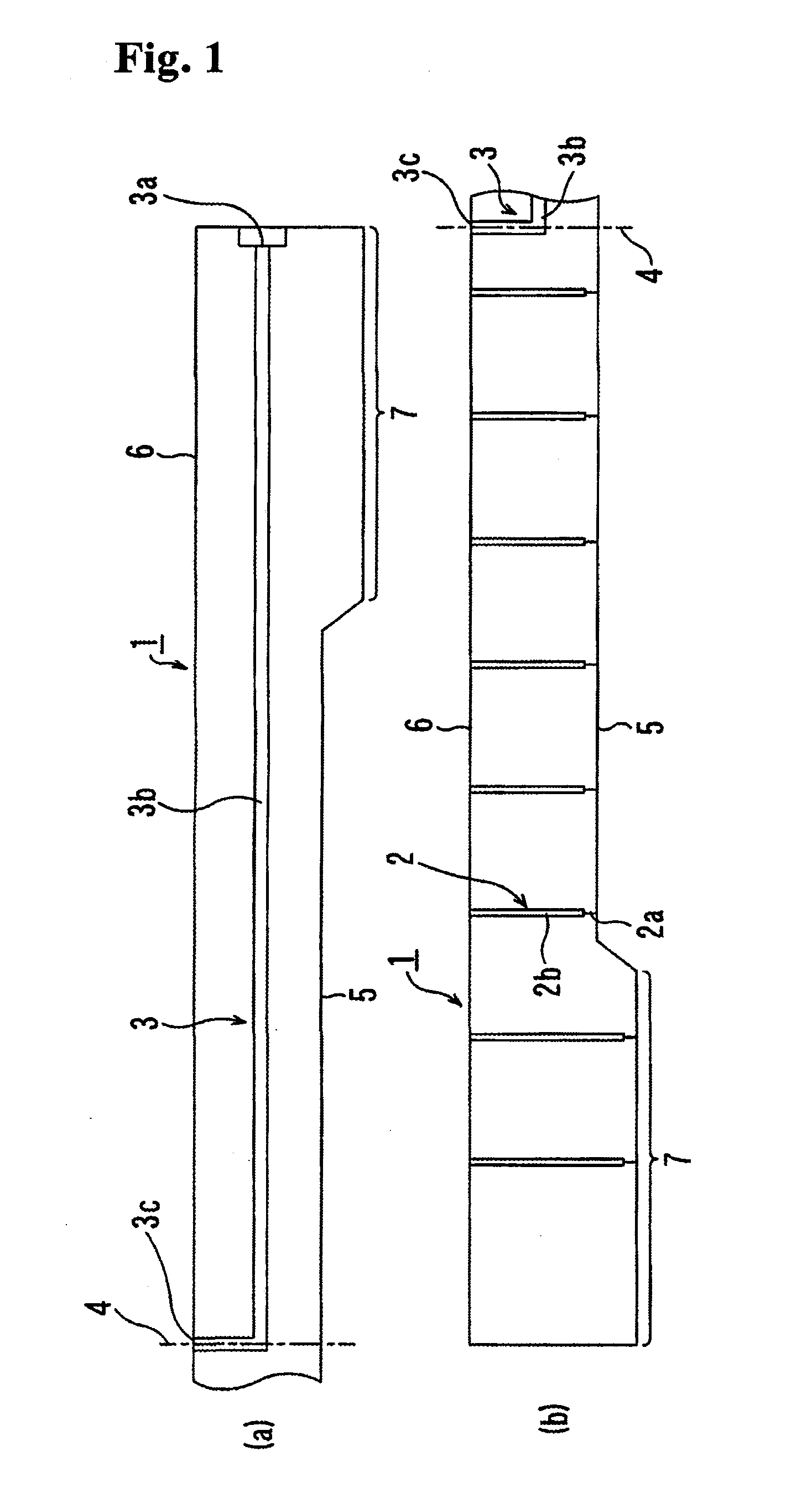

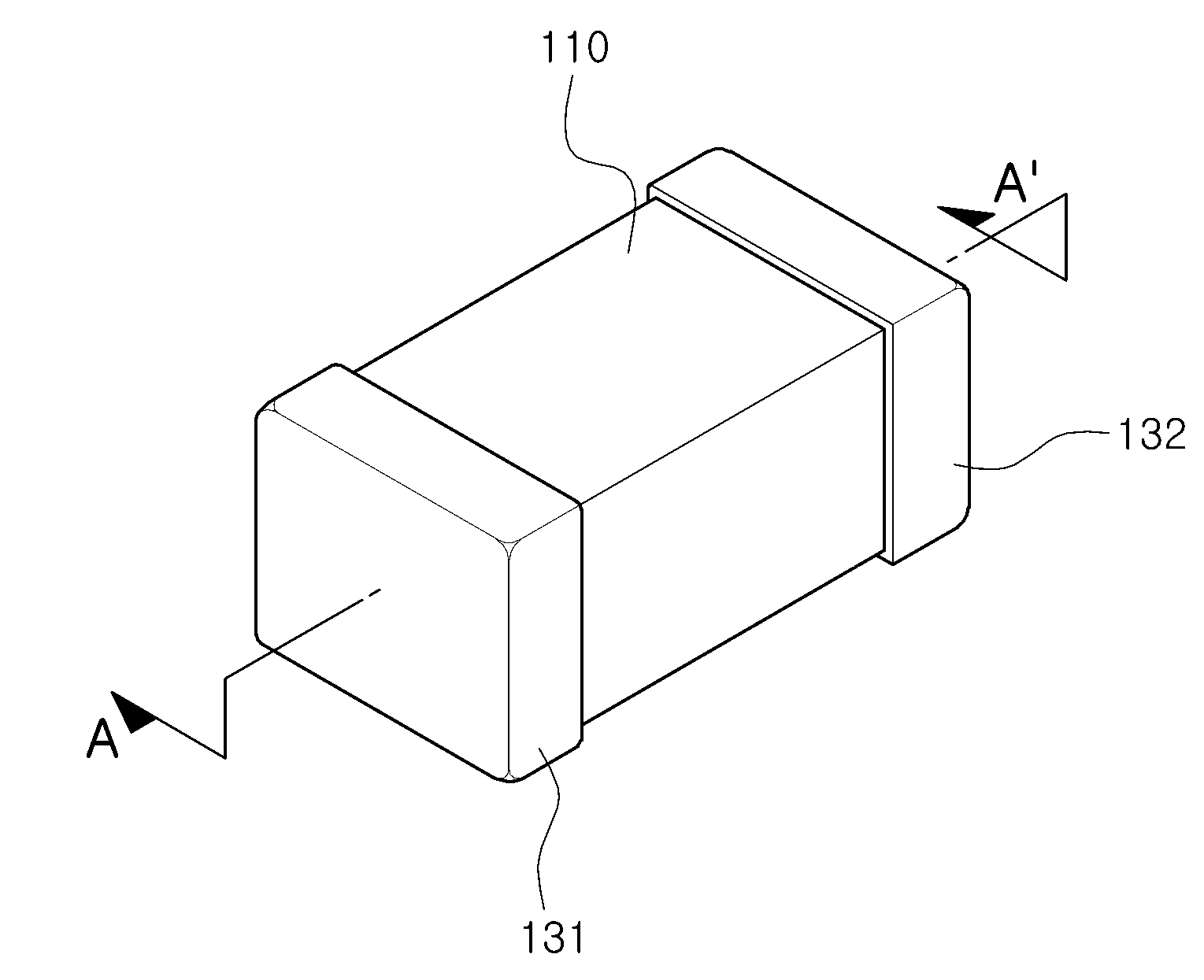

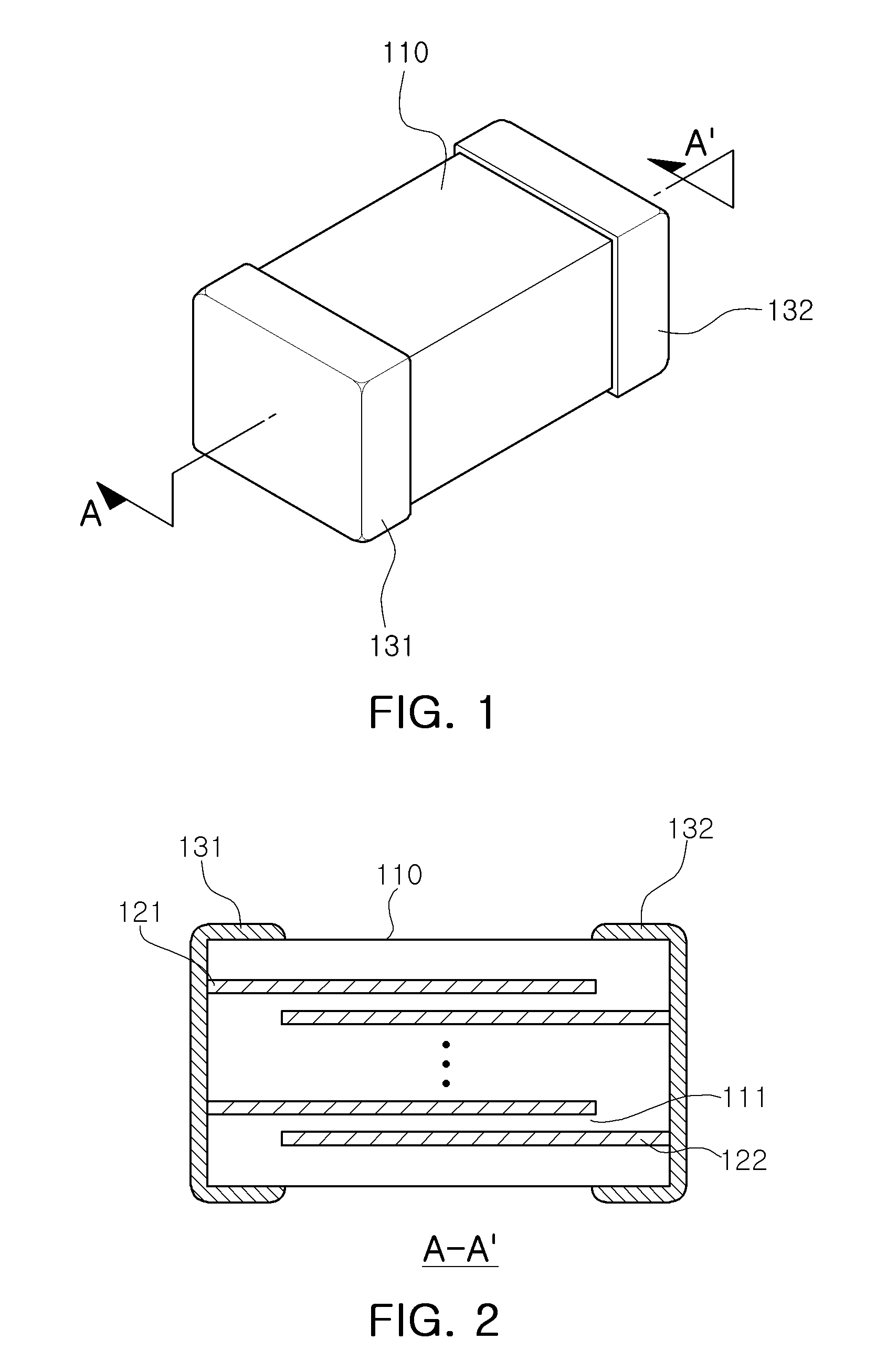

Glass ceramic multilayer substrate manufacturing method and glass ceramic multilayer substrate product

InactiveUS6797093B2Efficient solutionSemiconductor/solid-state device detailsSolid-state devicesMetallurgyGlass-ceramic

A glass ceramic multilayer substrate having a better flatness and a low sintering shrinkage ratio is made by sintering an unsintered laminated body formed by laminating together first and second green sheets capable of exhibiting different shrinking behaviors during a sintering process, thereby producing the desired glass ceramic multilayer substrate. When the shrinkage starting temperatures (°C.) of the first and second green sheets are TSa and TSb, the sintering process ending temperatures (°C.) of the first and second green sheets are TFa and TFb, and when the temperature rising speed is X° C. / min, the respective parameters satisfy (TFa+3X)<TSb or (TFb+3X)<TSA.

Owner:MURATA MFG CO LTD

Glass ceramic multilayer substrate manufacturing method and glass ceramic multilayer substrate product

InactiveUS20020189742A1Efficient solutionDead plant preservationArtificial flowers and garlandsMetallurgyGlass-ceramic

A glass ceramic multilayer substrate having a better flatness and a low sintering shrinkage ratio is made by sintering an unsintered laminated body formed by laminating together first and second green sheets capable of exhibiting different shrinking behaviors during a sintering process, thereby producing the desired glass ceramic multilayer substrate. When the shrinkage starting temperatures (° C.) of the first and second green sheets are TSa and TSb, the sintering process ending temperatures (°C.) of the first and second green sheets are TFa and TFb, and when the temperature rising speed is X° C. / min, the respective parameters satisfy (TFa+3X)<TSb or (TFb+3X)<TSa.

Owner:MURATA MFG CO LTD

Conductive paste composition, preparation of electrode using same and solar cell comprising same

InactiveCN101728438ALower impedanceReduce contact resistanceFinal product manufactureActive material electrodesConductive pasteContact impedance

The invention relates to a conductive paste composition, preparation of electrode using the same and solar cell comprising the same. The conductive paste composition comprises a mixing powder comprising a micro conductive metal powder with average grain size of below 0.5Mum and a conductive metal powder with average grain size of between 0.5 to 10Mum, an inorganic viscosity resin and an organic medium. The conductive paste composition can have high sintered density during preparing the electrode material and less sintering shrinkage, thereby providing lower electrode line impedance and contact impedance and increased efficiency of the solar cell.

Owner:DAEJOO ELECTRONICS MATERIALS CO LTD +1

Method for manufacturing light magnesia-alumina spinel insulation materials

The invention belongs to the technical field of insulation material manufacturing, in particular to a method for manufacturing light magnesia-alumina spinel insulation materials. The method includes the following steps: pouring magnesite powder or magnesia powder, alumina powder, water, foaming agents, monomers and cross linking agents successively into a stirring cylinder, and obtaining a foam slurry through mechanical stirring; adding initiating agents and catalytic agents into the foam slurry successively, and pouring the mixture into a mold rapidly; demoulding to obtain green bodies after slurry gel is solidified, and obtaining light magnesia-alumina spinel insulation materials though drying and sintering. The method has the advantages that magnesite or magnesia powder prepared by calcining magnesite which is abundant in our country is used as main materials, cracking problems caused by uneven sintering shrinkage are solved through cubical expansion during spinel petrifaction process, magnesia-alumina spinel insulation products with fixed forms, different shapes and sizes, low density and thermal conductivity and high strength are manufactured, the process is simple, the cost of used materials is low, and insulation materials are suitable for industrialized manufacture.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

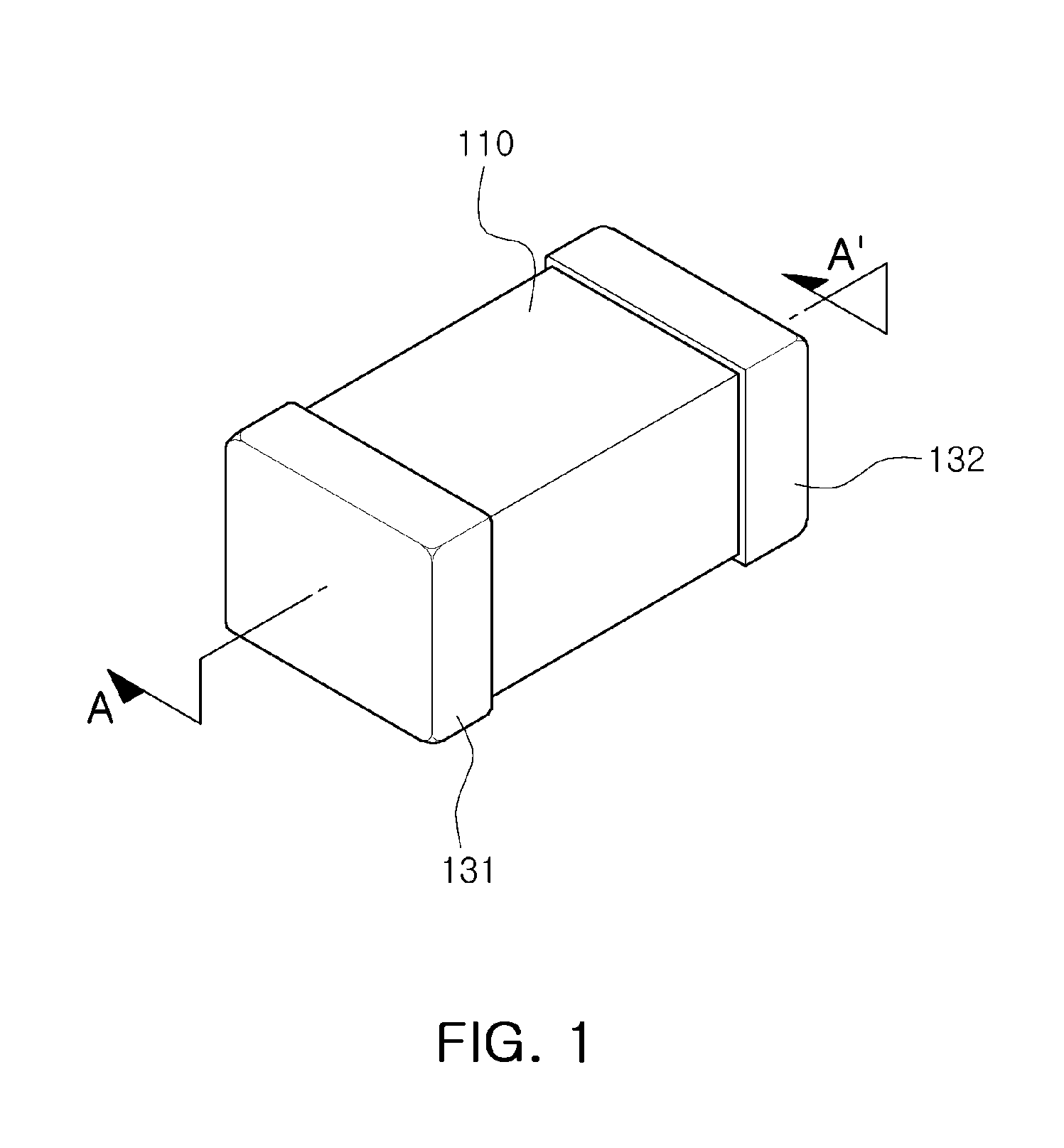

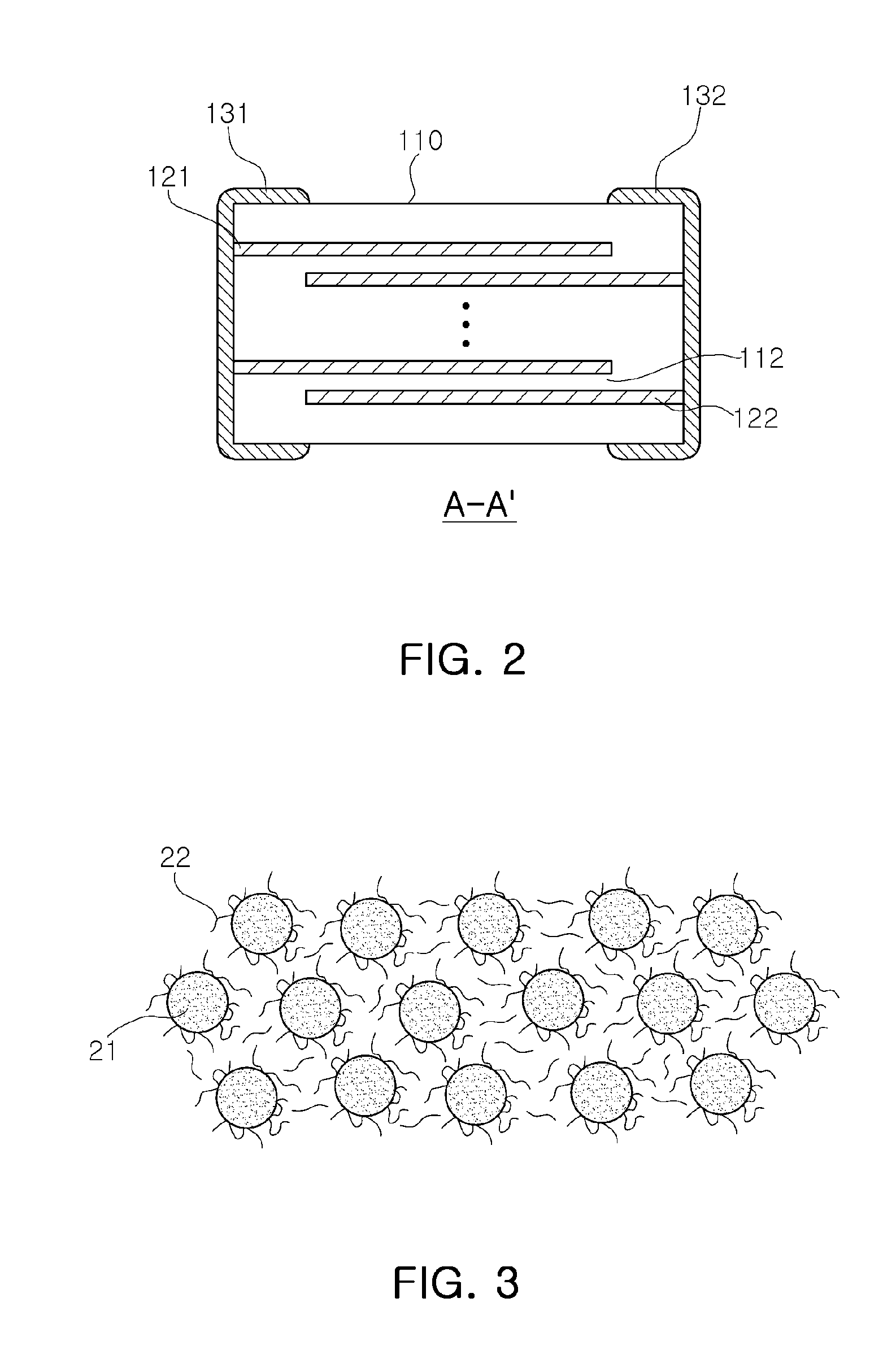

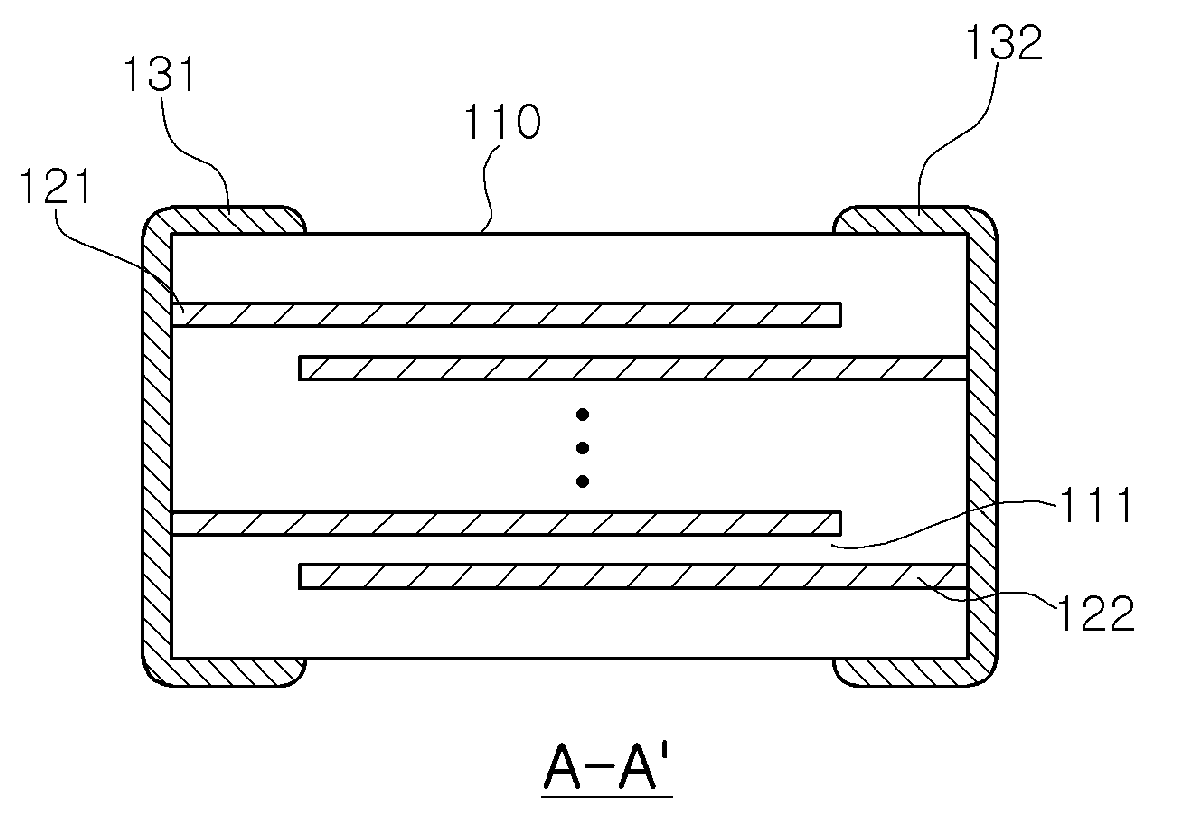

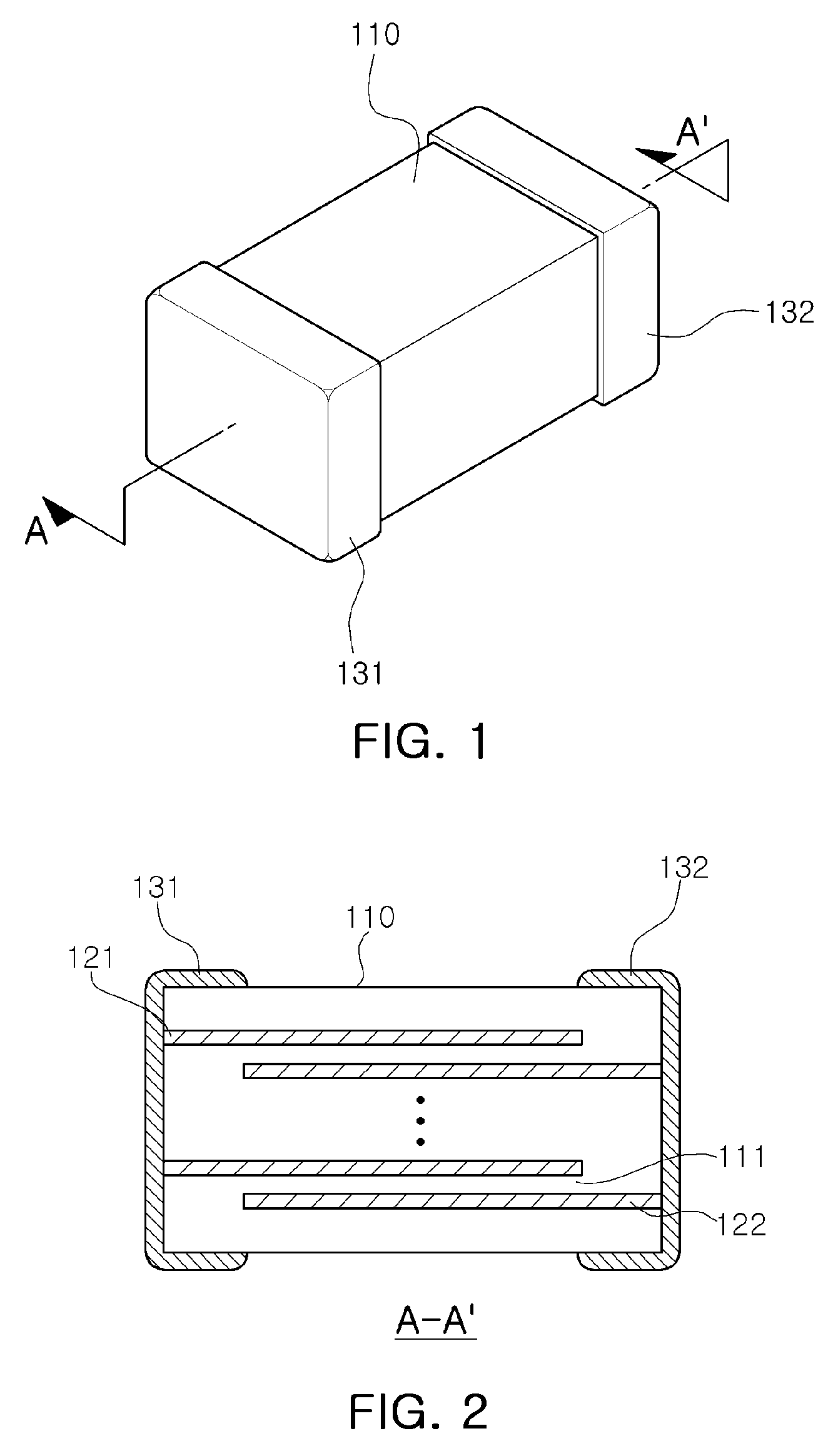

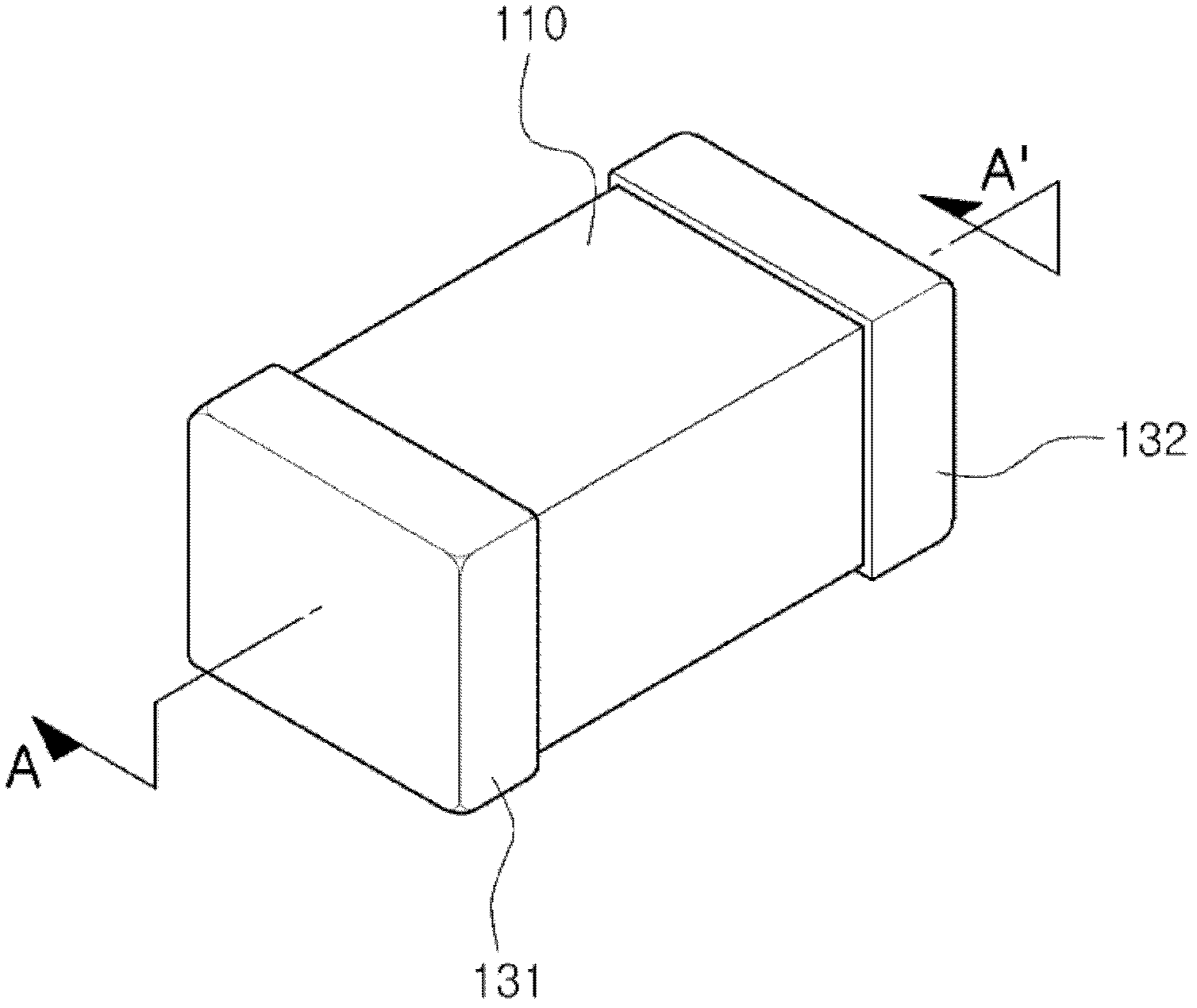

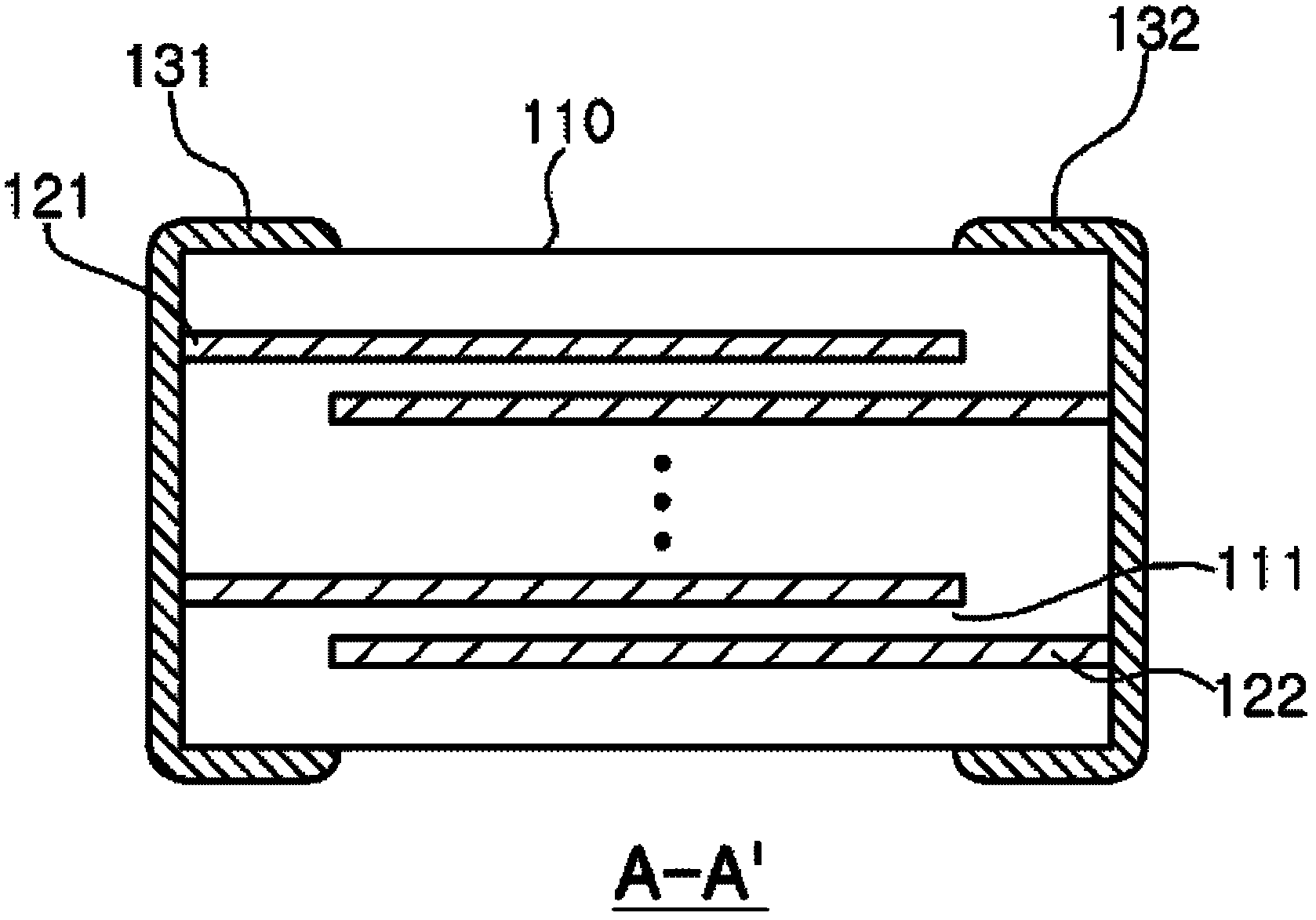

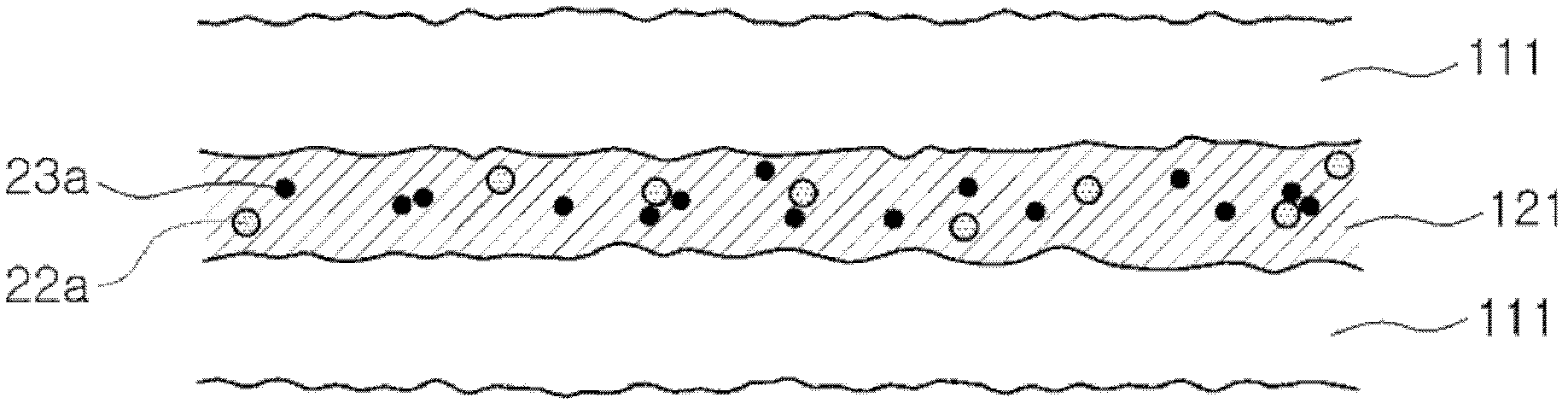

Conductive paste composition for internal electrode and multilayer ceramic capacitor including the same

InactiveUS20120327558A1Material nanotechnologyFixed capacitor electrodesConductive pasteCeramic capacitor

A conductive paste composition for an internal electrode, and a multilayer ceramic capacitor (MLCC) including the same are provided. The conductive paste composition for an internal electrode includes: 100 parts by weight of metal powder particles; and 0.1 to 10 parts by weight of carbon nano-tubes (CNTs). The conductive paste composition for an internal electrode may control sintering shrinkage of metal powder particles.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Solar cell front sliver paste adaptable to low-temperature sintering

ActiveCN103000255AReduce contact resistanceImprove compactnessNon-conductive material with dispersed conductive materialSemiconductor devicesPeak valueSolar cell

The invention relates to solar cell front sliver paste adaptable to low-temperature sintering. The solar cell front sliver paste adaptable to low-temperature sintering comprises, by weight percent, 55-90% of high tap density sliver powder, 1-5% of low temperature glass powder, 0.1-5% of sintering aid, 0-3% of inorganic additive, and the balance of organic carrier. The sintering aid is made from one or any of zinc, tin, cobalt, stadium and their compounds. The high tap density sliver powder is spherical or sphere-like and is 5.5g / cm<3> in tap density. The low-melting-point glass powder softens at 350-450 DEG C and is smaller than 2 micrometers in average particle size. Peak sintering temperature of the front sliver paste can be lowered. Production efficiency is improved while product performance is guaranteed. The solar cell front sliver paste adaptable to low-temperature sintering adapts to the future development trend of environment protection and energy conservation. In addition, the sliver paste is low in sintering shrinkage and has compact sliver film structure.

Owner:JIANGSU RUIDE NEW ENERGY TECH

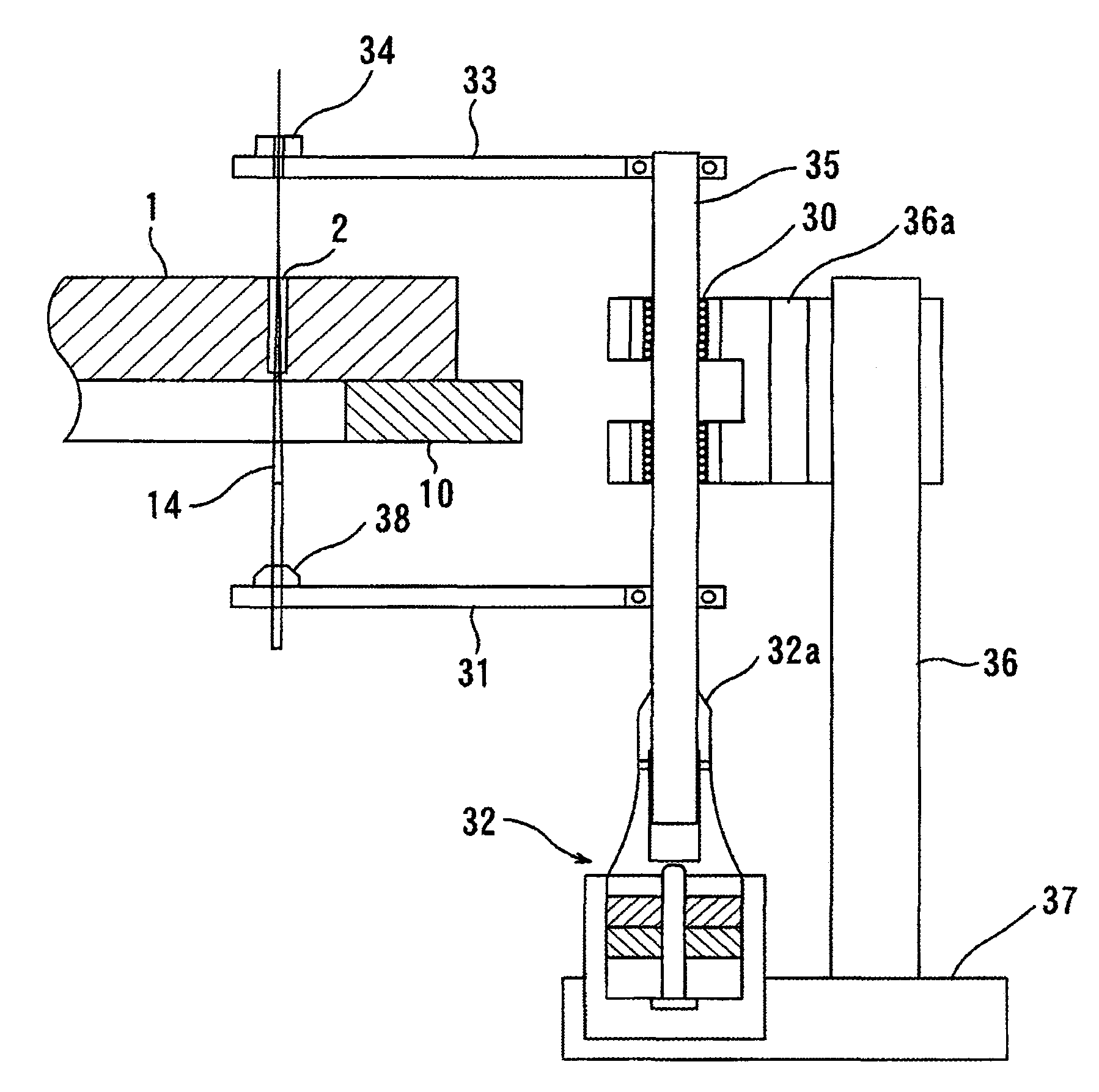

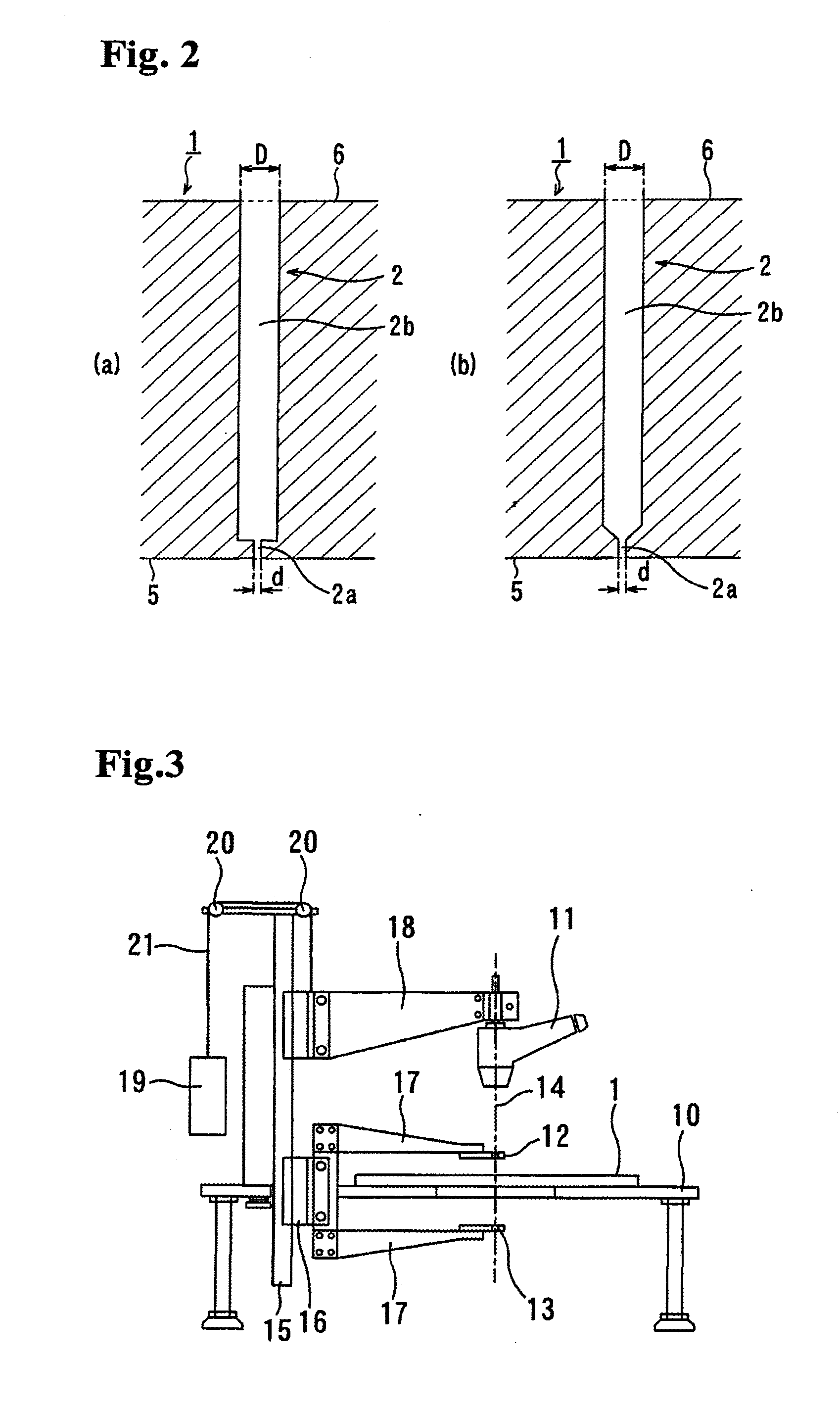

Shower Plate and Method for Manufacturing the Same

InactiveUS20090000742A1Prevent backflowQuality improvementRevolution surface grinding machinesSemiconductor/solid-state device manufacturingSurface roughnessHigh dimensional

Disclosed is a shower plate which is formed with a large number of process-gas blowing holes having a simple structure, high machinability and high dimensional accuracy without the risk of unevenness in blowing of a process gas and outbreak of particles, while ensuring constant quality and interchangeability. Through a press forming process, a powder for a ceramic material with a low dielectric constant is formed into a disc-shaped compact having dimensions determined in consideration of a sintering shrinkage value and a machining value. A gas inlet passage 3 and a large number of blowing holes 2 for a compact stage are bored in the disc-shaped compact, and then the disc-shaped compact is sintered. Subsequently, the gas inlet passage 3 and a main hole portion 2b in each of the blowing holes are subjected to grinding to have a surface roughness of Is or less. Further, a lapping wire having a taper-shaped end is inserted into an outlet port 2a of the blowing hole 2, and reciprocatingly moved while being slidingly displaced in such a manner that a portion of the lapping wire located in the outlet port 2a is gradually increased in wire diameter, so that the outlet port 2a is lapped to have a diameter of from 0.1 mm to less than 0.3 mm, a dimensional accuracy within ±0.002 mm, and a surface roughness of 1 s or less.

Owner:TOKYO ELECTRON LTD +1

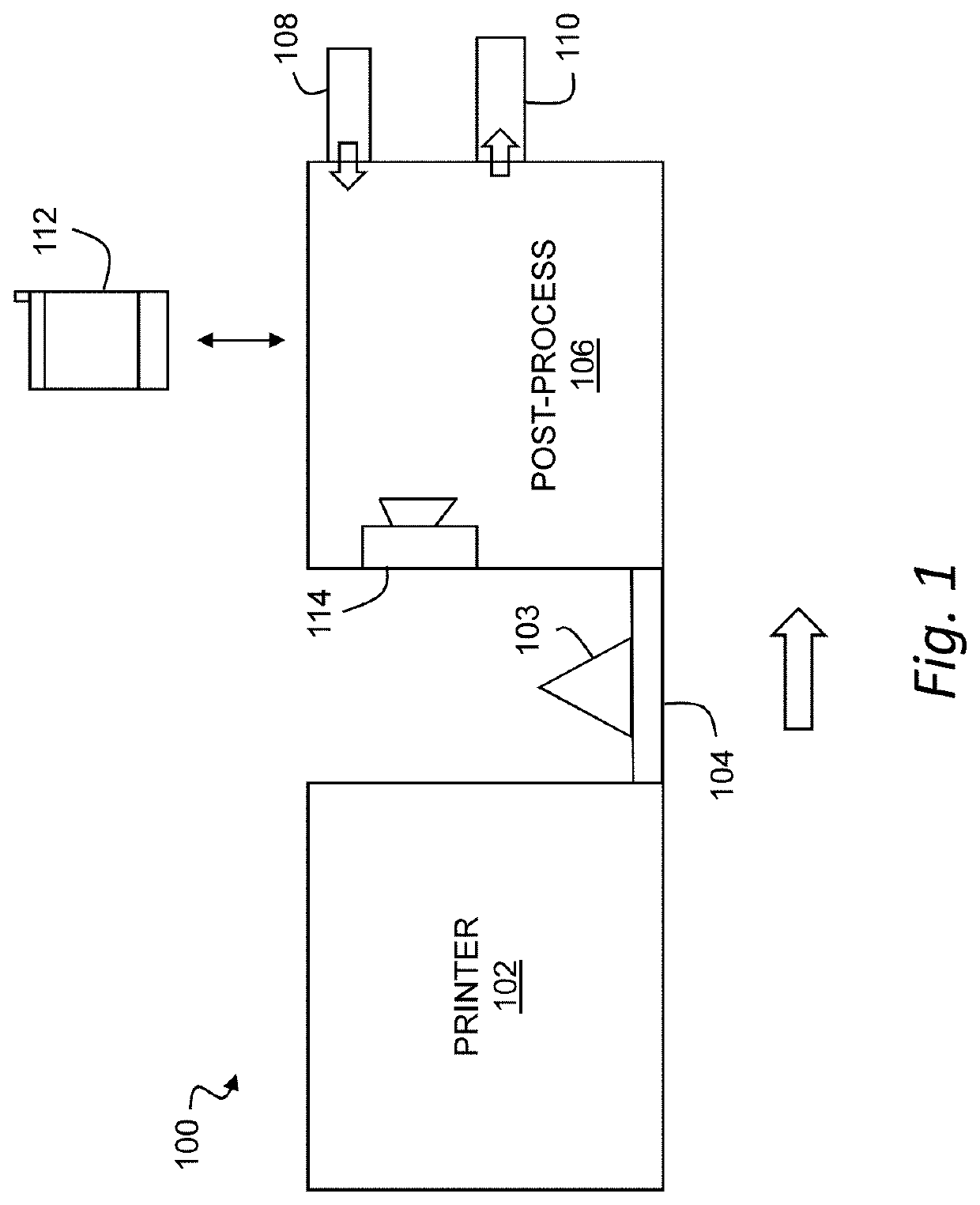

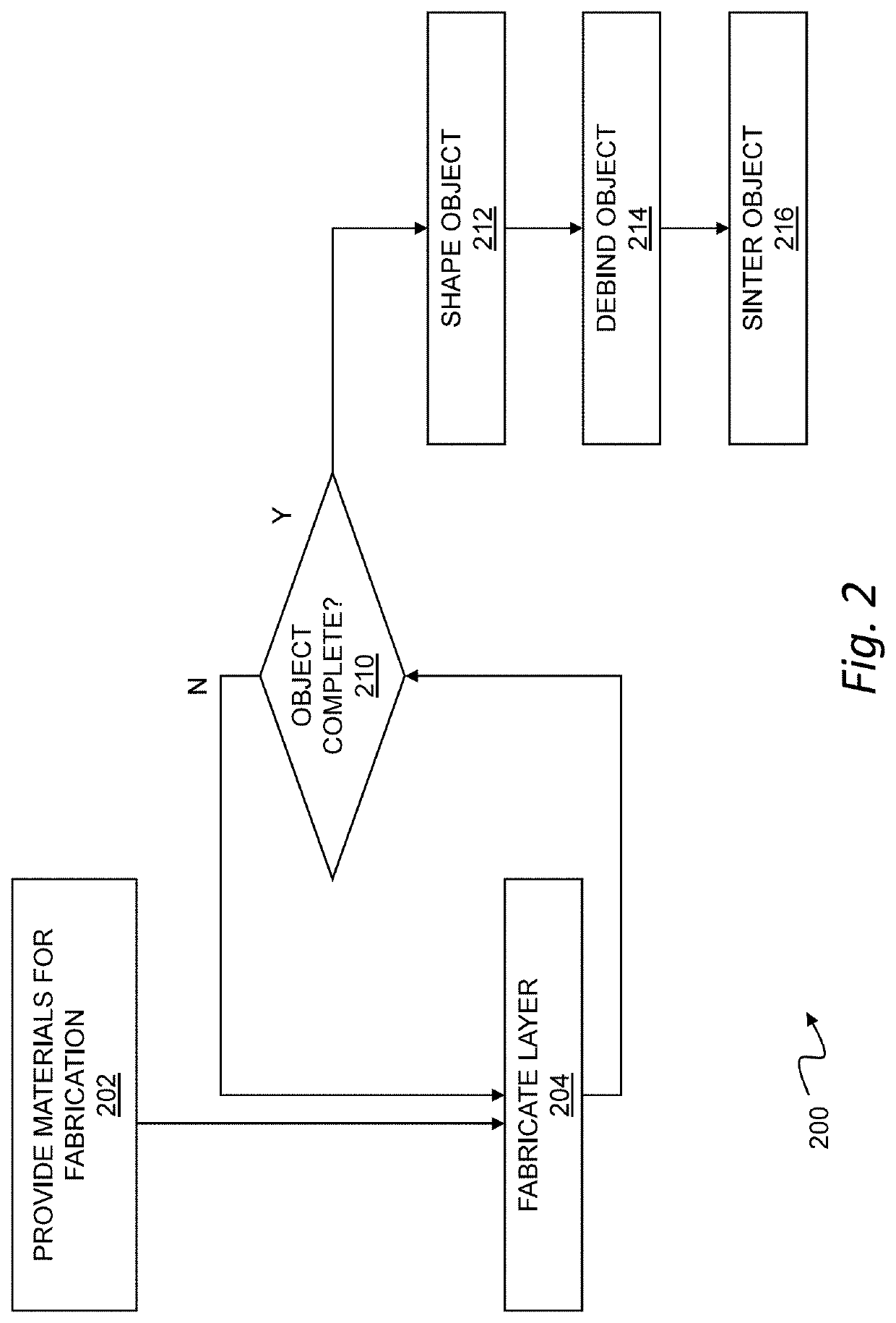

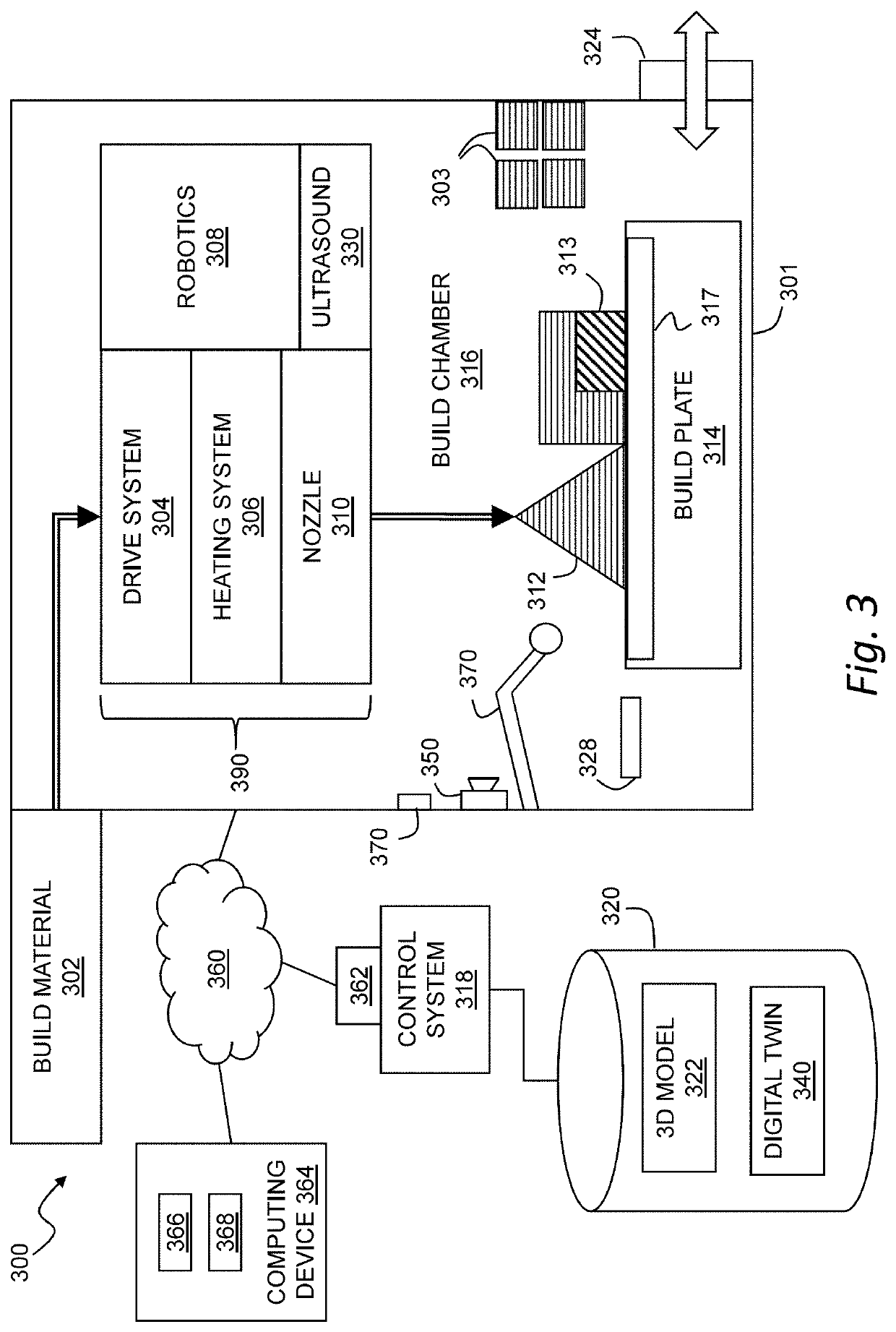

Shrinking interface layers

InactiveUS20190375014A1Additive manufacturing apparatusTransportation and packagingInterface layerSintering shrinkage

The present invention relates to a shrinking interface composition that allows for the accommodation of sintering shrinkage between two or more areas or sections of a three-dimensionally printed part and / or support structures for the part. The interface composition, which can be in the form of an interface layer, is used to prevent the fusing of the sections, parts or support structures to each other.

Owner:DESKTOP METAL INC

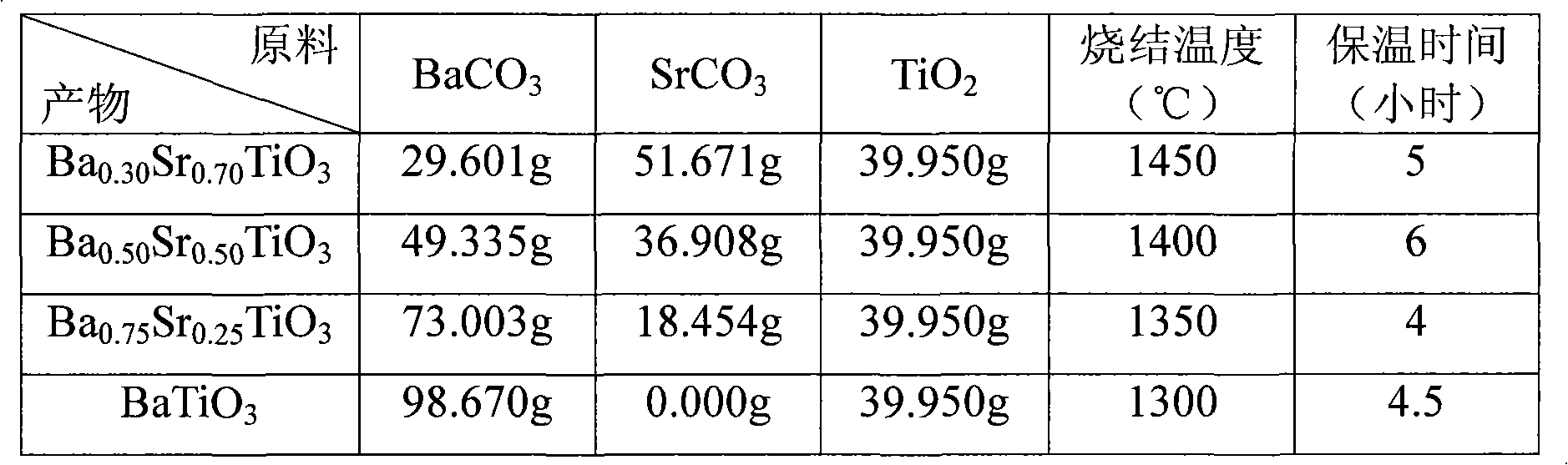

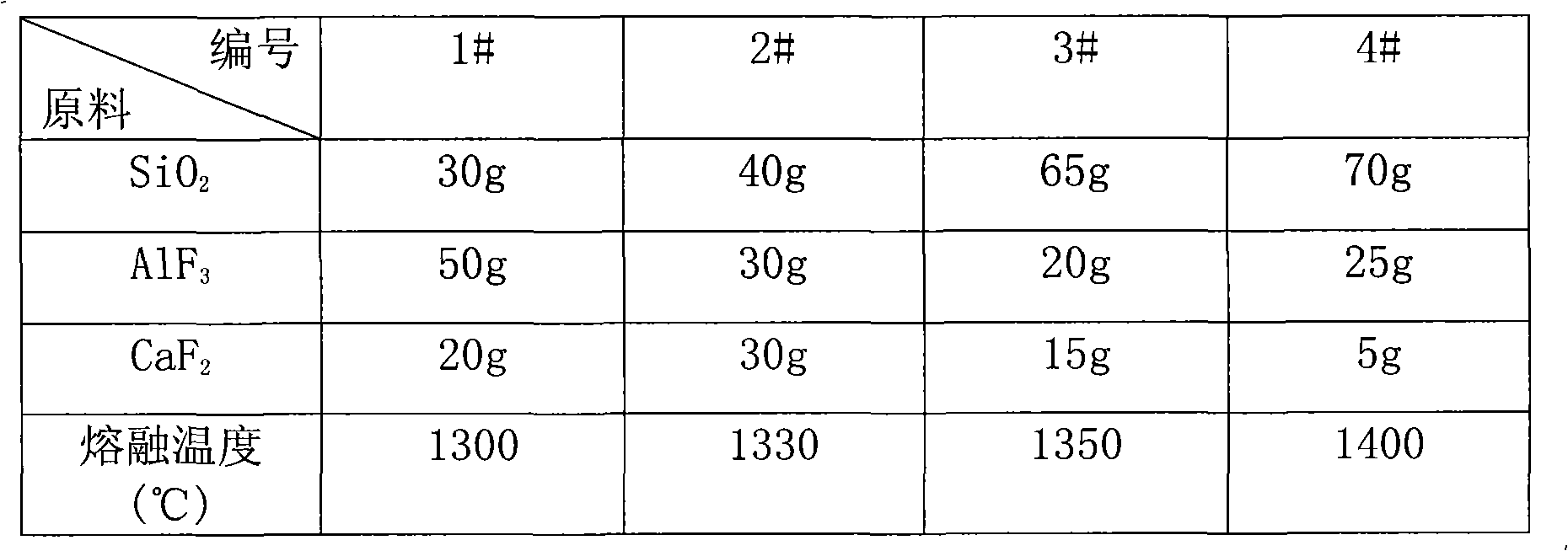

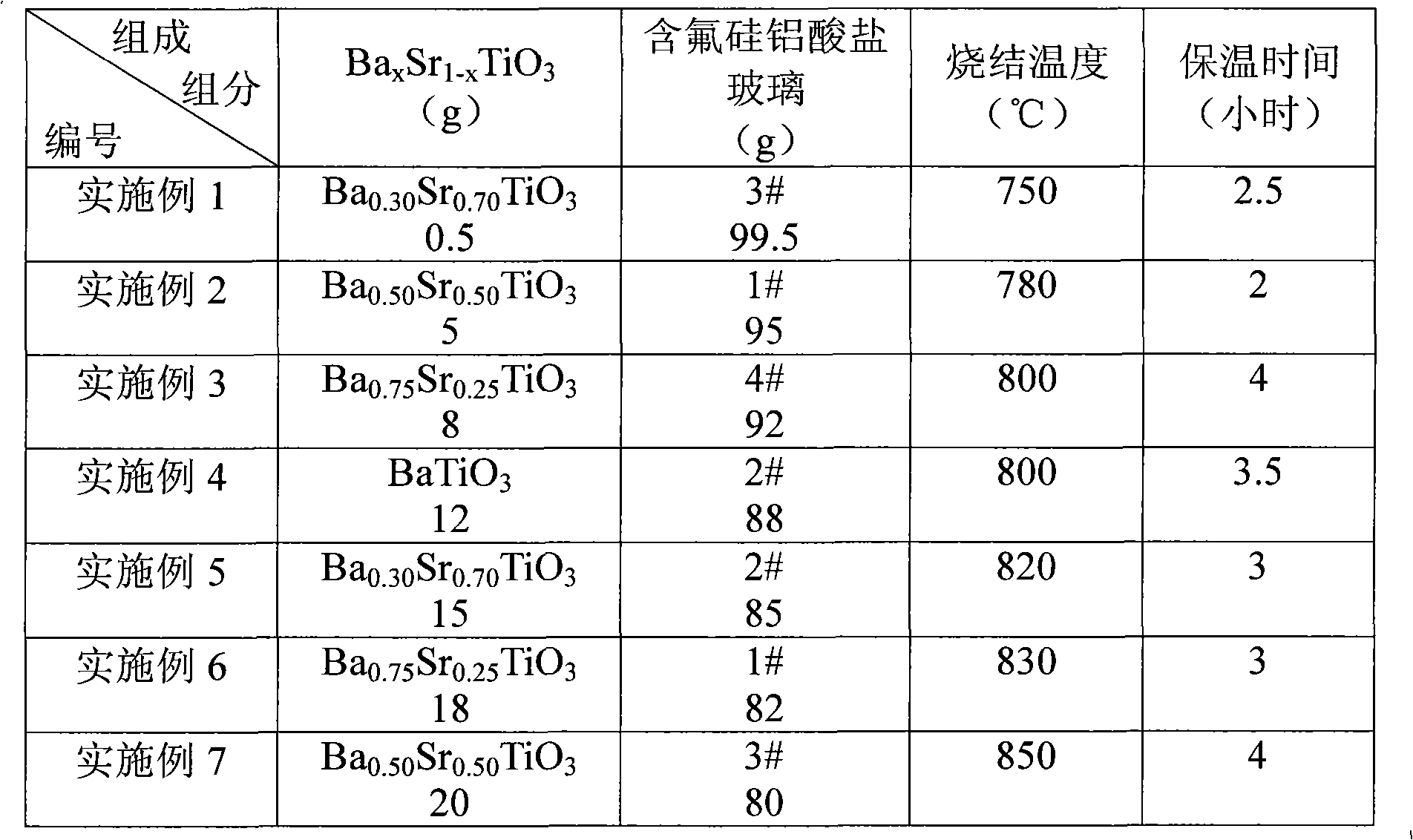

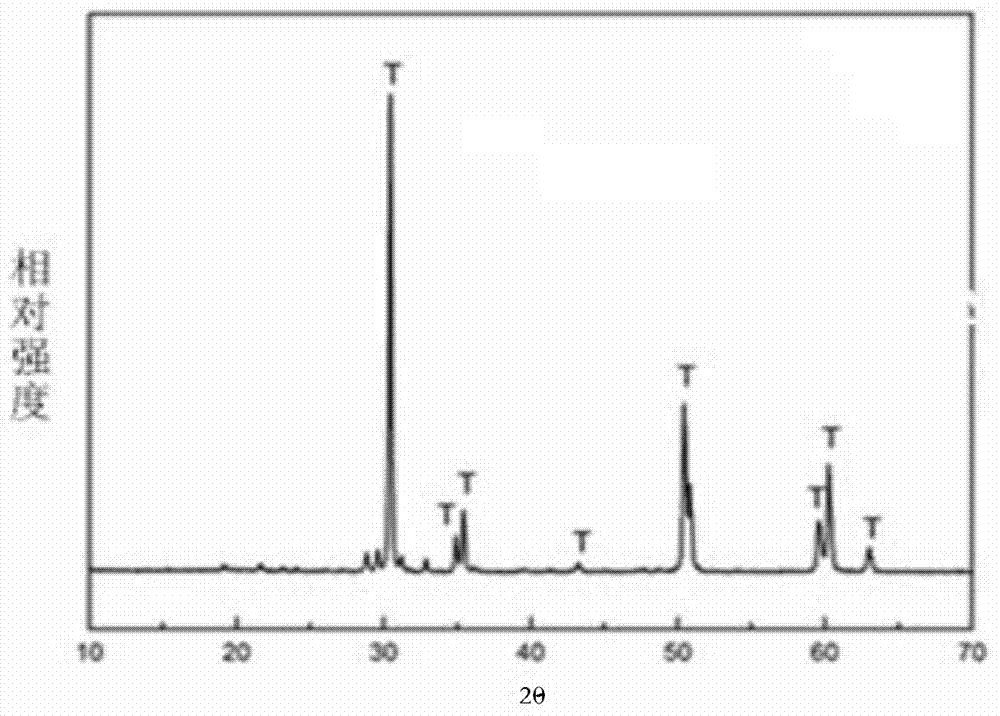

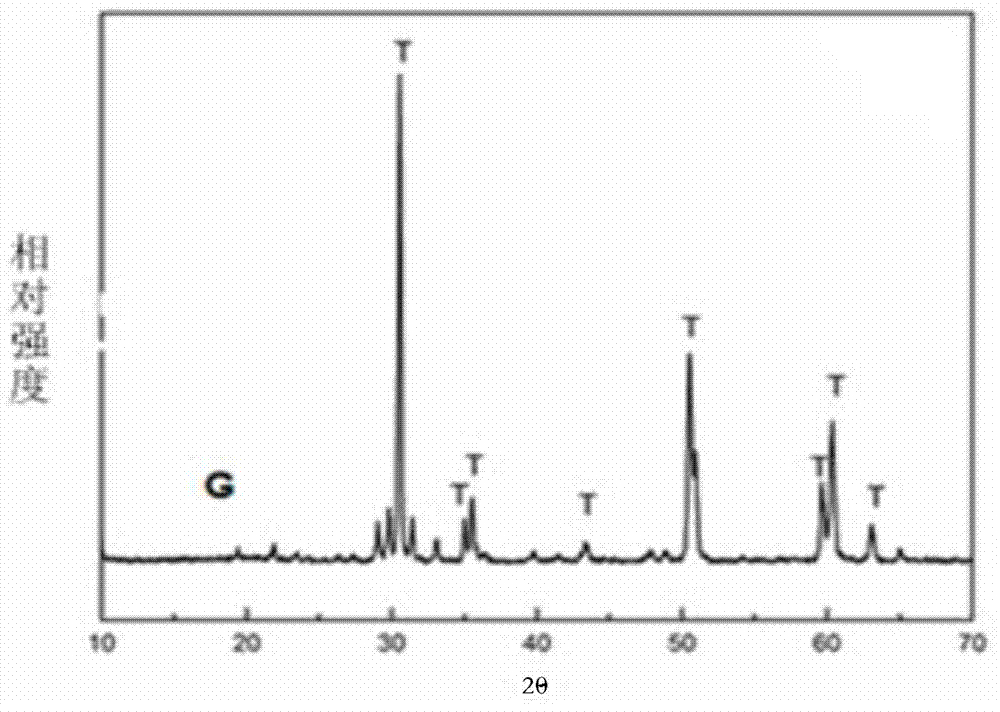

Low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and preparation method thereof

The invention discloses a low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and a preparation method thereof. The composite material is prepared from the following raw materials in percentage by mass: 0.5 to 20 percent of BaxSrl-xTiO3(x=0.3-1) and 80 to 99.5 percent of fluorinated aluminosilicate glass; wherein, the fluorinated aluminosilicate glass is prepared from the following raw materials in percentage by mass: 30 to 70 percent of SiO2, 20 to 50 percent of AlF3, and 5 to 30 percent of CaF2. After being mixed by the ratio, the components are added with ethanol or water, ball milled for 24h and dried to obtain low-temperature co-fired glass ceramic powder. The low-temperature co-fired glass ceramic composite material has the advantages that: (1) the sintering temperature is low (750 to 850DEG C) and the sintering shrinkage rate is 8 to 15 percent; and (2) the dielectric constant is adjustable from 8 to 50 (1GHz), and the dielectric loss is below 0.002 and the mechanical strength is higher. Consequently, the invention is applicable to low-temperature co-fired ceramic materials and electronic packaging materials.

Owner:TSINGHUA UNIV

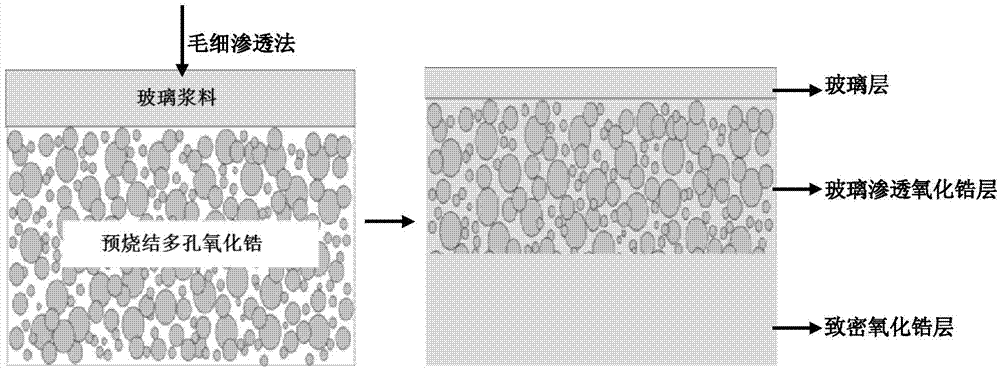

Preparation method of functionally graded zirconia ceramic material with dental glass part permeation

The invention discloses a preparation method of a functionally graded zirconia ceramic material of with dental glass part permeation. The preparation method comprises the specific steps: firstly preparing permeation glass with good wettability and good biology consistency, then pressing zirconia powder to green body by adopting a cold pressing molding method to be presintered to prepare a multihole presintered zirconia material, and finally permeating a glass sizing agent on the surface of multihole zirconia for dense sintering through capillary permeation technology. By utilizing the preparation method, under 1350 DEG C, glass permeation is carried out on zirconia by utilizing the capillary permeation technology, the wettable performances of permeation glass and zirconia are good, mutually blended compact structure is formed, zirconia does not have phase change, and sintering shrinkage rate is not increased significantly.

Owner:JINAN UNIVERSITY

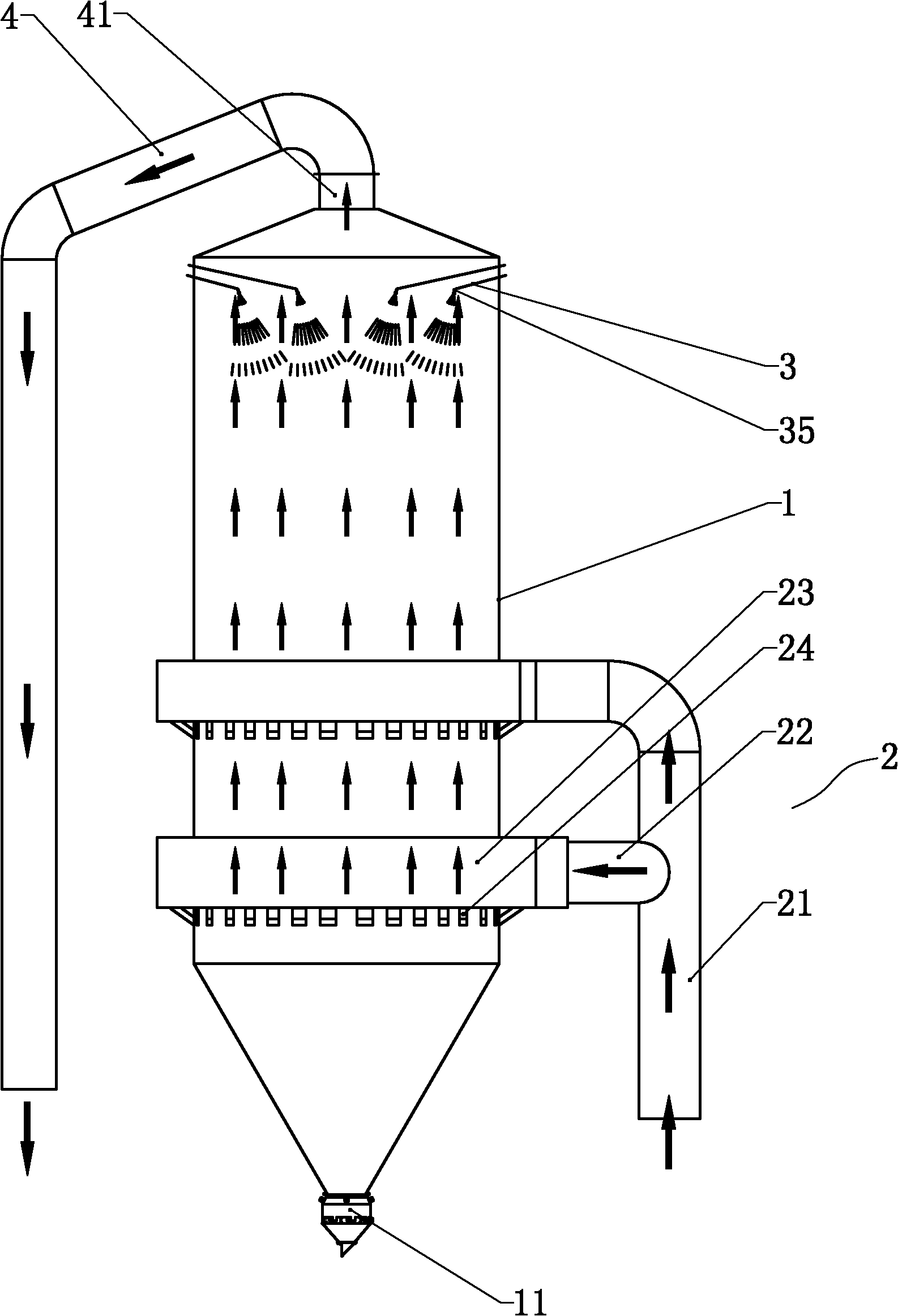

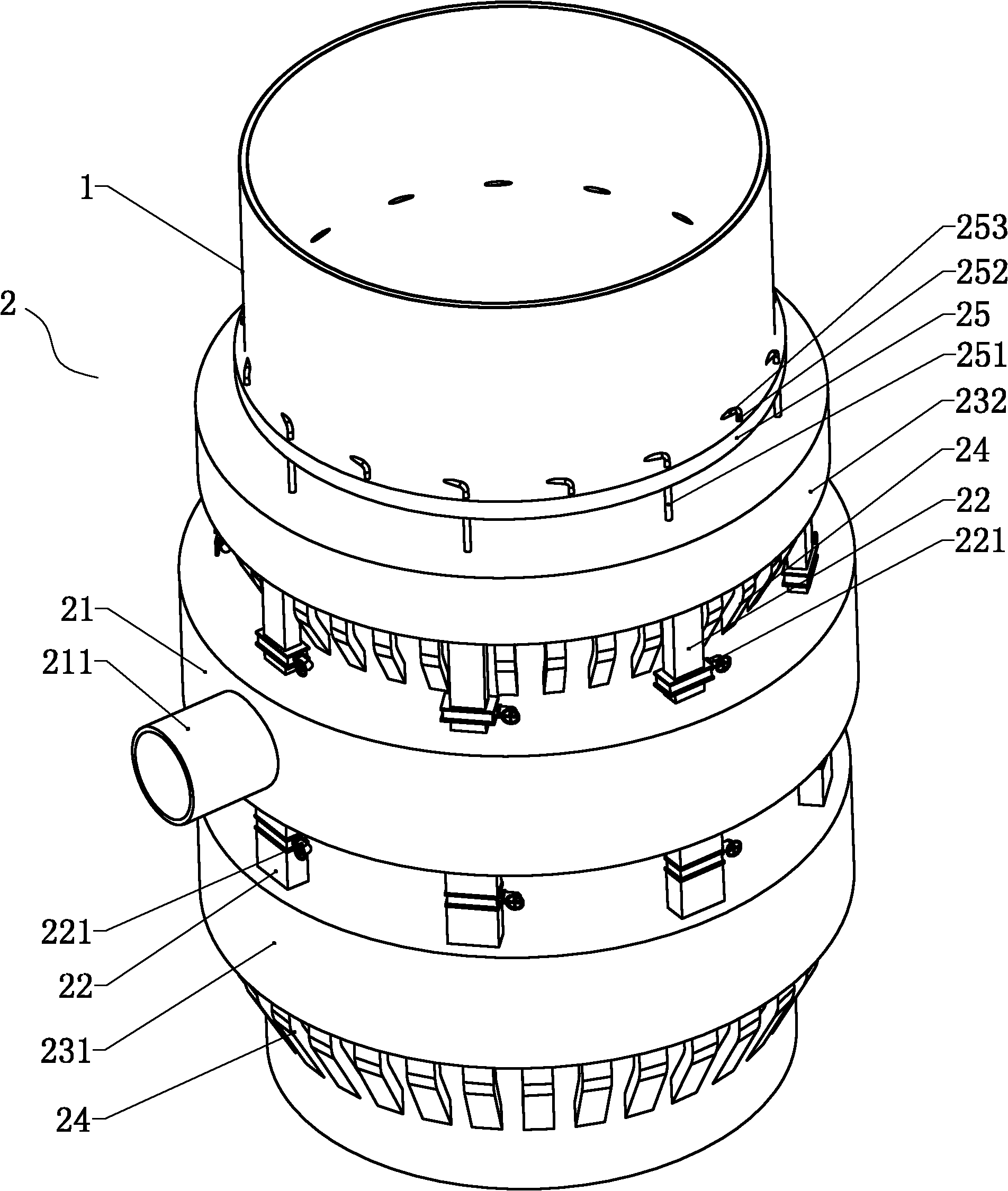

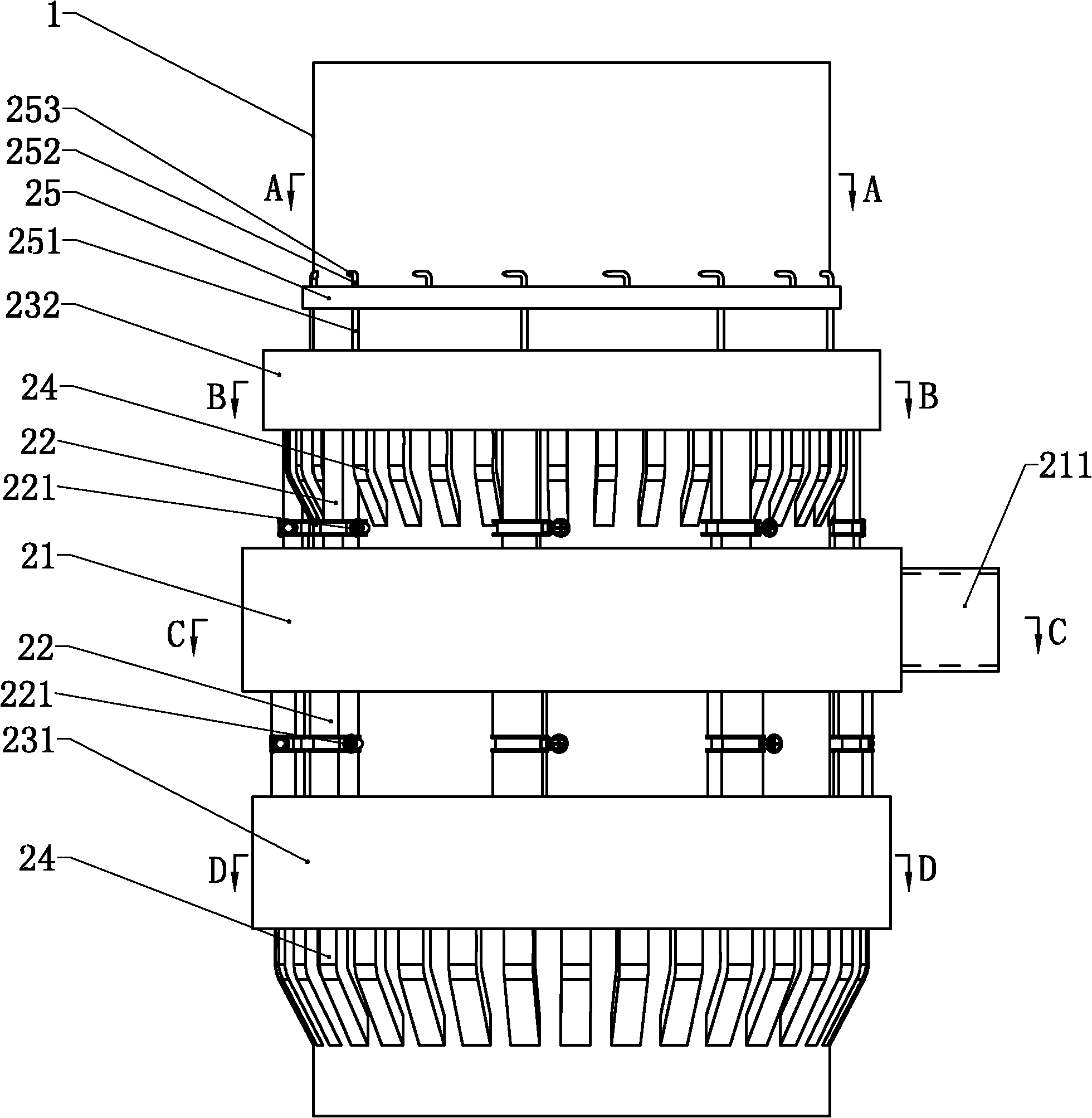

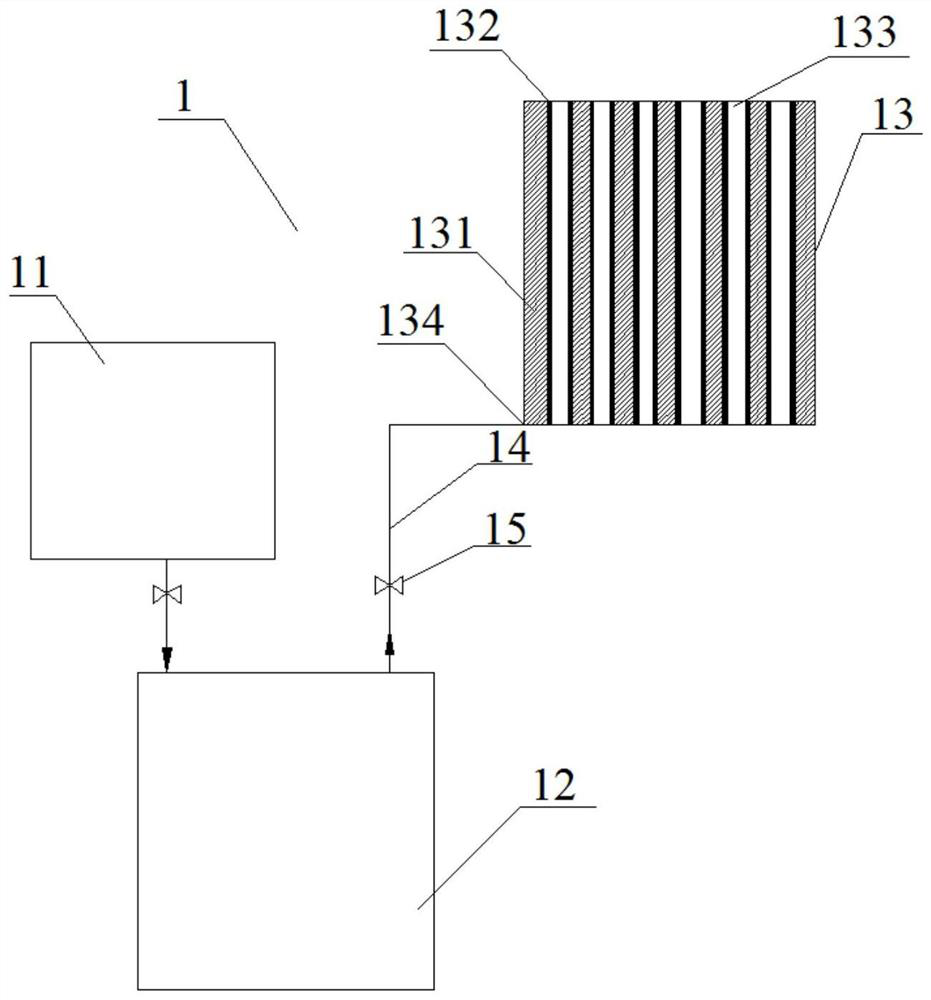

Spray drying tower for preparing powder

ActiveCN101979940AHigh strengthReduce energy consumptionDrying gas arrangementsDrying solid materialsCounter flowEngineering

The invention belongs to the technical field of spray drying, and discloses a spray drying tower for preparing powder. The spray drying tower comprises a tower body, wherein the tower body is provided with a hot air supply device, an exhaust device and a slurry-feeding atomization device; the bottom of the tower body is provided with a powder outlet; a plurality of tower air inlets of the hot airsupply device are formed on the inside walls of the middle part and the lower part of the tower body, and the temperature of the tower inlet hot air is gradually reduced from bottom to top; and the exhaust port of the exhaust device is formed on the upper part of the tower body. Through counter flow type structural design, the slurry is first contacted with the low-temperature hot air in the tower and then contacted with medium-temperature and high-temperature hot air in turn to generate solid spherical powder so as to effectively solve and improve the technical problems of the prior art. Thespray drying tower can make full use of waste heat, reduce energy consumption and reduce emission; and the ceramic powder treated by the tower can achieve the technical effects of improving the pressing forming efficiency, increasing the strength of the blank, reducing sintering shrinkage, reducing planed edge polishing quantity and the like. The spray drying tower is also suitable for other spray drying powder preparation processes.

Owner:佛山市科达机电有限公司

Low-temperature co-fired ceramic medium material and preparation method thereof

InactiveCN101823877AModerate sintering temperatureImprove performanceMetallic electrodeDielectric loss

The invention discloses a low-temperature co-fired ceramic medium material. The material consists of 1 to 16 weight percent of glass powder and 84 to 99 weight percent of Ba6-3x(Nd0.4Bi0.6)8+2xTi18O54, wherein the x is 0.5 to 1.5. The glass powder is at least one of the following two types of glass powder, namely glass powder B consisting of 30 to 50 mass percent of Li2CO3 and 5 to 20 mass percent of SiO2 and 40 to 60 mass percent of H3BO3 and glass powder C consisting of 15 to 40 mass percent of LiF and 60 to 85 mass percent of BaF2. In a preparation process, first, clinker is prepared; then, secondary preparation of the glass powder and the clinker is performed; and finally, sintering is performed. A BaO-Nd2O3-Bi2O3-TiO2 system is selected and a method of adding the glass powder as a sintering aid is adopted, so the material has the characteristics of sintering temperature below 900 DEG C, high dielectric constant and low dielectric loss, simultaneously has a wide sintering shrinkage range, and can be co-fired with a silver metallic electrode with high conductivity.

Owner:TIANJIN UNIV

Conductive paste composition for internal electrode and multilayer ceramic electronic component including the same

InactiveUS20130258551A1Material nanotechnologyFixed capacitor electrodesConductive pasteCeramic capacitor

There are provided a conductive paste composition for an internal electrode and a multilayer ceramic capacitor including the same. The conductive paste composition for an internal electrode includes metal powder; and chrome oxide (Cr2O3) or titanium oxide (TiO2) powder having a melting point higher than the melting point of the metal powder. The conductive paste composition for an internal electrode may increase a sintering shrinkage temperature of the internal electrode and improve connection properties of the internal electrode.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Grain-composition zirconia powder preparation and ceramic sintering method

The invention discloses a grain-composition zirconia powder preparation and ceramic sintering method. The method comprises the following steps: by adopting a co-precipitation method and taking water as a solvent under a weakly alkaline condition, synthesizing nano-scale and submicron-scale mixed particles with specific size distribution by one step at relatively low temperature; adding a fractional precipitation agent into the system, and controlling the proportions of the submicron particles and nanoparticles; drying and calcining the precipitate to obtain grain-composition zirconia powder with high crystallinity; adding a sintering aid; performing mixing, drying and dry pressing; and then sintering at 1,400-1,700 DEG C to obtain dense zirconia ceramic. The method disclosed by the invention is applicable to the grain composition of superfine powder and obtains close packing; and the biscuit density is increased, the sintering shrinkage is reduced, and the production technology is improved. The powder prepared by the method can be applied to the field of high-density zirconia preparation.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

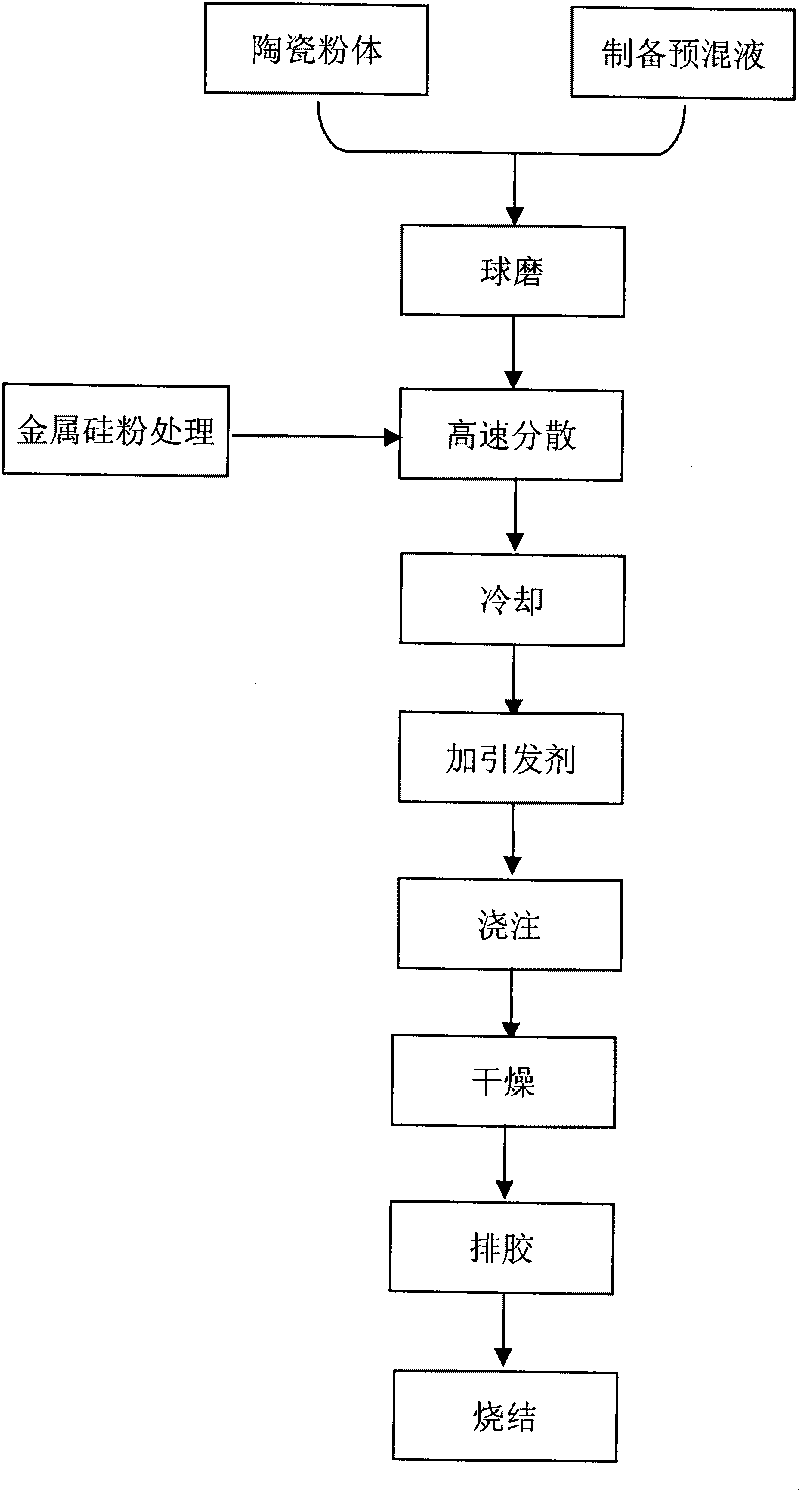

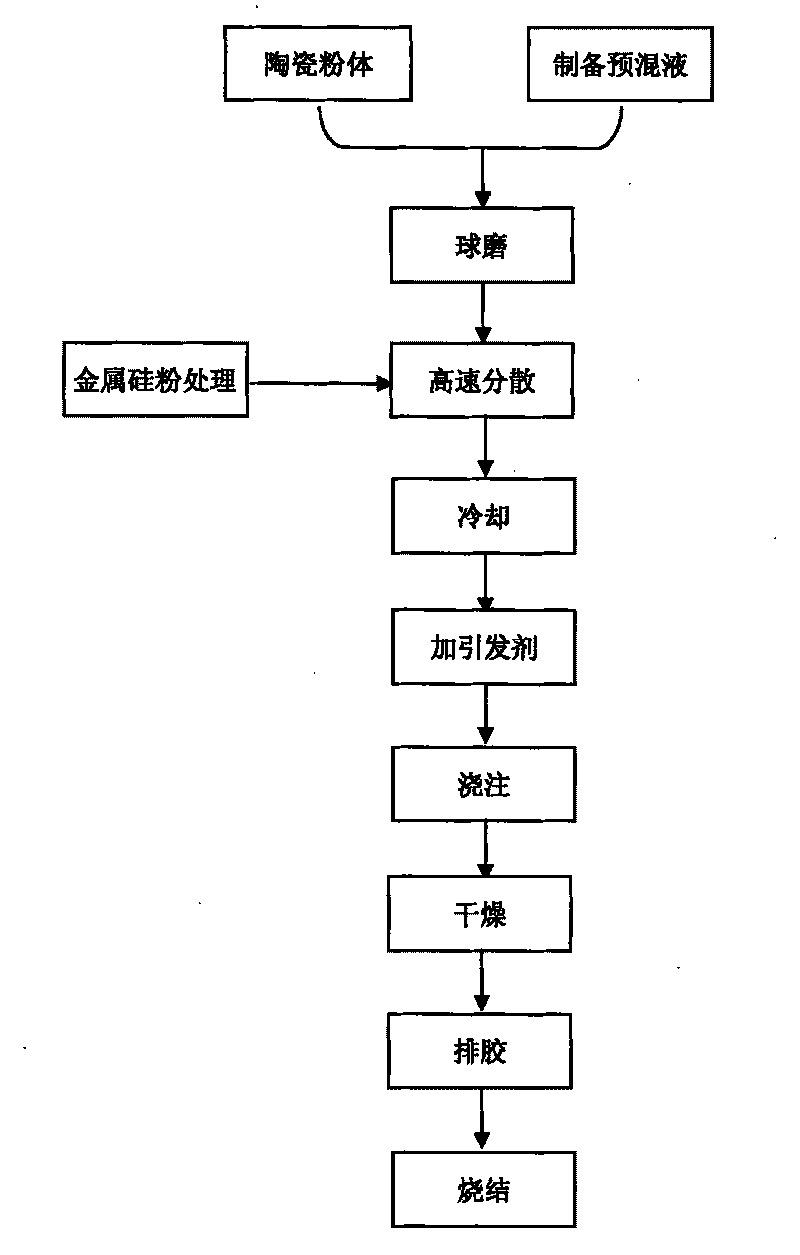

Gel-casting method of silicon nitride ceramic material containing silicon metal powders

InactiveCN101747054AGuaranteed dimensional accuracyReduce the amount of processingApparent densityShrinkage rate

The invention discloses a gel-casting method of a silicon nitride ceramic material containing silicon metal powders, which can be used for preparing silicon nitride ceramics through pressureless sintering and reaction sintering and comprises the following steps: (1) pretreatment of silicon metal powders, (2) slurry preparation, (3) casting molding, (4) drying, and (5) rubber removal and sintering. A gel system adopted is a polyacrylamide system, the solid content in the slurry is 65-77.7% by mass percent, the shrinkage rate of the sintering line of the obtained silicon nitride ceramic sintered body is 0.8-3.3%, the apparent density is 2.03-2.85g / cm<3>, and the intensity range is 136-378MPa. The gel-casting method is applicable to molding components with large dimension and complex shape and reaction sintering and preparing silicon nitride ceramics with low sintering shrinkage rate and low sintering temperature.

Owner:TIANJIN UNIV

Conductive paste composition for internal electrodes and multilayer ceramic electronic component including the same

InactiveCN102867564ANon-metal conductorsFixed capacitor electrodesConductive pasteElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

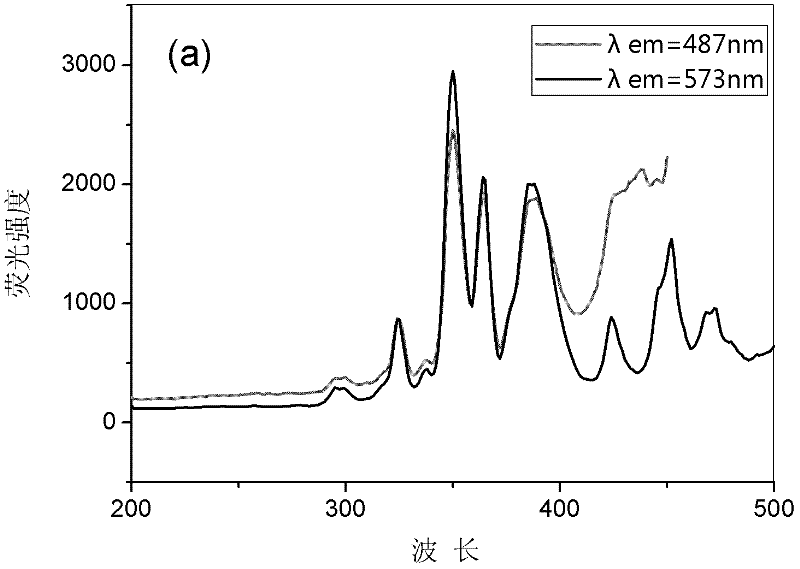

Low-temperature co-fired ceramic material emitting white light and preparation method thereof

The invention provides a low-temperature co-fired ceramic material emitting white light and a preparation method thereof. The ceramic material comprises the following components in percentage by mol: 10 to 20 percent of CaO, 20 to 30 percent of B2O3, 50 to 60 percent of SiO2, and 1 to 9 percent of optical activating agent ions. The invention also relates to the preparation method of the material, namely, a sol-gel method for preparing the low-temperature co-fired ceramic material emitting white light. The invention has the advantages that: 1, the preparation process is simple and advanced, the sintering temperature is low by adopting the Sol-gel method and is between 800 DEG C and 900 DEG C, the sintering shrink rate at the temperature is controllable between 13 percent and 17 percent, and a glass ceramic material has a flat and smooth surface, as well as higher strength; 2, the dielectric constant is adjustable between 4(1MHz) and 6 (1MHz), and the coefficient of dielectric loss is lower than 0.002; 3, the light emission intensity is high, the material can emit yellow and blue light under activation of ultraviolet light with the wavelength of between 320nm and 410nm, the white light obtained by mixing the blue light and the yellow light can be used for illuminating and displaying; and 4, based on the advantages, the low-temperature co-fired ceramic material can be applied to the fields of white light LED (Light Emitting Diode) lamps, integrated ceramic substrates and other electronic devices and semiconductors, as well as microelectronic packaging materials.

Owner:UNIV OF SCI & TECH BEIJING

Conductive paste composition for internal electrodes and multilayer ceramic electronic component including the same

InactiveUS20130009515A1Piezoelectric/electrostriction/magnetostriction machinesConductive materialVoltageSintering shrinkage

There are provided a conductive paste composition for an internal electrode and a multilayer ceramic electronic component including the same. The conductive paste composition includes: 100 moles of a metal powder; 0.5 to 4.0 moles of a ceramic powder; and 0.03 to 0.1 mole of a silica (SiO2) powder. The conductive paste composition can raise the sintering shrinkage temperature of the internal electrodes and improve the connectivity of the internal electrodes, and can improve the degree of densification of the dielectric layer, thereby improving withstand voltage characteristics, reliability, and dielectric characteristics.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Grout silver paste applied to thick film circuit

InactiveCN101872654AImprove conductivityReduce sintering shrinkageSemiconductor/solid-state device detailsSolid-state devicesSilver pasteFrit

The invention discloses grout silver paste applied to a thick film circuit, which consists of 60 to 90 weight percent of conductive powder, 1 to 6 weight percent of frit and 10 to 35 weight percent of organic carrier, wherein the total weight of the conductive powder, the frit and the organic carrier is 100 percent. The conductive powder is the powder of gold, silver, palladium, copper, nickel, tungsten and manganese alloys or the mixed powder of the powder; and the grain diameter of the conductive powder is controlled to be 1 to 10mu m. The grout silver paste applied to the thick film circuit prepared by the invention has the characteristics of high electrical conductivity, low sintering shrinkage rate and good matrix matching performance and the using requirement of a grout process of the thick film circuit is met in the using process.

Owner:IRICO

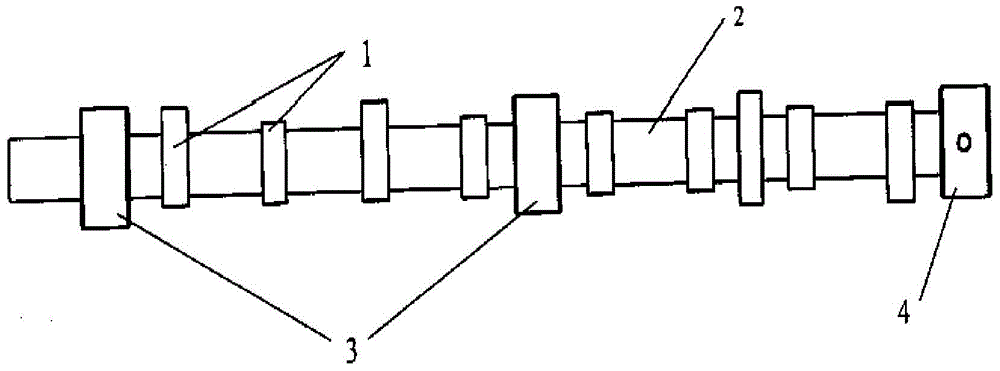

Manufacturing method for engine assembly type camshaft

InactiveCN104625583AFlexible control of material compositionReduce assembly processCamsManufacturing technologyCopper foil

The invention discloses a manufacturing method for an engine assembly type camshaft, and belongs to the field of manufacturing technologies of engine parts and components. Cam pieces of the camshaft are green bodies formed by pressing through powder metallurgy, gears, shaft necks and other assembly parts are powder metallurgy pressed green bodies or machined semi-finished products, a base body shaft is a hollow seamless steel tube and is connected with the assembly parts, then positions and angles of all components are guaranteed through key grooves or positioning clamps, by the utilization of the sintering shrinkage characteristic of powder metallurgy material, the powder metallurgy green bodies and the base body shaft are sintered and welded together at high temperature, and the mode that copper foil and other brazing filler metal are added is used for brazing the machined assembly parts and the base body shaft together, so that the assembly technology is completed. According to the manufacturing method for the camshaft, the powder metallurgy sintering welding technology and the common brazing technology are combined; compared with a traditional manufacturing technology for the camshaft, more materials of all components of the camshaft can be selected, the torque between the assembly parts and the base body shaft is large, the number of manufacturing steps is small, the period is short, and the manufacturing method has the advantage of obviously saving energy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

Stemming utilizing waste refractory material and preparation method thereof

InactiveCN102060548AImprove workabilitySmall sintering shrinkageProcess efficiency improvementSlagCorundum

The invention provides a stemming utilizing a waste refractory material and a preparation method thereof. The stemming comprises the following raw materials: silicon carbide particles or fine powder, high-temperature fine asphalt powder, Jilin fine clay powder, coke particles, industrial grade corundum particles or fine powder, wherein recovered aluminum and magnesium material particles or fine powder used for an electric furnace is added; and tar serves as a bonding agent. The preparation method comprises the following steps of: preparing the raw materials according to a proportion; after uniformly stirring particle materials in a stirring machine for 1 to 10 minutes, adding 20 to 30 percent of the tar; stirring for 5 to 10 minutes; adding fine powder materials; stirring for 5 to 15 minutes; adding the remaining tar and stirring for 25 to 40 minutes; and extruding by using a stemming extruder and packaging. The stemming has the following advantages: high operating performance, low stemming sintering shrinkage, rapid sintering property, high scour resistance and slag iron erosiveness. The invention provides a way for regenerating and utilizing the waste refractory material, and contributes to saving resources and protecting environment.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Preparation method of high-purity aluminum oxide ceramic substrate

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com