Environment-friendly lead-free semiconductor ceramic capacitive electrode silver paste and preparation method thereof

A ceramic capacitor and semiconductor technology, applied in fixed capacitor electrodes, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as large loss tangent value, poor printing performance, dull silver surface, etc. , to achieve the effect of reducing the loss tangent value, good weldability, and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

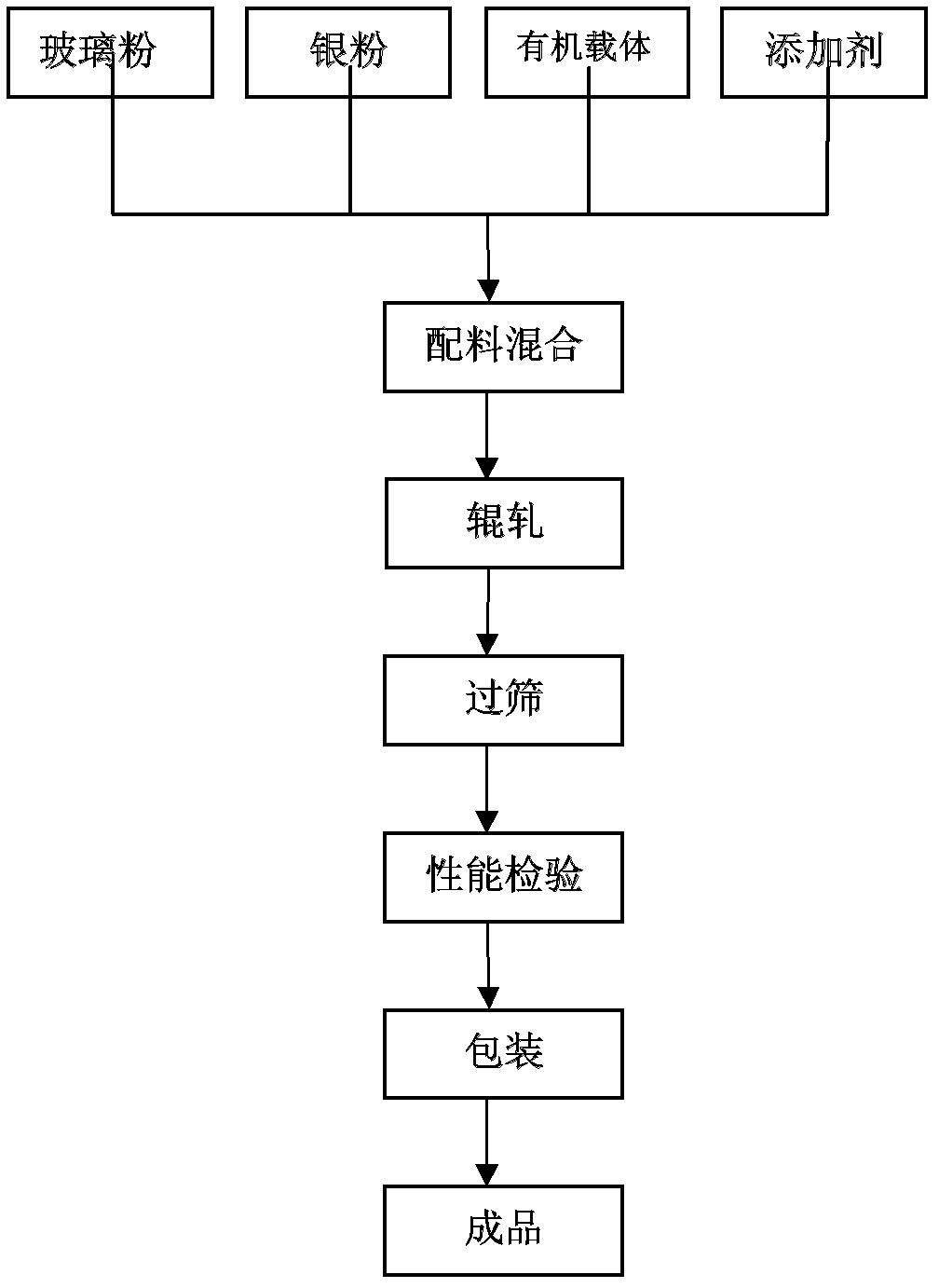

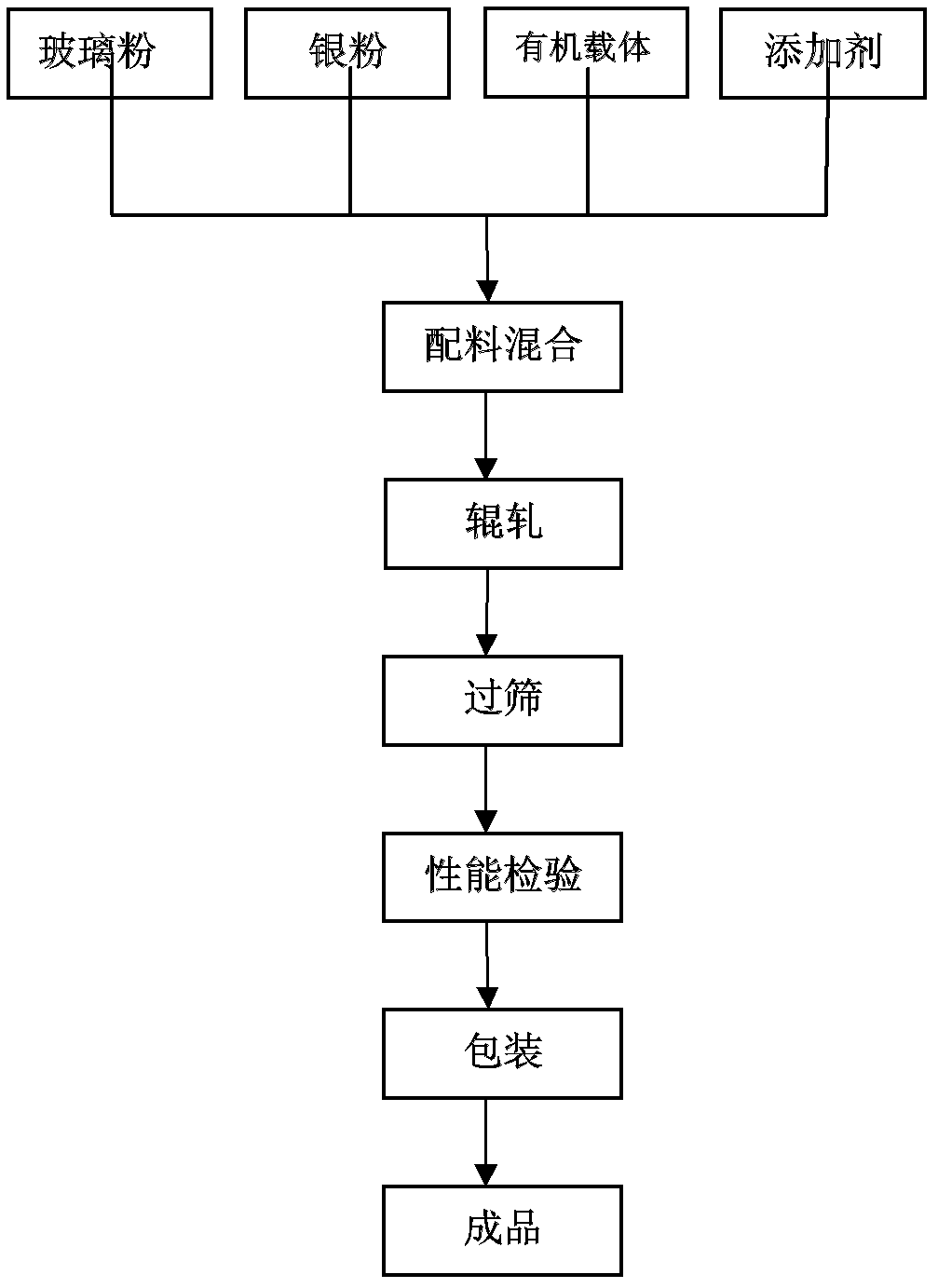

[0037] This example is a production example of silver paste for semiconductor ceramic capacitors. Follow these steps:

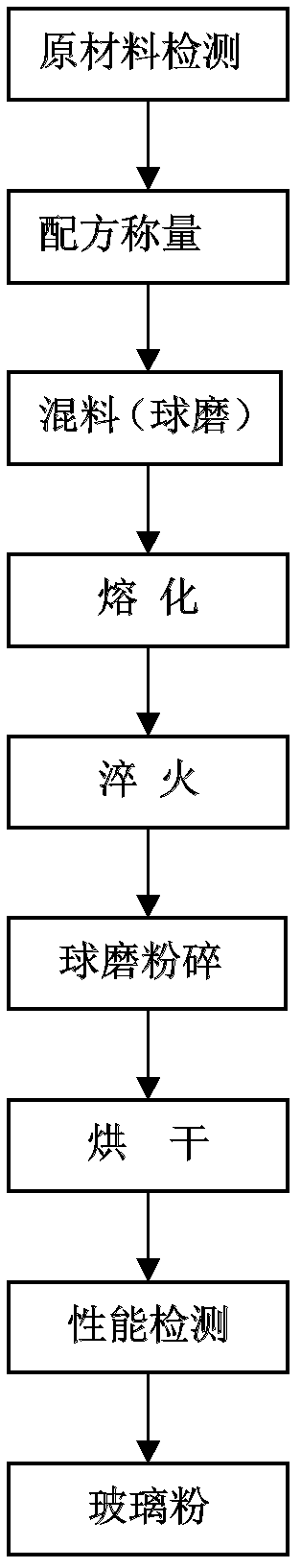

[0038] (1) Preparation of glass powder

[0039] Batching according to the following mass percentages:

[0040] B 2 o 3 20wt%, SiO 2 15wt%, Bi 2 o 3 60wt%, Al 2 o 3 3.5wt%, inorganic additive cerium oxide 1.5%.

[0041] Mix the above ingredients evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 15 μm, filter and dry.

[0042] (2) Preparation of organic carrier

[0043] Taking the total amount of organic carrier as 100%, the ingredients are formulated in the following mass percentages:

[0044] Ethylcellulose 20%,

[0045] Mixed solvent: terpineol 20%, diethylene glycol butyl ether 40%, diethylene glycol acetate 10%,

[0046] Organic additives: hydrogenated castor oil 1%, polyester modified polydimethylsilane 4%, diethyl phthalate 5%

[0047] After the...

Embodiment 2

[0055] This example is a production example of silver paste for semiconductor ceramic capacitors. Follow these steps:

[0056] (1), preparation of glass powder

[0057] Batching according to the following mass percentages:

[0058] B 2 o 3 30wt%, SiO 2 15wt%, Bi 2 o 3 50wt%, Al 2 o 3 3.5wt%, inorganic additive titanium dioxide 1.5%.

[0059] Mix evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 15 μm, filter and dry.

[0060] (2) Preparation of organic carrier

[0061] Taking the total amount of organic carrier as 100%, the ingredients are formulated in the following mass percentages:

[0062] Ethylcellulose 15%,

[0063] Mixed solvent: terpineol 40%, diethylene glycol butyl ether 30%,

[0064] Organic additives: hydrogenated castor oil 1%, polyester modified polydimethylsilane 4%, diethyl phthalate 10%

[0065] After the above materials are mixed, heat and dissolve a...

Embodiment 3

[0073] This example is the method of using silver paste, taking the silver paste in Example 1 as an example:

[0074] 1. screen-print the silver paste prepared in Example 1 on the semiconductor ceramic capacitor substrate (note: standard printing conditions: mesh: 250 orders)

[0075] ②Drying condition: 230℃ for 3 minutes

[0076] ③Sintering conditions: Sintering temperature: 800℃~830℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com