Oligomer containing fluorine and phthalonitrile, condensate and preparation method thereof

A technology of phthalonitrile and nitrophthalonitrile, which is applied in the field of oligomers containing fluorine and phthalonitrile and their cured products and preparation, can solve the problems of poor dielectric properties and achieve Low softening point, improved dielectric properties, good solubility in acetone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

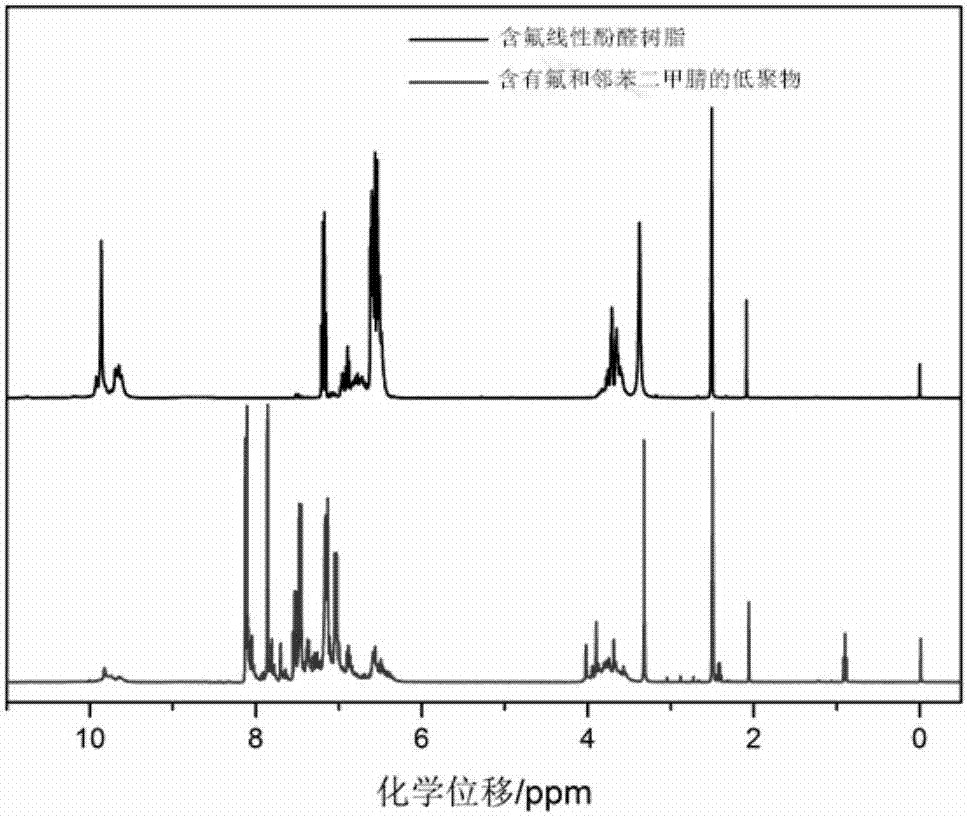

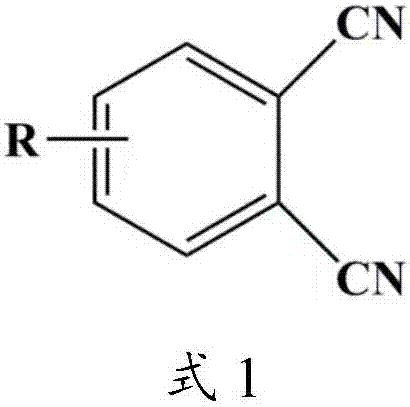

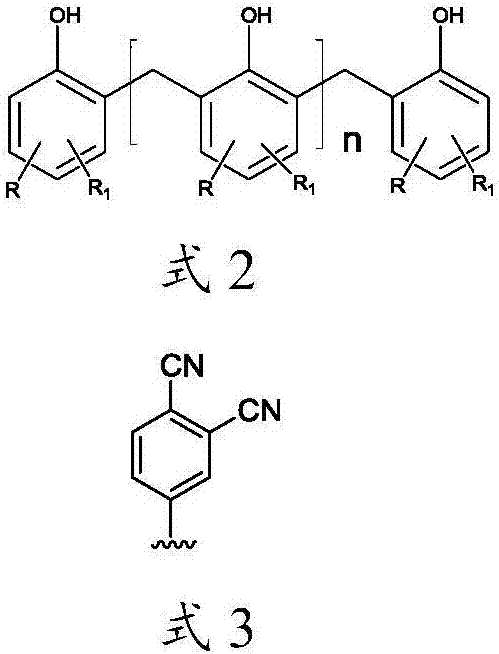

[0064] Mix 1 mol of m-fluorophenol with 0.4 mol of formaldehyde aqueous solution in a reaction vessel, heat up to 60°C, and add 0.005 mol of oxalic acid. After the oxalic acid was completely dissolved, the temperature was raised to 90°C and kept at 90°C for 3 hours. After the reaction is completed, the temperature of the reaction system is lowered to room temperature, the catalyst is washed away with distilled water at 50° C., and the distilled water is removed by vacuum distillation to obtain a fluorine-containing novolak resin. Under the protection of nitrogen at room temperature, the above-mentioned fluorine-containing novolac resin was dissolved in 150mL N,N-dimethylformamide (DMF), and 0.75mol 4-nitrophthalonitrile and 1.2mol anhydrous carbonic acid were added to it. Potassium, raise the temperature of the system to 80°C. Keep the reaction at 80°C for 8 hours. After the reaction is completed, cool the reaction system to room temperature, remove the reaction solvent in t...

Embodiment 2

[0068] Mix 1 mol m-trifluoromethylphenol with 0.4 mol formaldehyde aqueous solution in a reaction vessel, heat up to 60°C, and add 0.005 mol oxalic acid. After the oxalic acid was completely dissolved, the temperature was raised to 90°C and kept at 90°C for 3 hours. After the reaction is completed, the temperature of the reaction system is lowered to room temperature, the catalyst is washed away with distilled water at 50° C., and the distilled water is removed by vacuum distillation to obtain a fluorine-containing novolak resin. Under the protection of nitrogen at room temperature, the above-mentioned fluorine-containing novolak resin was dissolved in 150mol N,N-dimethylformamide (DMF), and 0.75mol 4-nitrophthalonitrile and 1.2mol anhydrous potassium carbonate were added to it , the temperature of the system was raised to 80°C. Keep the reaction at 80°C for 8 hours. After the reaction is completed, cool the reaction system to room temperature, remove the reaction solvent in...

Embodiment 3

[0071] Mix 1 mol m-trifluoromethylphenol with 0.4 mol formaldehyde aqueous solution in a reaction vessel, heat up to 60°C, and add 0.005 mol oxalic acid. After the oxalic acid was completely dissolved, the temperature was raised to 90°C and kept at 90°C for 3 hours. After the reaction is completed, the temperature of the reaction system is lowered to room temperature, the catalyst is washed away with distilled water at 50° C., and the distilled water is removed by vacuum distillation to obtain a fluorine-containing novolak resin. Under nitrogen protection at room temperature, dissolve the above-mentioned fluorine-containing phenolic resin in 150mol N,N-dimethylformamide (DMF), and add 0.55mol 4-nitrophthalonitrile and 1.2mol anhydrous potassium carbonate to it , the temperature of the system was raised to 80°C. Keep the reaction at 80°C for 8 hours. After the reaction is completed, cool the reaction system to room temperature, remove the reaction solvent in the system by rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com