Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

326results about How to "Improve dry strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

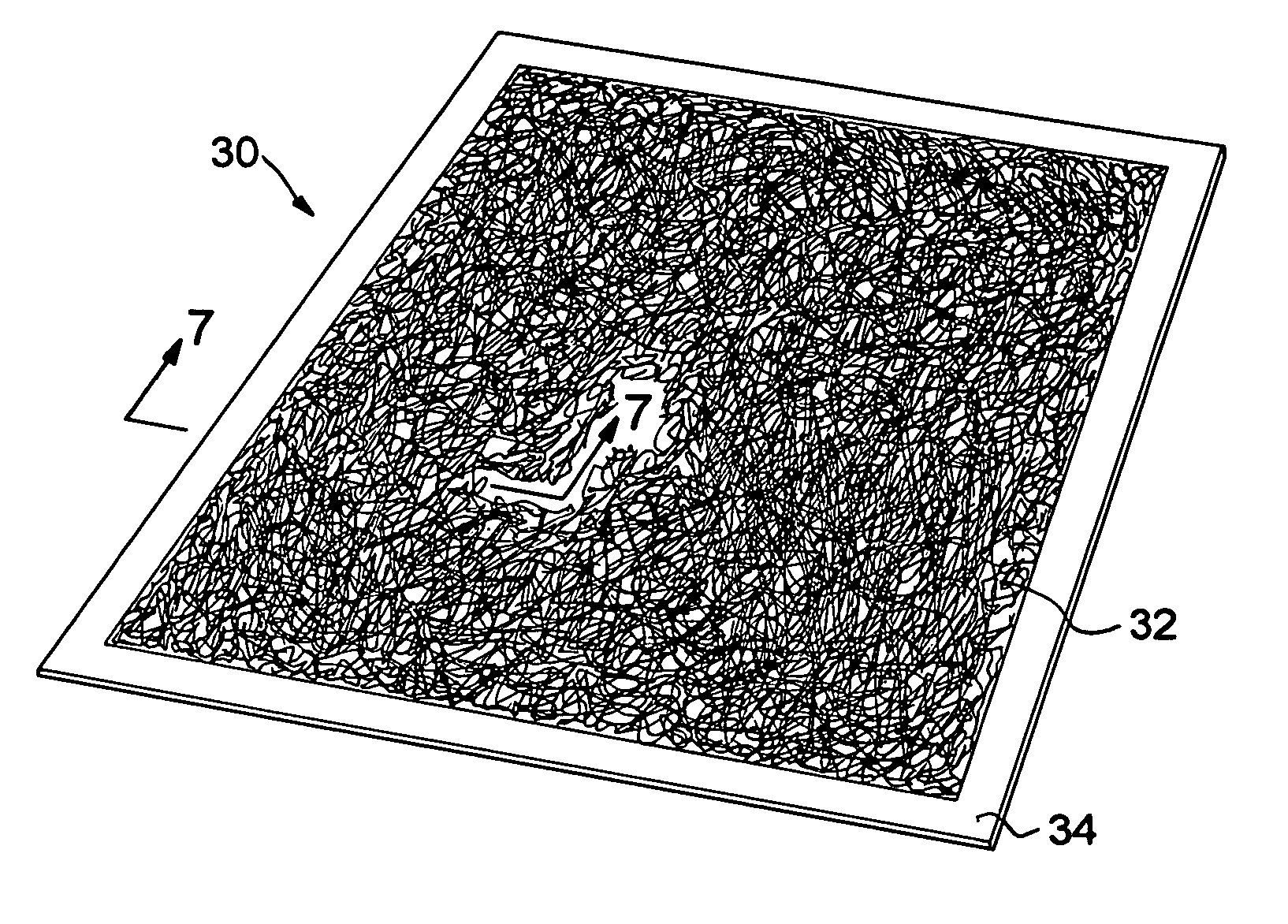

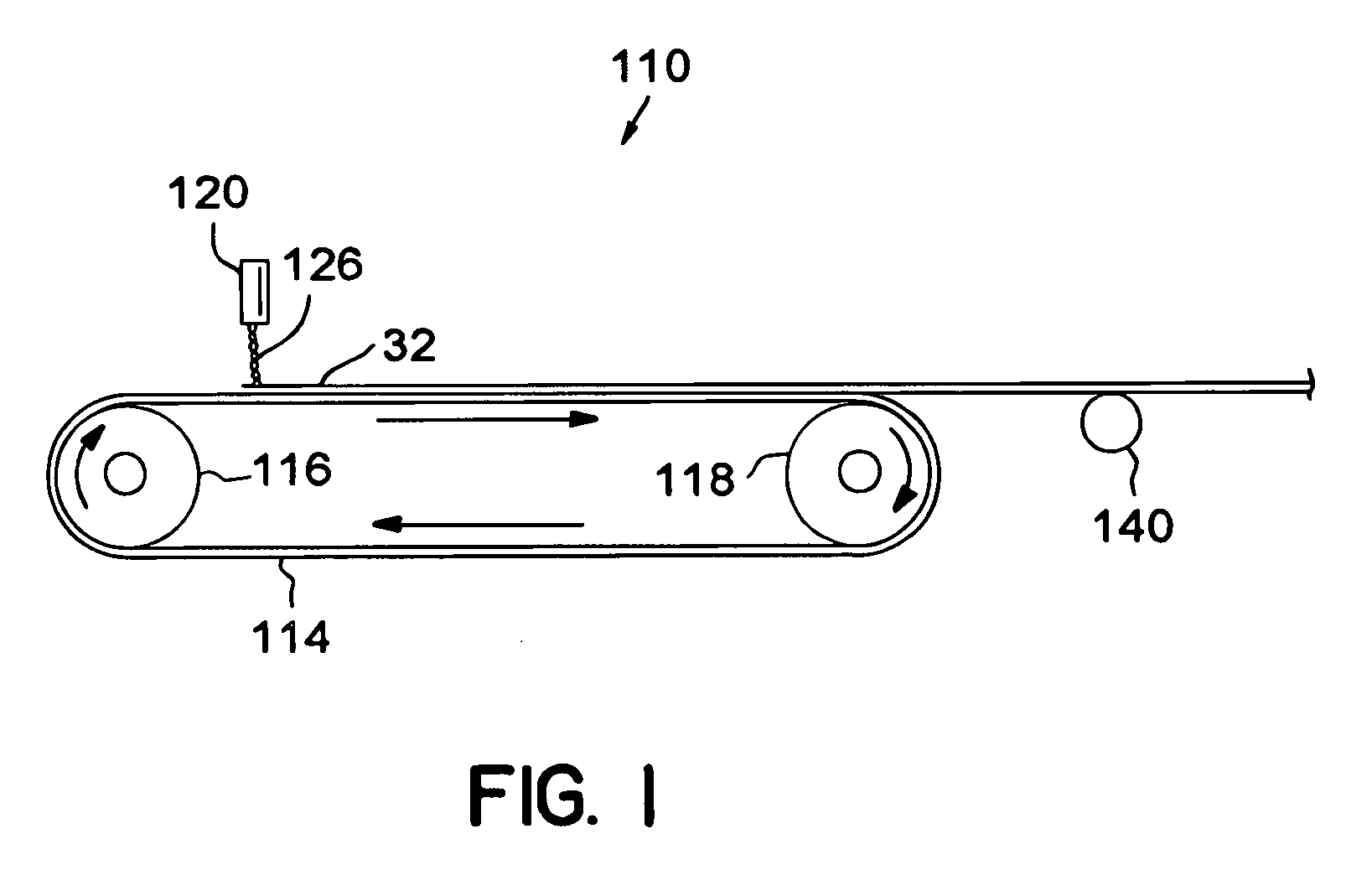

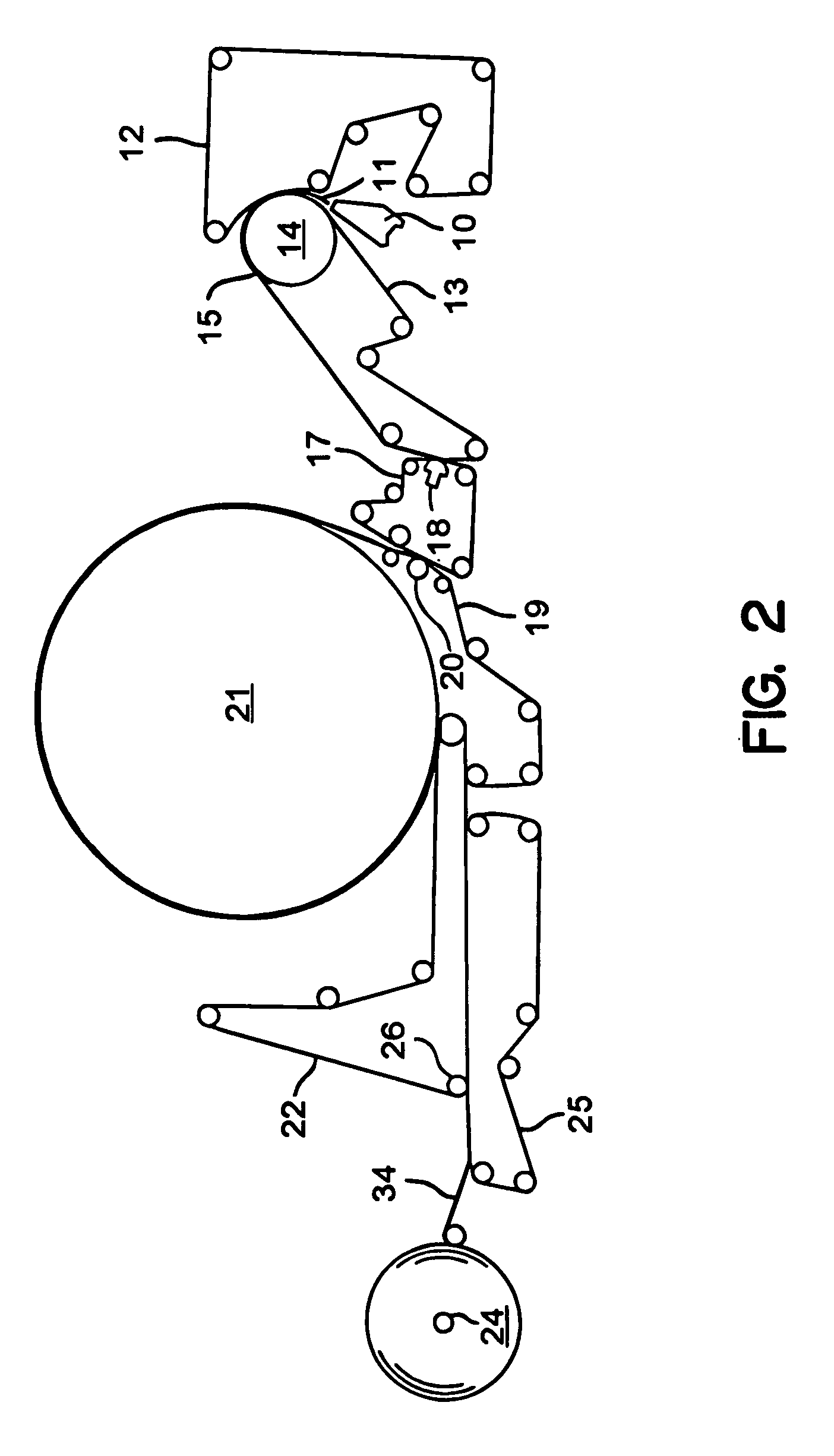

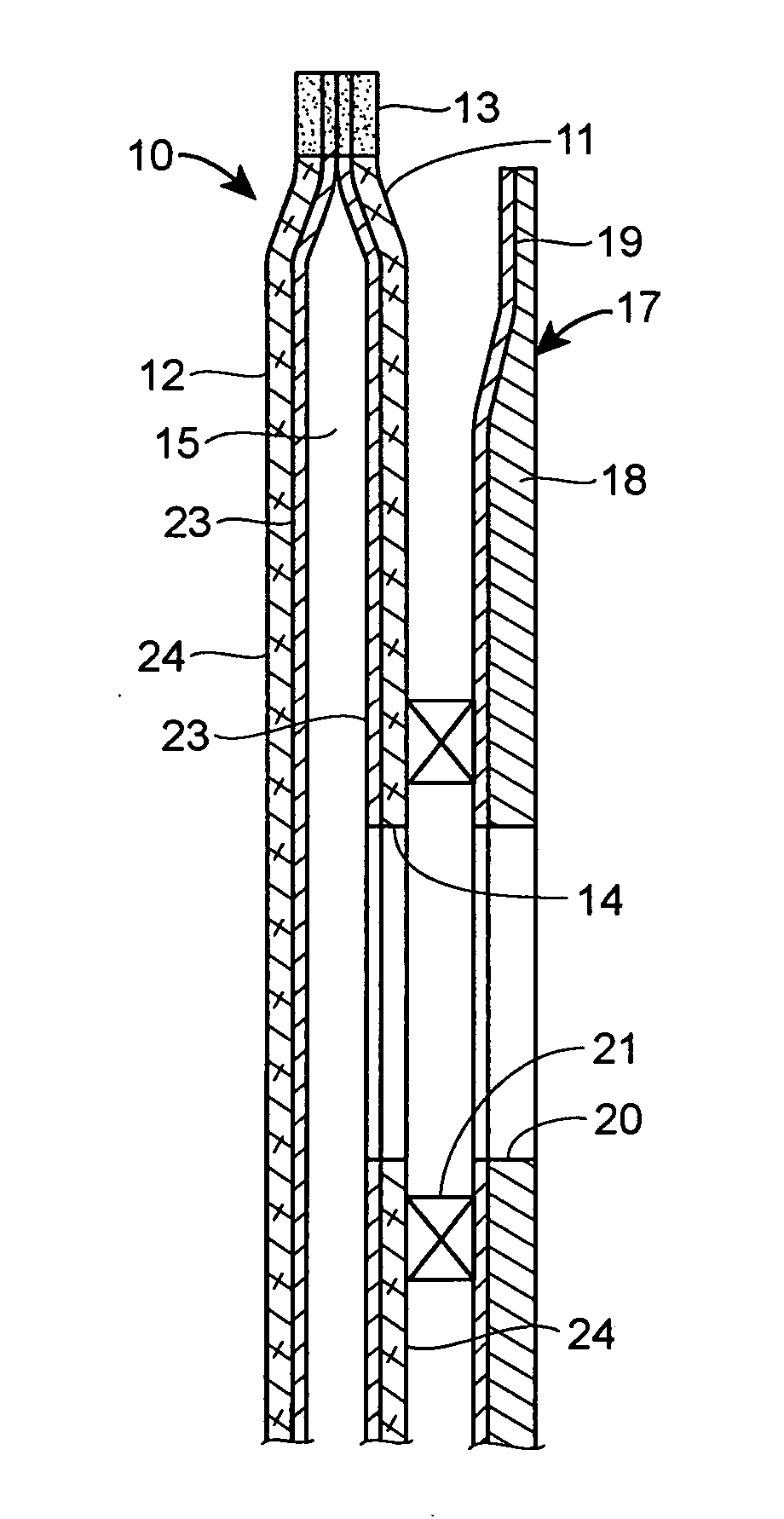

Disposable scrubbing product

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

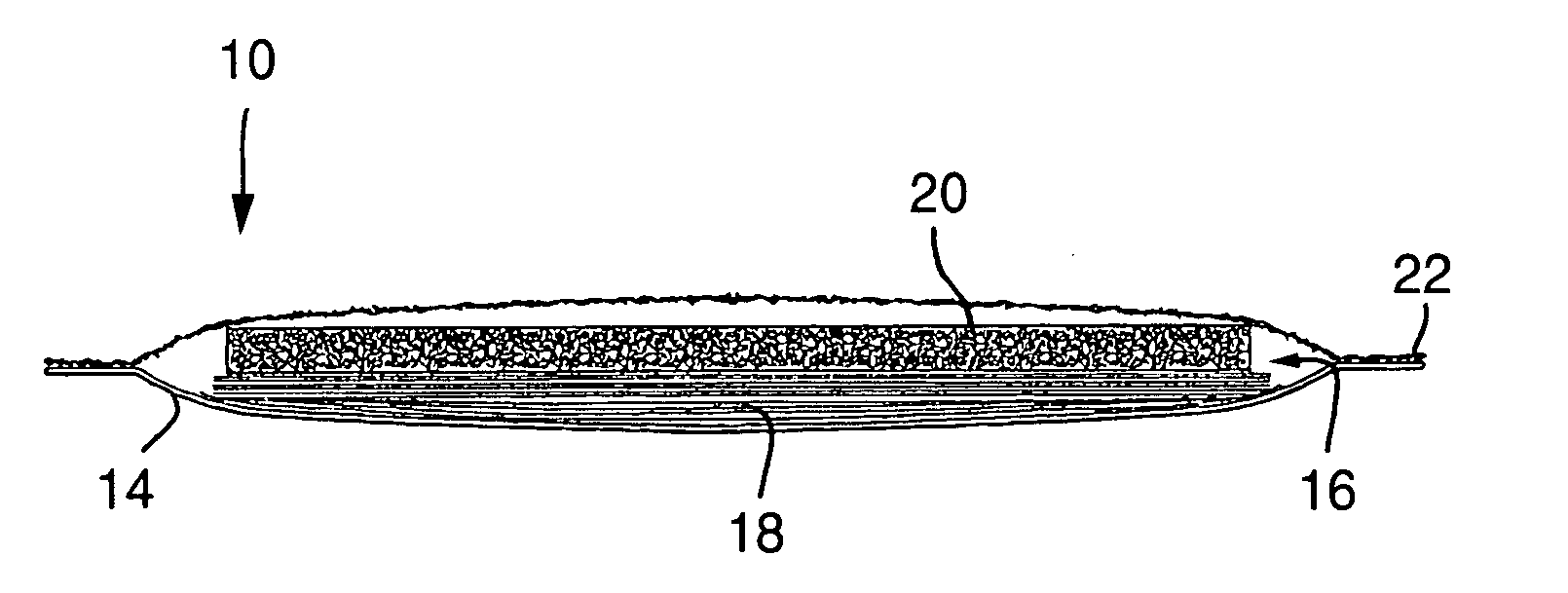

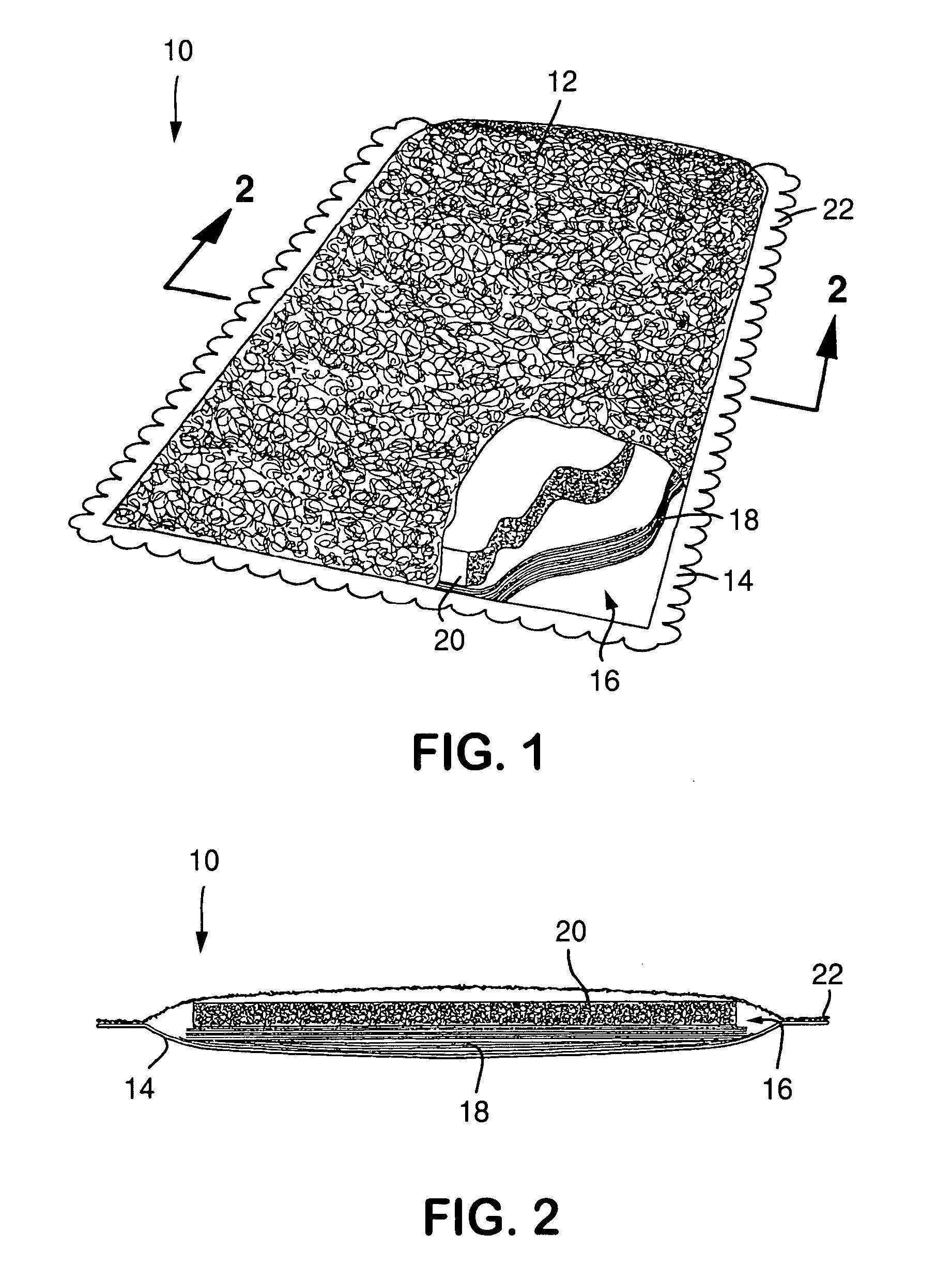

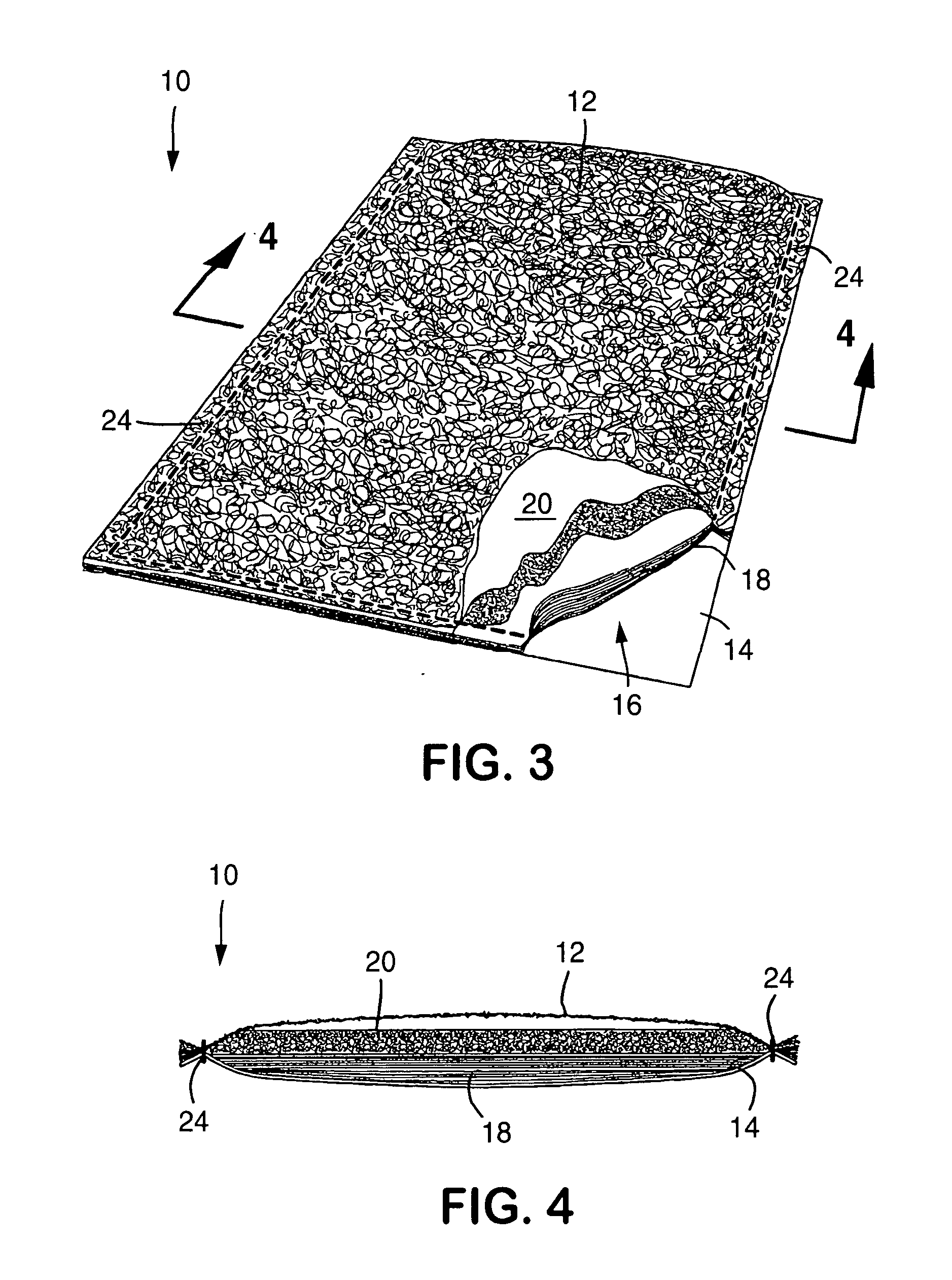

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

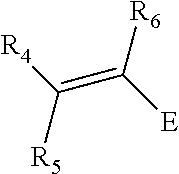

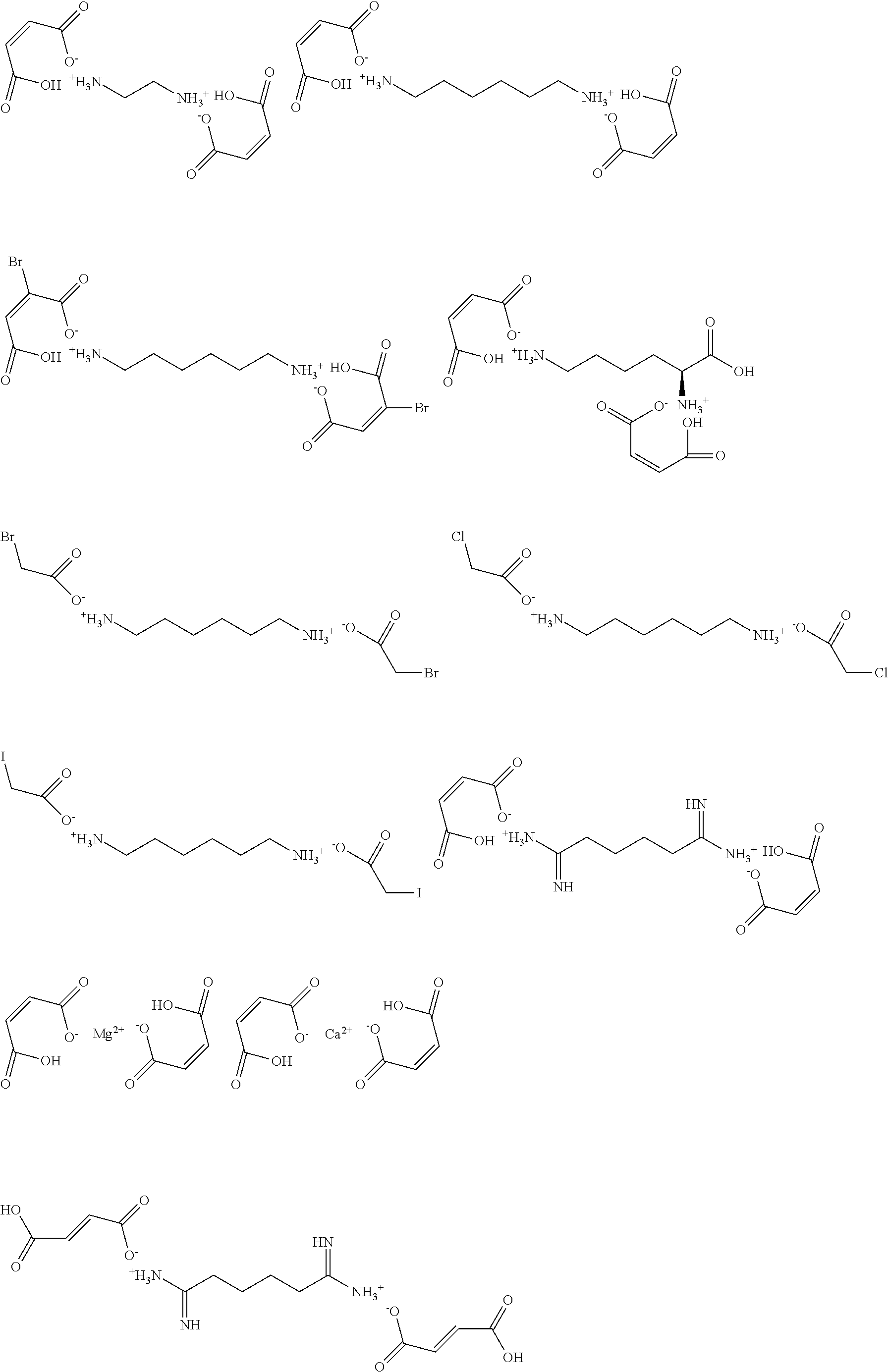

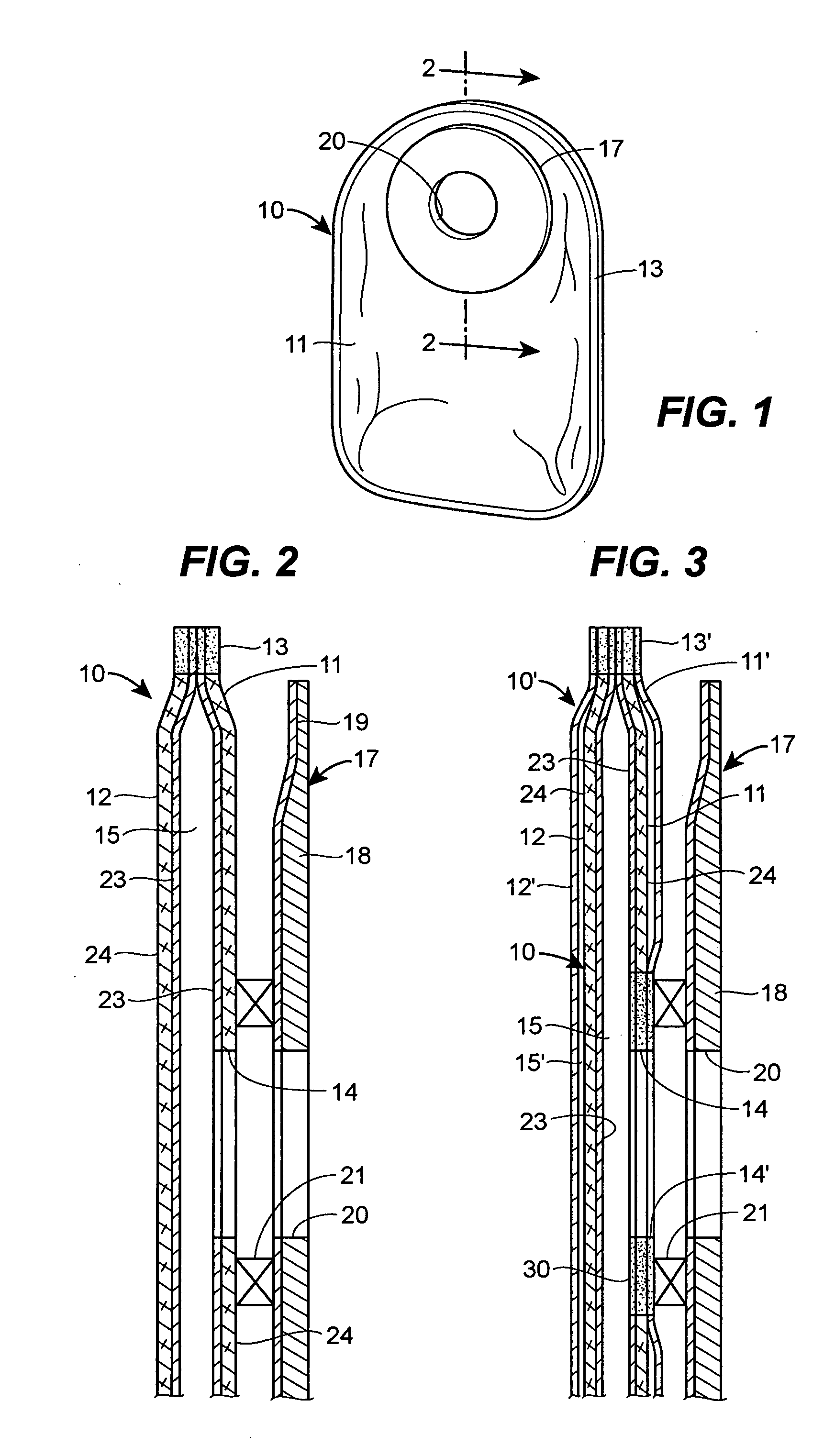

Methods for fixing hair and skin

ActiveUS20150034117A1Improve conditioning benefitImprove appearanceCosmetic preparationsBiocideLong lastingChemistry

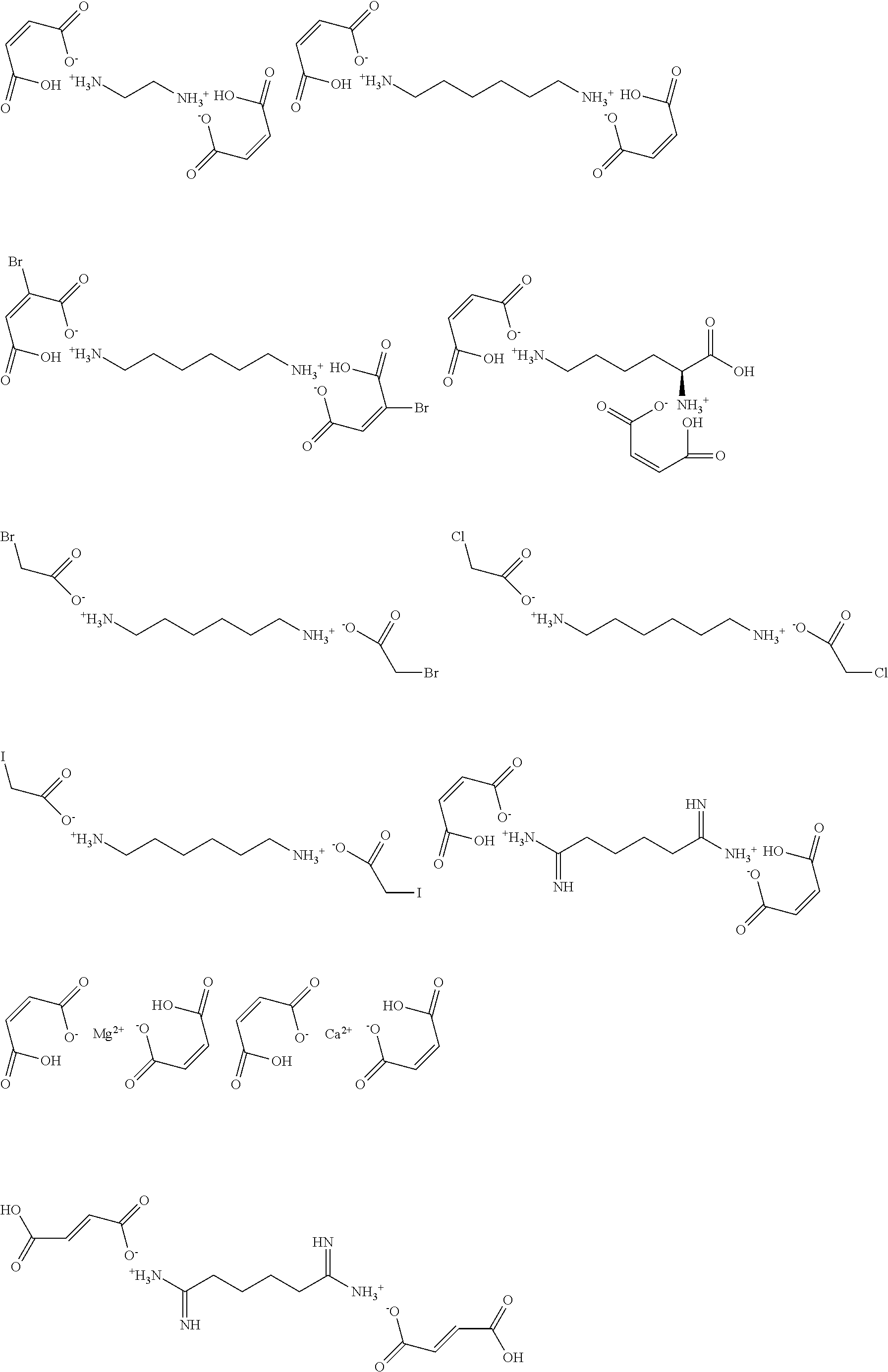

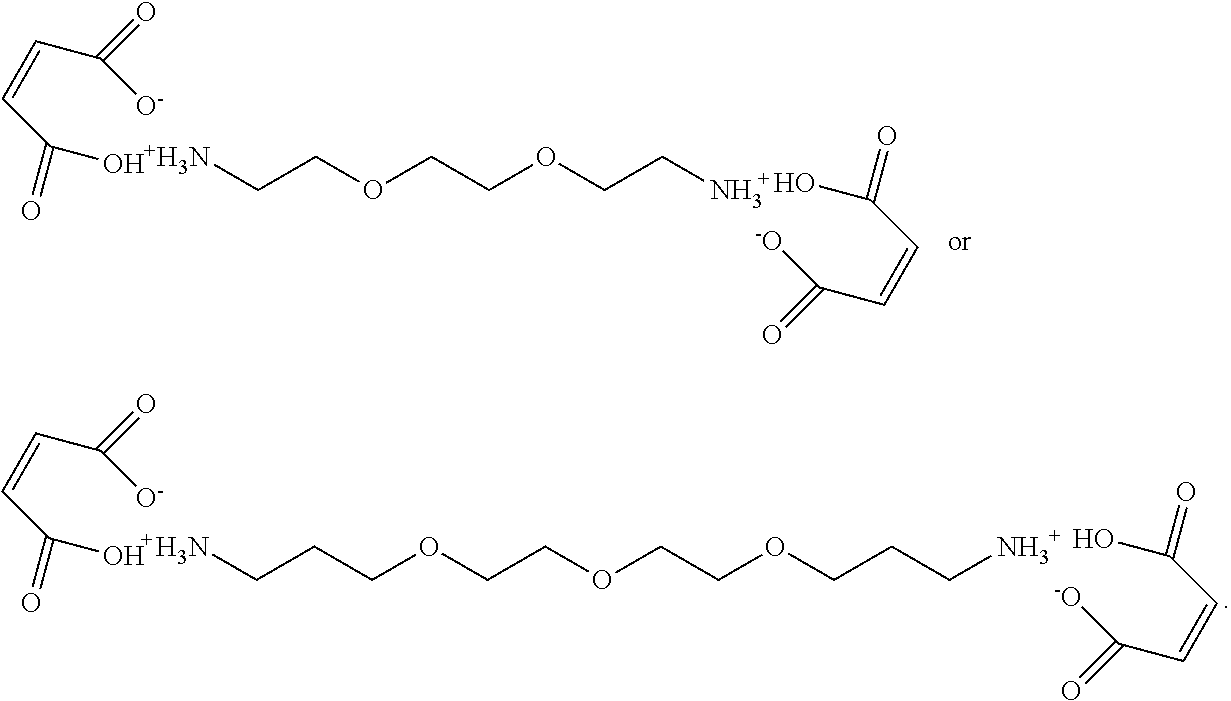

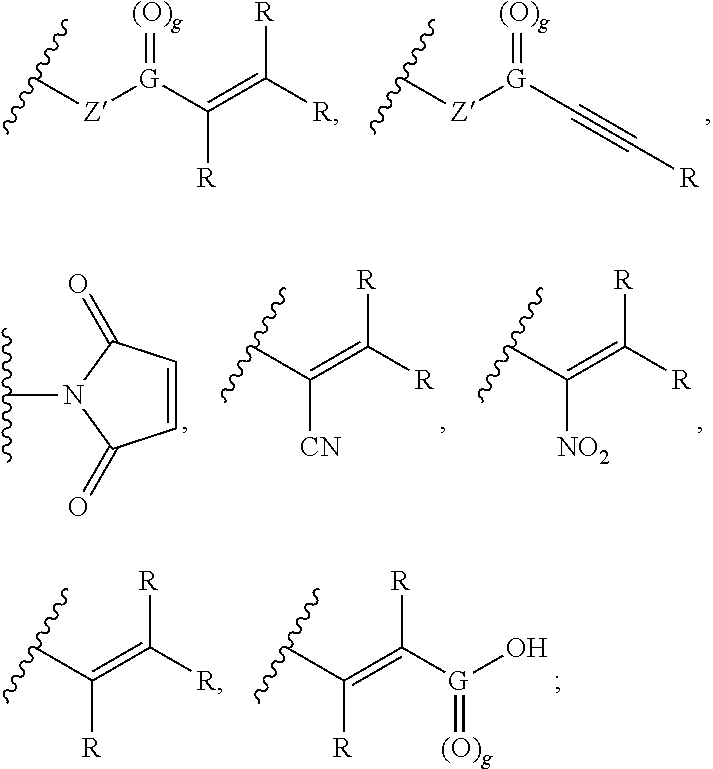

Compositions, kits, and methods for repairing bonds, for example, disulfide bonds, in hair or on the skin are disclosed. The compositions provide improved conditioning benefit for dry hair or moisturize the skin. The compositions also provide a long lasting moisturized feel and smooth feel to the skin or hair, without feeling greasy. The compositions contain one or more compounds that covalently bind at least two thiol groups in the hair or on the skin. Use of the binding compositions prevents reversion of the repaired bonds to their free thiol state, for at least one week or one month, or more, after a single application of the composition. Improved methods of styling hair, for example permanent hair waving, hair curling, hair coloring or highlighting, and hair straightening, are also provided.

Owner:LIQWD

Composite cleaning products having shape resilient layer

InactiveUS20060135026A1Resists effect of waterMaintain stiffnessCarpet cleanersLayered productsPersonal careEngineering

The present invention discloses a disposable cleaning product for use in household cleaning or personal care applications. The cleaning product of the invention is a multi-layer laminate product and may include at least two distinct layers, an abrasive layer and an absorbent layer. The absorbent layer contains a sponge-like member optionally in combination with a plurality of cellulosic fibrous webs. The sponge-like member can be made from various materials. For example, in one embodiment, the sponge-like member comprises one or more layers of a spunbond web containing crimped, bicomponent filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

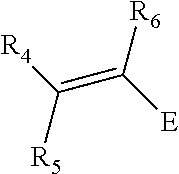

Process for Enhancing Dry Strength of Paper by Treatment with Vinylamine-Containing Polymers and Acrylamide-Containing Polymers

InactiveUS20110155339A1Improve dry strengthNatural cellulose pulp/paperSpecial paperPolymer chemistryAqueous solution

A process is disclosed for the production of paper with enhanced dry strength comprising adding to the wet end of a paper machine, (a) a vinylamine-containing aqueous solution polymer having a molecular weight of from 75,000 daltons to 750,000 daltons and (b) an amphoteric or cationic acrylamide-containing aqueous solution polymer having a molecular weight of from 75,000 daltons to 1,500,000 daltons, wherein the sum of the anionic and cationic monomers comprises at least 5% on a molar basis of the composition of the acrylamide-containing polymer.

Owner:SOLENIS TECH CAYMAN

Methods for fixing hair and skin

ActiveUS9095518B2Good benefitImprove dry strengthCosmetic preparationsHair cosmeticsHair straighteningCompound (substance)

Compositions, kits, and methods for repairing bonds, for example, disulfide bonds, in hair or on the skin are disclosed. The compositions provide improved conditioning benefit for dry hair or moisturize the skin. The compositions also provide a long lasting moisturized feel and smooth feel to the skin or hair, without feeling greasy. The compositions contain one or more compounds that covalently bind at least two thiol groups in the hair or on the skin. Use of the binding compositions prevents reversion of the repaired bonds to their free thiol state, for at least one week or one month, or more, after a single application of the composition. Improved methods of styling hair, for example permanent hair waving, hair curling, hair coloring or highlighting, and hair straightening, are also provided.

Owner:LIQWD

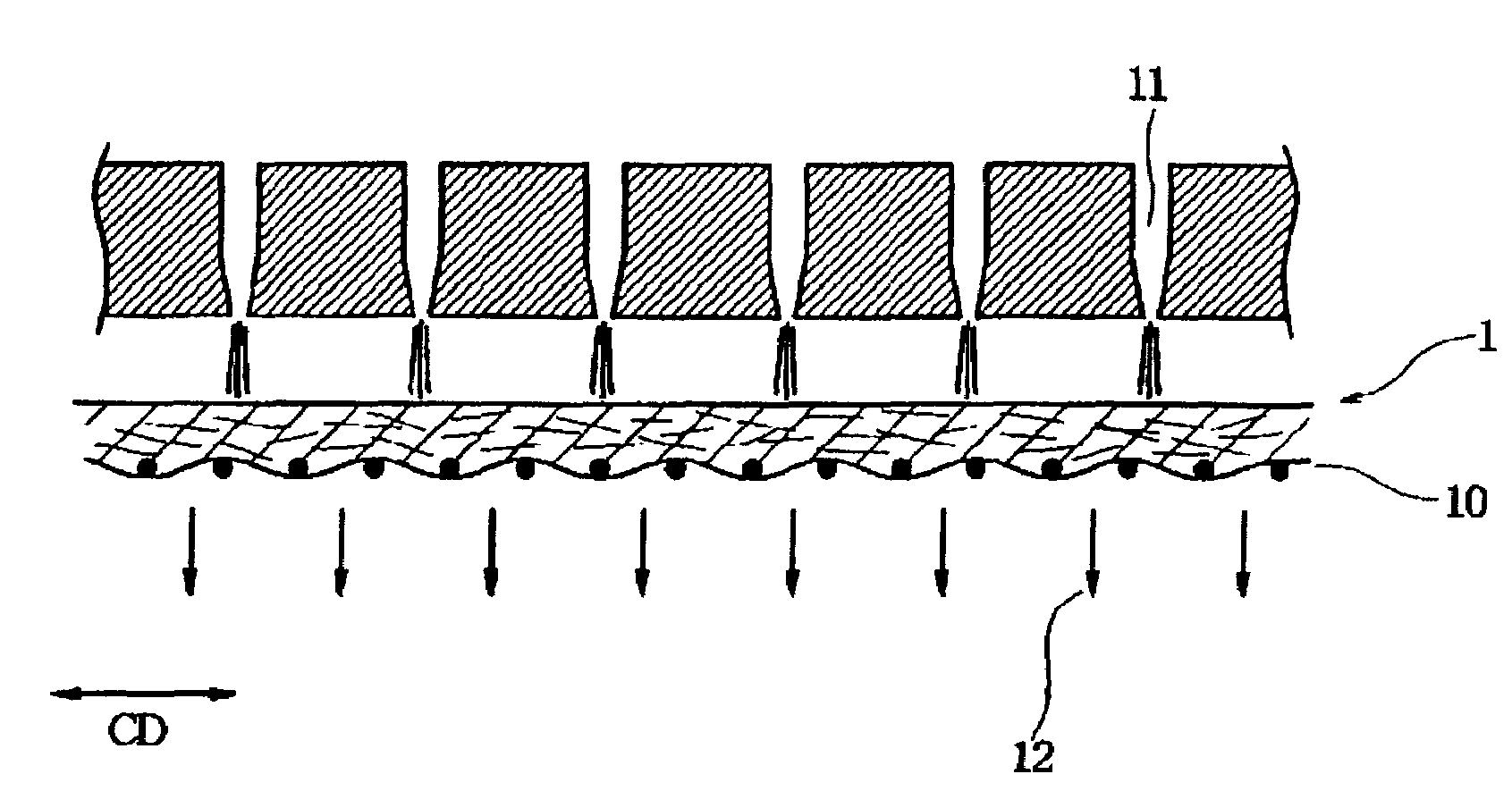

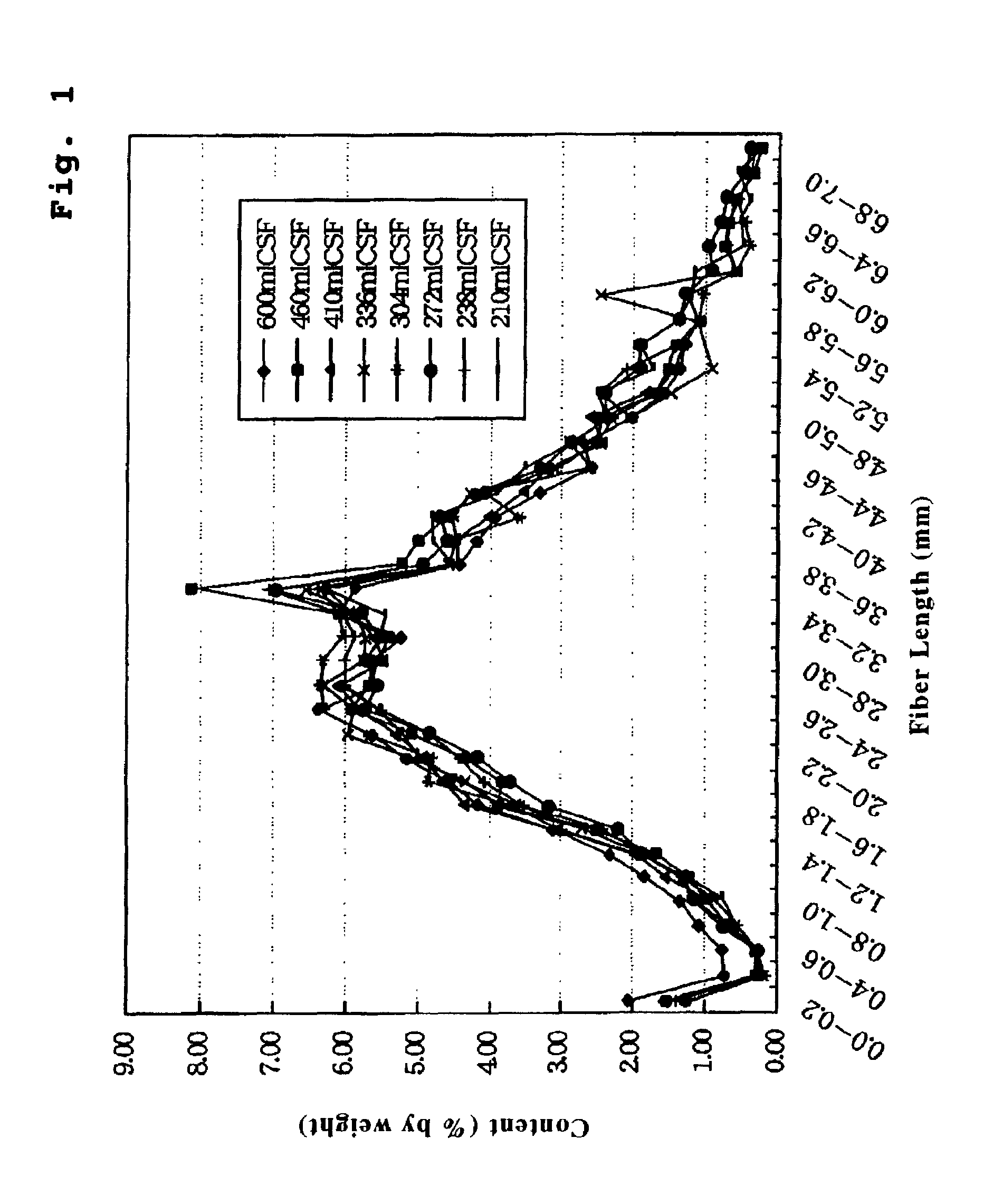

Water-disintegratable sheet and manufacturing method thereof

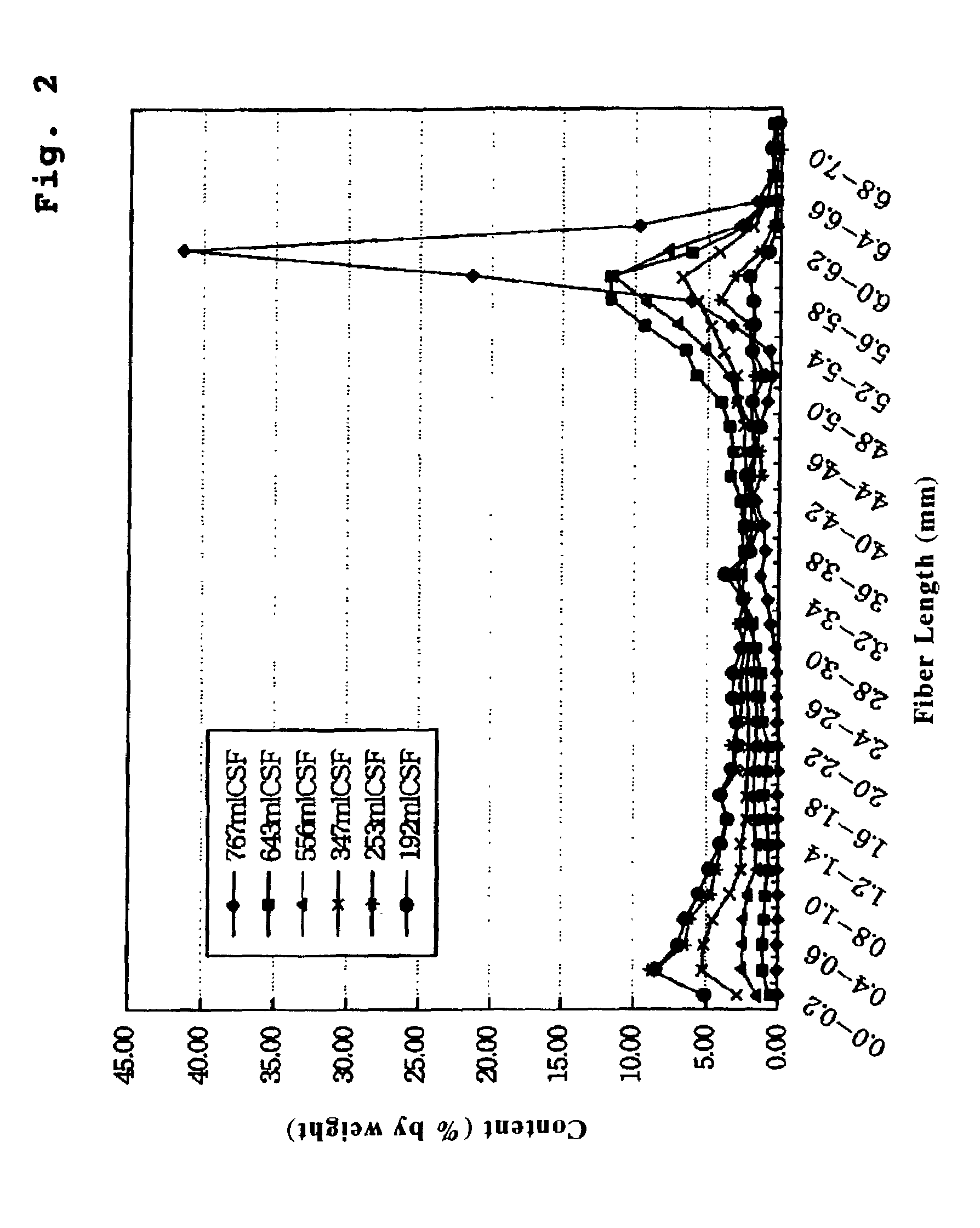

InactiveUS7241711B2Good wettingImprove dry strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Disclosed is a water disintegratable sheet of which fibers are hydroentangled about each other. The water disintegratable sheet includes: at least one kind of primary fibers having a fiber length of at most 10 millimeter; and bast / leaf fibers having a Canadian Standard freeness value of at most 600 milliliter and a fiber length of at most 10 millimeter.

Owner:UNI CHARM CORP

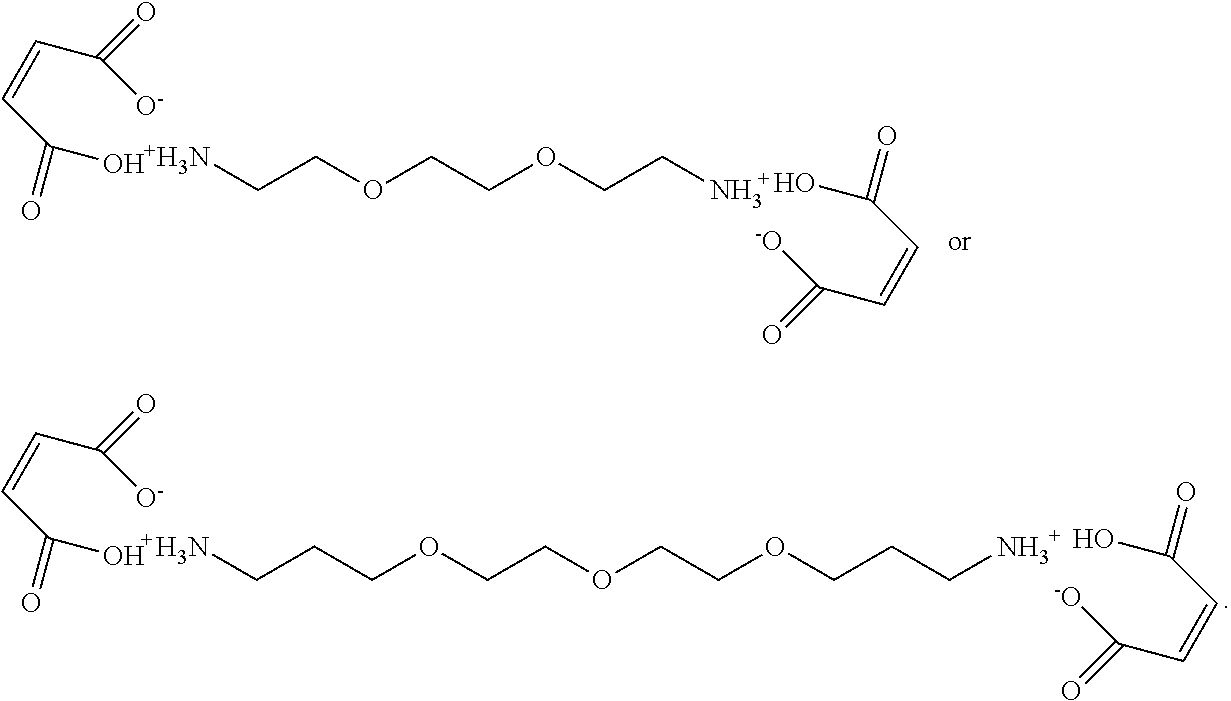

Flushable body waste collection pouch, pouch-in-pouch appliance using the same, and method relating thereto

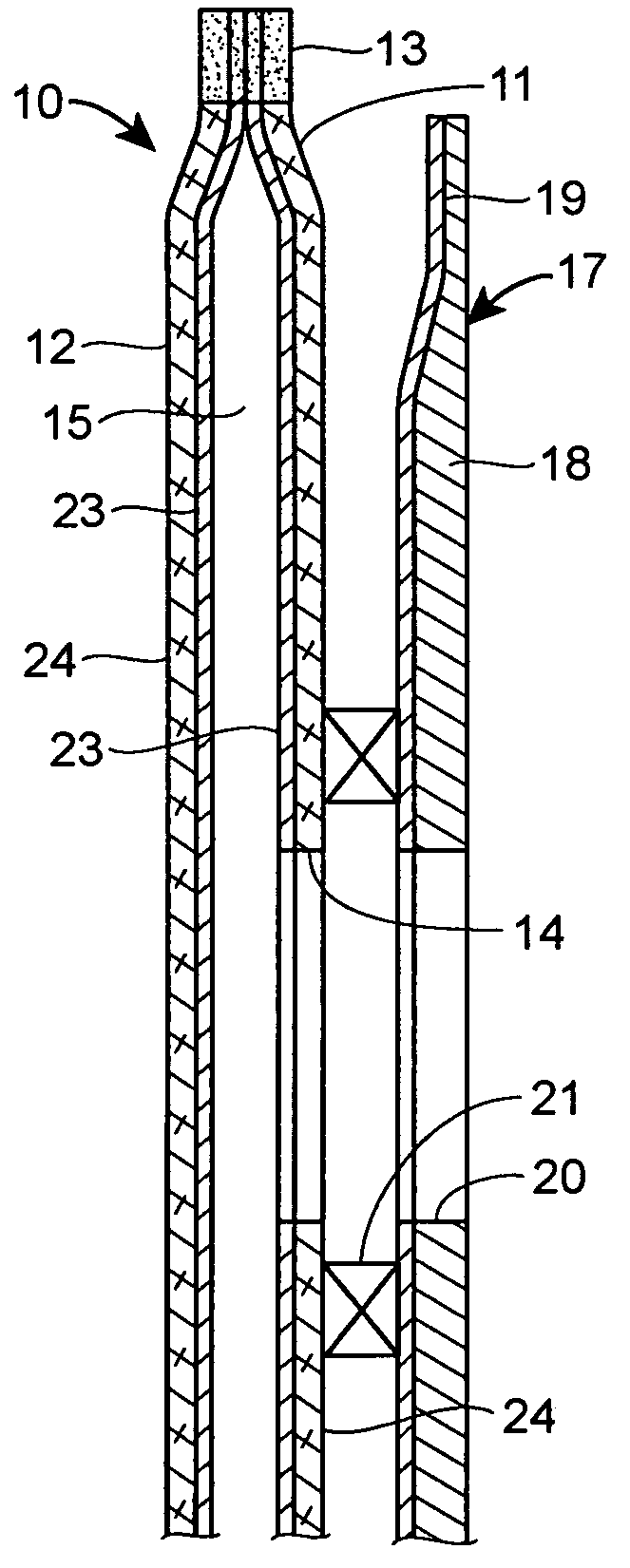

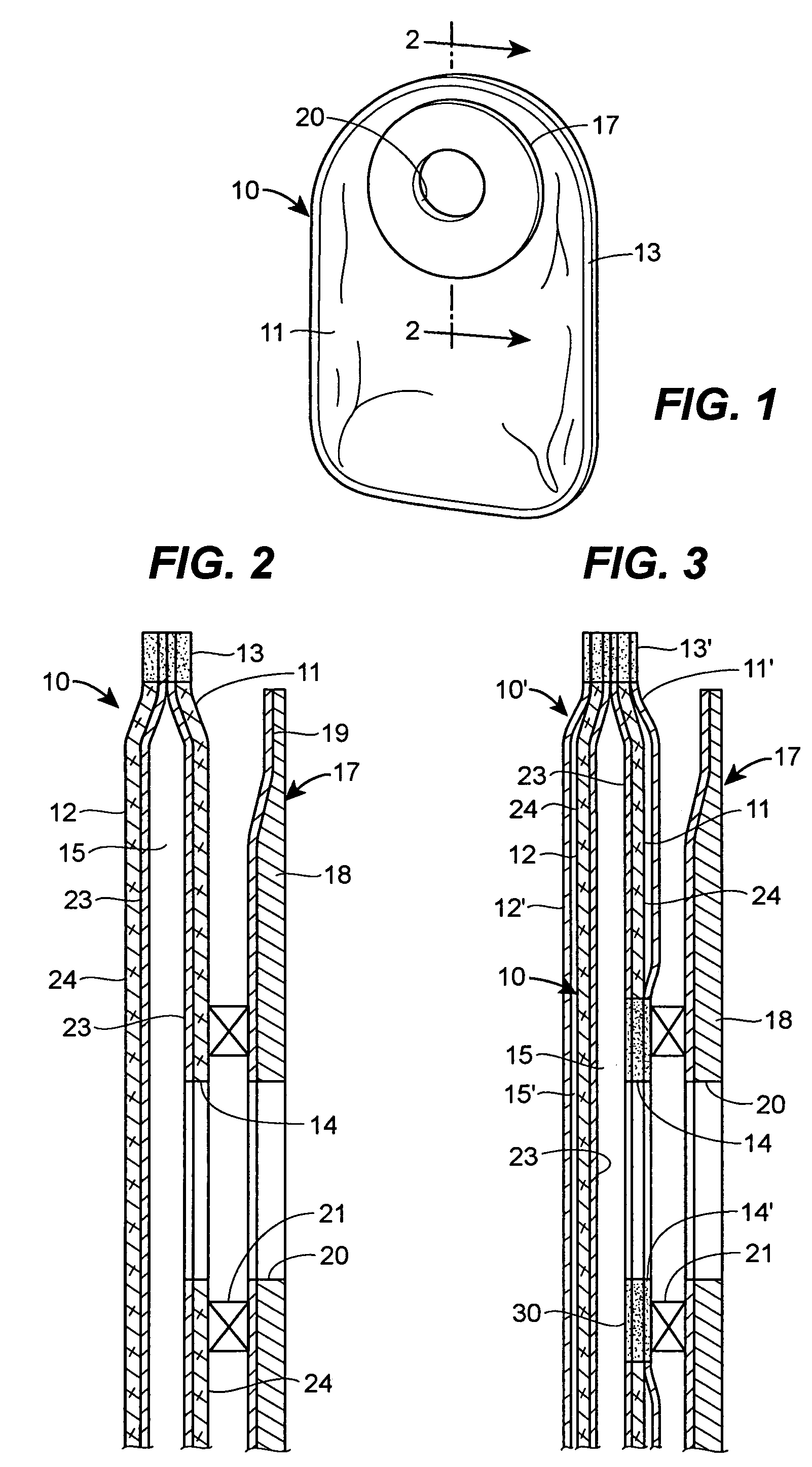

InactiveUS7179245B2Limited biodegradabilityReduce noiseSynthetic resin layered productsNon-surgical orthopedic devicesFiberPolymer science

A biodegradable and toilet-flushable body waste collection pouch, and an appliance in which such pouch constitutes the inner pouch of a peelably separable pouch-in- pouch system, are disclosed. The walls of the inner pouch are composed of an ultra-thin, heat-sealable film impermeable to body wastes comprising a plasticized biodegradable polyester or copolyester externally covered by a soft, porous, water-disintegratable cover layer of biodegradable and water-dispersible fibers.

Owner:HOLLISTER INCORPORAED

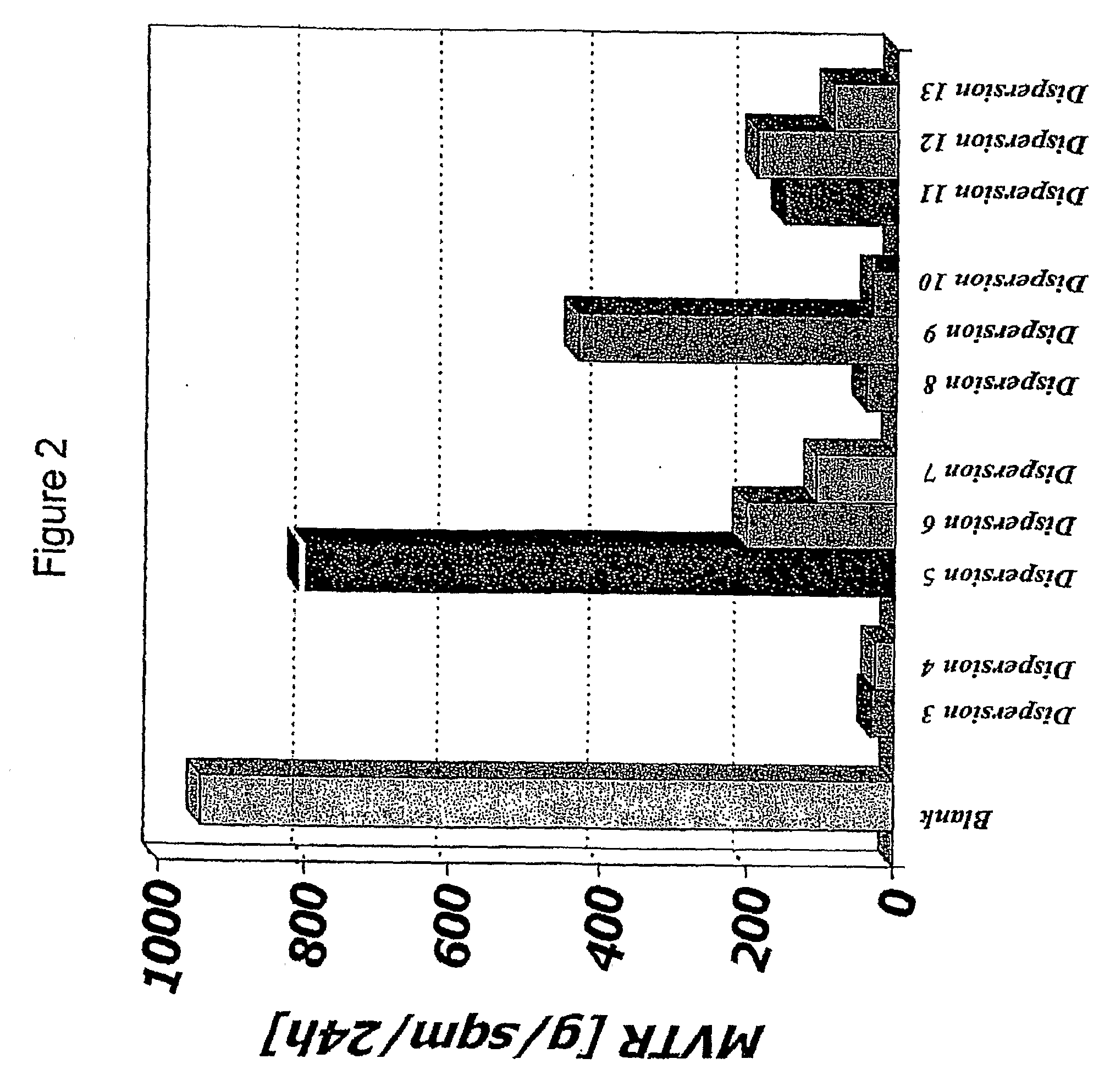

Cellulose Articles Containing an Additve Composition

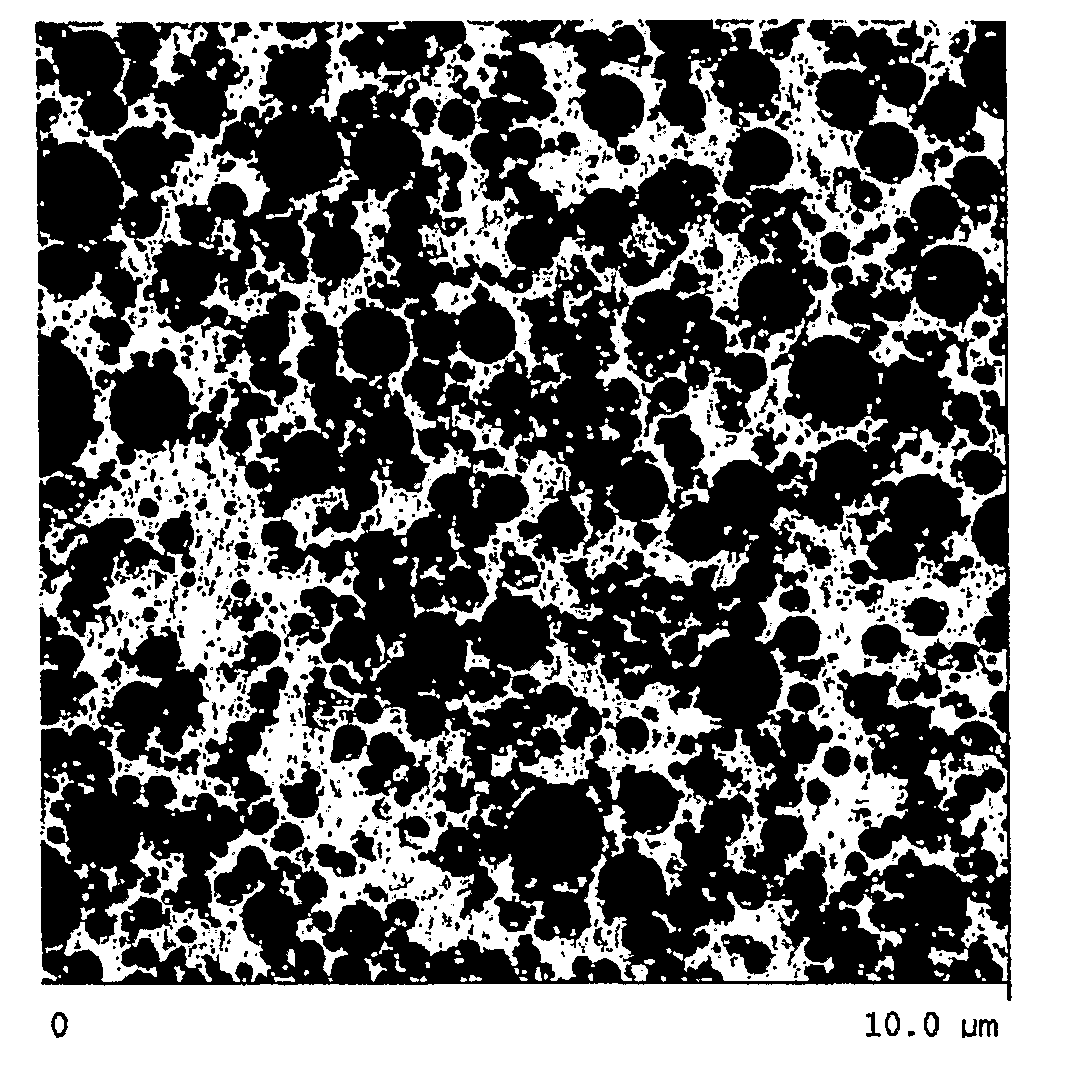

ActiveUS20080295985A1Improve propertiesImproved grease resistanceNatural cellulose pulp/paperSpecial paperSpecific volumeCellulose fiber

In one embodiment, the present invention provides a method of forming a cellulose article having a specific volume of less than 3 cc / gm. The method includes the step of incorporating cellulose fibers with a compound, wherein the compound includes an aqueous dispersion. The aqueous dispersion may have at least one polymer selected from the group consisting of an ethylene-based thermoplastic polymer, a propylene-based thermoplastic polymer, and mixtures thereof; at least one polymeric stabilizing agent; and water. In certain embodiments, a combined amount of the at least one polymer and the at least one stabilizing agent comprises about 25 to about 74 volume percent of the aqueous dispersion.

Owner:DOW GLOBAL TECH LLC

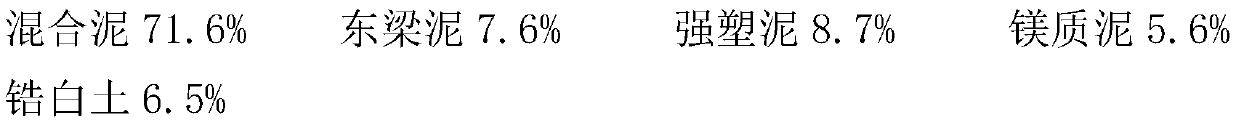

Ceramic rock plate and preparation method thereof

ActiveCN111470848AImprove plasticityGood molding effectCeramic materials productionClaywaresGlazeSpray dried

The invention relates to a ceramic rock plate and a preparation method thereof. A ceramic rock plate blank is composed of the following components in percentage by weight: 35-46.1% of mud; 50 to 60 percent of a water abrasive; 1-7% of a green body toughening material; 0.5 to 3 percent of a reclaimed material; and 0.1-0.8% of an additive. The preparation method comprises the following steps: preparing a green body, processing the green body, performing spray drying to prepare powder, performing dry pressing to form the green body (with a plane or concave-convex effect), drying, polishing the green body, blowing ash, spraying water, spraying white ink, spraying engobe, decorating patterns, decorating isolation glaze, decorating a transparent glaze layer, firing, polishing and edging.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +3

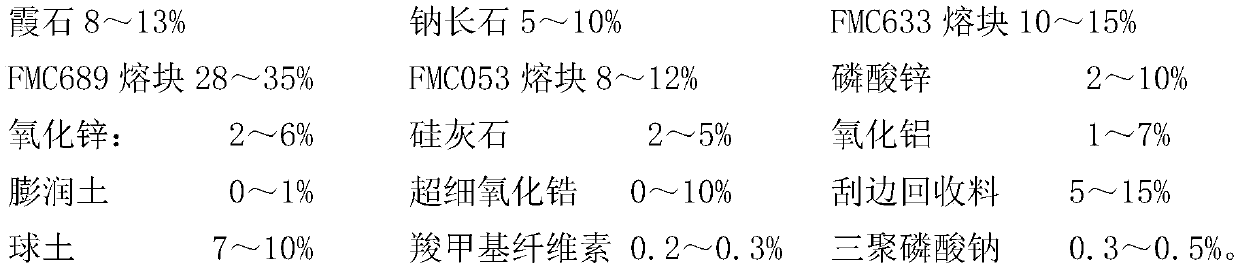

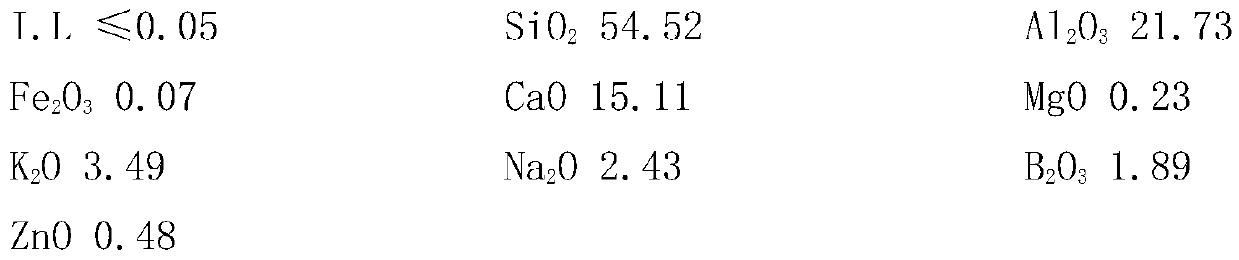

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

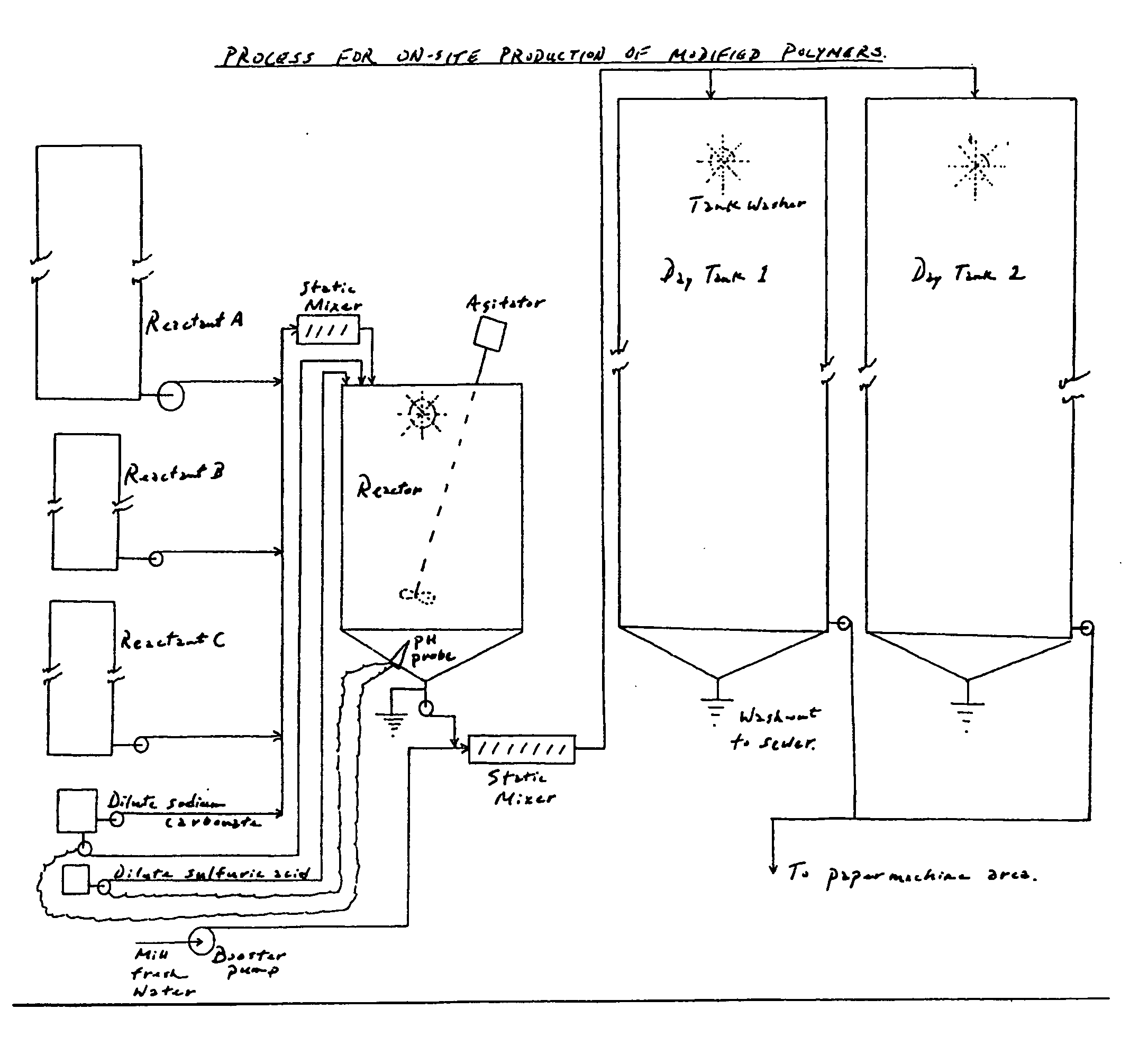

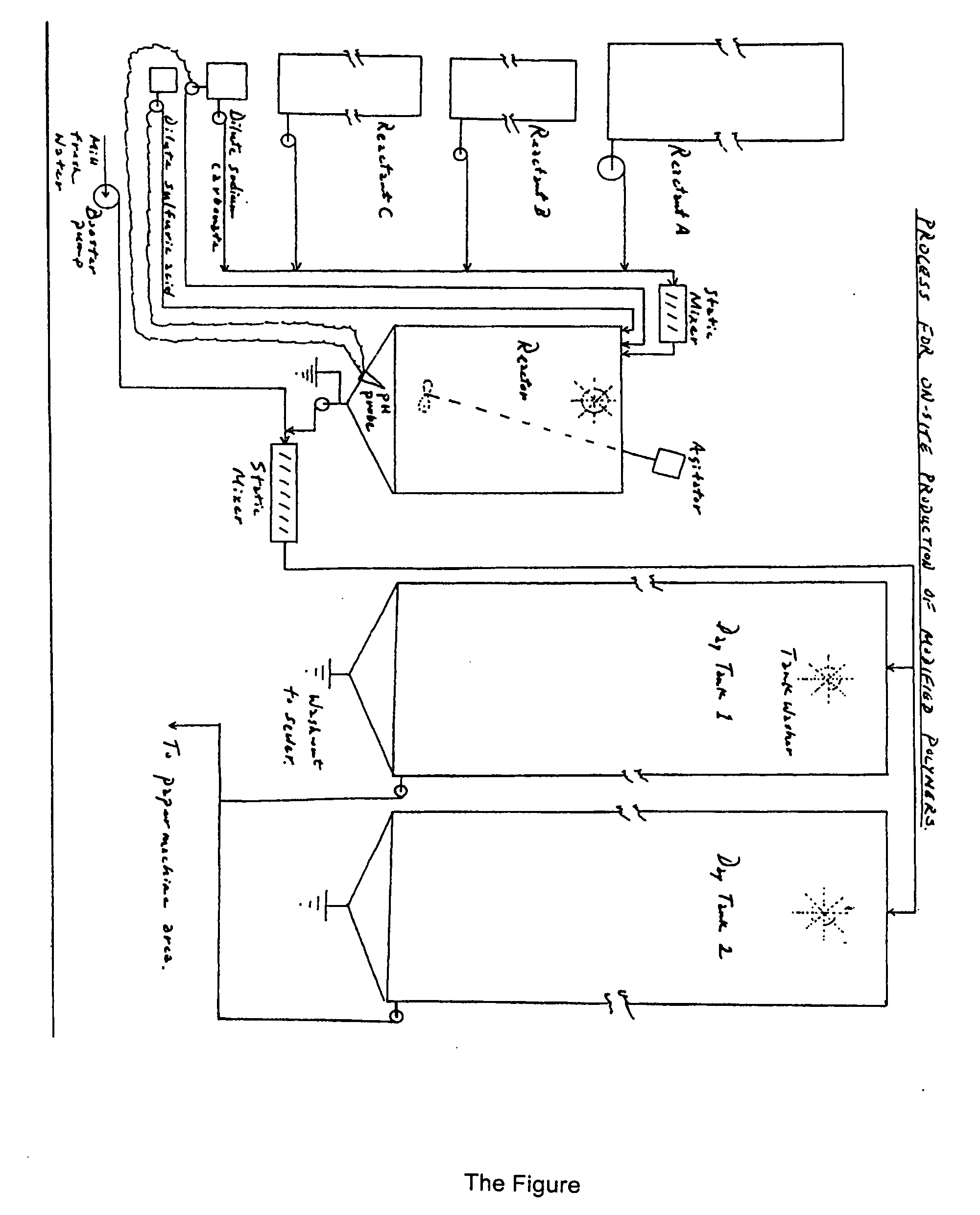

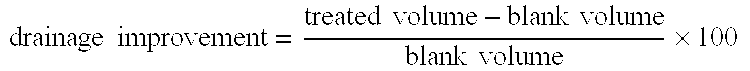

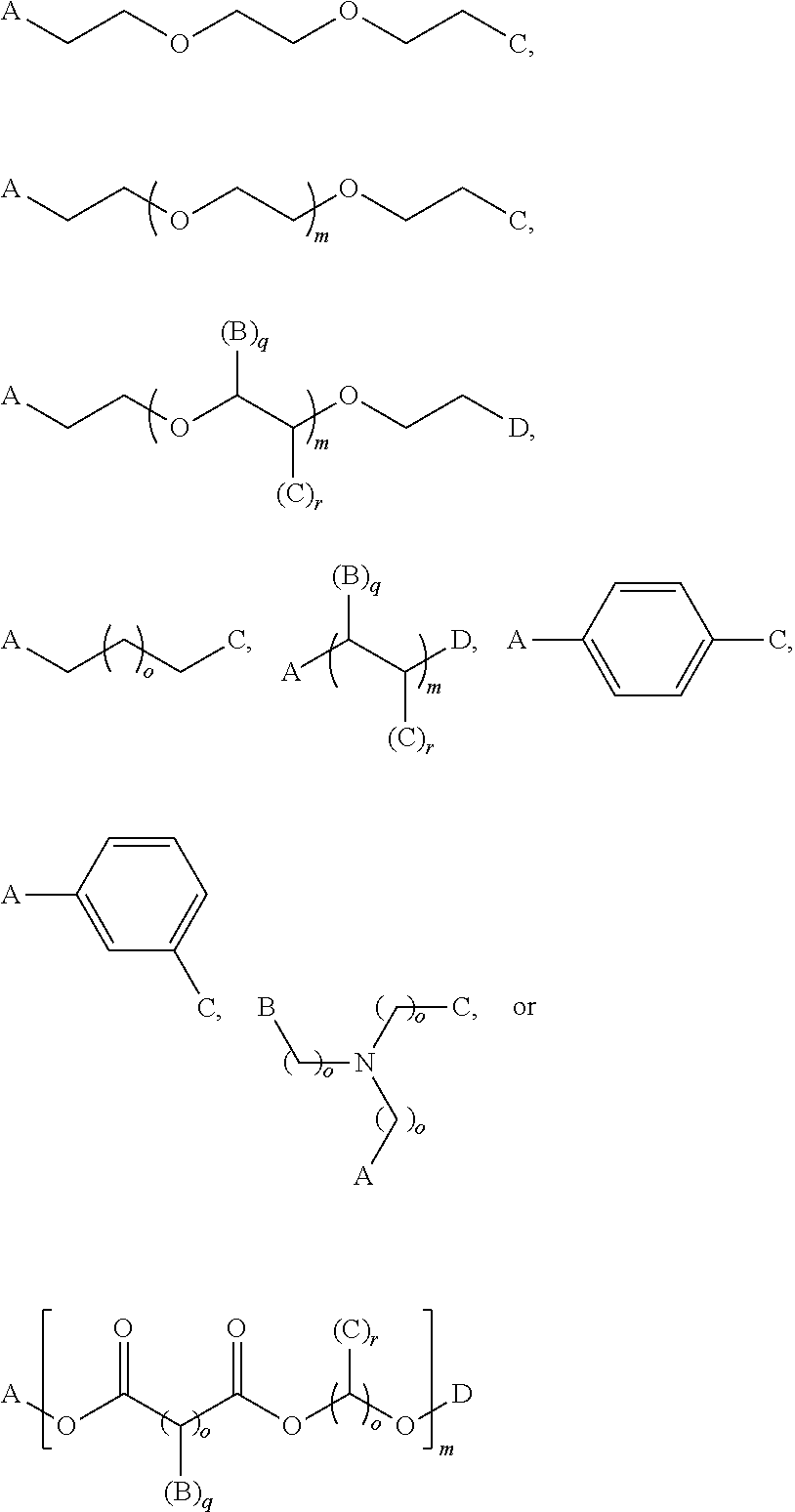

Process for improving dry strength and drainage of paper and paperboard

InactiveUS20060162886A1Good drainageImprove dry strengthNatural cellulose pulp/paperSpecial paperCellulosePaperboard

A process is provided of providing glyoxylated polymer additives to a paper making process which brings about improvements in drainage properties of a cellulosic pulp material along with the ability to increase the dry strength of a resulting paper product. The process uses concentrated glyoxal to generate a working solution of a glyoxylated polymer additive which can be generated on site in a paper mill and used within a 24 to 48 hour interval. The ability to glyoxylate polymers in a working solution concentration provides for a more active additive and which can be supplied in a more economical fashion than conventional glyoxylated polymers.

Owner:PARADIGM CHEM & CONSULTING

Methods for Fixing Hair and Skin

InactiveUS20160193129A1Good benefitImprove dry strengthCosmetic preparationsHair removalHair straighteningCompound (substance)

Owner:LIQWD

Methods for Treating Relaxed Hair

ActiveUS20160310394A1Improve dry strengthReduce hair breakageCosmetic preparationsHair cosmeticsActive agentHair streams

Methods and kits for treating hair or preventing damage in the relaxing of hair are disclosed herein. Hair that is damaged during a relaxing treatment with hydroxide-containing relaxing agents, can be treated with formulations containing one or more active agents. The active agent formulations can be applied simultaneously with the hair relaxing formulation, or optionally applied immediately following application of the relaxing formulation, to reduce damage and breakage. Use of the active agent formulation along with a relaxing treatment can be used to control the level of curl achieved or retained in the relaxed hair, as compared to the natural amount of curl in the untreated hair.

Owner:LIQWD

Methods for Fixing Hair and Skin

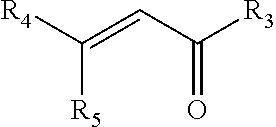

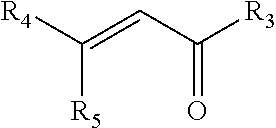

InactiveUS20150037271A1Good benefitImprove dry strengthCosmetic preparationsHair cosmeticsHair straighteningDisulfide bond

Compositions, kits, and methods for repairing bonds, for example, disulfide bonds, in hair or on the skin are disclosed. The compositions provide improved conditioning benefit for dry hair or moisturize the skin. The compositions also provide a long lasting moisturized feel and smooth feel to the skin or hair, without feeling greasy. The compositions contain one or more compounds that covalently crosslink at least two thiol groups in the hair or on the skin. Use of the crosslinking compositions prevents reversion of the repaired bonds to their reduced (thiol) state, for at least one week, one month, six months, or one year, after a single application of the composition. Improved methods of styling hair, for example permanent hair waving, hair curling, and hair straightening are also provided.

Owner:LIQWD

Flushable body waste collection pouch, pouch-in-pouch appliance using the same, and method relating thereto

InactiveUS20050084634A1Limited biodegradabilityReduce noiseSynthetic resin layered productsNon-surgical orthopedic devicesFiberPolymer science

A biodegradable and toilet-flushable body waste collection pouch, and an appliance and method in which such pouch constitutes the inner pouch of a peelably separable pouch-in-pouch system, are disclosed. The walls of the inner pouch are composed of an ultra-thin, heat-sealable film impermeable to body wastes comprising a plasticized biodegradable polyester or copolyester externally covered by a soft, porous, water-disintegratable cover layer of biodegradable and water-dispersible fibers. The cover layer and film are weakly bonded together in such a way as to avoid pinholes in the film that might otherwise be caused by the fibers. When used as the inner pouch of a pouch-in-pouch system, the film of the outer pouch is selected to have a melting temperature higher than that of the inner pouch film, with the result that a peripheral heat seal joining the walls of the two pouches together will allow the walls of the outer pouch to be peeled away without delaminating the film and cover layers of the inner pouch.

Owner:HOLLISTER INCORPORAED

Methods for treating relaxed hair

ActiveUS9597273B2Improve dry strengthGood conditionCosmetic preparationsHair cosmeticsActive agentDermatology

Methods and kits for treating hair or preventing damage in the relaxing of hair are disclosed herein. Hair that is damaged during a relaxing treatment with hydroxide-containing relaxing agents, can be treated with formulations containing one or more active agents. The active agent formulations can be applied simultaneously with the hair relaxing formulation, or optionally applied immediately following application of the relaxing formulation, to reduce damage and breakage. Use of the active agent formulation along with a relaxing treatment can be used to control the level of curl achieved or retained in the relaxed hair, as compared to the natural amount of curl in the untreated hair.

Owner:LIQWD

Low-temperature fast-fired lightweight ceramic heat insulation plate and preparation method thereof

A low-temperature fast-fired lightweight ceramic heat insulation plate and a preparation method thereof. The preparation method comprises: performing ball milling and powder spraying on a raw material containing foamable ceramic waste slag to prepare foamable powder, the foamable ceramic waste slag accounting for 80-100 wt % of the weight of the raw material; uniformly mixing 100 weight portions of the foamable powder with 3-15 weight portions of granular powder of a low-melting-point organic matter to obtain mixed powder materials; pressing the mixed powder materials under 10-20 MPa to prepare a ceramic green body; and firing the ceramic green body at a temperature of 1100-1170° C. to prepare the lightweight energy-saving ceramic heat insulation plate.

Owner:MONALISA GRP CO LTD

Method for preparing organosilicon modified paper sheet humidifying strong agent

InactiveCN101302731AImprove wet strengthImprove surface water resistanceReinforcing agents additionCross-linkEpoxy

The invention discloses a preparation method of a paper wet strengthening agent that is modified by organic silicon, which comprises the following steps: firstly combines the raw materials of dibasic acid and polyhydric amine into a polyamine intermediate compound of daiamid. A certain amount of the polyamine intermediate compound of daiamid, epoxy chloropropane and an organosilane coupling agent are taken to react under certain temperature so as to achieve certain viscosity, and the reaction is halted by adding acid, thus obtaining the paper wet strengthening agent that is modified by organic silicon. The preparation method of the paper wet strengthening agent that is modified by organic silicon can reduce the usage of the epoxy chloropropane and lower the organic chlorine content in discharged substances; the cross-linked product greatly increases molecular weight and active crosslinking points of molecular chain sections. The product of the paper wet strengthening agent that is modified by organic silicon achieves greatly raised retention degree, can improve not only the wet strength of paper but also the paper physical performance such as folding resistance, tensile strength and dry strength, etc., and the superficial water-proof performance of paper can be greatly raised if the paper wet strengthening agent is coated on the surface of paper.

Owner:SHAANXI UNIV OF SCI & TECH

Amphoteric guar gum, preparation method and application thereof

ActiveCN101514233AImprove dry strengthDoes not reduce softnessNon-fibrous pulp additionPaper/cardboardSolventAqueous solution

The invention discloses amphoteric guar gum, a preparation method and application thereof. The preparation method comprises the following steps: (A) adding guar gum raw powder into a low-polar or non-polar solvent at normal temperature, and adding a basic catalyst aqueous solution into the solvent for soaking and basifying; (B) adding a cationic etherifying agent into the mixture under the pressure of between 0.05 and 0.3 Mpa; and (C) adding an anionic etherifying agent into the mixture to react, and adding a neutralizing agent to neutralize the mixture until pH is between 7 and 8, and collecting the amphoteric guar gum from reactant. The prepared product has excellent viscosity stability and higher transparency. As a thickening agent, the amphoteric guar gum can be applied to paper making, foods, textile and other fields; and as a reinforcing agent, the amphoteric guar gum can be applied to the field of paper making, and can obviously improve the baked strength of paper without reducing the softness of the paper.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

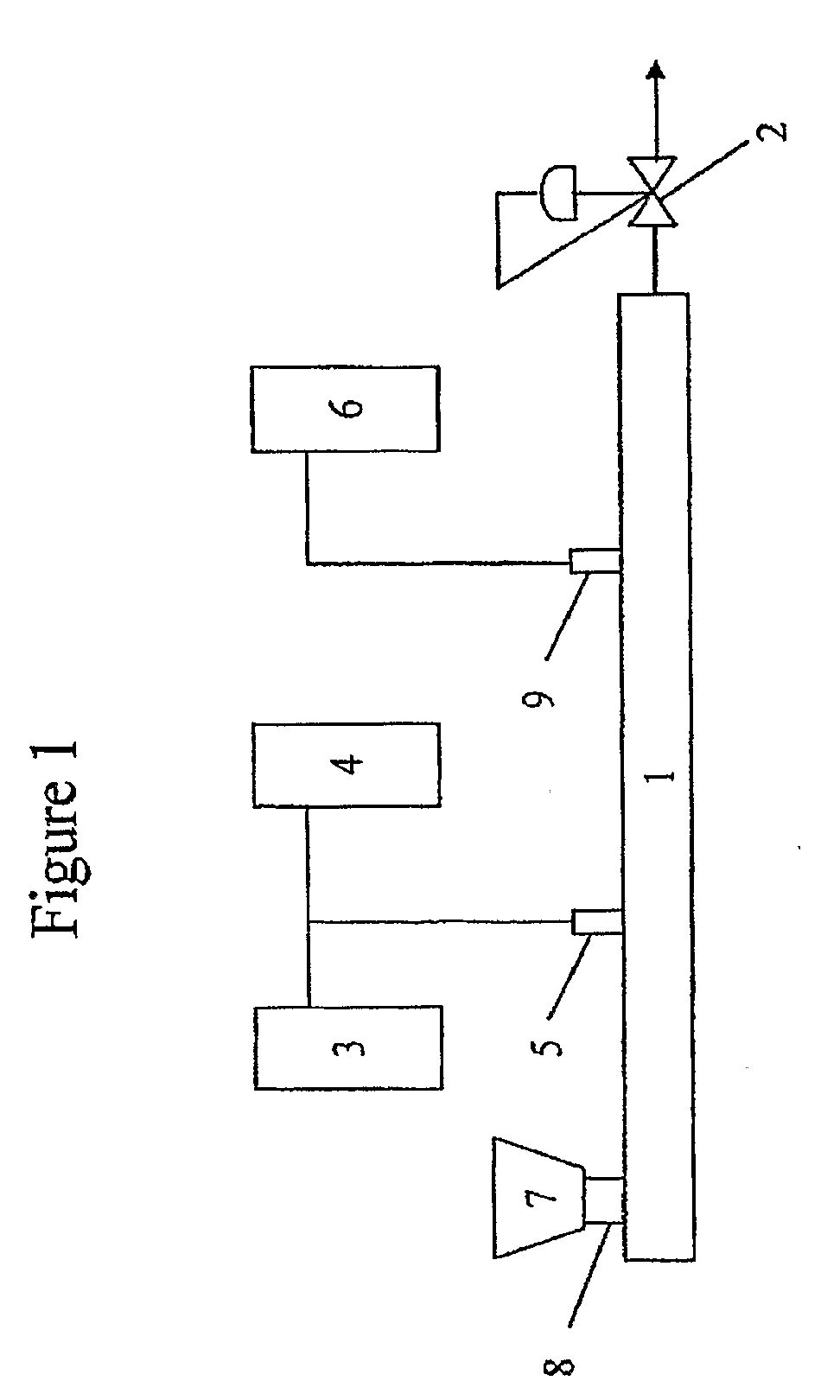

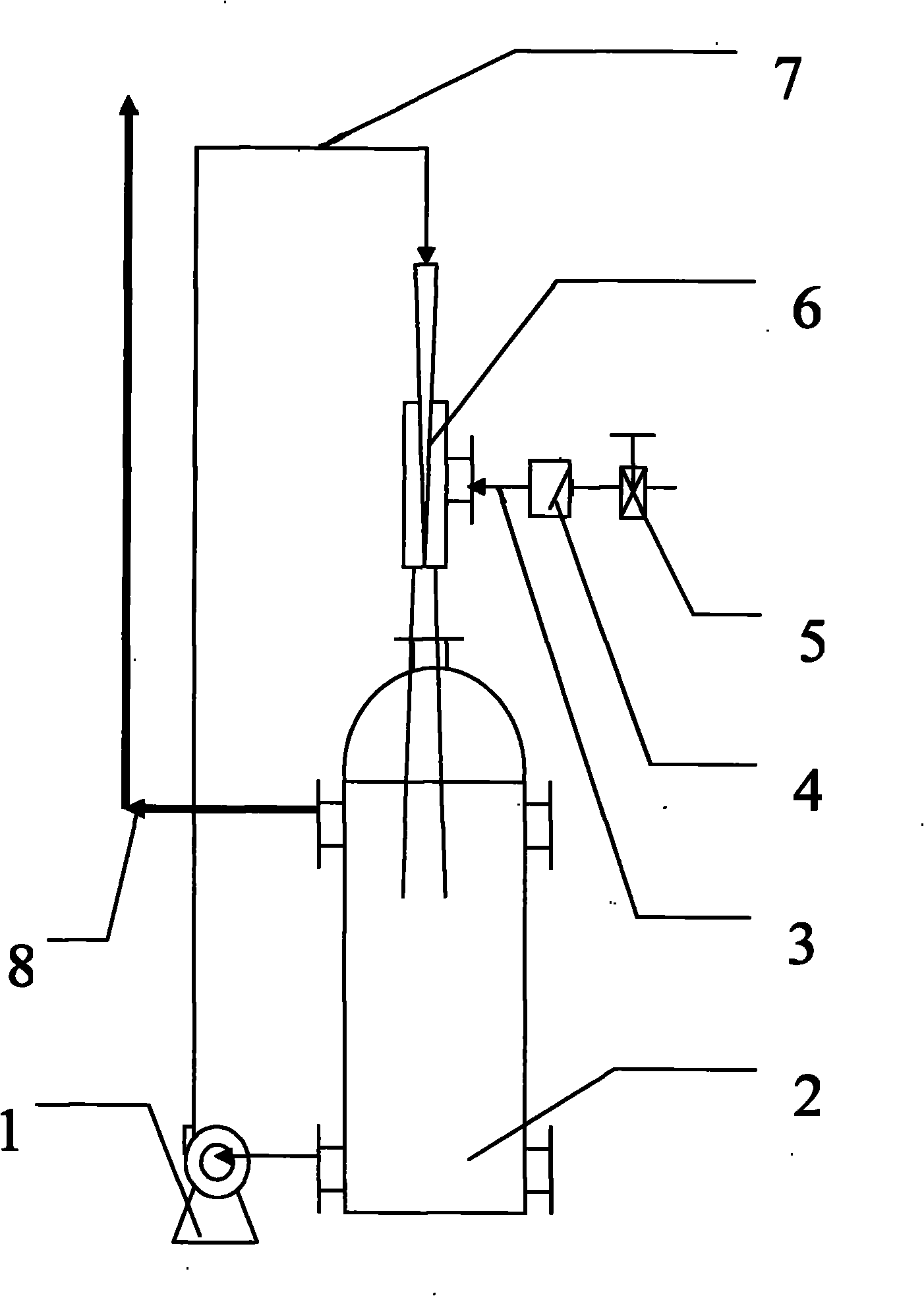

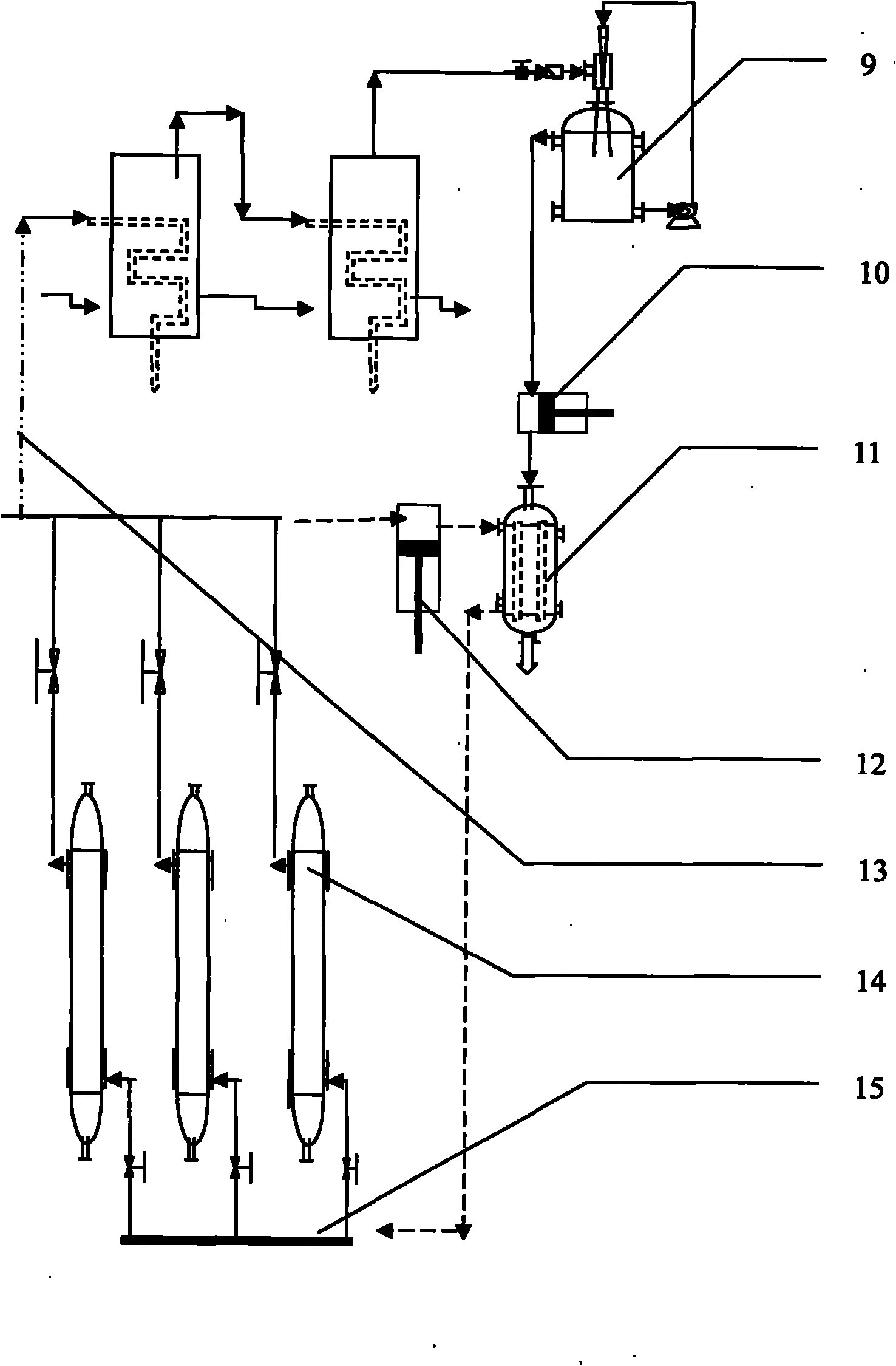

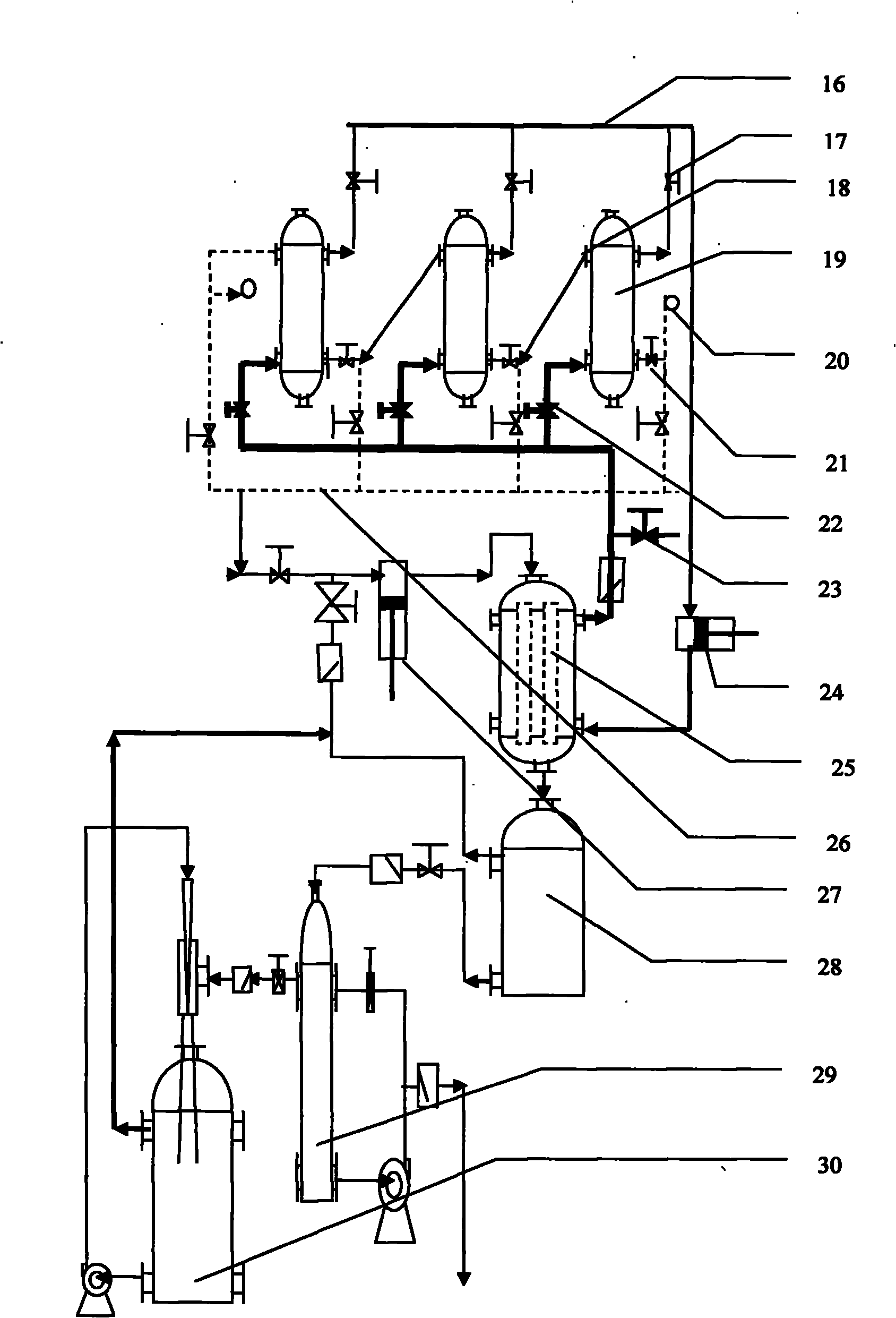

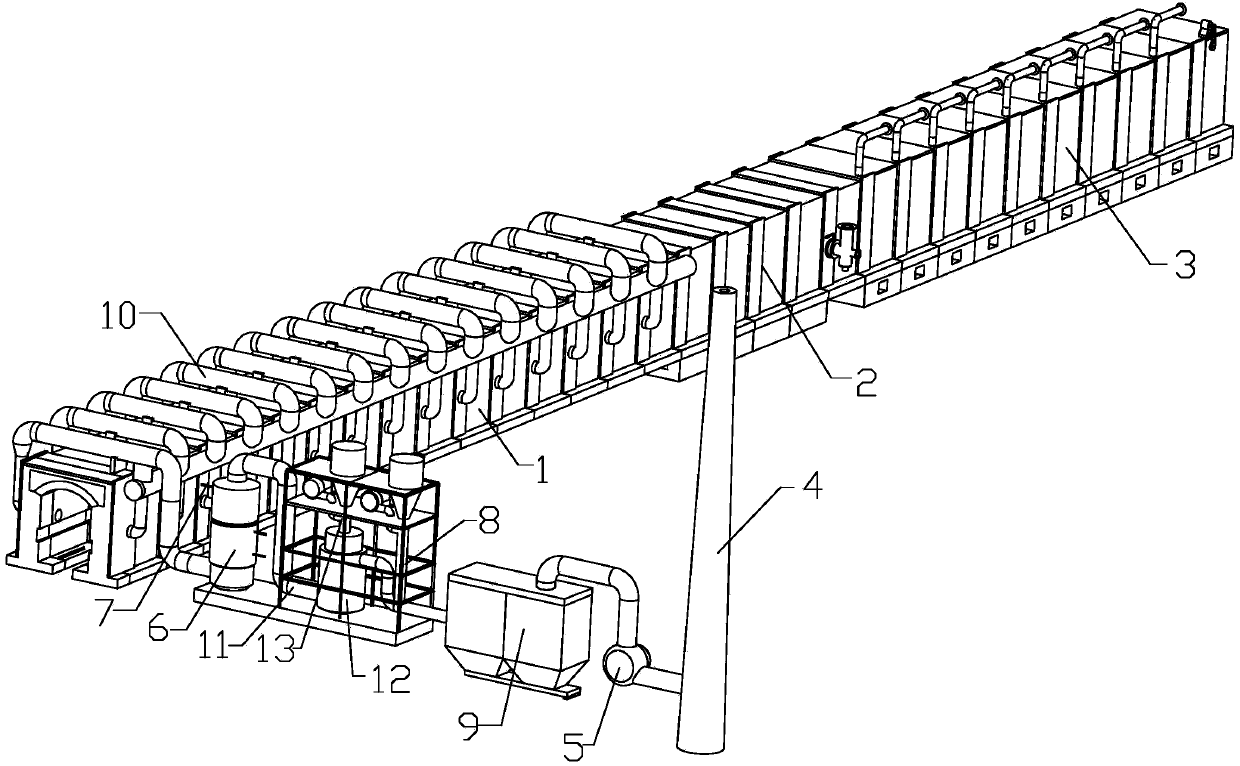

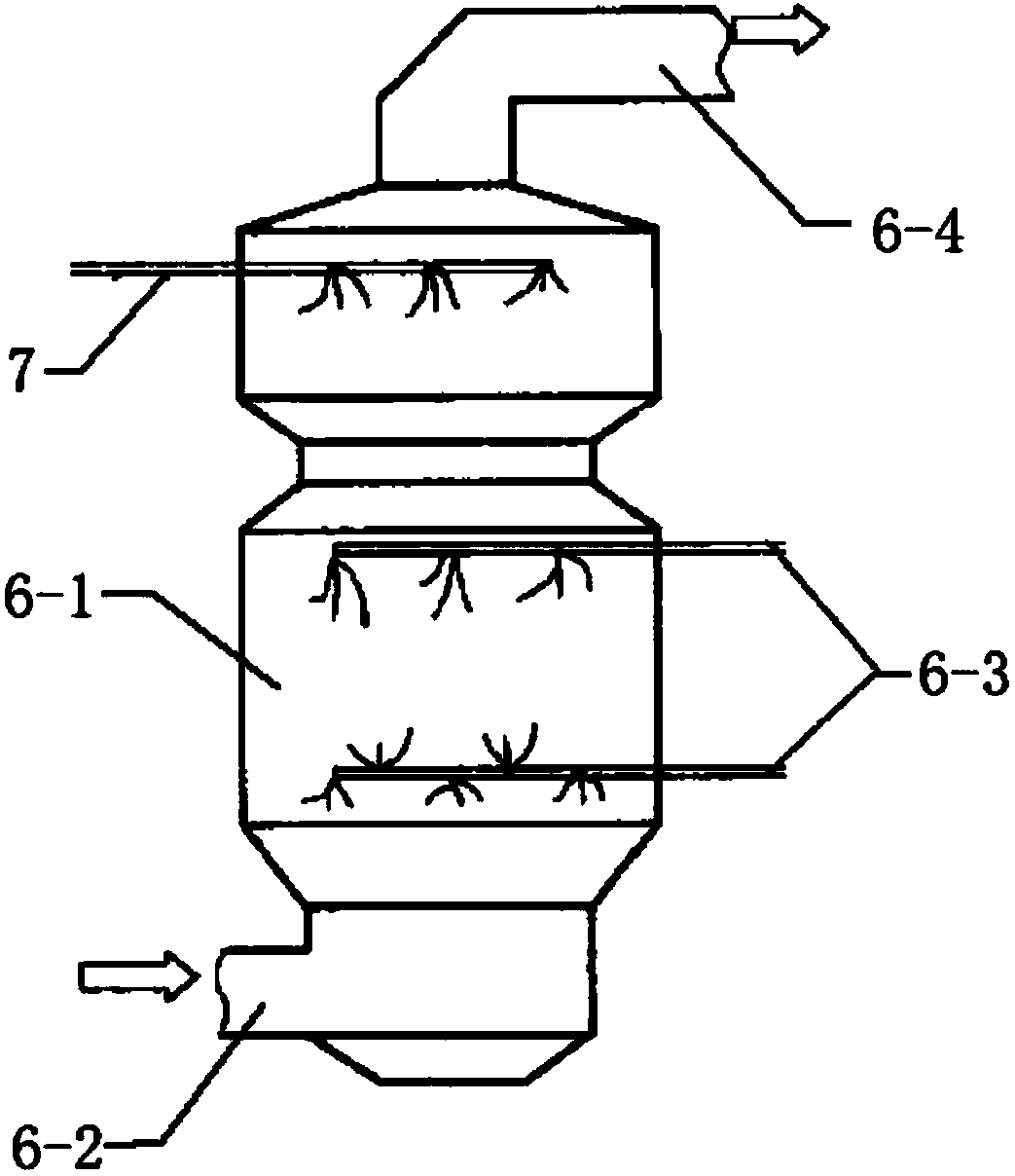

Method for drying materials by utilizing superheated steam

ActiveCN101968299AAvoid lostAvoid pollutionDrying solid materials with heatHearth type furnacesEvaporationEngineering

The invention discloses a method for drying materials by utilizing superheated steam, which is characterized in that the superheated steam is added into a sealed container in which materials to be dried are arranged, the superheated steam is used for evaporating the moisture in the materials to be dried to generate steam, and the superheated steam is cooled into low-temperature steam; the low-temperature steam enters a low-temperature steam system from the sealed container under the condition that the flow rate of the low-temperature steam is controlled; a mechanical pressurizing device is used by the low-temperature steam system for pressurizing the low-temperature steam to obtain the boosted steam; and the boosted steam is used for indirectly heating the steam in the sealed container, the boosted steam discharges the latent heat of vaporization to generate condensed water, and the steam in the sealed container receives the heat to become the superheated steam for continuously drying the materials to be dried. In the invention, the moisture of the materials to be dried is similar to the moisture of a multiple-effect evaporation system and is discharged in a form of the condensed water. The invention has the advantages of high drying efficiency, low energy consumption and simple processes, and has an industrial base of large-scale implementation.

Owner:武善东 +1

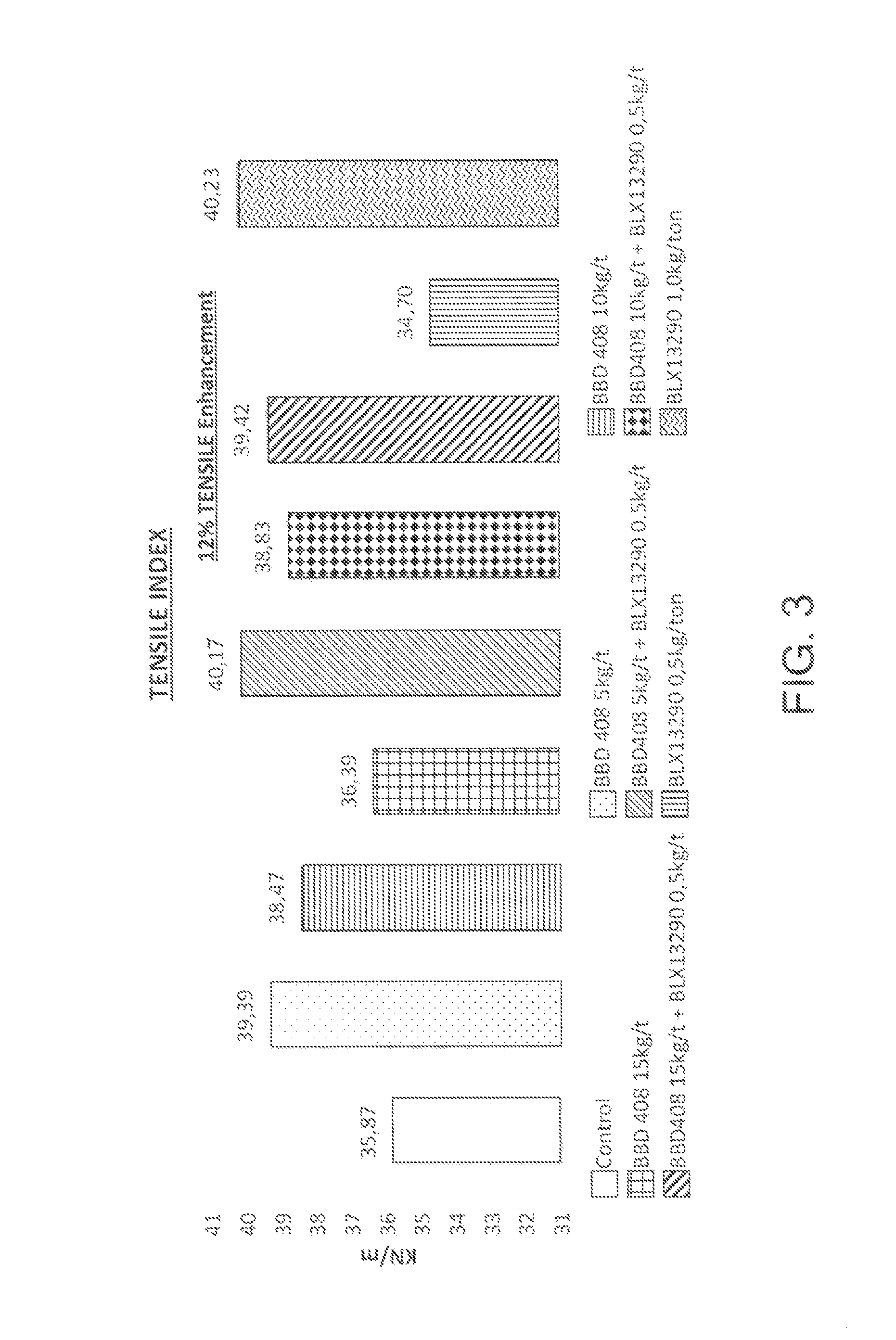

Methods For Enhancing Paper Strength

InactiveUS20140116635A1Enhance dry strengthImprove dry strengthNatural cellulose pulp/paperSpecial paperWater soluble polymersChemistry

Methods of making paper or paperboard having enhanced dry strength are provided. An enzyme and a polymer including at least one of a cationic water-soluble polymer and an amphoteric water-soluble polymer can be added to a papermaking pulp to yield a treated pulp. The treated pulp can then be formed into paper or paperboard having a dry strength greater than paper or paperboard formed from papermaking pulp without the addition of the enzyme and polymer. Any suitable enzyme can be used, for example, a laccase or a cellulase. Any suitable polymer can be used. For example, at least one of a glyoxylated polyacrylamide (gPAM), a polyvinylamine, a decarboxylated polyacrylamide, and a dimethylamine-epichlorohydrin (epi-DMA).

Owner:BUCKMAN LAB INT INC

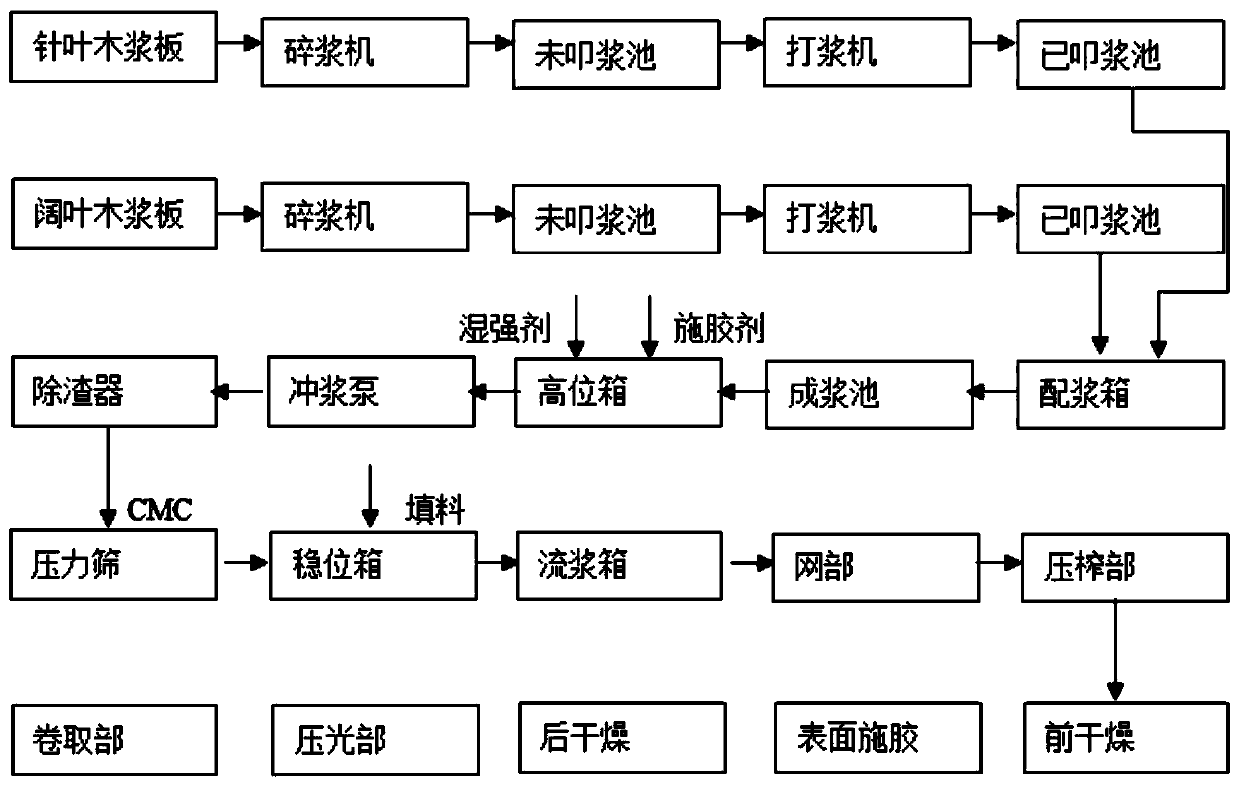

Manufacturing method of beverage drinking straw paper

InactiveCN110318302AImprove wet strengthIncrease paper dry strengthTextiles and paperHardwoodDrinking straw

The invention discloses a manufacturing method of a beverage drinking straw paper. The method comprises the technical processes of pulp beating, pulp blending, additive adding, wet paper making, pre-drying, surface sizing, after-drying, calendaring and rolling. The beverage drinking straw paper belongs to papers for foods and meets the sanitary requirements on the papers for foods. The beverage drinking straw paper is manufactured by choosing preferable raw and additive materials and chemicals and taking chlorine-free bleached softwood kraft paper pulp and chlorine-free bleached hardwood kraftpaper pulp as fiber raw materials, which contain no toxic chemical substances such as organic chlorides and are environmentally friendly, sanitary and free from damage to human body. The produced beverage drinking straw paper is high in dry strength and wet strength, free from breakage, high in humidity resistance and capable of being rapidly decomposed to meet the environmental requirements as we as the sanitary requirements on the papers for foods.

Owner:YUEYANG FOREST & PAPER CO LTD

Method of producing cordierite honeycomb structure

ActiveUS20050212186A1Improve dry strengthIncrease contact areaCeramic shaping apparatusFiltration separationMetallurgyCordierites

A method of producing a cordierite honeycomb structure includes: preparing clay containing a cordierite raw material having an aspect ratio of 1.5 or more; forming the clay to prepare a formed product of a honeycomb shape; drying the formed product to prepare a dried honeycomb product; and firing the dried honeycomb product to prepare a cordierite honeycomb structure. The production method can obtain a cordierite honeycomb structure capable of suppressing formation of cracks during firing.

Owner:NGK INSULATORS LTD

Smoke semi-closed circulating lignite straight pipe type airflow drying method

ActiveCN101726167AGood dispersionImprove dry strengthDrying solid materials with heatDrying gas arrangementsAir volumeDirect combustion

The invention relates to a smoke semi-closed circulating lignite straight pipe type airflow drying method, which ensures the safety and reliability of a device and makes the maximization of the device possible through direct combustion of lignite to generate smoke, once drying of a straight pipe type airflow dryer to meet the moisture requirement of a product, large-grain inertia setting, collection of a fine grain bag type dust collector, even blending of large grains and fine grains through a blending device, emptying and air quantity control through a mixed temperature fan and a booster fan.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

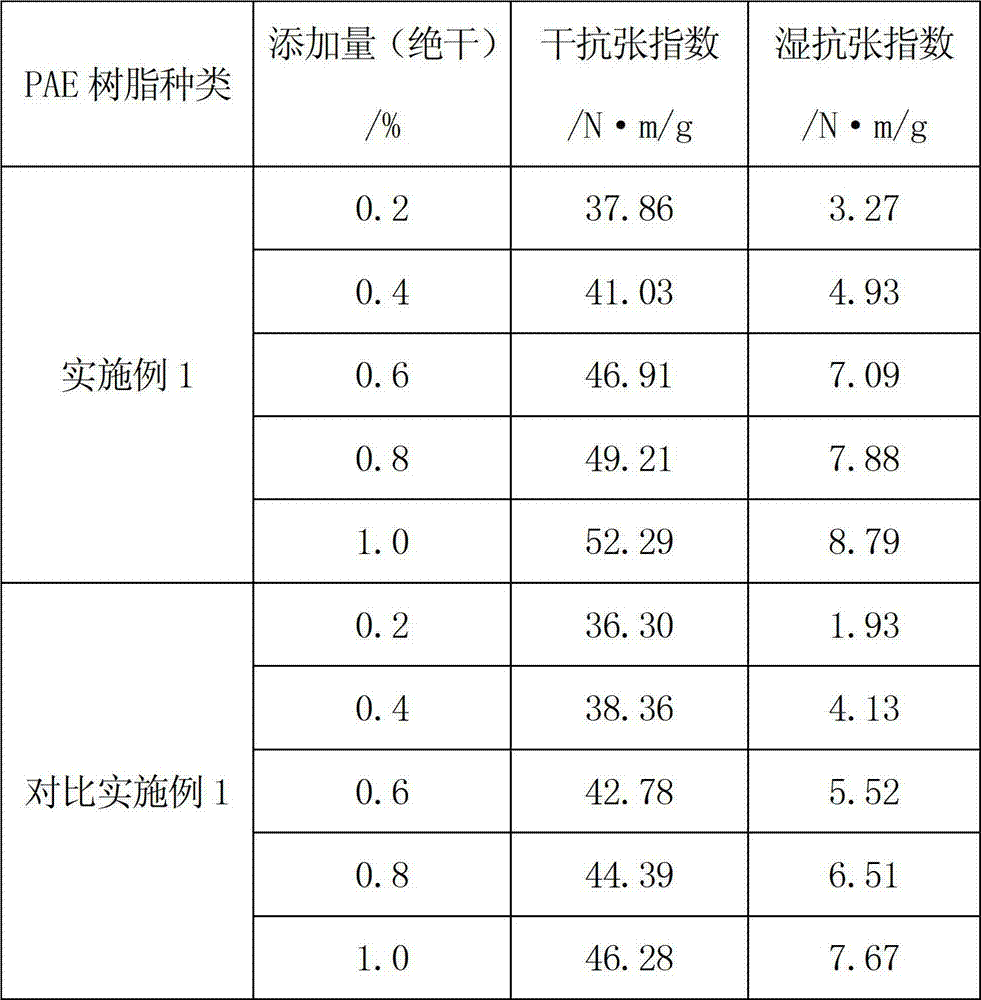

Preparation method of modified polyarylether (PAE) resin

InactiveCN102898643AAchieving charge controlImprove dry strengthReinforcing agents additionPaper/cardboardFiberPolyamine

A preparation method of modified polyarylether (PAE) resin comprises the following steps of: reacting polyethylene polyamine and binary acid under effects of a catalyst to synthesize polyamine prepolymer, adjusting a solid content of the polyamine prepolymer tobe 20-30%, adjusting a pH value to be 8-10, adding carboxyl modifier, then adding epichlorohydrin, adding hydrochloric acid after a reaction is completed, adjusting the pH value to be 3-4 and finishing the reaction to obtain the modified PAE resin. Carboxyl is introduced in a molecular structure of the PAE resin, the carboxyl is used for balancing positive electricity carried by the PAE resin, and electric charge control of the PAE resin is achieved. Simultaneously, after paper is used, the carboxyl carried by the modified resin can form hydrogen bonds between fibers, the carboxyl in a structure of the PAE resin and epoxy functional groups and the like exist simultaneously, after the carried carboxyl forms the hydrogen bonds between fibers, a distance of the epoxy functional groups and primary amine groups and the like between different PAE resins is reduced, covalent bonds are conveniently formed, time needed by curing is shortened, and accordingly, paper forming humidity and strength are improved, and a humidifying and strength performance are strengthened.

Owner:SHAANXI UNIV OF SCI & TECH

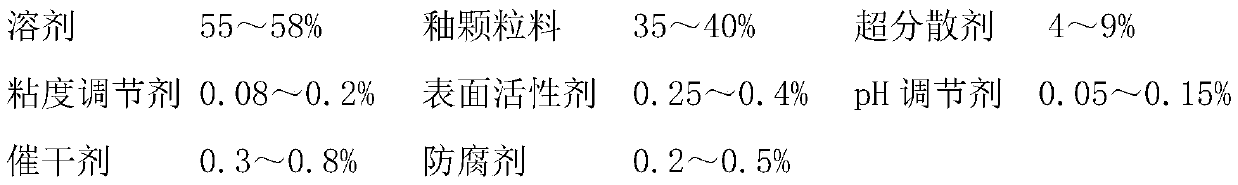

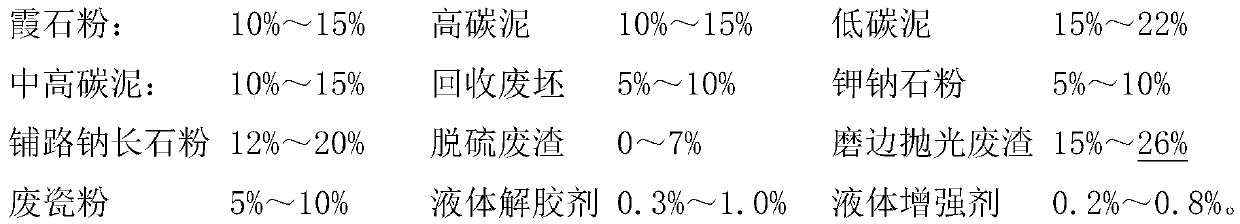

Silky fine matt ceramic tile and production method thereof

ActiveCN110204306AReduce consumptionSimplify product processCeramic shaping apparatusCeramic materials productionCeramic tilesPotassium

The invention relates to a silky fine matt ceramic tile and a production method thereof. The blank material of the ceramic brick comprises 10-15% of nepheline powder, 5-10% of high-carbon mud, 20-25%of low-carbon mud, 10-15% of medium-and-high-carbon mud, 5-10% of recovered waste blanks, 5-10% of potassium and sodium stone powder, 20-25% of paving albite powder, 5-10% of waste porcelain powder, 0-7% of desulfurization waste residues, 20-30% of edging and polishing waste residues, 0.3-1.0% of a liquid dispergator and 0.2-0.8% of a liquid reinforcing agent. The production method comprises the following processes: proportioning and ball milling of blank raw materials, spray drying, aging, blank compression molding, drying, blank polishing, water spraying, glazing, pattern decoration and firing.

Owner:JIANGXI HEMEI CERAMICS +4

Novel tunnel kiln structure and method for tunnel kiln to process organic polluted soil

ActiveCN104197702ASpeed up temperature riseImprove smoke exhaust effectFurnace typesCeramic materials productionTunnel kilnBrick

The invention provides a novel tunnel kiln structure and a method for processing organic polluted soil. The method comprises the steps of detecting types and contents of mineral substances in the organic polluted soil, then adding required materials according to the tile firing requirements or the firing requirements, adding internal fuel, adding water to mix the materials to obtain raw pug materials, sequentially pugging, pelletizing, extruding and forming the raw pug materials, decaying or curing the raw pug materials for 5-10 days, drying the raw pug materials, sending the raw pug material into the tunnel kiln to be fired, sequentially keeping green bricks or green tiles in a preheating zone kiln body at the temperature of 150-750 DEG C for 30 minutes to 1 hour and in a firing zone kiln body at the temperature of 750-1350 DEG C for 2-3 hours, then sending the green bricks or the green tiles into a cooling zone kiln body to be naturally cooled to the normal temperature and outputting the green bricks or the green tiles. The method can completely remove toxic substances like various pesticide residues in the soil through high temperature and is high in processing efficiency, low in cost, free of secondary pollution and obvious in environmental-friendly benefit.

Owner:WUHAN HUIZHONG DACHUAN AUTOMATIC CONTROL EQUIP CO LTD

Method of producing cordierite honeycomb structure

ActiveUS7364689B2Improve dry strengthSuppressing formation of cracks during firingCeramic shaping apparatusFiltration separationMetallurgyHoneycomb Pattern

A method of producing a cordierite honeycomb structure includes: preparing clay containing a cordierite raw material having an aspect ratio of 1.5 or more; forming the clay to prepare a formed product of a honeycomb shape; drying the formed product to prepare a dried honeycomb product; and firing the dried honeycomb product to prepare a cordierite honeycomb structure. The production method can obtain a cordierite honeycomb structure capable of suppressing formation of cracks during firing.

Owner:NGK INSULATORS LTD

Process for preparing magnesium sulfate monohydrate by using water-containing magnesium sulfate heptahydrate

ActiveCN102583459ASolve the problem of easy cakingContinuous stable operationMagnesium sulfatesFree waterMagnesium sulphate heptahydrate

The invention discloses a process for preparing magnesium sulfate monohydrate by using water-containing magnesium sulfate heptahydrate, comprising the following steps of: (1) wet material feeding: delivering water-containing magnesium sulfate heptahydrate into a drying chamber of a spin flash dryer; (2) hot air delivery: heating the air to 220-320 DEG C, pressurizing by using a draught fan, and delivering the air into the spin flash dryer; (3) drying process: remaining a wet material to be dried in the drying chamber of the spin flash dryer for 2-6s to obtain finished magnesium sulfate monohydrate containing free water less than or equal to 3wt%; and (4) discharging and tail gas treatment and exhaust: delivering the dried material into a discharging device, carrying out cyclone dust removal and water film dust removal, then collecting the dried magnesium sulfate monohydrate, and exhausting tail gas. The process for preparing the magnesium sulfate monohydrate by using the water-containing magnesium sulfate heptahydrate, provided by the invention, has the advantages of easiness in controlling the drying temperature, short process flow, strong adaptability, continuous, stable and reliable drying process and good drying effect.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Antibacterial paper production technique and antibacterial paper

InactiveCN103147351AImprove dry strengthGood adhesionSpecial paperPaper/cardboardPaper productionPapermaking

The invention relates to an antibacterial paper production technique which comprises the following steps of: providing paper pulp fibers; conducting papermaking by utilizing the paper pulp fibers; and adding an antibacterial agent with specific functional group into the paper pulp fibers before drying and dewatering paper webs formed by manufacturing paper with pulp, wherein the specific functional group comprises at least one of hydroxyl functional group, carboxyl functional group and amino functional group. Compared with the prior art, the antibacterial paper production technique not only avoids the waste of the antibacterial agent, but also effectively promotes the strength of the antibacterial paper. The invention further relates to antibacterial paper produced by utilizing the production technique.

Owner:GOLD HONG YE PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com