Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "High freeness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

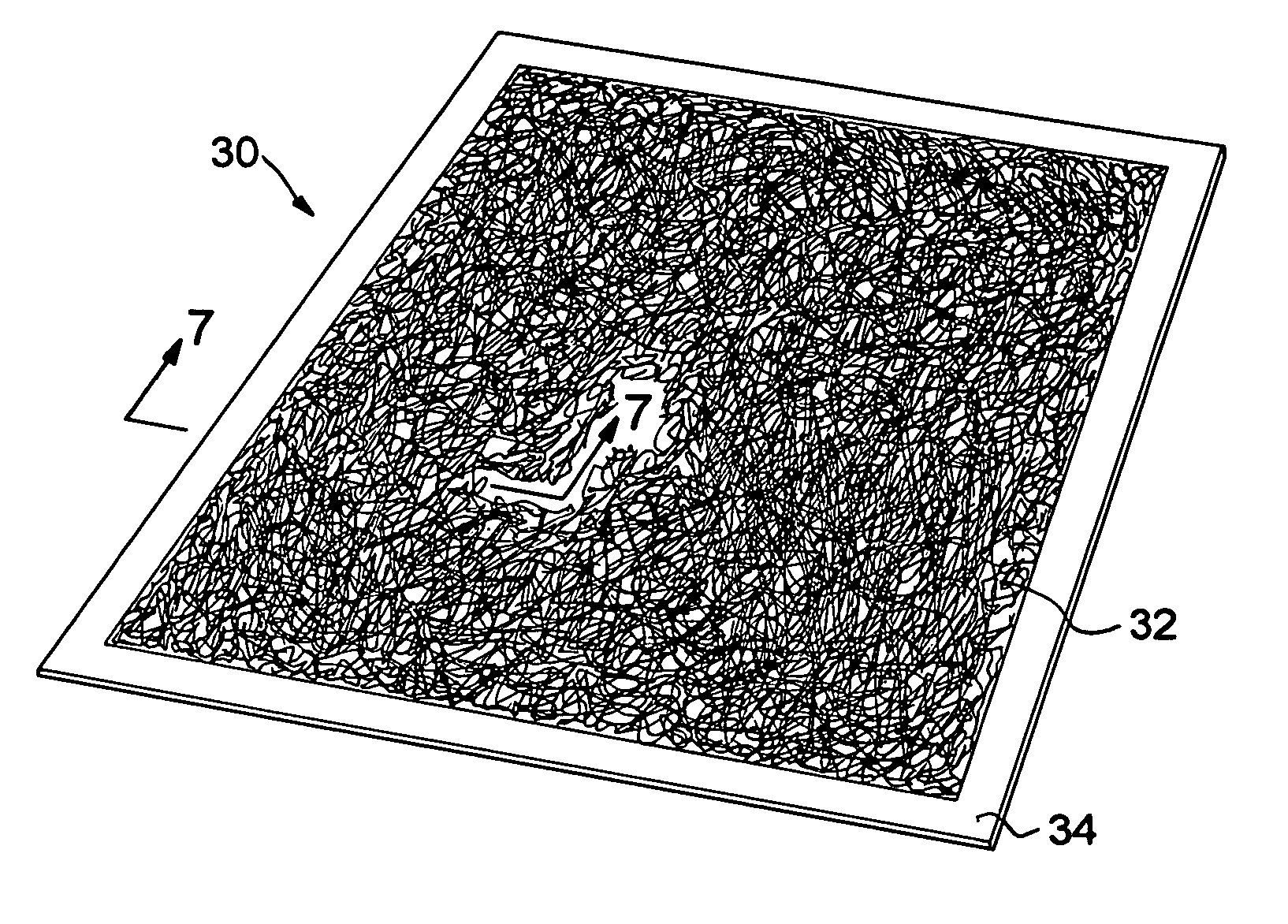

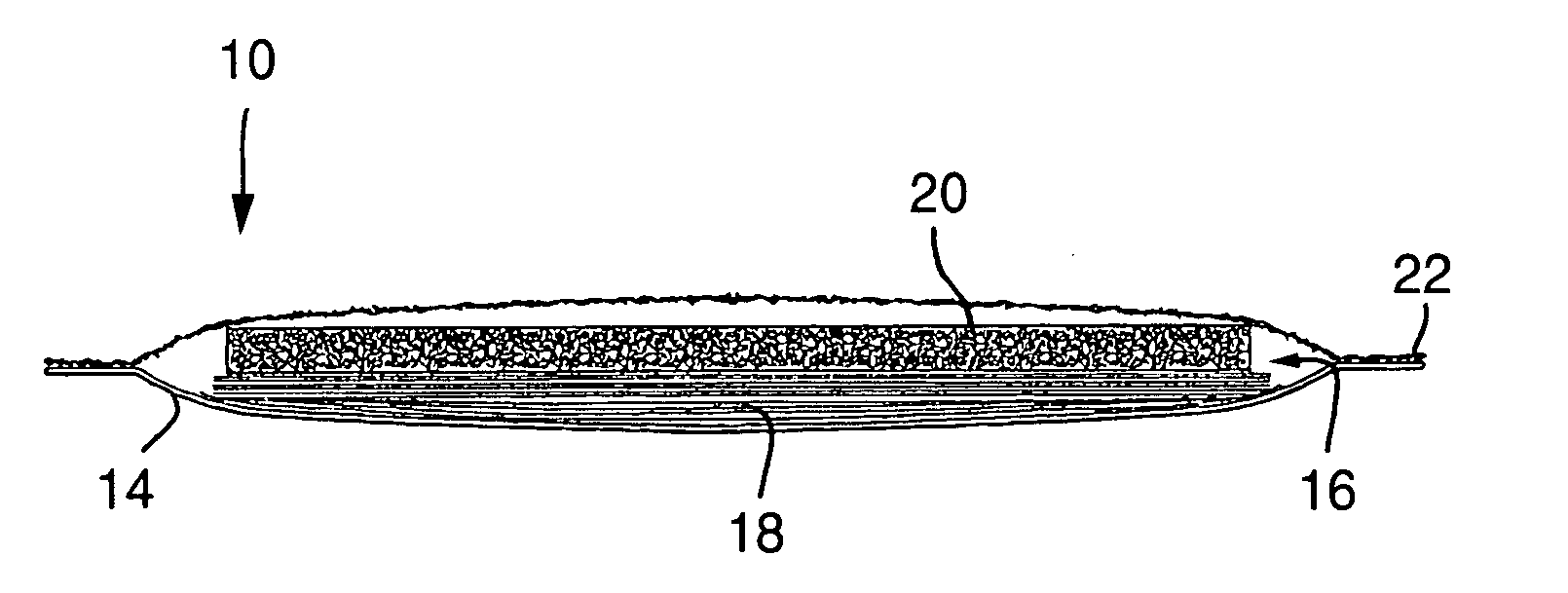

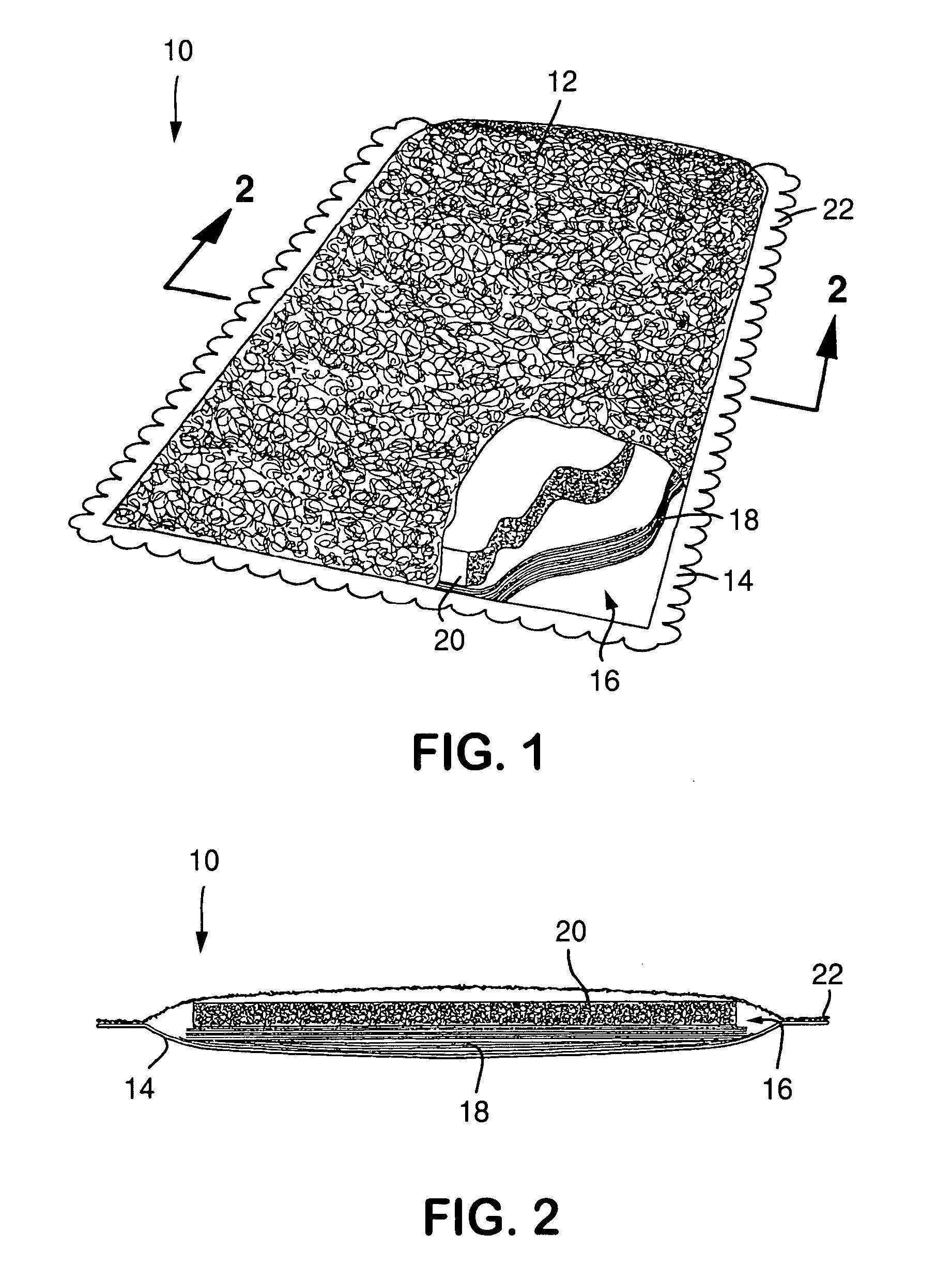

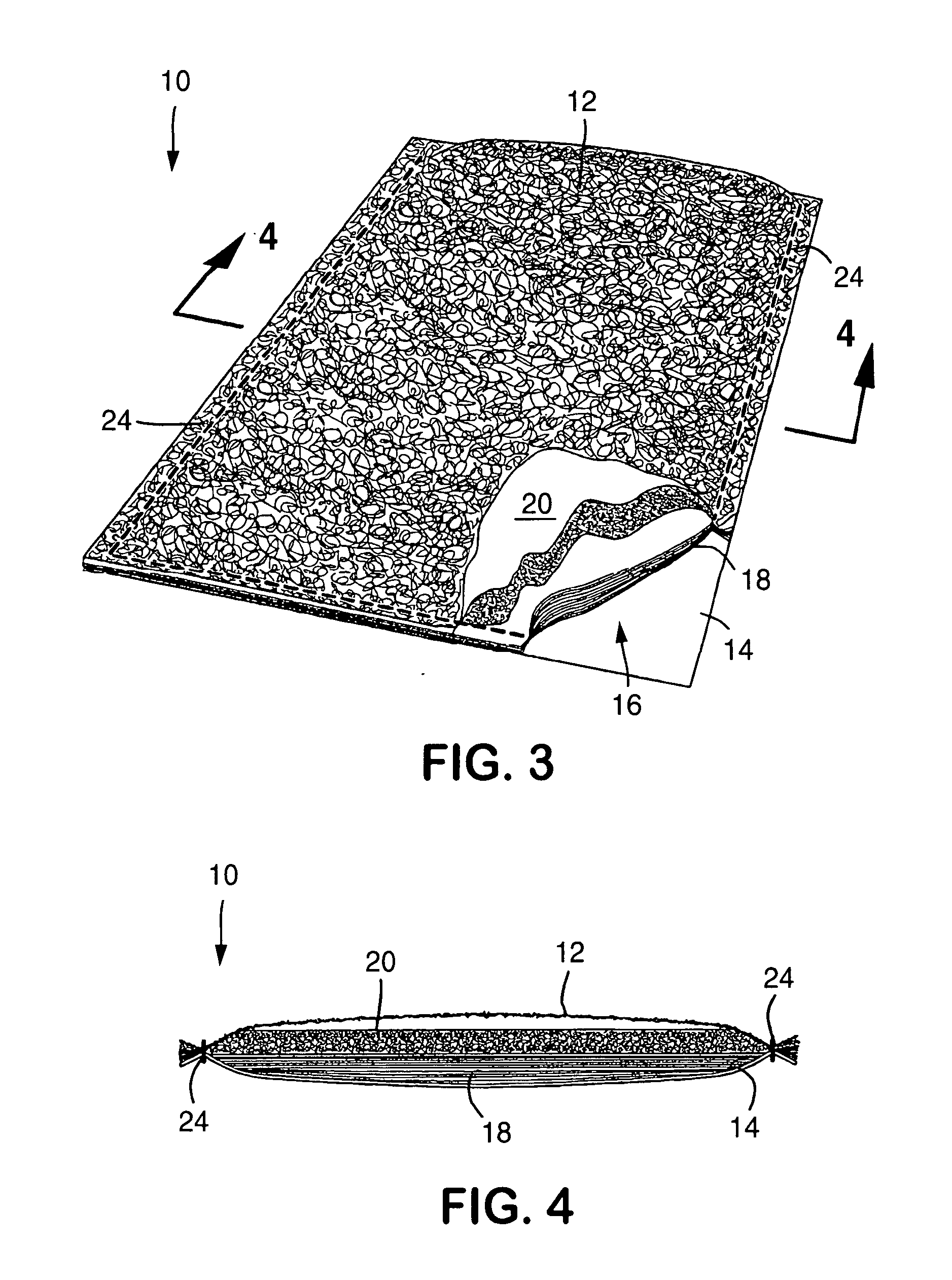

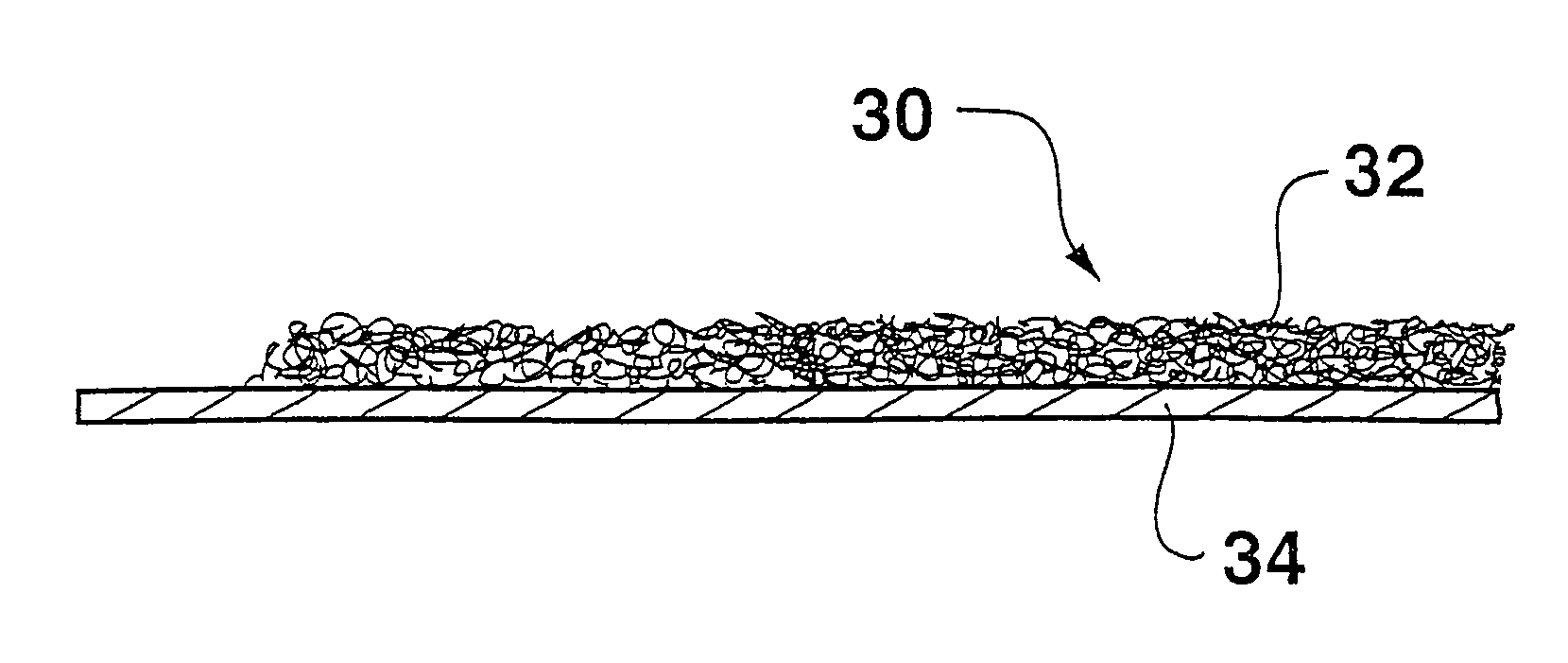

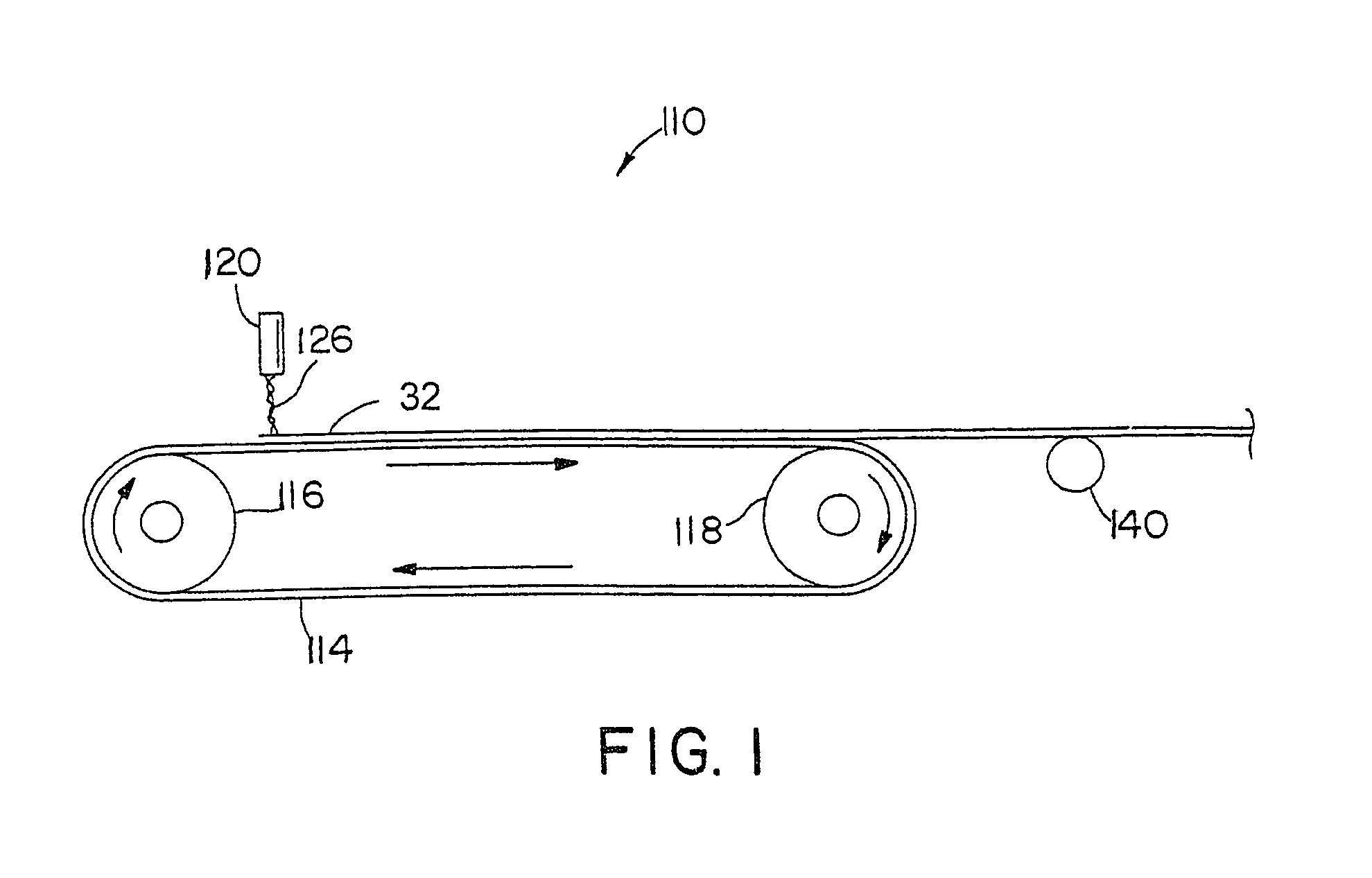

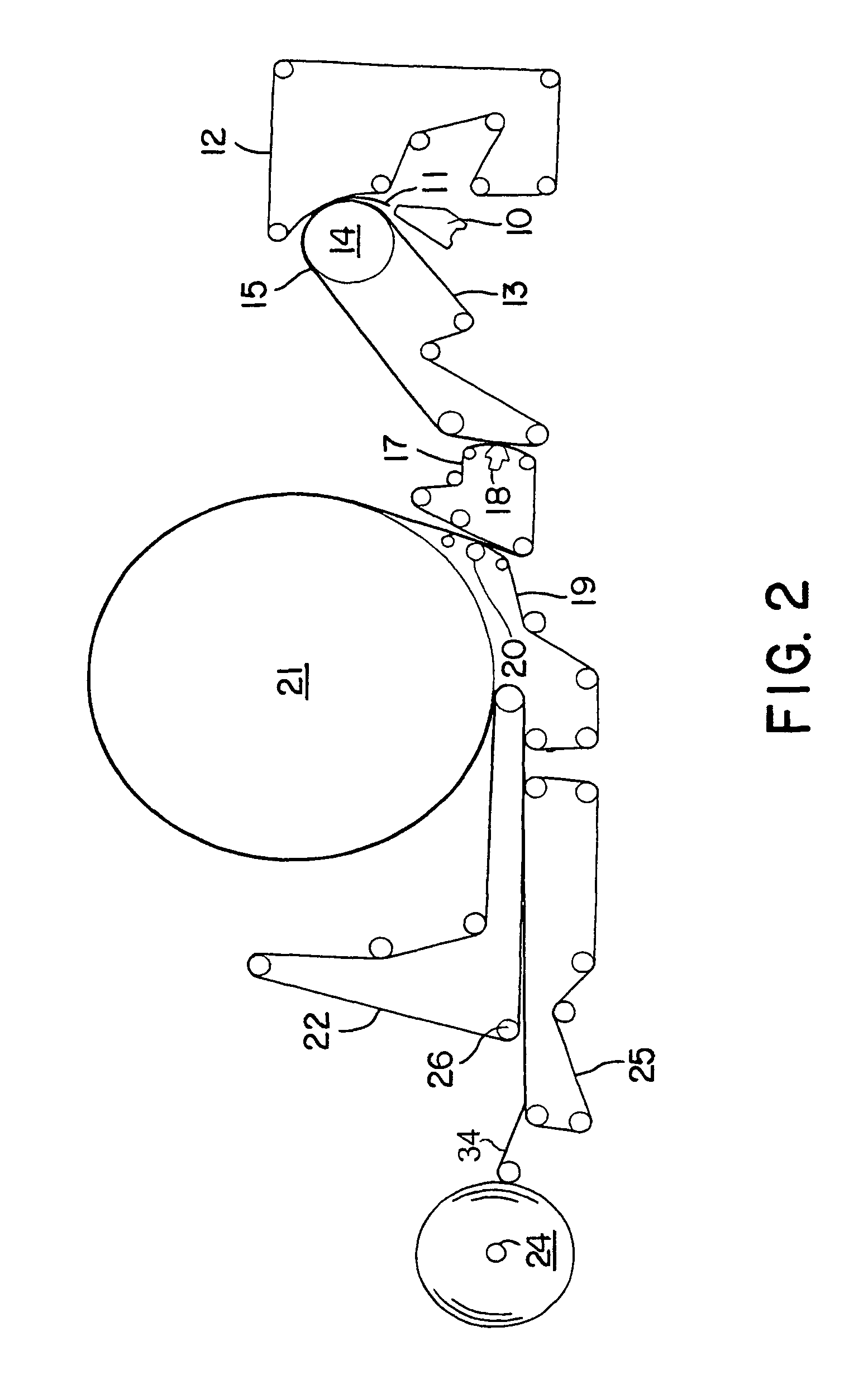

Disposable scrubbing product

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Composite cleaning products having shape resilient layer

InactiveUS20060135026A1Resists effect of waterMaintain stiffnessCarpet cleanersLayered productsPersonal careEngineering

The present invention discloses a disposable cleaning product for use in household cleaning or personal care applications. The cleaning product of the invention is a multi-layer laminate product and may include at least two distinct layers, an abrasive layer and an absorbent layer. The absorbent layer contains a sponge-like member optionally in combination with a plurality of cellulosic fibrous webs. The sponge-like member can be made from various materials. For example, in one embodiment, the sponge-like member comprises one or more layers of a spunbond web containing crimped, bicomponent filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

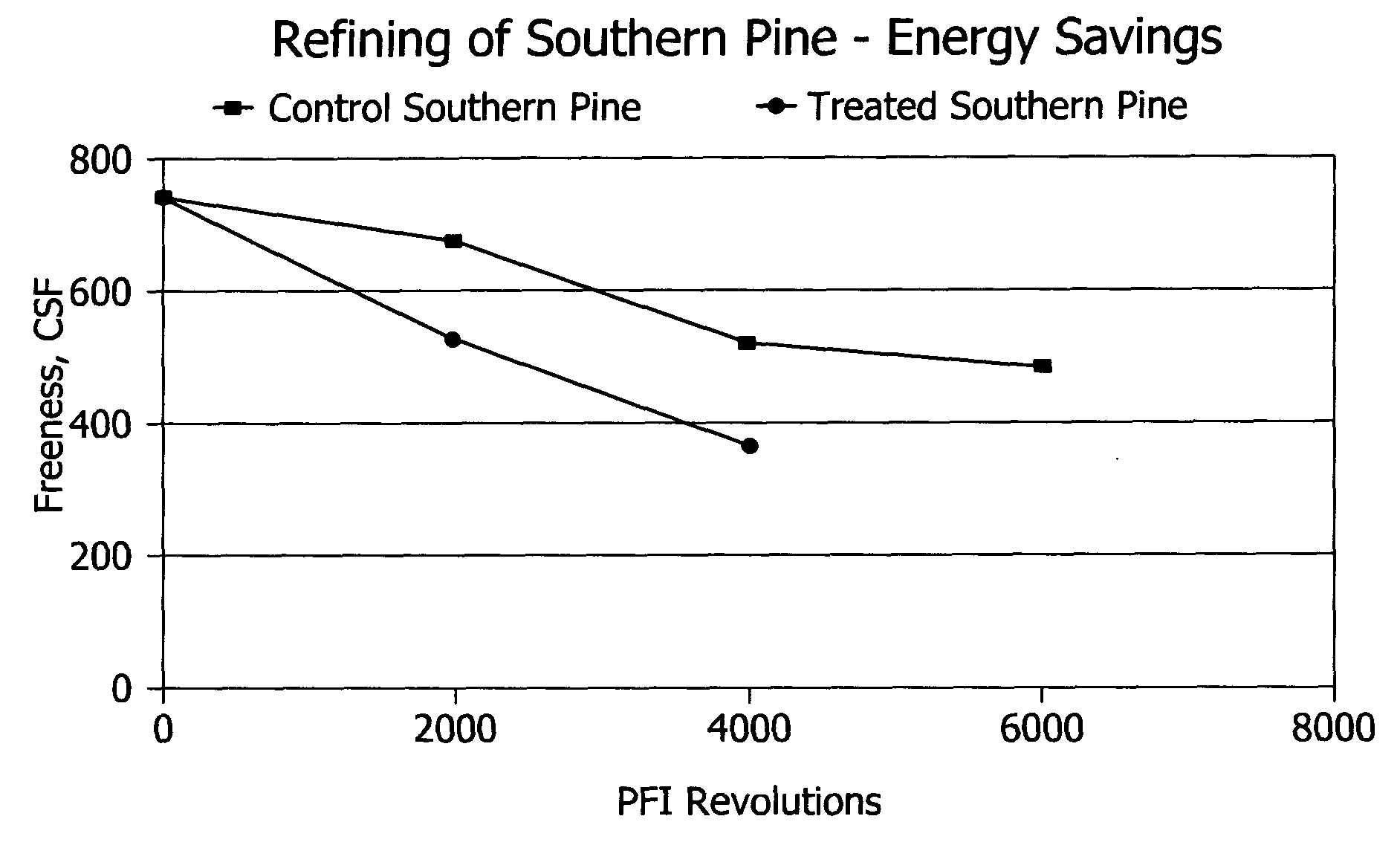

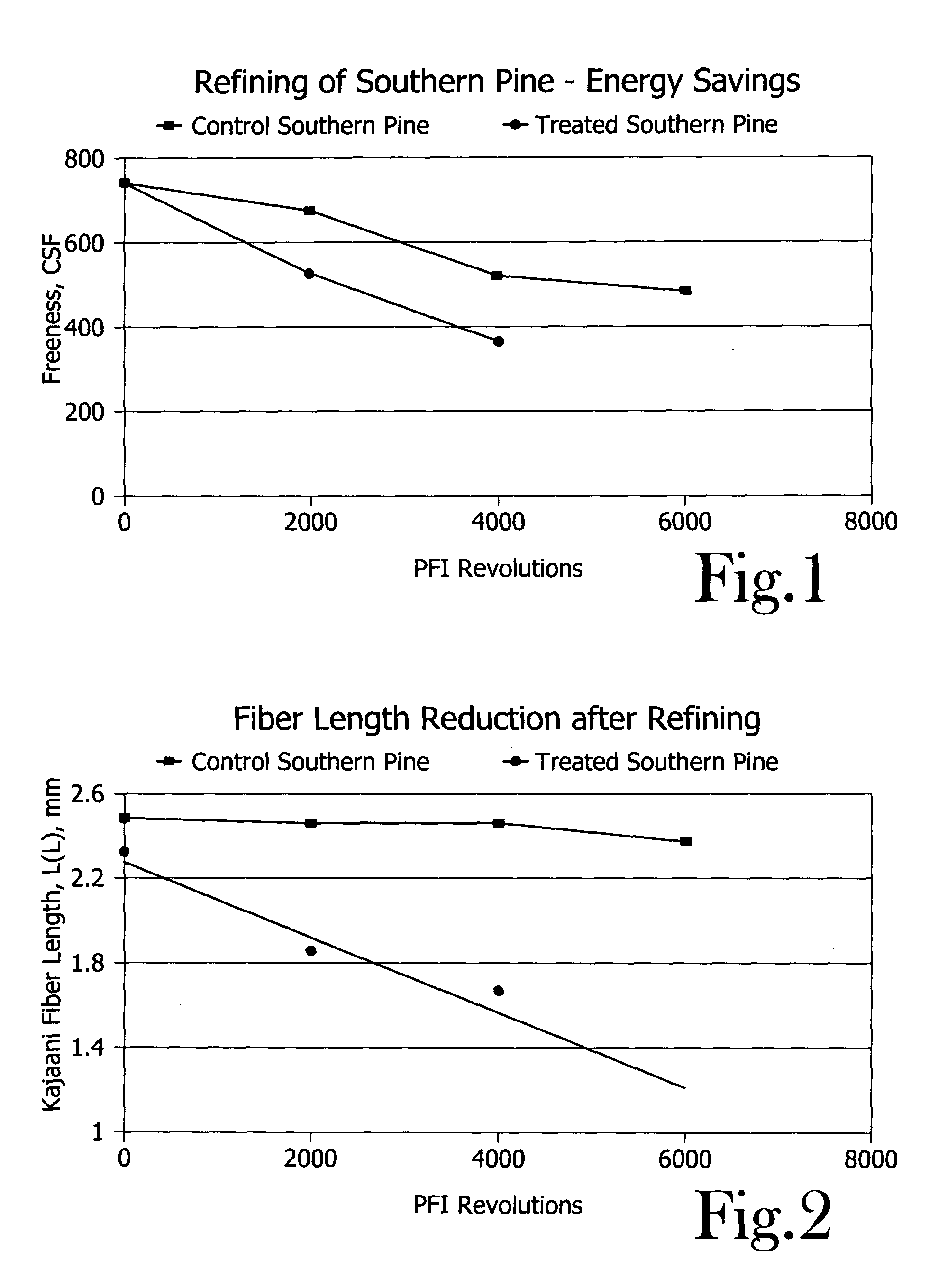

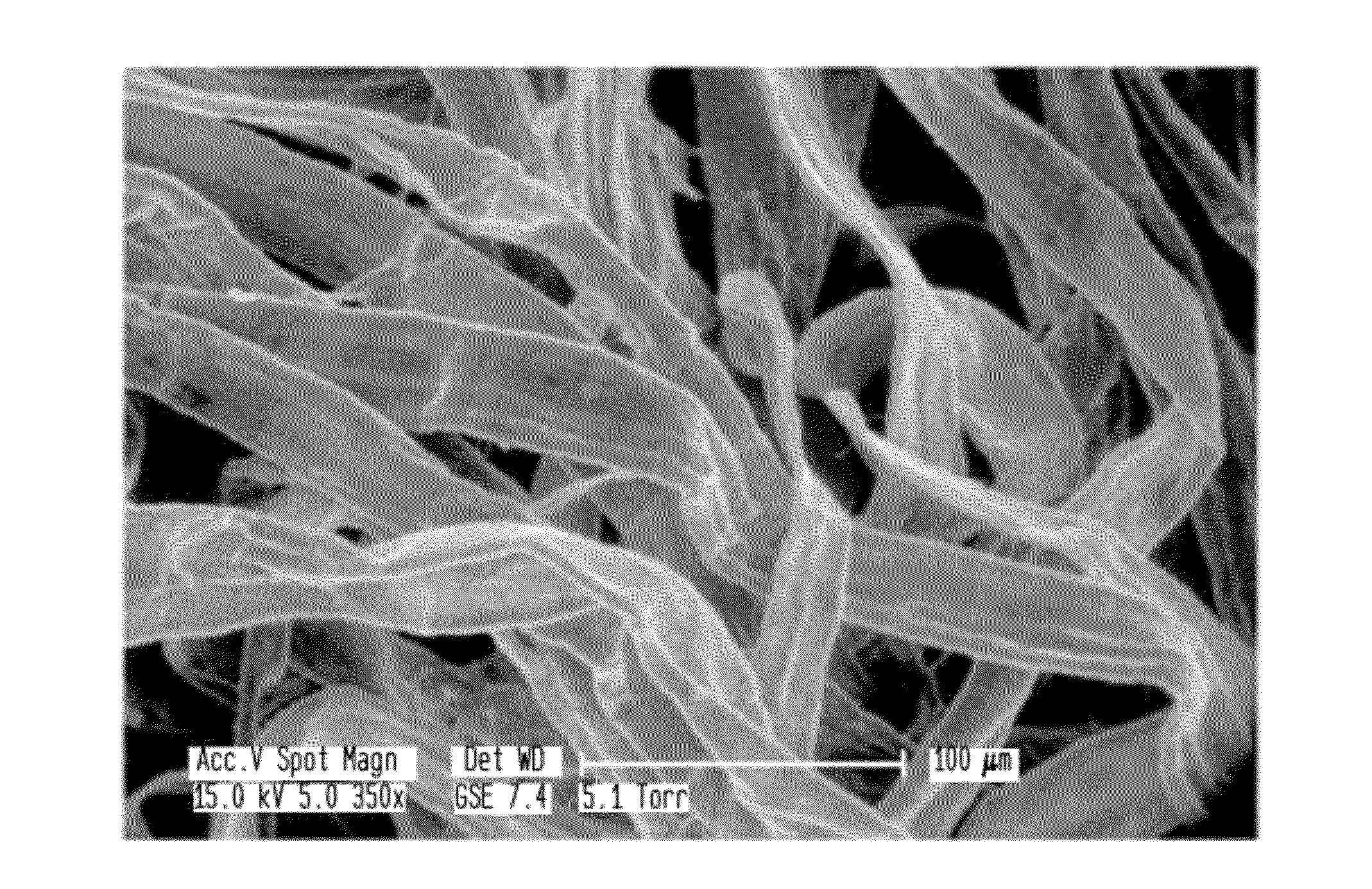

Chemical activation and refining of southern pine kraft fibers

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

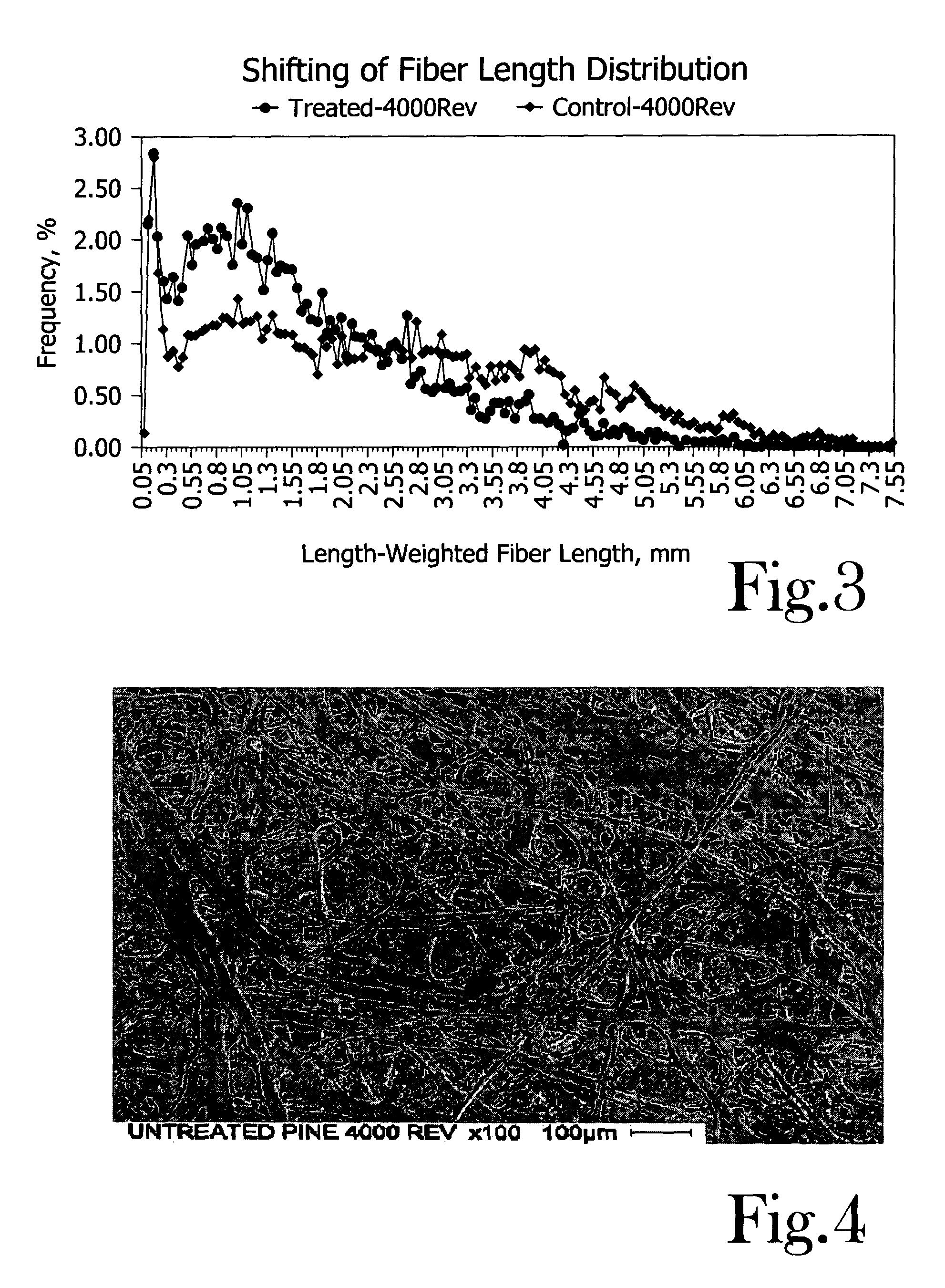

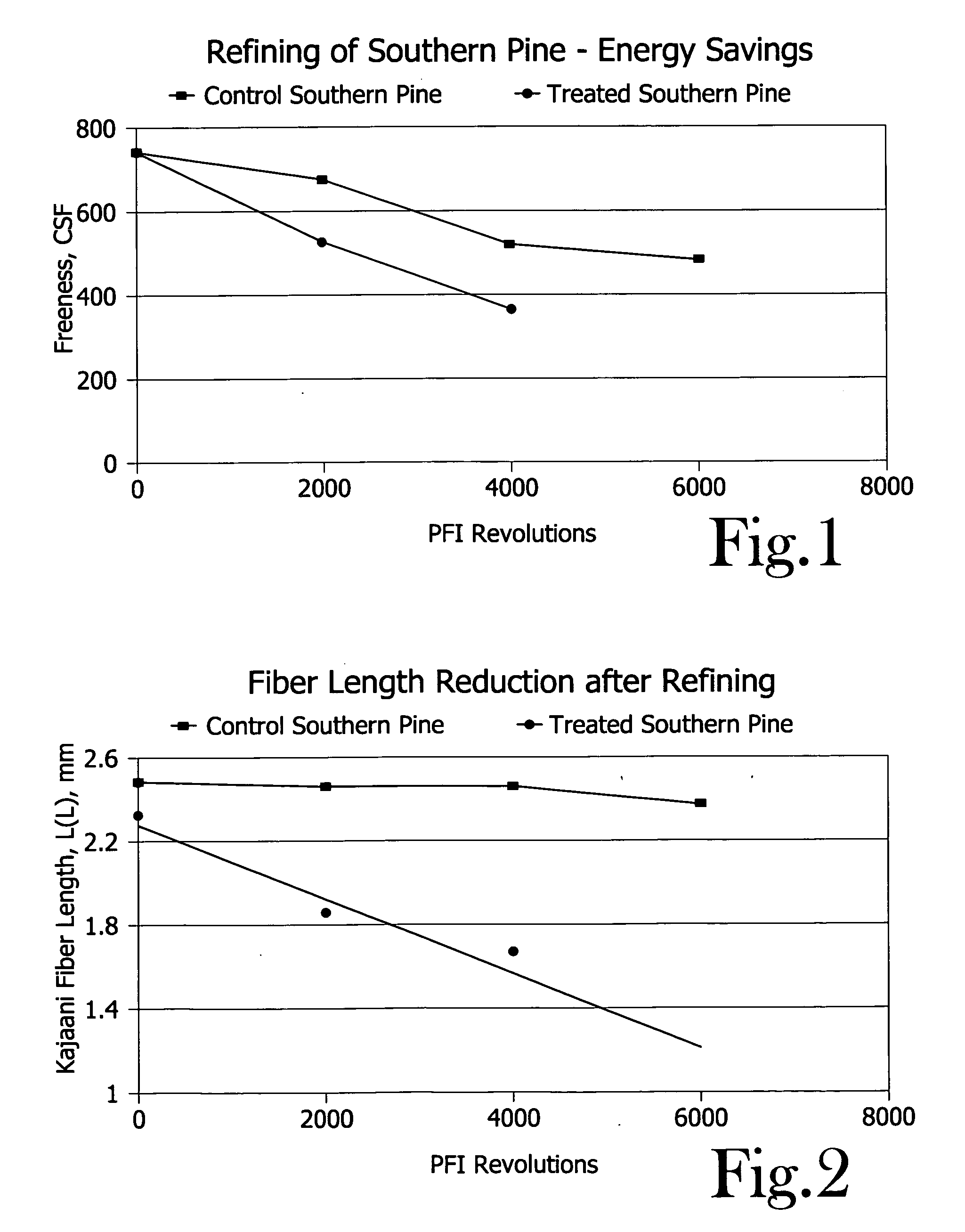

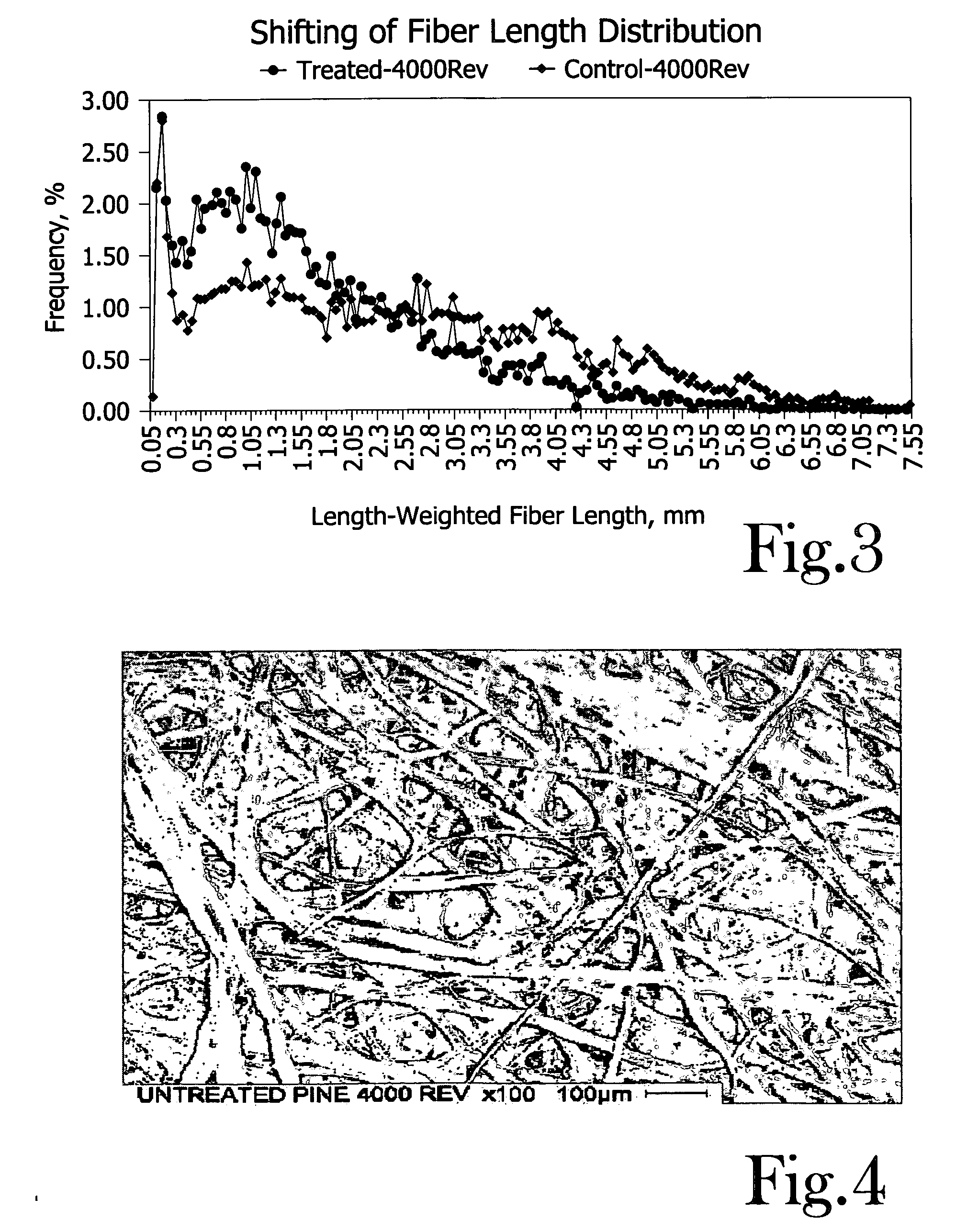

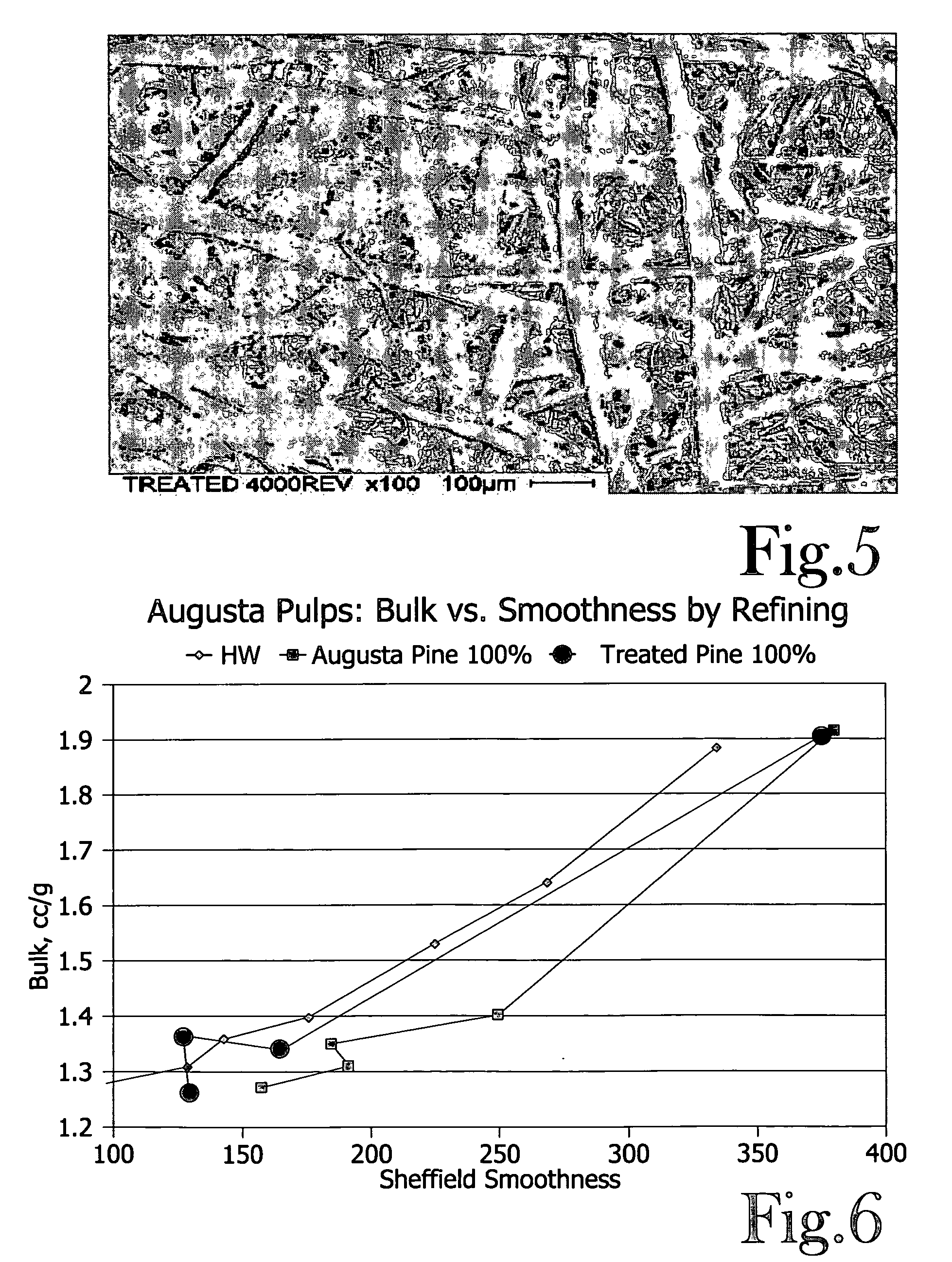

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

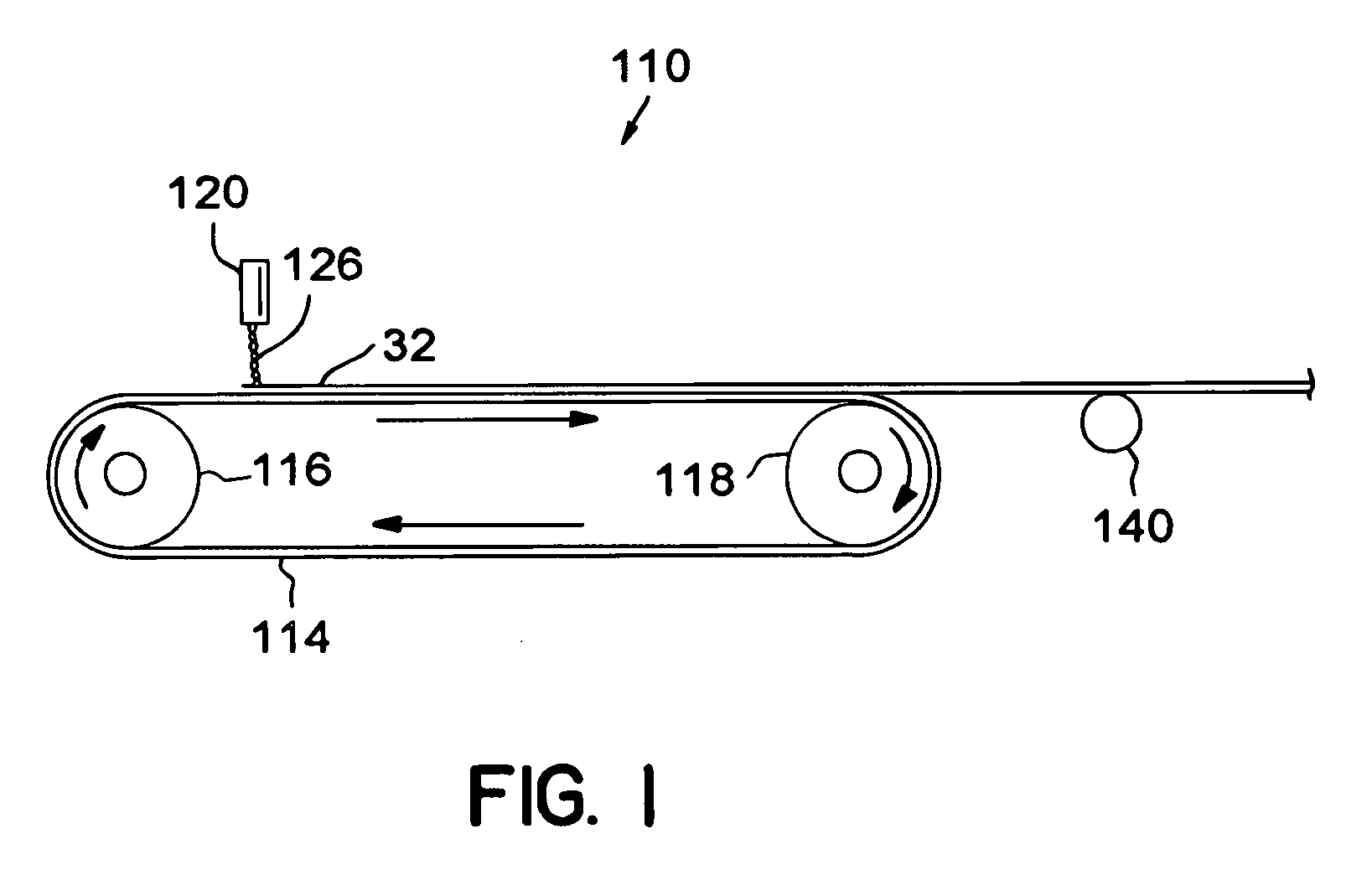

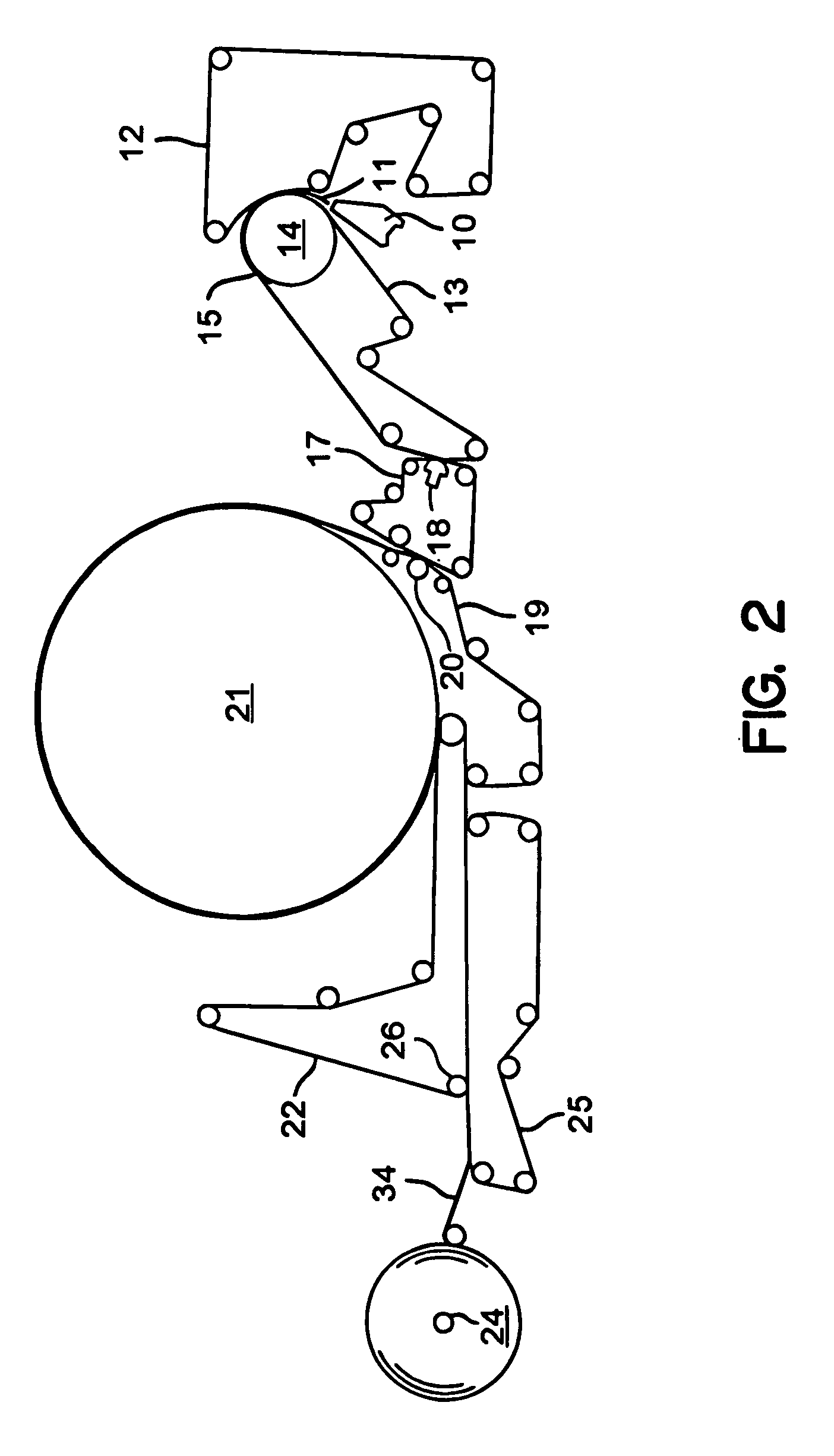

Meltblown scrubbing product

InactiveUS7994079B2Effective diameterEffective and abrasionAbrasion apparatusLaminationFiberPersonal care

The present invention discloses a disposable meltblown scrubbing product for use in household cleaning or personal care applications and an abrasive aggregate fiber which may be utilized in the scrubbing product. The meltblown web is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown processes so as to form an open, porous structure. The aggregate fibers of the present invention generally are formed of two or more separate abrasive polymer fibers or strands which are adhered together along at least about 5 mm of the fiber length. The abrasive fibers of the meltblown web are generally greater than about 15 microns in diameter.

Owner:KIMBERLY-CLARK WORLDWIDE INC

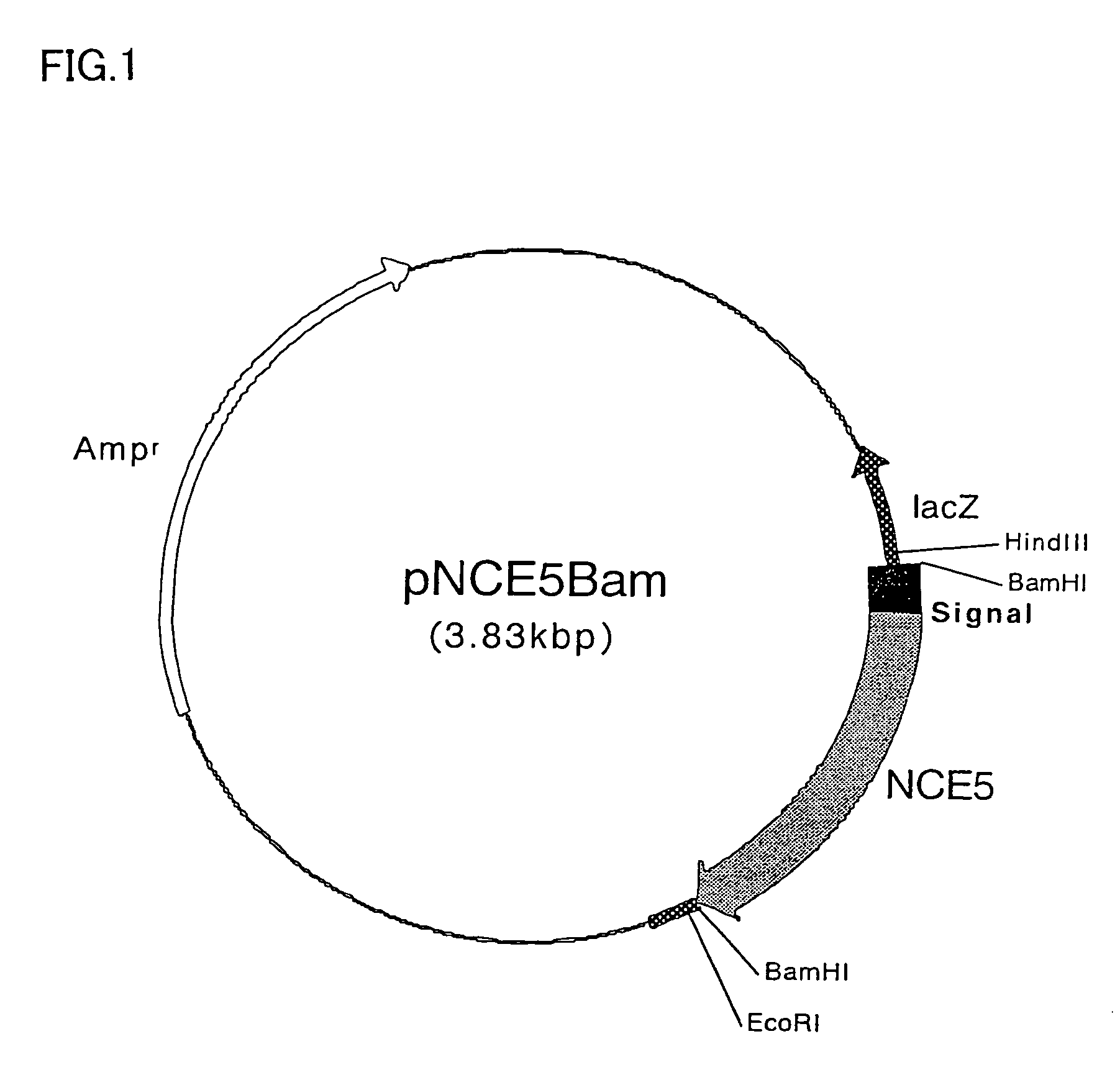

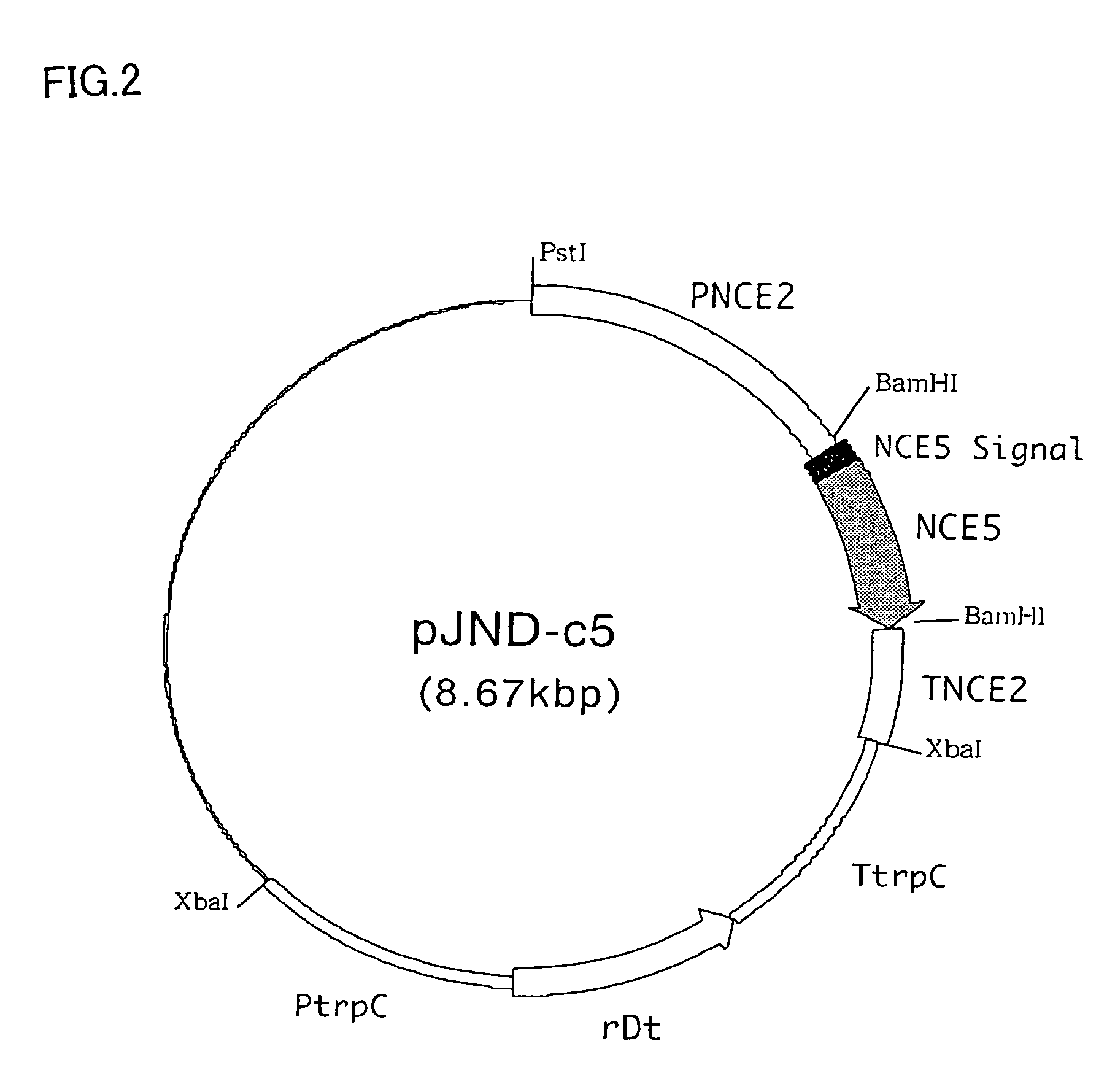

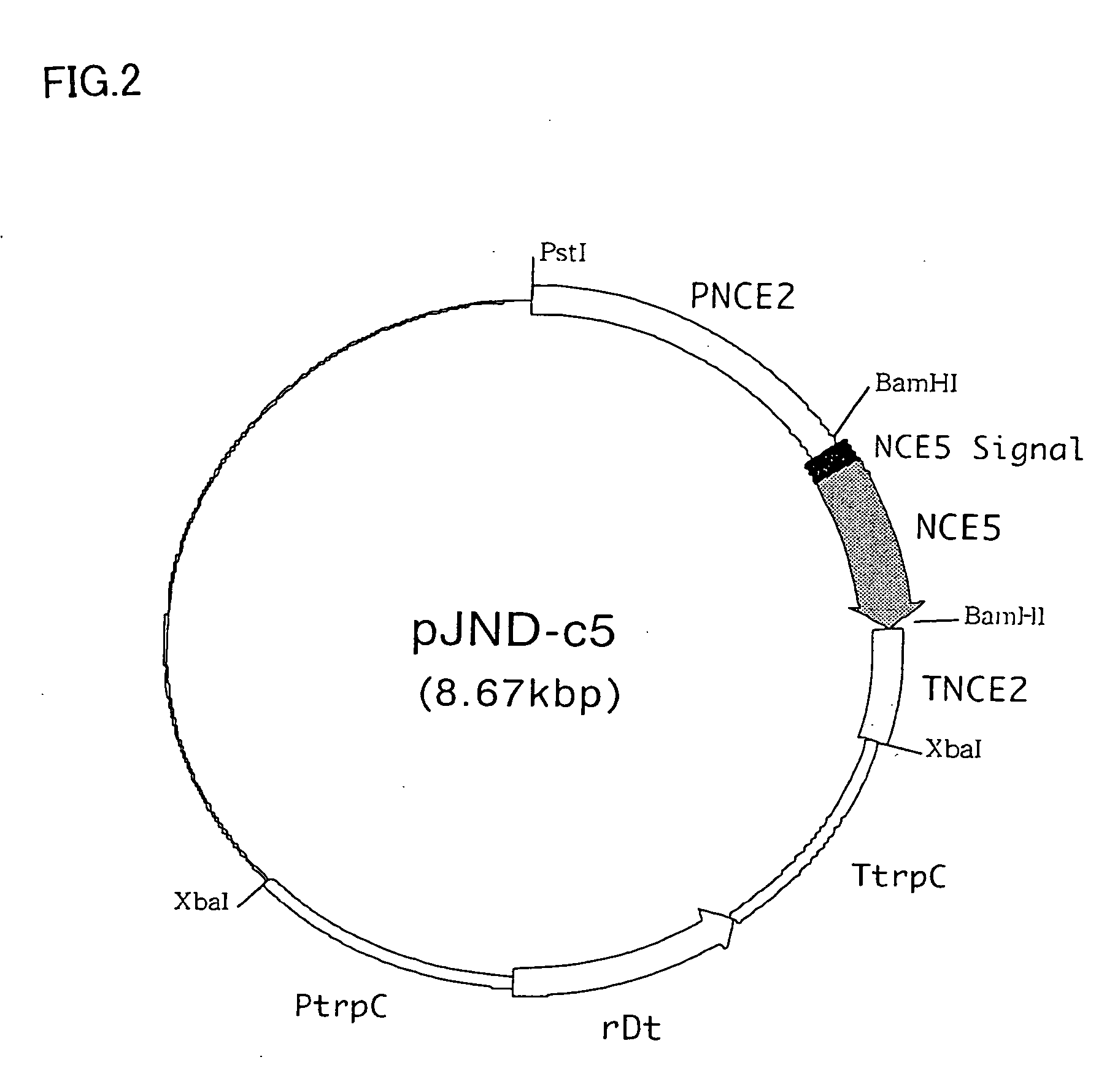

Endoglucanase enzyme NCE5 and cellulase preparations containing the same

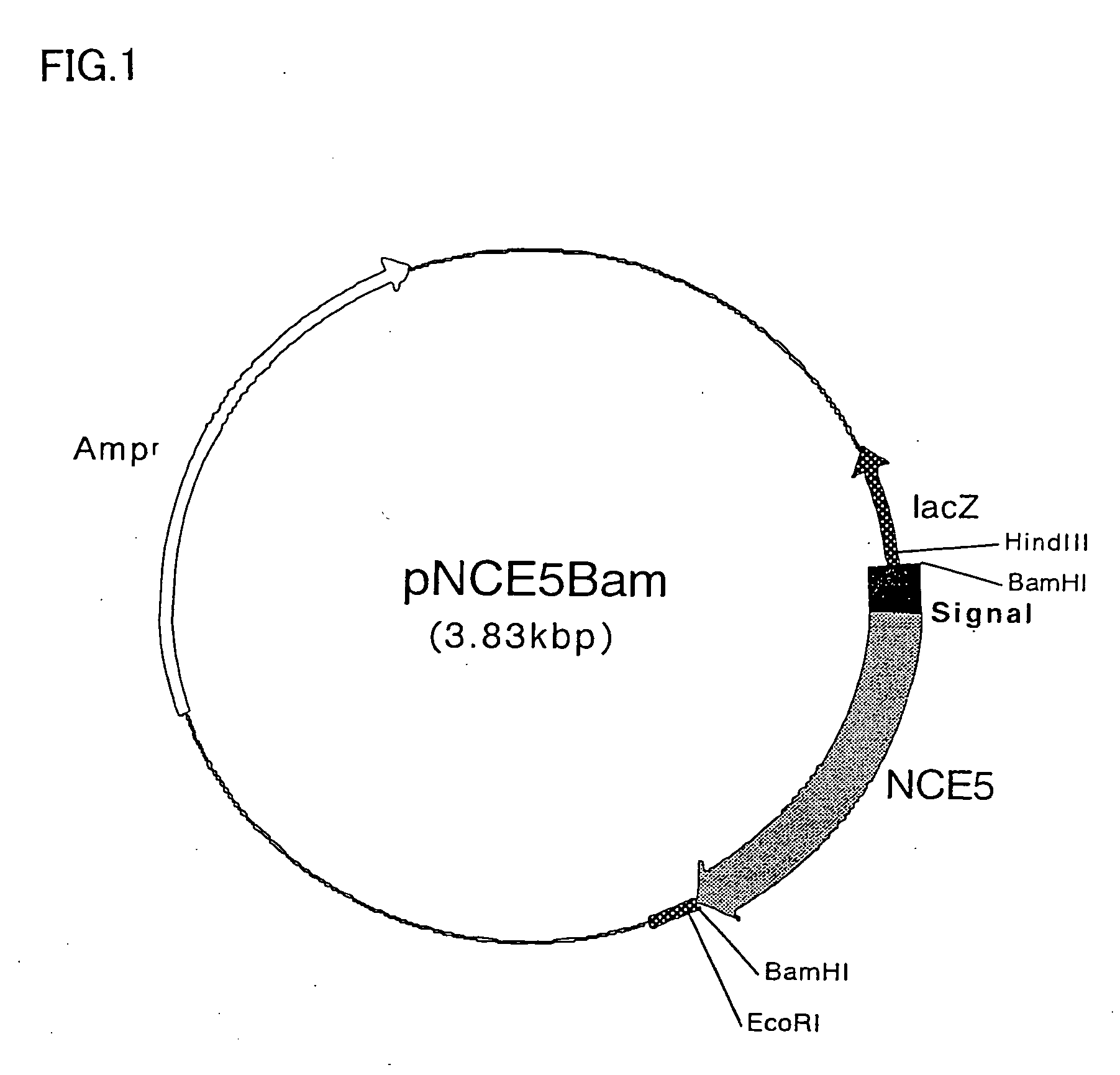

InactiveUS7138263B2Efficient and inexpensive treatmentLow degreeFungiOrganic detergent compounding agentsBiotechnologyCellulase

There is provided an endoglucanase enzyme, which is useful for reducing fuzz of regenerated cellulose-containing fabrics, improving the touch and appearance, color clarification, localized variation in color, reducing stiffness and using it as components of a detergent, as well as deinking waste paper and improving freeness of paper pulp. A cDNA coding for the endoglucanase enzyme NCE5 was cloned and its DNA sequence and amino acid sequence derived from it were determined.

Owner:MEIJI SEIKA KAISHA LTD

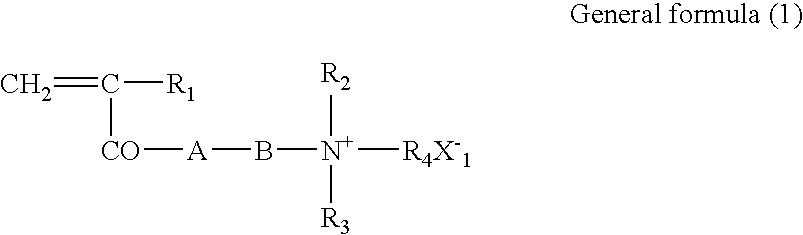

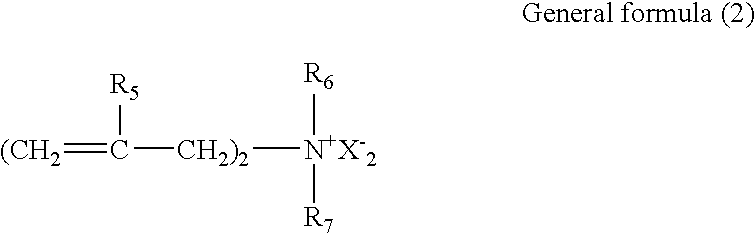

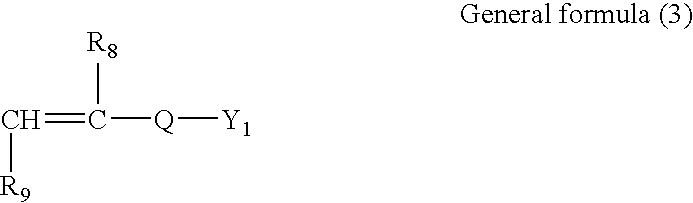

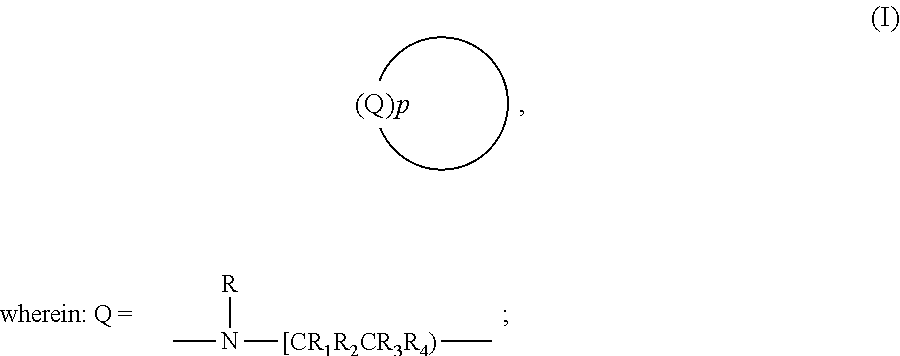

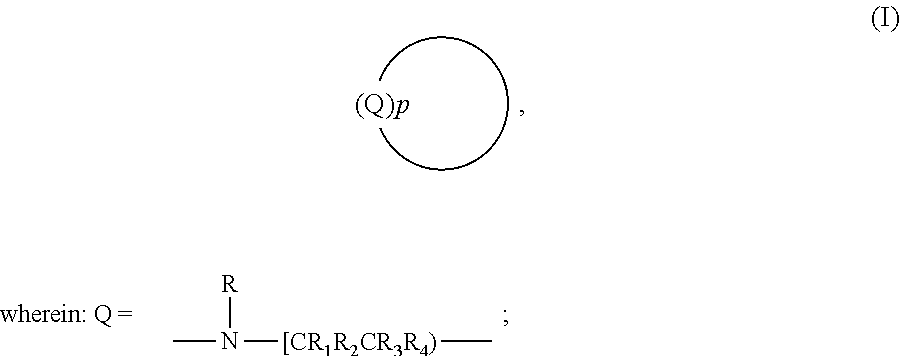

Water-soluble polymer dispersion, process for producing the same and method of use therefor

InactiveUS20060162882A1Marked effectImproved yieldNatural cellulose pulp/paperSpecial paperWater soluble polymersIon

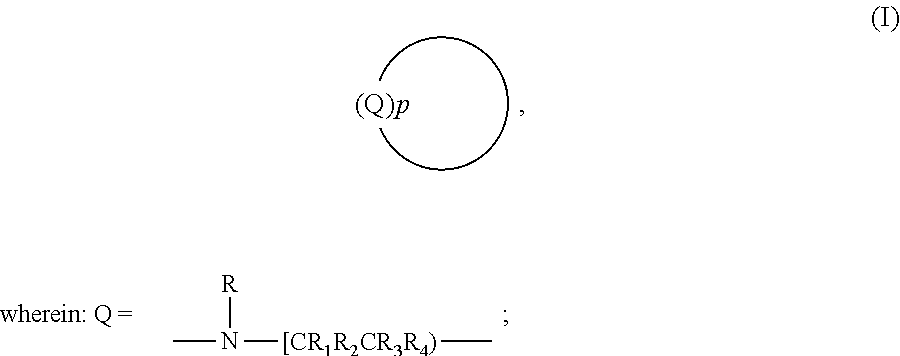

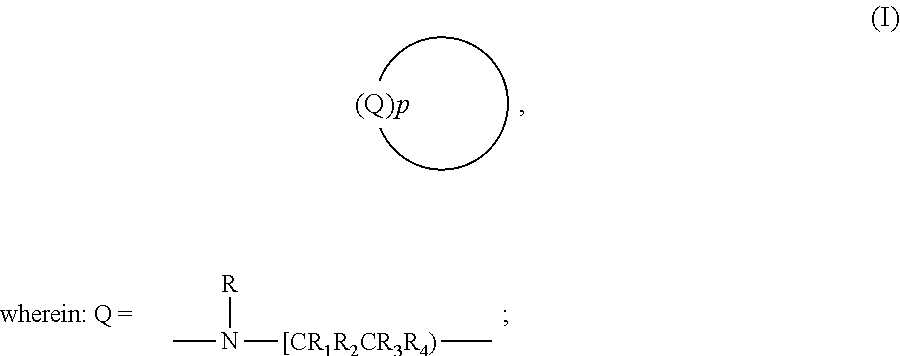

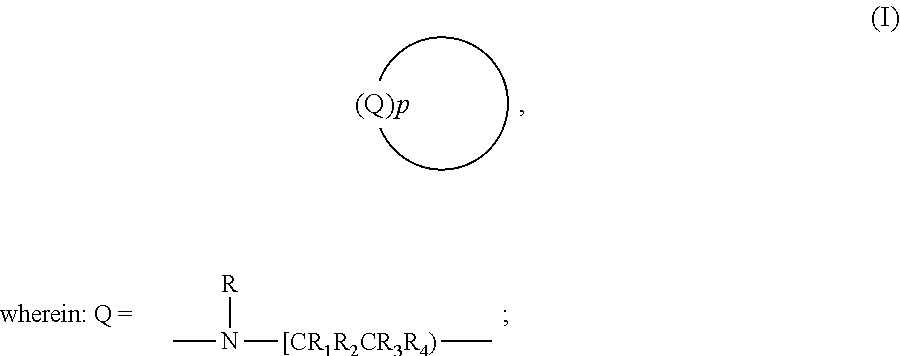

A water-solible polymer dispersion, p process for producing the same and a method of use therefor. In particular, the water-soluble polymer dispersion is one comprising water-soluble polymer fine particles of 100 μm or less diameter having at least one ionic property selected from among cationic, amphoteric, nonionic and anionic properties together with a polyalkyleneimine and / or a product of polyalkyleneimine modification wherein according to necessity an appropriate amount of water-soluble inorganic salt is incorporated. The provided process enables easily performing the production in dispersed form by means of production facilities of low cost. The obtained water-soluble polymer dispersion is excellent in storage stability and exhibits satisfactory fluidity and solubility so as to enable use in papermaking raw material pretreatments added to papermaking raw materials prior to machine operation and also for enhancement of freeness, increase of sizing degree and enhancement yield. Further use can be found in incorporation in an organic sludge or paper mill sludge for flocculation and ensuing drainage.

Owner:HYMO CORPORATION

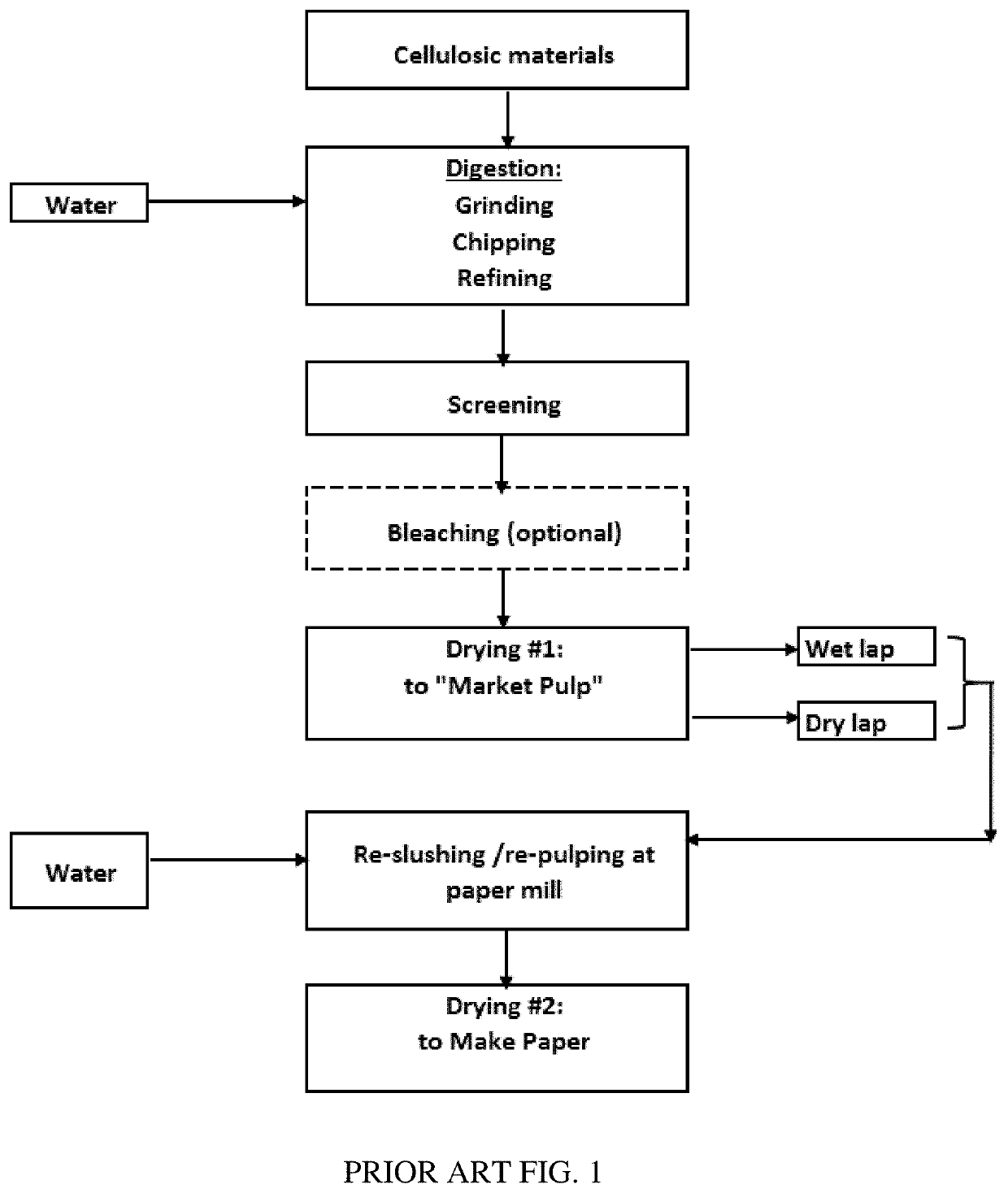

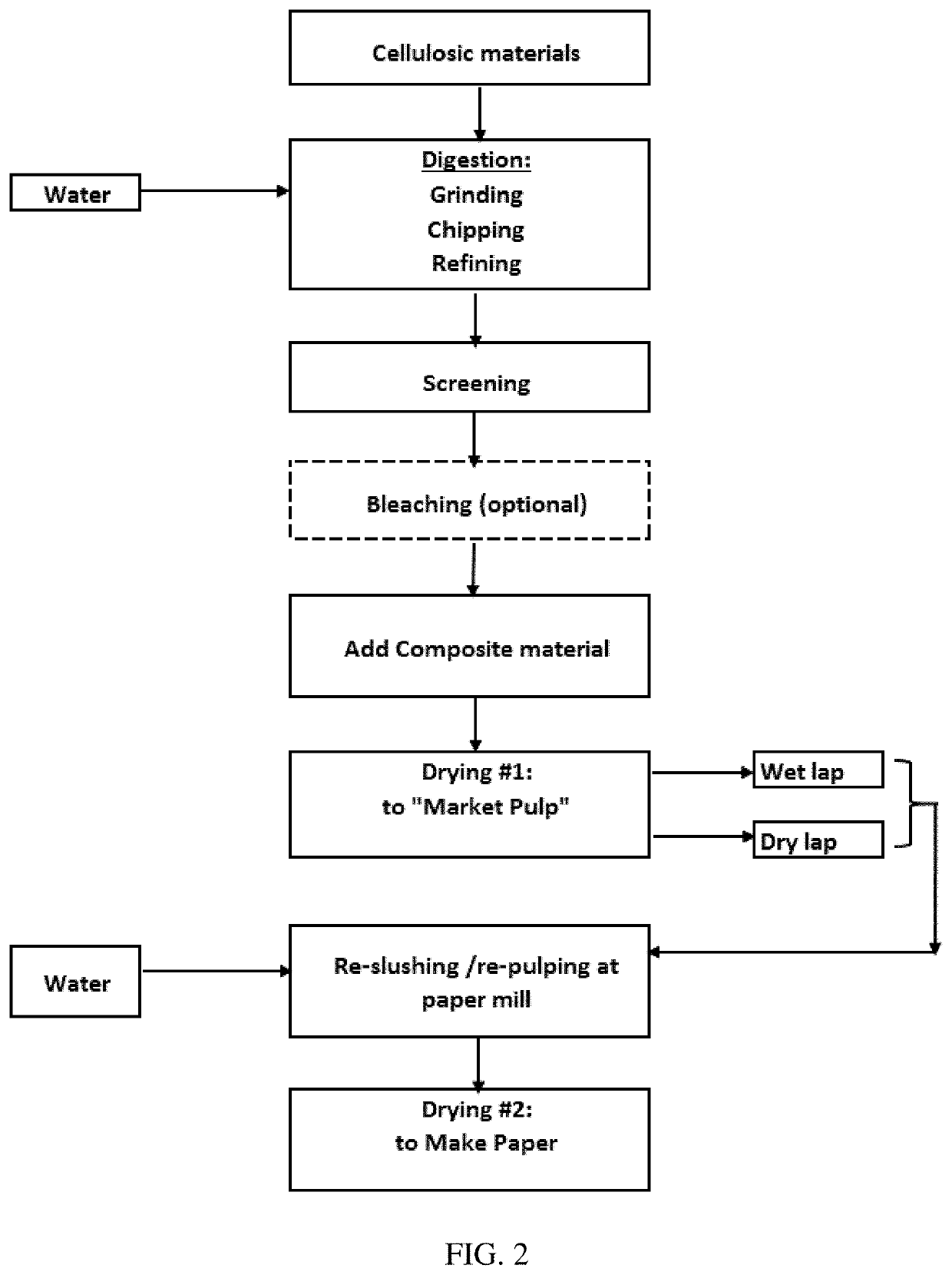

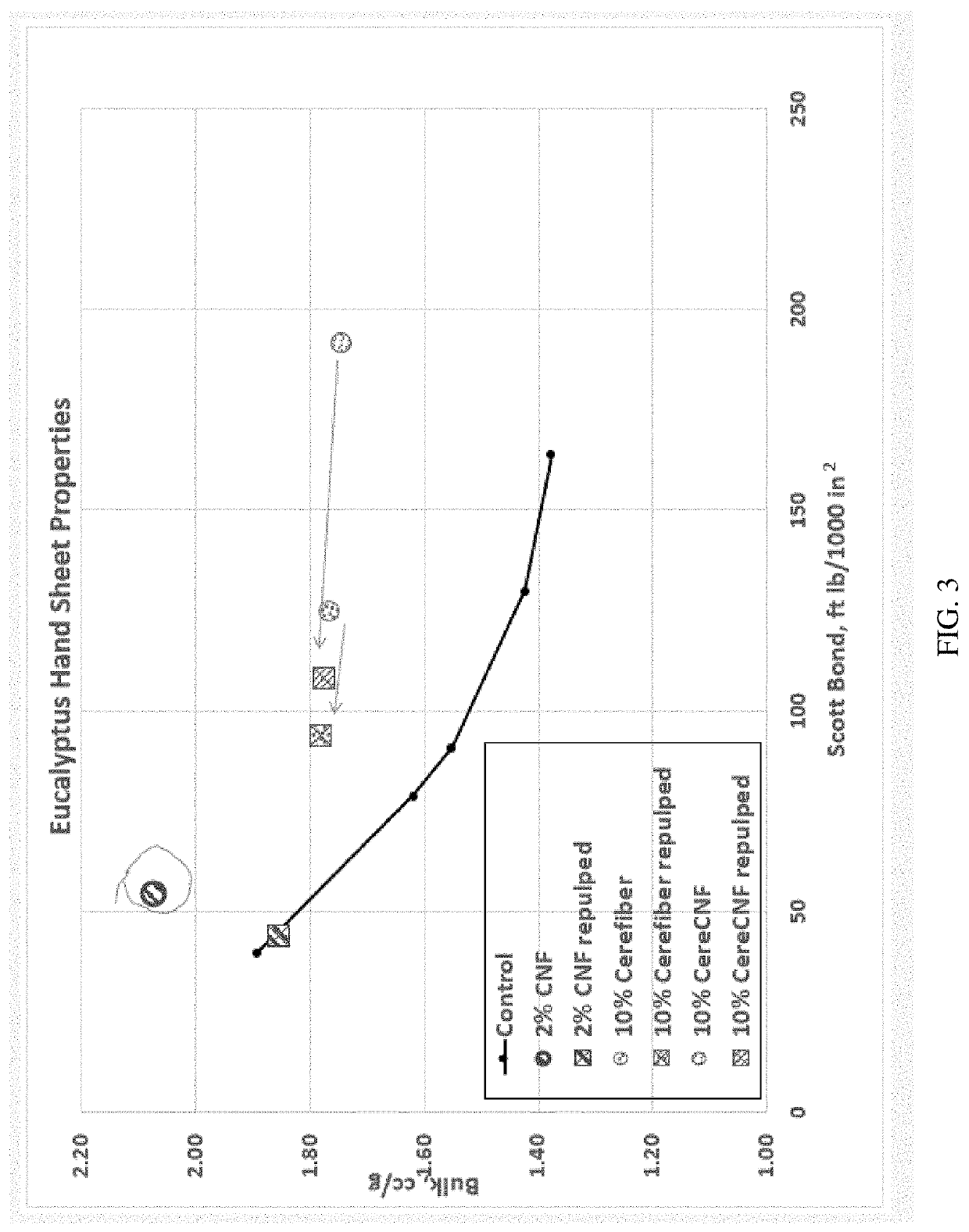

Method to Produce Composite-Enhanced Market Pulp and Paper

ActiveUS20200347549A1Enhanced market pulpHigh freenessPulp properties modificationNon-macromolecular organic additionFiberPolymer science

An improved market pulp and process for making the same by adding a composite material are described. The composite material includes cellulose nanocrystals, cellulose nanofibers, or another high aspect ratio, high surface area cellulose material (or a starch, or both) and a crosslinking compound that crosslinks a portion of the surface hydroxyl groups to form a 3-D matrix. Adding the composite material to market pulp has been shown to improve the strength of twice-dried paper products, made from such an enhanced market pulp. By crosslinking a portion of the surface hydroxyl groups in the market pulp to form a 3-D matrix, a first drying step may be accomplished without loss of benefits afforded when the market pulp is later re-pulped to make a paper product.

Owner:UNIVERSITY OF MAINE

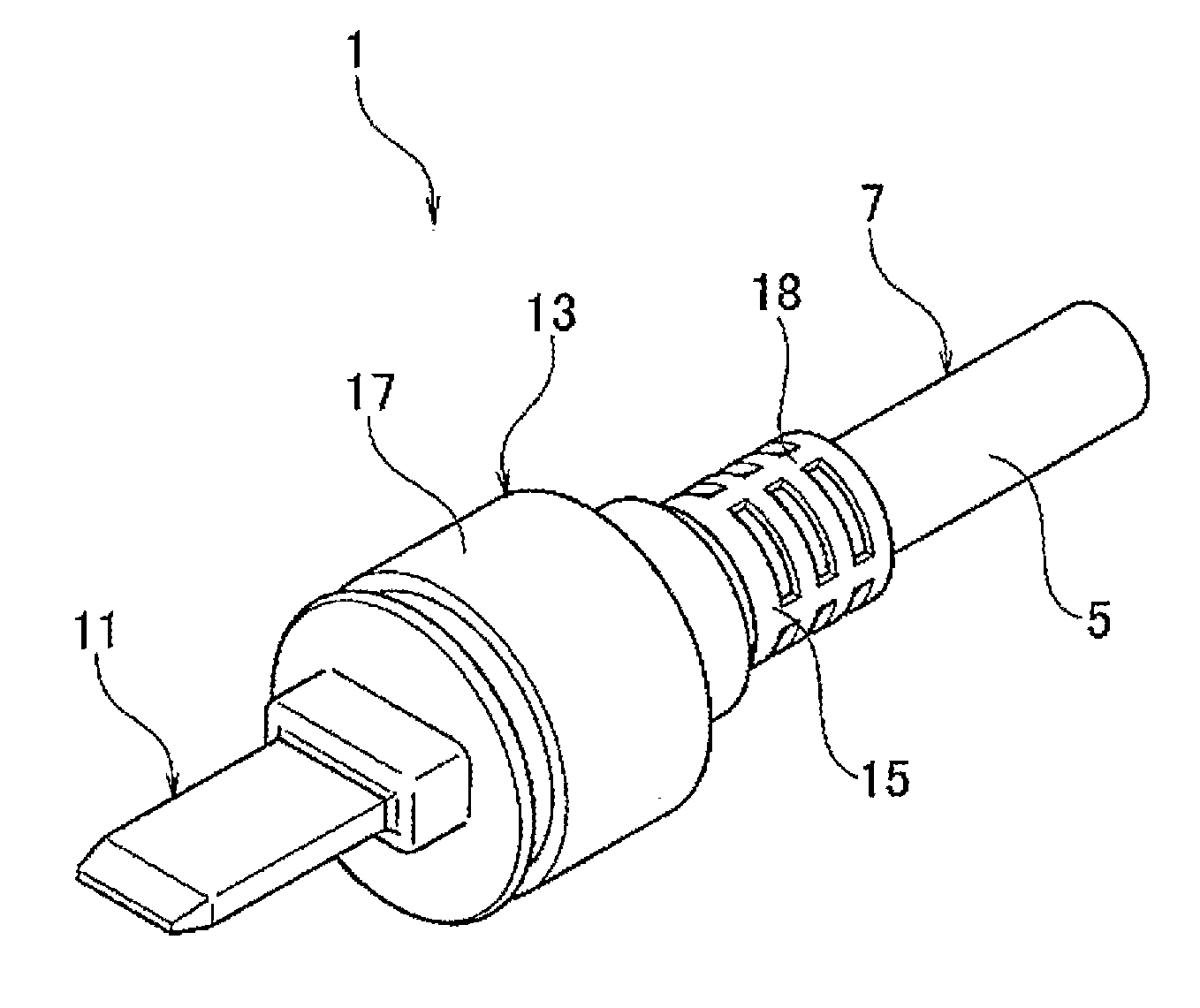

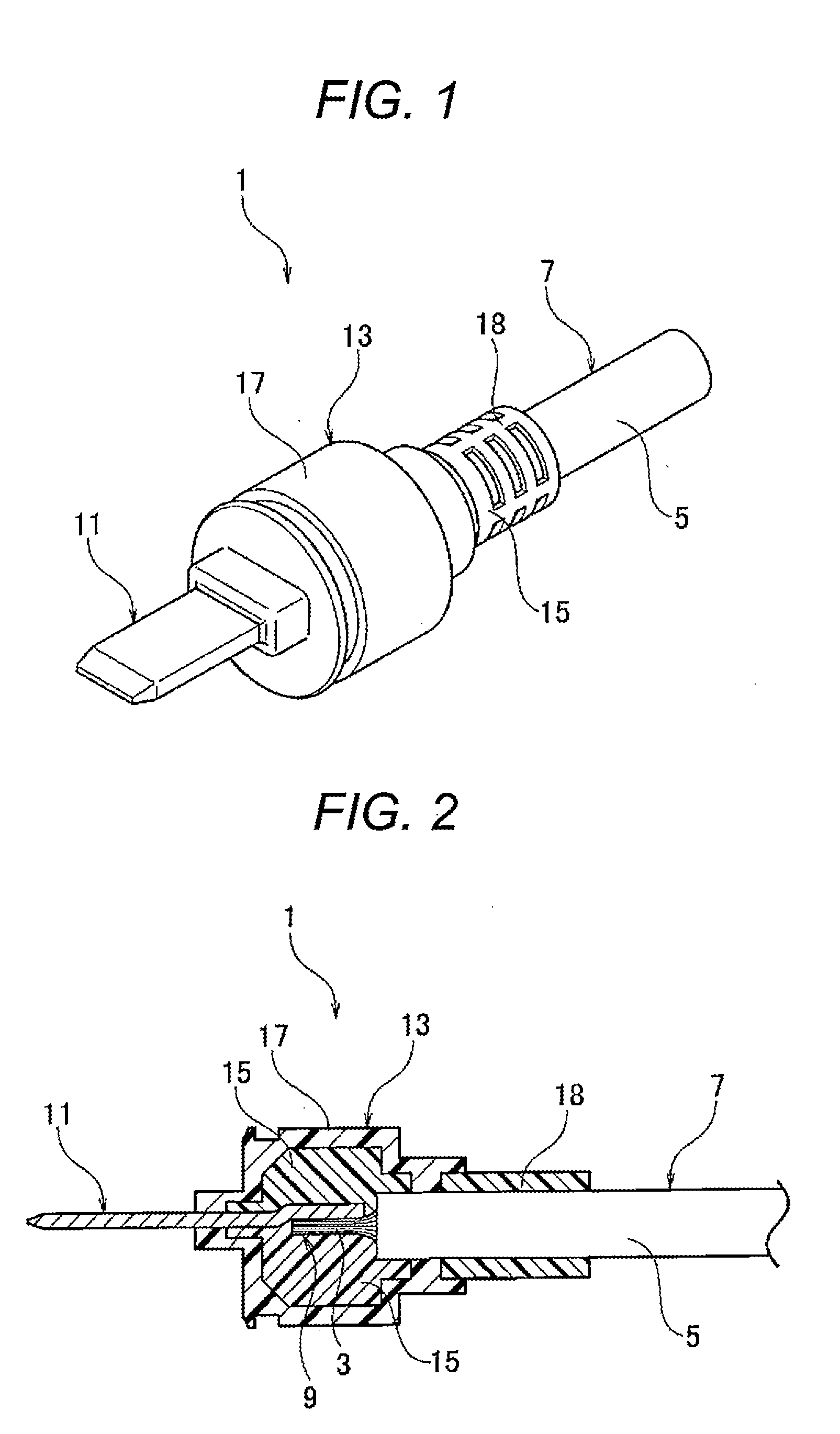

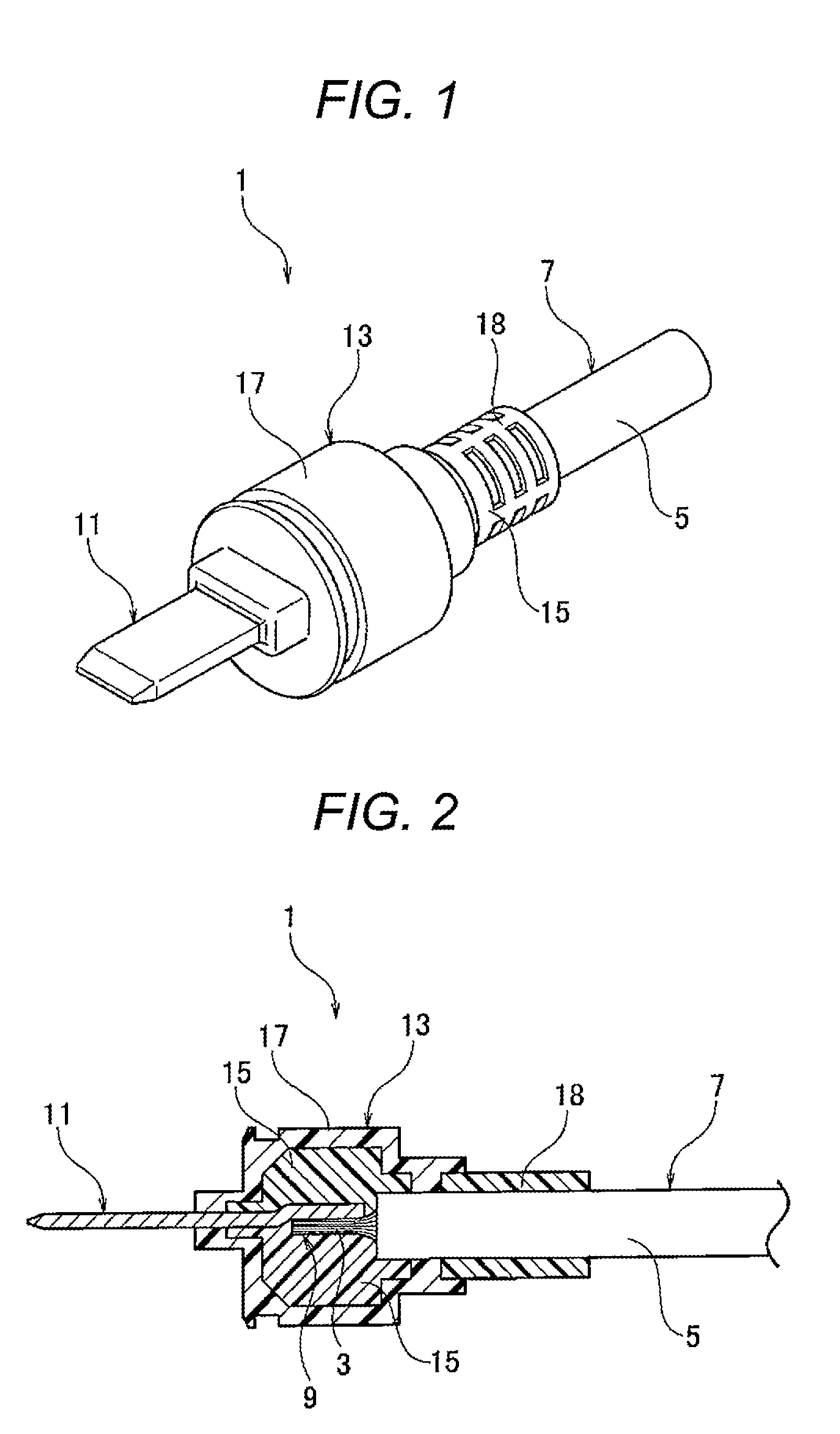

Method of integrally molding connector, and object connector

ActiveUS20120040571A1Improve performanceReduce adverse effectsRelieving strain on wire connectionContact member assembly/disassemblyProduction rateEngineering

There is provided a method of integrally molding a connector in which the number of components can be reduced, and productivity can be enhanced.The method of integrally molding a connector according to the invention includes a first step of injection molding elastic resin 15 around a connection part 9 and an end part of a cover part 5 of an electric wire which is positioned adjacent to the connection part 9 thereby to bond the cover part 5 and the elastic resin 15 to each other, and a second step of injection molding resin 17 around the elastic resin 15 so as to compress the elastic resin 15 thereby to press-fit the elastic resin 15 to a terminal 11, and at the same time, to bond the elastic resin 15 and the resin 17 to each other.

Owner:YAZAKI CORP

Method of integrally molding connector, and object connector

ActiveUS8480421B2Improve performanceReduce adverse effectsRelieving strain on wire connectionContact member assembly/disassemblyProduction rateMechanical engineering

There is provided a method of integrally molding a connector in which the number of components can be reduced, and productivity can be enhanced.The method of integrally molding a connector according to the invention includes a first step of injection molding elastic resin 15 around a connection part 9 and an end part of a cover part 5 of an electric wire which is positioned adjacent to the connection part 9 thereby to bond the cover part 5 and the elastic resin 15 to each other, and a second step of injection molding resin 17 around the elastic resin 15 so as to compress the elastic resin 15 thereby to press-fit the elastic resin 15 to a terminal 11, and at the same time, to bond the elastic resin 15 and the resin 17 to each other.

Owner:YAZAKI CORP

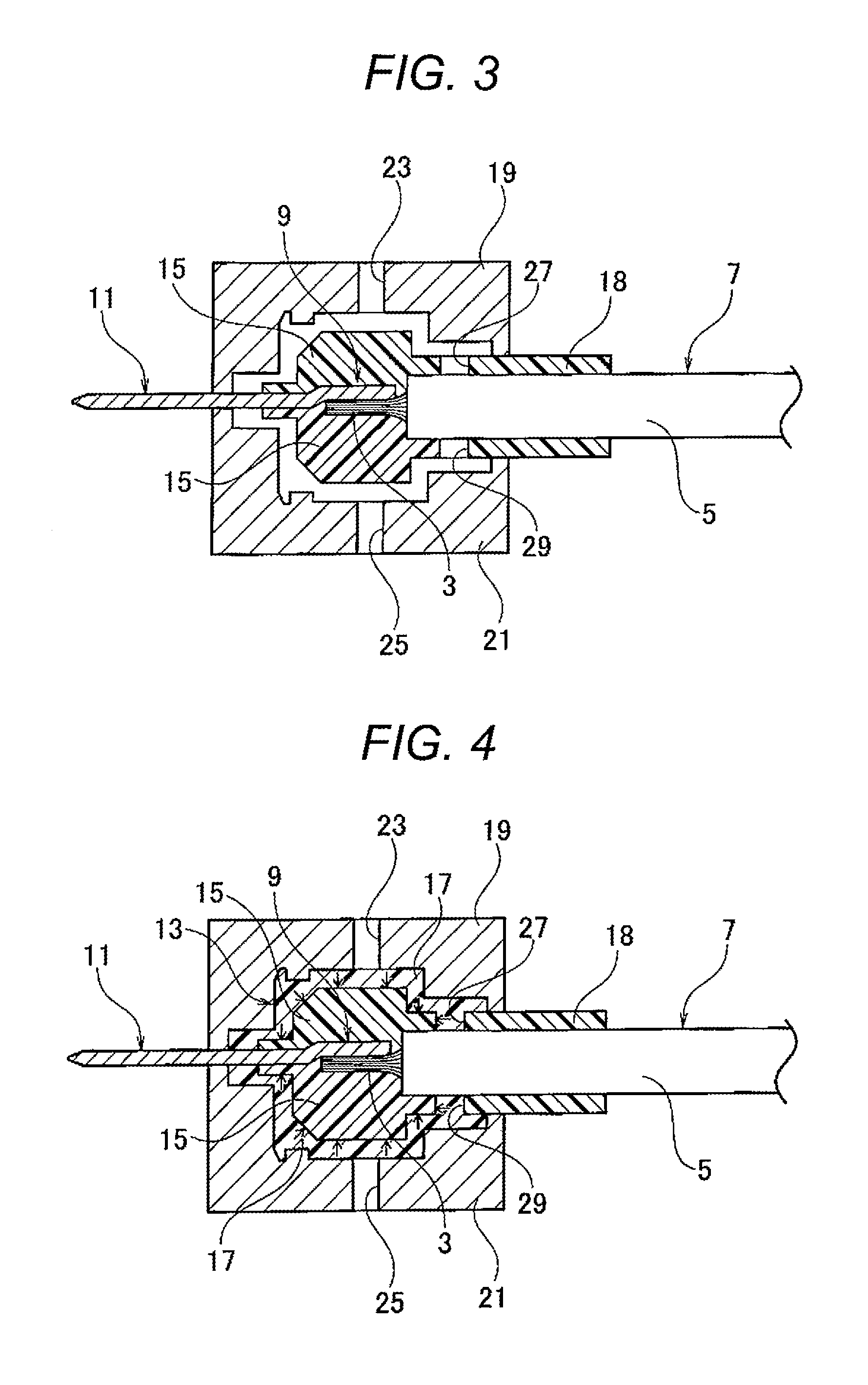

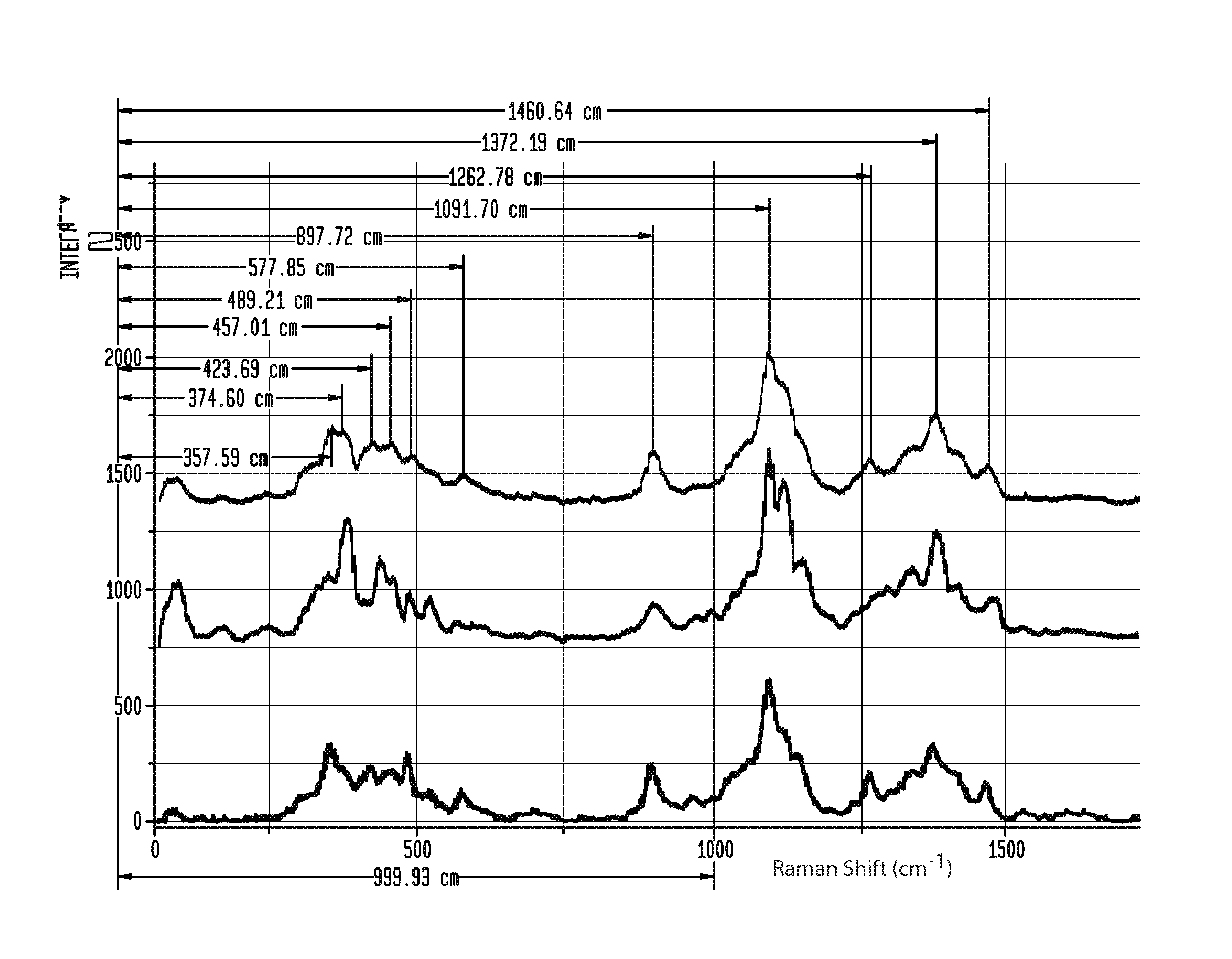

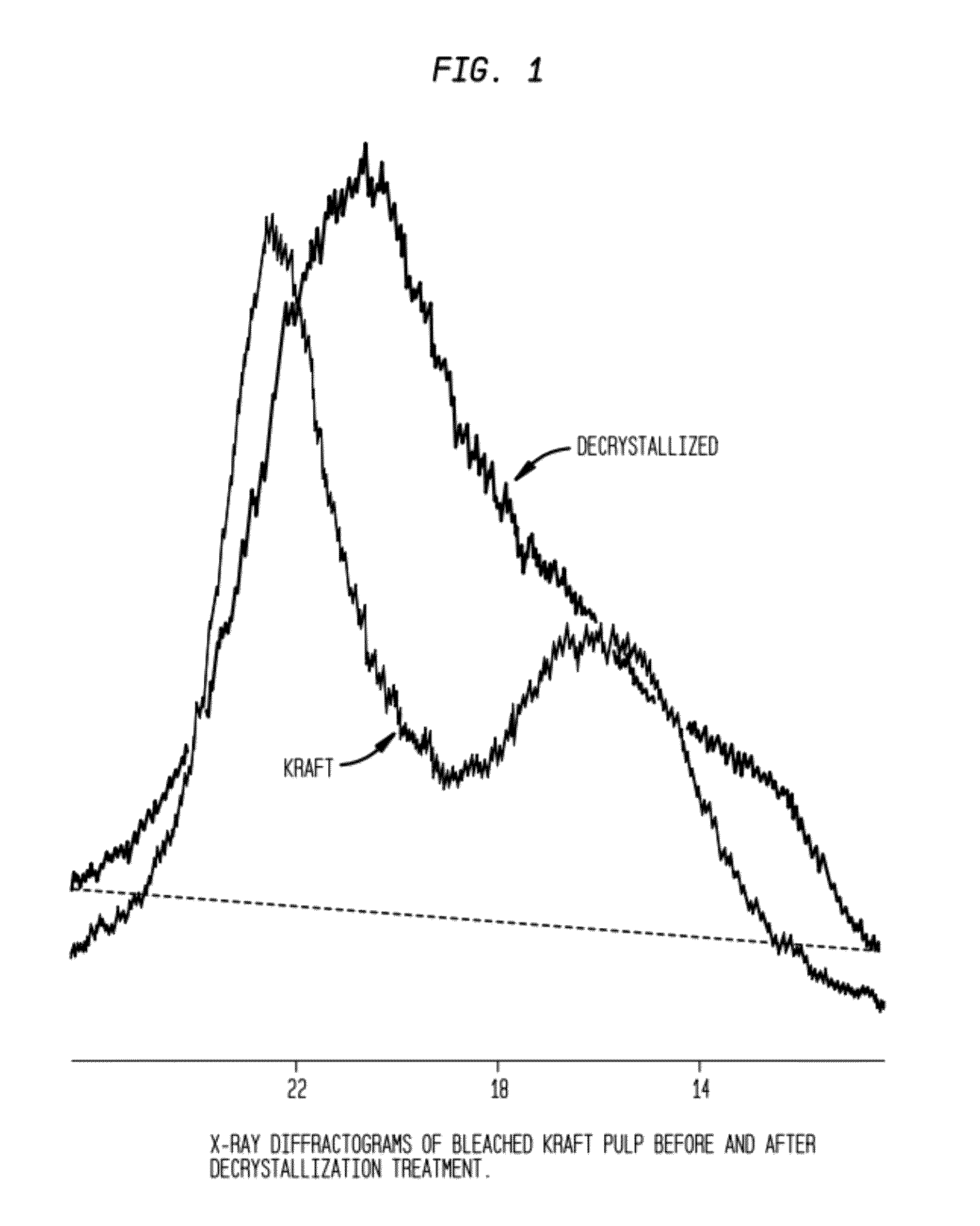

Tissue products incorporating nanoporous cellulose fiber

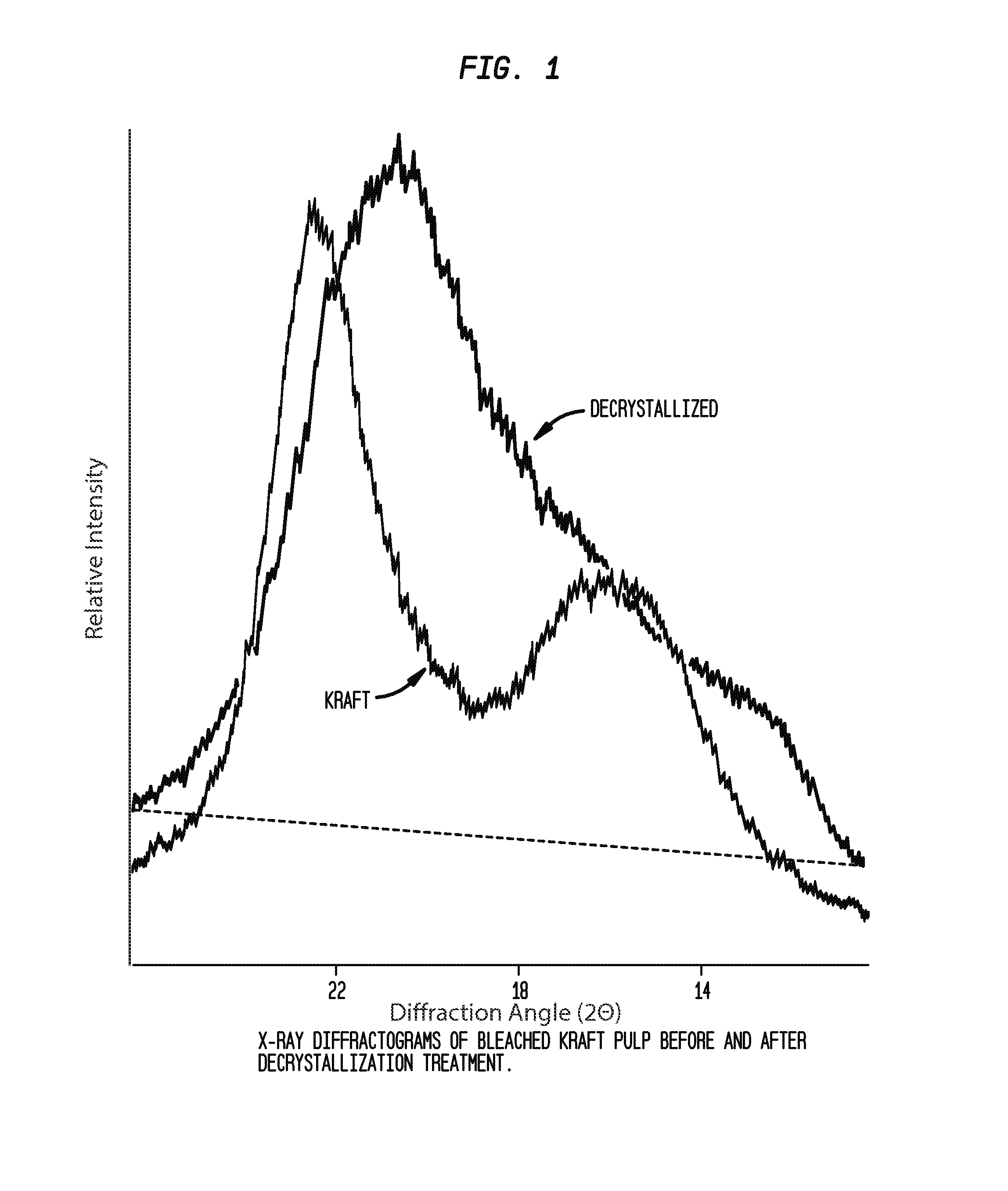

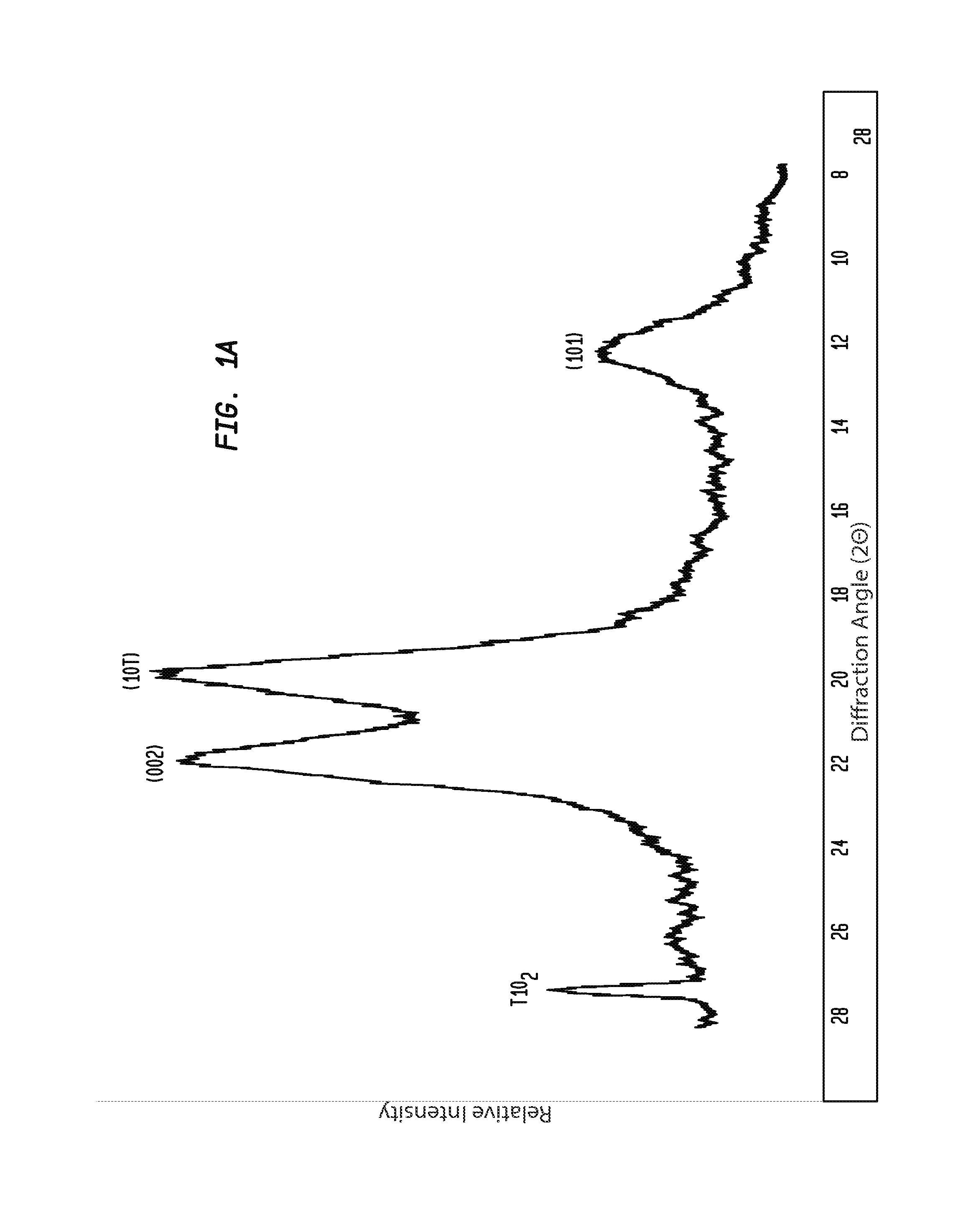

ActiveUS8741104B2Increasing chemical accessibilityPromote productionNon-fibrous pulp additionPaper after-treatmentPorosityMedicine

Fibrous cellulosic products incorporating both conventional cellulosic fibers and laterally expanded cellulose fibers exhibit exceptional porosity, bulk, absorbency and resiliency properties. Typical products include absorbent tissue products, absorbent fluff products and flat papers. The laterally expanded cellulose fibers exhibit: (i) a broadened X-Ray diffraction peak for the most prominent reflection having a width at half-height, (W1 / 2h)A, of at least about 3.0° 2Θ, (ii) broad overlapping maxima in their Raman spectrum between 285 and 500 cm−1, the height of the two tallest of said maxima in said spectrum between 285 and 500 cm−1 being between 35 and 50% of the height of the peak near 1098 cm−1 and (iii) a blue stain when treated with Graff C-stain, the stain exhibiting less red than the stains exhibited with bleached hardwood kraft fibers and bleached softwood kraft fibers.

Owner:CELLLOSE SCI INT

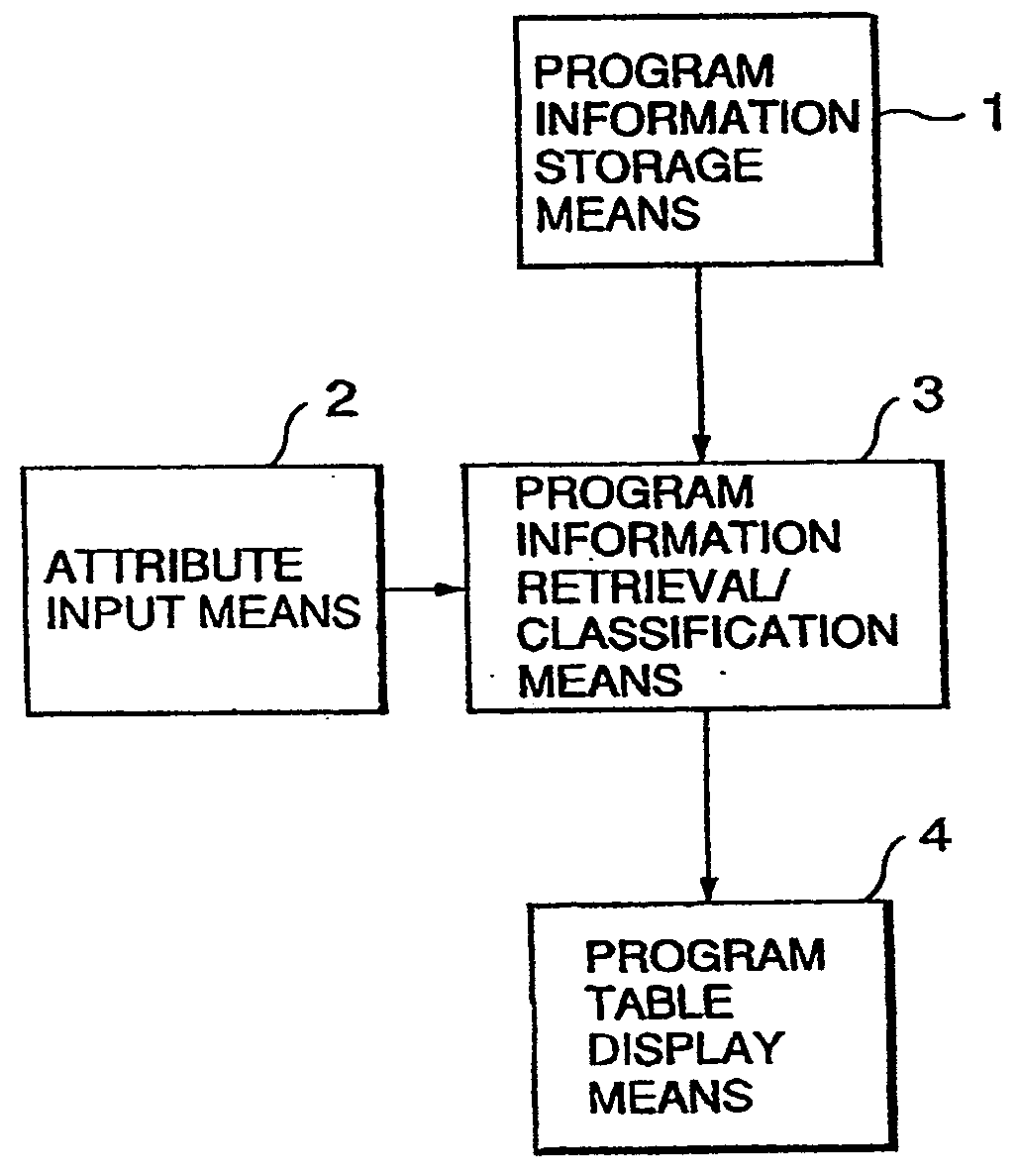

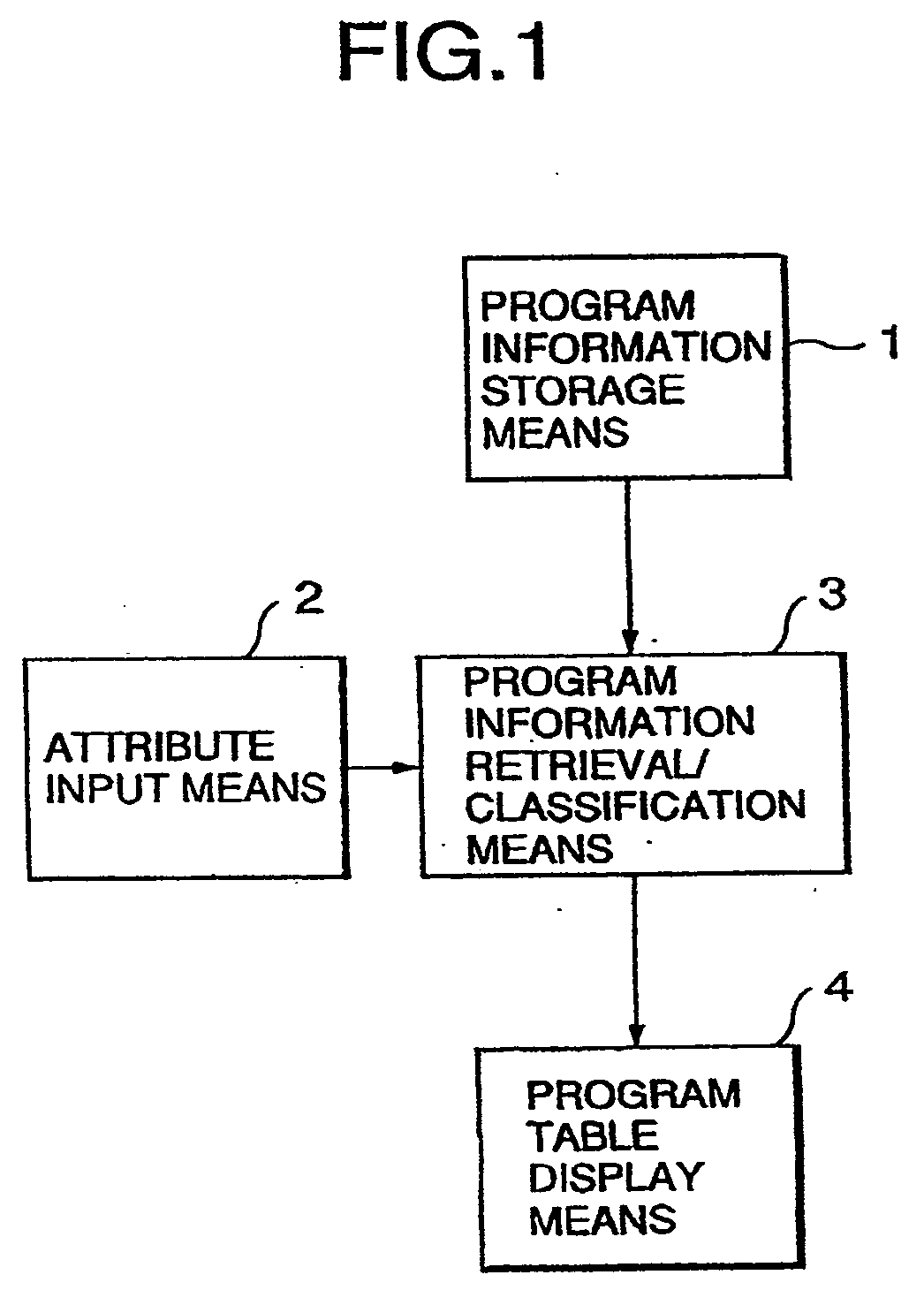

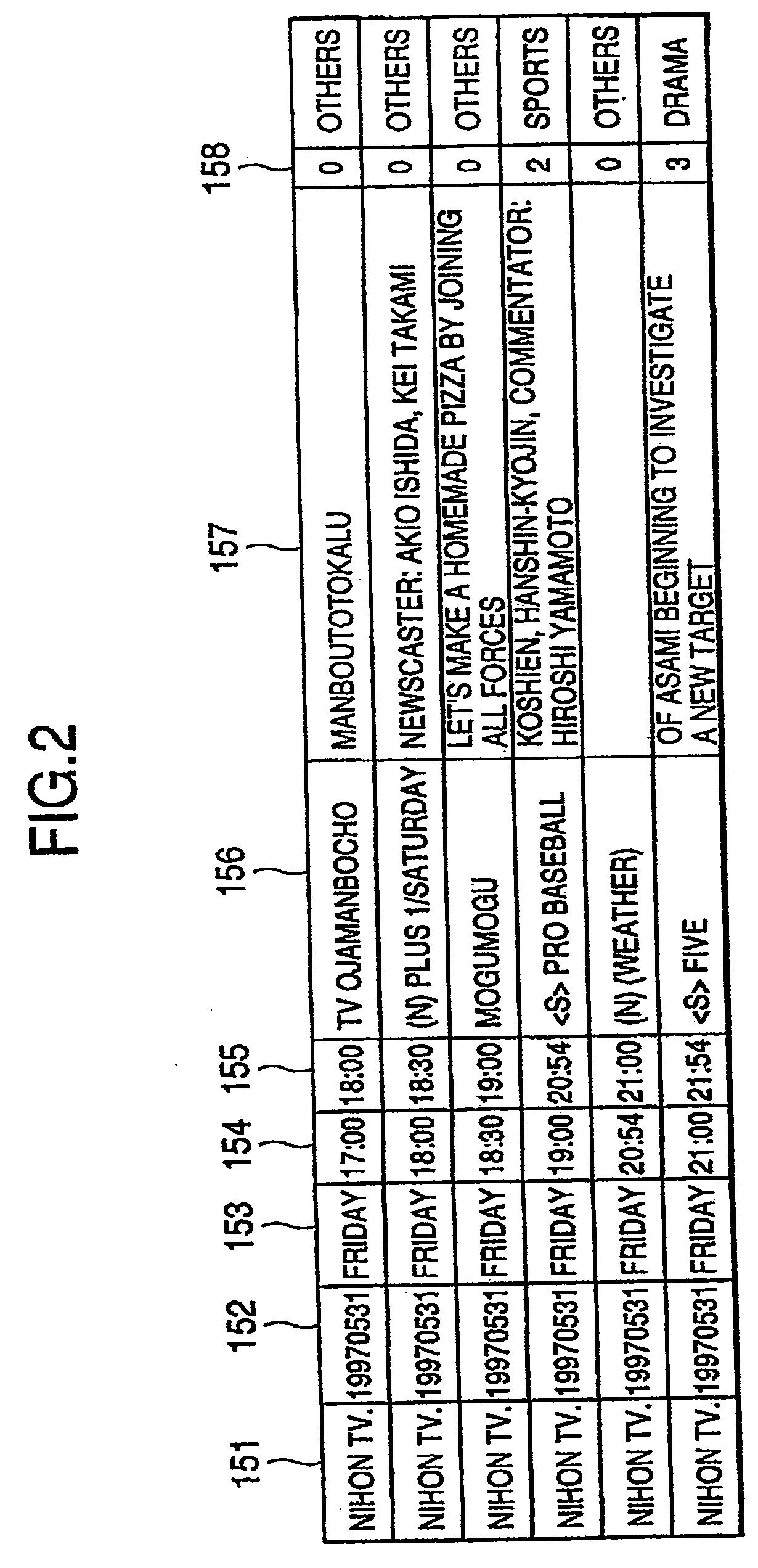

System for processing program information

InactiveUS20070277198A1Free structureIncrease choiceTelevision system detailsFilamentary/web carriers operation controlInformation processingProgram planning

To provide a system for processing program information in which the display structure of a program table can freely be changed in accordance with a requirement or a taste of an audience, the system for processing program information is constructed to include program information storage means 1 for storing program information, and program table display means 4 for two-dimensionally displaying a program table following two axes in accordance with two attributes 102 and 103 among attributes given to each piece of program information, to make the program table 101 for two-dimensionally displaying programs with two axes of free attributes. For the audience, program tables of various constructions can be displayed on the display means at will and in respective program retrieval operations, the program table easy to look for a program can be obtained. An objective program can be found in a short time by coming up with ideas for the extraction of the program or the like, and this is useful for making a broadcast view plan of himself.

Owner:PANASONIC CORP

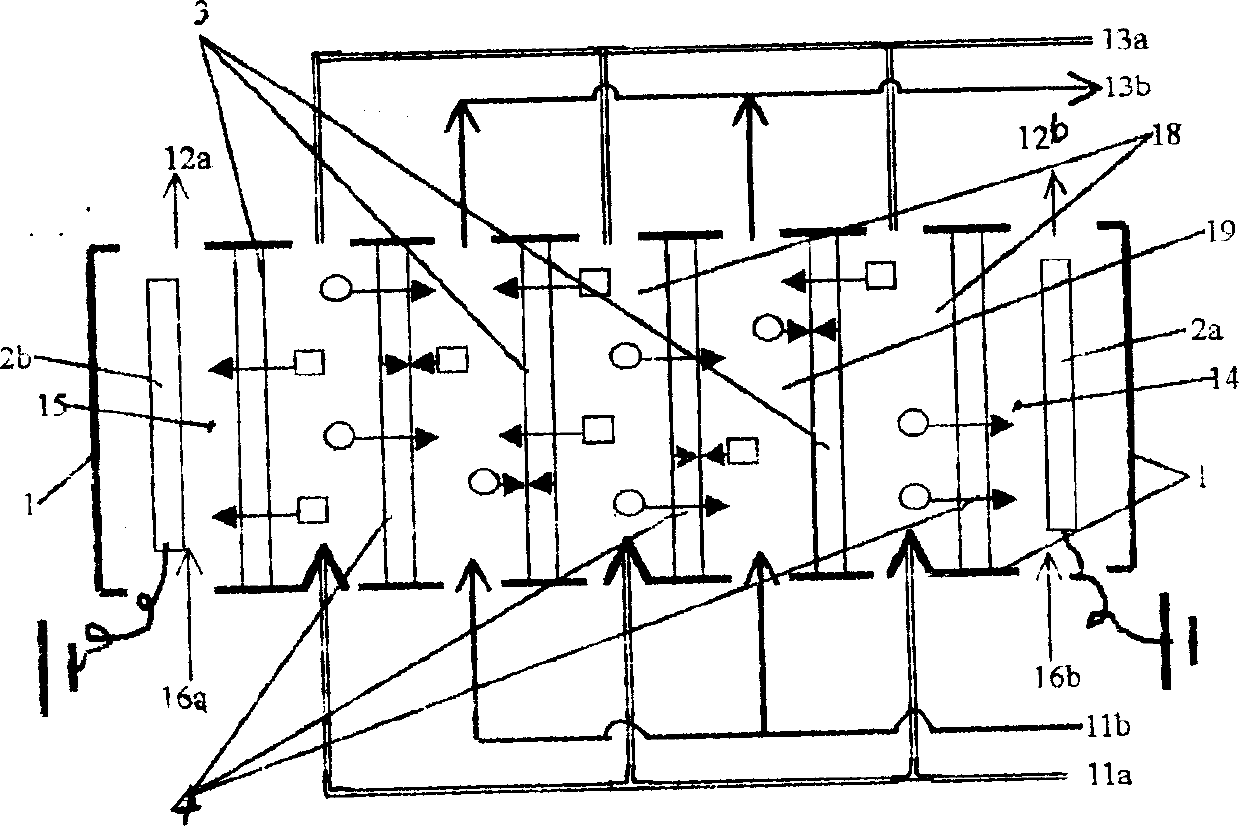

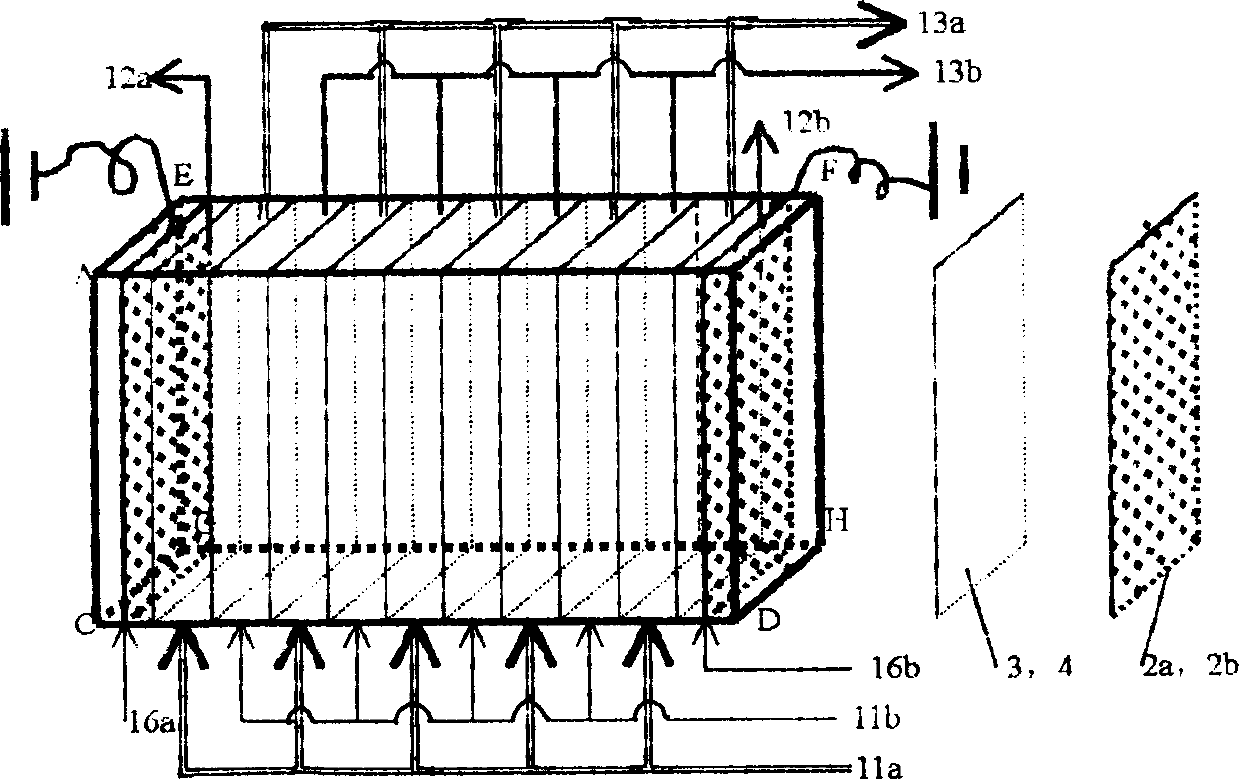

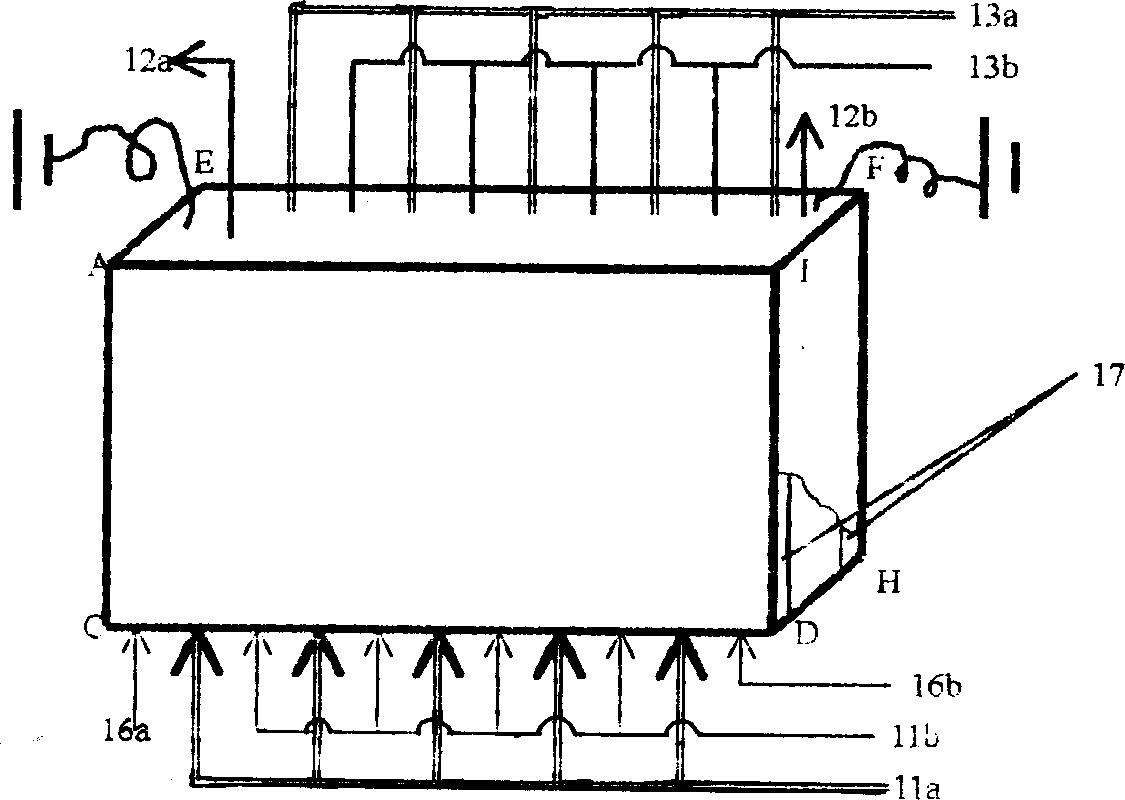

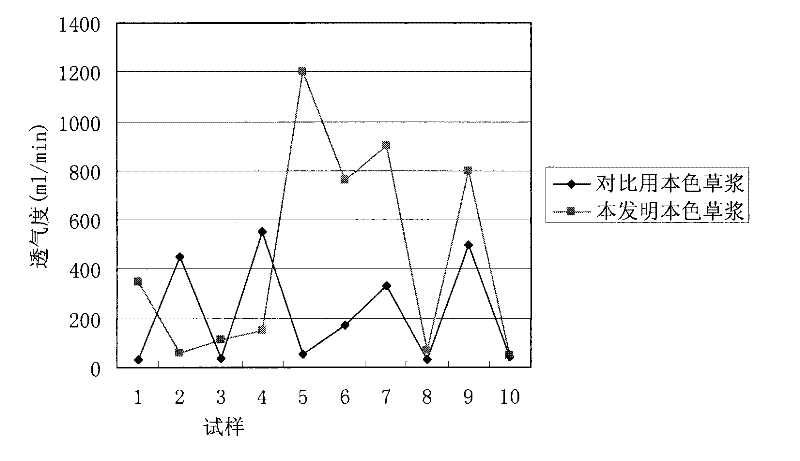

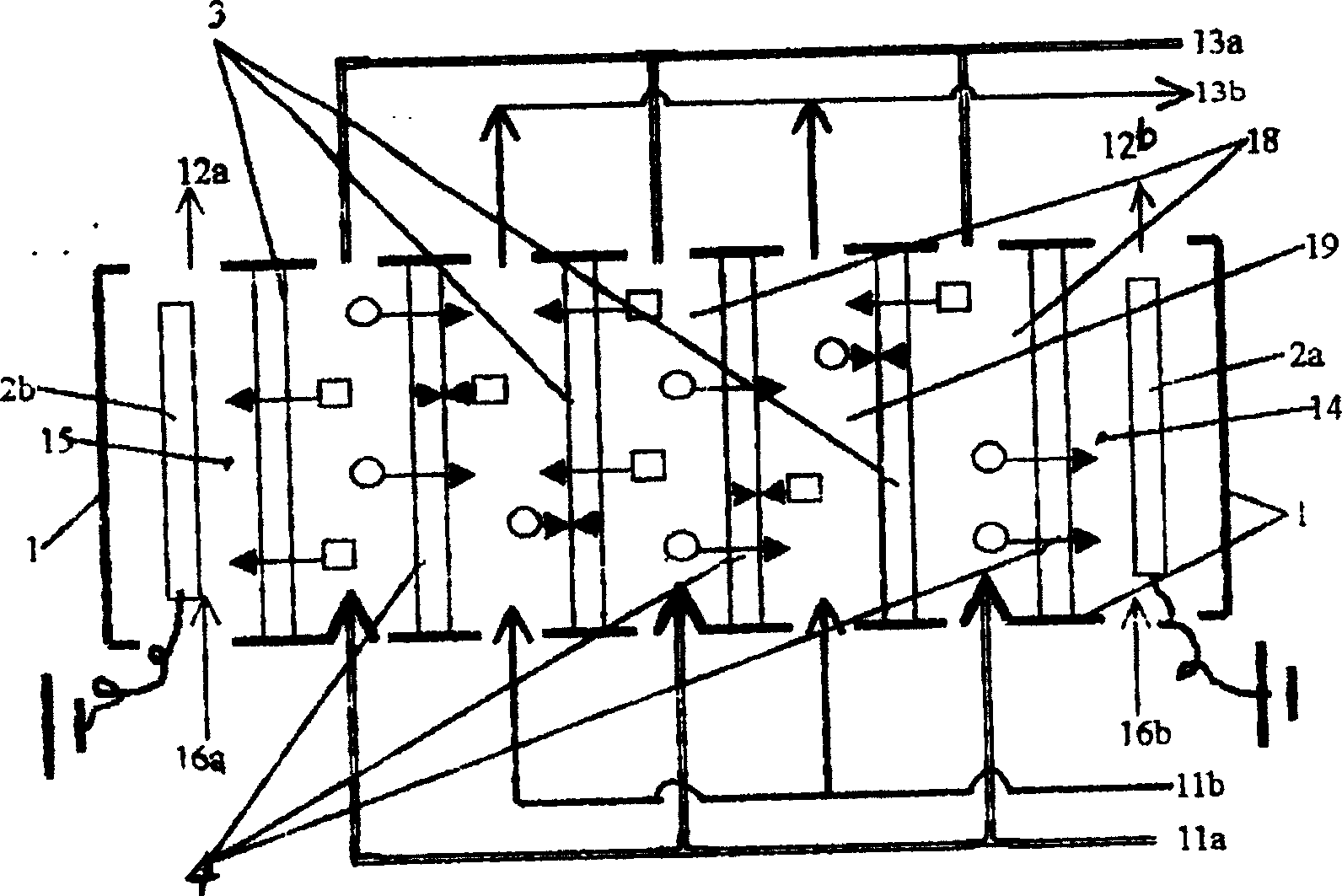

Process and apparatus for treating water by magneto-electric dialysis

InactiveCN1359857AImprove processing efficiencyIncrease directional forceGeneral water supply conservationDispersed particle separationMagnetic tension forceElectric consumption

A magneto-electric dialysis process for desalinating seawater, preparing salt from seawater and desalting industrial water is characterized by that on the basis is existing electric dialysis equipment, a static magnetic field is additionally used to directionally shift the cations and anions in flowing solution. Its apparatus is composed of a casing with different water inlets and outlets and electrodes, a group of cationic exchange membranes and anionic exchange membranes, which are alternatively arranged between anode and cathode, and a permanent magnet attached to each wall of the casing. Its advantages are high throughput, less electric consumption and not scaling.

Owner:陈树庆 +1

Corrugated paper production method using waste paper pulping to improve fiber utilization rate

The invention discloses a corrugated paper production method using waste paper pulping to improve the fiber utilization rate. The method comprises the following steps: waste paper pulp adjustment, waste paper pulp soaking and swelling, waste paper pulp puffing, waste paper pulp breaking, shredded kraft paper puffing, kraft paper pulp breaking, residue removal and screening, mixing with a grindingaid, grinding for forming a pulp, mesh papermaking pressing and subsequent papermaking. The waste paper and the shredded kraft paper are used to produce the corrugated paper, and the papermaking material is sufficiently preprocessed before the above pulp breaking step to maximally dissociate fibers in the papermaking material in the pulp breaking step and keep the integrity of the fibers, so the utilization rate of secondary fibers in the papermaking step is improved. The method has the advantages of simple process, energy-saving, environmentally-friendly, clean and pollution-free production process, great reduction of fiber damages and the broken rate of the fibers in the pulping process, and high fiber utilization rate, and the toughness and the strength of the prepared corrugated paperare greatly improved.

Owner:东莞顺裕纸业有限公司

Freeness of paper products

InactiveUS20130126111A1Good effectImprove propertiesPulp properties modificationPulp bleachingPulp and paper industryPaper sheet

Owner:CATEXEL

Endoglucanase nce5 and cellulase preparations containing the same

InactiveUS20050143275A1Efficient and inexpensive treatmentLow degreeFungiOrganic detergent compounding agentsBiotechnologyGlucanase

There is provided an endoglucanase enzyme, which is useful for reducing fuzz of regenerated cellulose-containing fabrics, improving the touch and appearance, color clarification, localized variation in color, reducing stiffness and using it as components of a detergent, as well as deinking waste paper and improving freeness of paper pulp. A cDNA coding for the endoglucanase enzyme NCE5 was cloned and its DNA sequence and amino acid sequence derived from it were determined.

Owner:MEIJI SEIKA PHARMA CO LTD

Tissue products incorporating nanoporous cellulose fiber

ActiveUS20120273147A1Increase overlapReduce the maximumNon-fibrous pulp additionPaper after-treatmentPorosityMedicine

Fibrous cellulosic products incorporating both conventional cellulosic fibers and laterally expanded cellulose fibers exhibit exceptional porosity, bulk, absorbency and resiliency properties. Typical products include absorbent tissue products, absorbent fluff products and flat papers. The laterally expanded cellulose fibers exhibit: (i) a broadened X-Ray diffraction peak for the most prominent reflection having a width at half-height, (W1 / 2h)A, of at least about 3.0° 2Θ, (ii) broad overlapping maxima in their Raman spectrum between 285 and 500 cm−1, the height of the two tallest of said maxima in said spectrum between 285 and 500 cm−1 being between 35 and 50% of the height of the peak near 1098 cm−1 and (iii) a blue stain when treated with Graff C-stain, the stain exhibiting less red than the stains exhibited with bleached hardwood kraft fibers and bleached softwood kraft fibers.

Owner:CELLLOSE SCI INT

Freeness of paper products

InactiveUS20140000824A9Good effectImprove propertiesPulp properties modificationPulp bleachingPulp and paper industryHydrogen peroxide

Owner:CATEXEL

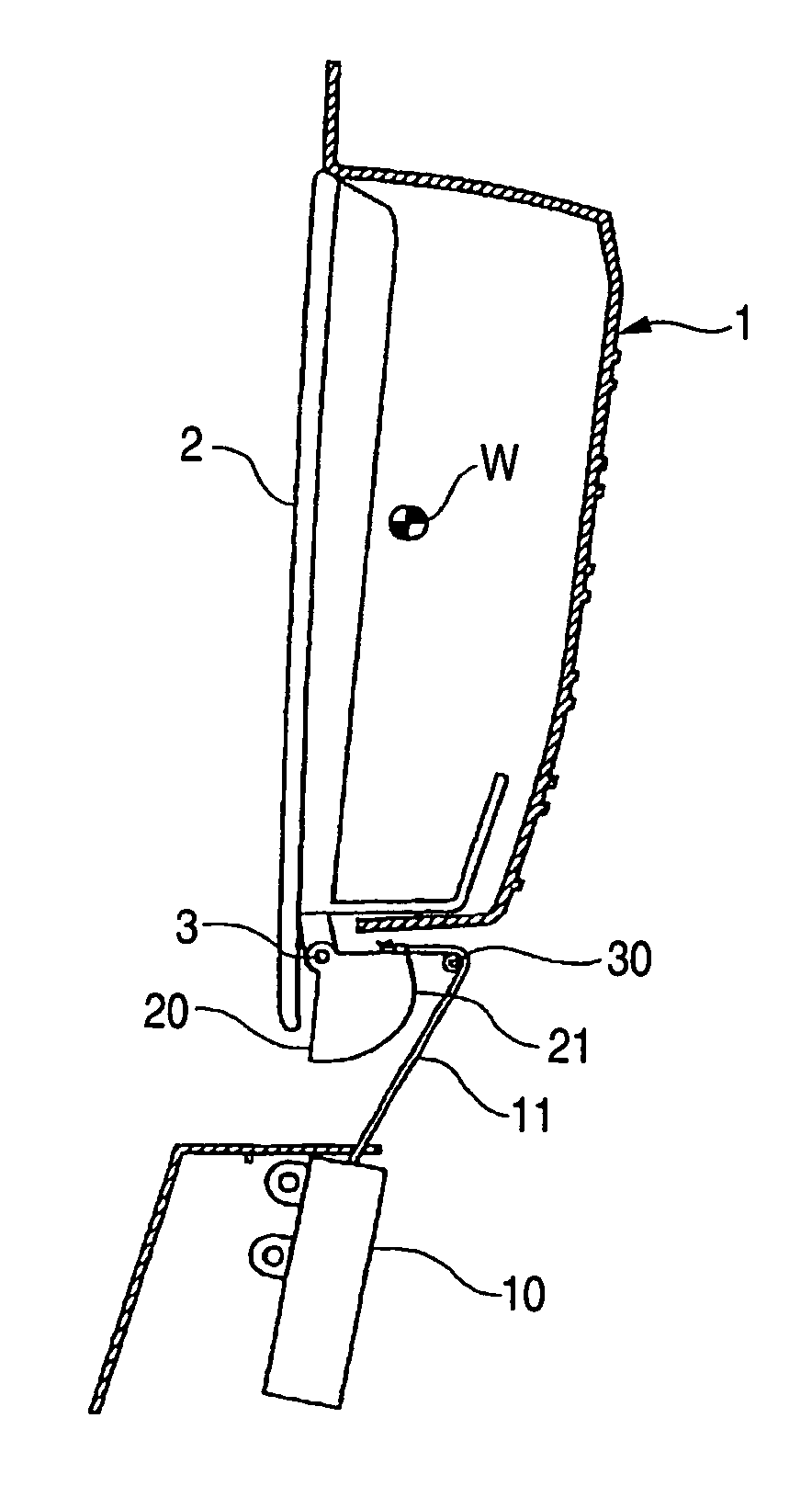

Storage apparatus for vehicle

InactiveUS7114758B2Reduce forceIncrease forceVehicle arrangementsPassenger spacePull forceEngineering

In a storage apparatus for a vehicle including a lid which can rotate about a pivot, and a damper device having a cord-like connecting member and adapted to generate damping force against pulling force from the connecting member, wherein a connecting wire (the connecting member) is pulled, when the lid rotates in one direction, thereby to generate the damping force in the damper device, it is so constructed that a damping force control member having a guide face for the connecting wire is fixed to the lid, and when the lid has rotated in a direction of receiving the damping force, the connecting wire is wound around the guide face and pulled.

Owner:PIOLAX CO LTD

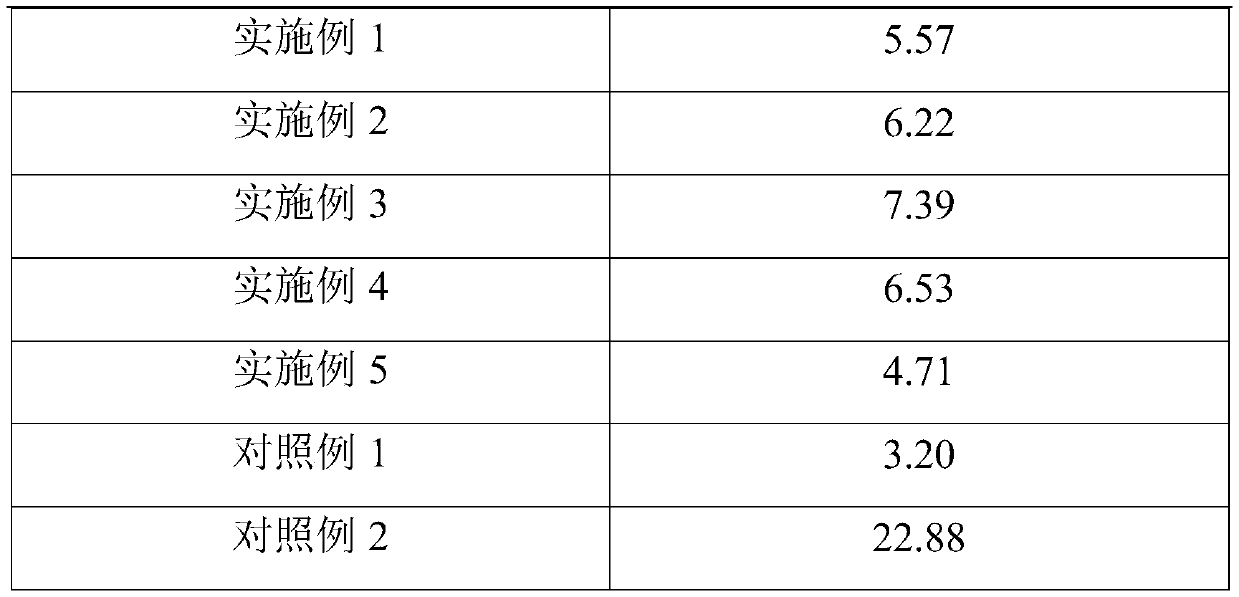

Complex enzyme preparation for extracting maize yellow pigment and extraction method

The invention provides a complex enzyme preparation for extracting a maize yellow pigment and an extraction method. The complex enzyme preparation comprises the following components in percentage by mass: 1 to 5% of cellulase, 5 to 10% of beta-mannase, 2 to 8% of xylanase, 10 to 20% of protease, 2 to 8% of lipase, 10 to 20% of alpha-amylase, 5 to 10% of glucoamylase, 1 to 5% of pectinase, 1 to 5%of glucosaccharase and the balance of water. The complex enzyme preparation for extracting the maize yellow pigment and the extraction method are simple in process and convenient to operate; enzymolysis preprocessing is carried out on corn gluten meal by adopting a biological enzyme method, macromolecular substances such as polysaccharides, proteins, pectins and the like which are connected with the maize yellow pigment are degraded, simultaneously, network structures of the proteins are hydrolyzed so as to improve freeness of the maize yellow pigment and make the maize yellow pigment easier to extract, and moreover, after enzymolysis processing, the maize yellow pigment and zein are separated by adopting two ethanol solutions with different concentration so as to obtain the high-purity maize yellow pigment; and an extraction rate of the maize yellow pigment can be up to 7.39%.

Owner:WUHAN SUNHY BIOLOGICAL

Method for producing paper and paper board

InactiveCN1676748AHigh freenessHigh yieldRetention agents additionPulp material addition processesPaper sheetChemistry

This invention provides a method for producing paper and cardboard, corresponding to paper-making facilities in which an acidic paper-making process and a neutral paper-making process are intermingled, without collapsing the formation in both of the acidic paper-making and neutral paper-making and improving water filterability and yield. This method for producing the paper and cardboard is provided by adding a branched or cross-linked amphoteric polymer, water soluble anionic polymer and / or anionic organic polymer fine particles or water soluble cationic polymer to a paper stock, making it a sheet form by dehydration and then drying.

Owner:KURITA INDUSTRIAL CO LTD

Heating material for carbon dioxide cracker and preparation method of heating material

InactiveCN109912371AImplement flow controlMeet heating requirementsPressure gas generationDesorptionPeat

The invention relates to the field of carbon dioxide cracking in coal mine, in particular to a heating material for a carbon dioxide cracker. The heating material is prepared from following raw materials in parts by weight: 45-55 parts of Chinese locust charcoal powder, 10-14 parts of calcium peroxide, 7-9 parts of sodium bismuthate, 13-19 parts of peat and 12-16 parts of activated clay. The invention further discloses a preparation method of the heating material for the carbon dioxide cracker. The preparation method comprises following steps: 1), the Chinese locust charcoal powder, the activated clay, calcium peroxide, sodium bismuthate and the peat are weighed in a formula ratio and poured into a beaker in sequence; 2), the materials in the beaker are slowly stirred to be uniform by a glass bar; 3), the materials obtained after sufficient mixing are put in a storage bag. Liquid carbon dioxide can be converted into gaseous carbon dioxide, so that a coal bed is subjected to technical treatment of cracking, penetration enhancement and desorption by carbon dioxide, and purposes of safe and fast extraction and outburst elimination are achieved.

Owner:贵州致裂科技有限公司

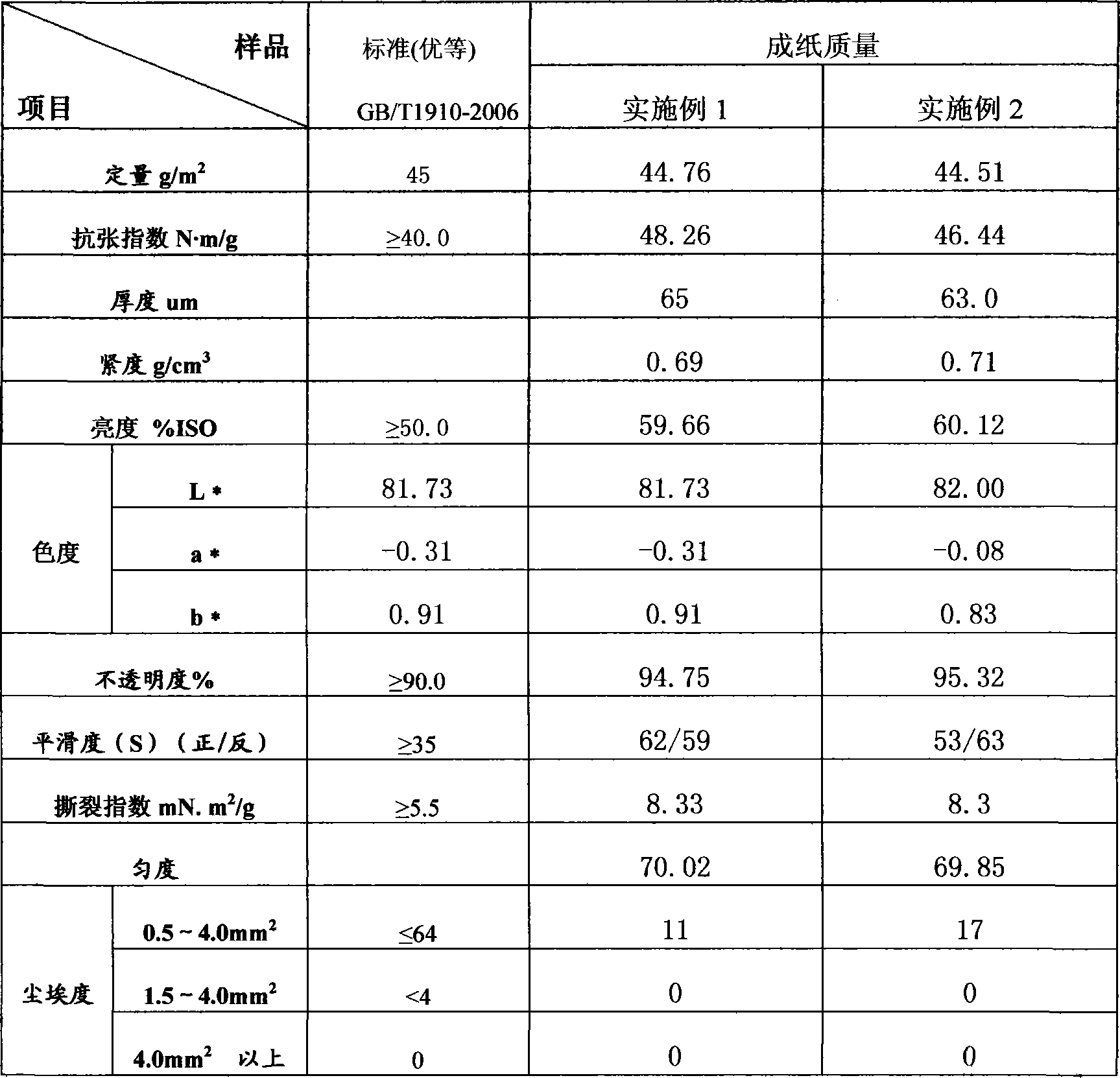

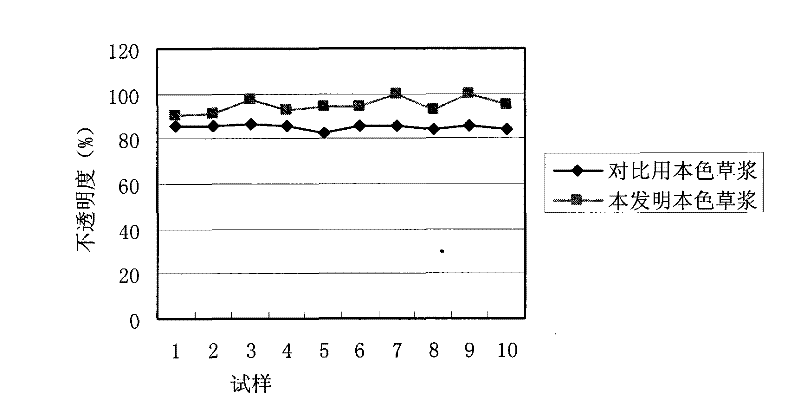

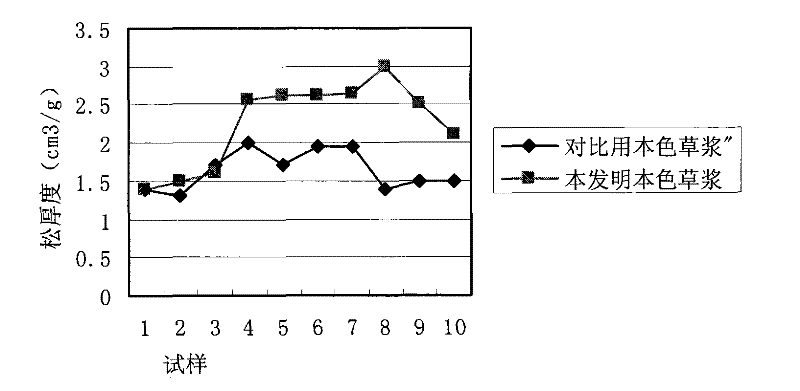

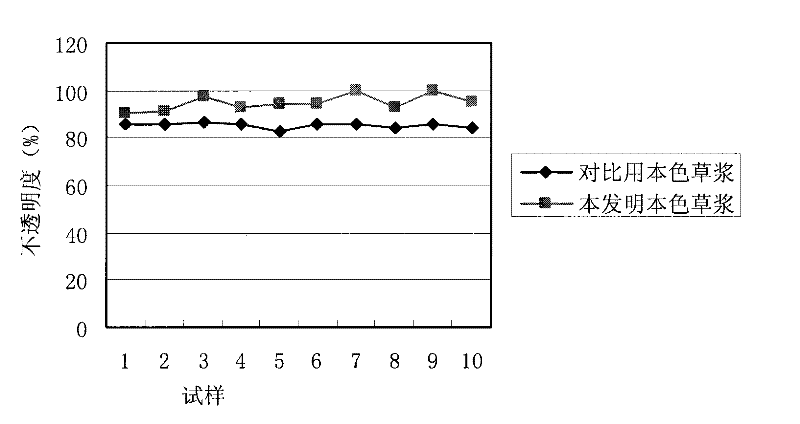

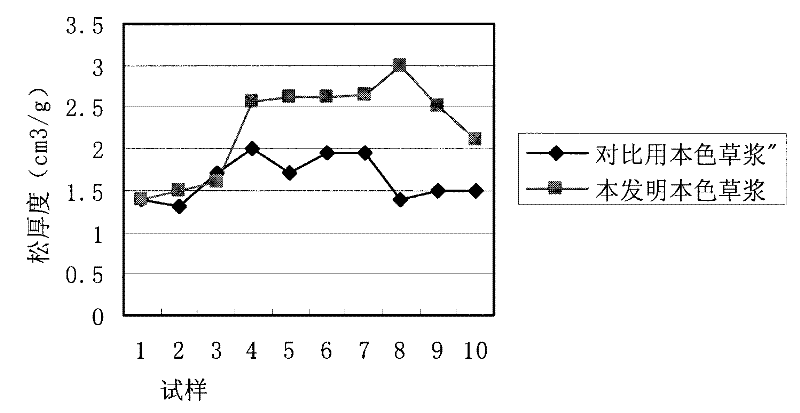

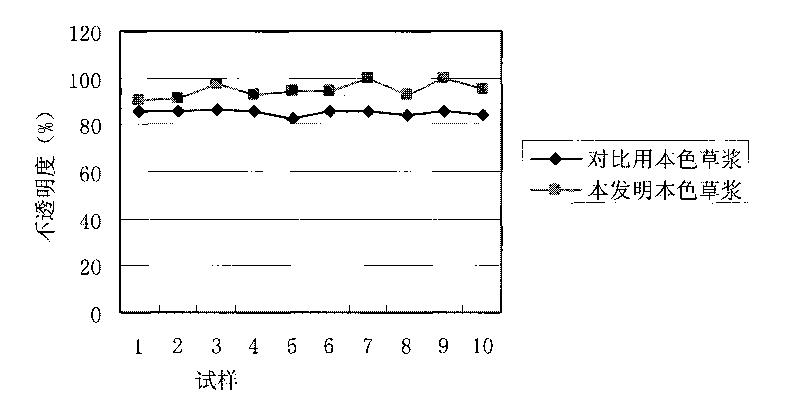

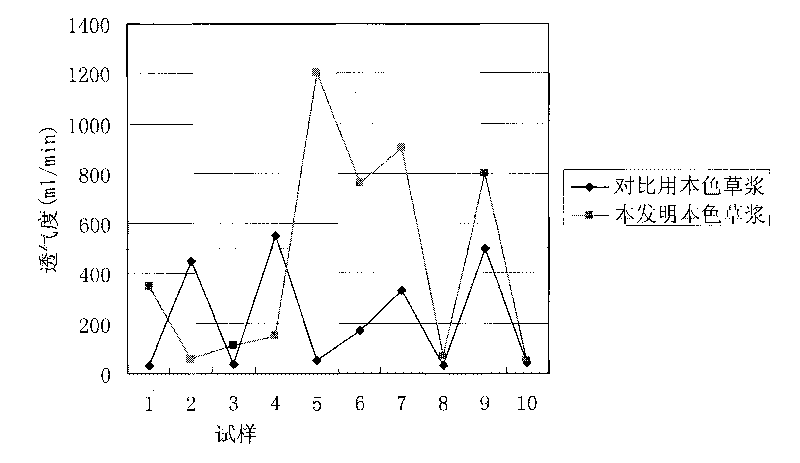

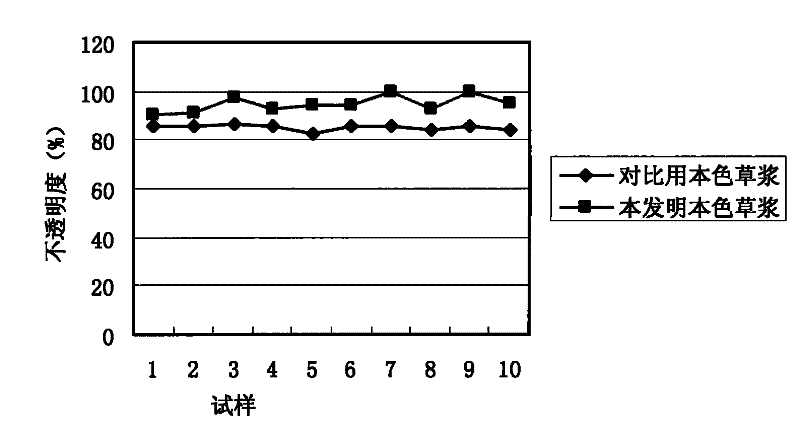

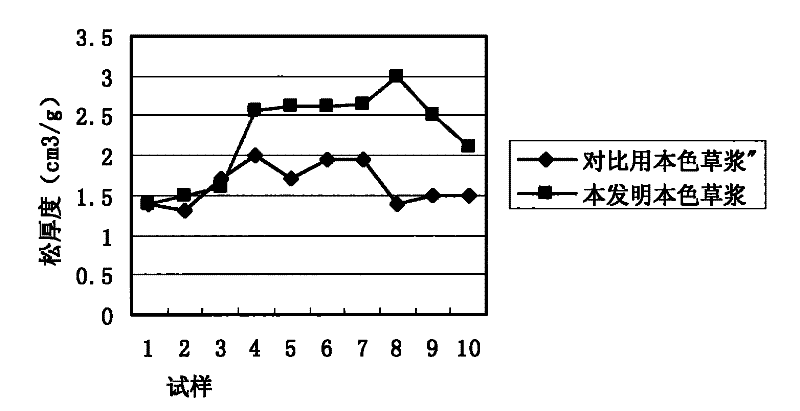

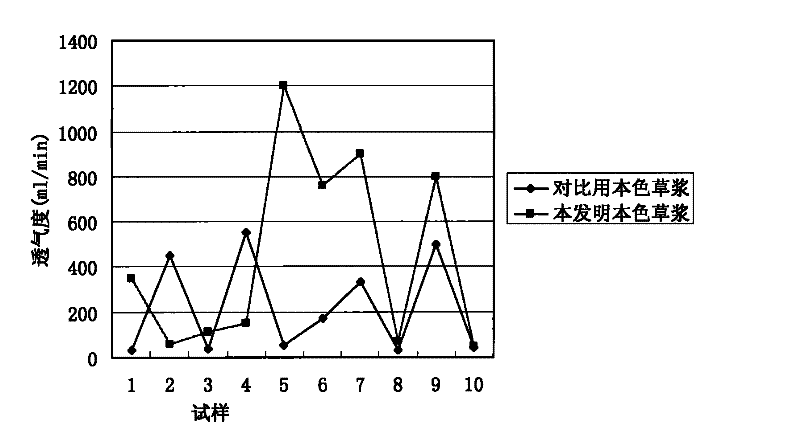

Natural-color straw pulp with improved tearing index, freeness and tensile index, and stable performance

ActiveCN101691703AReduce quality fluctuationsSlurry data is stableNon-woody plant/crop pulpPulp and paper industry

The invention relates to natural-color straw pulp with improved tearing index, freeness and folding strength, and stable performance, in particular to natural-color straw pulp and application thereof in mixed pulp and paper products. The straw pulp has the advantages that: color phase or whiteness of the straw pulp is remarkably improved; the bulk and air permeability are high; and the acquired data of the sizing agent of the natural-color straw pulp is more stable because of small quality fluctuation of sizing agent.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for producing low basis weight newsprint by 100 percent deinking waste pulp added with retention and drainage agent

InactiveCN101225615BEmission reductionReduce pollutionNon-fibrous pulp additionPaper recyclingFiberPolyacrylamide

Owner:GUANGDONG IND TECHN COLLEGE +1

Natural-color straw pulp with improved color phase, freeness and bulk and stable performance

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Natural-color straw pulp with improved color phase, opacity and freeness, and stable performance

The invention relates to natural-color straw pulp with improved color phase, opacity and freeness, and stable performance, in particular to natural-color straw pulp and application thereof in mixed pulp and paper products. The straw pulp has the advantages that: color phase or whiteness of the straw pulp is remarkably improved; the opacity and freeness are high; and the acquired data of the sizing agent of the natural-color straw pulp is more stable because of small quality fluctuation of sizing agent.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Process and apparatus for treating water by magneto-electric dialysis

InactiveCN1162341CSimple structureEasy to manufactureGeneral water supply conservationDispersed particle separationMagnetoElectric consumption

A magneto-electric dialysis process for desalinating seawater, preparing salt from seawater and desalting industrial water is characterized by that on the basis is existing electric dialysis equipment, a static magnetic field is additionally used to directionally shift the cations and anions in flowing solution. Its apparatus is composed of a casing with different water inlets and outlets and electrodes, a group of cationic exchange membranes and anionic exchange membranes, which are alternatively arranged between anode and cathode, and a permanent magnet attached to each wall of the casing. Its advantages are high throughput, less electric consumption and not scaling.

Owner:陈树庆 +1

Natural-color straw pulp with improved color phase, freeness and bulk, and stable performance

ActiveCN101691706AReduce quality fluctuationsSlurry data is stableNon-woody plant/crop pulpPulp and paper industry

The invention relates to natural-color straw pulp with improved color phase, freeness and bulk, and stable performance, in particular to natural-color straw pulp and application thereof in mixed pulp and paper products. The straw pulp has the advantages that: color phase or whiteness of the straw pulp is remarkably improved; the bulk and air permeability are high; and the acquired data of the sizing agent of the natural-color straw pulp is more stable because of small quality fluctuation of sizing agent.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Natural-color straw pulp with improved freeness, air permeability and folding strength, and stable performance

ActiveCN101691710BImprove breathabilityIncreased tear indexNon-woody plant/crop pulpPulp and paper industry

The invention relates to natural-color straw pulp with improved freeness, air permeability and folding strength, and stable performance, in particular to natural-color straw pulp and application thereof in mixed pulp and paper products. The straw pulp has the advantages that: color phase or whiteness of the straw pulp is remarkably improved; the bulk and freeness are high; and the acquired data of the sizing agent of the natural-color straw pulp is more stable because of small quality fluctuation of sizing agent.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

A kind of production process of white flour kraft cardboard

ActiveCN105735033BEfficient removalRemove completelySecondary cellulose fibresPaper-making machinesFiberSurface layer

The invention relates to a production technology of a white top liner. The technology comprises the following steps that 1, ONP pulp is prepared, water is added to fibers obtained from first flotation of the ONP pulp, bleaching is conducted, first ONP pulp is obtained, water is added to fibers obtained from second flotation of the ONP pulp, bleaching is conducted, second ONP pulp is obtained, concentration is conducted on ONP pulp of two times of flotation, and third ONP pulp is conducted; 2, DMOW pulp is conducted, water is added to fibers obtained from first flotation of the DMOW pulp, bleaching is conducted, first DMOW pulp is obtained, water is added to fibers obtained from second flotation of the DMOW pulp, bleaching is conducted, second DMOW pulp is obtained, concentration is conducted on DMOW pulp of two times of flotation, and third DMOW pulp is conducted; 3, the first DMOW pulp, the first ONP pulp and original wood pulp are mixed, a surface layer is obtained after the mixture flows to paper-making meshes, the second DMOW pulp and the second ONP pulp are mixed, a bottom layer is obtained after the mixture flows to the paper-making meshes, the third DMOW pulp, the third ONP pulp and OCC pulp are mixed, and a core layer is obtained after the mixture flows to the paper-making meshes.

Owner:JIANGSU LEE & MAN PAPER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com