Process and apparatus for treating water by magneto-electric dialysis

A technology of water treatment and electrodialysis, applied in the fields of magnetic field/electric field water/sewage treatment, separation method, general water supply saving, etc., can solve the problems of water treatment speed and treatment quality that can no longer be improved, seawater desalination speed slowing down, current efficiency Can no longer improve the problem, to achieve the effect of reducing the frequency of dismantling and washing pauses or frequent electrode reversal, which is conducive to descaling and improving water treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1. The method of this embodiment is to add a static magnetic field to make the negative and positive ions in the flowing solution do directional deviation in the space of electrodialysis treatment water.

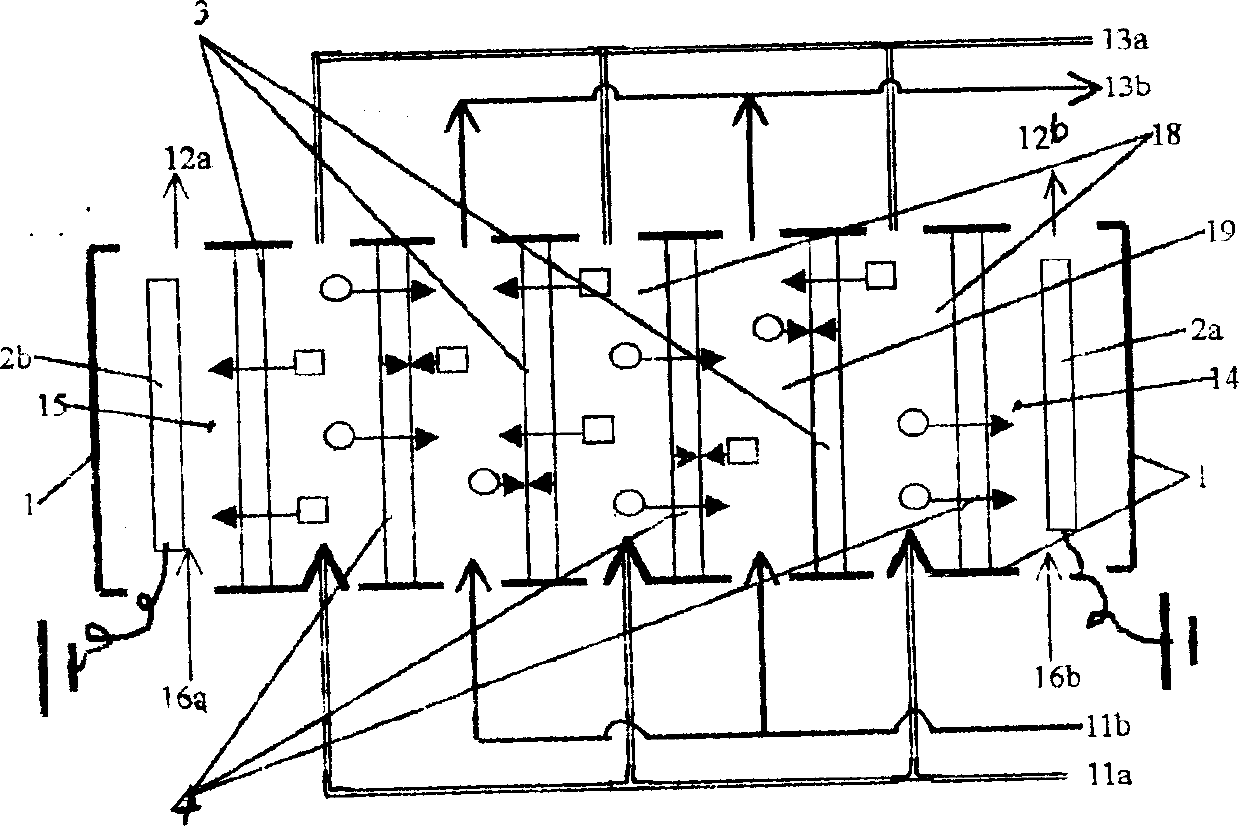

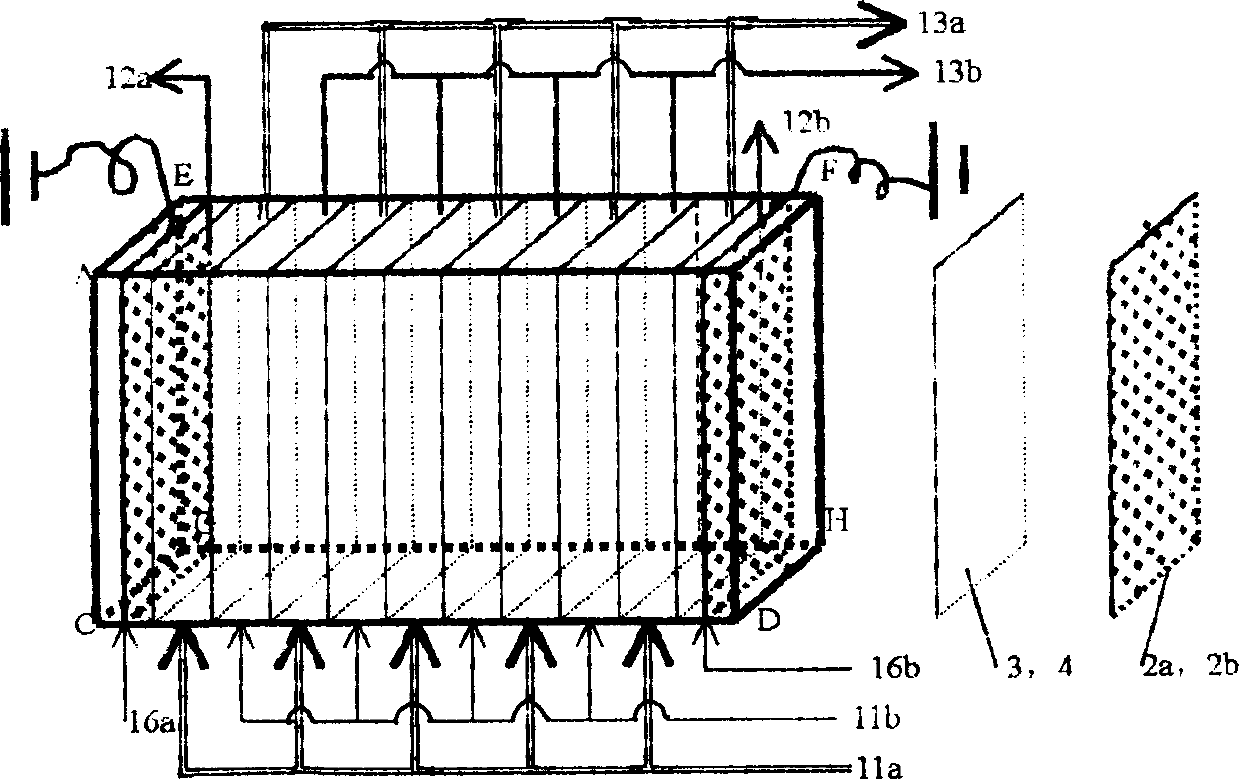

[0019] The so-called electrodialysis space can be obtained from figure 1 with figure 2 It can be seen in the structural schematic diagram and perspective view of the existing electrodialyzer in the solution that the positive and negative ions in the solution (in the figure, ←□ represents the migration of positive ions, and ○→ represents the migration of negative ions), under the action of a direct current electric field , the positive ions shift to the cathode and selectively pass through the cation exchange membrane, and the negative ions shift to the anode and selectively pass through the anion exchange membrane. The electricity, E is the electric field strength). For example, in the space of electrodialysis treatment water, add a Figure 4 The two pe...

Embodiment 2

[0022]Embodiment 2. The difference from the method of Embodiment 1 is that the strength of the static magnetic field should not be less than 0.5T (Tesla). Because the Lorent magnetic force Fm is proportional to the magnetic field strength B, the greater the magnetic field strength, the better the effect; it is more ideal if a superconductor with a strong magnetic field above 20T can be used. In addition, since the Lorent magnetic force Fm=qvB is a vector, the electrodialysis space of the magnetoelectric dialysis device of the present invention must be non-loop type, so that the liquid flow flows along the entire membrane surface, and the general direction of the flow velocity remains consistent. It can also be known from Fm=qvB that increasing the liquid flow velocity is not only conducive to improving the design offset force of the static magnetic field on the ions, but also conducive to improving the water treatment speed of the entire magnetoelectric dialysis equipment.

Embodiment 3

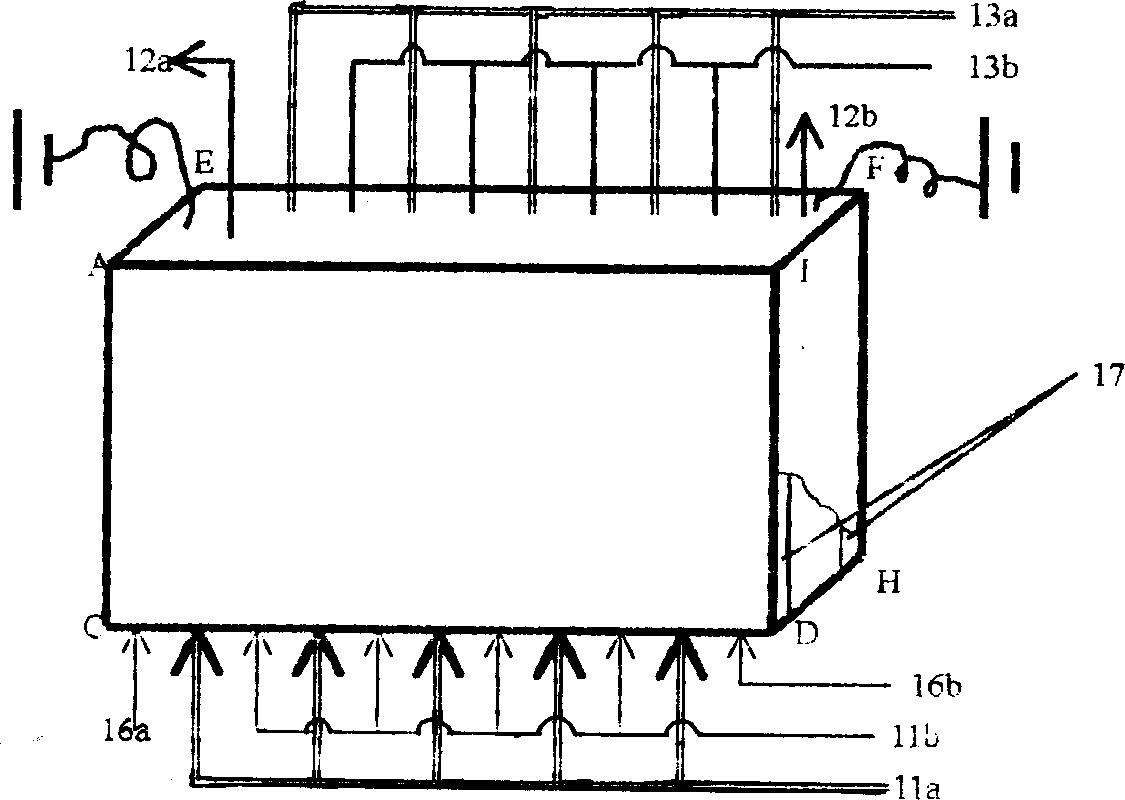

[0023] Example 3. Available from Figure 5 It can be seen from the figure that the difference from Embodiment 1 and Embodiment 2 is that the two shell walls of the shell parallel to the water flow and the current direction are high magnetic permeability material plates 17, and the rest of the shell walls are all low magnetic permeability materials. plate. In order to overcome the magnetic field shielding effect of the remaining shell walls, the effect on the applied magnetic field is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com