Complex enzyme preparation for extracting maize yellow pigment and extraction method

A technology of zeaxanthin and compound enzyme preparation, which is applied in the direction of chemical instruments and methods, biochemical equipment and methods, enzymes, etc., can solve the problems of low purity, complicated process of zeaxanthin, and low extraction rate, and achieve high purity, Increased freeness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

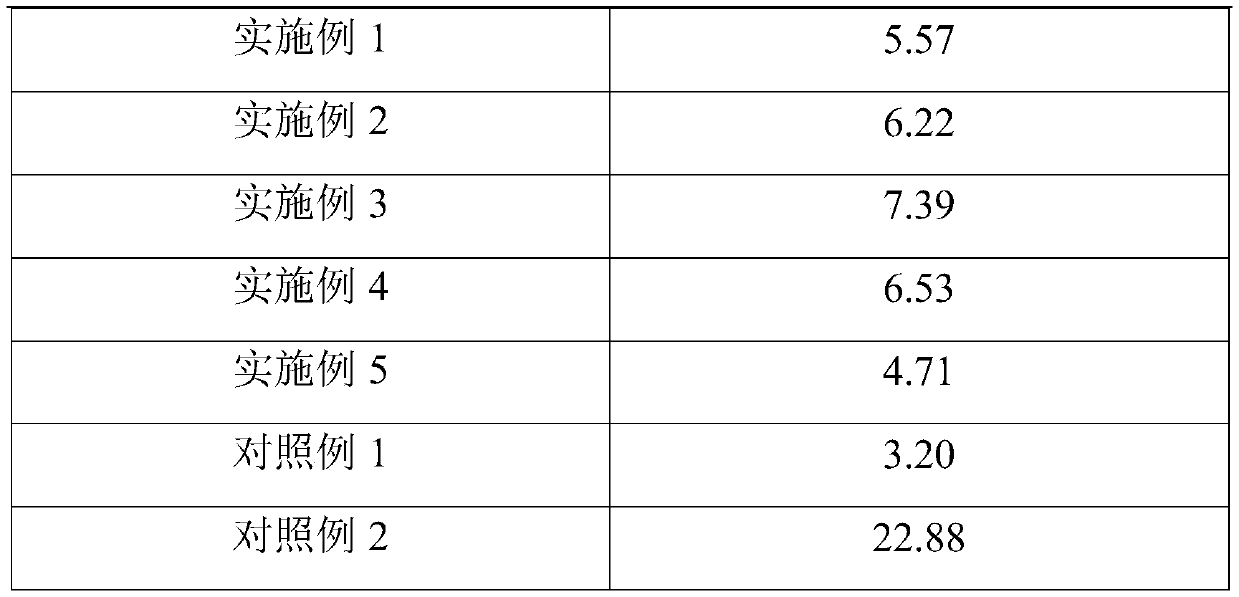

Embodiment 1

[0022] According to mass percentage, cellulase 5%, β-mannanase 5%, xylanase 8%, glucosidase 2.5%, protease 15%, lipase 2%, α-amylase 10%, glucose 5% amylase and 1% pectinase, weigh the required quality biological enzyme preparation, make up 100% with water, and mix evenly to obtain the compound biological enzyme preparation.

[0023] Crush corn gluten powder to 80 mesh, add water to soak according to the ratio of material to liquid 1:6, adjust the pH value to 4.5 with dilute hydrochloric acid, add 5% of the above-mentioned compound biological enzyme preparation, keep warm at 45°C for enzymolysis reaction for 1 hour, and then centrifuge After removing the supernatant, add 75% ethanol solution with a volume ratio of 1:5 to the precipitate, ultrasonically extract for 30 minutes, and concentrate under low-temperature vacuum distillation; then add absolute ethanol to the concentrated solution at a volume ratio of 1:5, After stirring and dissolving for 15 minutes, the supernatant wa...

Embodiment 2

[0025] According to mass percentage, cellulase 2.5%, β-mannanase 8%, xylanase 2%, glucosidase 2%, protease 10%, lipase 5%, α-amylase 15%, glucose 7% amylase and 2% pectinase, weigh the required quality of the biological enzyme preparation, make up 100% with water, and mix evenly to obtain the compound biological enzyme preparation.

[0026] Crush corn gluten powder to 80 mesh, add water to soak according to the ratio of material to liquid at 1:10, adjust the pH value to 5.0 with dilute hydrochloric acid, add 1% of the above-mentioned compound biological enzyme preparation, keep warm at 50°C for enzymolysis reaction for 2 hours, and then centrifuge After removing the supernatant, add 80% ethanol solution with a volume ratio of 1:6 to the precipitate, ultrasonically extract for 30 minutes, and concentrate under low-temperature vacuum distillation; then add absolute ethanol to the concentrated solution at a volume ratio of 1:6, After stirring and dissolving for 15 minutes, the su...

Embodiment 3

[0028] According to mass percentage, cellulase 4%, β-mannanase 6%, xylanase 5%, glucosidase 2%, protease 12%, lipase 5%, α-amylase 12%, glucose 5% amylase and 2.5% pectinase, weigh the required quality biological enzyme preparation, make up 100% with water, and mix evenly to obtain the compound biological enzyme preparation.

[0029] Crush the corn gluten powder to 60 mesh, add water to soak according to the ratio of material to liquid at 1:7, adjust the pH value to 6.5 with dilute hydrochloric acid, add 4% of the above-mentioned compound biological enzyme preparation, keep warm at 30°C for enzymolysis reaction for 4 hours, and then centrifuge After removing the supernatant, add 70% ethanol solution with a volume ratio of 1:7 to the precipitate, ultrasonically extract for 25 minutes, and concentrate under low-temperature vacuum distillation; then add absolute ethanol to the concentrated solution at a volume ratio of 1:5, After stirring and dissolving for 15 minutes, the supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com