Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491 results about "Honeycomb Pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

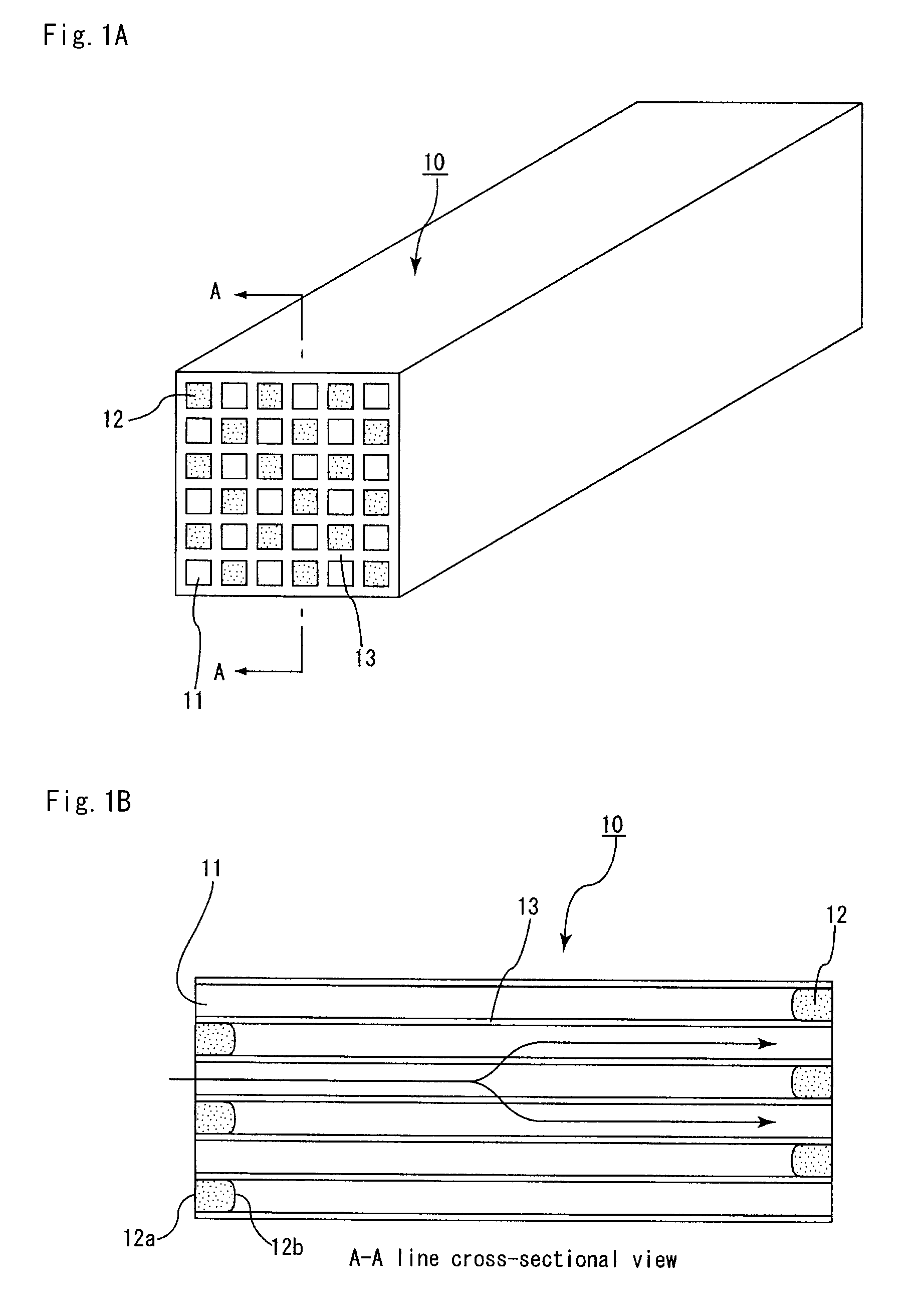

Method for manufacturing a honeycomb structured body

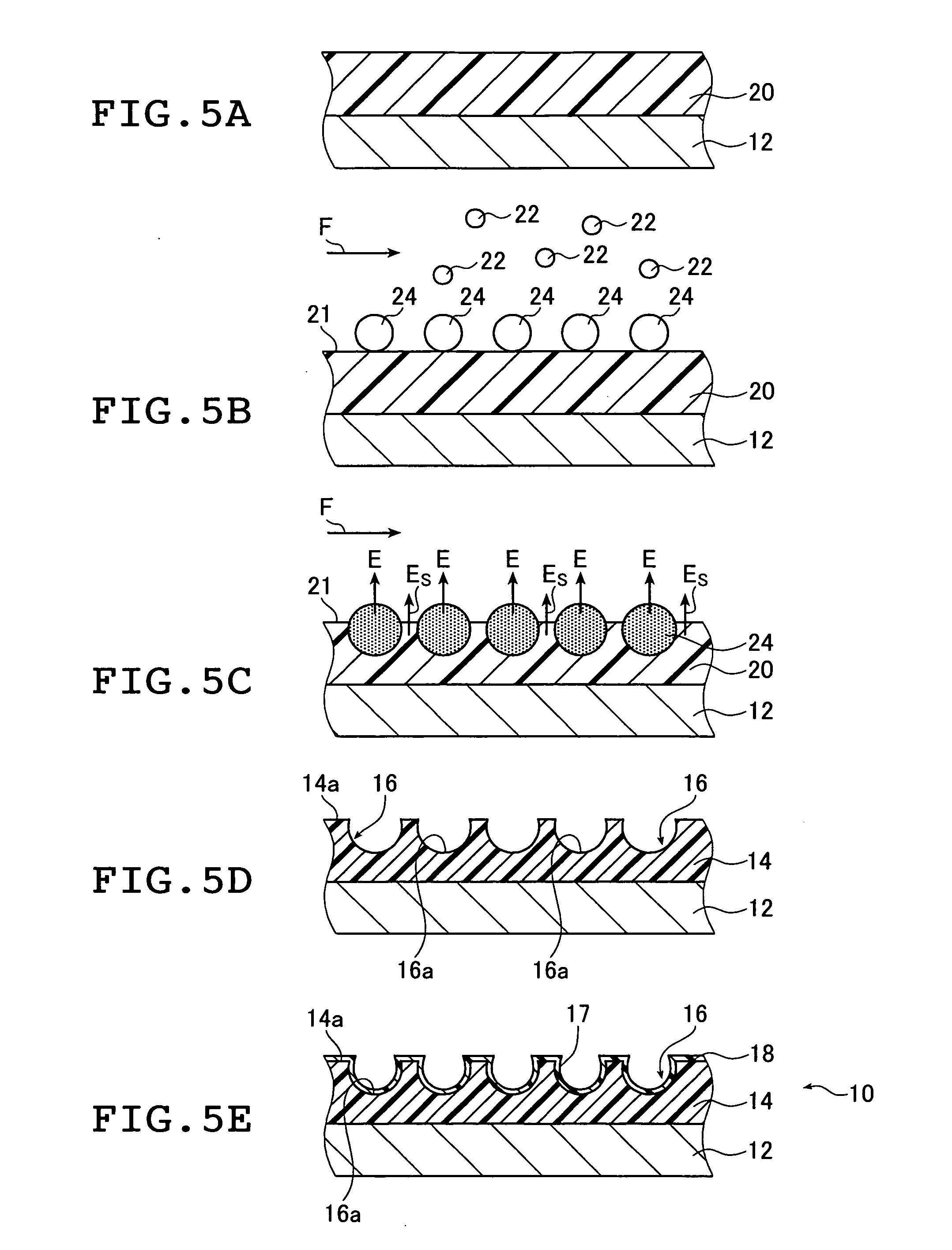

A method for manufacturing a honeycomb structured body including molding ceramic raw material to form a pillar-shaped honeycomb molded body having a multiplicity of cells disposed in parallel with one another in the longitudinal direction with a cell wall therebetween, and filling in either one of the end portions of each of the cells with a plug material paste, and firing the honeycomb molded body to manufacture a honeycomb structured body comprising a honeycomb fired body, wherein after having filled in either one of the end portions of each of the cells of the honeycomb molded body with the plug material paste, a plug material paste drying process to dry the plug material paste is conducted by blowing hot air to an end face of the honeycomb molded body using a hot air drying apparatus.

Owner:IBIDEN CO LTD

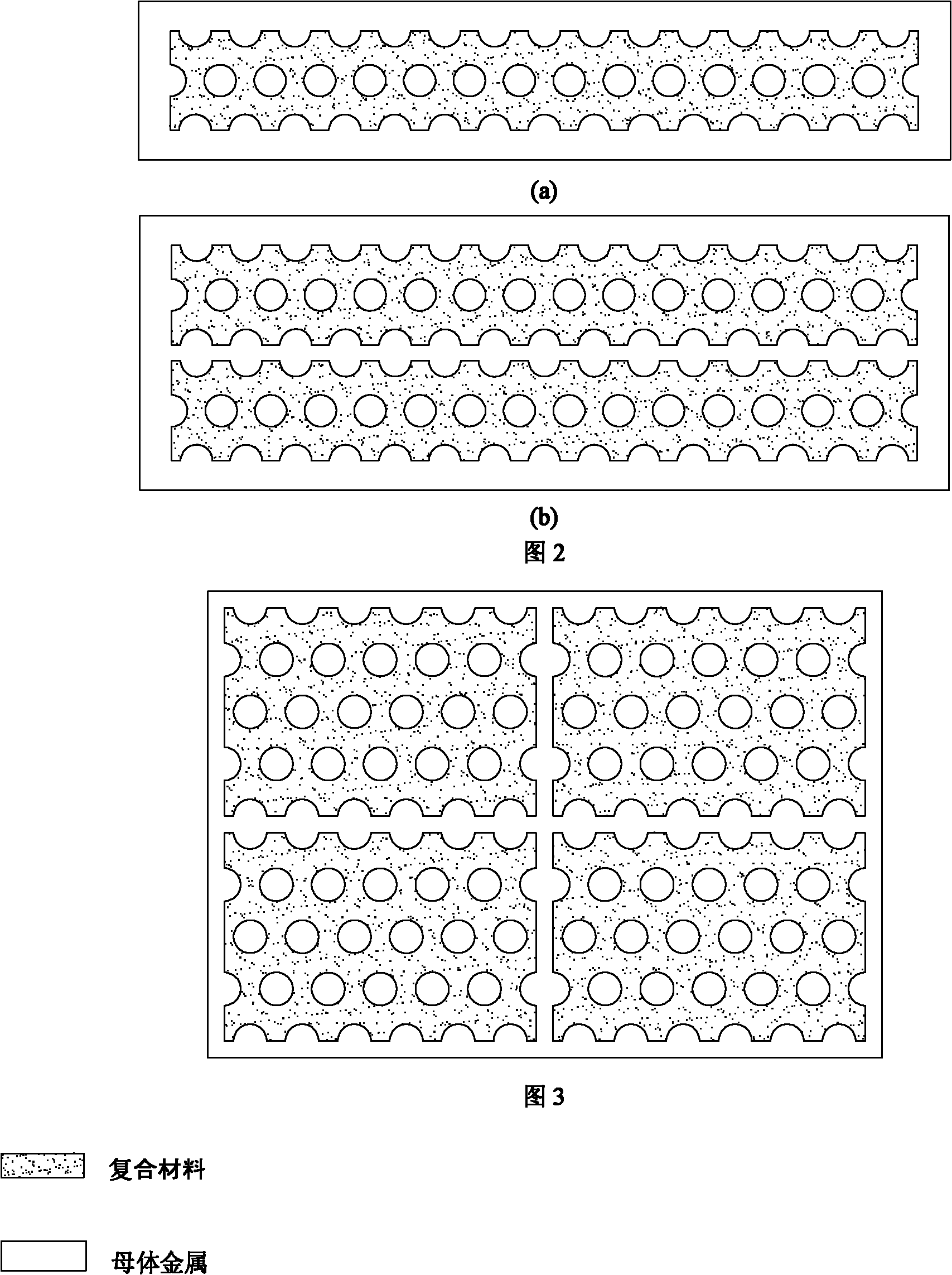

Prefabricated part of composite abrasion-resistant part and method for manufacturing abrasion-resistant part with same

The invention relates to a prefabricated part of a composite abrasion-resistant part and a method for manufacturing the abrasion-resistant part with the same. The prefabricated part is formed by mixing metal powder with carbide ceramic particles or particles by crushing a hard alloy and sintering the mixture at a high temperature and can be made into special shapes of columns, strips, blocks, honeycombs, and the like. The method comprises the following steps of: regularly arranging prefabricated parts on the end surface of a cast form; casting liquid metal by adopting a common or negative pressure cast method; impregnating the liquid metal into the prefabricated parts to form an abrasion-resistant part of a composite material, wherein the surface layer of the abrasion-resistant part comprises a matrix metal and a composite material. The abrasion-resistant part of the composite material, which is made by using the method, ensures the wear-resistant performance of the abrasion-resistant part and has high anti-impact capability.

Owner:XI AN JIAOTONG UNIV +1

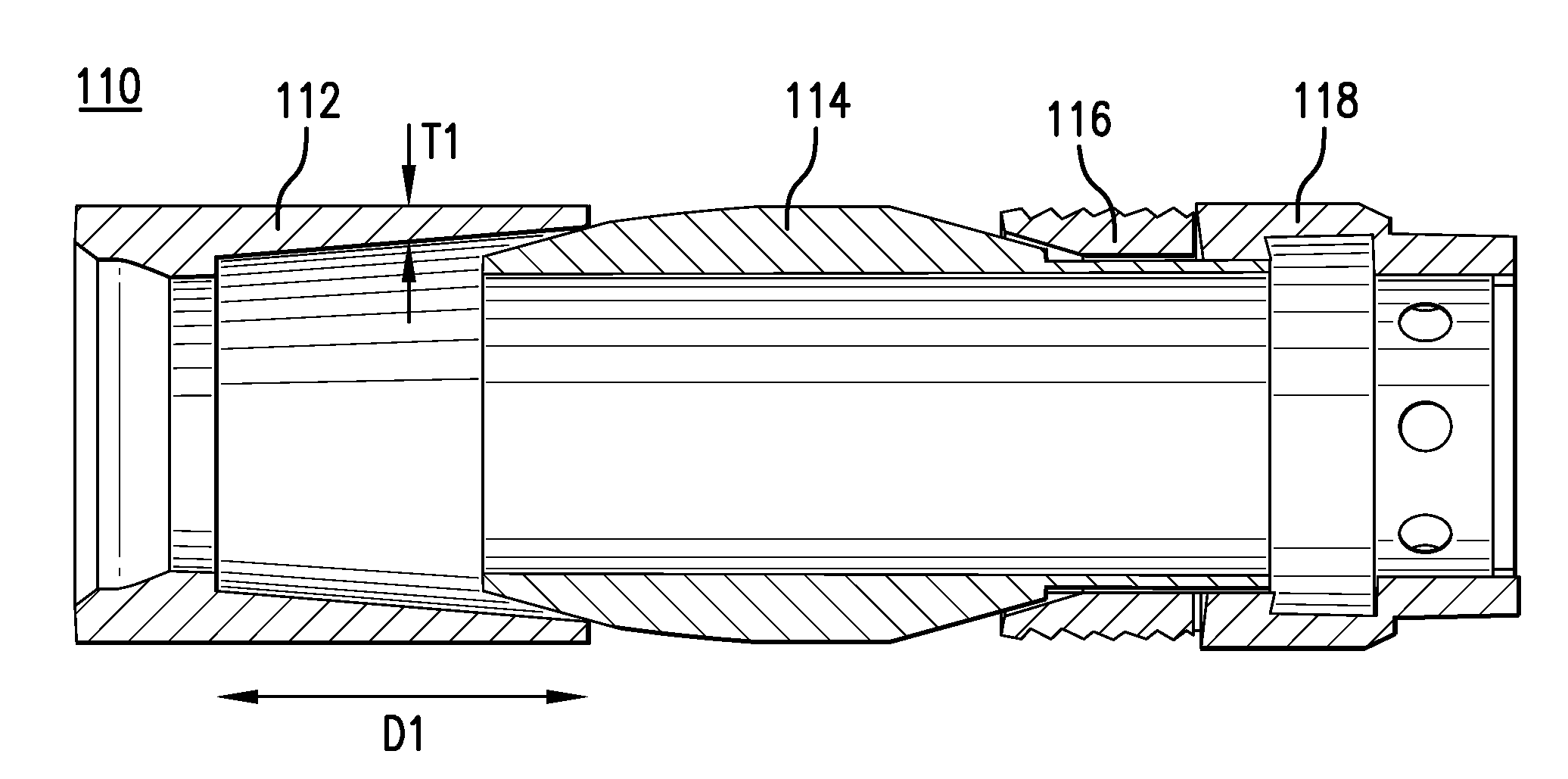

Disintegrable tubular anchoring system and method of using the same

A disintegrable tubular anchoring system comprises a frustoconical member; a sleeve with at least one first surface being radially alterable in response to longitudinal movement of the frustoconical member relative to the sleeve, the first surface being engagable with a wall of a structure; a seal with at least one second surface being radially alterable; and a seat having a land being sealingly engagable with a removable plug runnable thereagainst. The frustoconical member, sleeve, seal, and seat are disintegrable and independently comprise a metal composite which includes a cellular nanomatrix comprising a metallic nanomatrix material; and a metal matrix disposed in the cellular nanomatrix. A process of isolating a structure comprises disposing the disintegrable tubular anchoring system in the structure; radially altering the sleeve to engage a surface of the structure; and radially altering the seal to the isolate the structure.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

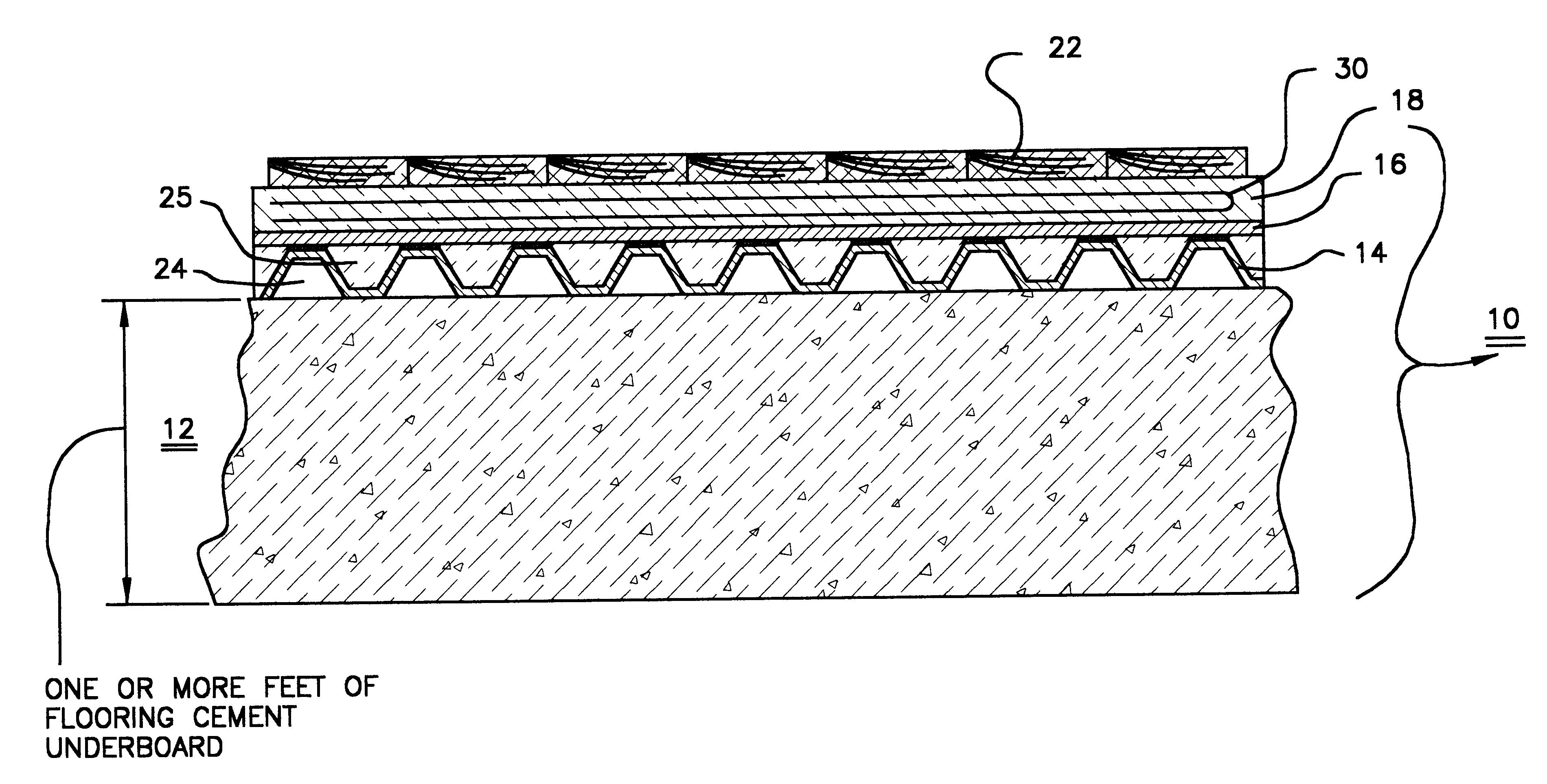

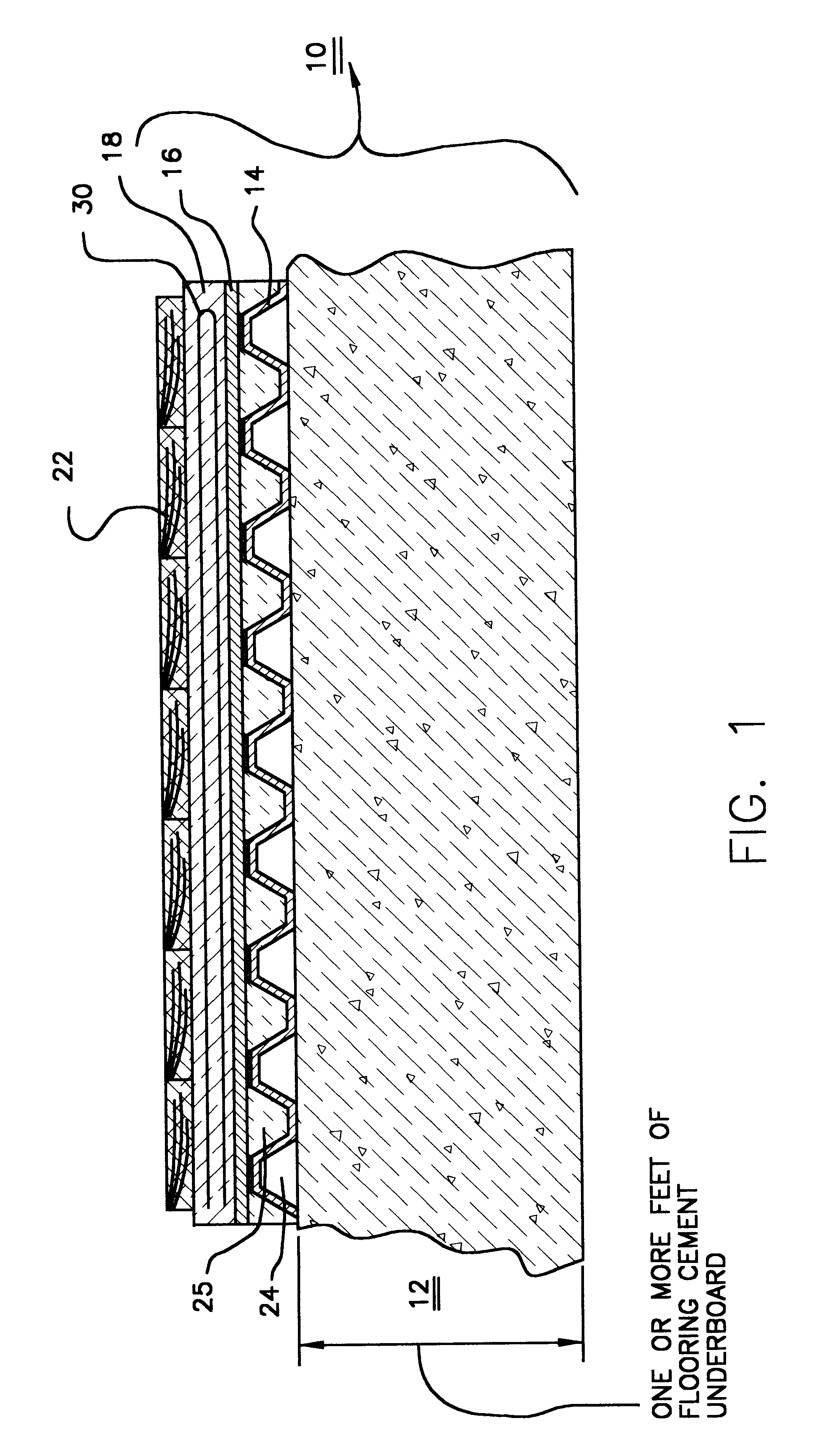

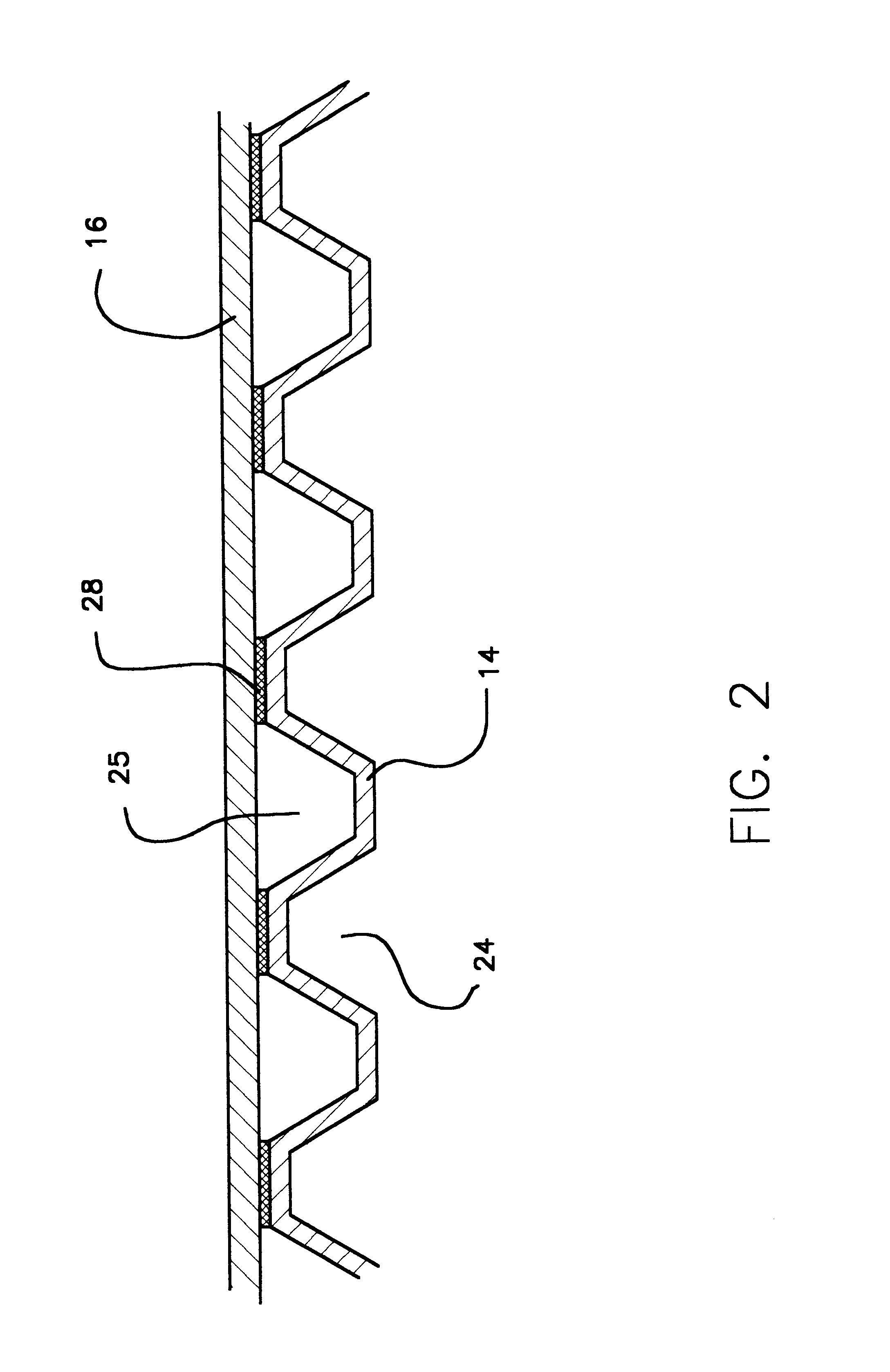

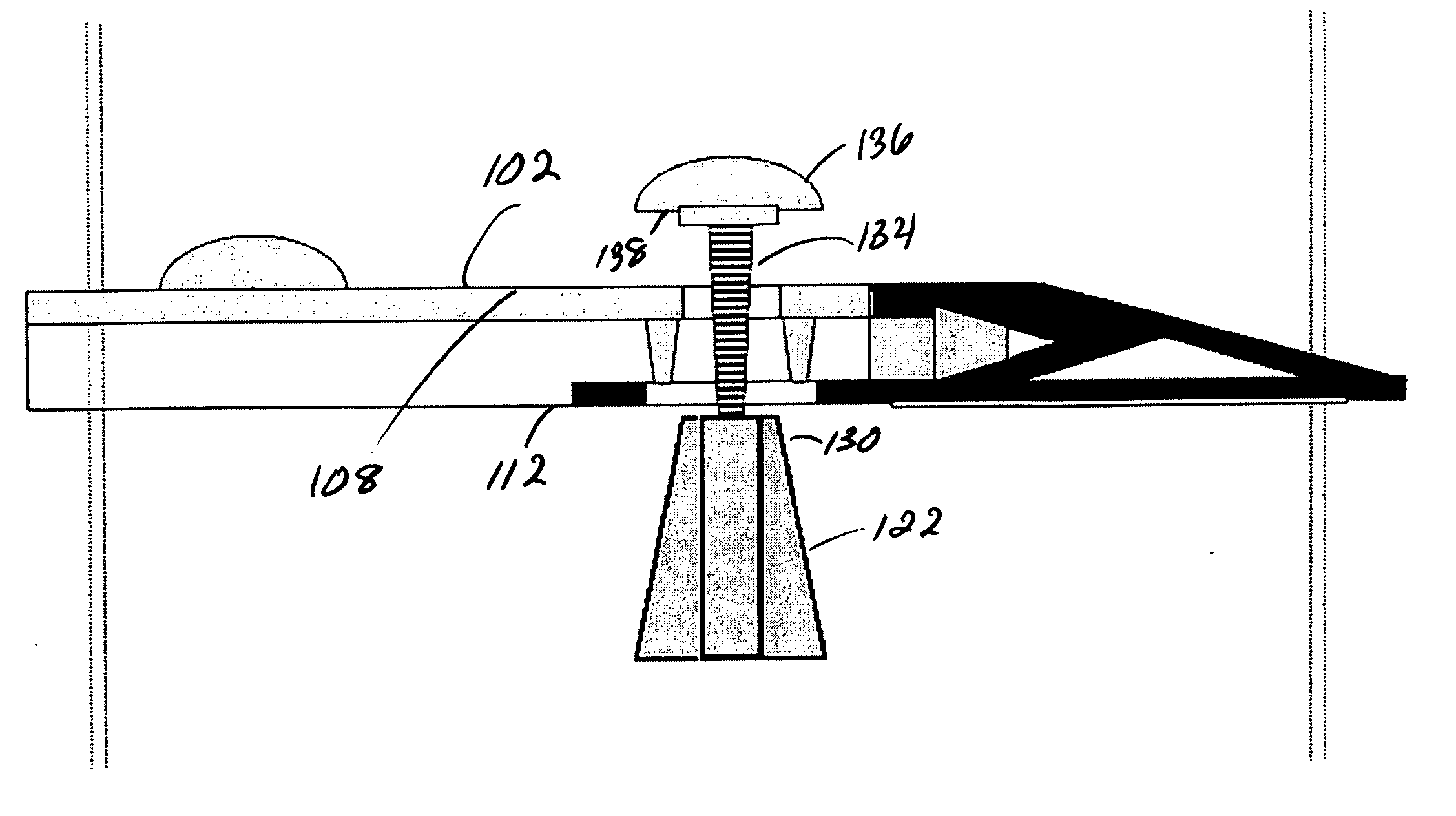

Radiant floor heating system with reflective layer and honeycomb panel

InactiveUS6188839B1Prevent heat lossPrevents dispersal (and hence waste)Fluid heatersLayered productsThermal breakHoneycomb

A radiant floor heating system and method of installation is provided, the system of the present invention being disposed within a solidified cement or under board. A panel member having a laminated reflective material which serves as a thermal break is placed upon the hardened cement or under board. The panel member may be comprised of any substance to which the reflective material may be secured such as a honeycombed plastic panel to which the reflective material layer is laminated. A heating element is disposed on the reflective material. Thereafter, both the heating element and the reflective layer are coated with a layer of thin set or cement. The heating element may include a heated wire element which is unwound off a roll, or the heating element may be meshed within a web of material which is cut to match the dimensions of the floor and then disposed on top of the reflective layer. After the thin set or cement dries with the heating element embedded within, marble or other types of tiles may be laid as flooring.

Owner:PENNELLA RONALD J

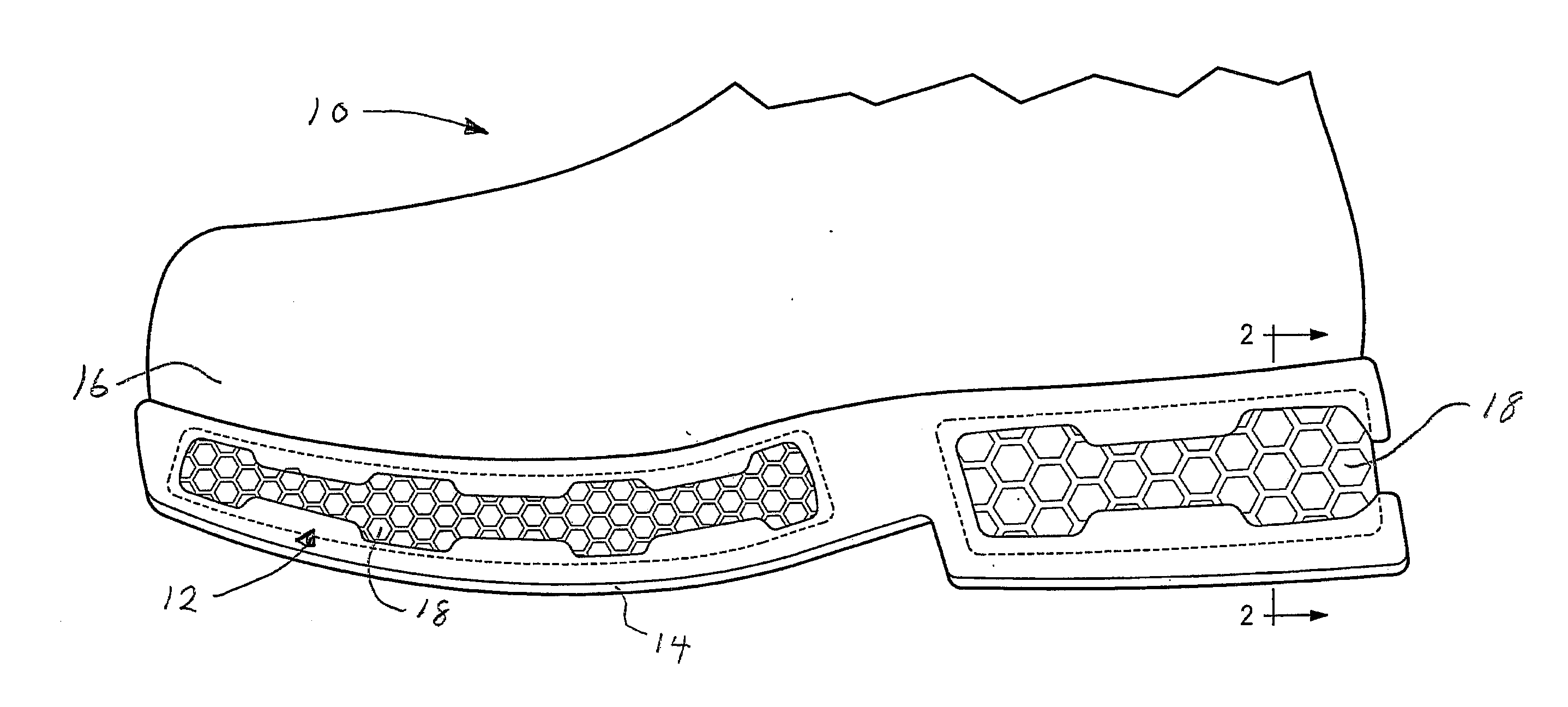

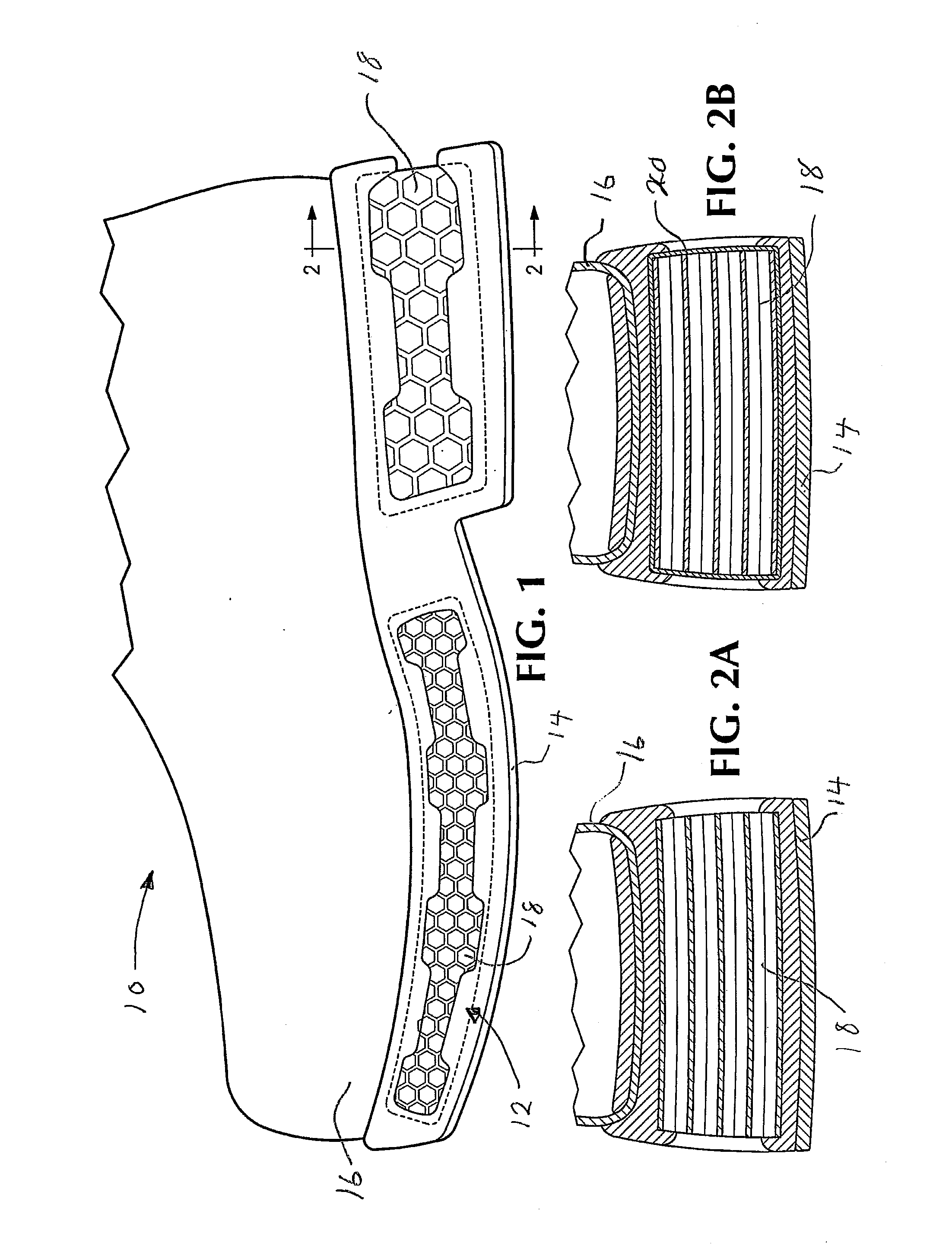

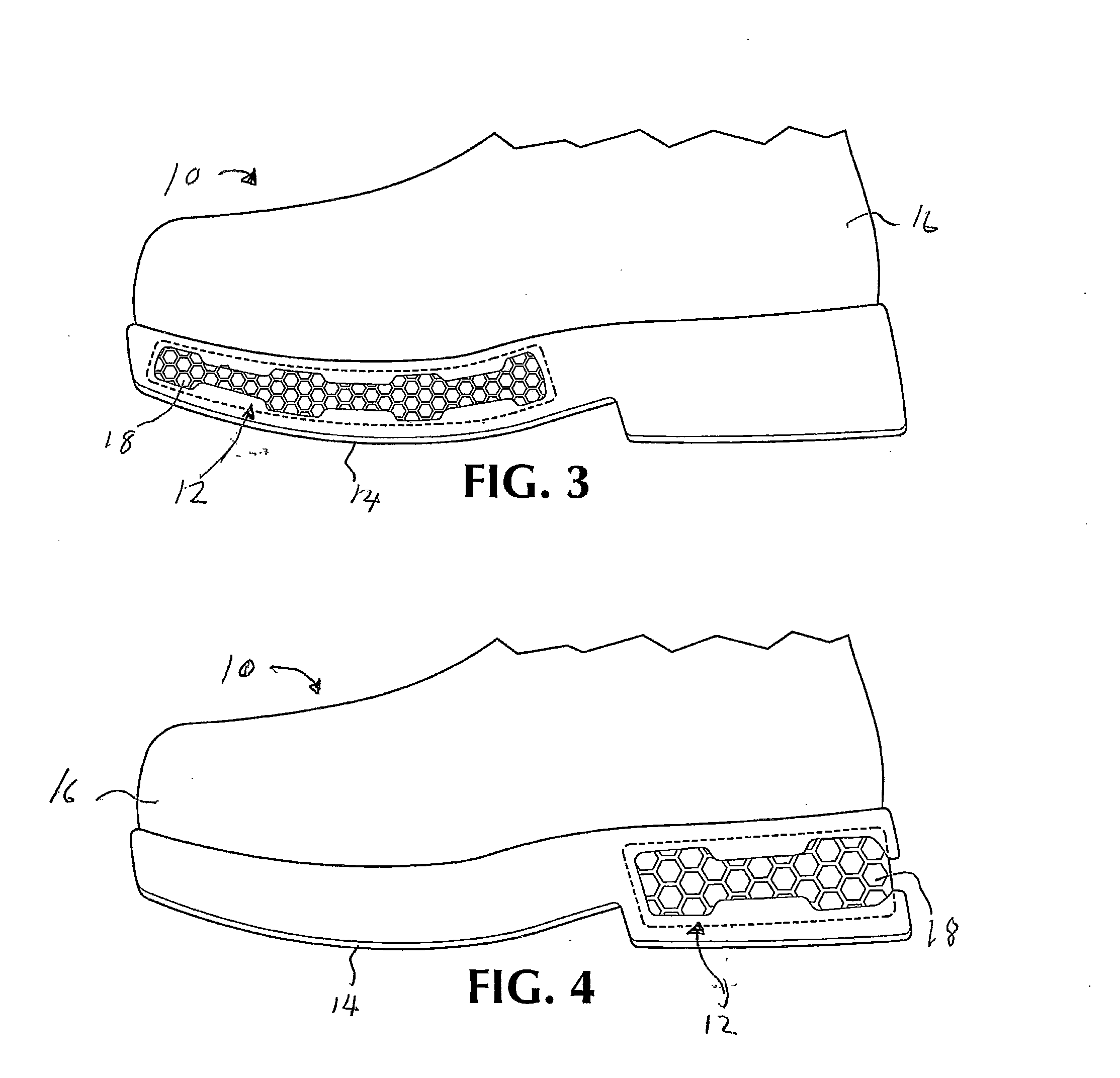

Footwear cushioning system

An footwear cushioning system comprising a matrix of elongate, hollow, elastomer tubes joined together in a honeycomb matrix which extends laterally at least partially across selected portions of the sole of the footwear. The tubes may or may not be enclosed in an air bag.

Owner:CHINOOK ASIA

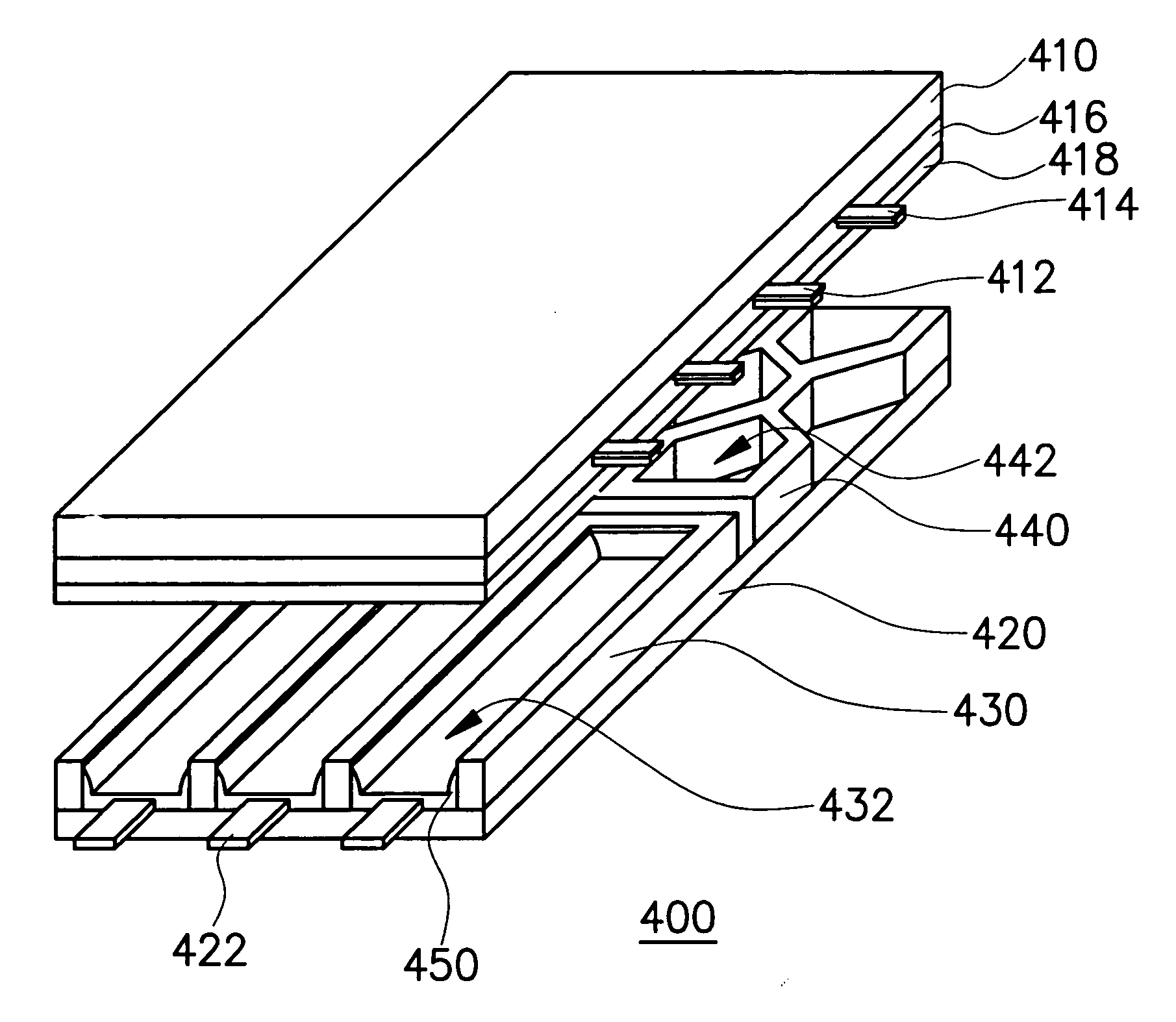

Plasma display panel and manufacturing method of barrier ribs thereof

InactiveUS20070046200A1Improve structural strengthAvoid crackingAlternating current plasma display panelsCold-cathode tubesHoneycombHoneycomb Pattern

A plasma display panel and a manufacturing method of barrier ribs thereof are provided. The plasma display panel is divided into a display area and a non-display area located in the periphery of the display area. When discharge space is formed in the display area by barrier ribs, a plurality of honeycomb supporting structures are formed in the non-display area at the same time. The honeycomb supporting structures can increase the yield factor of assembling the substrates, and then the display quality of the plasma display panels can be improved.

Owner:CHUNGHWA PICTURE TUBES LTD

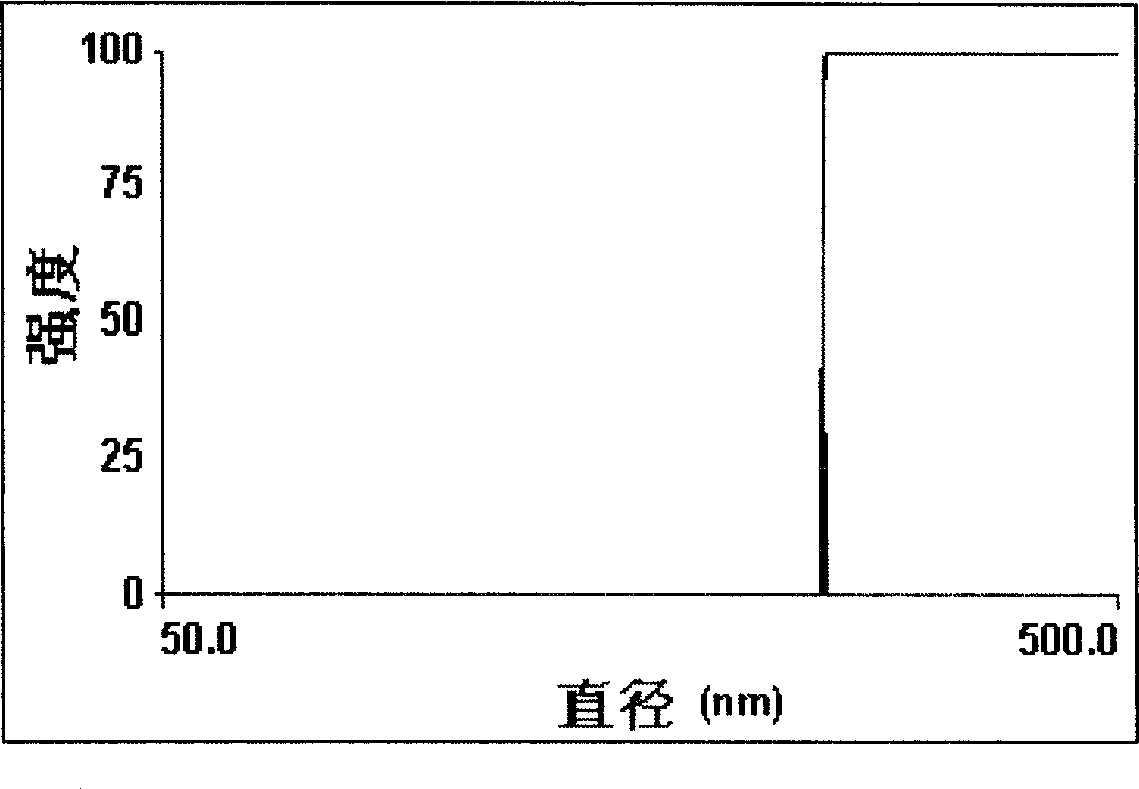

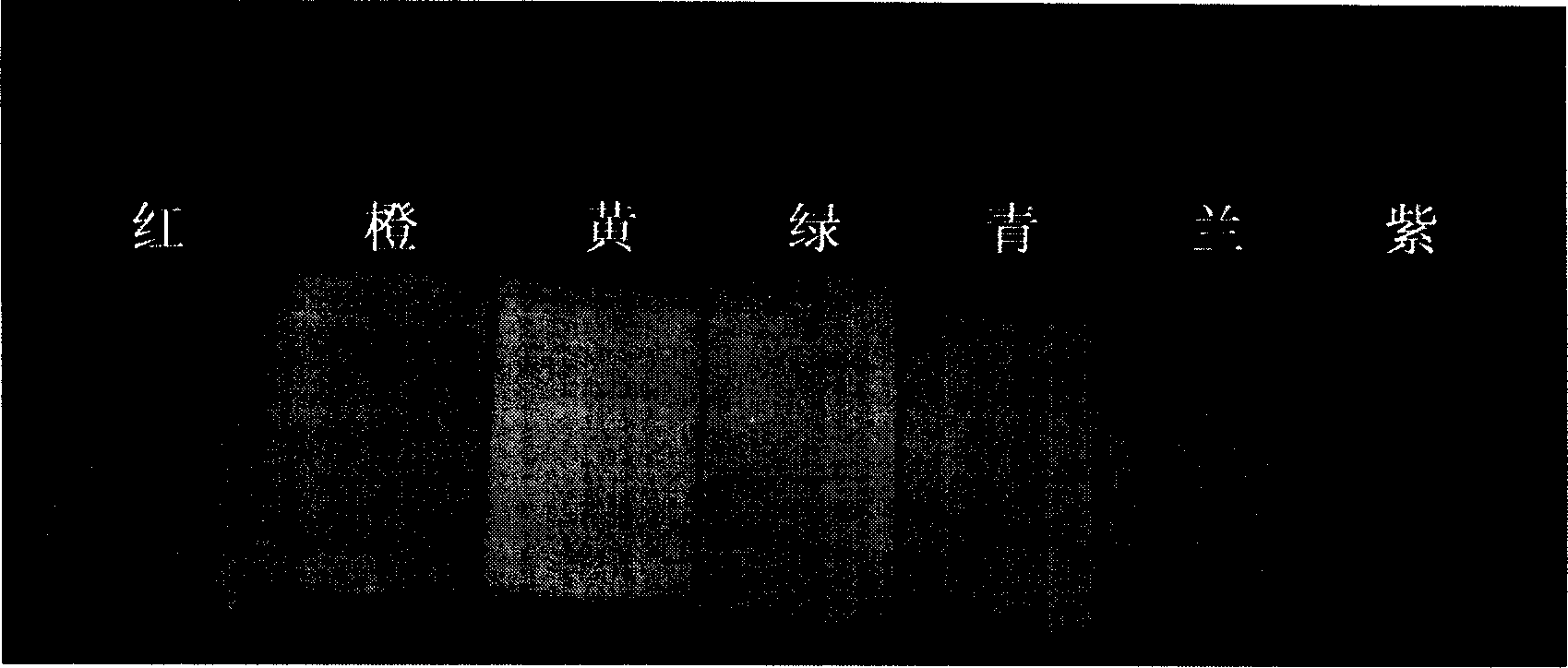

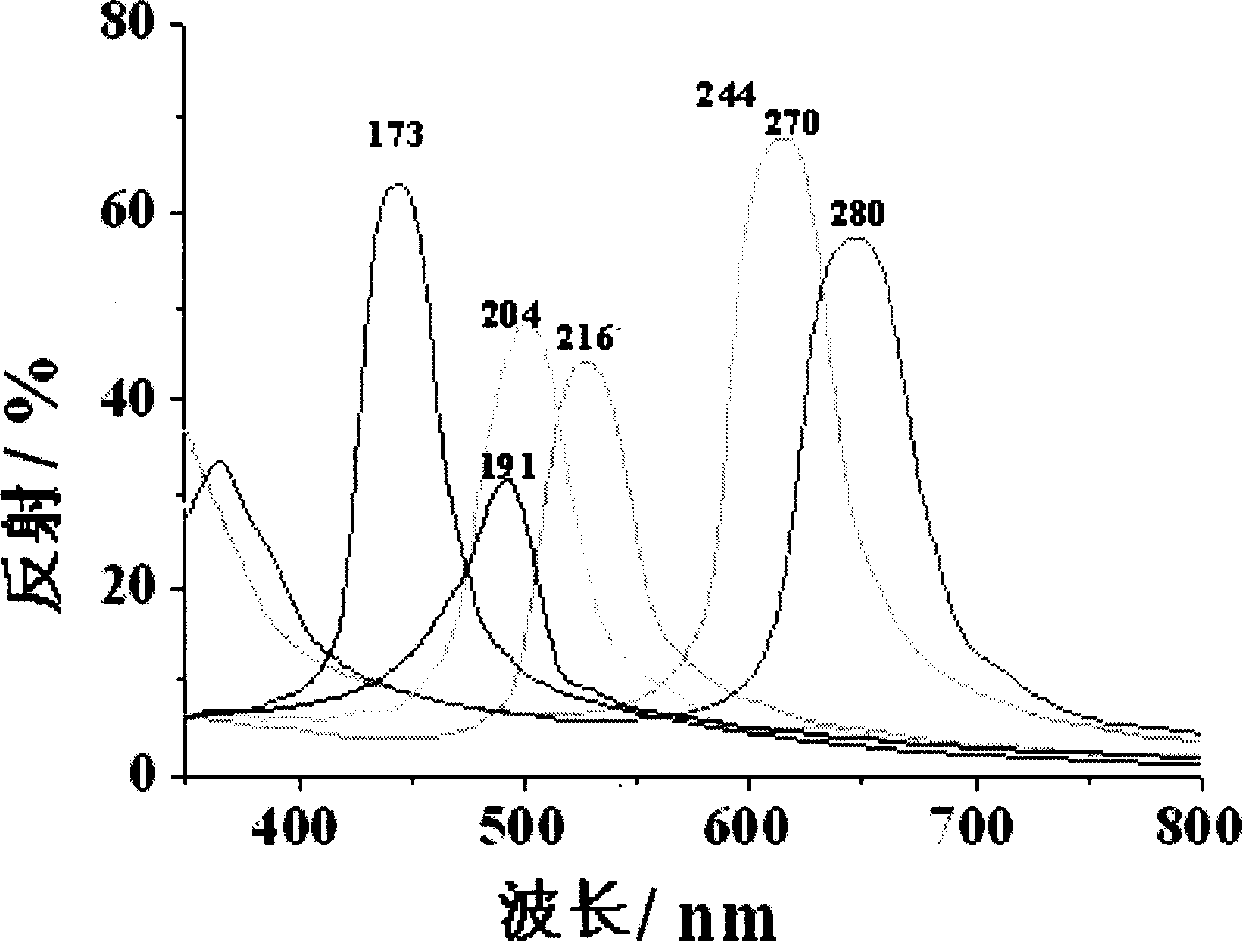

Full-color colloid photonic crystal film and its preparation method and use

ActiveCN1808214AThe monodispersity index is smallThe size is easy to controlNon-linear opticsPolymer chemistryPolymer

The invention relates to a large size full color colloid photon crystal membrane and the method for making the same. The method comprises: covering monodisperse polymer emulsion particle with hard shell-soft shell structures on the flat base material to form full color colloid photon crystal membrane after dispersion volatilizing, the model having cellular structure; the thickness of the single dispersion polyaromatics emulsion particle shell is 20-50nm, the range of the diameter of emulsion particle is 170í½300nm, and the multi dispersion index is less or equal to 0.005.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Panel-form loudspeaker

InactiveUS6247551B1Easy to operateImprove conversion efficiencyLoudspeaker transducer fixingThermometer applicationsHoneycomb PatternAluminum honeycomb

A panel-form loudspeaker has a resonant multi-mode radiator panel which is excited at frequencies above the fundamental frequency and the coincidence frequency of the panel to provide high radiation efficiency through multi-modal motions within the panel, in contrast to the pistonic motions required of conventional loudspeakers. The radiator panel is skinned composite with a honeycomb or similar core and must be such that it has a ratio of bending stiffness to the third power of panel mass per unit area (in mks units) of at least 10 and preferably at least 100. An aluminum skinned, aluminum honeycomb cored composite can meet this more severe criterion easily.

Owner:QINETIQ LTD

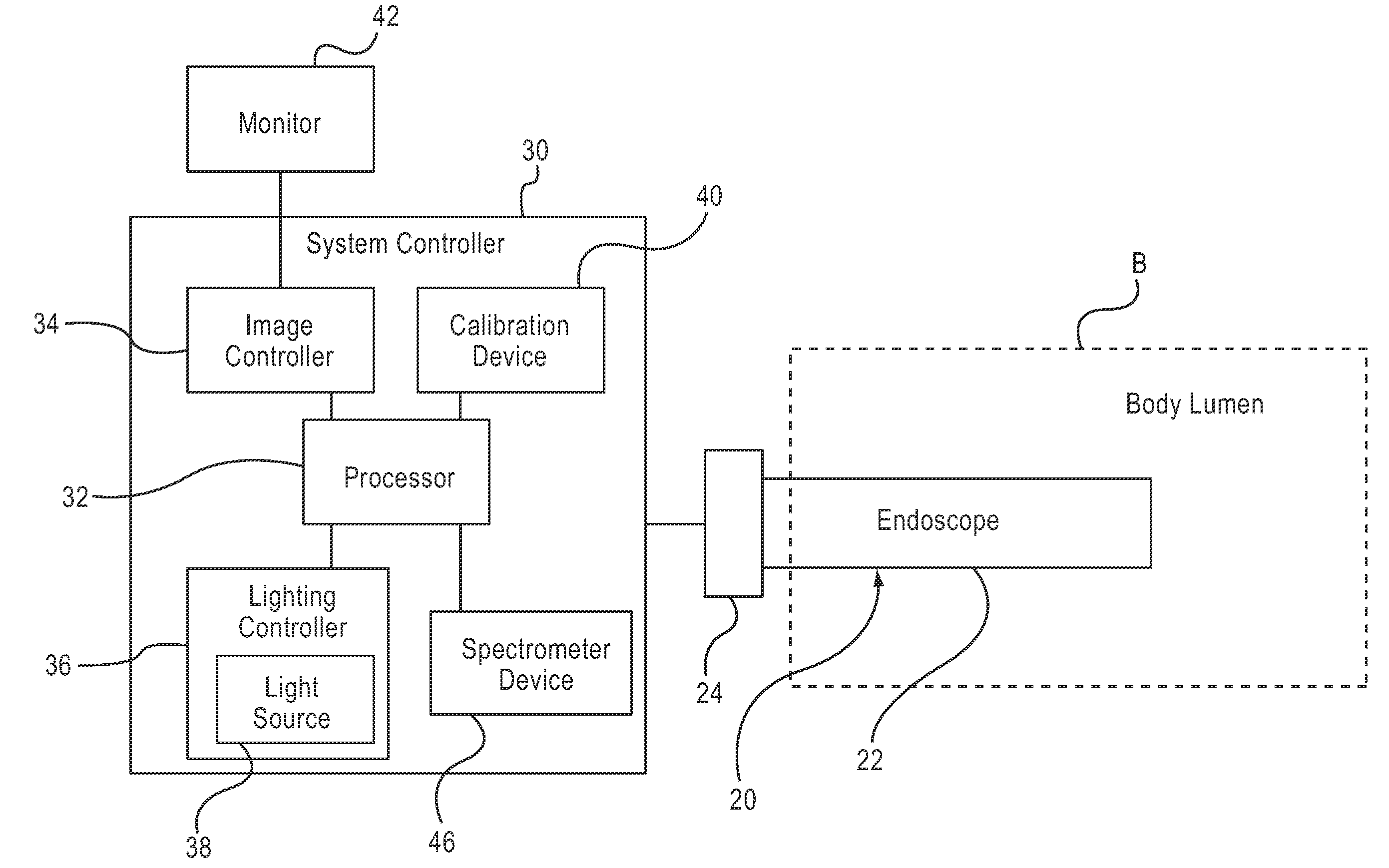

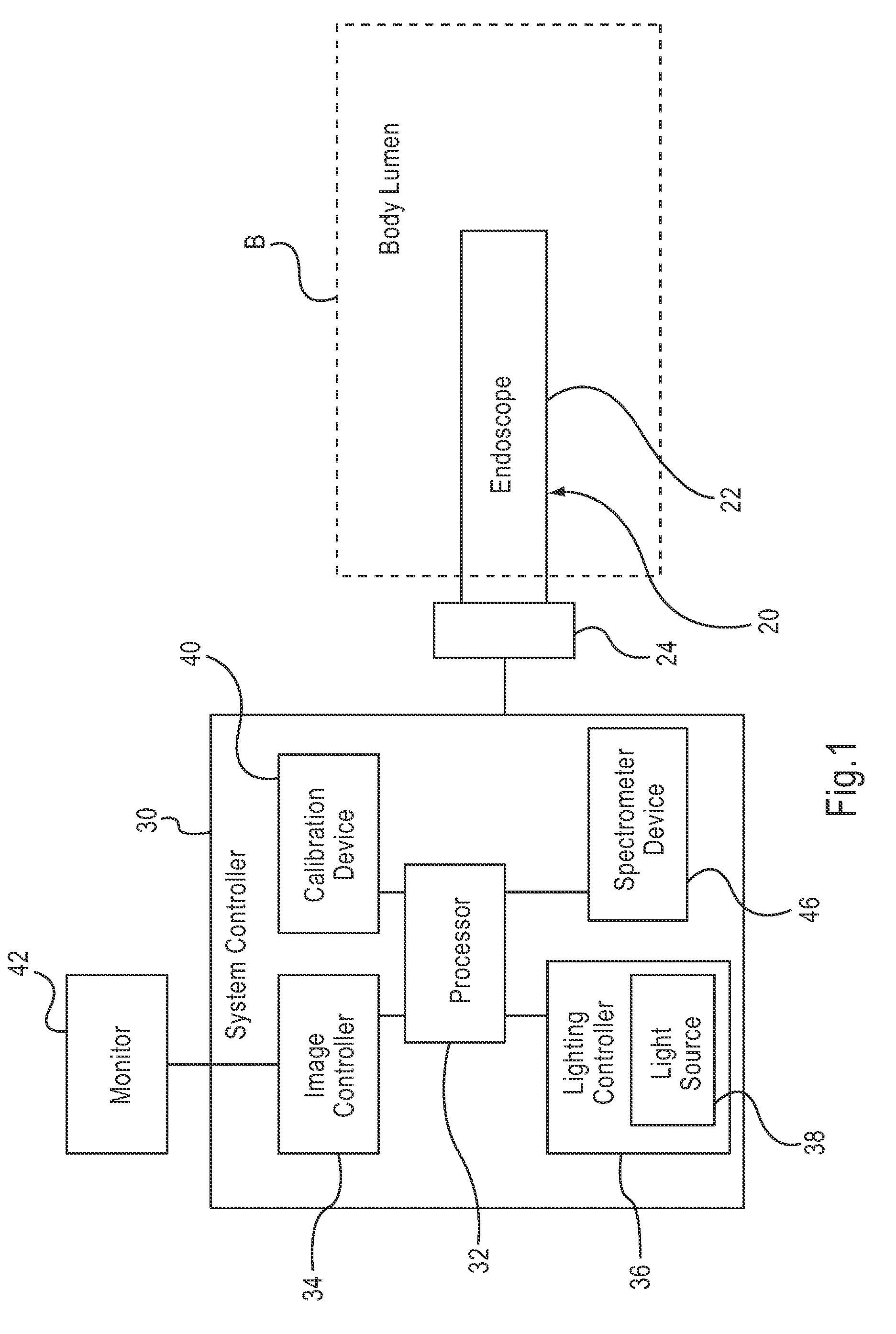

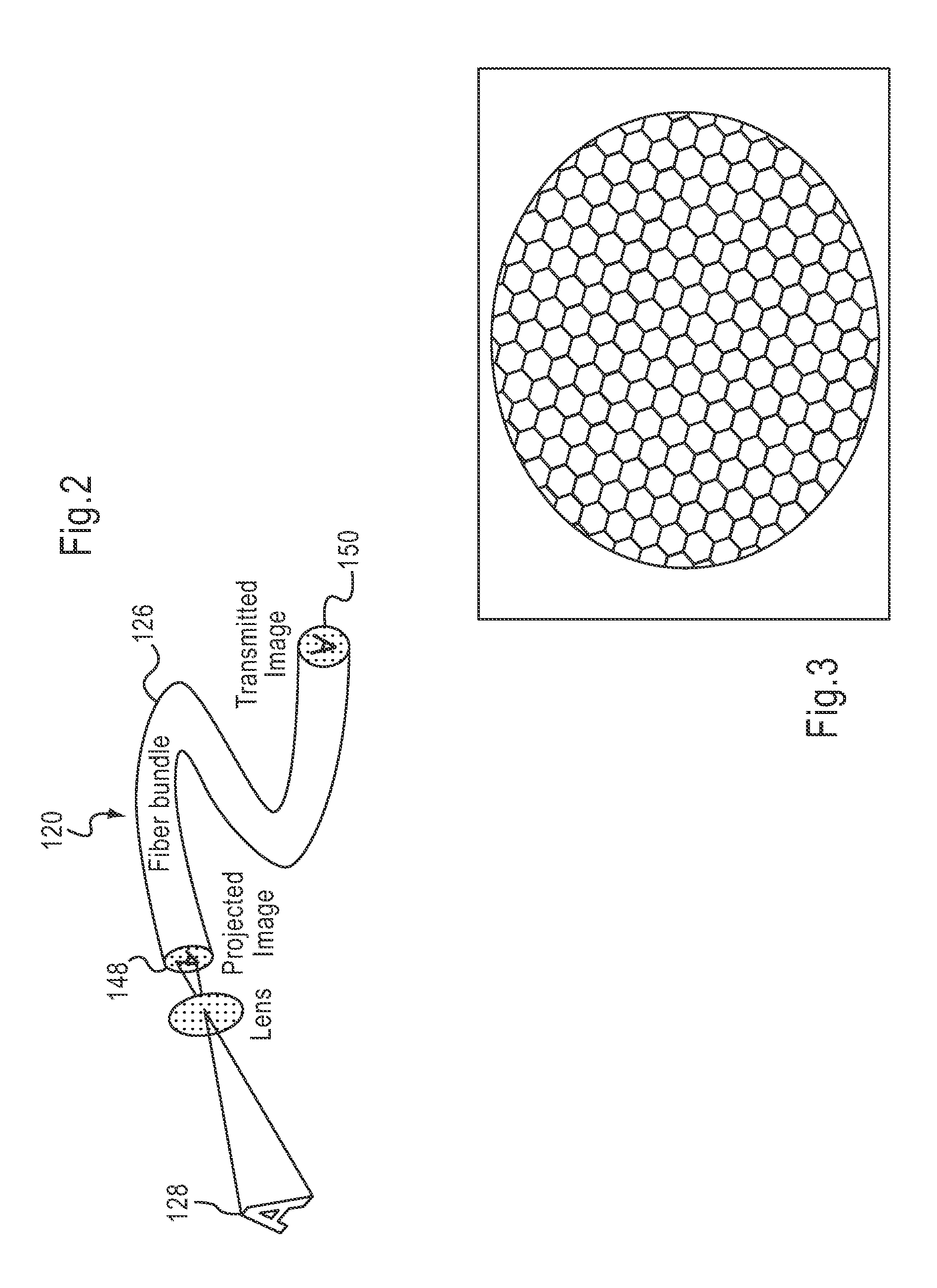

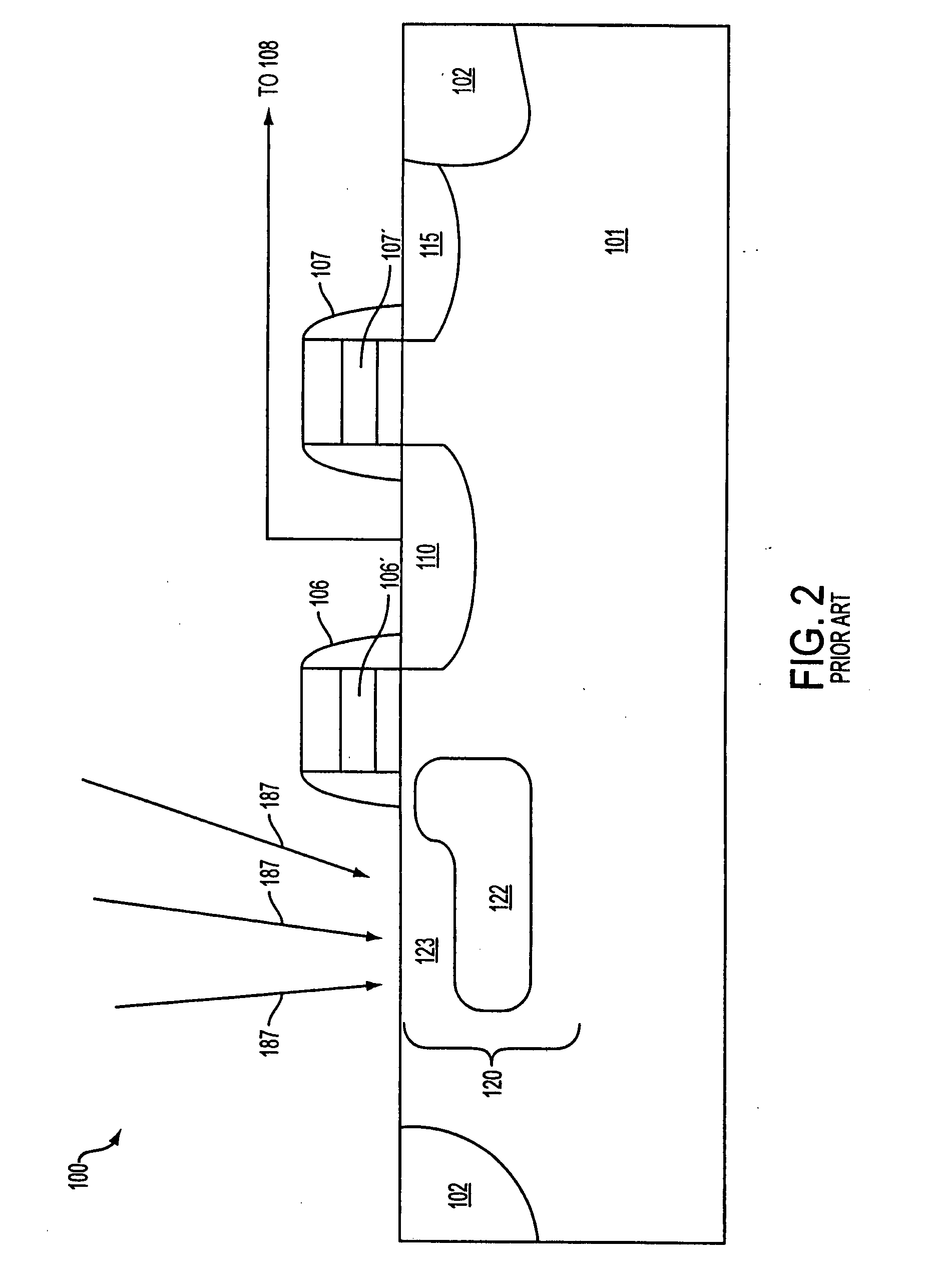

System and methods for the improvement of images generated by fiberoptic imaging bundles

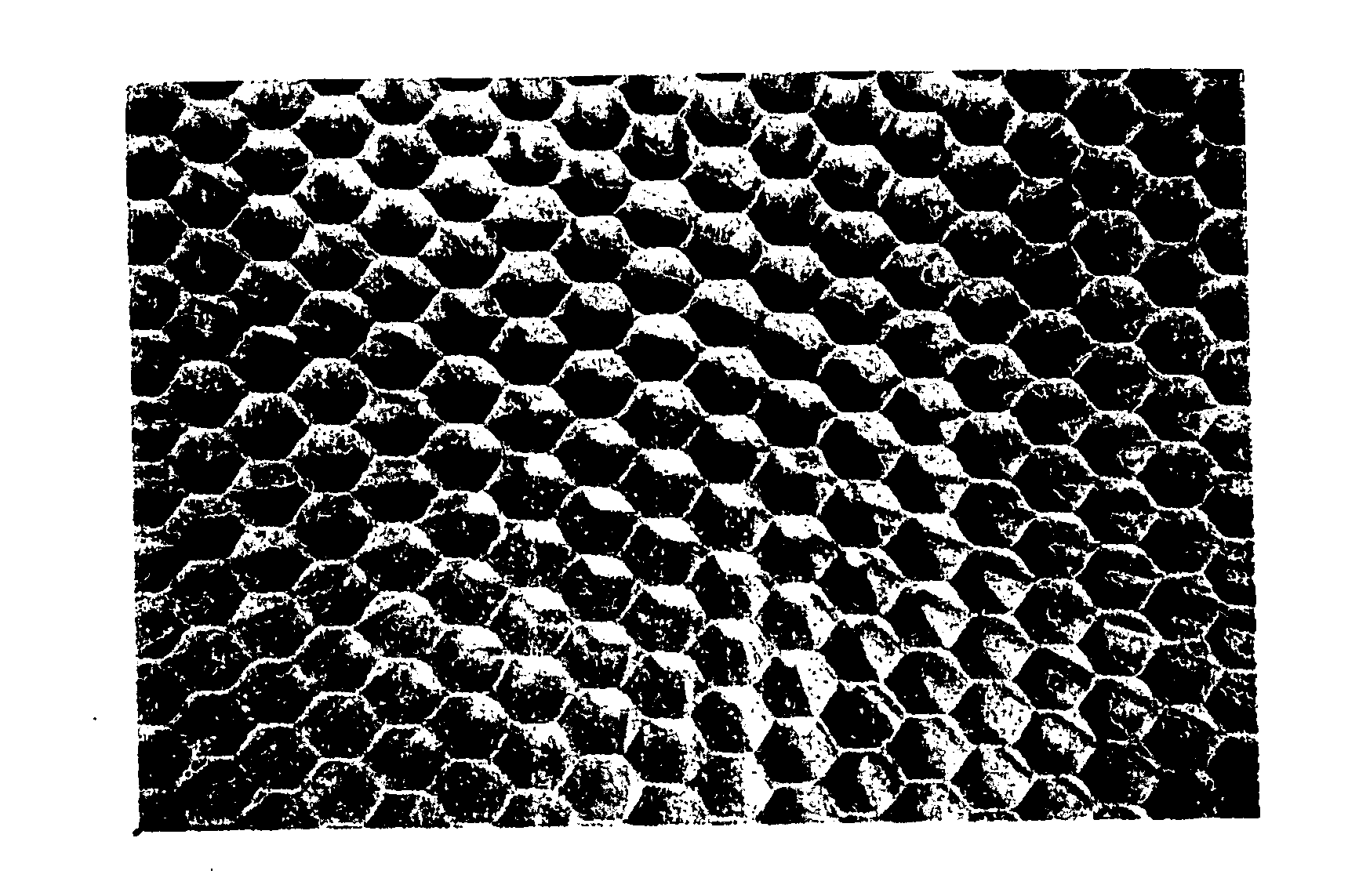

A method according to an embodiment of the invention includes receiving a first optical image from an endoscope having a plurality of imaging fibers. A spatial frequency is identified that is associated with the plurality of imaging fibers. A second optical image is received from the endoscope. The spatial frequency is filtered from the second optical image. A method according to another embodiment includes producing an optical image of at least a portion of a body lumen using a fiberscope. The optical image is transmitted to a video camera coupled to the fiberscope. A honeycomb pattern associated with a fiber bundle of the fiberscope is removed from the optical image. In some embodiments, the honeycomb pattern can be removed in substantially real time. In some embodiments, prior to producing the optical image, a calibration cap is coupled to the fiberscope and used in a calibration process.

Owner:BOSTON SCI SCIMED INC

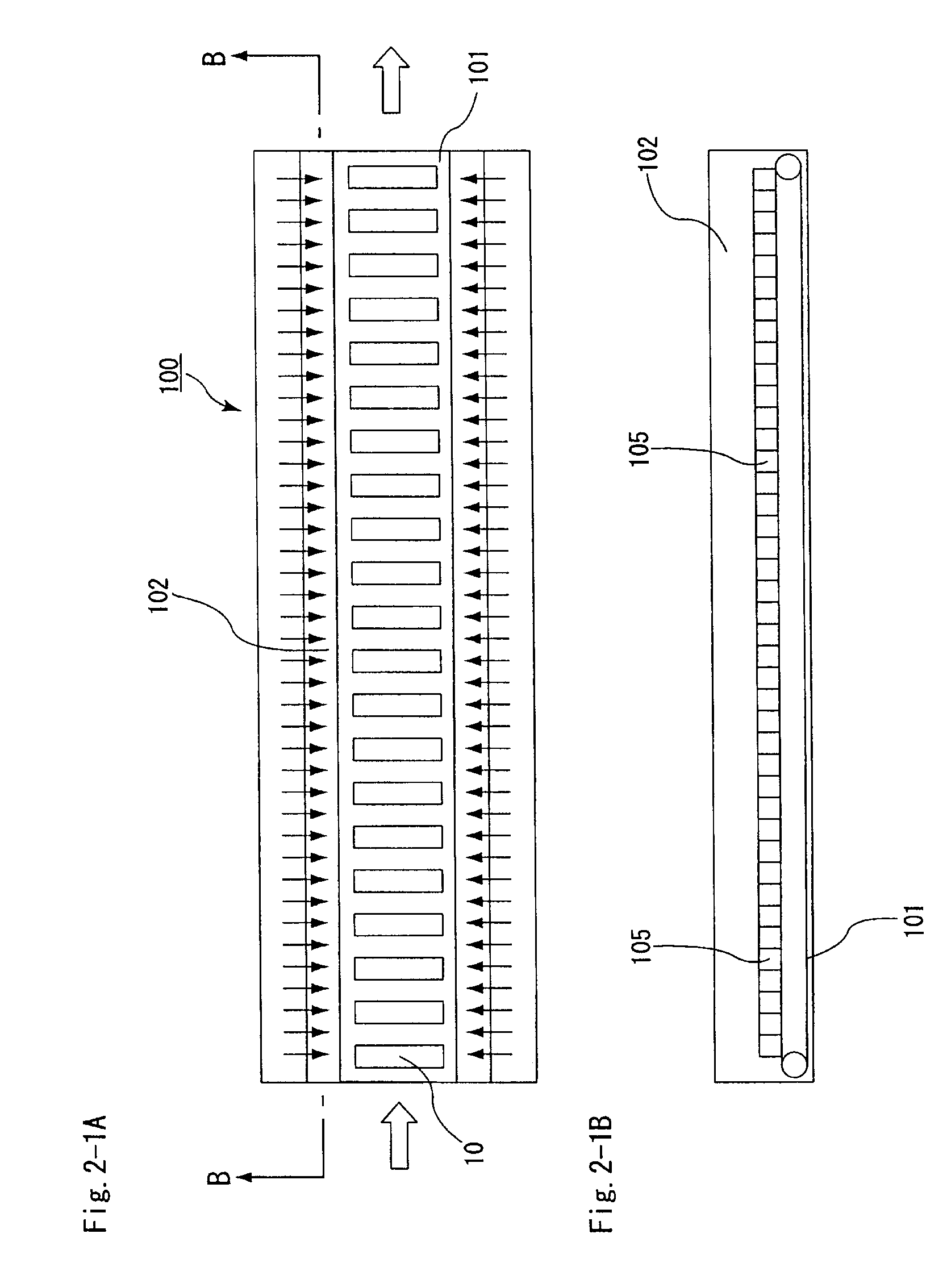

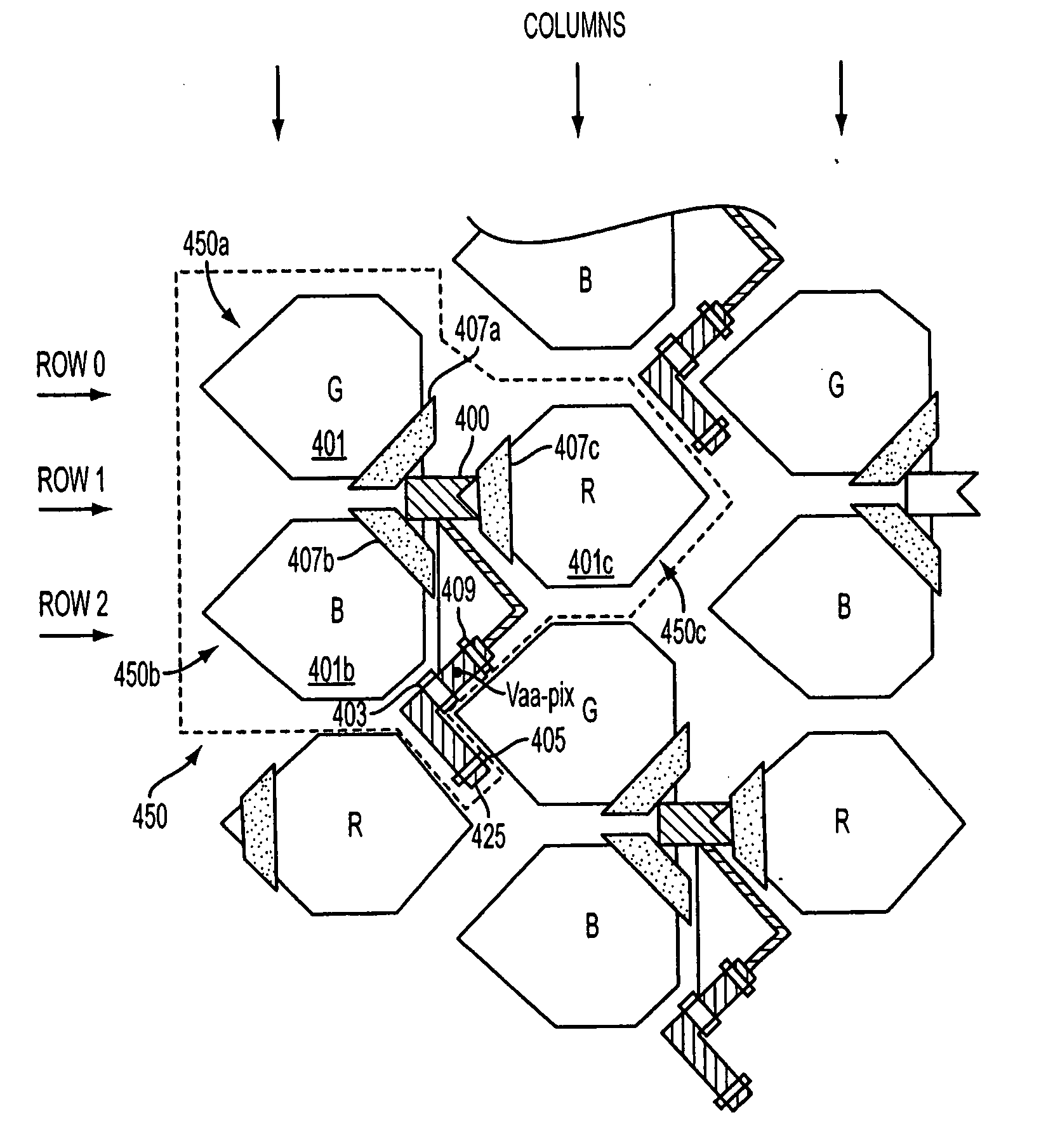

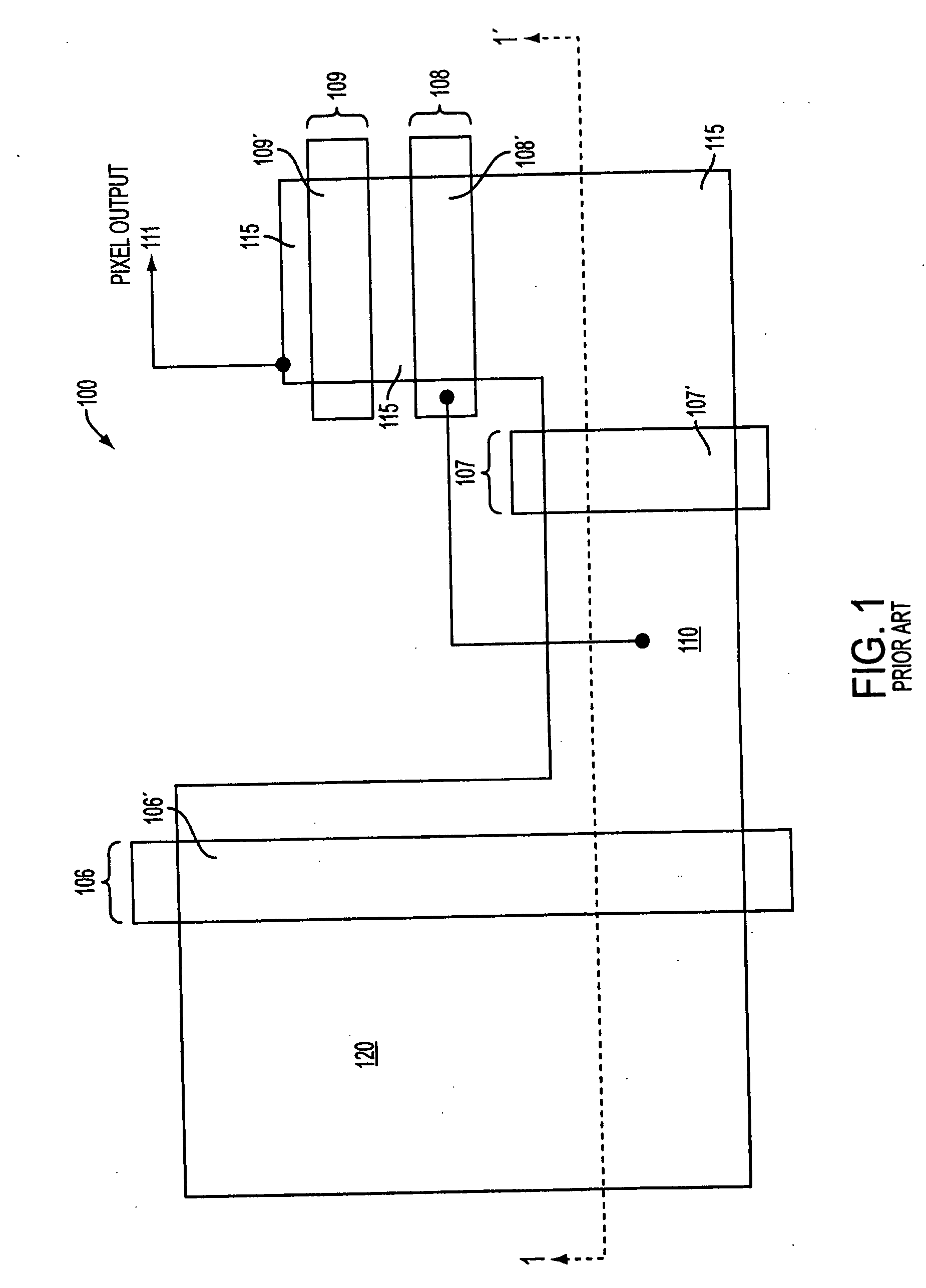

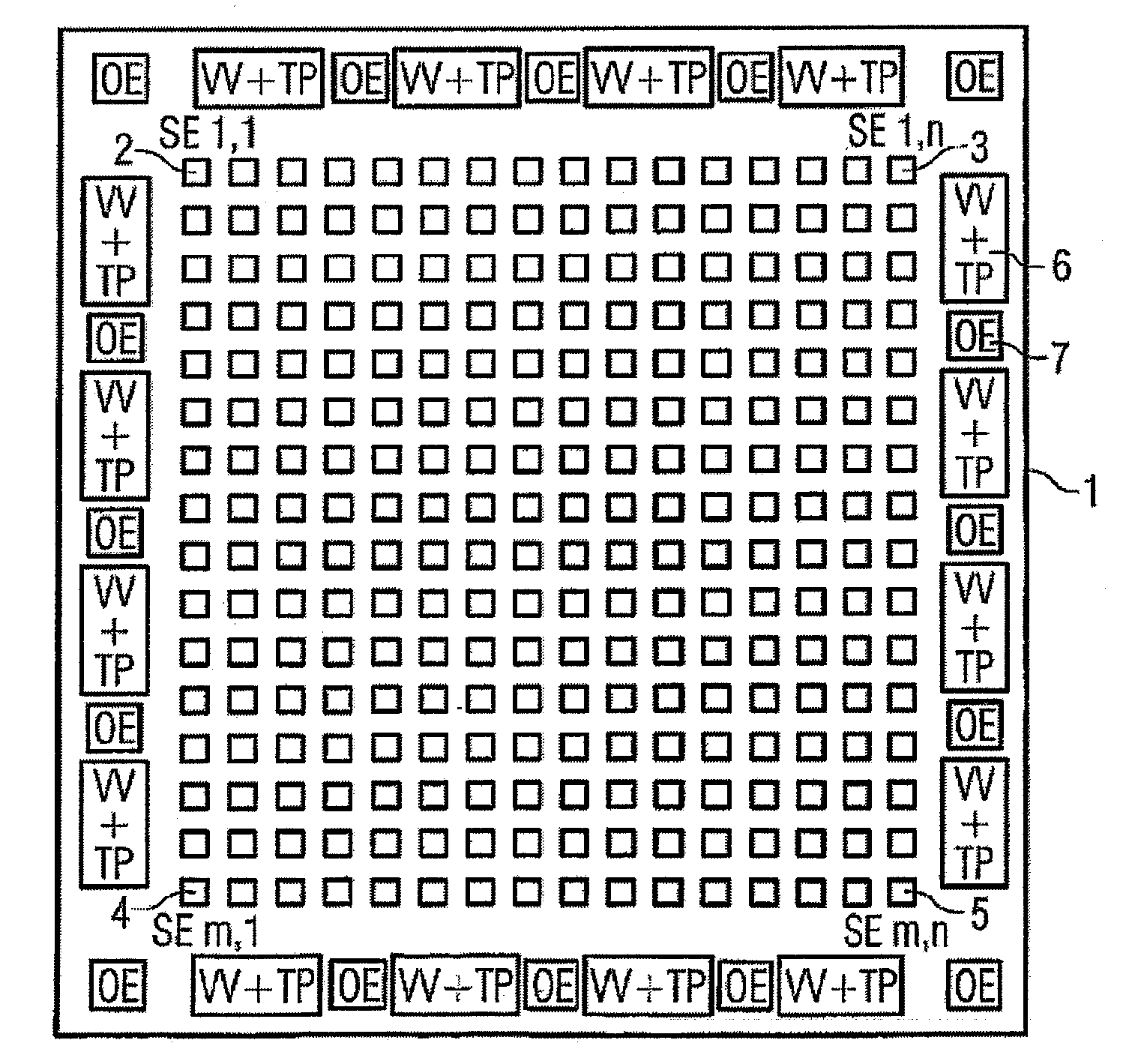

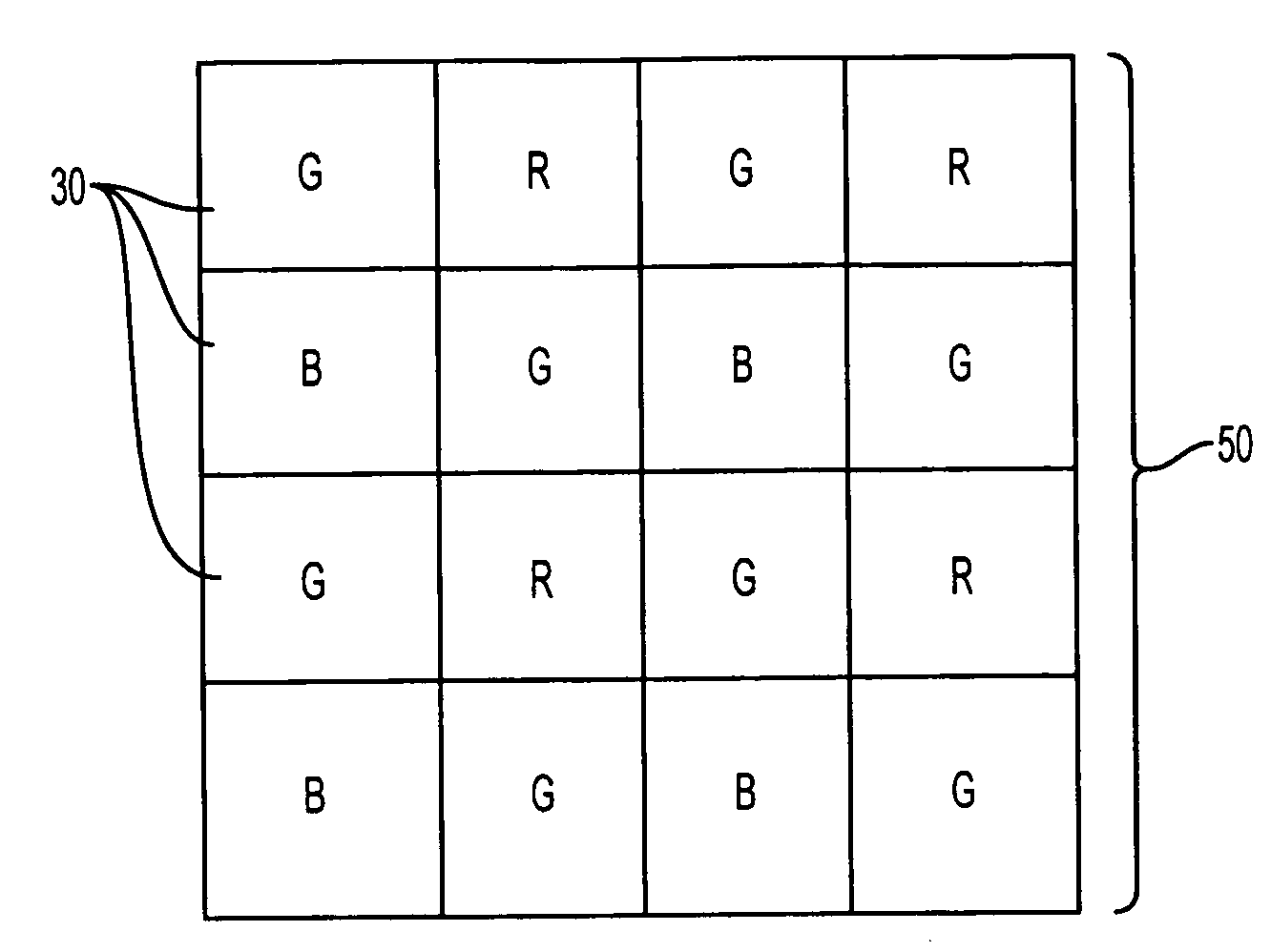

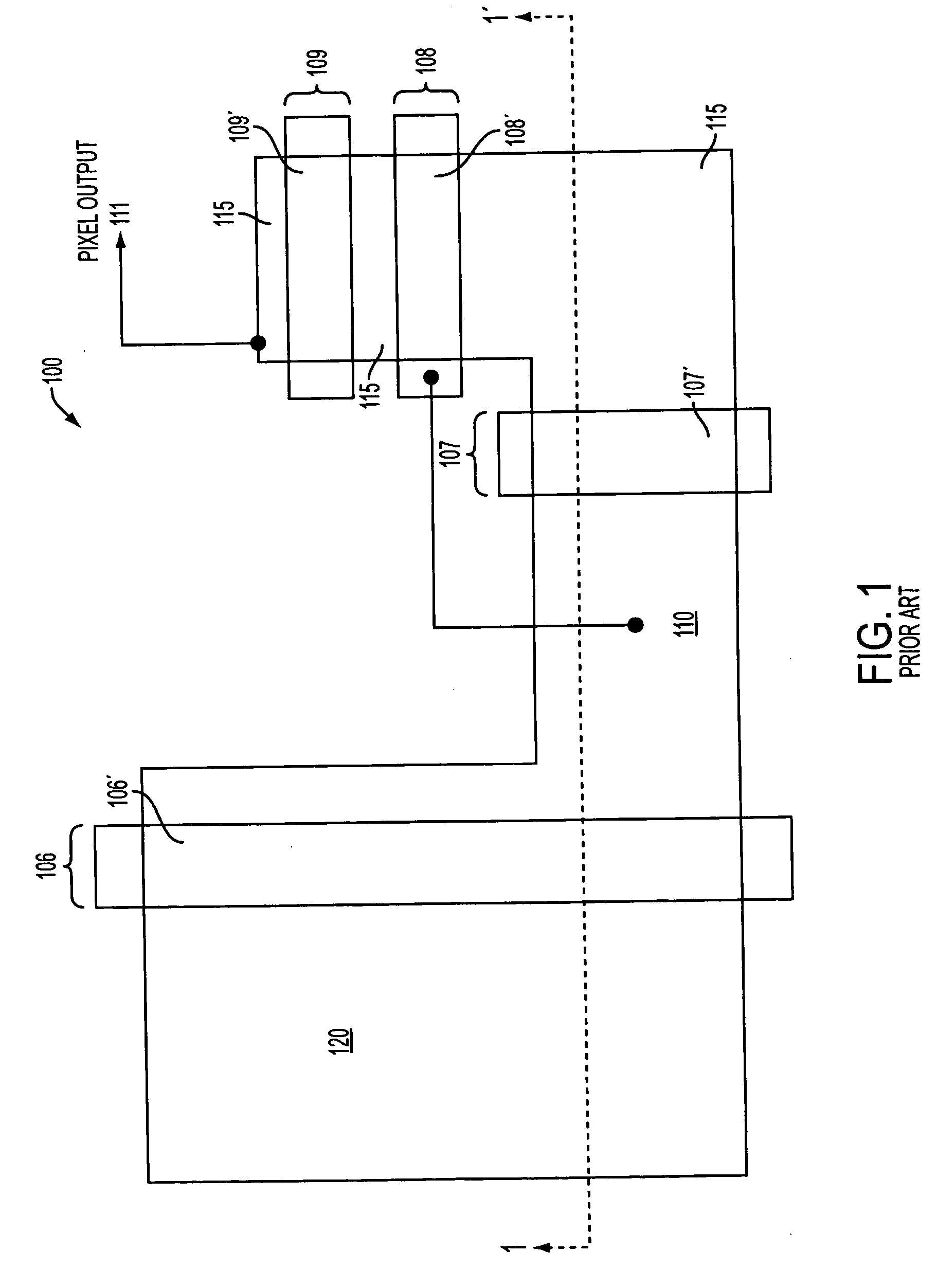

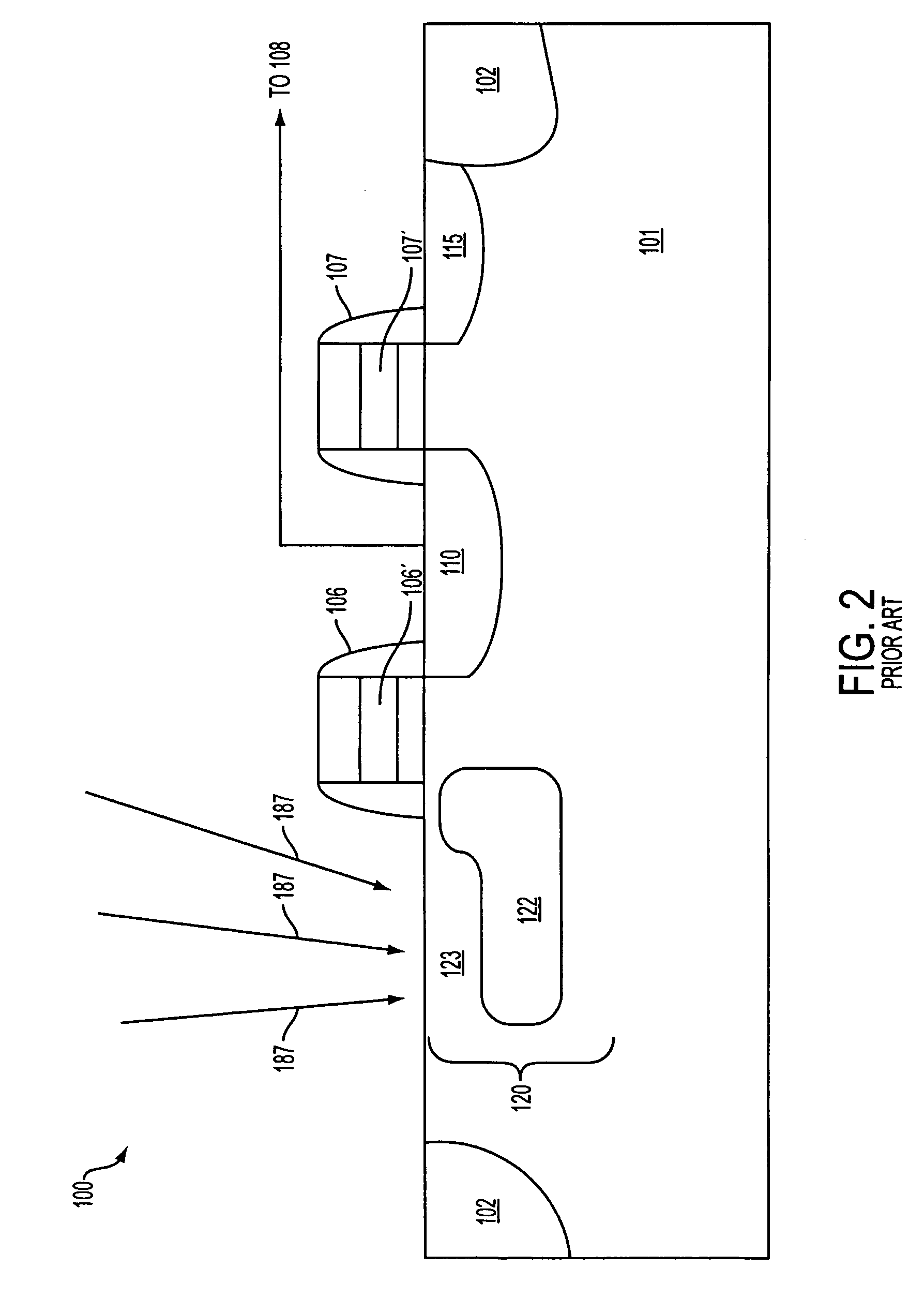

Pixel cells in a honeycomb arrangement

ActiveUS20070164335A1Promote conversionTelevision system detailsTelevision system scanning detailsHoneycomb PatternColor filter array

The present invention, in the various exemplary embodiments, provides a RGB color filter array. The red, green and blue pixel cells are arranged in a honeycomb pattern. The honeycomb layout provides the space to vary the size of pixel cells of an individual color so that, for example, the photosensor of blue pixels can be made larger than that of the red or green pixels. In another aspect of the invention, depicted in the exemplary embodiments, the honeycomb structure can also be implemented with each pixel rowing having a same color of pixel cells which can simplify can conversion in the readout circuits. In another aspect of the invention, the RGB honeycomb pixel array may be implemented using a shared pixel cell architecture.

Owner:APTINA IMAGING CORP

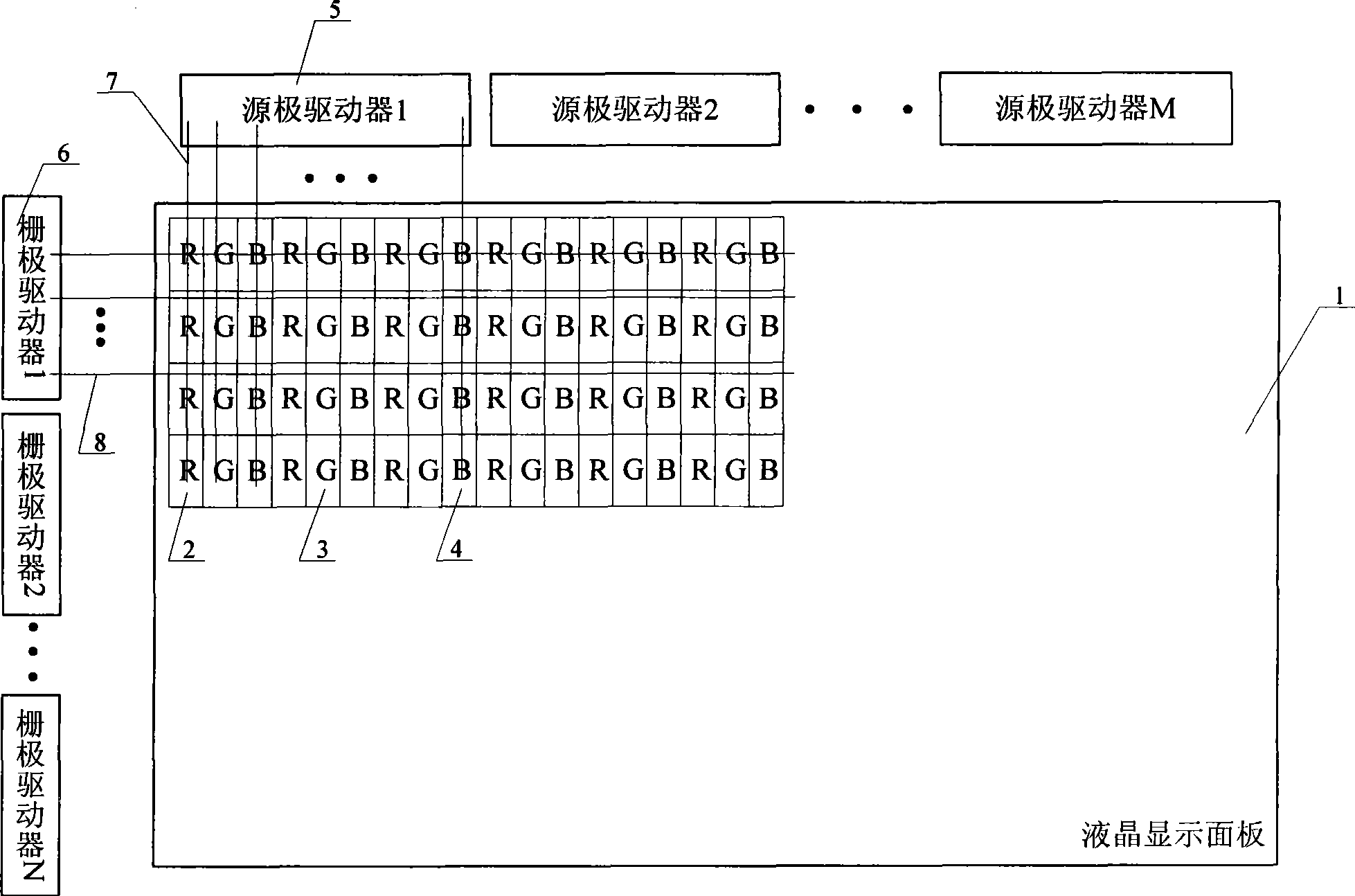

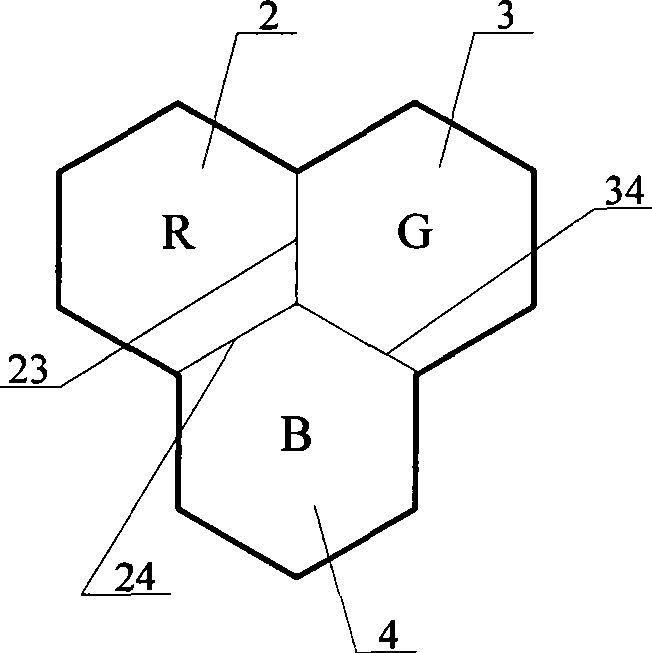

Pixel, pixel module and liquid-crystal display panel

InactiveCN101393366AReduce the total number of source/gate channelsReduced drive capability requirementsStatic indicating devicesNon-linear opticsLiquid-crystal displayHoneycomb

The present invention provides a pixel, a pixel module and a liquid crystal display panel. The liquid crystal display panel consists of the pixel modules which are in honeycomb-shaped arrangement. The pixel module consists of a red sub-pixel, a green sub-pixel and a blue sub-pixel which are of regular hexagon shapes respectively. All sub-pixels in the pixels are in honeycomb-shaped arrangement. Each sub-pixel is different in color from six adjacent sub-pixels. A unique pixel structure and a unique pixel module structure are provided and the liquid crystal display panel is provided based on the special structures. The number of the source electrode drive channels required by the pixels on the panel is reduced, and the increased number of the required grid electrode drive channels is reduced as possible so that the number of the required source / grid electrode drive channels is minimized and the cost of the liquid crystal display panel is reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

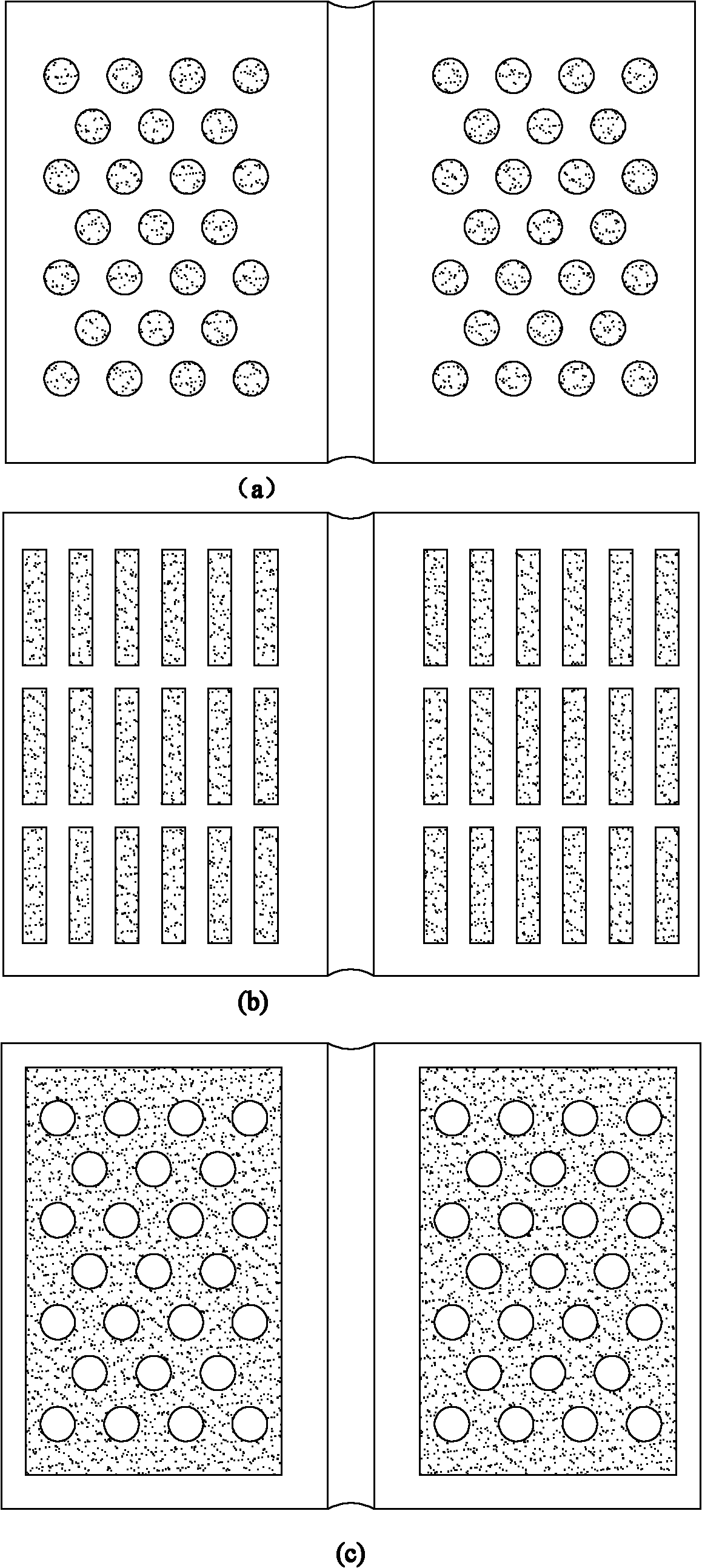

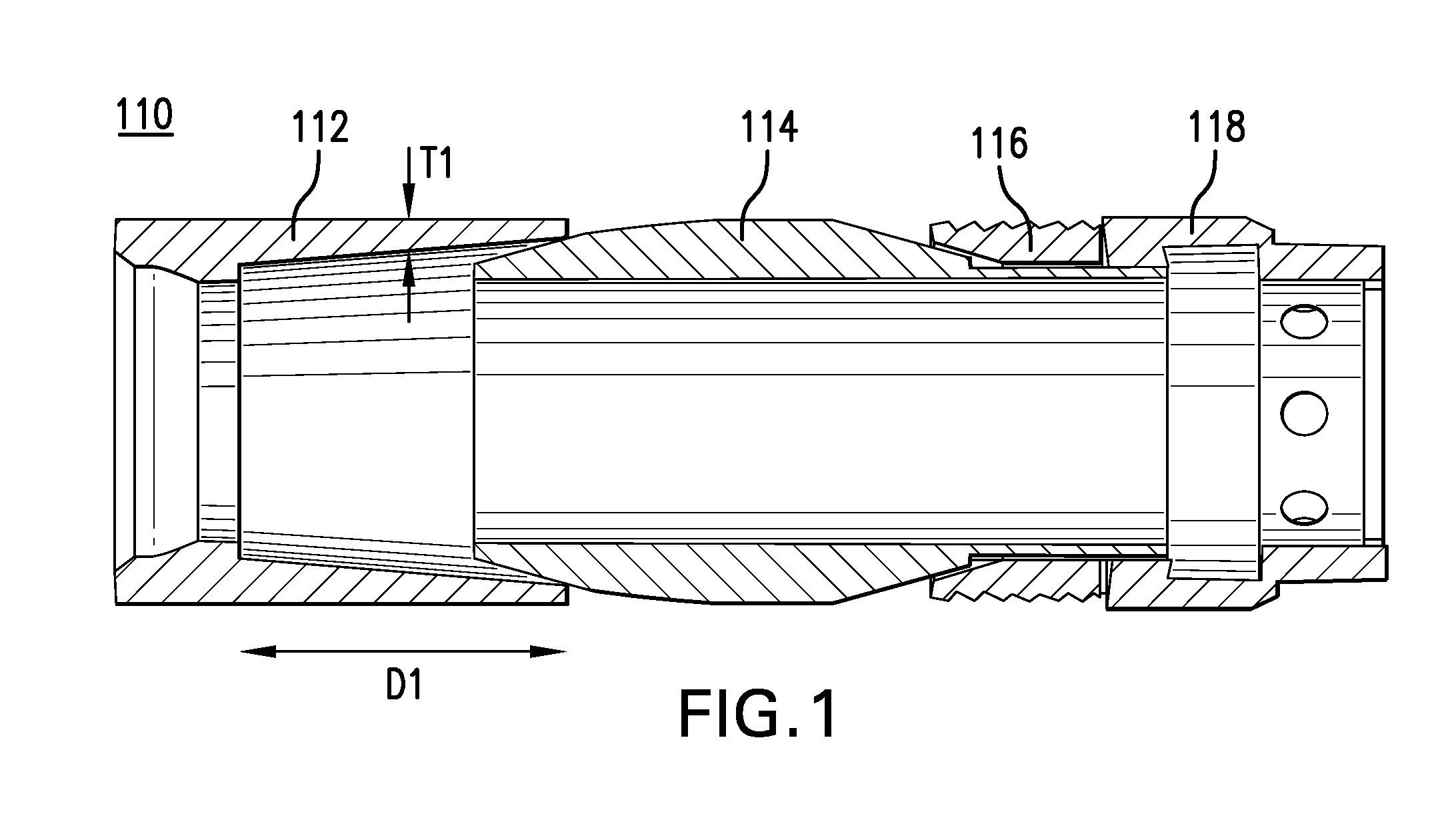

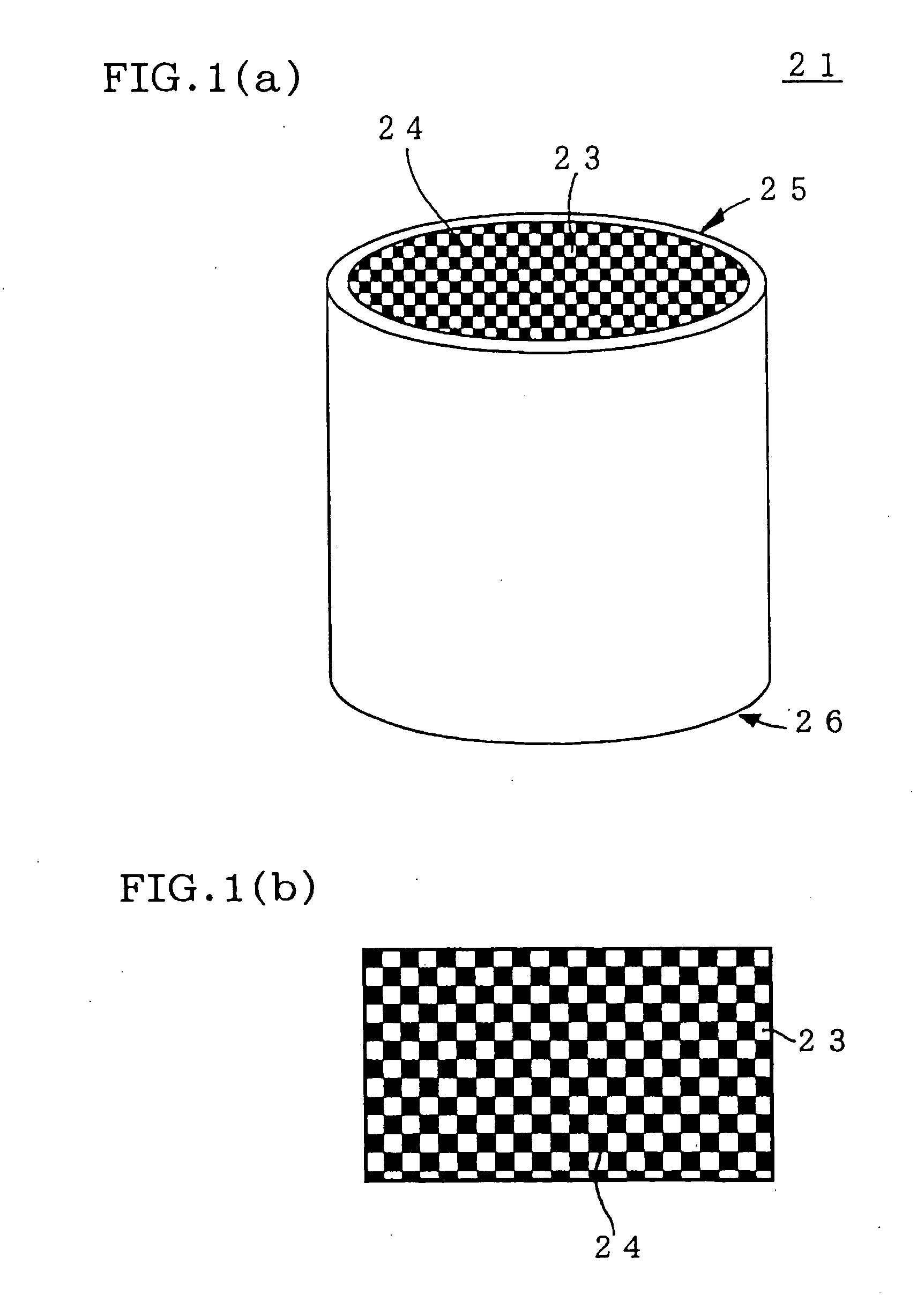

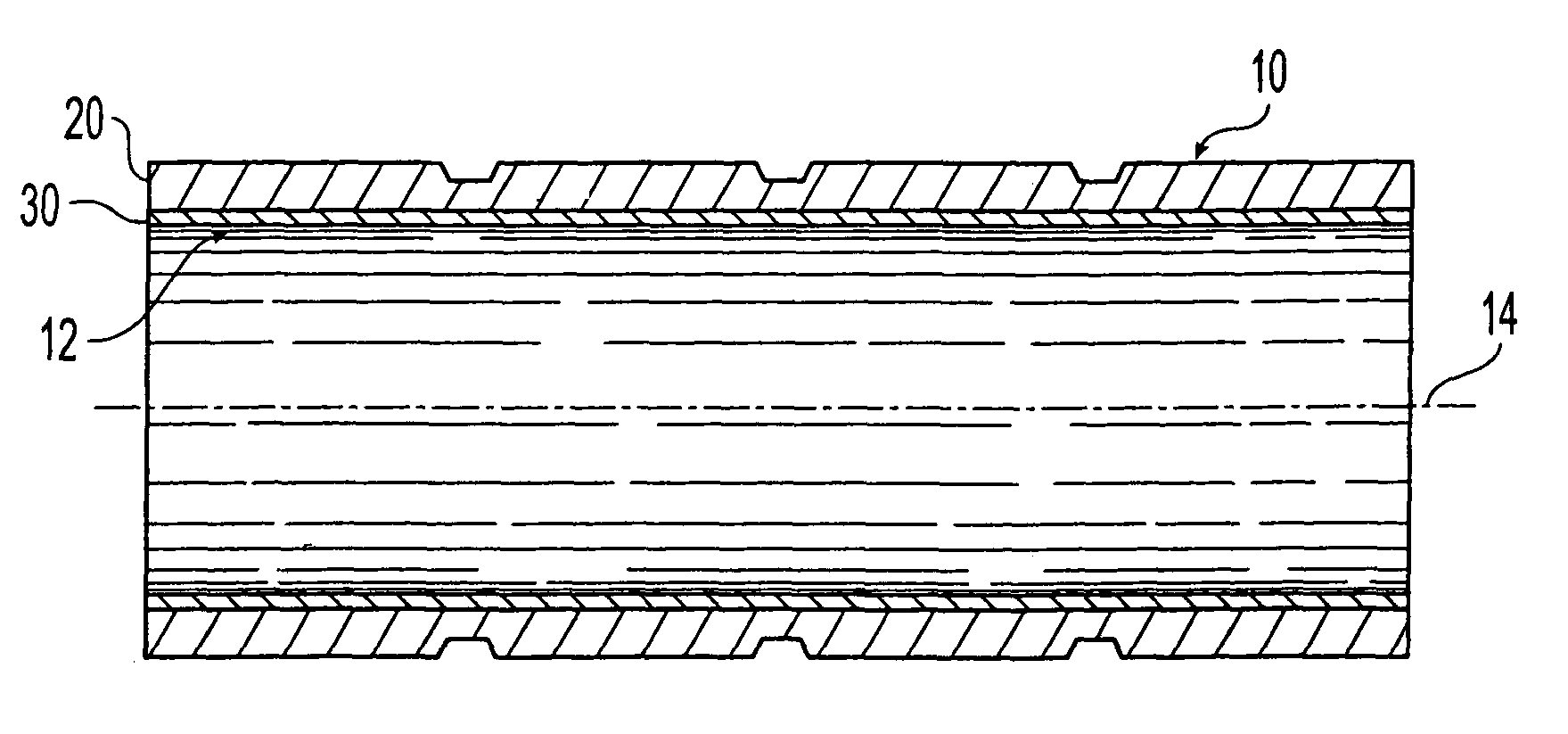

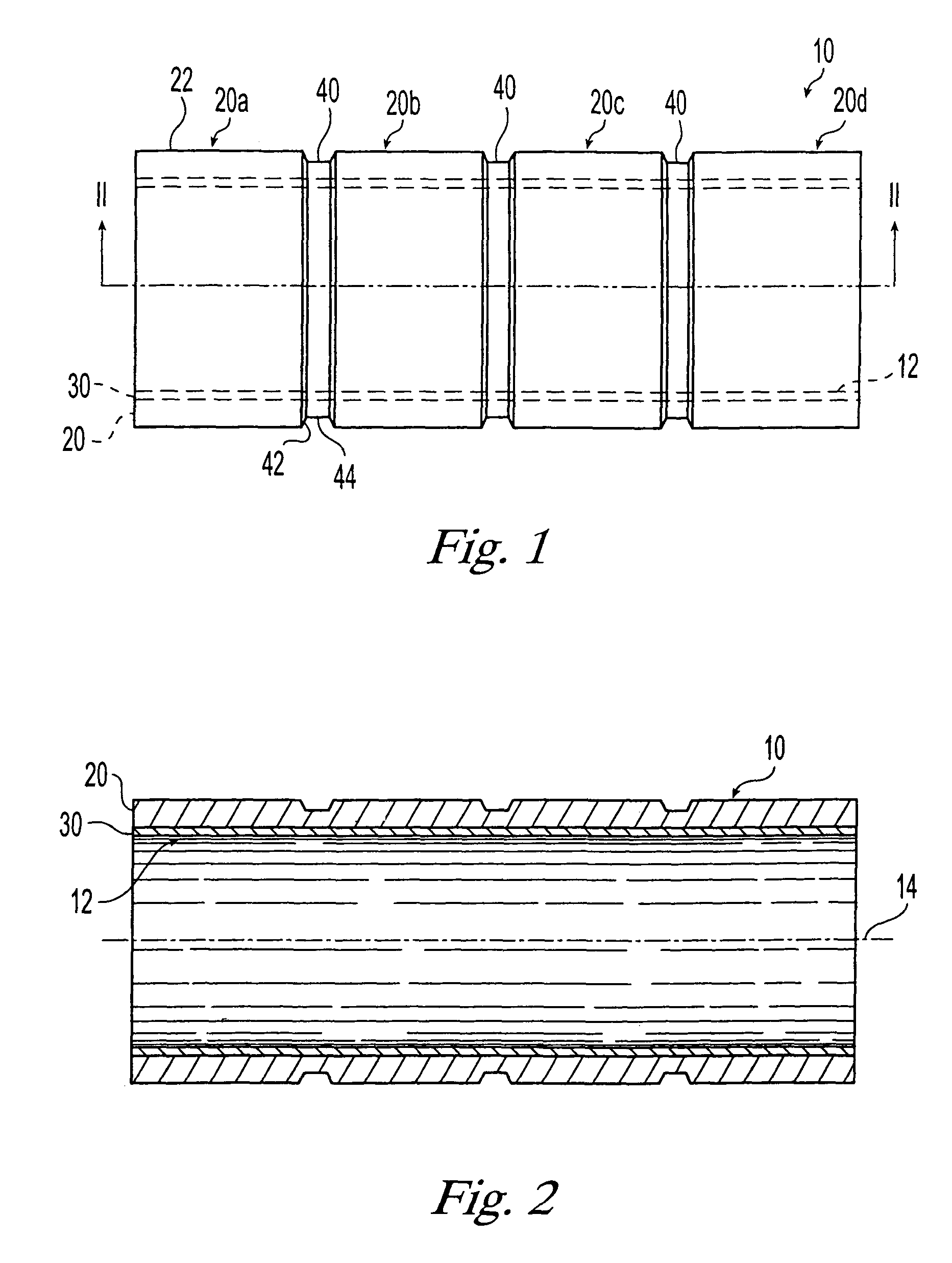

Fiber bundles and methods of making fiber bundles

InactiveUS20060257083A1Easily fixtured in deviceIncrease the number ofLaser detailsOptical fibre with multilayer core/claddingFiber bundleHoneycomb Pattern

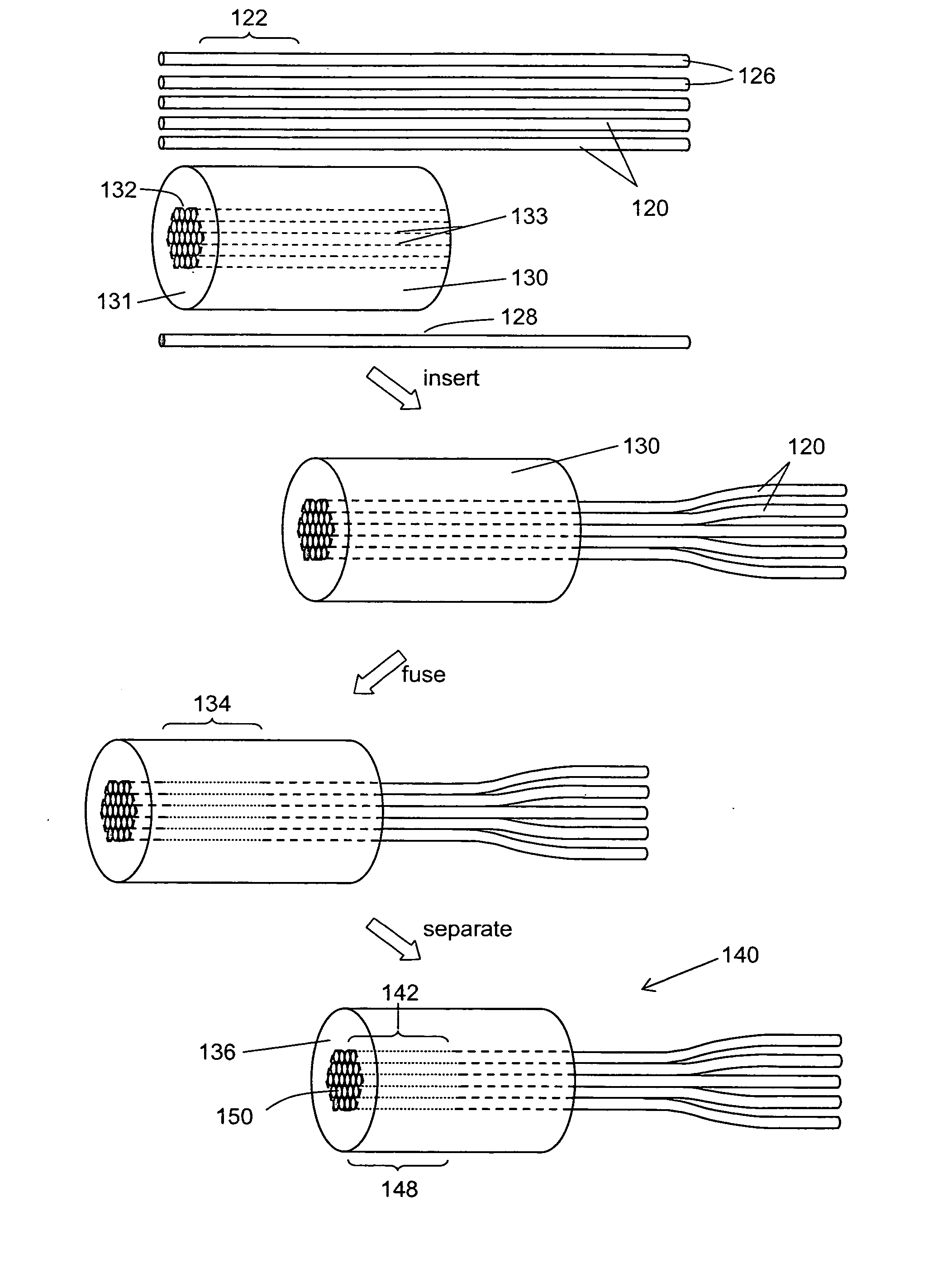

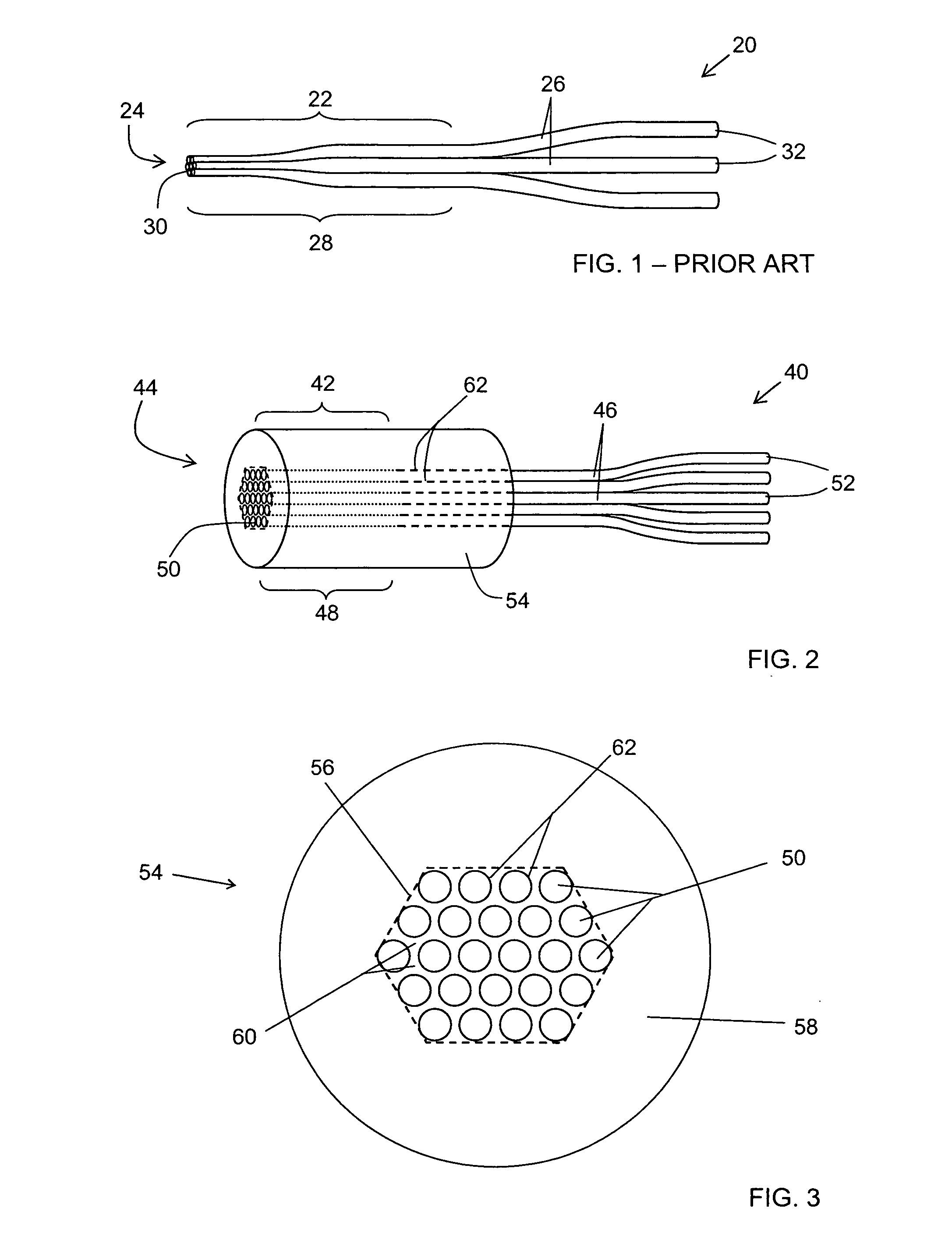

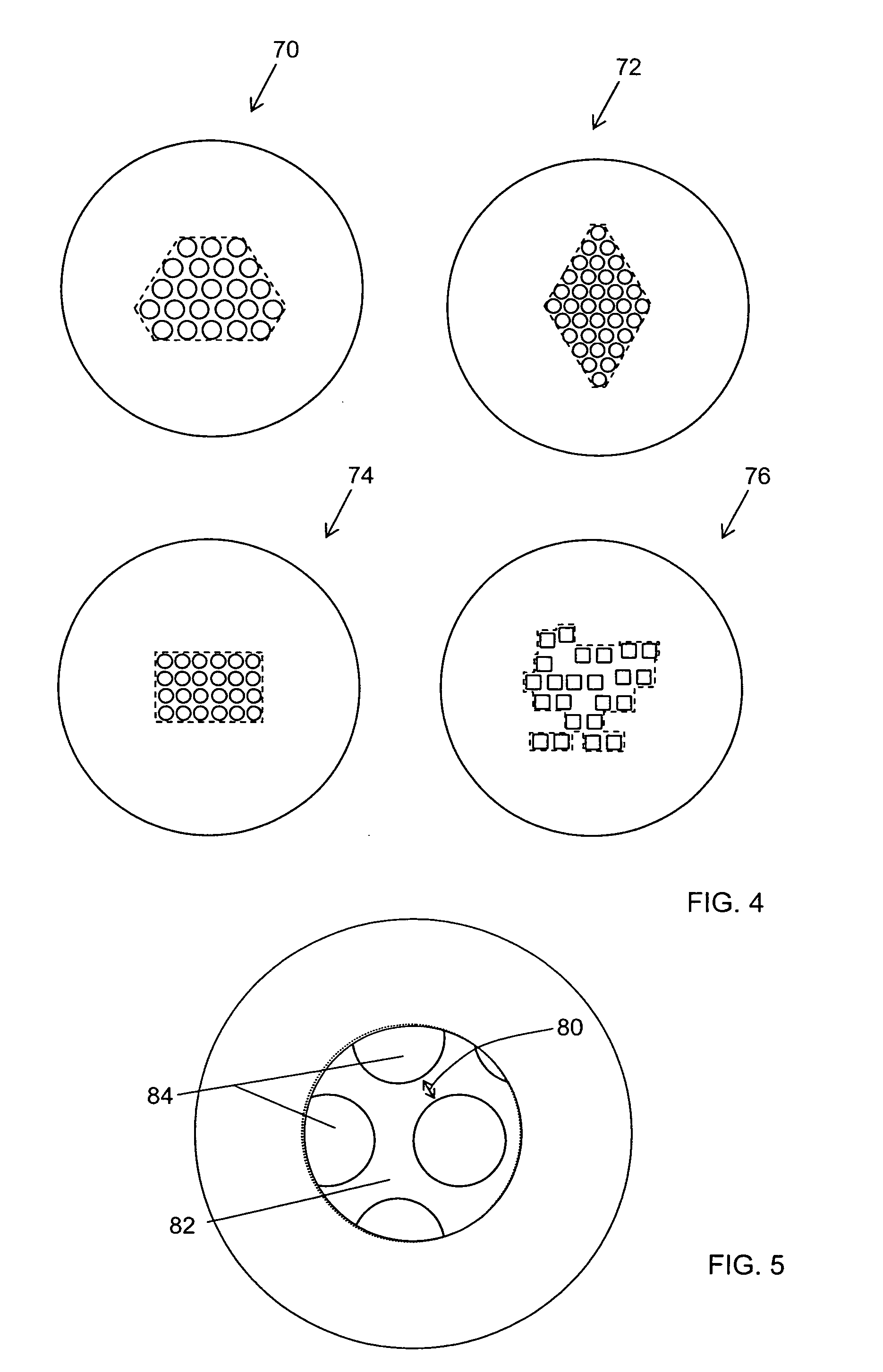

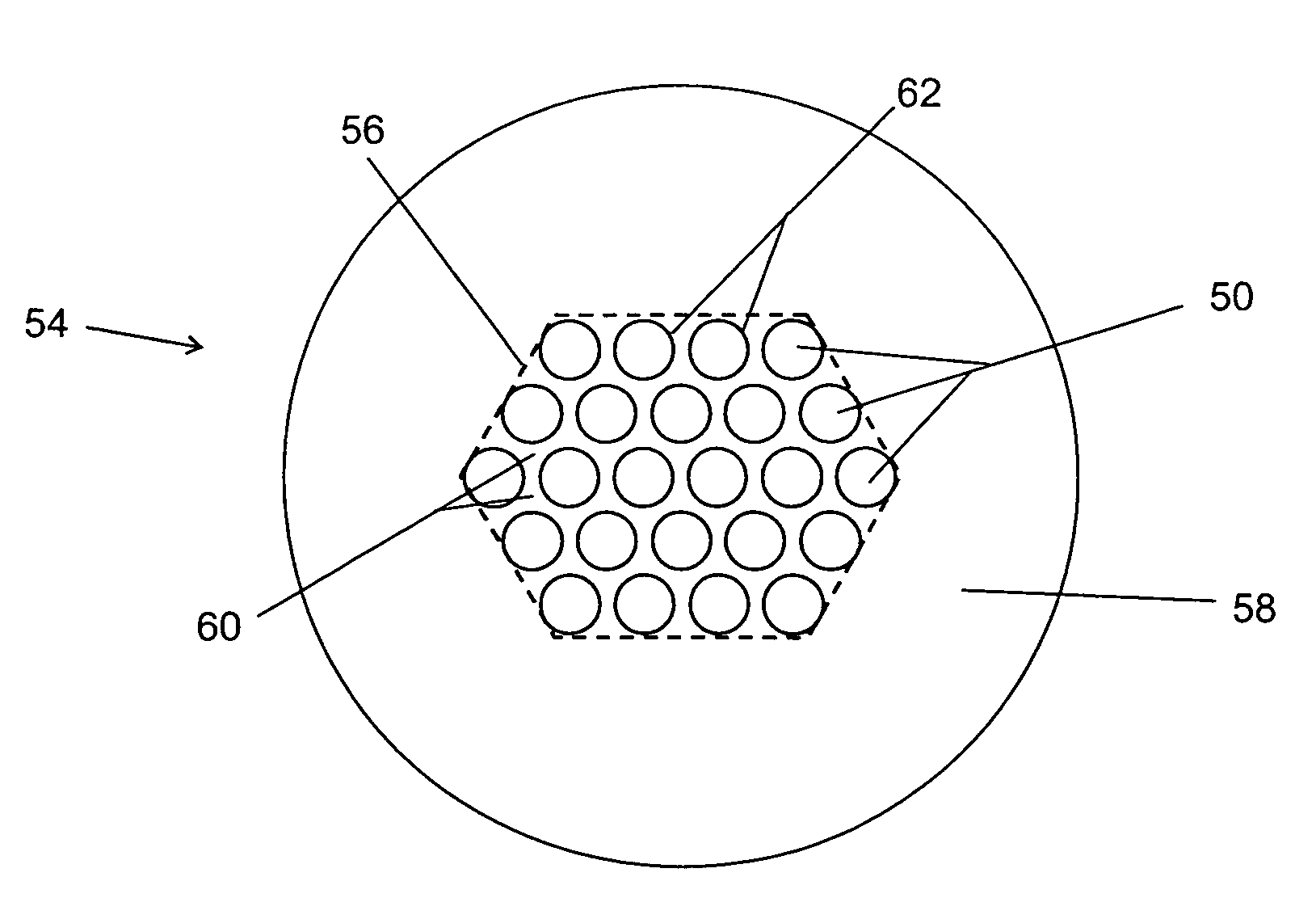

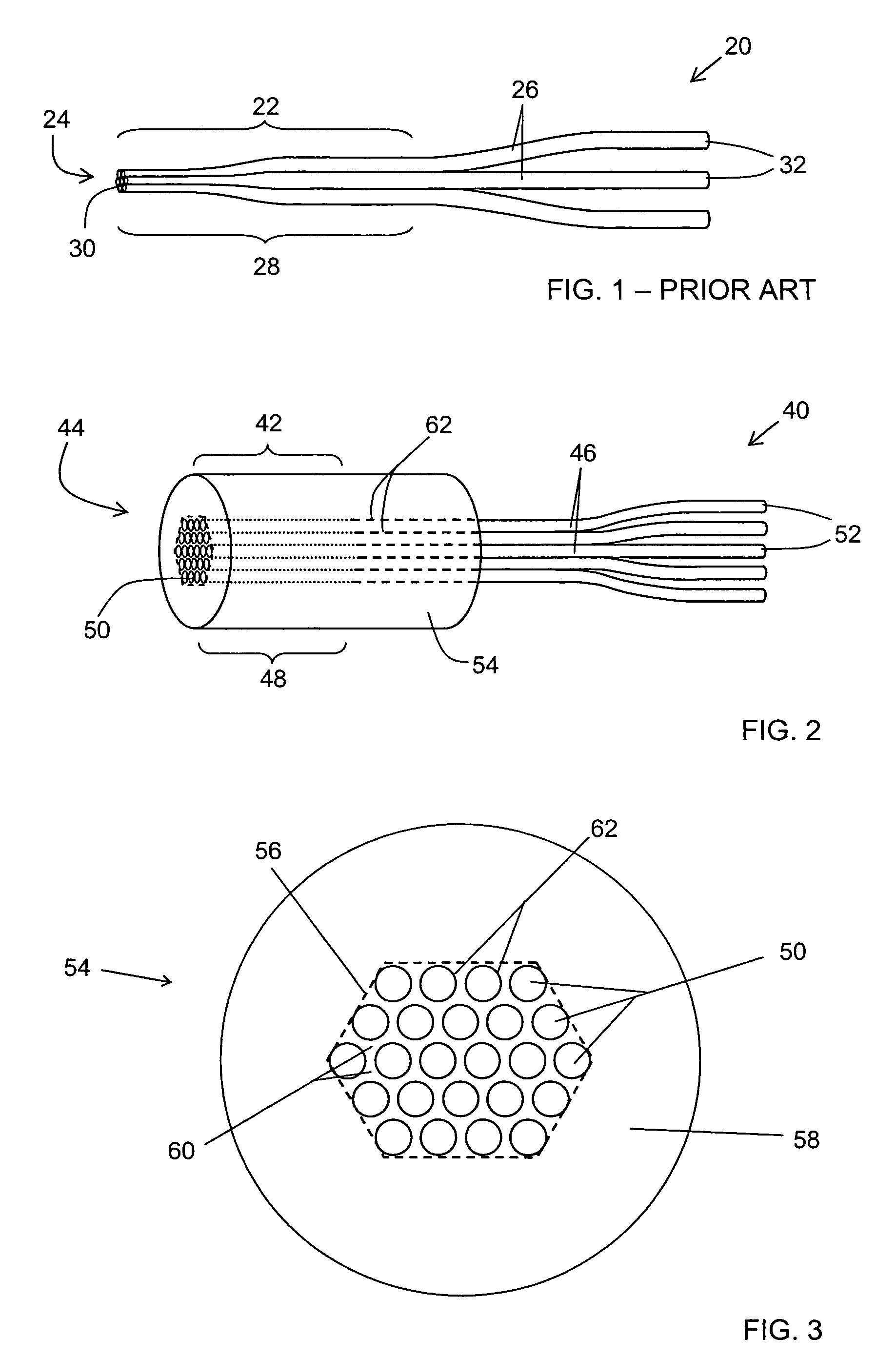

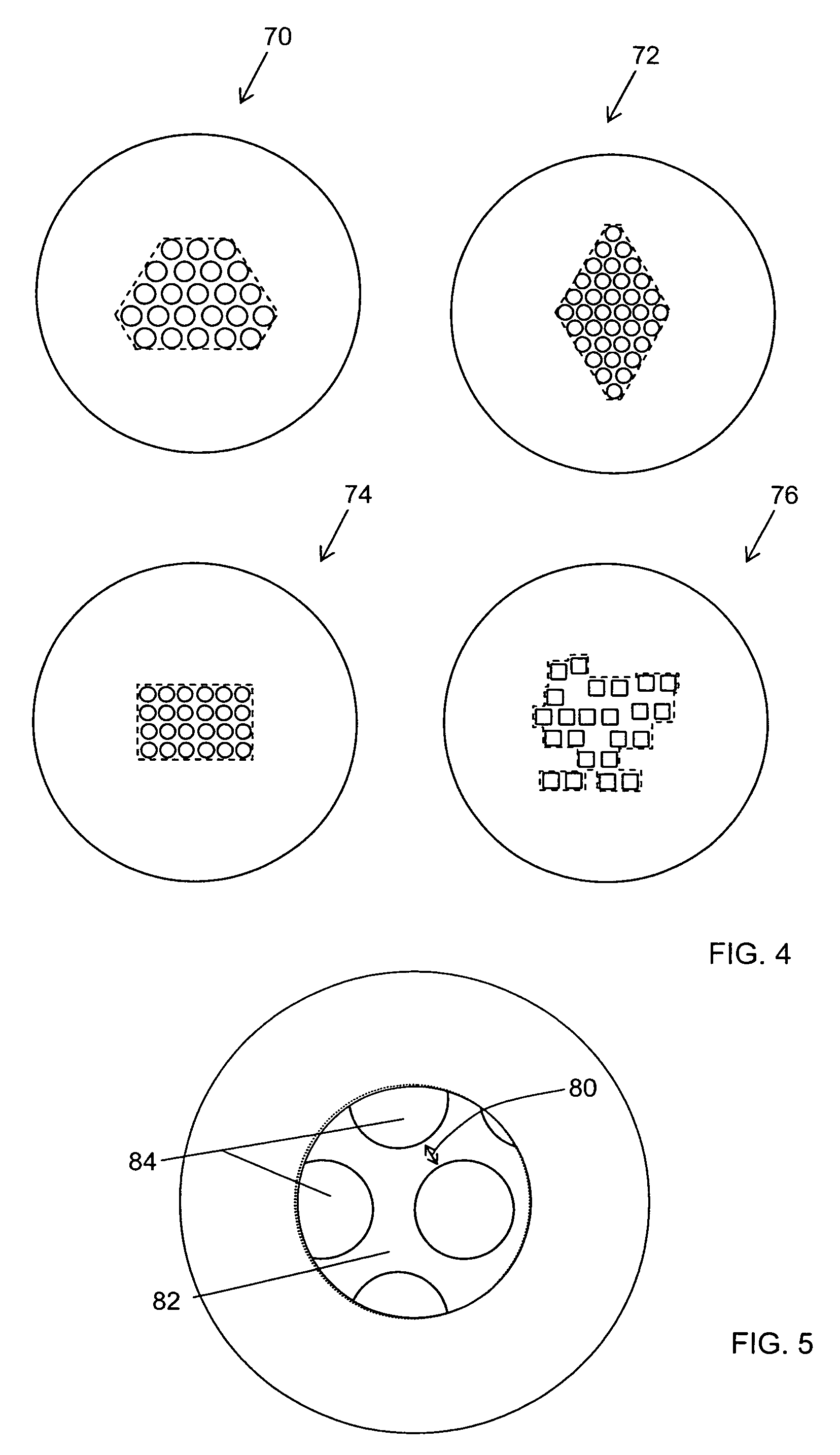

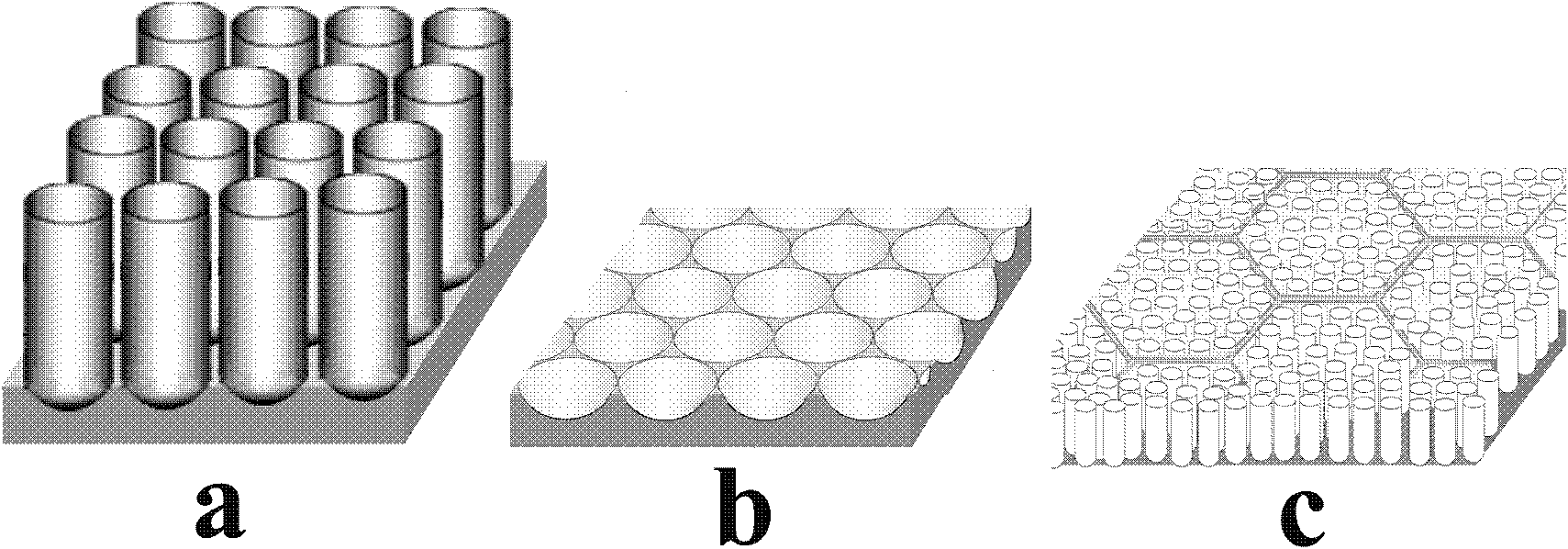

The present invention relates to fiber bundles and methods for making fiber bundles. According to one embodiment of the invention, a fused fiber bundle has a terminal section ending with an endface, and includes a plurality of optical fibers, each of the optical fibers having a terminal segment ending with a proximal end, and a distal end; and a cellular holding structure, the cellular holding structure including a cellular web portion having a plurality of longitudinal cells arranged substantially in parallel and surrounded by a web material; and a tube portion surrounding the cellular web portion. The terminal segments of the optical fibers are arranged substantially in parallel, and the terminal segment of each optical fiber is disposed in a longitudinal cell of the cellular holding structure and substantially fused to the web material, thereby forming the terminal section of the fused fiber bundle.

Owner:CORNING INC

Honeycomb composite silicon carbide mirrors and structures

Owner:FANTOM MATERIALS INC

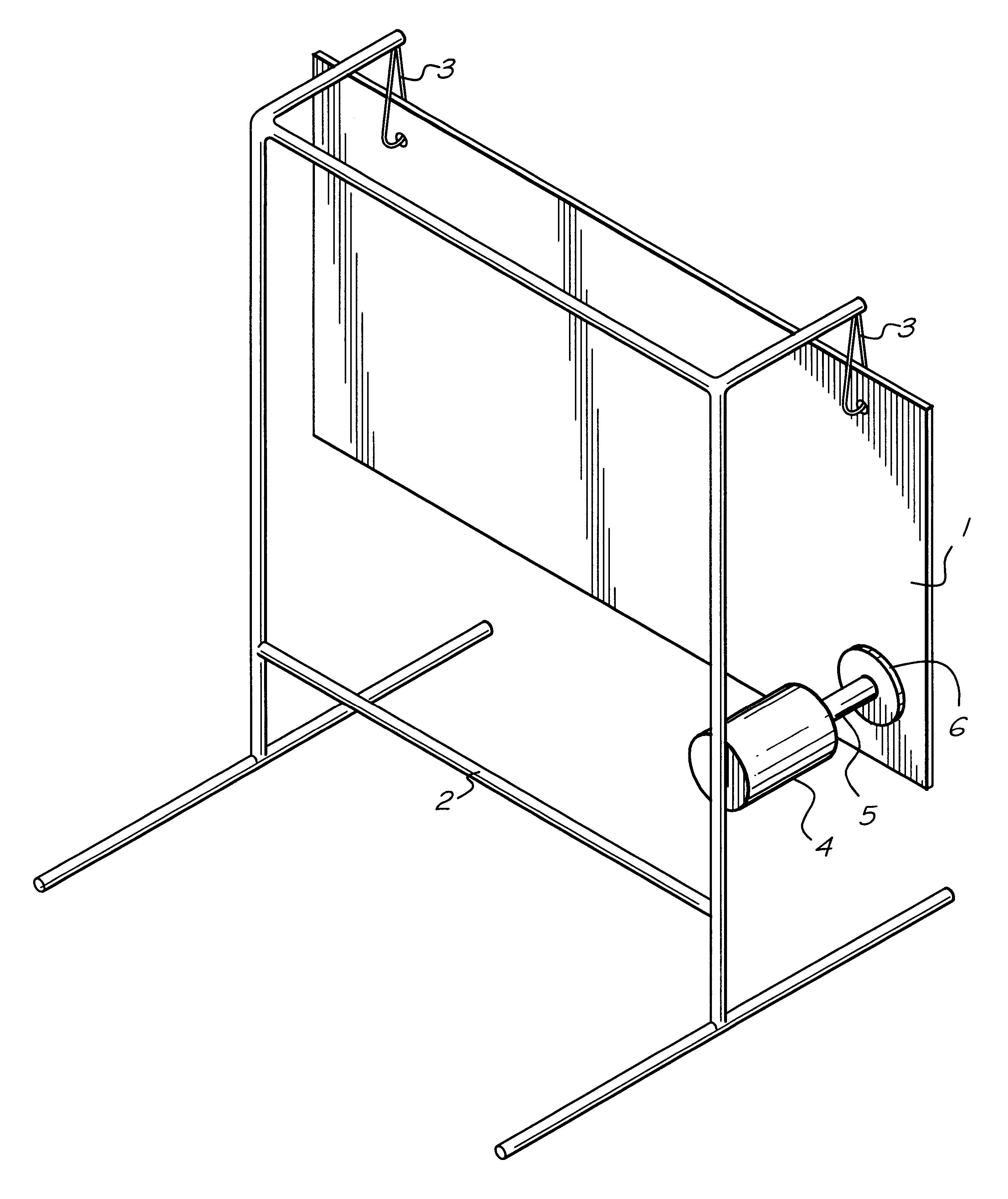

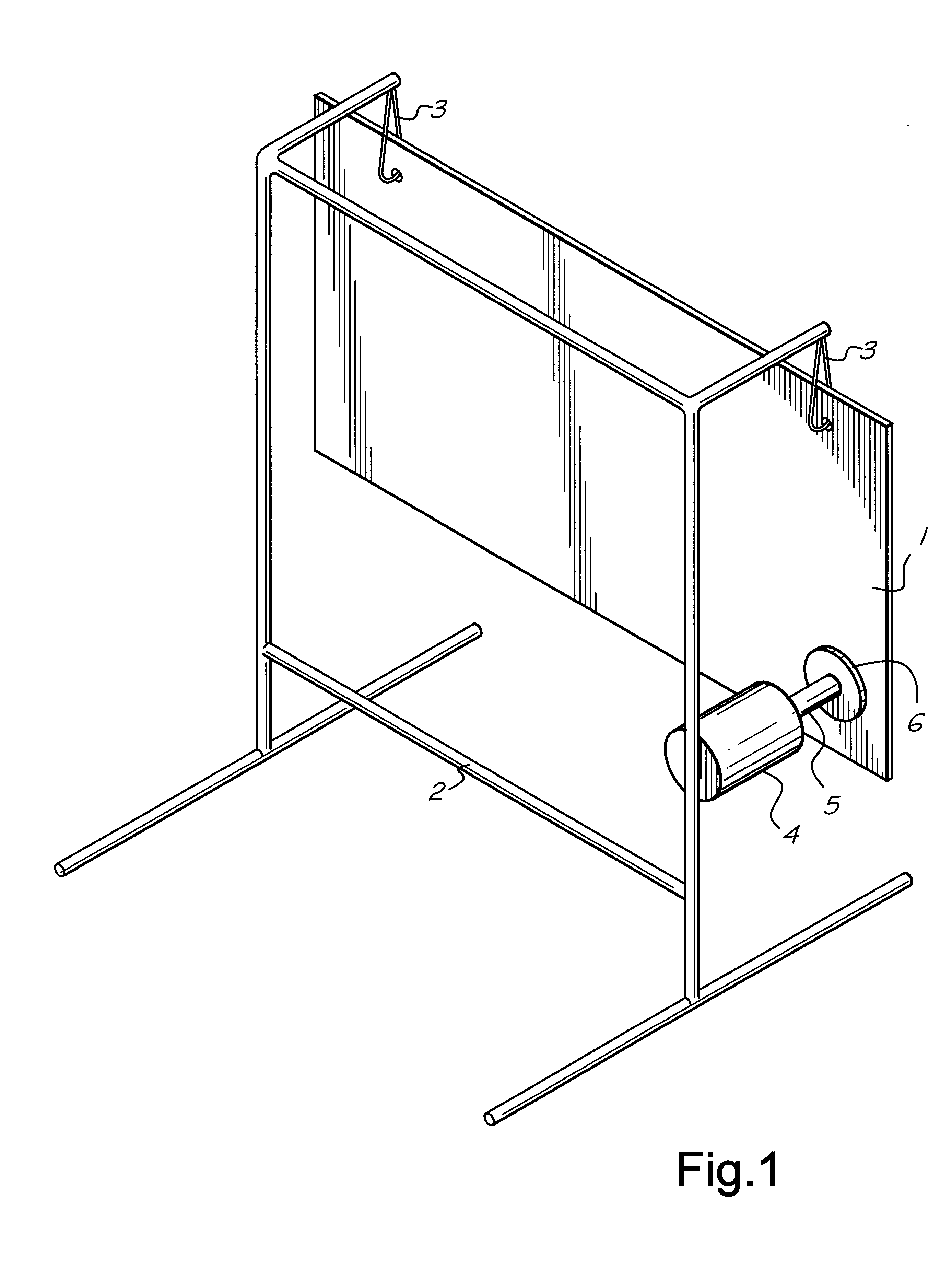

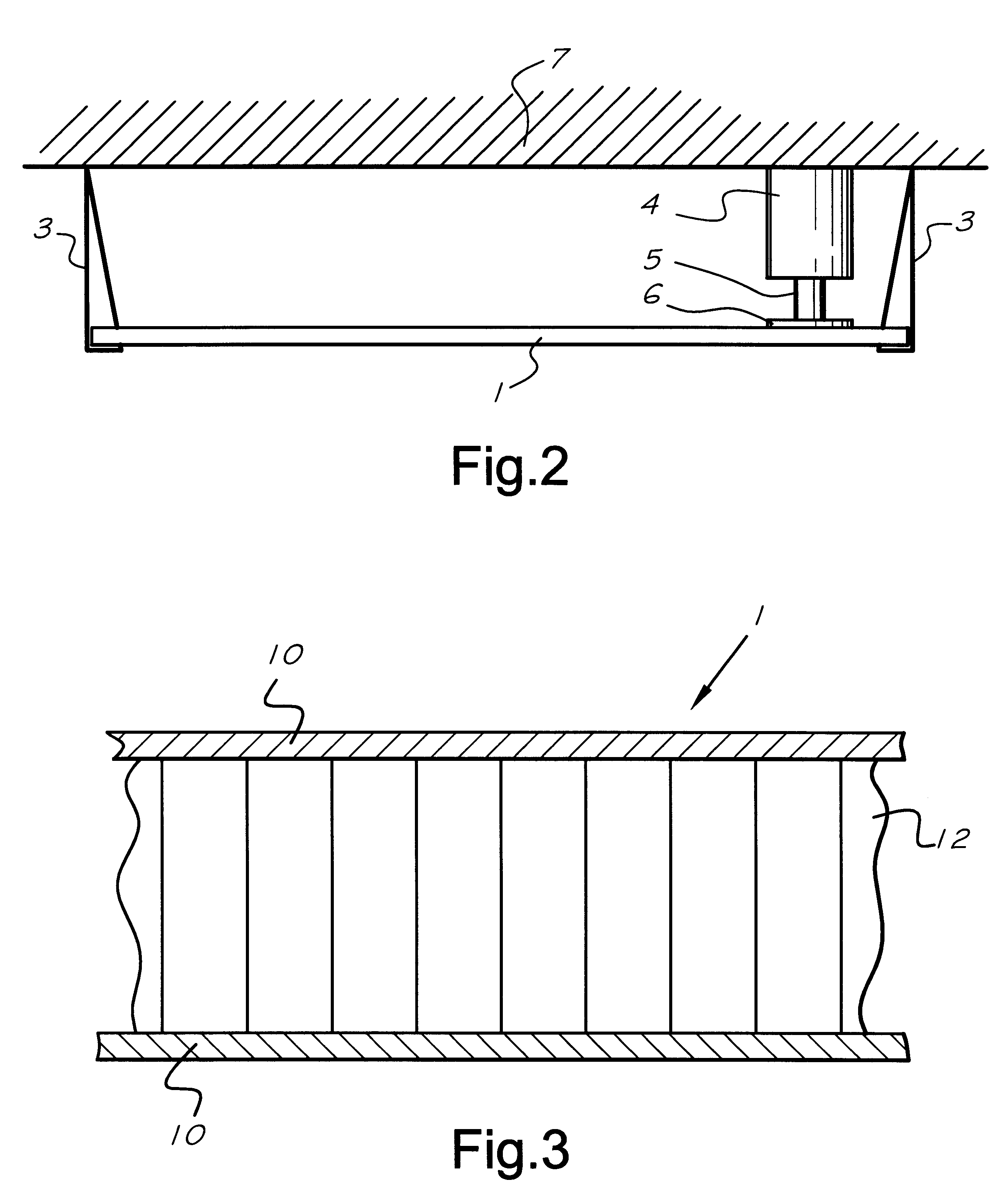

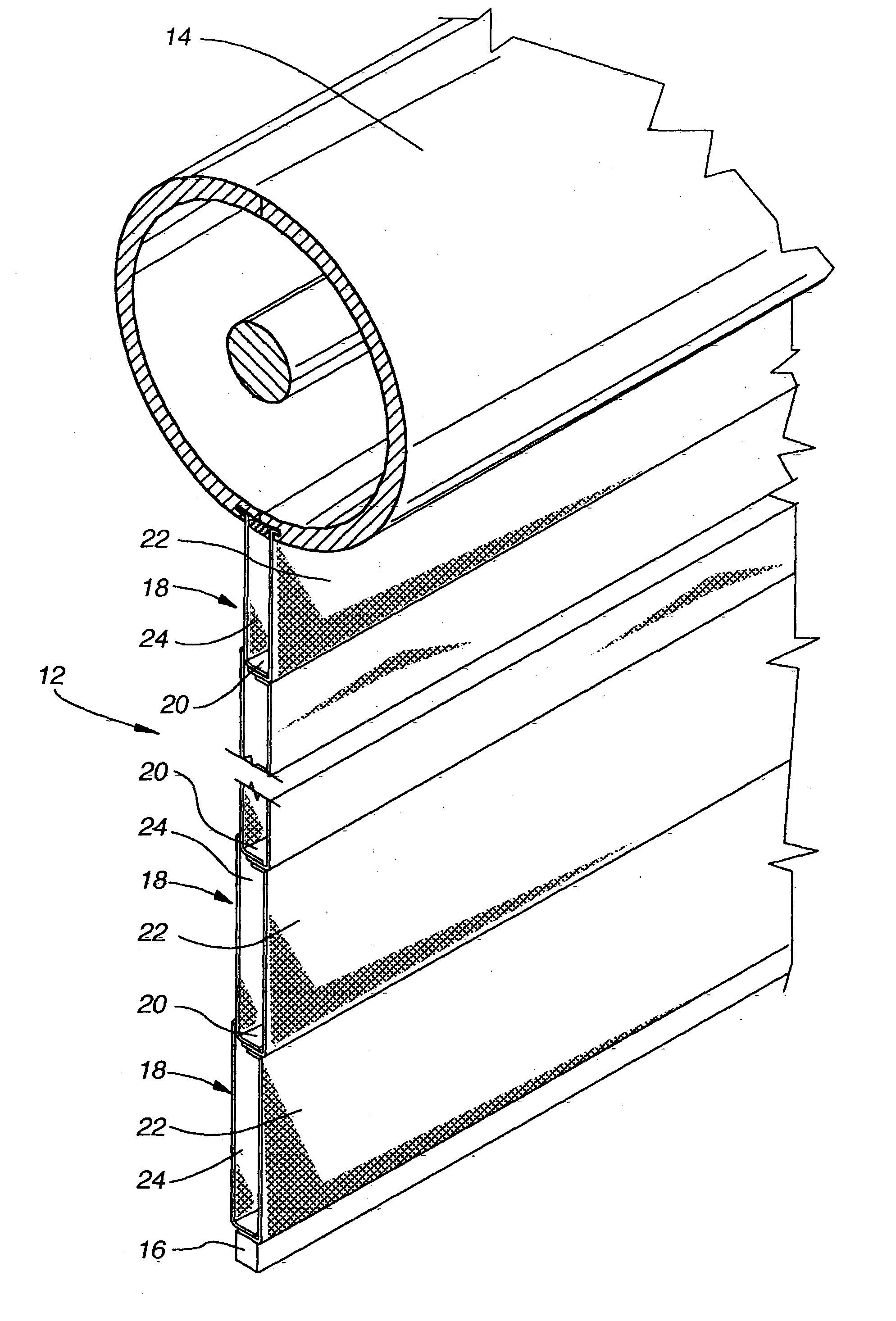

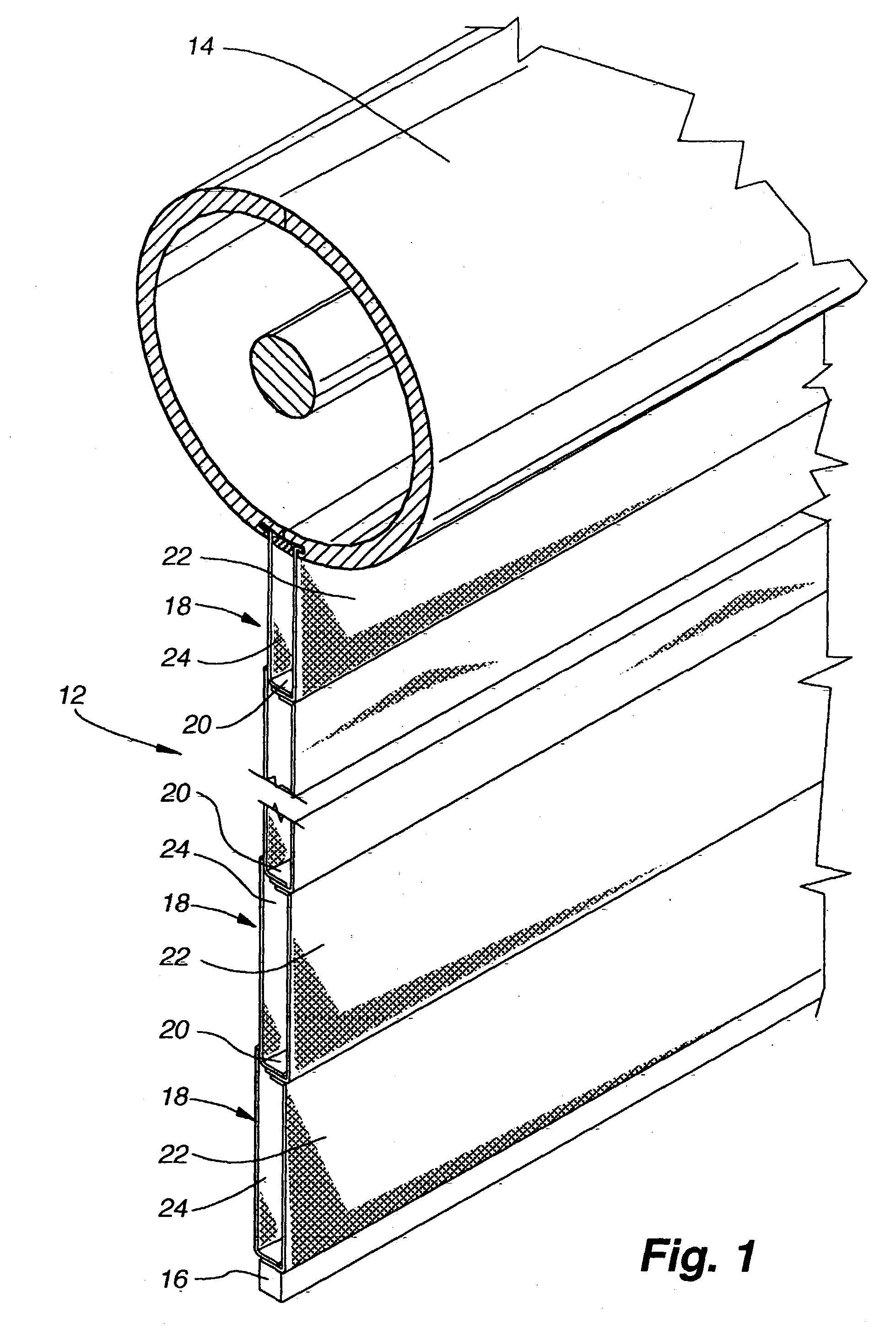

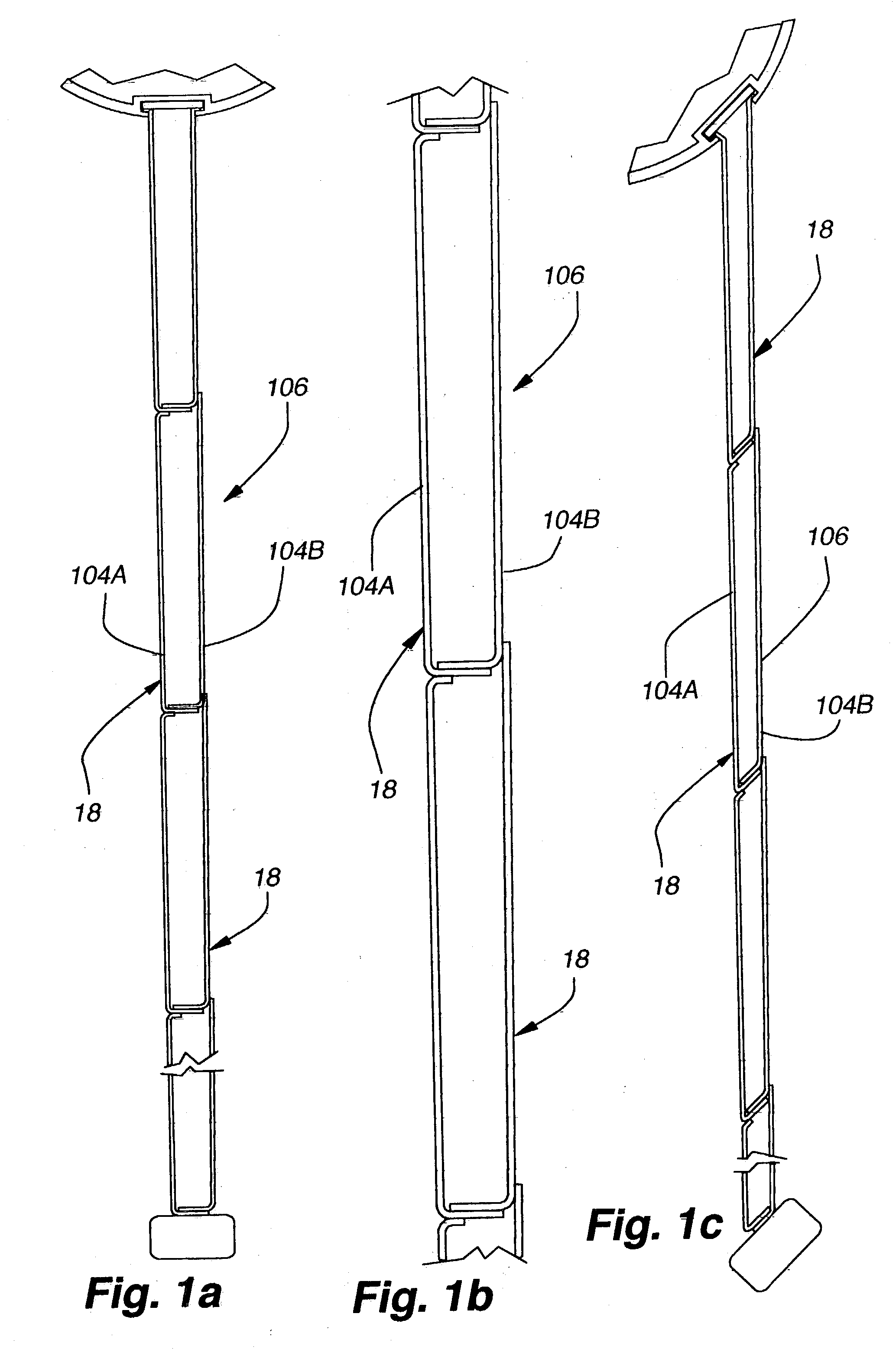

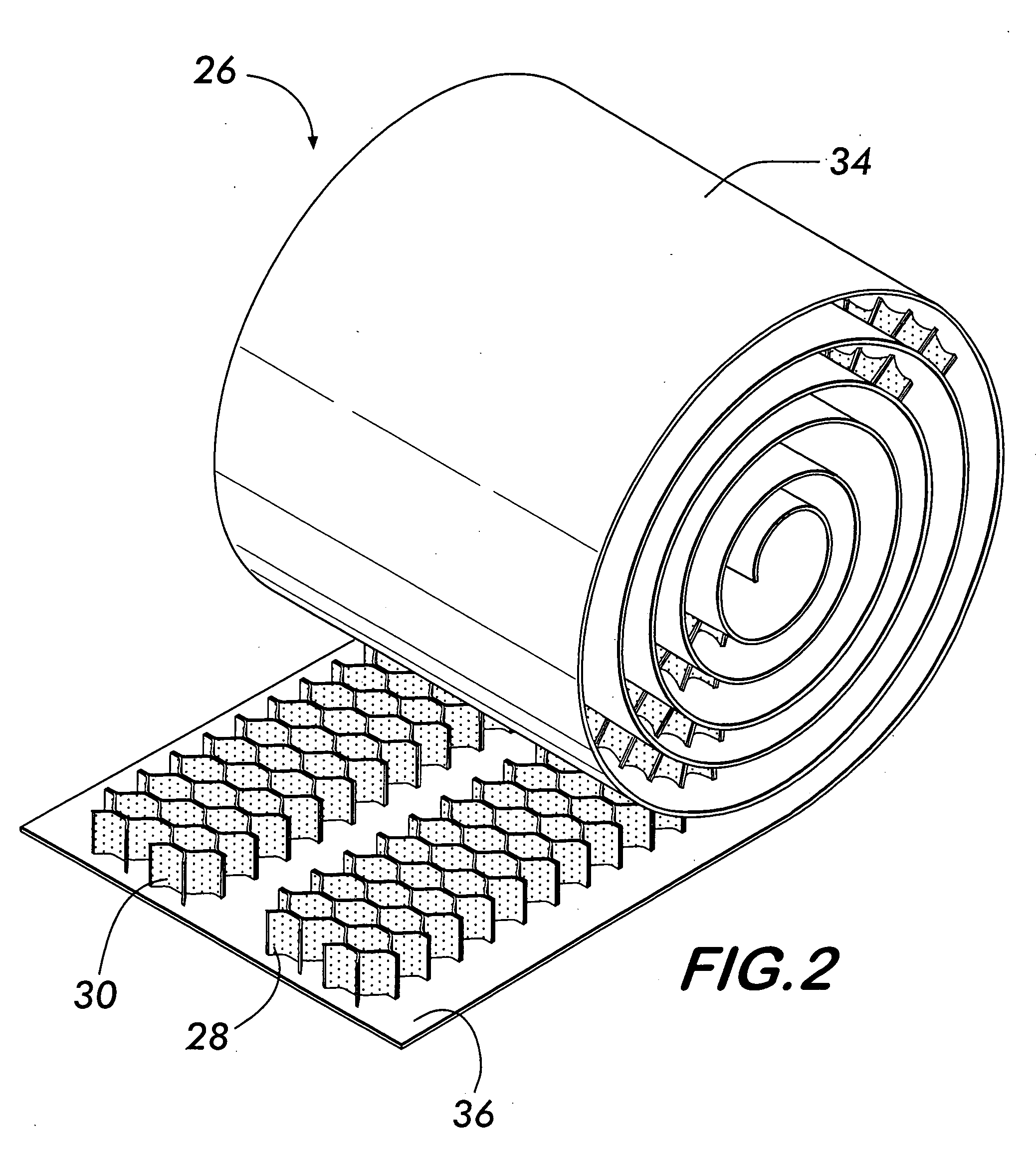

Cellular shade material for coverings for architectural openings

InactiveUS20040065416A1Extensible doors/windowsCurtain accessoriesHoneycomb PatternMechanical engineering

An apparatus and method for fabricating a cellular roller shade material for use in roller shade coverings for architectural openings is described. In a preferred embodiment, two fabric tapes are joined proximate an edge of each to form a wide fabric tape. The wide fabric tape is then pulled through a folding horn to fold the tape along a longitudinal axis that is laterally offset from the tape's longitudinal axis. Two longitudinal adhesive beads are applied to the folded tape by an adhesive applicator. The folded tape is then continuously wound onto tubular surface with the surfaces of the folded tape containing the adhesive beads being placed in an overlapping relationship with a portion of a previously wrapped section of the folded tape. The wrapped and joined tubular tape is cut to form a sheet of shade material that comprises plurality of horizontally-extending cells when utilized in a roller shade.

Owner:HUNTER DOUGLAS INC

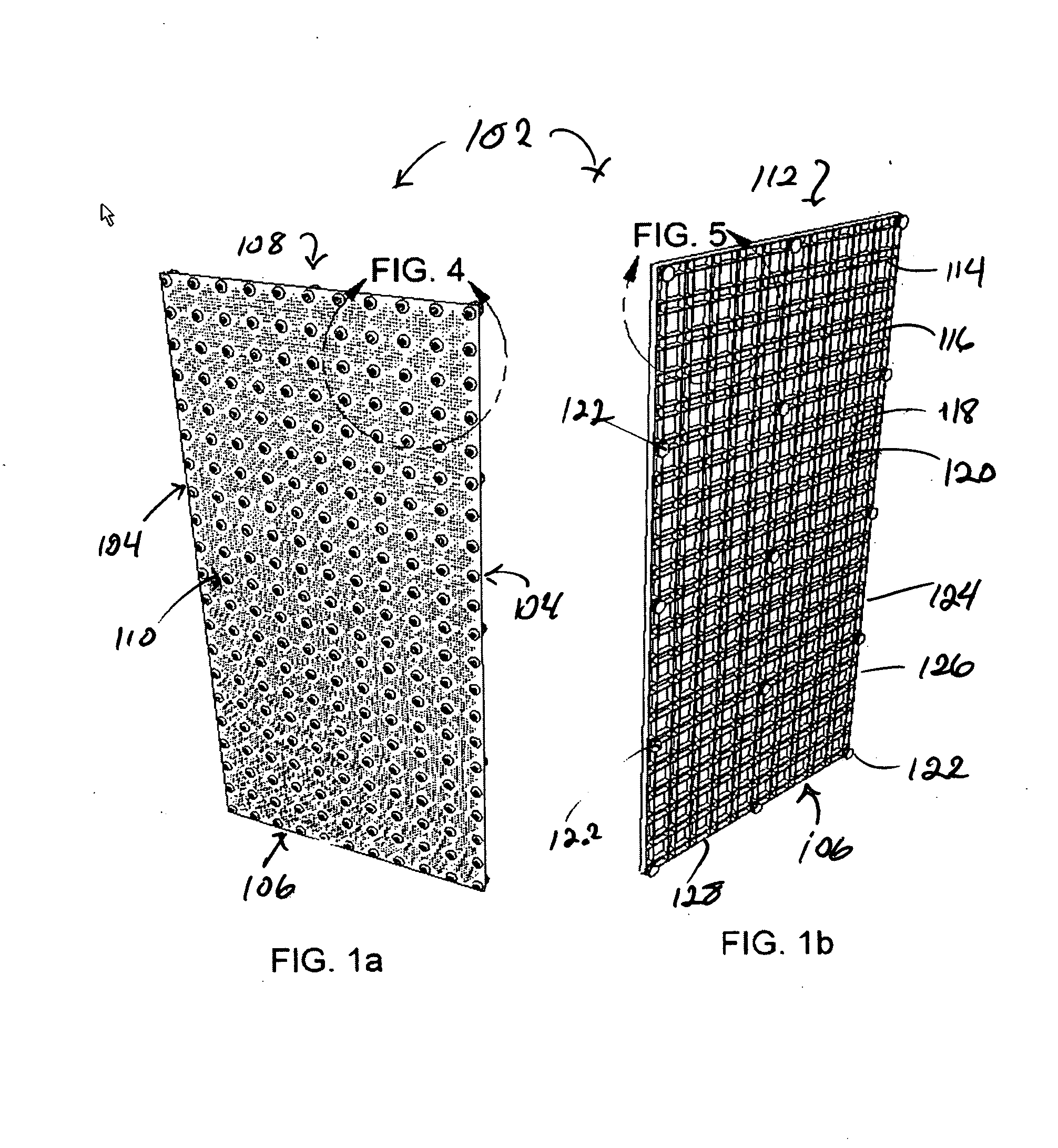

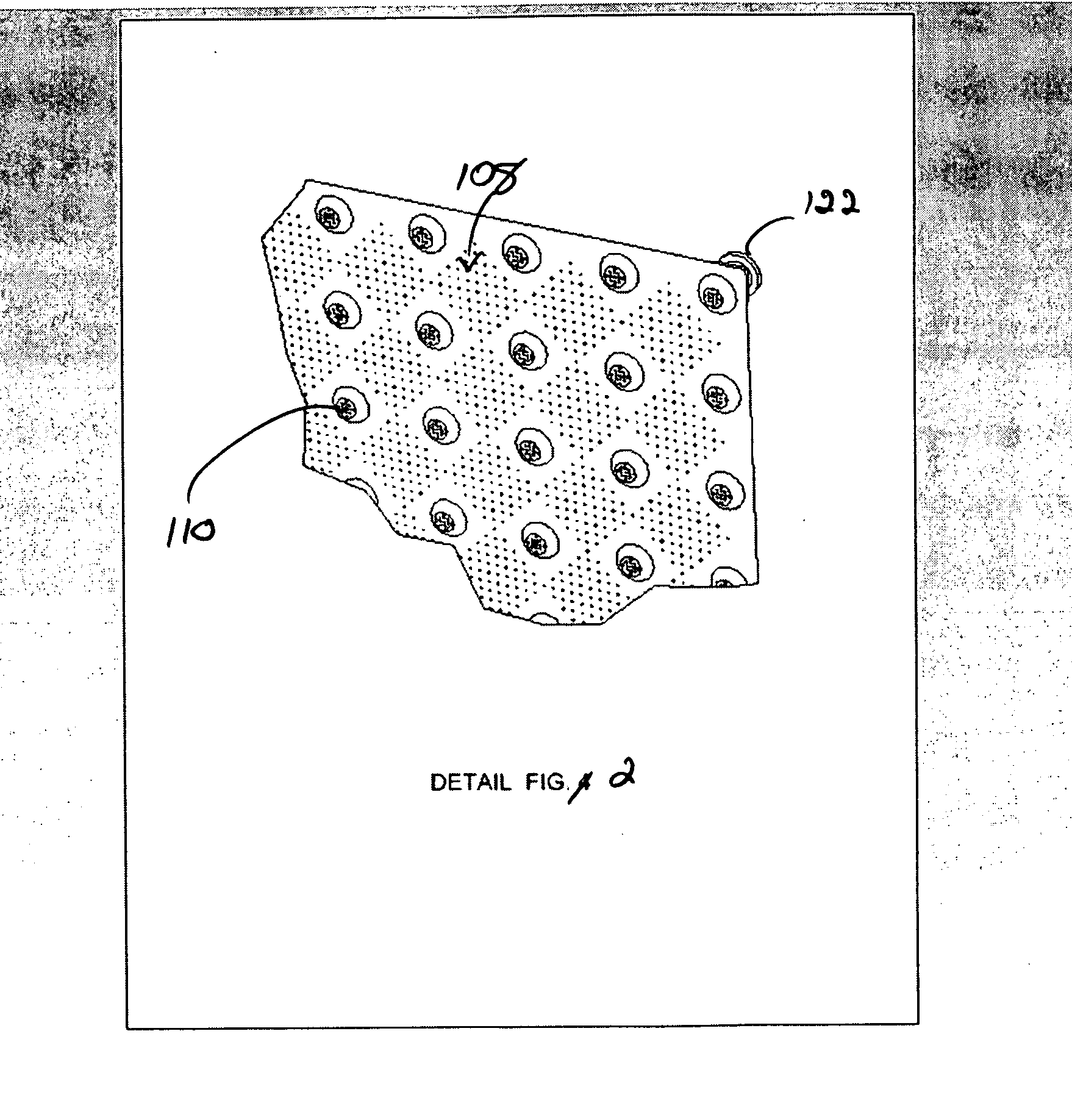

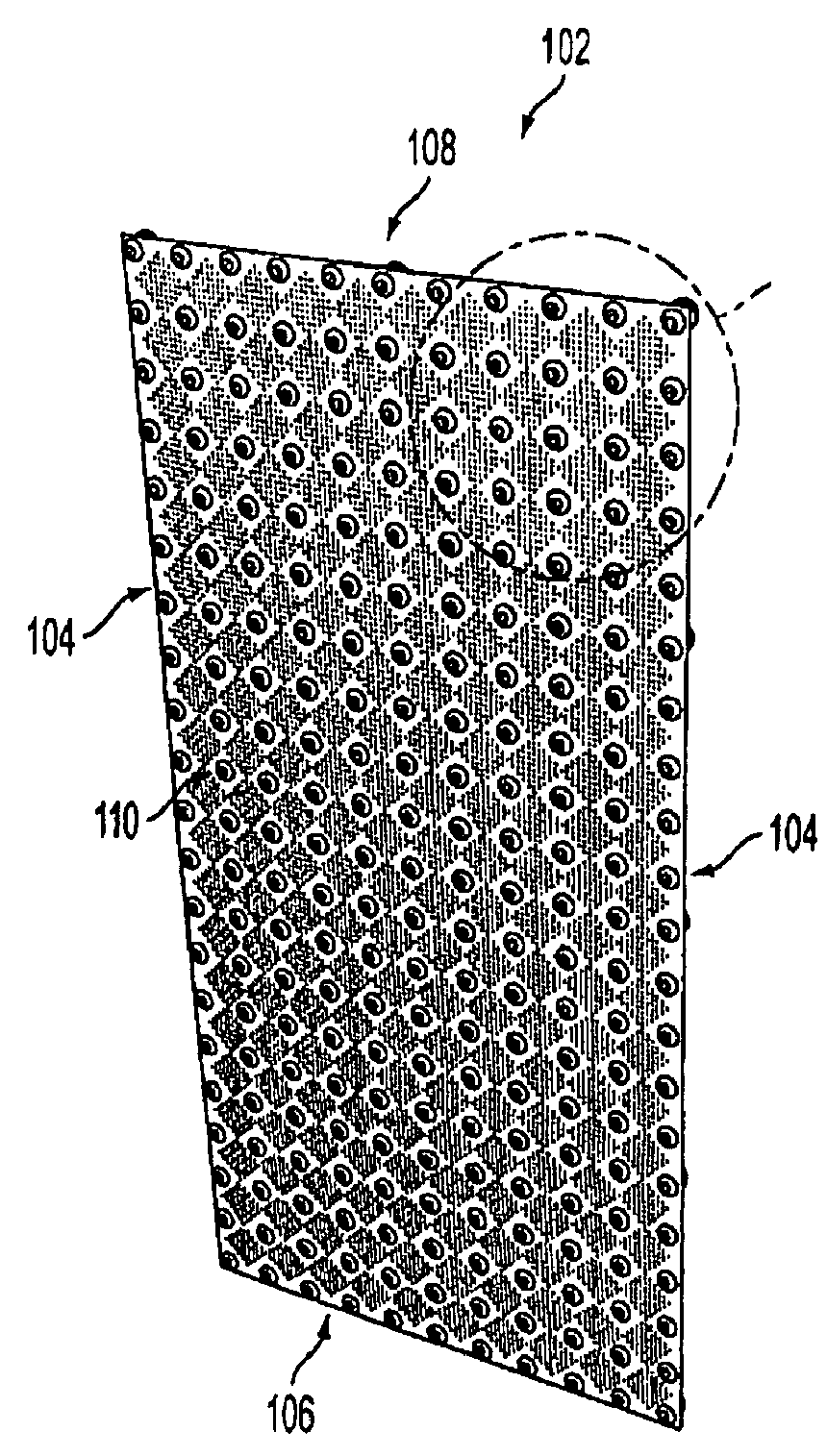

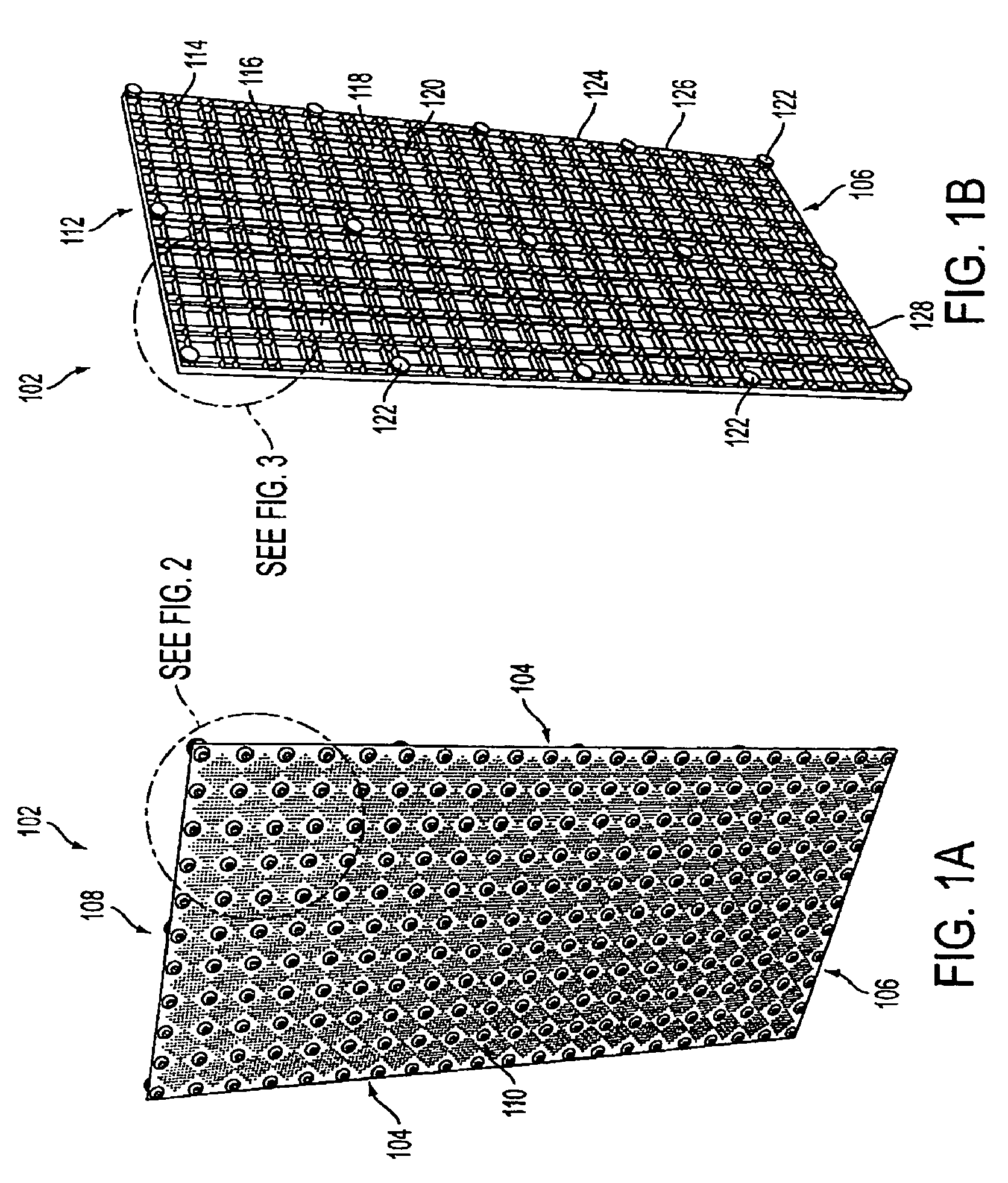

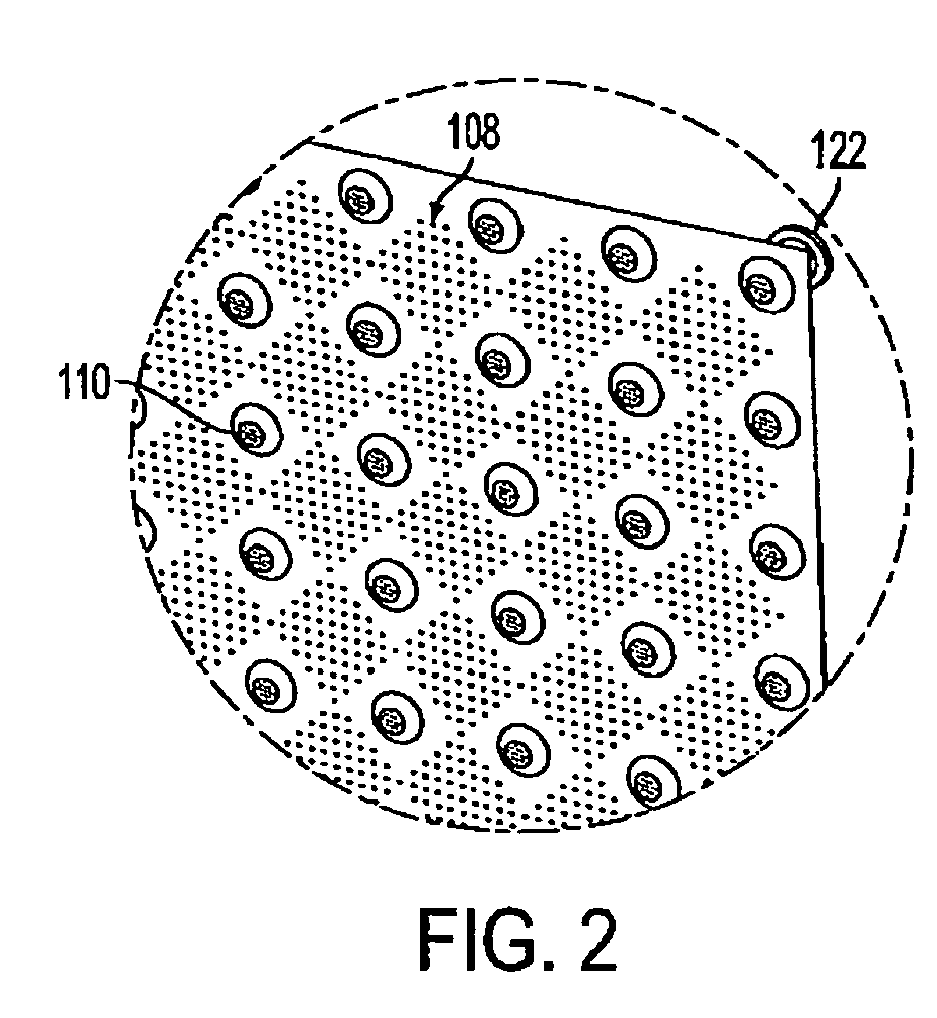

Tactile tile product for the visually impaired, method of manufacture and methods of conducting business therewith

The present invention provides a tactile tile comprising hemispherical outward protruding domes on an upper surface for pedestrian traffic, and a plurality of longitudinal and transverse members integral with each other and integral with a bottom side of the tile opposite the upper surface forming a honeycomb pattern.

Owner:WEHMEYER DONALD

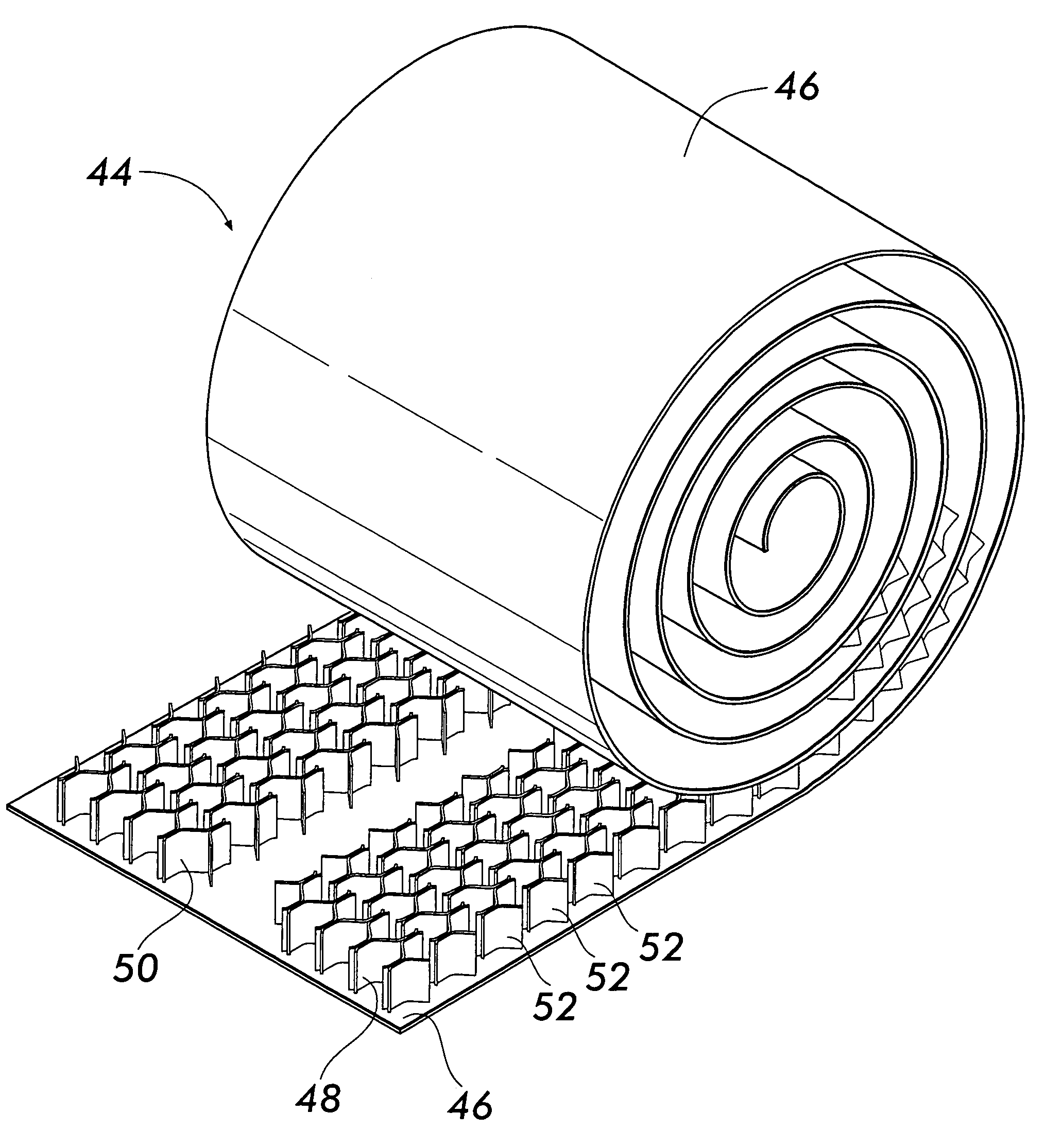

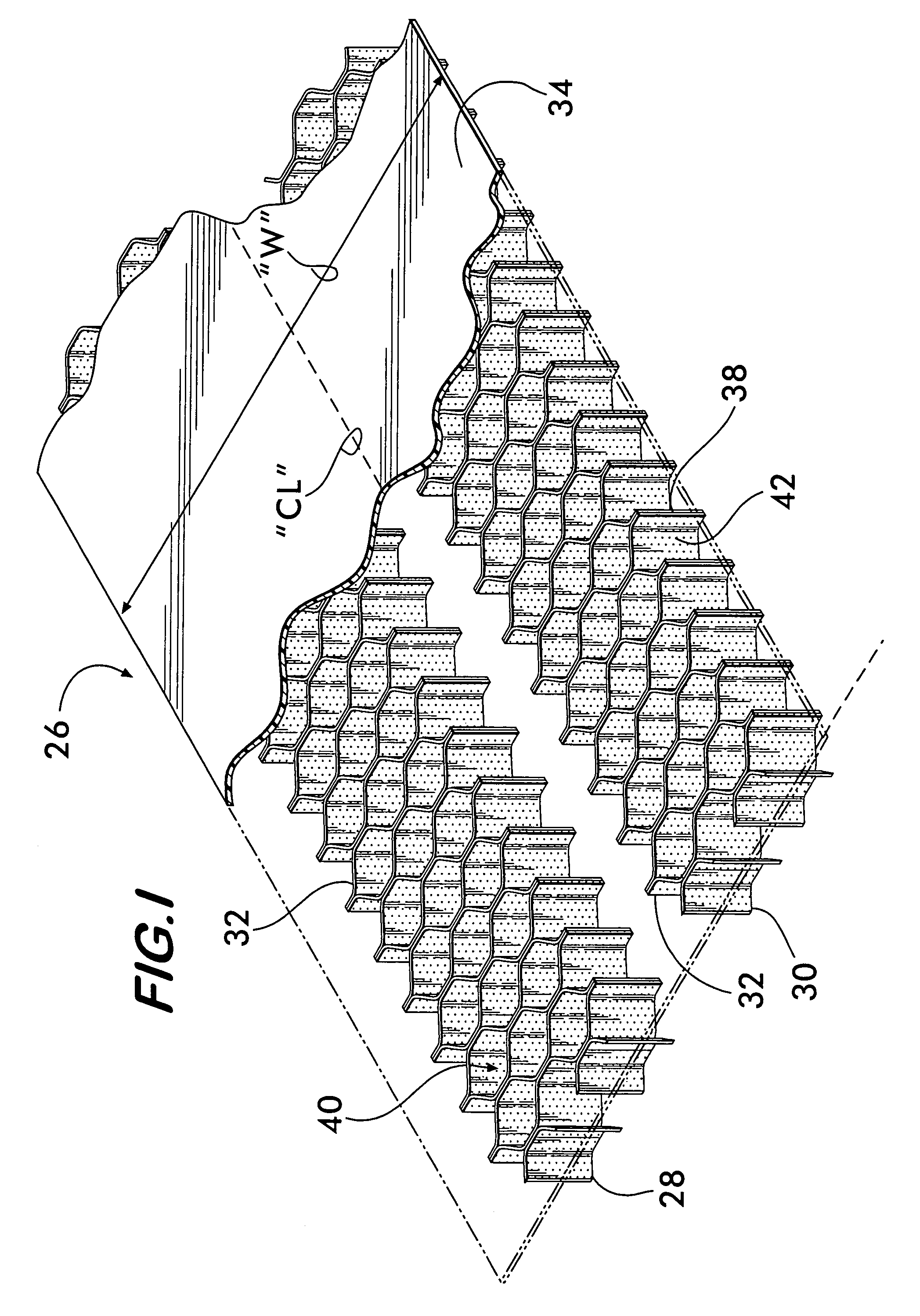

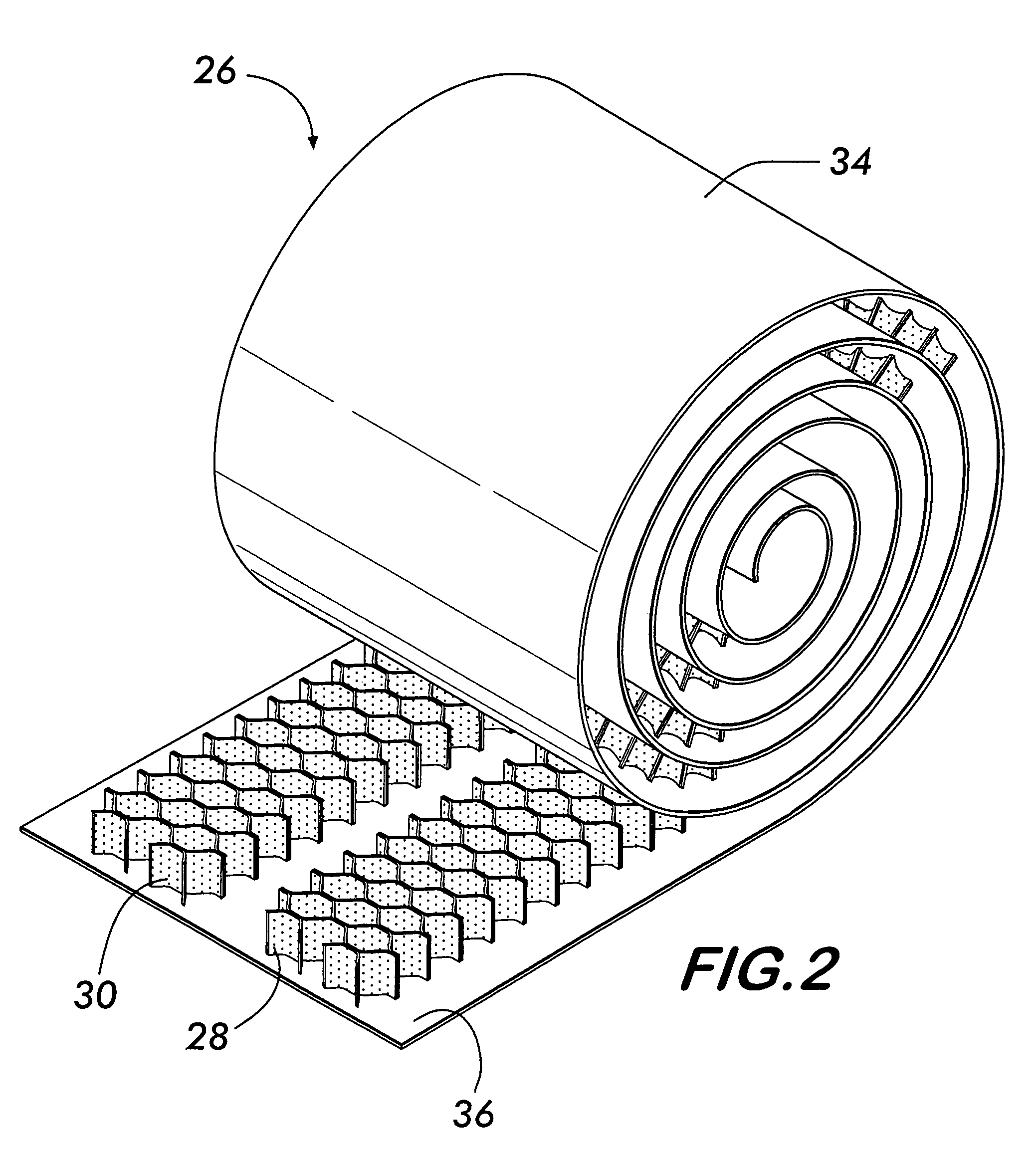

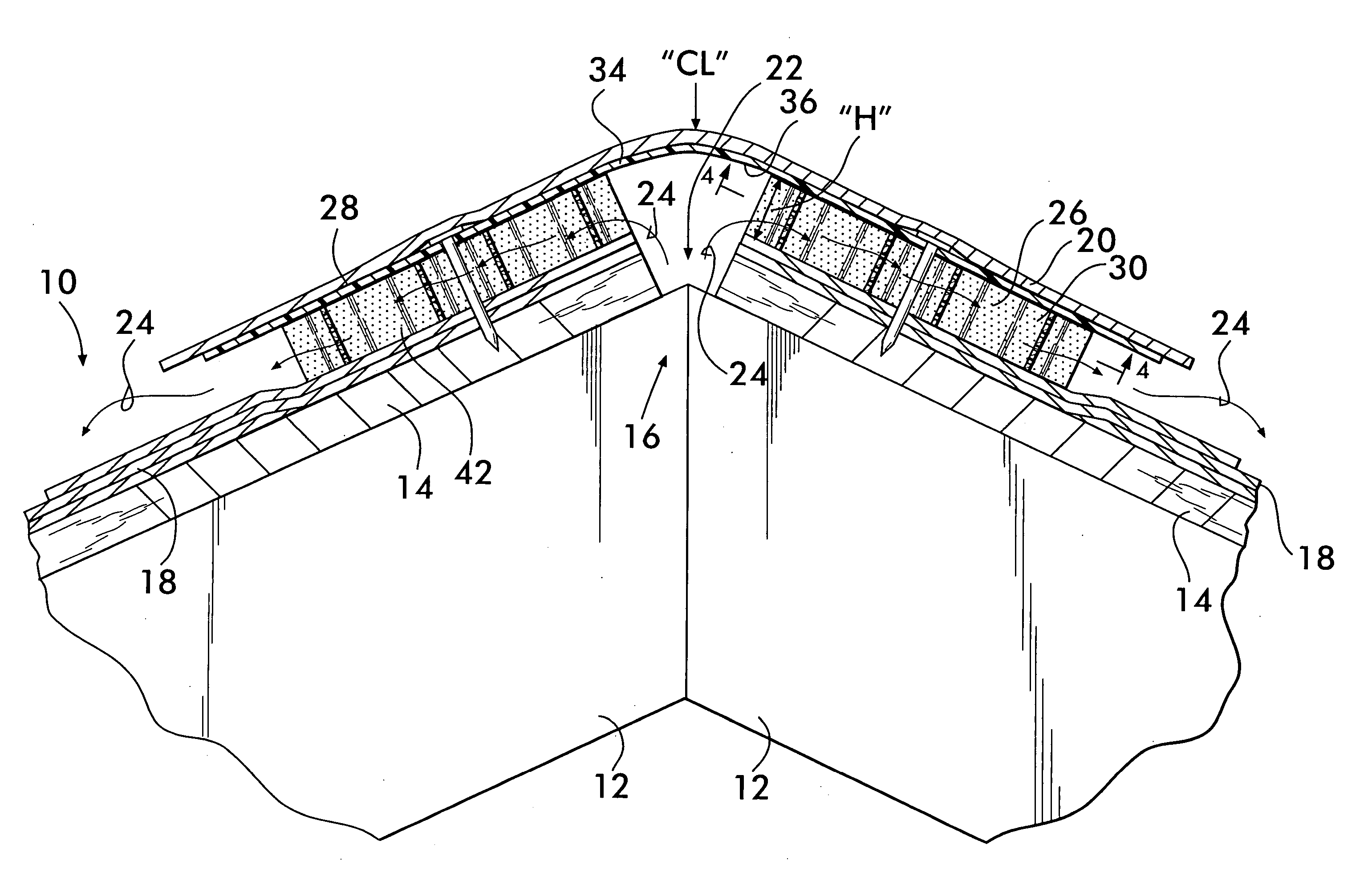

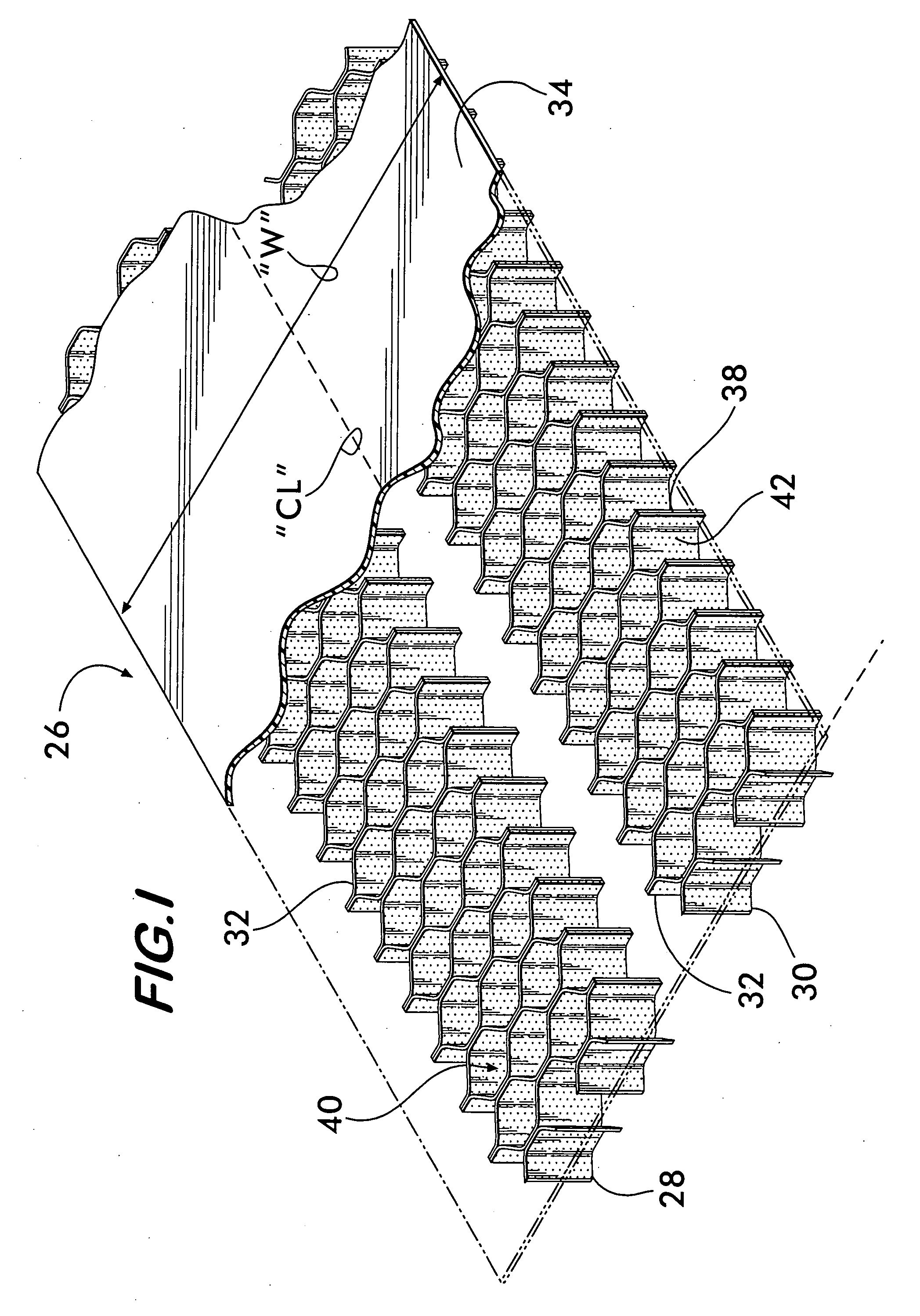

Roof ridge vent having honeycomb or like ventilation material

A roof ridge vent and installation includes a ventilation material having walls defining a plurality of separate open cellular cavities, such as a honeycomb material, that may or may not extend from the underside of a separate sheet material. Preferably, the walls of the ventilation material extend substantially vertically within the vent, and paths of ventilation, which extend from on open slot on the roof ridge to either longitudinally-extending side edge of the vent, extend transversely through the walls of the ventilation material. To this end, the walls are perforated or are made of an air permeable material, more preferably, a non-wicking hydrophobic material or a non-woven fabric having a multiplicity of closely spaced openings. Alternatively, paths of ventilation can be provided by channels formed between adjacent, spaced-apart sections of the ventilation material. Preferably, the vent is continuous and elongate and is stored and shipped in a spiral roll.

Owner:BENJAMIN OBDIKE

Roof ridge vent having honeycomb or like ventilation material

ActiveUS20060079173A1Prevent weather infiltrationRoof coveringLighting and heating apparatusHoneycombHoneycomb Pattern

A roof ridge vent and installation includes a ventilation material having walls defining a plurality of separate open cellular cavities, such as a honeycomb material, that may or may not extend from the underside of a separate sheet material. Preferably, the walls of the ventilation material extend substantially vertically within the vent, and paths of ventilation, which extend from on open slot on the roof ridge to either longitudinally-extending side edge of the vent, extend transversely through the walls of the ventilation material. To this end, the walls are perforated or are made of an air permeable material, more preferably, a non-wicking hydrophobic material or a non-woven fabric having a multiplicity of closely spaced openings. Alternatively, paths of ventilation can be provided by channels formed between adjacent, spaced-apart sections of the ventilation material. Preferably, the vent is continuous and elongate and is stored and shipped in a spiral roll.

Owner:BENJAMIN OBDIKE

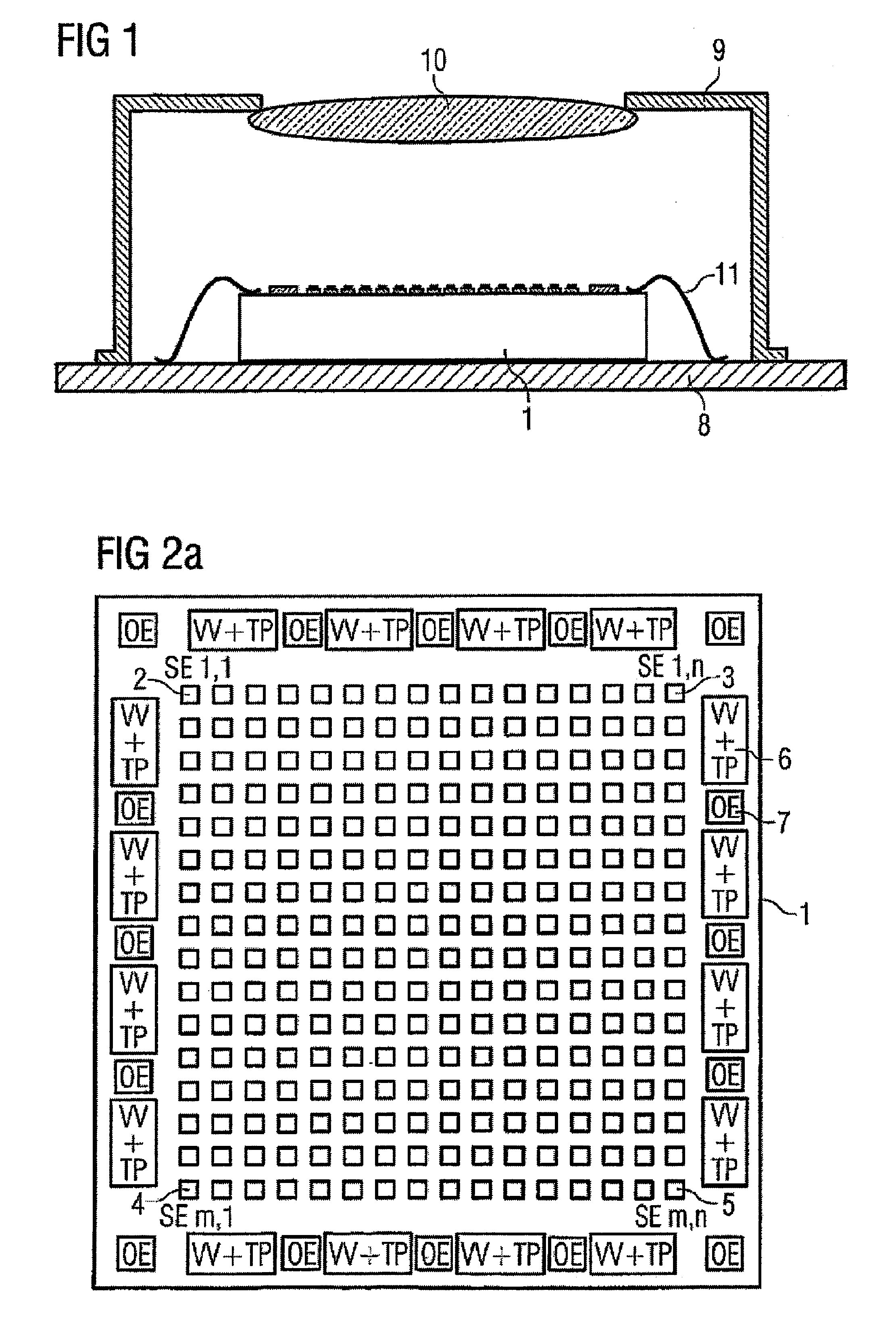

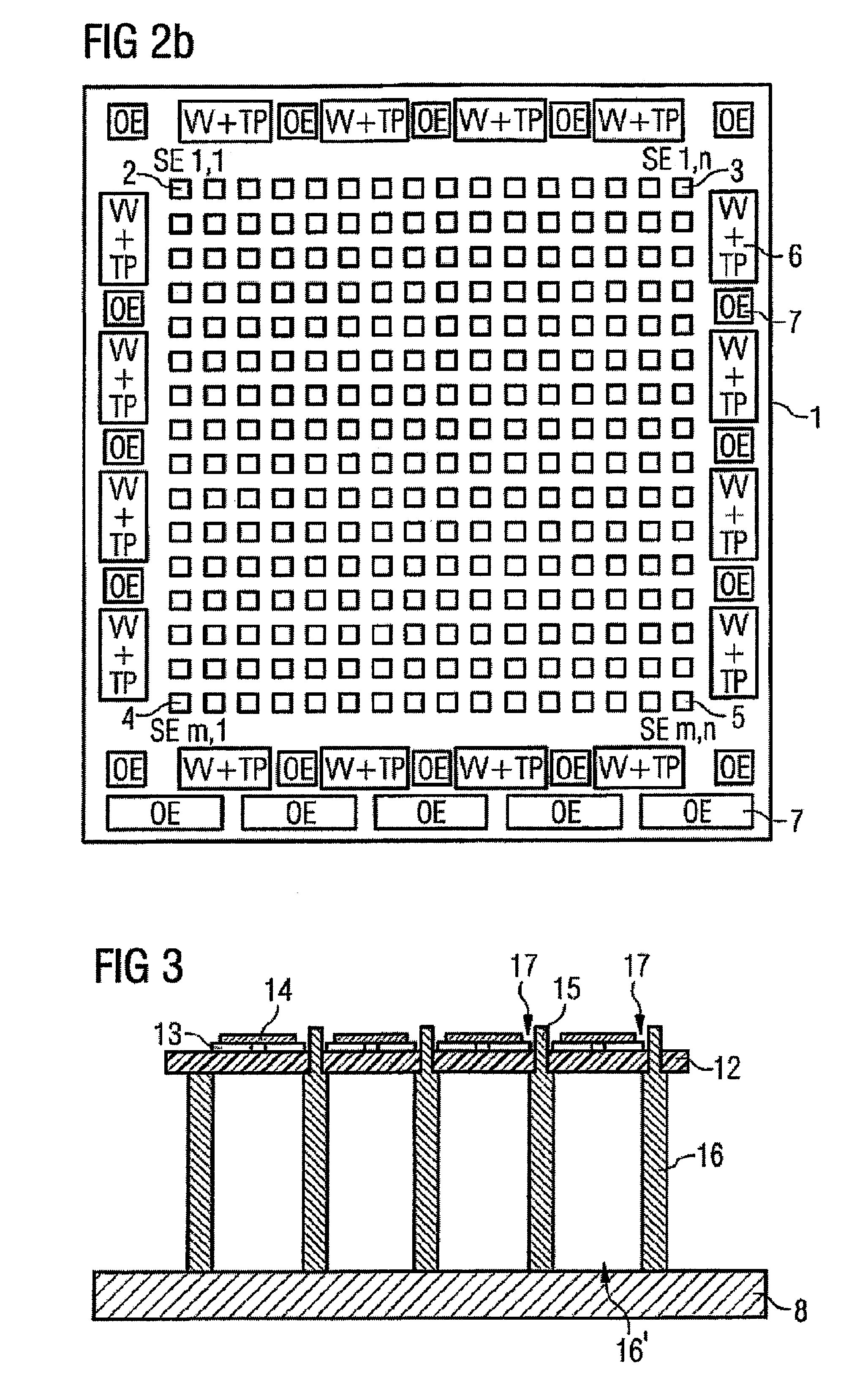

Thermopile infrared sensor array

ActiveUS7842922B2Increase capacityPower Loss MinimizationTelevision system detailsThermoelectric device with peltier/seeback effectSensor arrayLow-pass filter

A thermopile infrared sensor array, comprises a sensor chip with a number of thermopile sensor elements, made from a semiconductor substrate and corresponding electronic components. The sensor chip is mounted on a support circuit board and enclosed by a cap in which a lens is arranged. The aim is the production of a monolithic infrared sensor array with a high thermal resolution capacity with a small chip size and which may be economically produced. The aim is achieved by arranging a thin membrane made from non-conducting material on the semiconductor substrate of the sensor chip on which the thermopile sensor elements are located in an array. Under each thermopile sensor element, the back side of the membrane is uncovered in a honeycomb pattern by etching and the electronic components are arranged in the boundary region of the sensor chip. An individual pre-amplifier with a subsequent low-pass filter may be provided for each column and each row of sensor elements.

Owner:HEIMANN SENSOR GMBH

Tactile tile product for the visually impaired, method of manufacture and methods of conducting business therewith

The present invention provides a tactile tile comprising hemispherical outward protruding domes on an upper surface for pedestrian traffic, and a plurality of longitudinal and transverse members integral with each other and integral with a bottom side of the tile opposite the upper surface forming a honeycomb pattern.

Owner:WEHMEYER DONALD

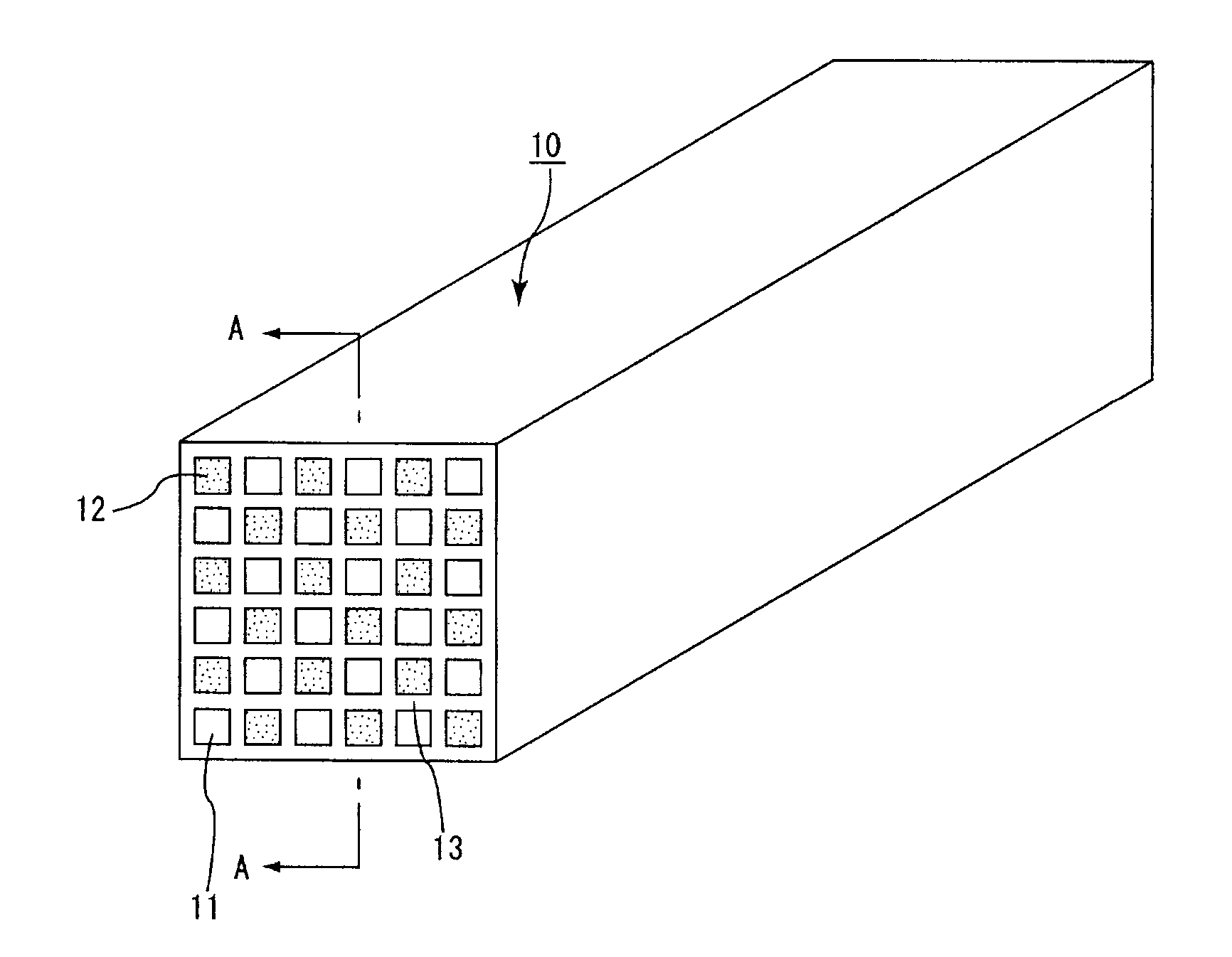

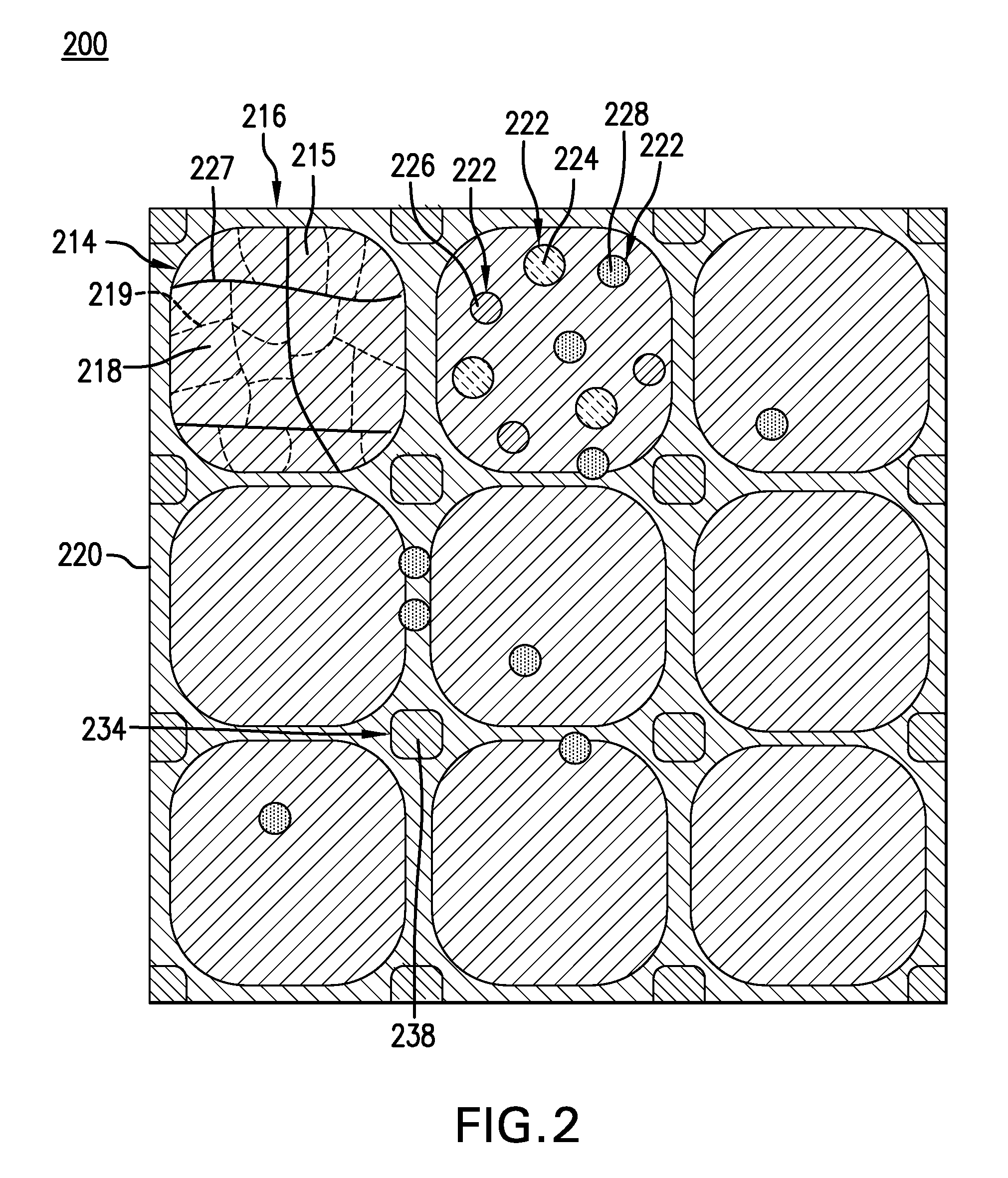

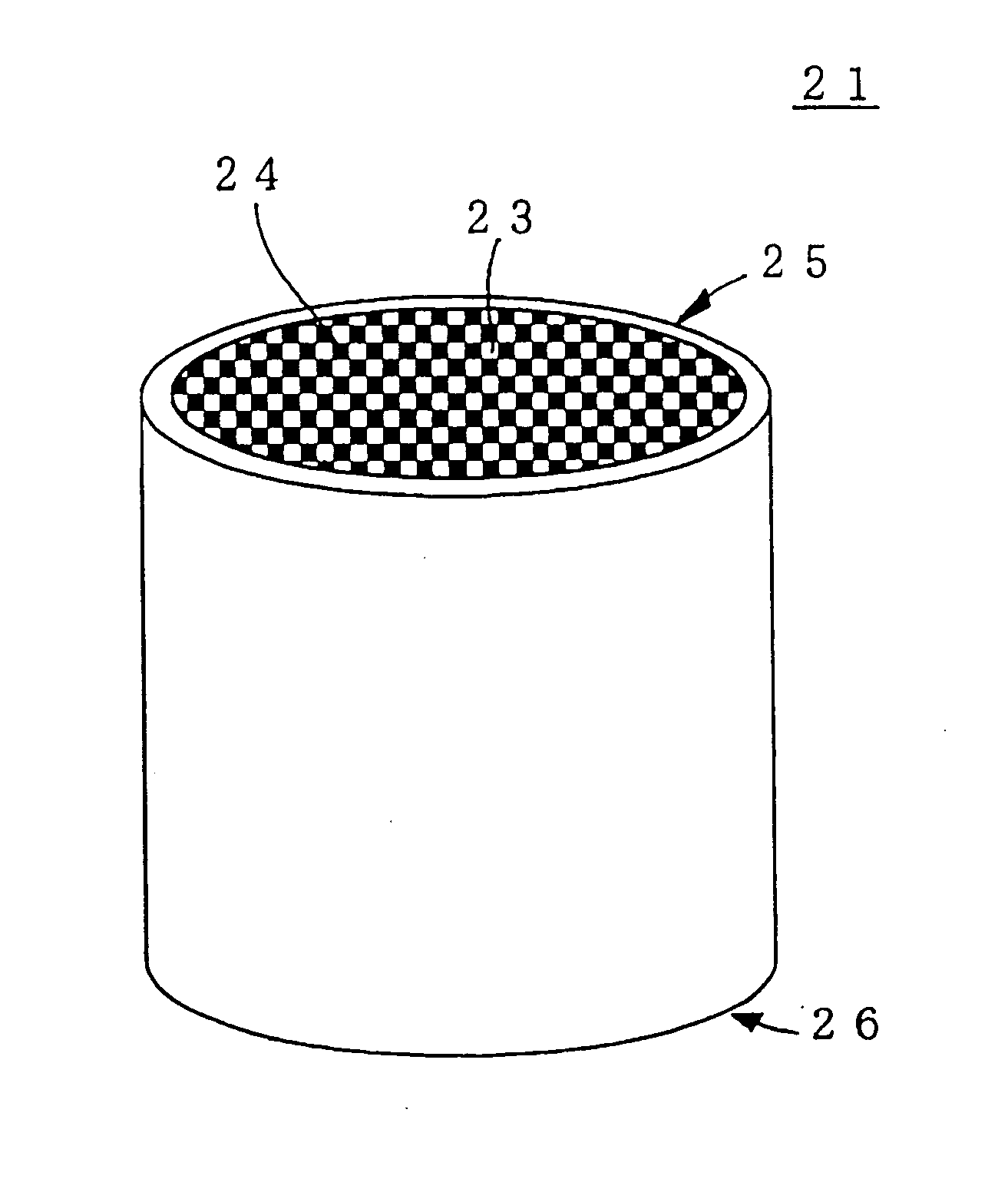

Honeycomb structure

ActiveUS20050050845A1Physical/chemical process catalystsDispersed particle filtrationInorganic particleHoneycomb Pattern

The present invention provides a honeycomb structure in which a plurality of honeycomb segments each constituted by a cell structure having a plurality of cells divided from each other by partition walls and functioning as a passage for fluid and an outer wall provided at the circumference of the cell structure are bonded to each other at the outer walls by a bonding layer made of a bonding agent and converted into one piece, which honeycomb structure is characterized in that the bonding agent does not contain inorganic particles having diameters (μm) of at least 1.1 times the average surface roughness Ra (μm) of the outer wall, in an amount exceeding 30% by mass relative to the total of the bonding agent. In the honeycomb structure, the honeycomb segments as a constituent are strongly bonded to each other by a bonding agent and converted into one piece.

Owner:NGK INSULATORS LTD

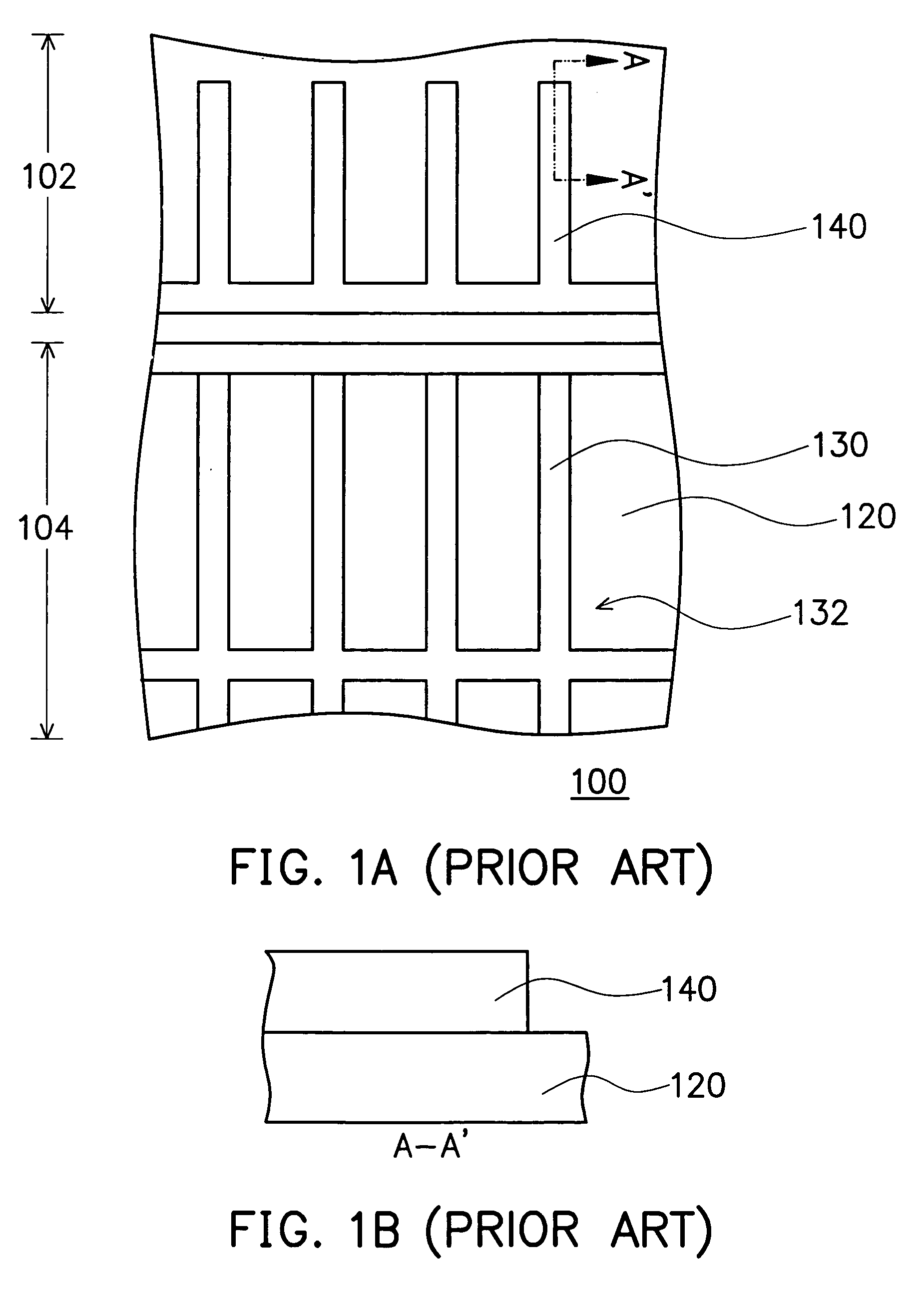

Pixel cells in a honeycomb arrangement

ActiveUS20070034884A1Promote conversionTelevision system detailsSolid-state devicesHoneycomb PatternColor filter array

The present invention, in the various exemplary embodiments, provides a RGB color filter array. The red, green and blue pixel cells are arranged in a honeycomb pattern. The honeycomb layout provides the space to vary the size of pixel cells of an individual color so that, for example, the photosensor of blue pixels can be made larger than that of the red or green pixels. In another aspect of the invention, depicted in the exemplary embodiments, the honeycomb structure can also be implemented with each pixel rowing having a same color of pixel cells which can simplify can conversion in the readout circuits. In another aspect of the invention, the RGB honeycomb pixel array may be implemented using a shared pixel cell architecture.

Owner:APTINA IMAGING CORP

Fiber bundles and methods of making fiber bundles

InactiveUS7236671B2Easily fixtured in deviceIncrease the number ofLaser detailsOptical fibre with multilayer core/claddingFiber bundleHoneycomb Pattern

The present invention relates to fiber bundles and methods for making fiber bundles. According to one embodiment of the invention, a fused fiber bundle has a terminal section ending with an endface, and includes a plurality of optical fibers, each of the optical fibers having a terminal segment ending with a proximal end, and a distal end; and a cellular holding structure, the cellular holding structure including a cellular web portion having a plurality of longitudinal cells arranged substantially in parallel and surrounded by a web material; and a tube portion surrounding the cellular web portion. The terminal segments of the optical fibers are arranged substantially in parallel, and the terminal segment of each optical fiber is disposed in a longitudinal cell of the cellular holding structure and substantially fused to the web material, thereby forming the terminal section of the fused fiber bundle.

Owner:CORNING INC

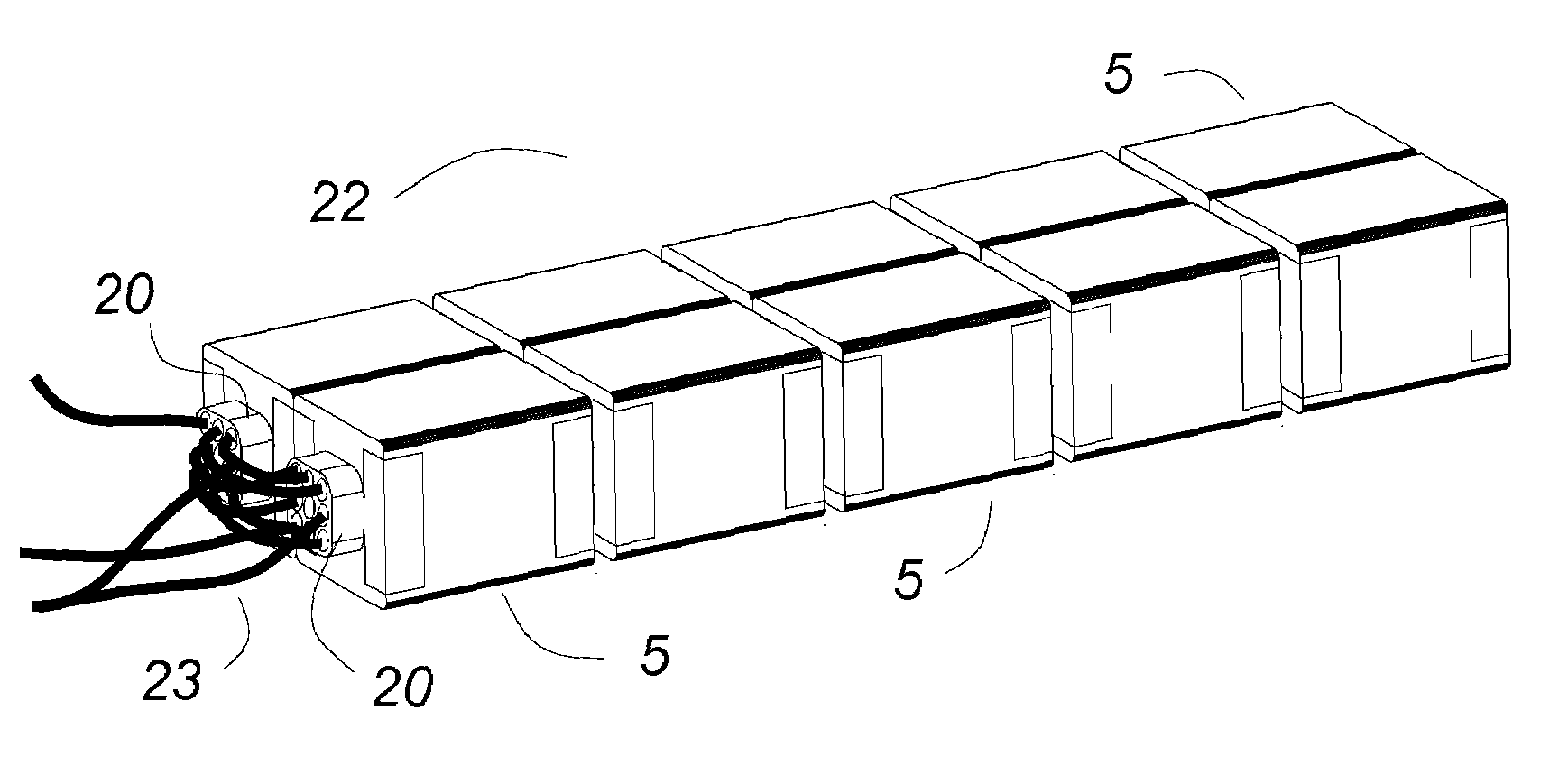

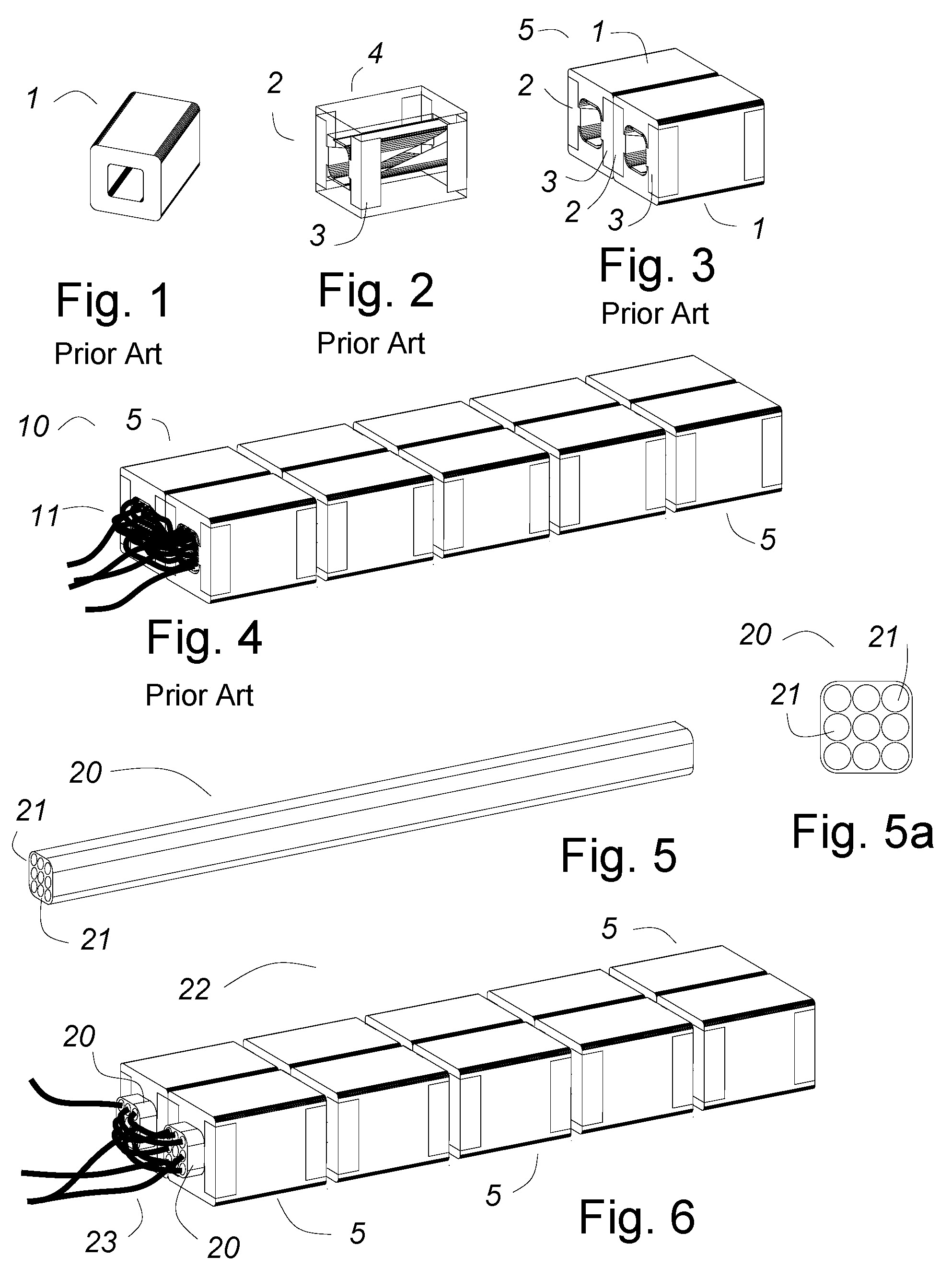

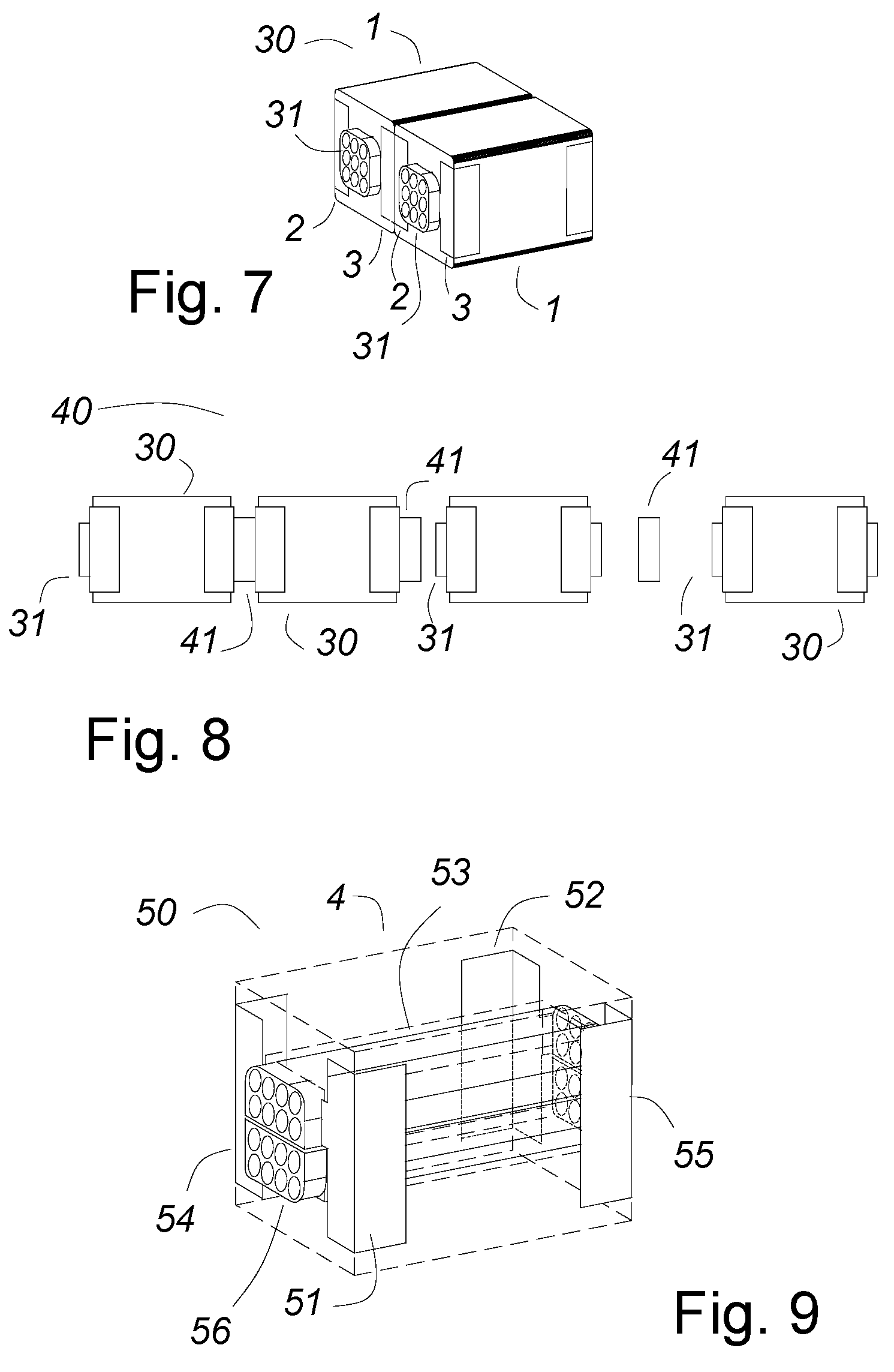

Cellular transformers

InactiveUS7023317B1Winding simpleTransformers/inductances coils/windings/connectionsFixed transformersElectrical conductorHoneycomb Pattern

The winding of matrix transformers having multiple turn primary windings is made much easier, and the resulting transformer is much more consistent, if a “cellular” insert having a plurality of through holes is placed through each trough hole of the matrix transformer. Preferably, there is one hole in the cellular insert for each wire, though two or more wires can be placed in each hole. In one embodiment, insulating cellular inserts are placed through the entire length of the cellular transformer to guide and locate the primary windings. In another embodiment, each element of the cellular transformer has cellular inserts, and the elements are coupled together. In another embodiment, the cellular insert is a conductor and is part of the secondary circuit.

Owner:HERBERT EDWARD

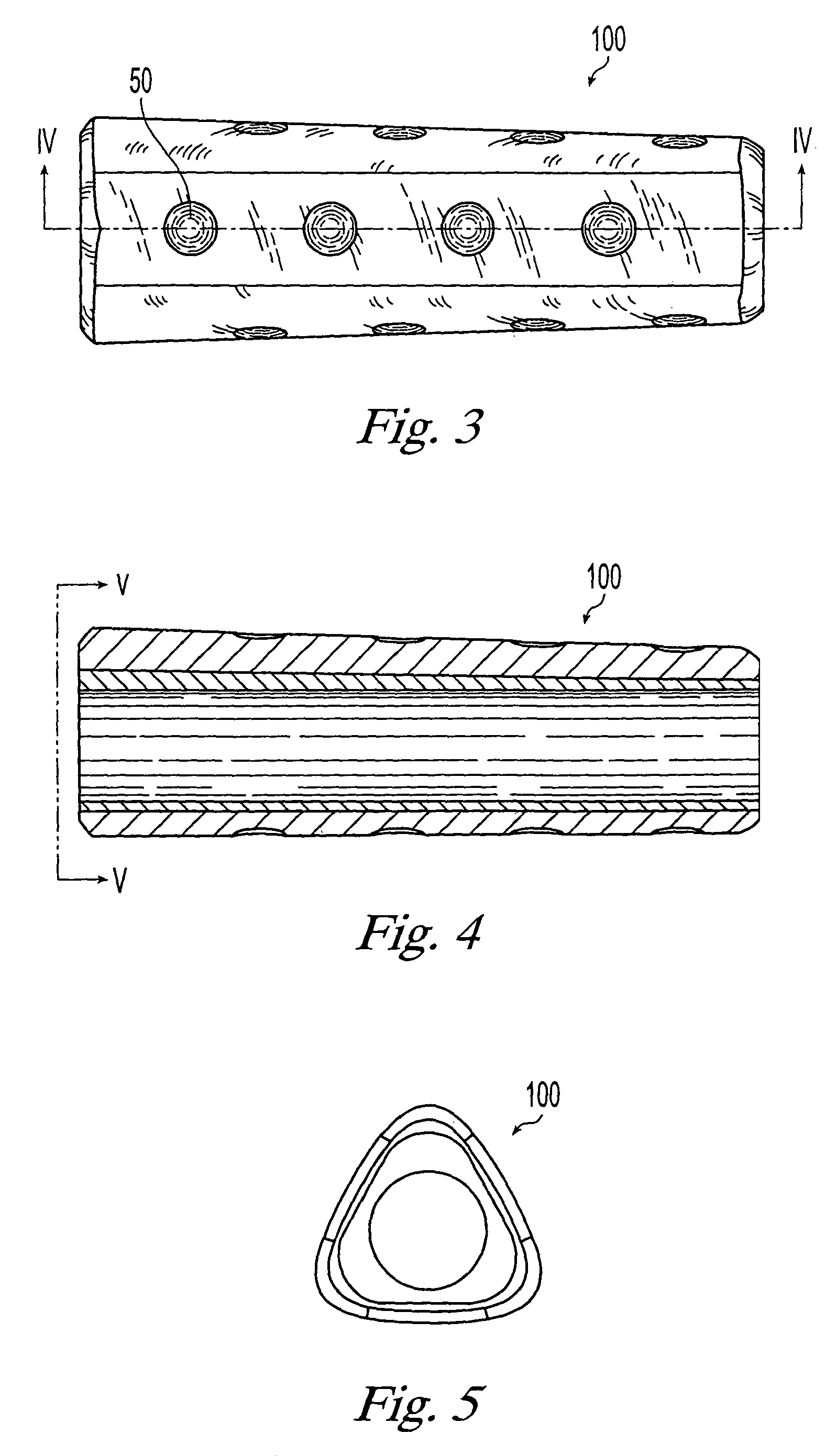

Grip element

InactiveUS7141197B2Improve productivityAvoid insufficient lengthWriting connectorsMouldsCushioningHoneycomb Pattern

A grip element having a soft, compressible and deformable outer layer supported by an underlying support structure sufficiently rigid to maintain a receiving channel of the grip element in an open configuration. The support structure facilitates manipulation of the grip element and assembly of the grip element onto a hand-held article without having the outer layer collapse on itself as would occur without the support structure as a result of the soft, deformable nature of the outer layer. The grip element may be formed separately from the hand-held article on which it is to be assembled, and then positioned thereon such that the hand-held article is sold with the grip element pre-assembled thereon. If desired, the grip element may be provided separate from the hand-held article, the outer layer providing a readily compressible and deformable soft cushioning surface and the support structure facilitating insertion of the outer layer over at least a portion of a hand-held article. The outer layer and support structure may be co-molded such that the materials thereof are permanently and directly bonded together. If desired, a pattern may be formed on the outer layer, such as grooves, dimples, ribs, bumps, a lattice pattern, or a honeycomb pattern.

Owner:SOC DITE SOC BIC

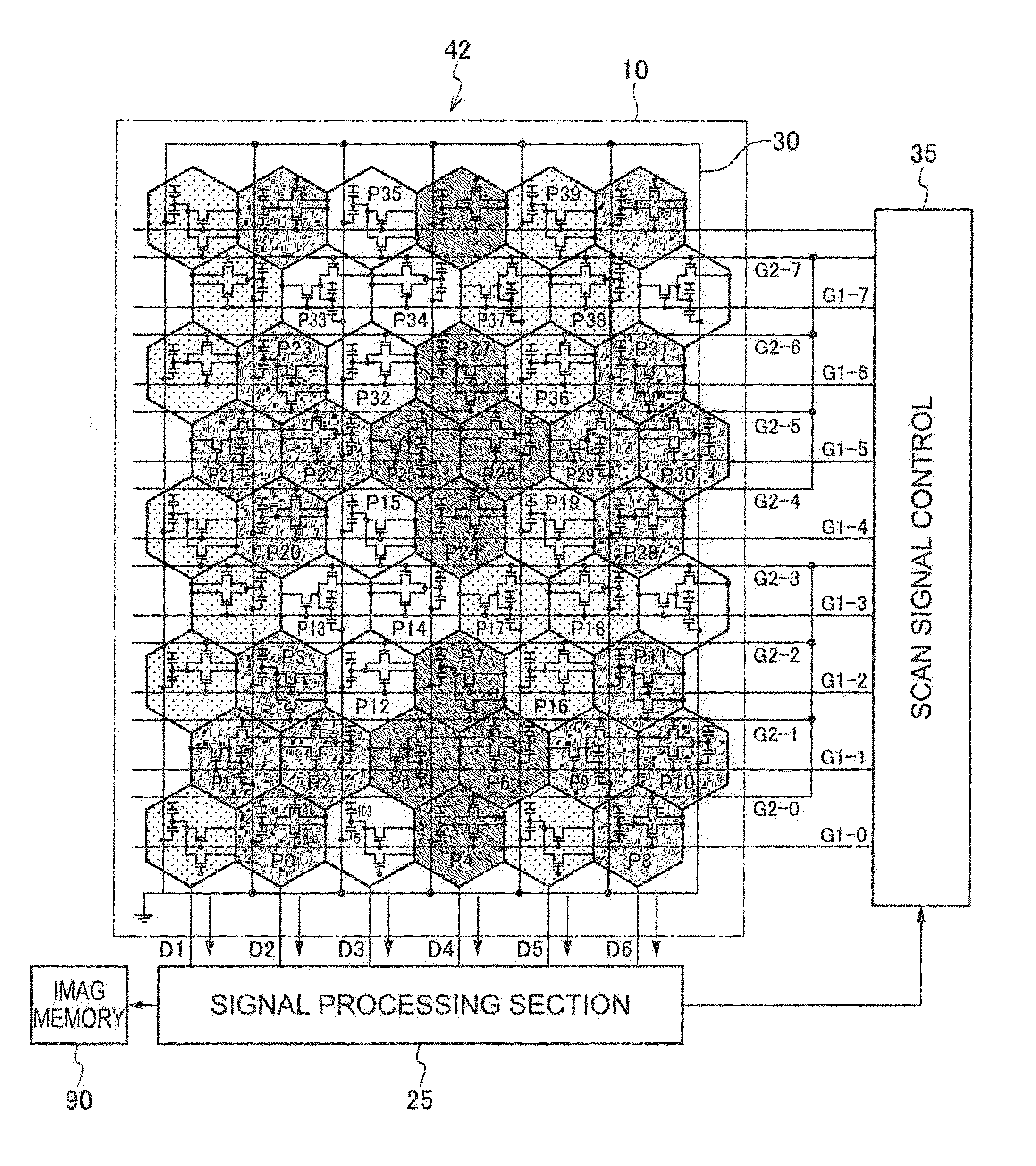

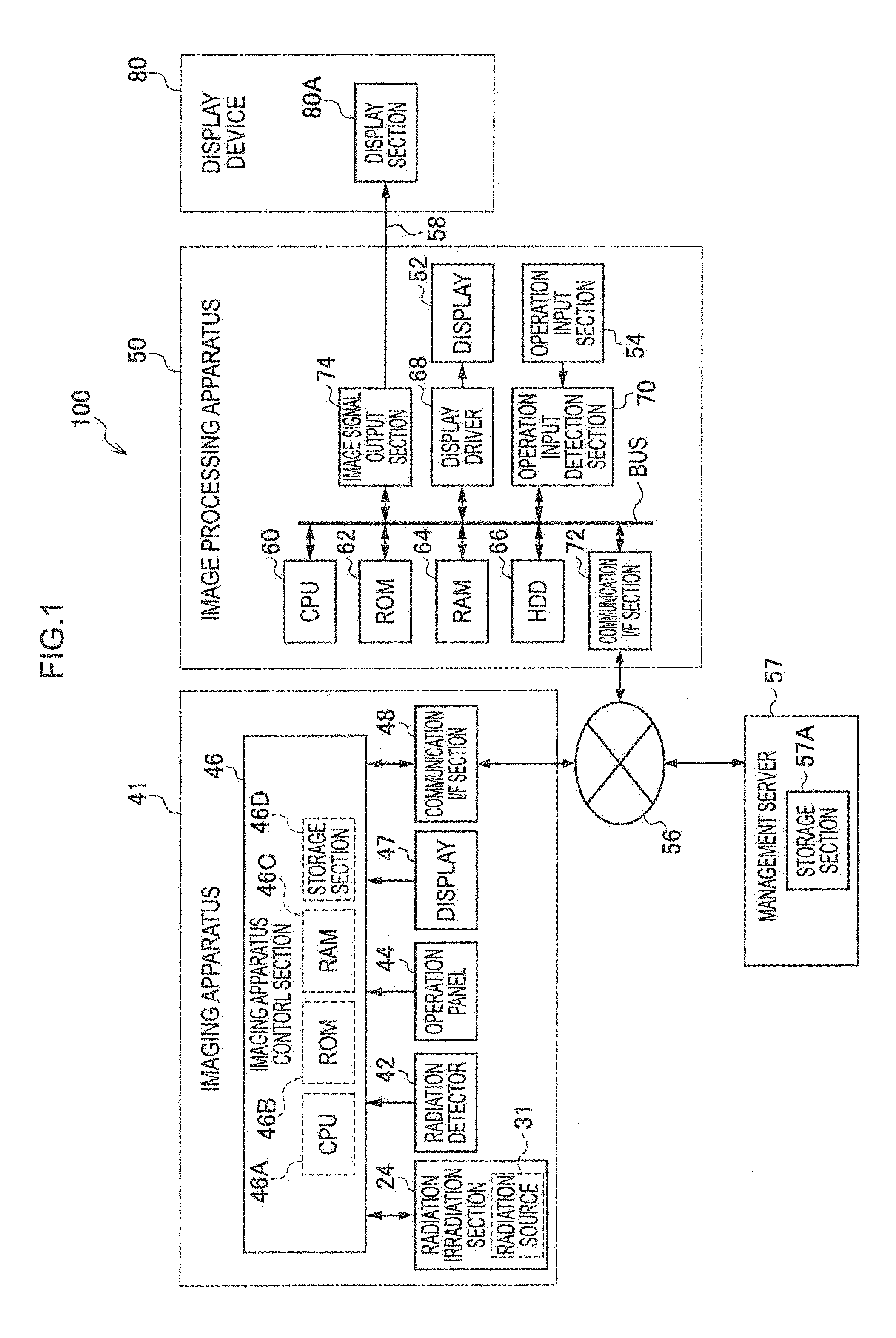

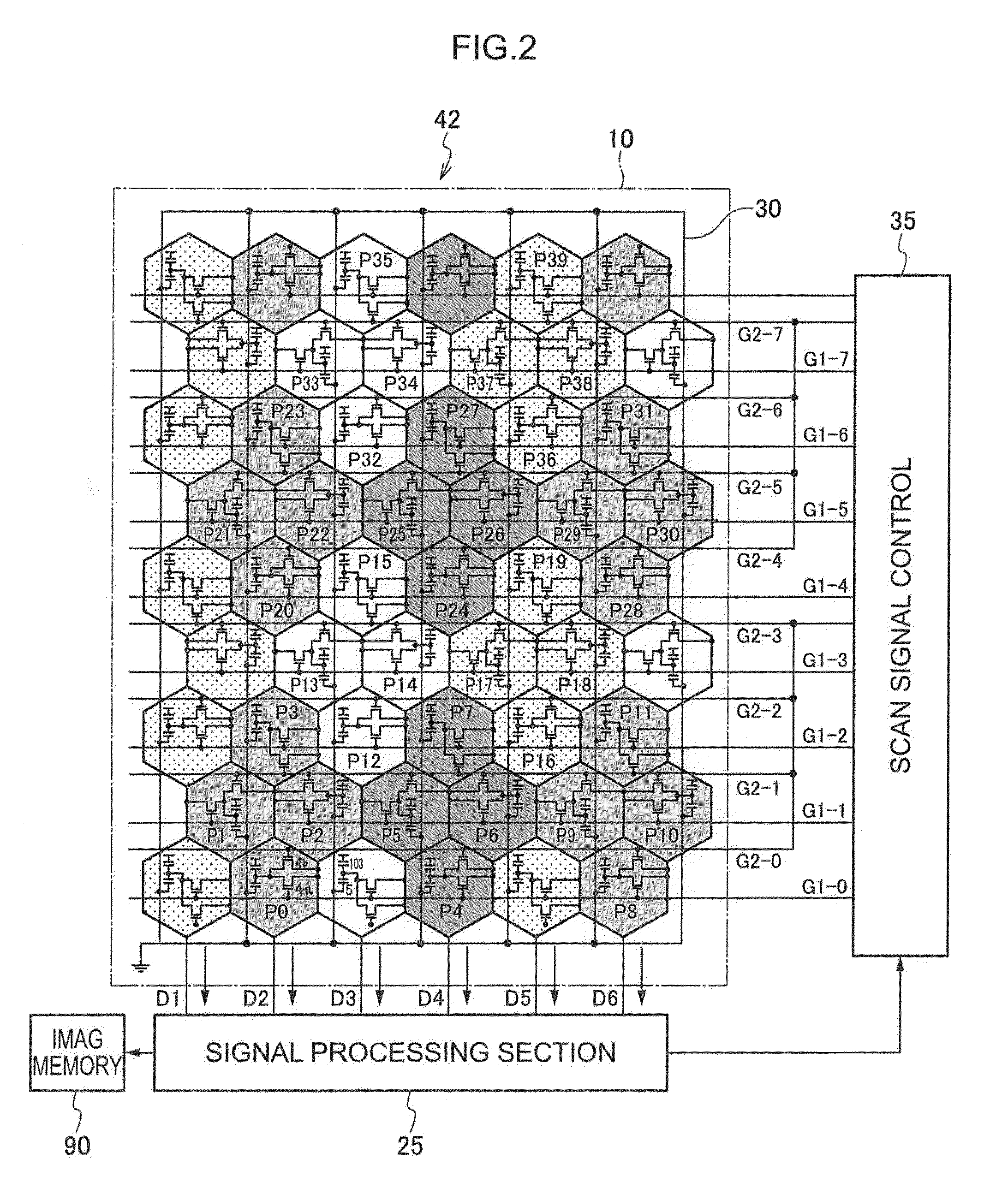

Radiographic image detector, radiographic imaging apparatus, radiographic imaging system

ActiveUS8879686B2Faster rateUniform resolutionTelevision system detailsRadiation/particle handlingScan lineImage resolution

The present invention provides a radiographic image detector that may maintain even resolution in 6 directions before and after 3-pixel binning process or 4-pixel binning process. A radiation detector is disposed with plural pixels that have hexagonal shaped pixel regions, arrayed in a honeycomb pattern. Scan lines connected to TFT switches in each of the pixels are disposed one for each of the pixel rows. Grouped scan lines are also disposed one for each of the pixel rows for reading and combining 3 pixels or 4 pixels worth of charges at the same timing for plural pixel groups, each configured from 3 pixels or 4 pixels in a radiation detection element. ON signals are simultaneously sent by the grouped scanned lines to the TFT switches to perform 3-pixel binning or 4-pixel binning.

Owner:FUJIFILM CORP

Honeycomb ordered titanium dioxide nanotube array film and preparation method thereof

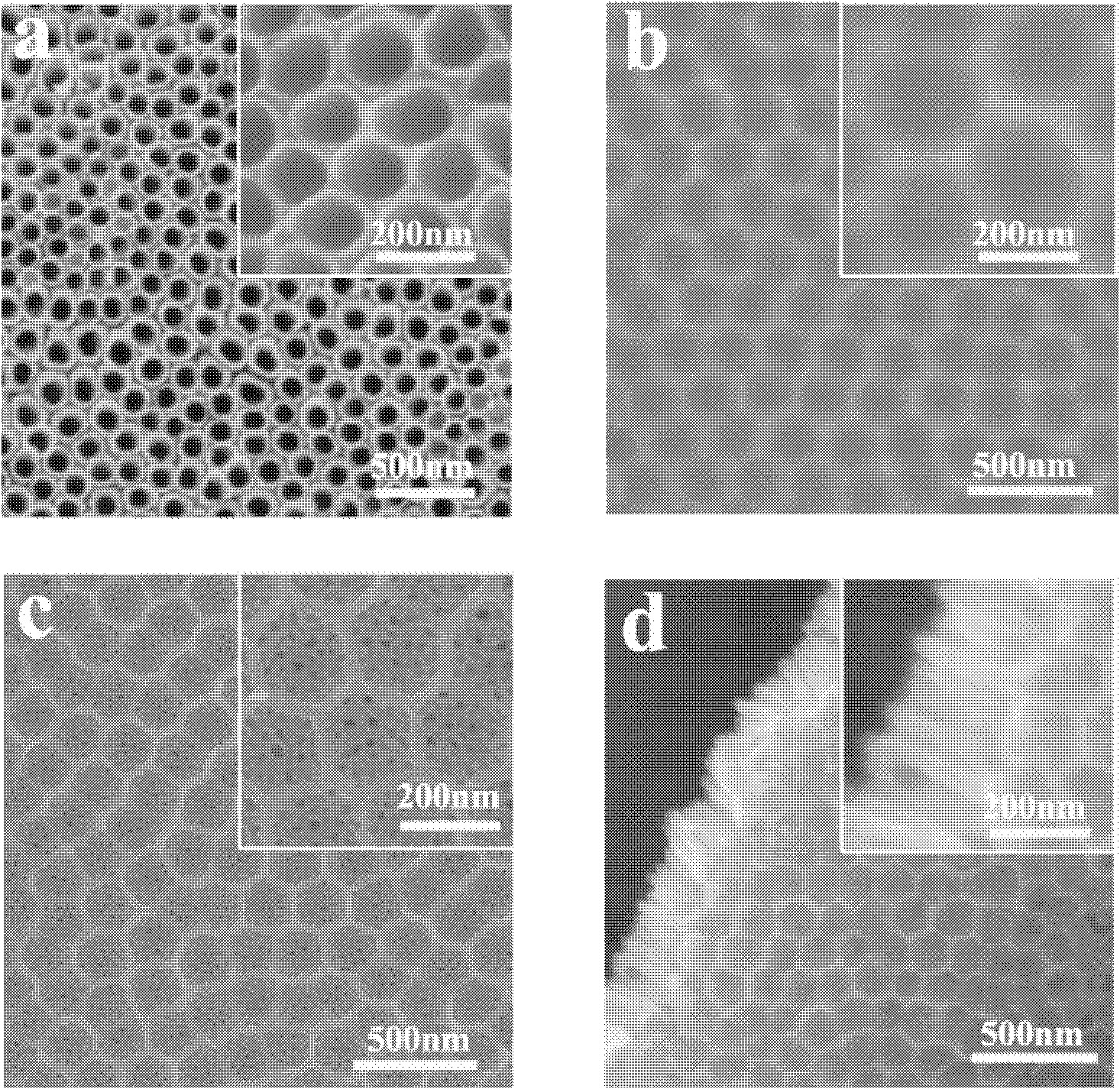

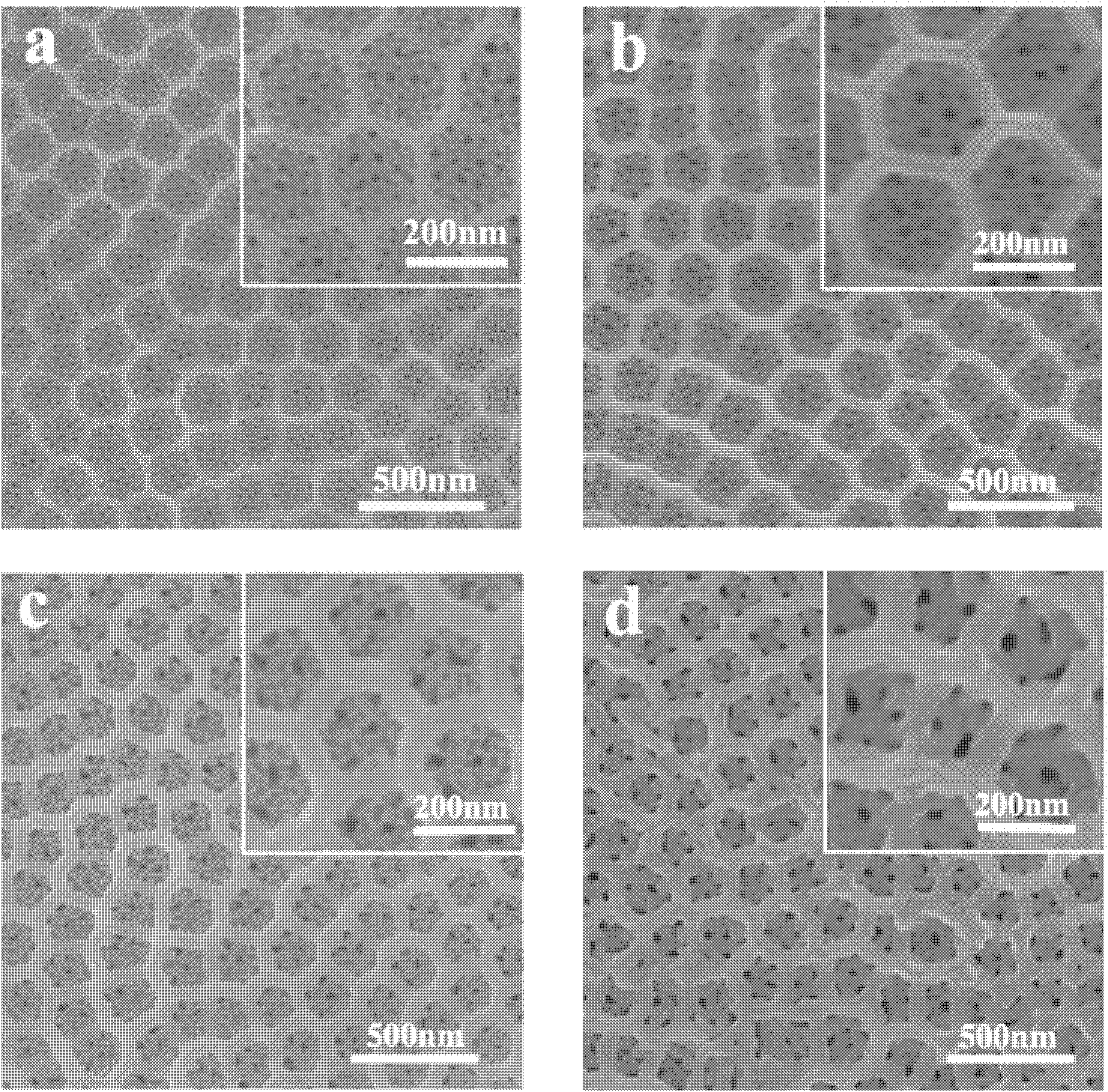

InactiveCN102191529AGood size controlEasy to operatePolycrystalline material growthSurface reaction electrolytic coatingPhotonicsHoneycomb structure

The invention discloses a honeycomb ordered titanium dioxide nanotube array film and a preparation method thereof. The honeycomb ordered titanium dioxide nanotube array film consists of an upper-layer ordered structure and a lower-layer ordered structure, namely an upper-layer large-diameter regular hexagonal titanium dioxide nanopore array and a lower-layer small-diameter titanium dioxide nanotube array, wherein a low-layer nanotube orifice end is positioned in upper-layer titanium dioxide nanopores and the upper-layer nanopores are communicated so as to form a honeycomb structure. The method is easy to operate, equipment is cheap, and parameters of the structure can be effectively controlled by changing the oxidation voltage and the oxidation time of an anode; moreover, titanium dioxidewith the hierarchical structure can be widely applied to dye-sensitized solar cells, gas sensors, hydrogen preparation from water by photodecomposition, and photonic crystals.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

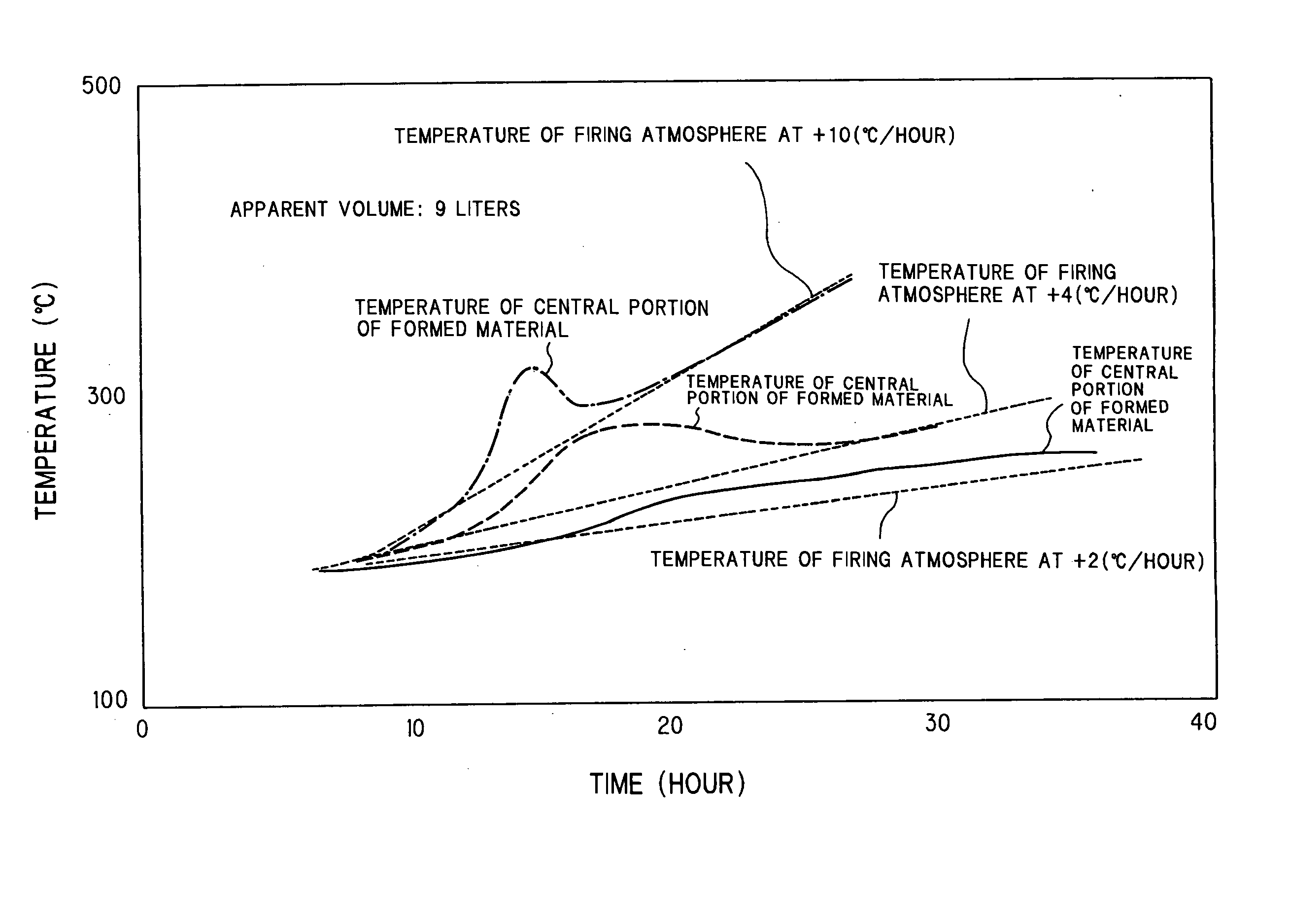

Method of baking ceramic honeycomb structure

InactiveUS20050253311A1Shorten ignition timePrevent firing defectsExhaust apparatusSilencing apparatusMetallurgyHoneycomb Pattern

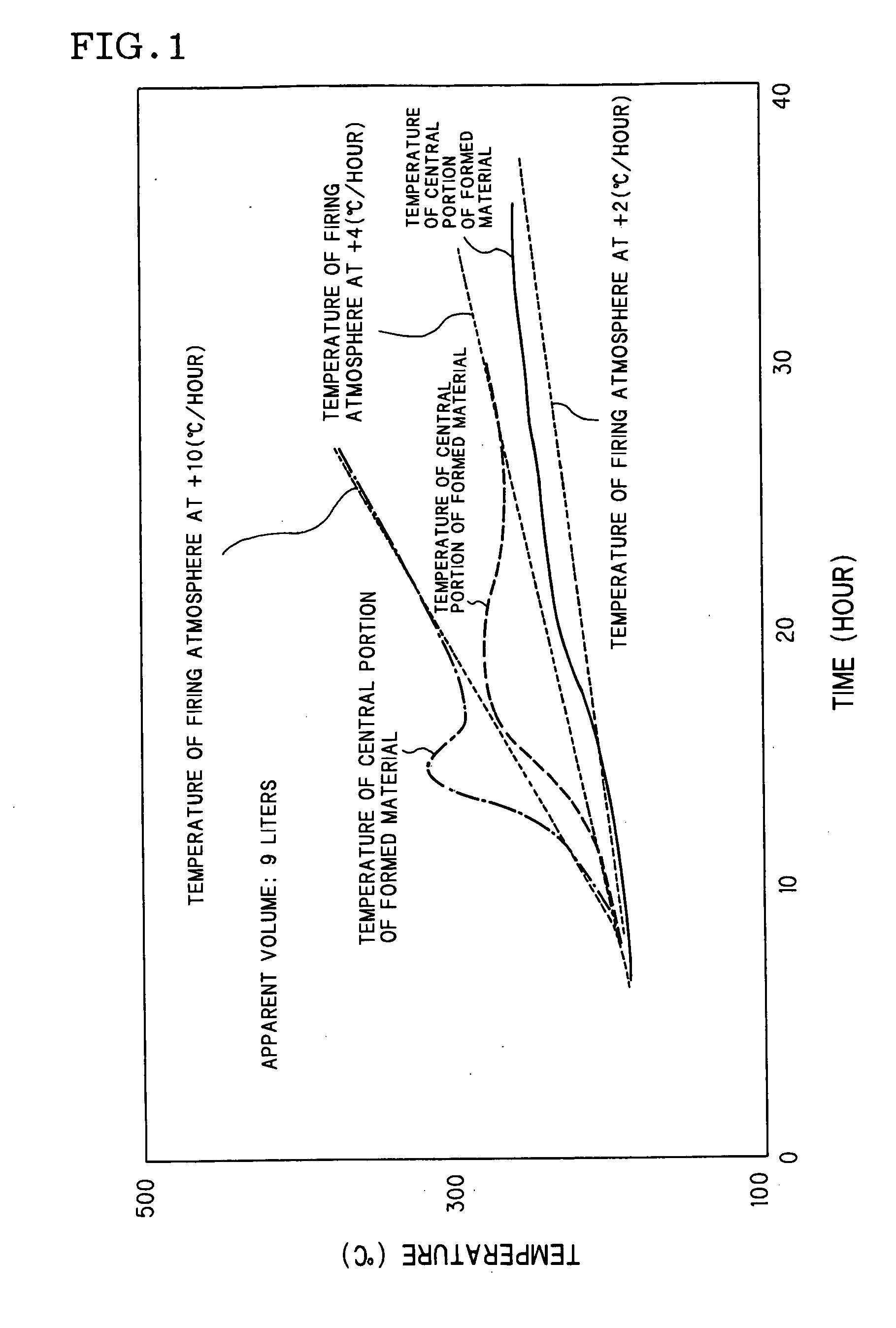

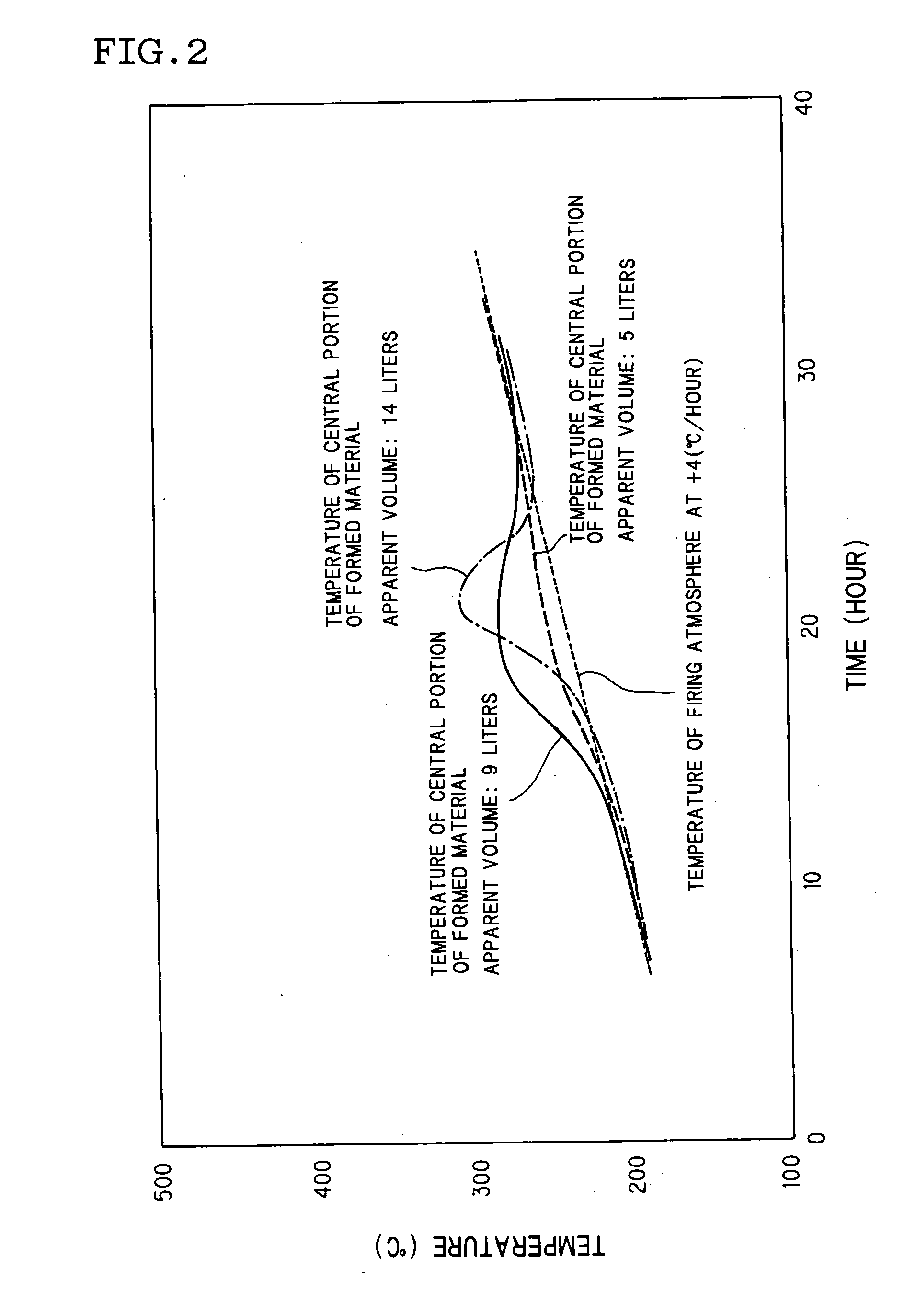

In the method for firing of ceramic honeycomb structure according to the present invention, when a formed honeycomb material having an apparent volume of 5 liters or more is fired in a firing atmosphere, the heating of the firing atmosphere from a temperature (180 to 300° C.) at which the organic binder contained in the formed honeycomb material begins to burn, to 300° C. is conducted at a temperature elevation rate of +25 (° C. / hr) or more and also at such a temperature elevation rate that the difference of the temperature of the central portion of the formed honeycomb material from the temperature of the firing atmosphere is kept in a given temperature range.

Owner:NGK INSULATORS LTD

Method for compounding solid netted black porcelain sunlight absorbing layer on ceramic solar panel

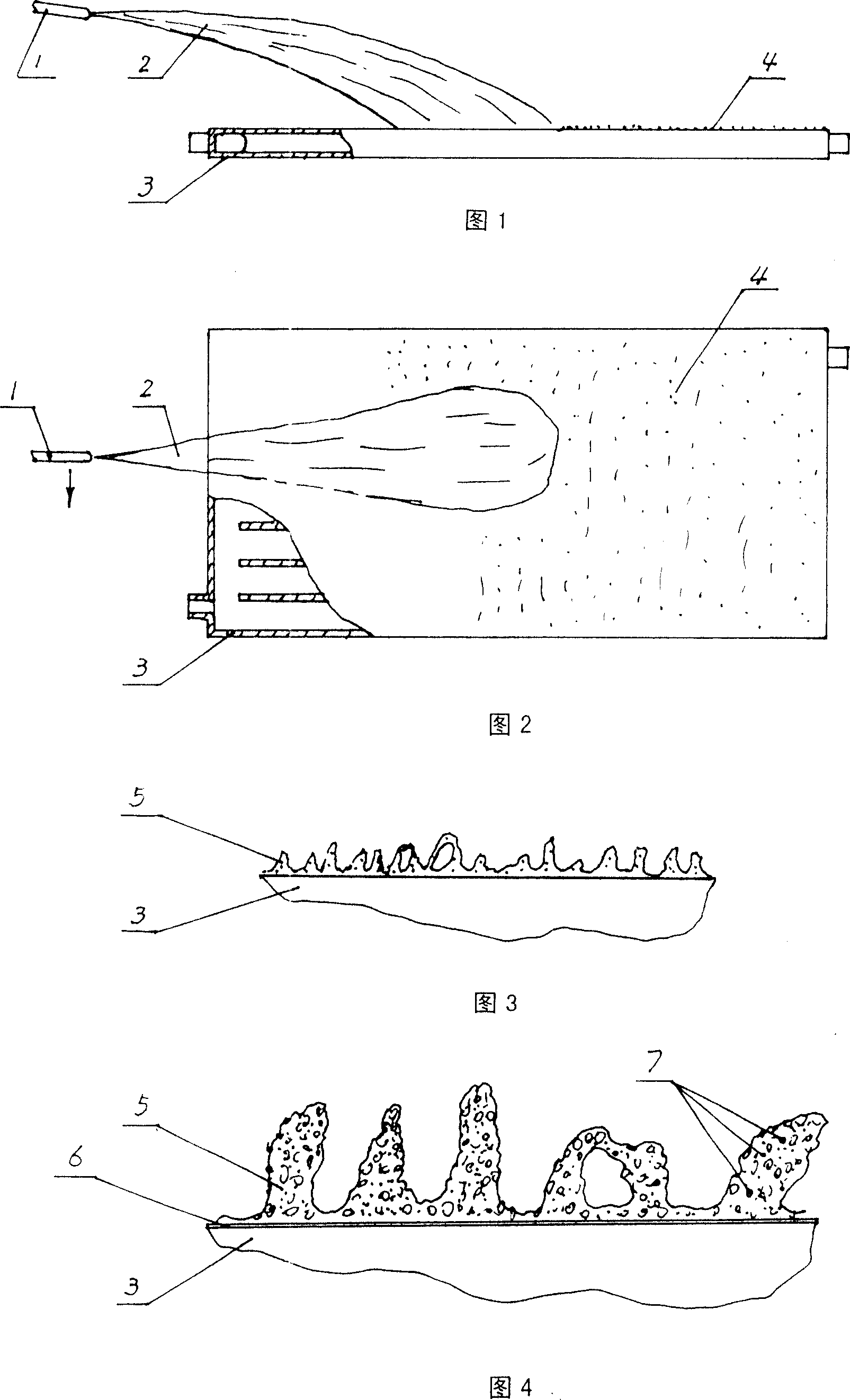

The present invention relates to a method for compounding solid reticular black porcelain sunlight absorbing layer on ceramic solar plate, wherein, industrial waste residues and metal minerals rich in the transition elements in fourth period are used as main raw materials to be ground into slurry; the slurry is sprayed on the dry surface of a green body of a hollow ceramic solar plate through compressed air by adopting a single spray gun or a plurality of spray guns; the pressure and the flow rate of the compressed air and the proportion of the slurry are controlled, so as to lead fog drops in initial contact with the dry green body surface of the ceramic solar plate to form mud particles which have a certain strength, are relatively dry and adhere to the surface of the green body plate because of the fast water absorption of the dry green body and the surface tension of the fog drops; the subsequently sprayed fog drops first meet the mud particles which have a certain moisture absorption ability and protrude from the surface, and then the fog drops adhere to the mud particles, thus the heteropic incontinuous fog drop mud accumulation bodies which are in columnar shapes, steeple shapes, vertical wall shapes, honeycomb shapes or porous shapes, have moisture absorbed and have a certain strength are accumulated in turn; spraying is stopped before the solid accumulation bodies reach to a certain height and lose moisture absorption ability, thereby getting a solid reticular black porcelain green body layer on the surface of the hollow ceramic solar green body plate; the hollow ceramic green body plate having the solid reticular black porcelain green body layer is dried and fired under high temperature; the firing temperature and time are controlled to ensure that the solid reticular black porcelain green body layer and the green body of a hollow ceramic solar plate are simultaneously sintered into a solid reticular black porcelain layer and a porcelain hollow solar.

Owner:SHANDONG TIANHONG CAMBERED PLATE

Bionic honeycomb-type plate sheet for plate-type heat exchanger

InactiveCN102435086AEfficient heat exchangeImprove heat exchange efficiencyLaminated elementsConvex structureHoneycomb

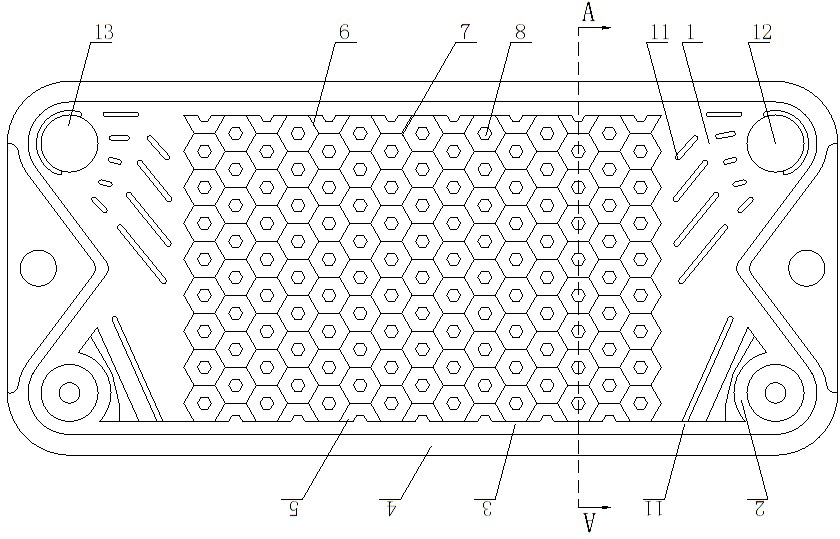

The invention discloses a bionic honeycomb-type plate sheet for a plate-type heat exchanger, comprising a flow guiding region, a sealing region, a honeycomb region and a frame, wherein the honeycomb region is composed of a plurality of peripheral regular hexagons which are sequentially connected with each other in longitudinal and transverse directions, so as to form a honeycomb shape; a plurality of peripheral regular hexagons are uniformly and densely distributed on the bionic honeycomb-type plate sheet; a central regular hexagon is arranged at the center of each peripheral regular hexagon and the central regular hexagon is in a protruding structure; a connecting part between two peripheral regular hexagons is in a protruding structure and a ripple-like structure is formed by connection of connecting parts among the plurality of the peripheral regular hexagons; and a flow channel is formed by the peripheral regular hexagons between each protruding central regular hexagon and the ripple-like structure. According to the invention, the fluid is interfered by the flow channel and concave-convex structures of the central regular hexagons and the ripple-like structure in the process of flowing in a hollow cavity, and the heat-exchanging efficiency is improved; and the dense honeycombs such a plurality of I beams, which are mutually limited, can dispersedly bear pressure from a panel, so as to increase the use condition and range of the plate sheet.

Owner:广州汇迪新能源科技有限公司

Liquid repellent structure, method of producing the same, liquid ejection head and protective film

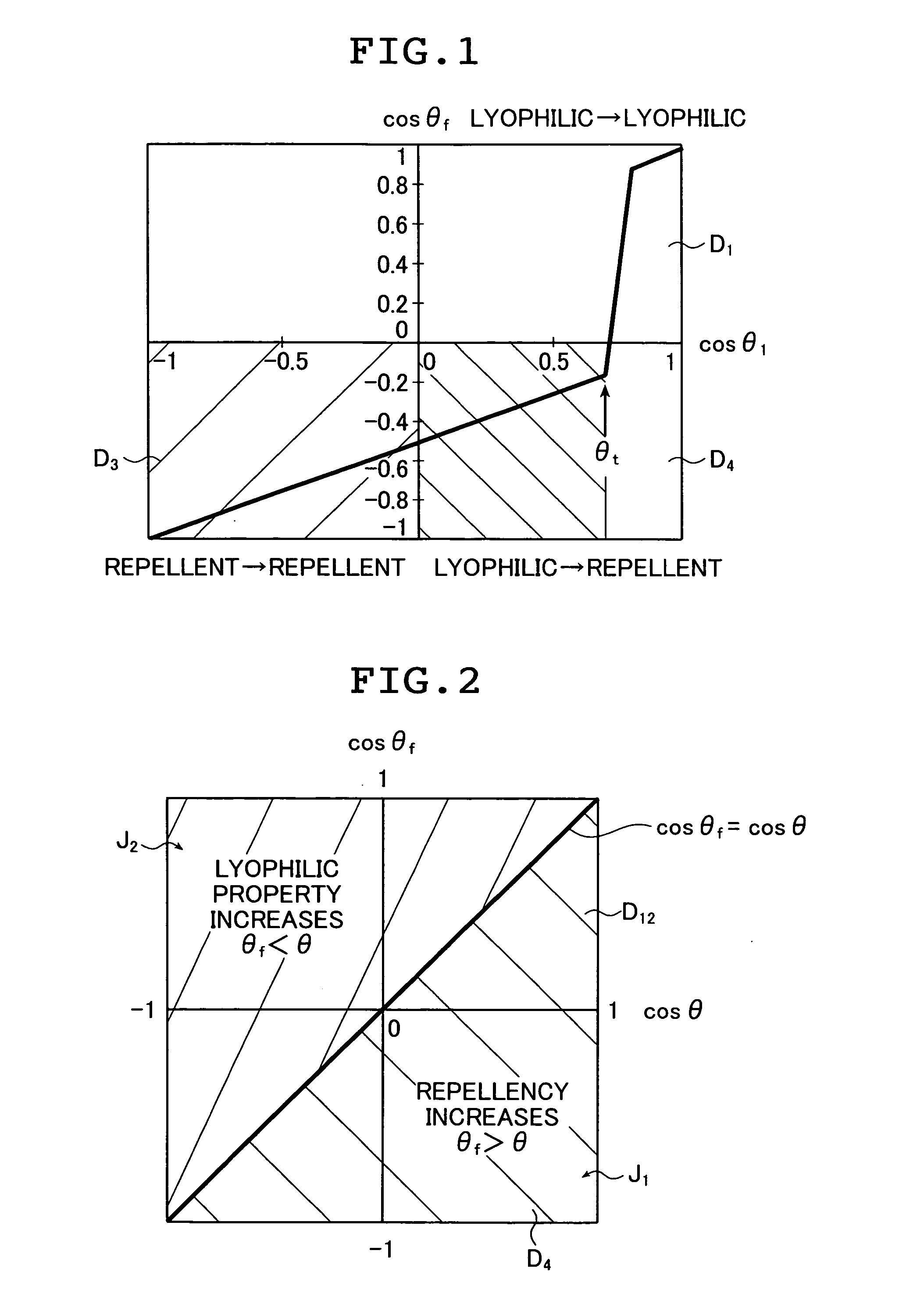

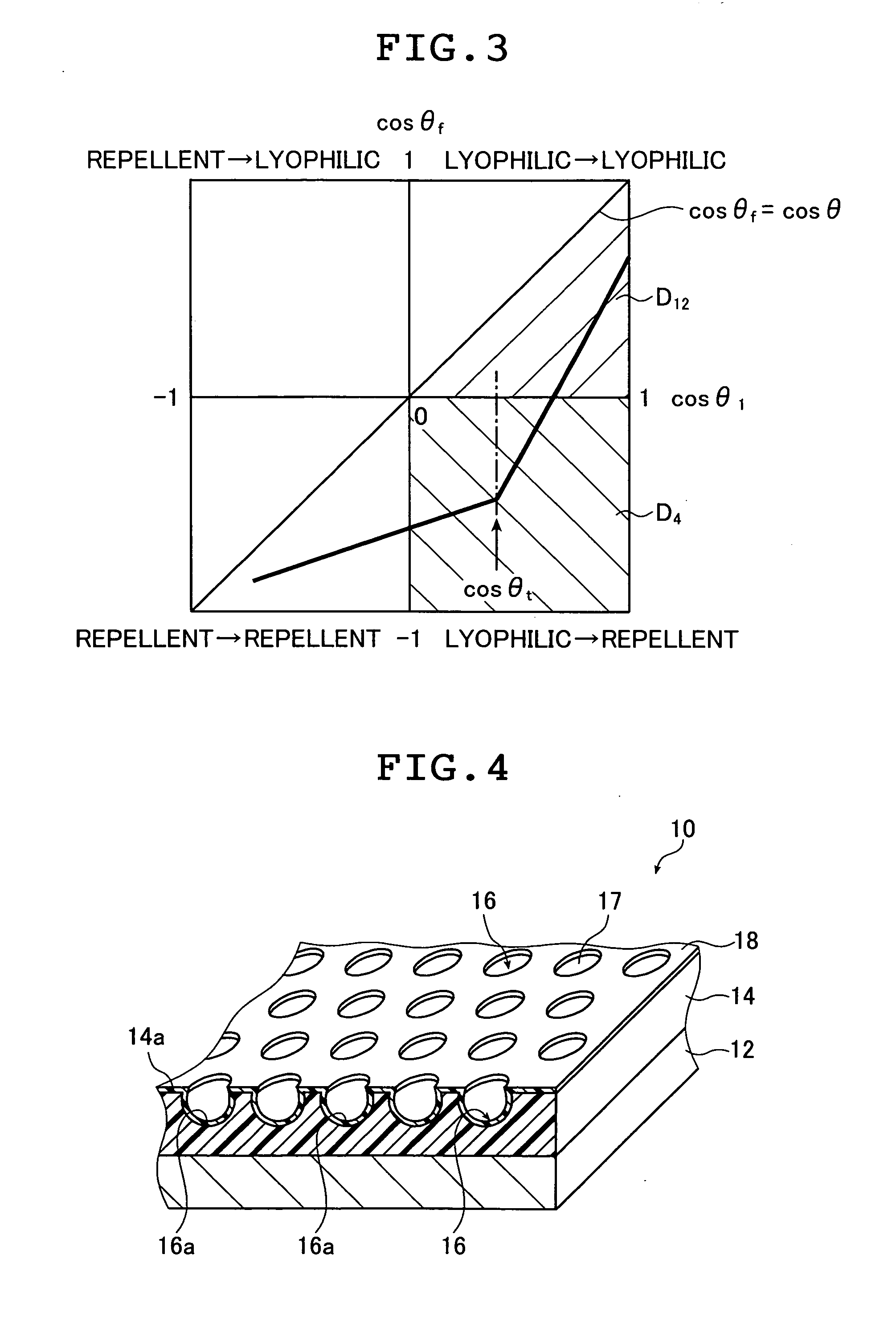

InactiveUS20070160790A1Increase repulsionIncrease contact angleMovable spraying apparatusSynthetic resin layered productsTectorial membraneSimple Organic Compounds

The liquid repellent structure includes a support, and a honeycomb-patterned film and a coating film on the honeycomb-patterned film or a liquid repellent film. The method of producing the structure applies a solution of an organic compound in an organic solvent onto the support, places the support in an atmosphere containing water vapor to form water droplets on a surface of the solution film, evaporates the organic solvent and the droplets to form the honeycomb-patterned film, and forms the coating film made of a fluorine-containing material on a surface of the honeycomb-patterned film or etches the honeycomb-patterned film to form a second honeycomb-patterned film. The liquid ejection head includes an ejection substrate having the liquid repellent structure. The protective film includes a support base and the liquid repellent structure.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com