Method for drying materials by utilizing superheated steam

A superheated steam and drying technology, which is applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of low production efficiency, difficulty in large-scale industrial use of drying methods, and low thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

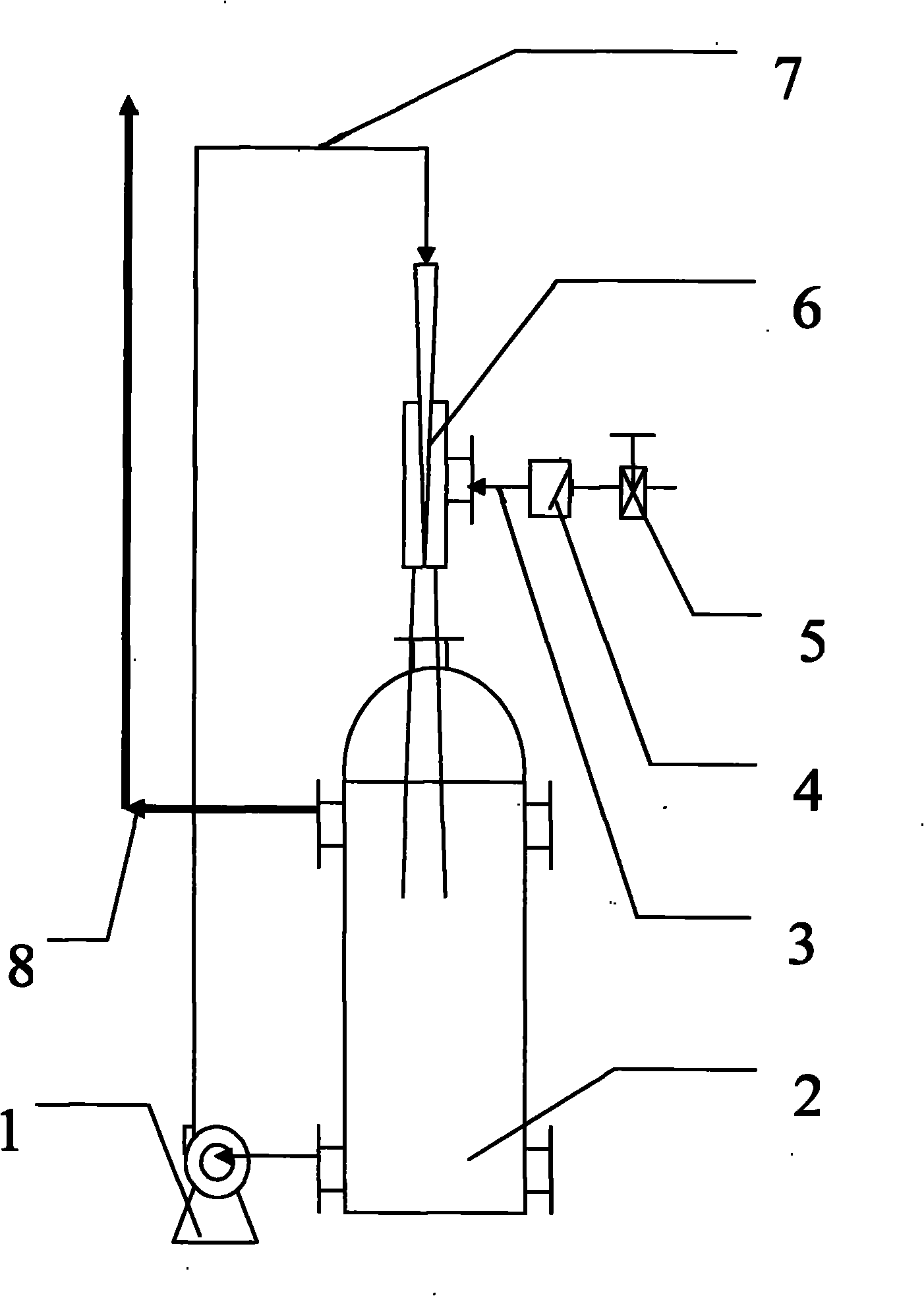

[0021] In step a: the material to be dried is placed in a closed container. The main purpose of this is to recover all the drying medium and water vapor after the moisture of the material to be dried is evaporated into water vapor.

[0022] Add superheated steam into the airtight container, and use superheated steam to evaporate the moisture contained in the material to be dried, so that the moisture will generate water vapor, and the superheated steam will be lowered in temperature and pressure to become low-temperature steam. The present invention uses superheated steam as the drying medium, which has four advantages. One is that the water vapor has strong thermal conductivity and heat carrying capacity. In a closed container, higher steam pressure can be used, which greatly increases the amount of drying medium. High production efficiency can be obtained. The second is that the moisture of the material to be dried evaporates into water vapor, which is the same substance as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com