Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Simple drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

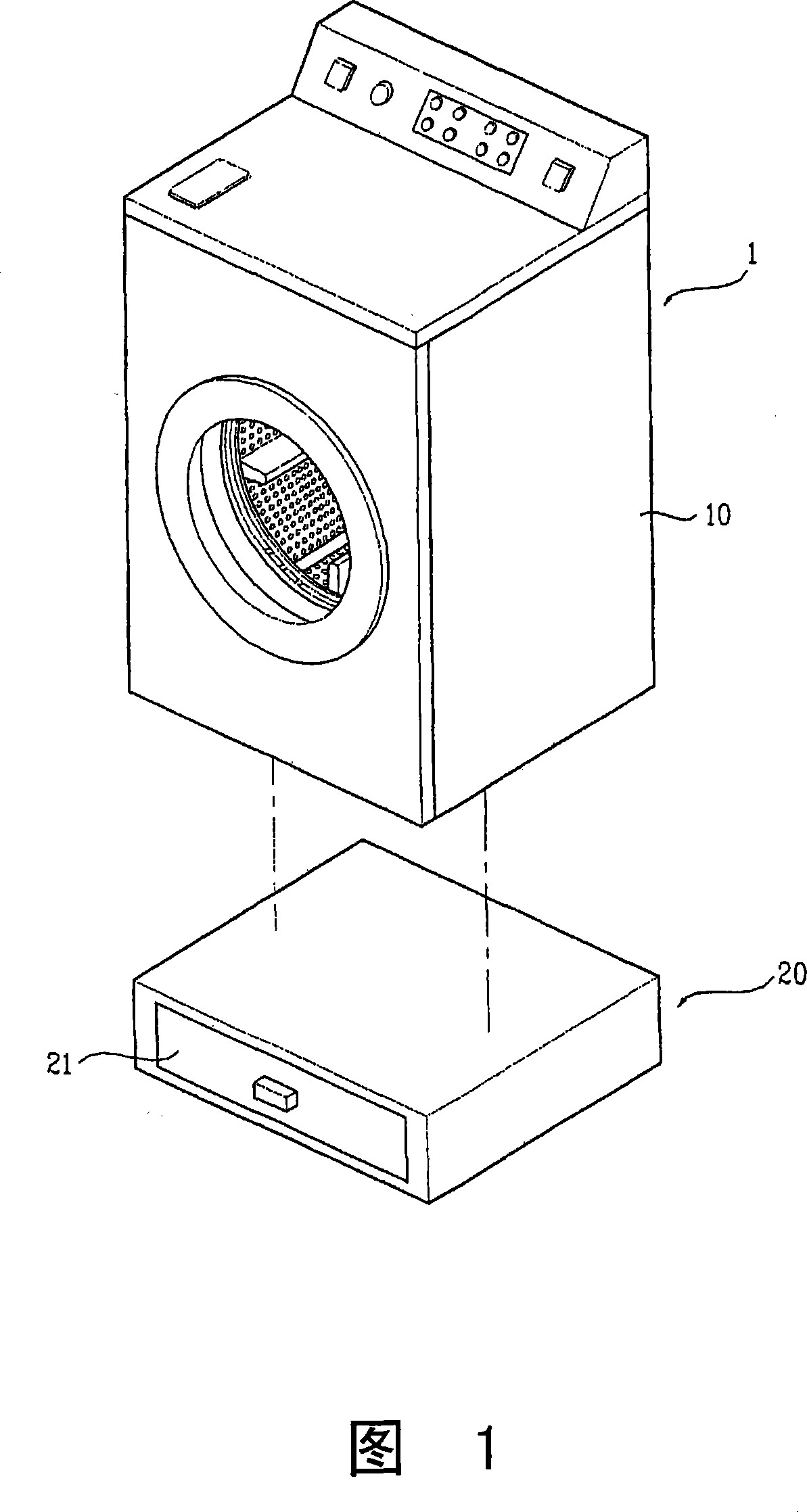

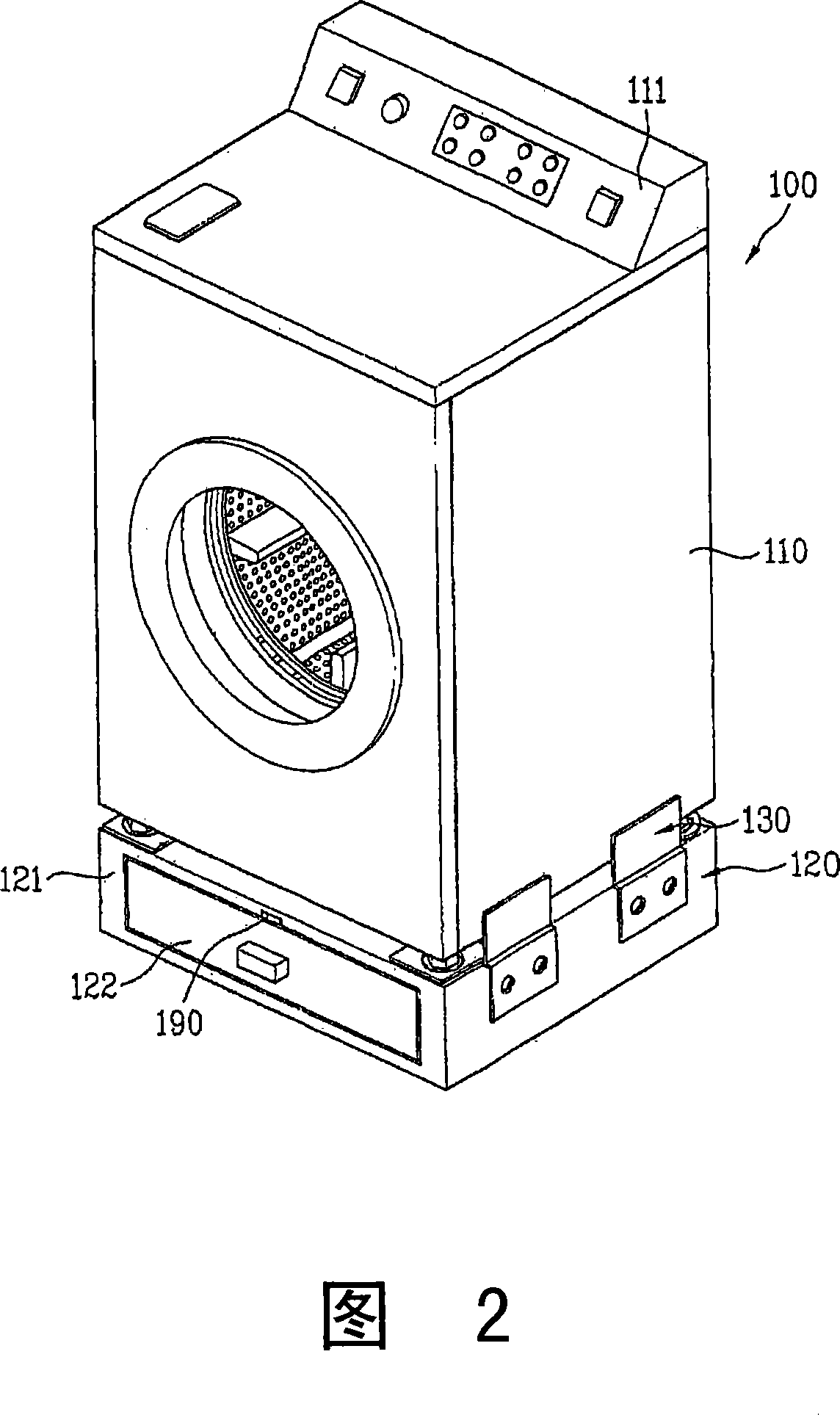

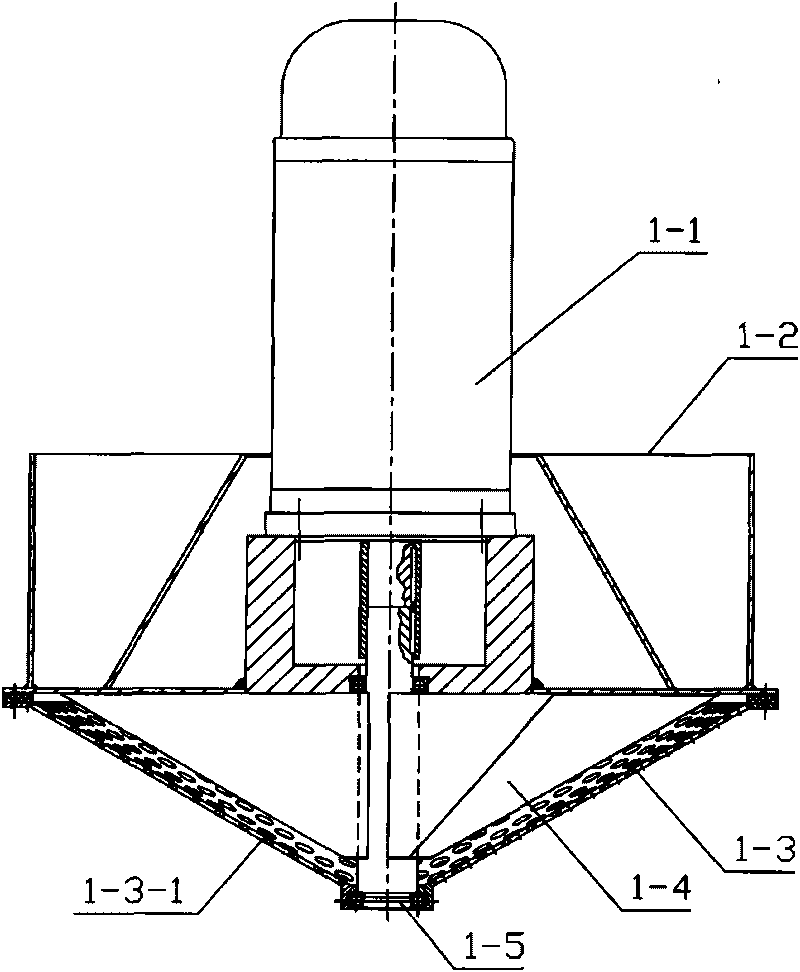

Auxiliary dryer and complex laundry machine including the same

ActiveCN101153456AEnsure normal communicationAvoid safety accidentsOther washing machinesWashing machine with receptaclesLaundryLarge size

An auxiliary dryer and a complex laundry machine are disclosed, by which a laundry machine having a relatively large size can be conveniently operated to save energy in a manner of handling a small laundry and the like without out driving the laundry machine. The present invention includes a body having a laundry accommodating part for accommodating a laundry therein, a hot air supplying means provided within the body to supply hot air to the laundry accommodating part, and a safety means for preventing a safety accident from being caused to a user by the hot air supplying means.

Owner:LG ELECTRONICS INC

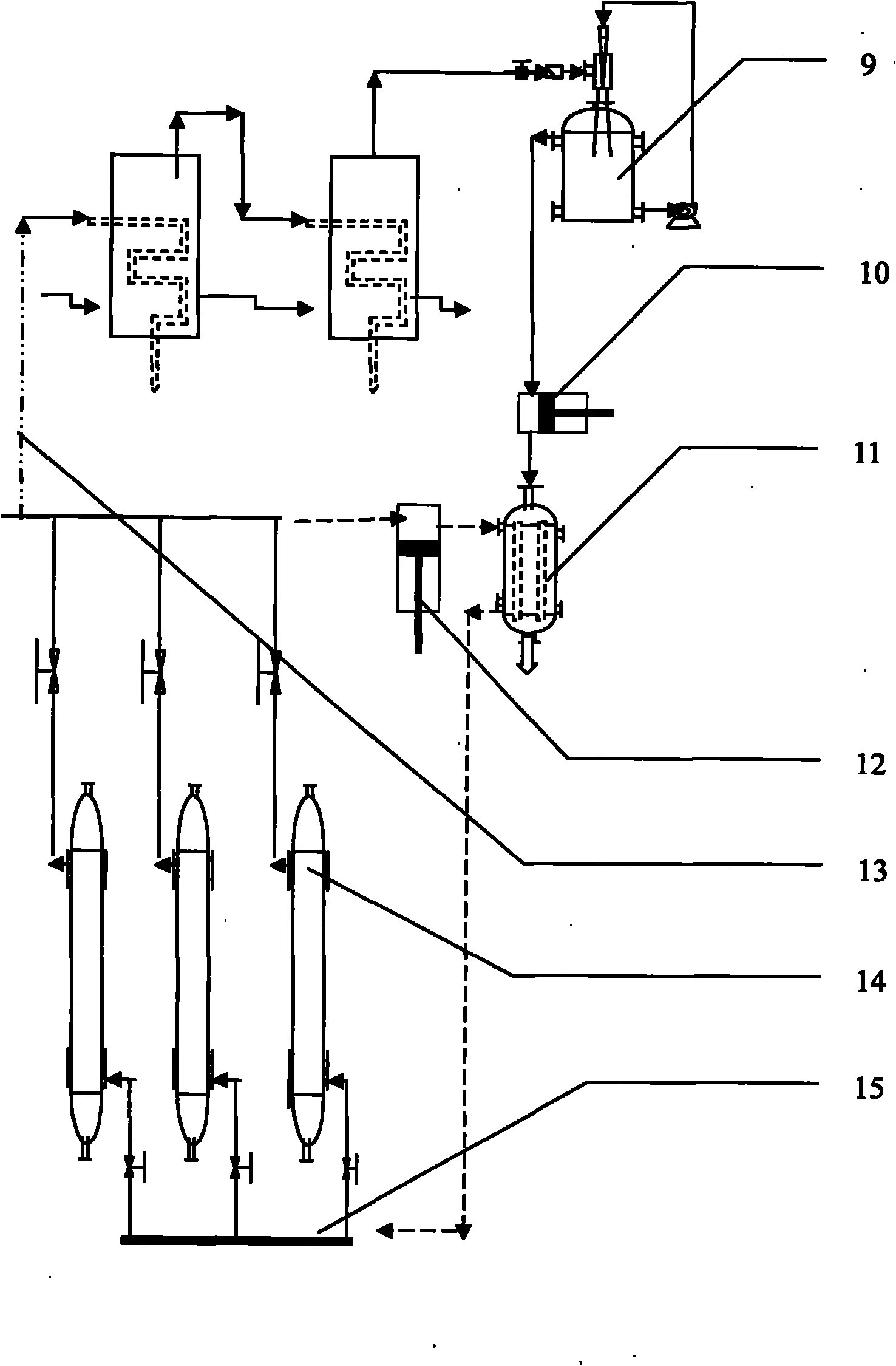

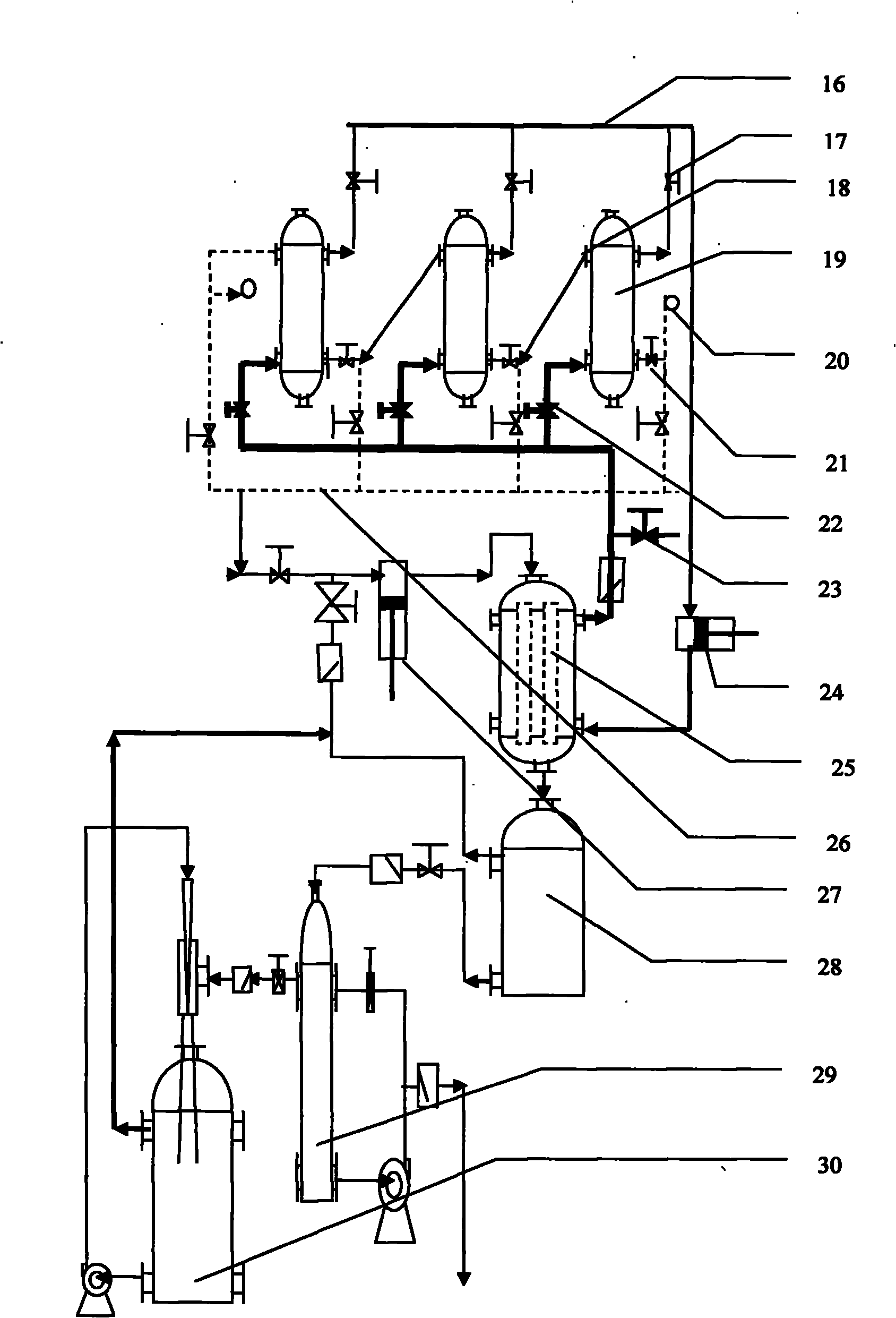

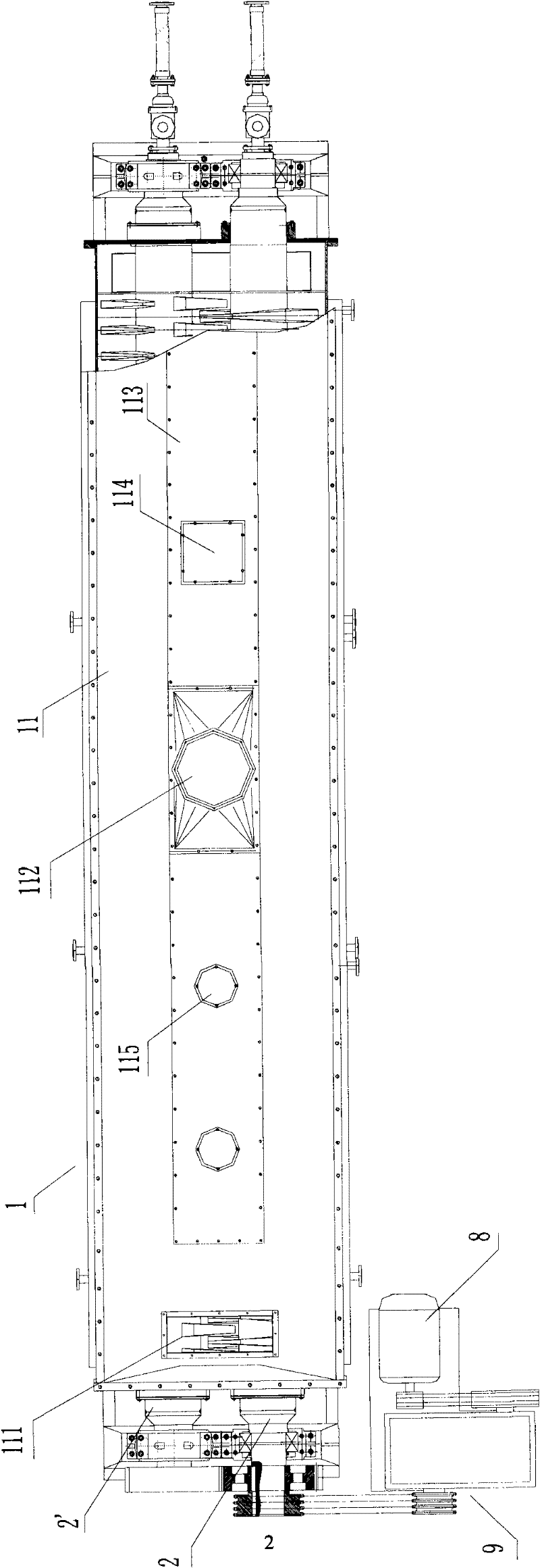

Multistage continuous overheated steam drying system and method of low-rank coal

InactiveCN102410705AEasy to handleImprove drying efficiencyDrying solid materials with heatHearth type furnacesFluidized bed dryingEngineering

The invention discloses a multistage continuous overheated steam drying system and method of low-rank coal. The multistage continuous overheated steam drying system comprises at least two stages of fluidized bed drying devices, wherein a discharging port of the first stage of fluidized bed drying device is connected with a feeding port of the second stage of fluidized bed drying device, and an air outlet at the top of the second stage of fluidized bed drying device is connected with an air inlet at the bottom of the first stage of the fluidized bed drying device; a feeding hole of the first stage of fluidized bed drying device is connected with a raw coal feeding device, an air outlet at the top of the first stage of fluidized bed drying device is connected with a dust removing device, an air outlet of the dust removing device is connected with a circulating fan, and an air outlet of the circulating fan is connected with a heating furnace; and a discharge port of the last stage of fluidized bed drying device is connected with a dry coal warehouse, and an air inlet at the bottom of the last stage of the fluidized bed drying device is connected with the heating furnace. Overheated steam and raw coal are dried by adopting a countercurrent operation, and partial purified steam can be recycled, therefore high heat utilization rate is achieved; and the multistage continuous overheated steam drying system and method disclosed by the invention have the advantages of simple whole drying process, continuous operation capability in an anaerobic environment, safety and reliability.

Owner:SHENWU TECH GRP CO LTD

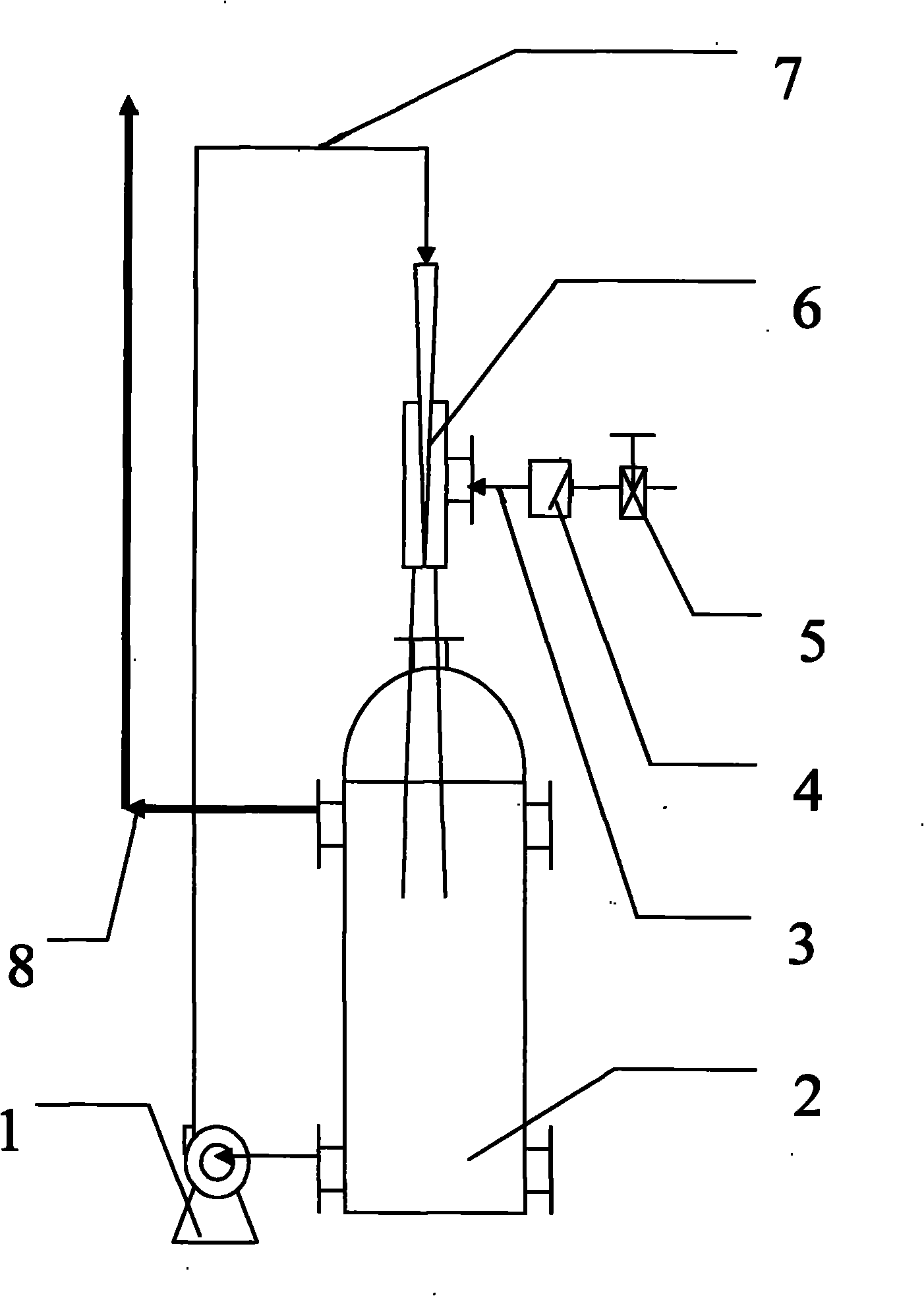

Method for drying materials by utilizing superheated steam

ActiveCN101968299AAvoid lostAvoid pollutionDrying solid materials with heatHearth type furnacesEvaporationEngineering

The invention discloses a method for drying materials by utilizing superheated steam, which is characterized in that the superheated steam is added into a sealed container in which materials to be dried are arranged, the superheated steam is used for evaporating the moisture in the materials to be dried to generate steam, and the superheated steam is cooled into low-temperature steam; the low-temperature steam enters a low-temperature steam system from the sealed container under the condition that the flow rate of the low-temperature steam is controlled; a mechanical pressurizing device is used by the low-temperature steam system for pressurizing the low-temperature steam to obtain the boosted steam; and the boosted steam is used for indirectly heating the steam in the sealed container, the boosted steam discharges the latent heat of vaporization to generate condensed water, and the steam in the sealed container receives the heat to become the superheated steam for continuously drying the materials to be dried. In the invention, the moisture of the materials to be dried is similar to the moisture of a multiple-effect evaporation system and is discharged in a form of the condensed water. The invention has the advantages of high drying efficiency, low energy consumption and simple processes, and has an industrial base of large-scale implementation.

Owner:武善东 +1

Method for producing chondroitin sulfate by reverse precipitation

The invention discloses a method for producing chondroitin sulfate by reverse precipitation, comprising the following steps of: adjusting pH of the chondroitin sulfate solution obtained by oxidation to 5-6, controlling the temperature at 15-20 DEG C and slowly adding the solution in 95% alcohol which is being stirred, wherein the weight concentration of alcohol in the whole process is always maintained in 75% or above. The precipitated chondroitin sulfate is loose in texture, easy to dehydrate and dry and not necessary to be smashed and has the advantages of saving energy and production cost.The product is coloury and stable in quality. The content of chondroitin sulfate is above 98%. The product has extremely low content of organic solvent which is lower than 0.2%.

Owner:江苏麦德森制药有限公司

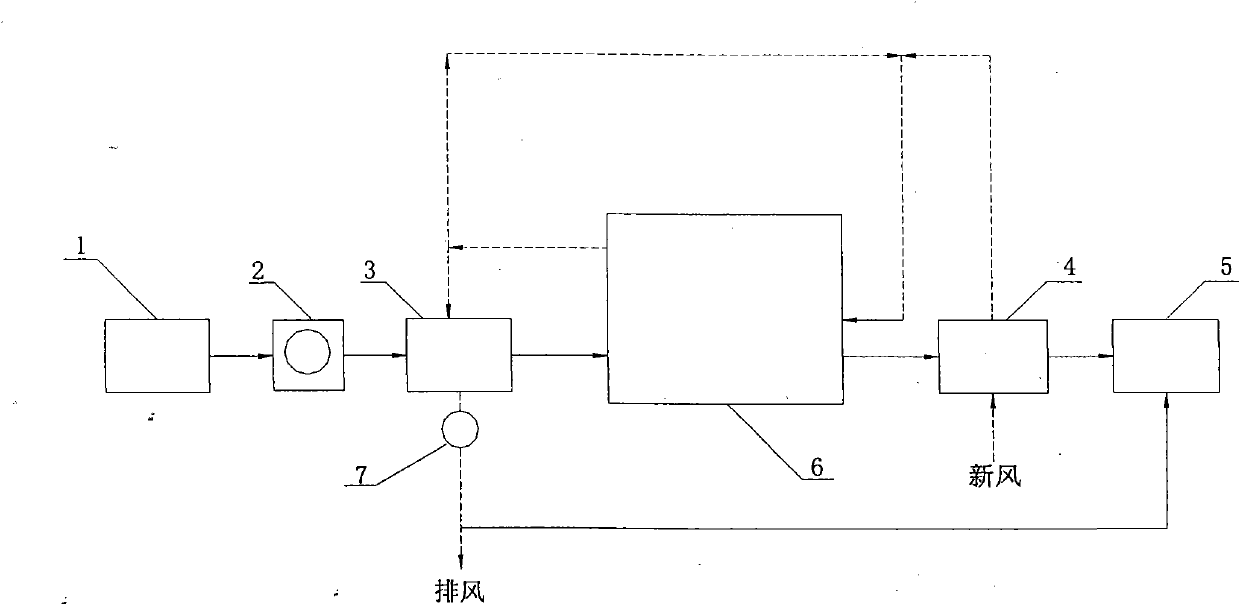

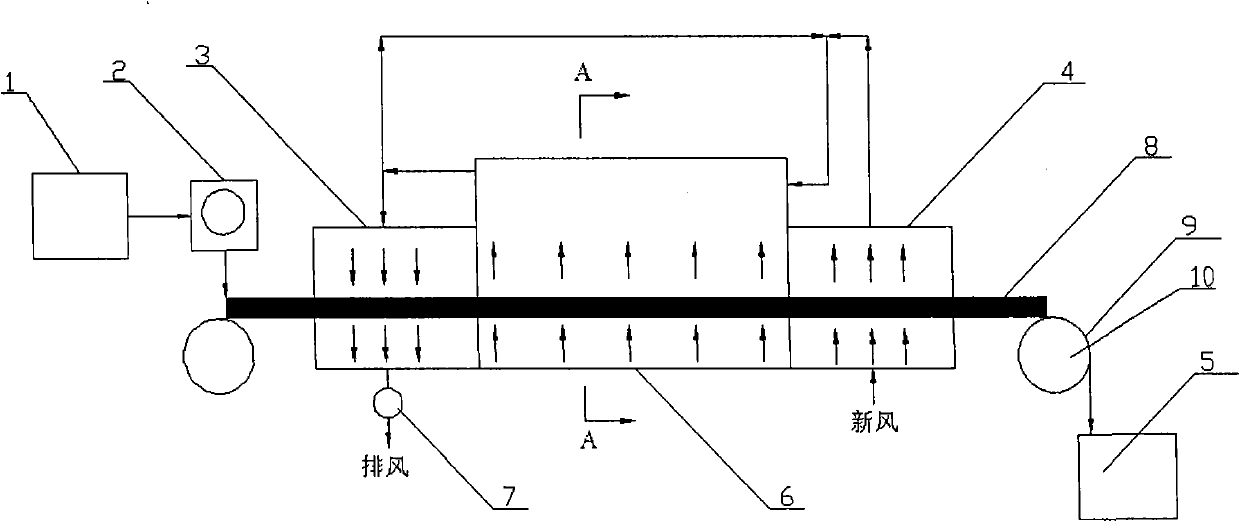

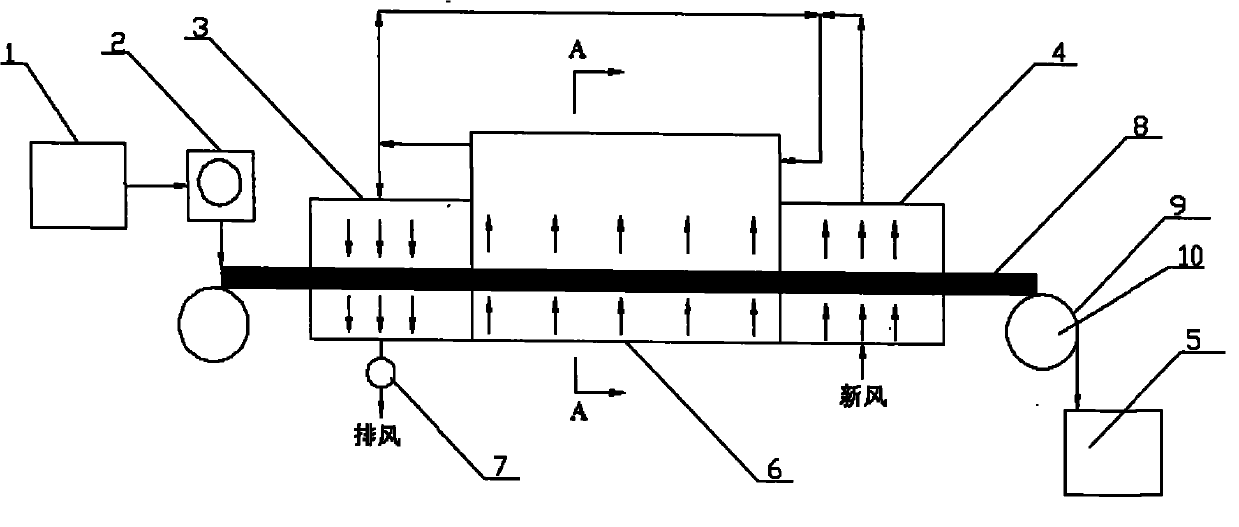

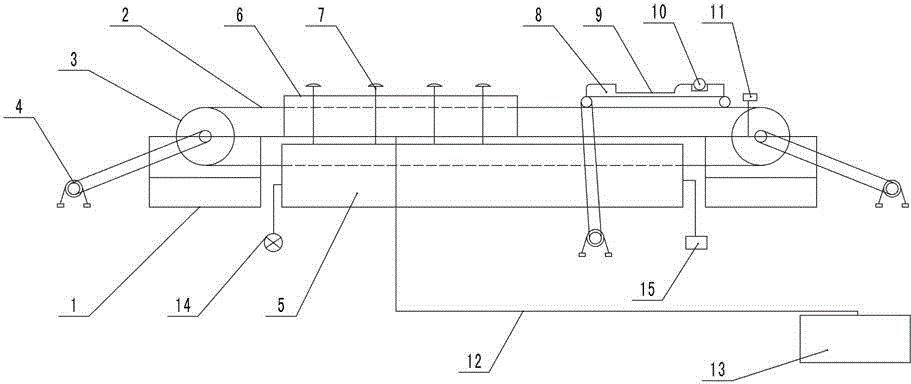

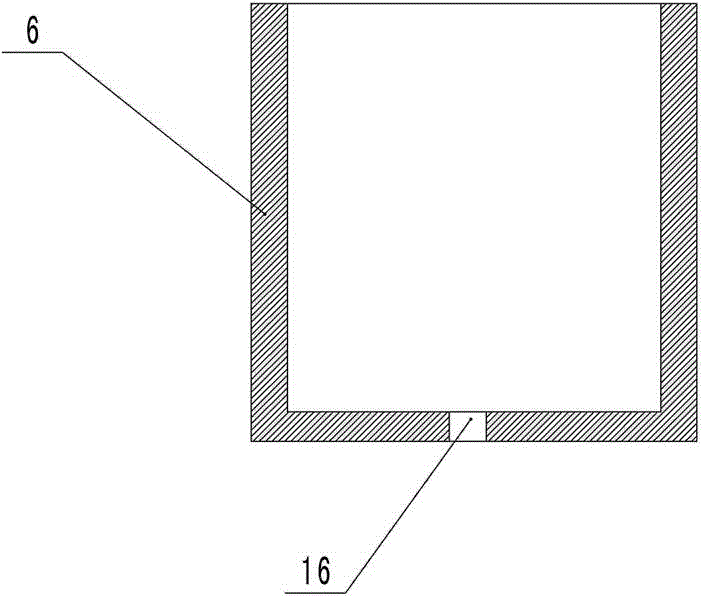

Belt-conveying drying system and method for realizing dehydration upgrading of lignite by using solar energy

InactiveCN101907383AGood energy saving and emission reduction effectEmission reductionDrying solid materials with heatDrying gas arrangementsFresh airCooling chamber

The invention relates to the field of coal high-efficiency utilization and aims to provide a belt-conveying drying system and a belt-conveying drying method for realizing the dehydration upgrading of lignite by using solar energy. The system comprises a feed preheating chamber, a dryer and a discharged material cooling chamber, which are connected in turn by a belt-conveying equipment, wherein the dryer is divided by a vertical partition into an air preheating chamber and a drying chamber, through holes are formed on the partition, and the air preheating chamber is provided with an air inlet, a drying chamber and an air outlet; and the discharged material cooling chamber is provided with a fresh air inlet, the air outlet of the discharged material cooling chamber is connected with the air inlet of the air preheating chamber by an air duct, the air outlet of the drying chamber is connected with the air inlet of the feed preheating chamber and the air inlet of the air preheating chamber by air ducts at the same time, and the air outlet of the feed preheating chamber is connected to a coal powder separation system. The system and the method have the advantages that: the energy-conservation and emission-reduction effect is obvious; the drying process is simple; the initial investment is small; the operation cost is low; the normal energy consumption is low; the pollutant emission is small; and the management and use of the whole device can be accepted by a user more easily.

Owner:ZHEJIANG UNIV

Method for precisely shaping non-water-base injection molding gel of ceramic body

ActiveCN102085688AAchieve precision moldingAchieve sintering densificationCeramic shaping apparatusCross-linkWater based

The invention belongs to the field of inorganic nonmetallic materials, relating to a method for precisely shaping the non-water-base injection molding gel of a ceramic body. The method comprises the following steps of: mixing one or more of anhydrous alcohol organic solvents with low viscosity to serve as a solvent; adding ceramic powder, an organic monomer and a cross linking agent, wherein the organic monomer and the cross linking agent can be dissolved in a solvent system; after mixed milling, obtaining the non-water-base ceramic slurry with high ceramic powder volume weight and good flowability; adding a proper quantity of initiator; pouring the initiator into a die after the initiator is evenly mixed with the mixture; solidifying slurry gel in the presence of a catalyst or reducing agent or under the heating condition so as to precisely shape the non-water-base ceramic solvent; removing glue and sintering for the obtained blank to obtain the required ceramic. Because of adopting the non-aqueous solvent in the process, the method can be suitable for precisely shaping the gel of the easily-hydrolytic ceramic powder raw material, and the danger that the large-size ceramic blank is easy to deform and crack in the drying process can be avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of chondroitin sulfate

The invention discloses a preparation method of chondroitin sulfate, which comprises the following steps of: adding water until cartilage is immersed; adjusting the pH value to be 8-9 with alkali and preserving heat at a temperature of 55-60DEG C for 4-6h; adding 2709 alkali protease and stirring for 6-8h, raising the temperature to boiling and filtering to obtain a chondroitin sulfate solution; adding sodium chloride to the chondroitin sulfate solution; adding alcohol of which the volume is 2-3 times of that of the solution, standing for 6h and filtering to obtain chondroitin sulfate precipitate; adding the chondroitin sulfate precipitate into water and dissolving; meanwhile, adding sodium chloride to the water, adjusting the pH value to be 10-12, adding hydrogen peroxide which accounts for 1-3 percent of the weight of the solution, oxidizing for 6h and filtering to obtain filtrate; adjusting the pH value of the chondroitin sulfate filtrate to be 5-6, adding alcohol of which the volume is 4-6 times of filtrate for secondary precipitation to obtain the chondroitin sulfate precipitate; pouring the secondary chondroitin sulfate precipitate into a dehydration tank provided with an emulsifying machine; pumping alcohol of which the volume is 3-5 times that of the chondroitin sulfate precipitate into the dehydration tank; and carrying out suction filtering, collecting the precipitate and drying to obtain a chondroitin sulfate finished product. The chondroitin sulfate obtained by the preparation method disclosed by the invention has the advantages of loose texture, fine particles, easiness of dehydration and drying, low energy consumption, extremely-low residual organic solvent and short production period.

Owner:江苏麦德森制药有限公司

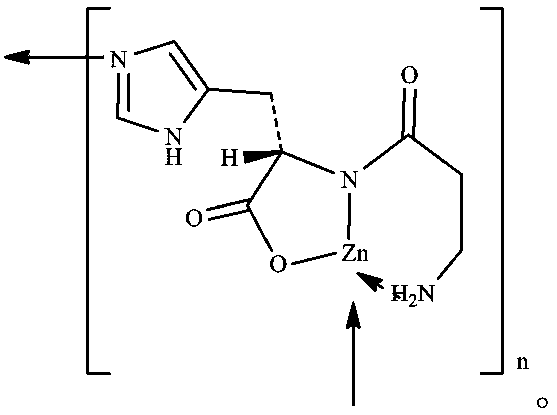

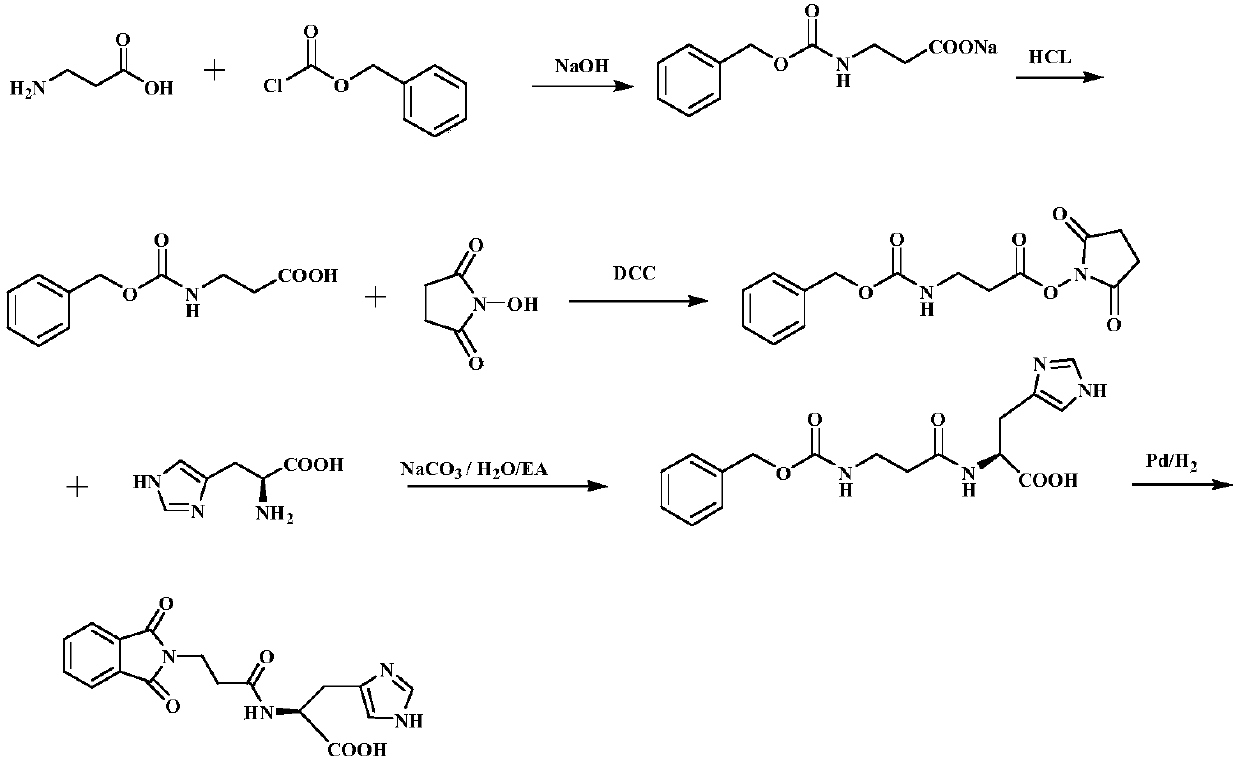

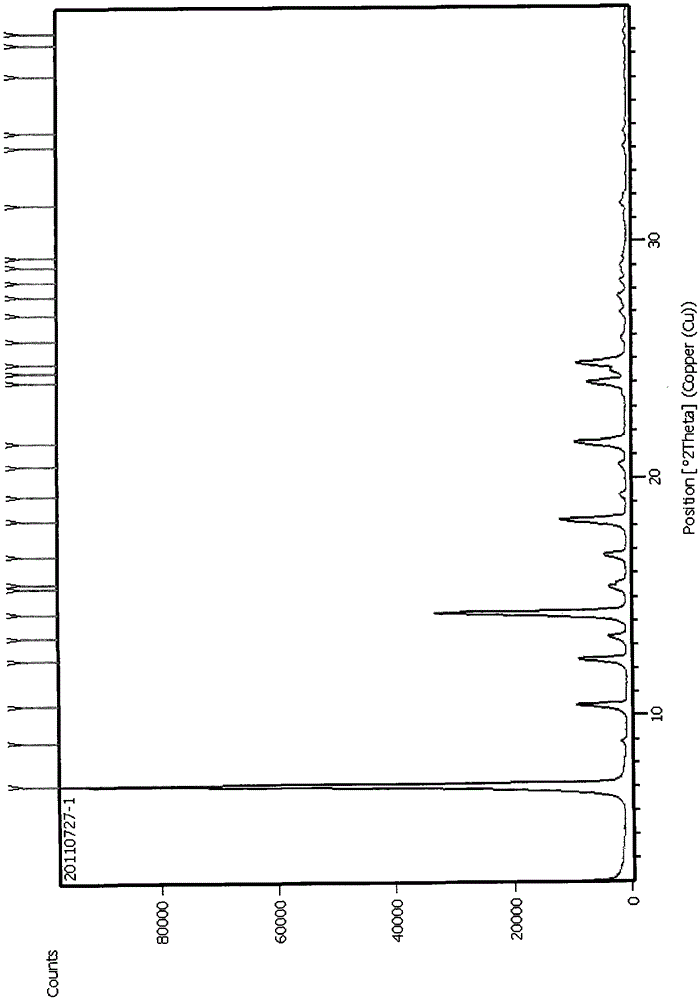

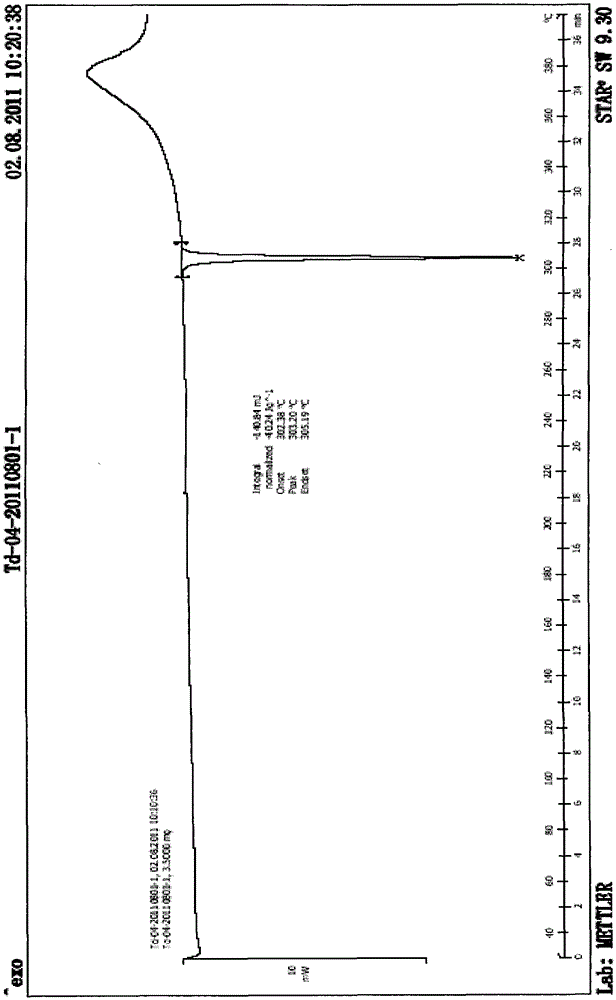

Method for preparing polaprezinc

ActiveCN107602661AHigh purityThe refining and drying process takes less timePeptide preparation methodsPropanoic acidL-Carnosine

The invention discloses a method for preparing polaprezinc, and belongs to the technical field of pharmacy. The method comprises the following steps: 1, preparing a solution to 2-cyano acetyl chlorideand dichloromethane, dropwise adding the solution to a trimethylsilyl-protected dichloromethane solution of L-histidine, and adding imidazole to obtain (s)-2-cyanoacetamido-3-(1H-imidazole-4-yl)propionic acid; carrying out a catalytic hydrogenation reaction to obtain crude L-carnosine; carryin gout alkaline macro-porous ion exchange resin adsorption, flushing the adsorbed L-carnosine with an aqueous solution of alkali metal acetate, and carrying out spray drying to obtain an alkali metal salt solid of the L-carnosine; and dissolving the alkali metal salt solid of the L-carnosine in methanol,adding a methanol solution of zinc acetate, and beating and refining the obtained solution by using a methanol-water solution to obtain refined polaprezinc. The method allows highly-pure L-carnosine sodium and polaprezinc to be obtained, and allows the time of the refining and drying process of the polaprezinc to be short, and the refined polaprezinc has the advantages of easiness in crushing, high yield and low cost, so the method is suitable for industrial production.

Owner:烟台万润药业有限公司

A method for preparing tadala amorphous form a

The invention discloses a method for preparing Tadalafil crystal form A. The method is characterized in that the crystallization solvent is a binary mixed solvent of a C1-C4 alcohol and acetic acid or a ternary mixed solvent of a C1-C4 alcohol, acetic acid and water. The method has the characteristics that: a mixed solvent system is used, thus the dosage of the crystallization solvent can be greatly reduced, the drying process can be simplified and the corrosion of acidic materials to the equipment can be reduced.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

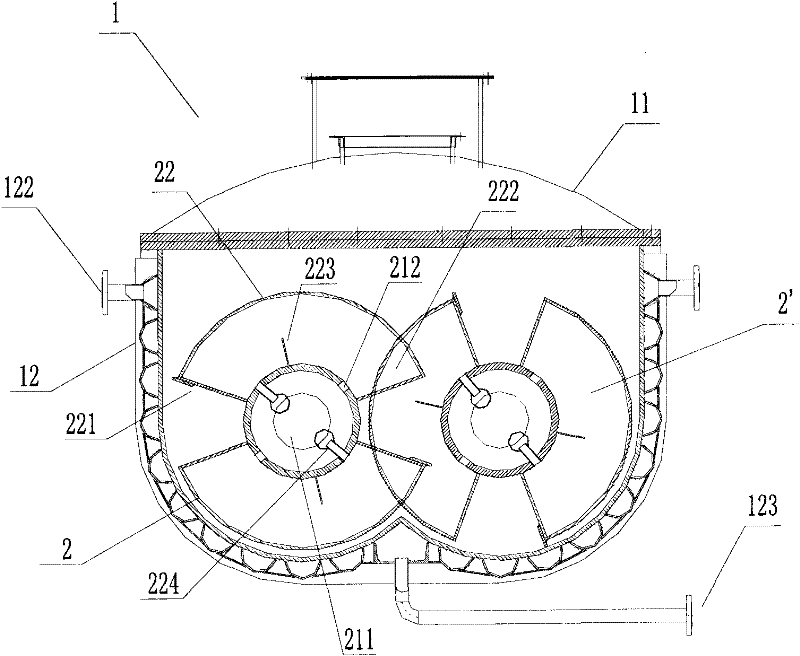

Sludge drying process and equipment

InactiveCN102295398ASmall starting currentImprove winding capacitySludge treatment by de-watering/drying/thickeningWater contentPre treatment

The invention relates to a sludge drying process and equipment. The process is: pretreat the sludge with high moisture content until the moisture content is lower than the set value, keep the temperature of the sludge constant, and input it into the sludge drying equipment, in which the sludge is continuously discharged to the It is pushed by the mouth, and the sludge is heated to above 120°C, accompanied by continuous stirring and crushing, and at the same time, the water vapor volatilized from the sludge is continuously drawn out by the air-inducing equipment until the sludge with the required moisture content is produced. The sludge is discharged from the drying equipment. The sludge drying equipment is produced for the improvement of the traditional hollow paddle dryer. The process of the present invention is simple and easy to operate, runs smoothly, and can make the degree of sludge drying more controllable, the sludge treatment capacity is larger, and there is no risk of secondary pollution; the equipment of the present invention has simple structure, stable operating performance, and high efficiency. High, and can achieve the goal of energy saving and emission reduction, it is expected to be widely used in the field of environmental protection and in chemical, pharmaceutical, food and other industries.

Owner:SUZHOU ZILI CHEM EQUIP

Distannous citrate preparation method

ActiveCN1995005ASimple drying processBeautiful appearanceFood preservationCarboxylic acid salt preparationDielectricCITRATE ESTER

The invention discloses a making method of tin disodium citrate, which comprises the following steps: making ditin citrate sediment in the water dielectric; reacting ditin citrate and citrate in the alcohol to form tin citrate; reacting with sodium hydroxide to form the sediment of tin disodium citrate; filtering; drying to obtain loose white powder of tin disodium citrate or the composition of tritin citrate and trisodium citrate; dissolving the composition to obtain the disodium citrate.

Owner:XILONG SCI CO LTD

Millet granule processing method

ActiveCN105766139AReduce harmThe particle number is accurate and flexibleSeed coating/dressingSowing

The invention relates to a millet granule processing method, and belongs to the technical field of millet sowing. Millet seeds for sowing are pelleted, each millet seed is coated, 5-8 coated millet seeds are combined together to form seed balls, the seed balls are coated to obtain formed millet granules, and then a sower is used for sowing and planting. By means of the mode of sowing millet granules, sowing is convenient, seed mobility is good, the emergence rate is large, seedling heights are uniform, and later-stage maintenance is easy.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

Dried-crisp flavor bean curd thin sheets

InactiveCN106561834AFully soakedGuaranteed yieldMilk preservationCheese manufactureCooking & bakingFood flavor

The invention relates to dried-crisp flavor bean curd thin sheets, which are produced by sequentially carrying out soaking, grinding, pulp filtering, pulp cooking, solidification, molding, pressing, cutting, stirring, baking, packaging and other technical steps. According to the present invention, the dried-crisp flavor bean curd thin sheets have advantages of green property, health, high protein content, thin skin, easy taste achieving, good taste, crispness, long shelf life, easy eating, easy water returning, good toughness after water returning, and significant economic value.

Owner:金仁元

Preparing method of digital printing shading fabric

InactiveCN110592964AGuaranteed stabilityHigh occlusion rateCoatingsTextiles and paperWater basedSlurry

The invention belongs to the field of advertising materials, and relates to a preparing method of a digital printing shading fabric, in particular to water-based acrylate resin and a modified polymer-based high-flame-retardance full-shading advertising material thereof. The method includes the step of preprocessing a warp knitting fabric, scrape-coating one side of the warp knitting fabric with alayer of white slurry foamed through a foaming process, then a layer of black slurry foamed through the foaming process and finally a layer of qualified foam foamed through the foaming process or directly coating one side of the warp knitting fabric with transparent slurry through a direct-coating process, wherein the parameters of a foaming machine include the foam density of 250-400 g / L and themachine speed of 20-30 m / min. The prepared digital printing shading fabric has the advantages of being slightly elastic, high in softness and firmness and 100% high in shading; the most importantly, apattern to be digitally printed or printed is stable in image size and not prone to deformation, and images are of more textural quality due to the clear fabric surface.

Owner:浙江亦阳新材料有限公司

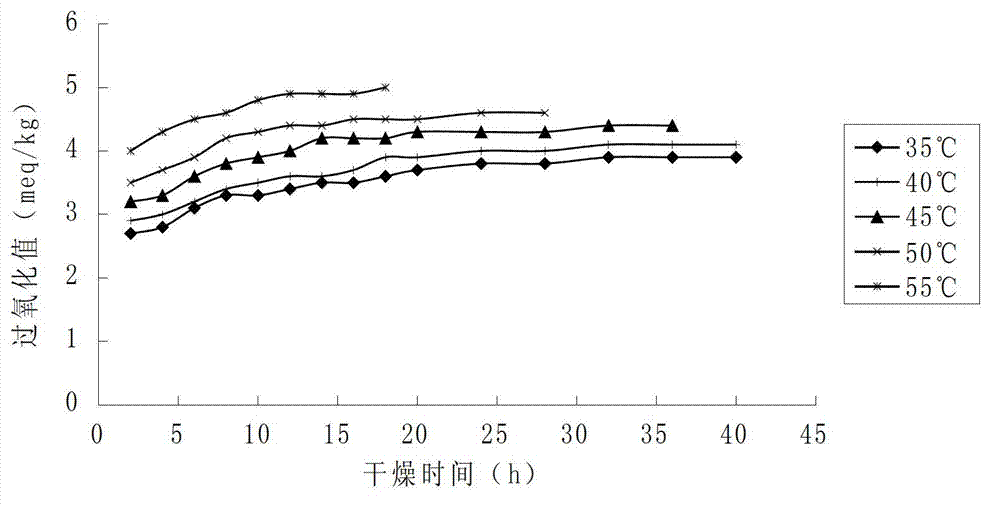

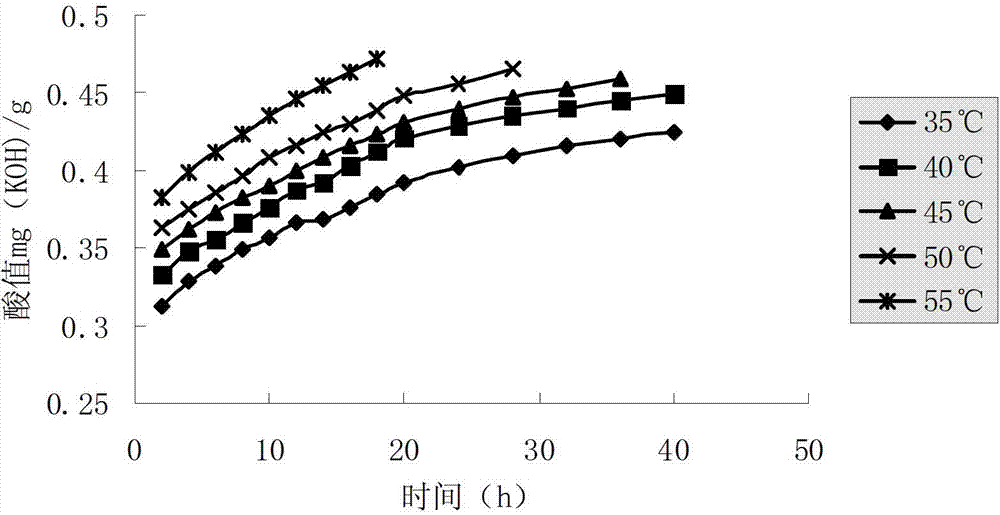

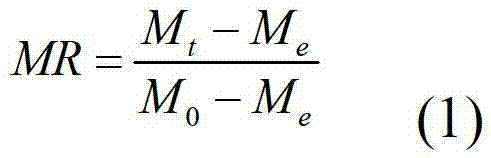

Method for drying walnuts with hot air based on parabolic temperature rise method

InactiveCN103110147AEvenly heatedDrain evenlyDrying solid materials with heatFood preparationFlavorProcess engineering

The invention relates to a method for drying walnuts with hot air based on a parabolic temperature rise method, wherein the relative humidity of the environment is controlled and the drying temperature is controlled by the parabolic temperature rise method, so that even heating of walnut roasting and even moisture removal are realized; as a result, the walnut drying time is effectively shortened and the interior quality and flavor of the dry walnuts are guaranteed; and the air-drying process is simple.

Owner:SHAANXI ZHIDAO AGRI SCI & TECH DEV CO LTD

Vitamin D and calcium composition chewable tablet and preparation method thereof

InactiveCN106138087ASimple drying processGood formabilityOrganic active ingredientsMetabolism disorderMagnesium stearateBioavailability

The invention provides a vitamin D calcium composition chewable tablet and a preparation method thereof, belonging to the field of pharmaceutical preparations. Contains Vitamin D Calcium, Sorbitol, Pigment, Flavor, Magnesium Stearate. The tablet overcomes the disadvantages of common chewable tablets, has high bioavailability, moderate taste and has important clinical application value.

Owner:合肥远志医药科技开发有限公司

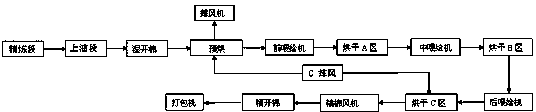

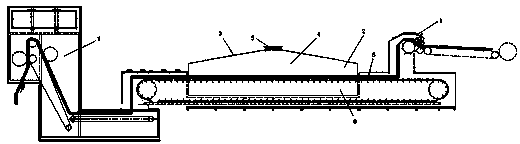

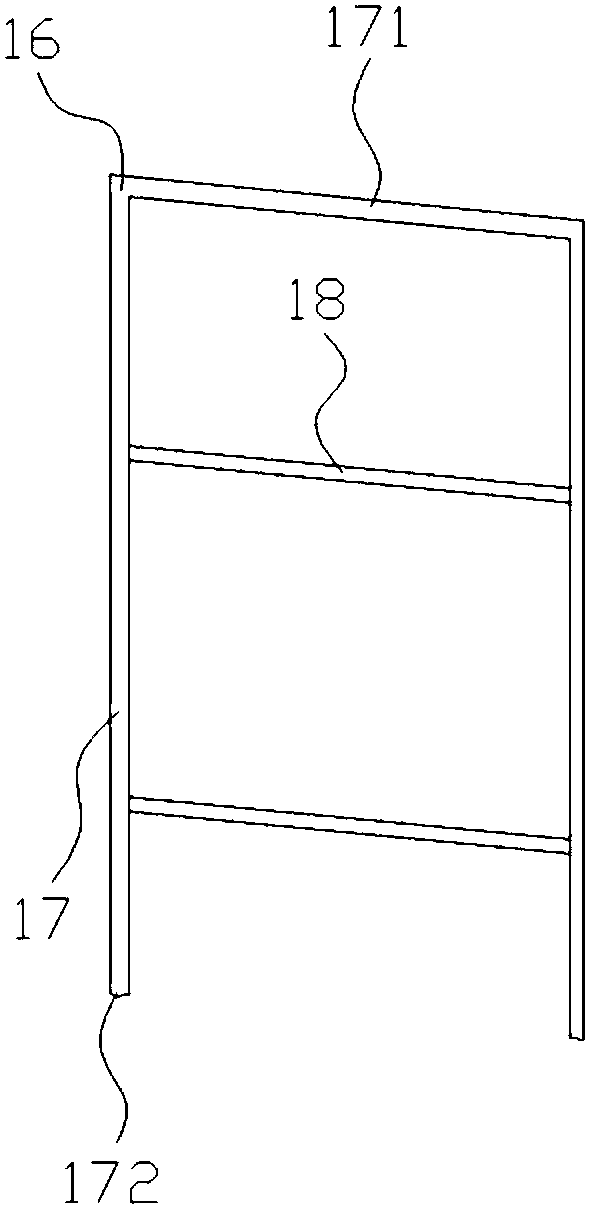

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290AIncrease washing timeWash Time GuaranteeSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

Multifunctional wardrobe

InactiveCN106880181ASpeed up dryingFully and evenly irradiated for disinfectionWardrobesDeodrantsEngineeringMechanical engineering

The invention discloses a multifunctional wardrobe, which belongs to the technical field of wardrobes. The multifunctional wardrobe includes a cabinet body and a cabinet door hinged with the cabinet body, a drying device and a rotating mechanism are arranged in the cabinet body, the rotating mechanism is arranged on the drying device, and the rotating mechanism is connected to the The drying device is connected to the same controller, the outer surface of the cabinet is provided with a first switch for controlling the controller, and the top and / or sides of the cabinet are provided with through holes for discharging water vapor , the rotating mechanism is also provided with a first ultraviolet light tube. The invention enables the clothes in the closet to be rotated while being dried by the drying device, which accelerates the drying process of the clothes and improves the drying efficiency, and also sets an ultraviolet lamp tube on the rotating shaft of the rotating mechanism, The clothes can be fully and evenly irradiated and sterilized while drying.

Owner:韦健

Automatic 350 g bean curd stick forming machine

InactiveCN104543017AHigh yieldConsistent qualityCheese manufactureFood scienceElectric machinerySpray nozzle

The invention relates to the field of food processing machinery, in particular to an automatic bean curd stick forming machine. Rollers are fixed at the two ends of a bracket respectively, are connected through a conveying belt, and are provided power by motors; the conveying belt is long enough; the forming machine further comprises a primary pulp heating container; a plurality of spraying devices extend out from the primary pulp heating container; the spray nozzles of the spray devices face to the conveying belt; a forming mobile cart powered by a motor is arranged on the conveying belt; a slurry heating container and a forming wheel are arranged on the forming mobile cart; a truncation component is arranged on the bracket at the rear of the forming mobile cart; baffle plate frames are arranged on the two sides of the conveying belt; positions corresponding to the spraying devices on the conveying belt, of the baffle plate frames are fixed on the bracket; liquid leaking holes are formed in the bottoms of the baffle plate frames on the two sides, and are connected with return pipes respectively; the return pipes extend into the a recovery container. The forming machine adopts semi-automatic control, and is higher in production efficiency.

Owner:王纪栓

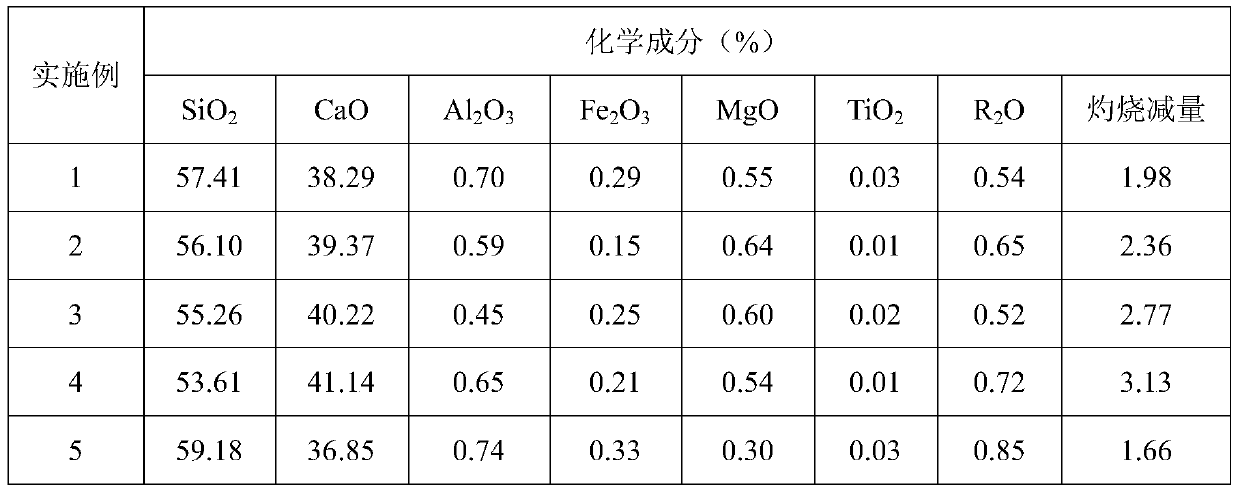

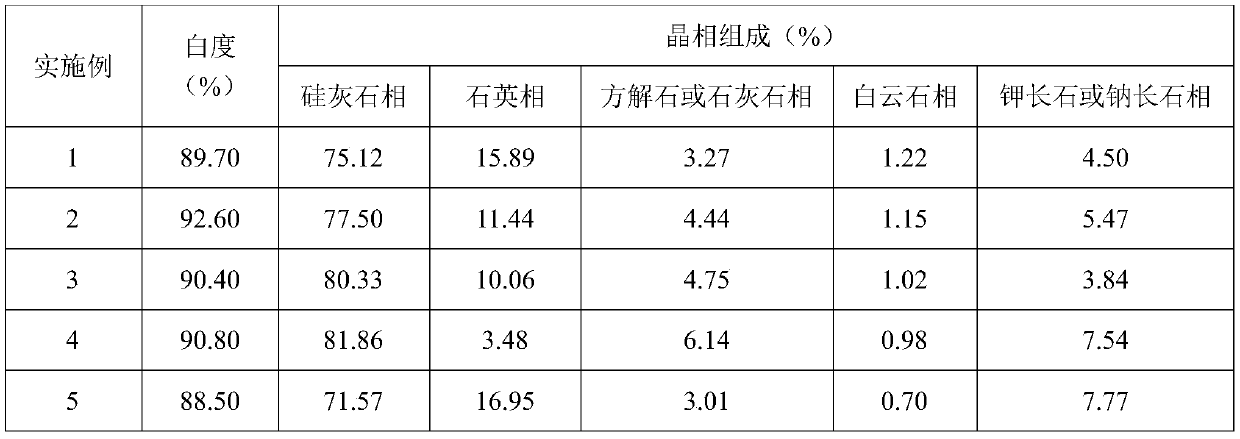

High-whiteness wollastonite powder and preparation method thereof

InactiveCN110589844AImprove stabilityEfficient removalAlkaline-earth metal silicatesGrain treatmentsWollastoniteMaceral

The invention belongs to the technical field of non-metallic mineral processing, and particularly relates to high-whiteness wollastonite powder and a preparation method thereof. The preparation methodcomprises the following steps: selecting marble type wollastonite, crushing and sorting to obtain rough concentrate, mixing the rough concentrate with auxiliary mineral raw materials to obtain a mixture, grinding the mixture into sand, removing iron, and grinding the sand into a powder. Auxiliary materials are added to control powder components, so that the high-whiteness wollastonite powder is prepared; iron is deeply removed in the preparation process, and secondary processing pollution is avoided, the stability of the whiteness of the powder is ensured, and reasonable-stage grinding is beneficial to energy conservation and consumption reduction.

Owner:广东五岭硅灰石有限公司

Preparation method of pure oatmeal

PendingCN106879940AWill not changeWon't be lostFood dryingFood ingredient as mouthfeel improving agentPre treatmentDeep processing

The invention discloses a preparation method of pure oatmeal and belongs to the technical field of food deep processing. The preparation method of pure oatmeal disclosed by the invention comprises the following steps: (1) raw material pre-treatment; (2) crushing; (3) dissolving of an enzymic preparation; (4) enzymolysis; (5) drying; and (6) crushing and cooling. The preparation method disclosed by the invention overcomes the defect in the prior art that the pure oatmeal is coarse in taste, and the invention provides the preparation method of pure oatmeal, wherein the nutritional value of oatmeal is kept, and the oatmeal is fine and smooth in taste.

Owner:GUILIN TOURISM UNIV

Roll sticking prevention lithium battery cathode material and preparation method thereof

The invention provides a roll sticking prevention lithium battery cathode material and a preparation method thereof. The cathode material is prepared by the following raw materials of, by weight, 50-96 parts of carbon powder, 0.5 part of a conductive agent, 0.6-2.0 parts of a thickening agent, 2.0-3.0 parts of an adhesive, 5-10 parts of an oiliness agent and a proper amount of deionized water. The preparation method comprises the following steps of a. weighing the carbon powder, the conductive agent, the thickening agent, the an adhesive, the oiliness agent and the deionized water according to the above weight parts; b. adding the thickening agent into the proper amount of the deionized water, stirring for 3-5 hours with a high speed, standing for 3-5 hours to prepare a thickening agent aqueous solution with a solid content being 1.0791%-2.5% by mass; c. adding the conductive agent, stirring for 0.8-1.2 hours with a high speed; d. adding the oiliness agent, stirring for 0.8-1.2 hours with a high speed; e. adding the adhesive, stirring for 0.8-1.2 hours with a high speed; f. adding the carbon powder in four times, adding half the amount for the first time, and adding a half of the left amount for the subsequent time, stirring for 8-12 minutes with a low speed after the addition of each time to make the carbon powder moist enough; and g. stirring for 3-5 hours with a high speed, vacuum-pumping and stirring uniformly at a low speed to obtain the roll sticking prevention lithium battery cathode material.

Owner:焦作市亿锂达能源科技有限公司

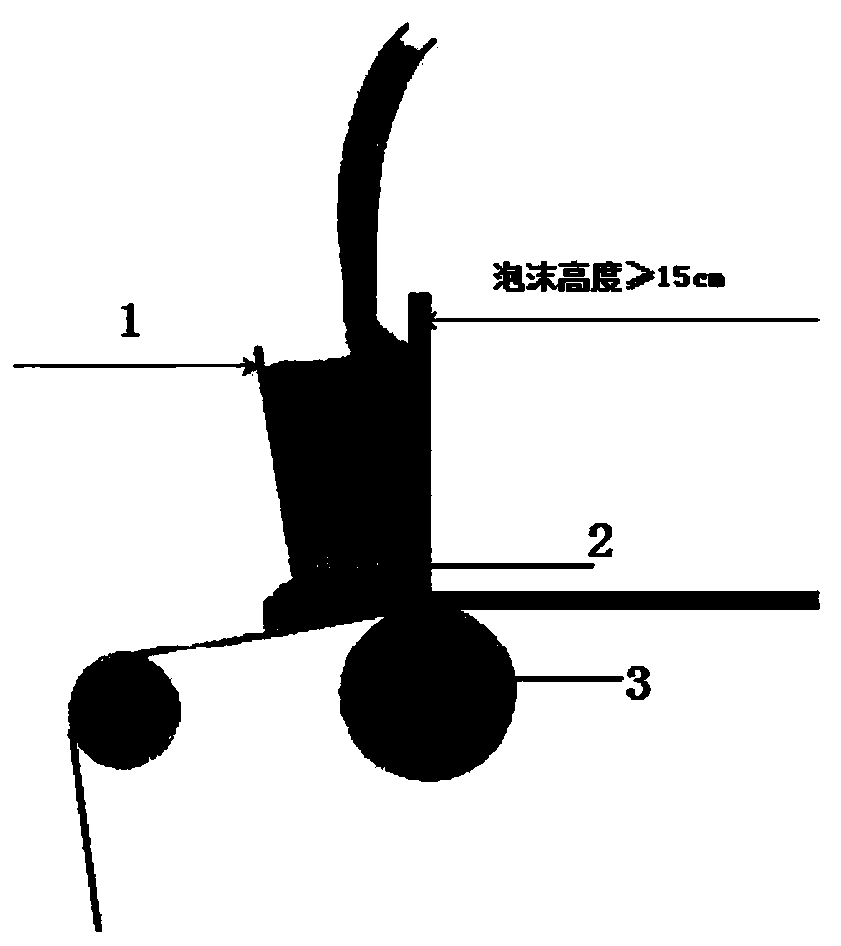

Method and equipment for granulating wet sludge soft particles

InactiveCN101703907AFine grainReduce drying costsSludge treatment by de-watering/drying/thickeningGranulation in rotating dishes/pansCombustionSludge

The invention discloses a method for granulating wet sludge soft particles. Sludge after being pressed and filtered is extruded into sludge strings by a sludge string extrusion machine at the top of a mixing tank, combustible powder is sprayed to the sludge strings for serving as an isolator by adopting a powder spraying machine of a powder spraying gun which is fixedly connected on the side wall of the mixing tank in the process that the sludge strings fall from top to bottom, the sludge strings coated with the combustible powder fall on a turntable granulating machine of which the bottom is laid with the combustible powder, and soft body granulation is carried out under the rotation of the turntable granulating machine to form dispersive wet sludge soft particles. The invention also discloses equipment for realizing the method. The invention simplifies a subsequent sludge drying process; the sprayed combustible powder can be used as the isolator, which is beneficial to sludge granulation and solves the problems of sludge caking and wall sticking effectively; moreover, the sprayed combustible powder can also act as a combustion-supporting function when sludge is incinerated; and the invention has simple equipment, low energy consumption and high benefit, is safe and sanitary, is convenient for popularization and use and can promote the industrialization progress of the drying incineration of the sludge.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Biological fertilizer processing equipment

InactiveCN109603664AReduce volumeSimple drying processTransportation and packagingMixersBiochemical engineeringFertilizer

The invention belongs to the technical field of biological processing equipment, in particular to biological fertilizer processing equipment. The biological fertilizer processing equipment comprises aframe body and a controller; a first rotating wheel and a second rotating wheel are rotationally connected in the frame body through a first rotating shaft and a second rotating shaft respectively; the first rotating wheel and the second rotating wheel are both in cam-shaped design; one end of a conveying plate is rotationally connected to the inner wall of the frame body through a third rotatingshaft, the other end of the conveying plate extends to the position under the second rotating wheel; the surface of a rotating ring is uniformly and fixedly connected with elastic plates; the side wall of a stirring bucket is uniformly provided with discharging holes; a transmission rod is arranged under the stirring bucket; the stirring bucket is internally and slidably provided with a bearing disc; the bearing disc is of arc-shaped design, is made from a magnetic material and can generate magnetism attracting with a magnetic block; the surface of a protective cover is uniformly and fixedlyconnected with stirring rods; the stirring rods are internally provided with second heating devices respectively. The biological fertilizer processing equipment has the advantages that the structure is simple, a fertilizer can be in contact with a pesticide sufficiently, and the fertilizer is dried uniformly and thoroughly.

Owner:倪晓燕

Rotary clothes dryer

InactiveCN107904893AEvenly heatedSimple drying processTextiles and paperLaundry driersElectric machineryAir pump

The invention discloses a rotary clothes dryer, and belongs to the field of articles for daily use. The rotary clothes dryer comprises a hot air pump, a fixing device and clothes hangers, wherein thefixing device comprises a fixing support, a carrier table, supporting rods, a fixed plate and a hollow upright column; the carrier table is fixedly arranged to the fixing support, the hot air pump isarranged on the carrier table, the hollow upright column is communicated with the fixed plate, the hot air pump is connected with an air delivery pipe, and the air delivery pipe is arranged in the hollow upright column; a plurality of air nozzles penetrating through the hollow upright column are formed in the outer wall of the air delivery pipe from top to bottom at intervals; the end, away from the fixed plate, of each hollow upright column is connected with a horizontal branch pipe; the end, away from the hollow upright column, of each horizontal branch pipe is provided with a transmission device; the transmission devices drive the clothes hangers located below the transmission devices to rotate. Hot air is conveyed to the air delivery pipe through the hot air pump, and the hot air is sprayed out through the air nozzles formed in the air delivery pipe; meanwhile, a speed reducing motor is controlled to work, so that the clothes hangers rotate, clothes on the clothes hangers can be heated more evenly, and the clothes can be more easily dried.

Owner:柳州市金升汽车配件有限公司

Method for recycling waste yogurt

ActiveCN102334590AReduce mortalityReduce lossesFood processingAnimal feeding stuffFeed conversion ratioAdditive ingredient

The invention discloses a method for recycling waste yogurt. The method is realized by utilizing nutriments, such as lactic acid, milk sugar, protein, and the like, in the yogurt as probiotic bacteria protective agents and utilizing sodium alga acid and chitosan as capsule materials for compounding and embedding. The method is used for realizing the recycling of waste yogurt, greatly promoting the livability of probiotic bacteria and reducing the loss of nutriments, such as protein in the yogurt. A yogurt-sodium alga acid / chitosan capsule prepared by using the method has relative high activity and strong acid resistance; the inactivation problem of lactic acid bacteria caused by gastric acid, digestive ferment and antibiotics is solved; the yogurt-sodium alga acid / chitosan capsule is released after reaching large intestine, thereby adjusting the balance of flora in an intestinal canal, promoting the immunity of animals, reducing the morbidity, promoting the conversion rate of forages and achieving environmentally-friendly cultivation; and the capsule can be stored for a long time and is simple in production process and low in cost.

Owner:广州拜晴生物科技有限公司

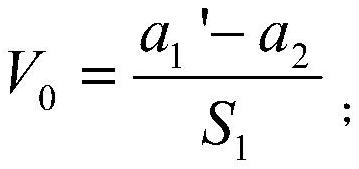

Quantitative analysis method for pore volume increments of hydrated shale in different scales

ActiveCN112129802AImprove seepage capacityHigh pore volumePreparing sample for investigationWater resource assessmentHydration reactionRock sample

The invention belongs to the technical field of oil-gas exploration and development, and particularly relates to a quantitative analysis method for pore volume increments of hydrated shale in different scales. According to the quantitative analysis method for the pore volume increments of the hydrated shale in different scales, saturation of a standard rock sample is carried out by adopting a first solvent which does not generate hydration reaction with the shale, data of original effective pore volume is obtained through testing, and then saturation testing is carried out by adopting water; and therefore, real change data of pores of different scales after shale hydration can be obtained. The method can quantitatively evaluate the absolute increase amplitude of the effective pore volumesof different scales in the shale under the hydration effect, and has practical significance for guiding field screening of shale reservoirs suitable for production increase of after-fracturing "soaking".

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Textile dyeing and drying system

InactiveCN104894783AEasy to dryReduce processLiquid/gas/vapor removalTextile treatment machine arrangementsTextile printerEngineering

The invention discloses a textile dyeing and drying system. The textile dyeing and drying system comprises a controller, a temperature sensor, a humidity sensor, a support and at least one heating tube disposed on the support; and the heating tube is provided with a plurality of hot air holes, the support is fixedly disposed at a position of an outlet of a dyeing machine, the internal of the external of the heating tubes are provided with a hot air generation device, hot air is applied to a textile through the hot air holes in the heating tubes, the hot air generation device is connected with the controller, the temperature sensor and the humidity sensor are both disposed on the heating tubes, the temperature sensor acquires temperature information of the heating tubes, the humidity sensor acquires humidity information of the textile, and the temperature sensor and the humidity sensor are both connected with the controller. The system increases auxiliary drying equipment, effectively and rapidly performs drying after textile printing and dyeing are completed, saves working procedures, and improves working efficiency.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

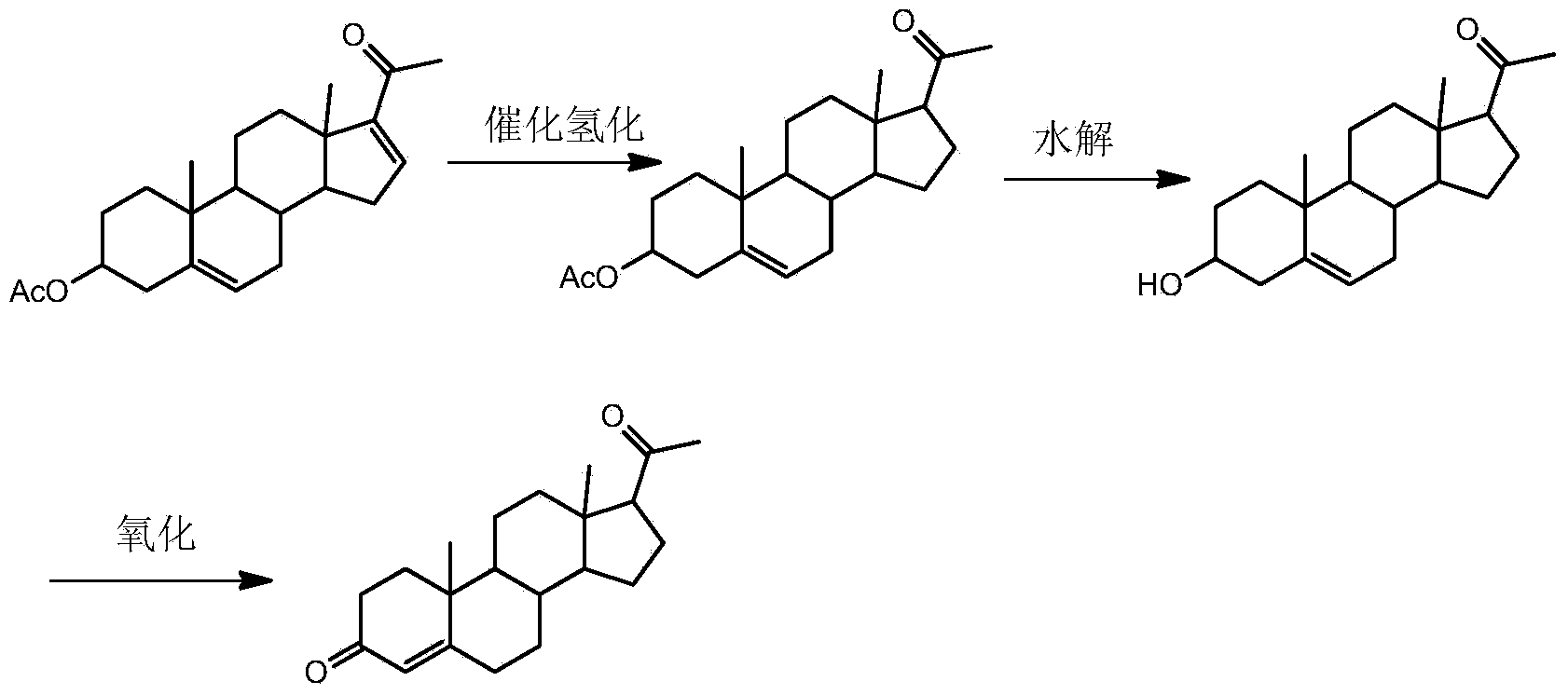

Synthetic method of pregnenolone acetate

The invention discloses a synthetic method of pregnenolone acetate. The method comprises the following steps of: 1, carrying out hydrogenation reaction of dehydropregnenolone acetate at a temperature ranging from 35 to 45 DEG C and under 0.4 MPa to 0.8 MPa by taking ethyl acetate as a solvent and a compound catalyst of a palladium / carbon catalyst and ammonium acetate; 2, filtering the reaction liquid after reaction, concentrating the filtrate under normal pressure, then adding a mixed solvent to the concentrated filtrate, and carrying out centrifugal drying after cooling to obtain crude pregnenolone acetate; 3, washing the crude pregnenolone acetate, then carrying out drip washing by using methanol, and drying to obtain white sandy solid pregnenolone acetate. The synthetic method provided by the invention is mild in reaction conditions; ethyl acetate is used as the solvent, and the solvent is high in recovery and low in dosage; as the palladium / carbon catalyst and ammonium acetate are used as the compound catalyst, the catalytic hydrogenation selectivity is high and no impurity is generated; besides, the aftertreatment is simple and the yield is high; the mass purity of the product can be higher than 99.5%.

Owner:西安高远生物科技有限公司

Use method of modified bentonite by lithiation in casting dry type clay sand

InactiveCN101376160AReduce intensityHigh strengthFoundry mouldsFoundry coresWater wetSodium Bentonite

The invention discloses an application method of lithiation modified bentonite clay in moulding dry clay sand and comprises the following steps: original sand is composed of 50-90 percent (wt) of old sand with the grain size of 15Q (H), and 50-90 percent (wt) of new sand with the grain size of 15Q (H); according to the reference of 100 weight parts of the original sand, lithiation bentonite clay accounting for 2-10 percent of the weight of the original sand is added to mix with 0-8 percent of calcium bentonit clay, and 5-7 percent of water is added when the moulding sand is wet-mixed; the mixed production is conducted by using an ordinary sand roller mill, the new sand, the old sand, the lithiation bentonite clay and the calcium bentonit clay are dry-mixed for two minutes, and then the wet mixture is conducted by adding the water for ten minutes; the drying temperature is 120-160 DEG C, the drying time is 60 minutes, and finally the dry pressing intensity of the obtained moulding sand is 360-405KPa.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com