Method and equipment for granulating wet sludge soft particles

A technology of granulation equipment and wet sludge, applied in the direction of granulation of raw materials, sludge treatment, chemical instruments and methods, etc., can solve energy waste, complex drying system, reduce the production capacity of sludge drying equipment, etc. problems, achieve cost reduction, simple equipment, and solve the problems of sludge agglomeration and wall sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

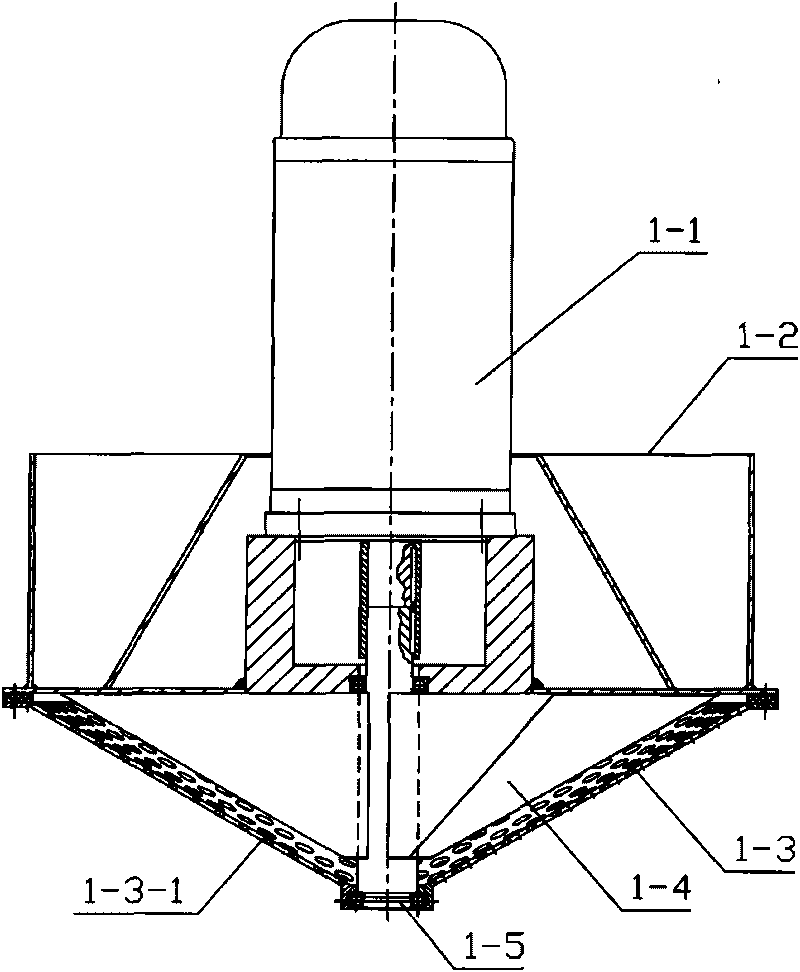

[0022] see figure 1 , a method for granulating wet sludge soft particles in the present invention. The specific process is to directly extrude the sludge after press filtration in the sewage plant from the mud squeezing machine 1 at the top of the mixing tank 6 into sludge strings, and the sludge strings are from top to bottom During the falling process, the powder spraying machine 3 with its powder spraying gun arranged around the mixing tank 6 sprays combustible powder from the outside to the sludge string as a spacer. The combustible powder is sawdust, coal powder, coal gangue powder or straw powder, and the sludge wrapped in a thin layer of powder falls on the turntable granulator 4, and soft granulation is performed under the rotation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com