Belt-conveying drying system and method for realizing dehydration upgrading of lignite by using solar energy

A drying system and solar energy technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., to achieve the effect of less conventional energy consumption, small initial investment, and low-cost utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

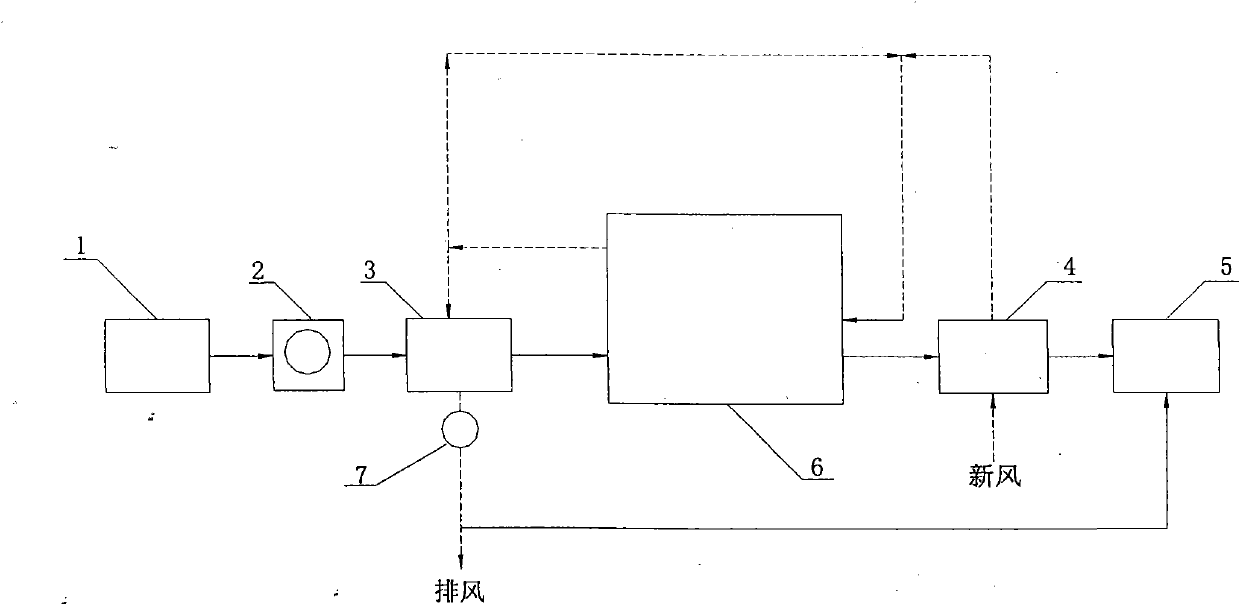

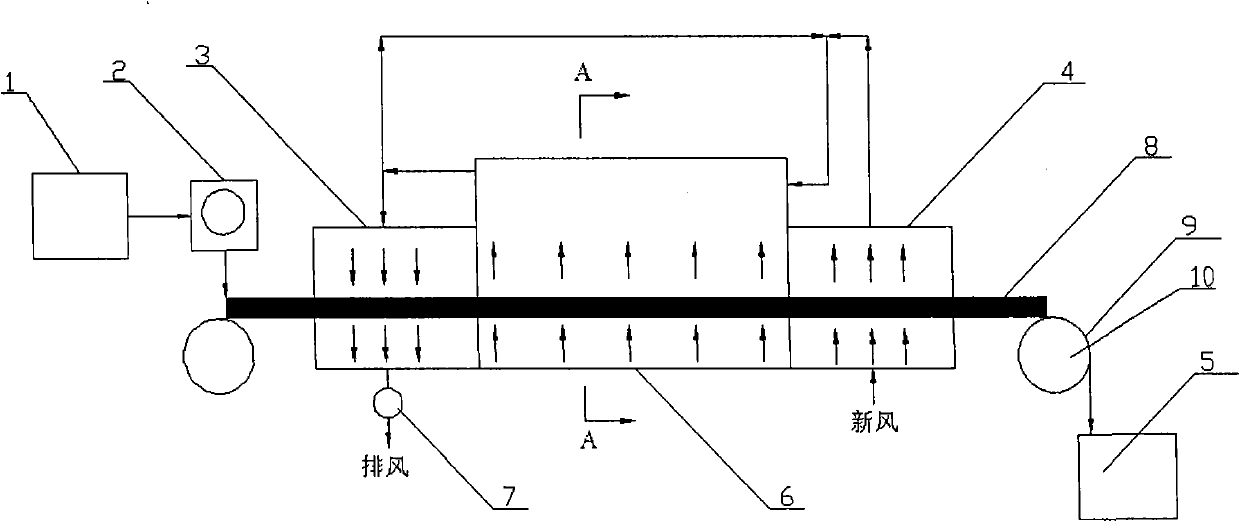

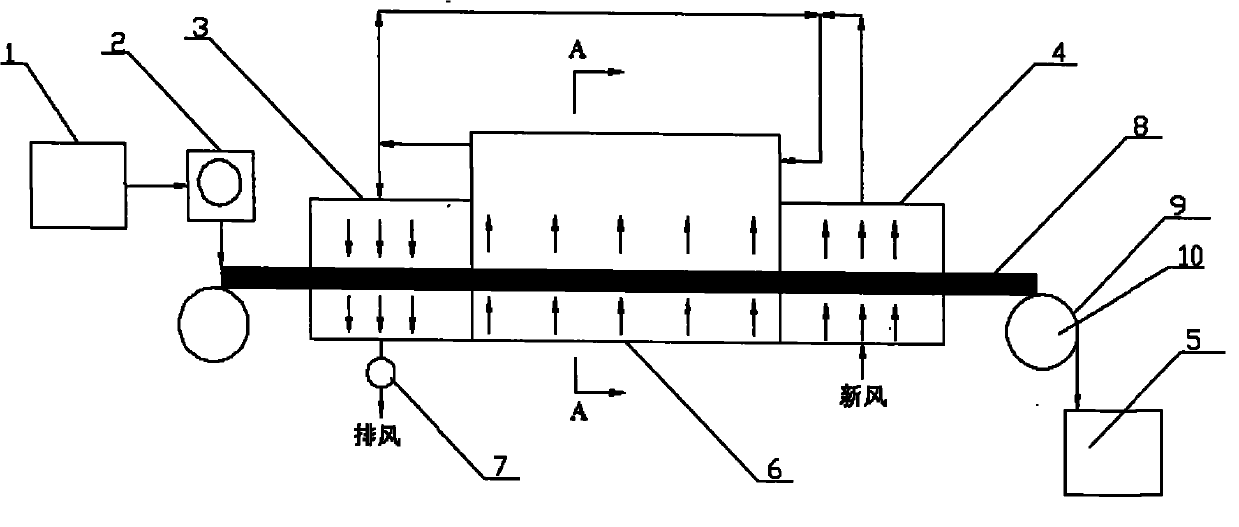

[0040] figure 1 Schematic diagram of the process of using solar energy to realize lignite dehydration and upgrading system. The device includes a coal bunker 1, a crushing device 2, a product coal bunker 5, a pulverized coal separation system 7, a feed preheating chamber 3, a dryer with built-in air preheating 6, and a discharge cooling chamber 4; the coal bunker 1 passes through raw coal The conveying equipment is connected to the crushing device 2, and the crushing device 2 passes through the feeding preheating chamber 3, the dryer 6, and the discharging cooling chamber 4 in turn through the belt conveying device with holes, and then connects to the product coal bunker 5; the discharging cooling chamber 4 Set the fresh air inlet, the air outlet of the discharge cooling chamber 4 is connected to the air inlet of the preheating chamber 11 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com