Smoke semi-closed circulating lignite straight pipe type airflow drying method

An airflow dryer and straight tube technology, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of inability to meet industrialized large-scale production, large-scale promotion of equipment, and large scale-up difficulty coefficient, etc. problems, to achieve the effect of preventing spontaneous combustion of pulverized coal, occupying a small area, and having high drying strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

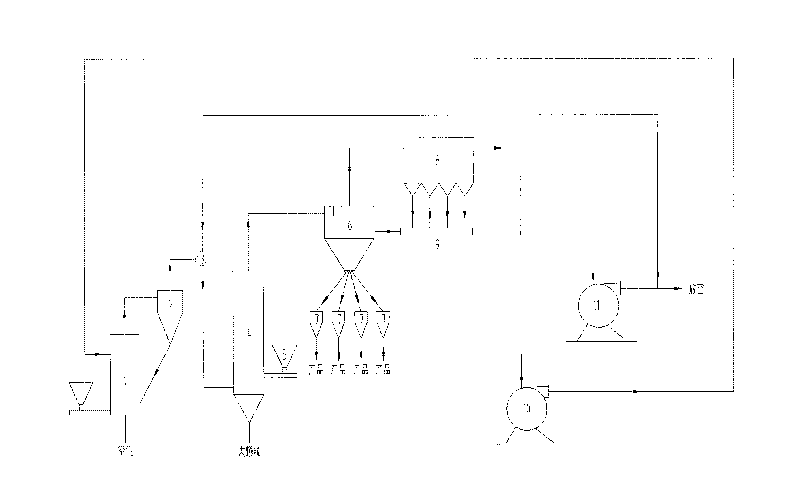

[0037] Now combined figure 1 A detailed description of the flue gas semi-closed cycle lignite straight-pipe airflow drying process.

[0038] After the external combustion air is pressurized, it enters the coal-fired hot blast stove 1, the fuel lignite is added to the coal-fired hot blast stove 1 through the feeding device for combustion, and the exhaust gas at about 110℃ is blown out into the furnace through the booster fan 11 to control the coal-fired type The outlet temperature of the hot blast stove 1 is 850°C, and the oxygen content of the flue gas is controlled to be less than 8%. After the high-temperature cyclone separator 2 further separates the ash carried by the combustion of the coal-fired hot blast stove 1, the clean high-temperature flue gas produced is combined with the exhaust and mixing The clean tail gas from the outlet of the warm air blower 10 is mixed by the pipeline mixer 3, the temperature is controlled at 650°C, and is sent to the air inlet of the straight-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com