Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Suitable for continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

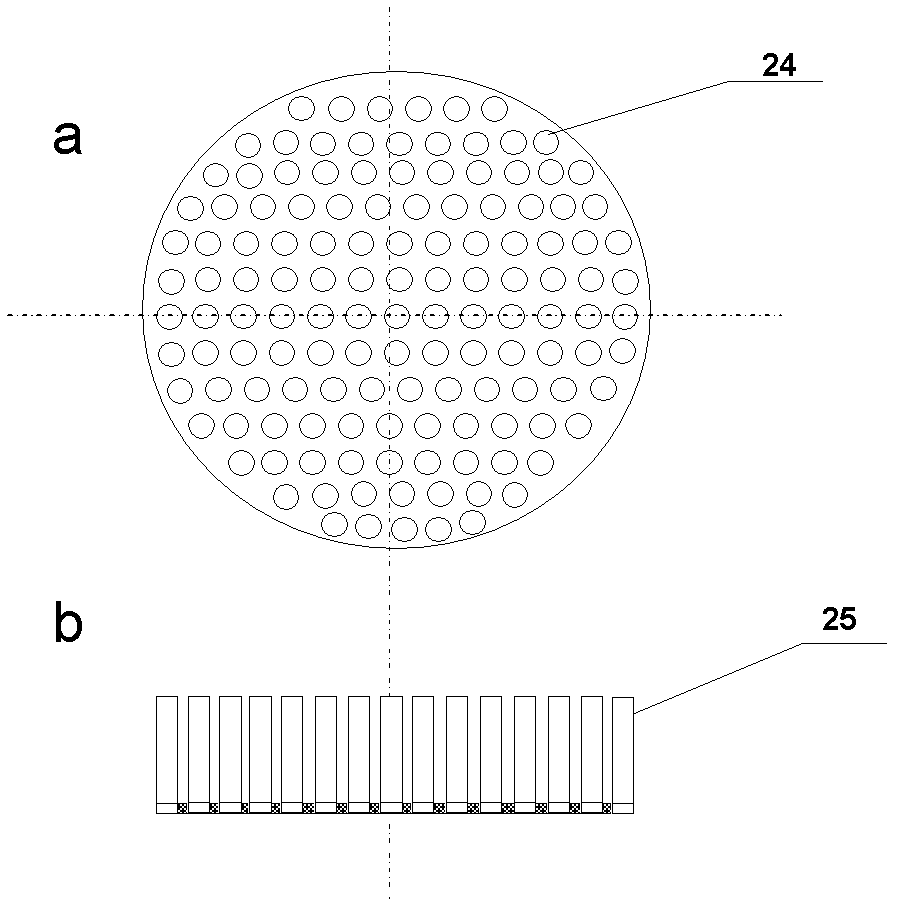

Method for preparing 4-amino diphenylamine by catalytic hydrogenation

ActiveCN101691332AEasy to cleanImprove regenerative abilitySemi-permeable membranesAmino compound purification/separationNitrosoNitrobenzene

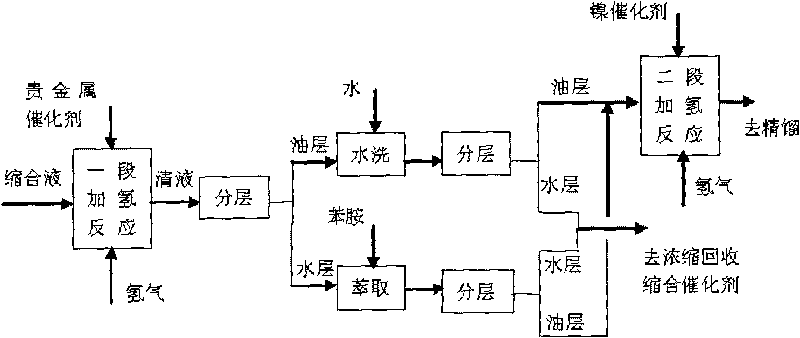

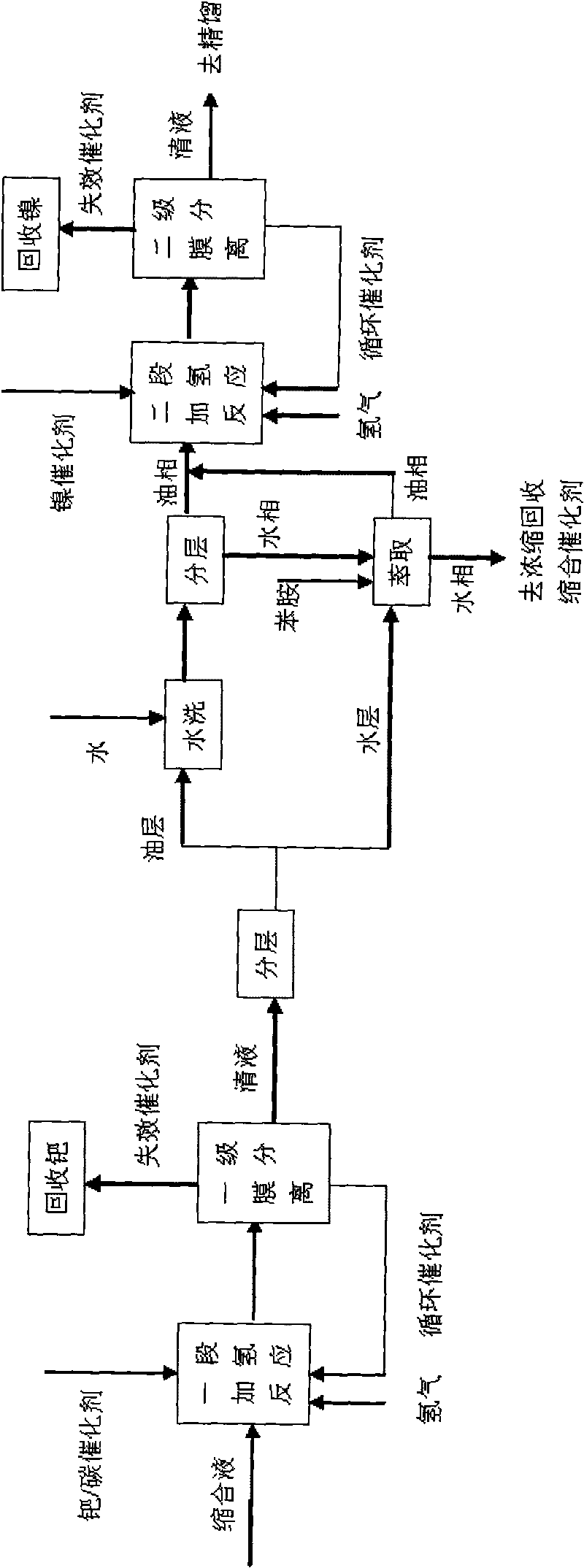

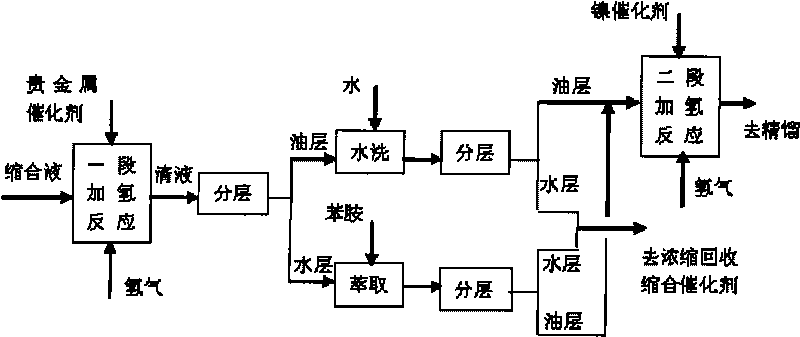

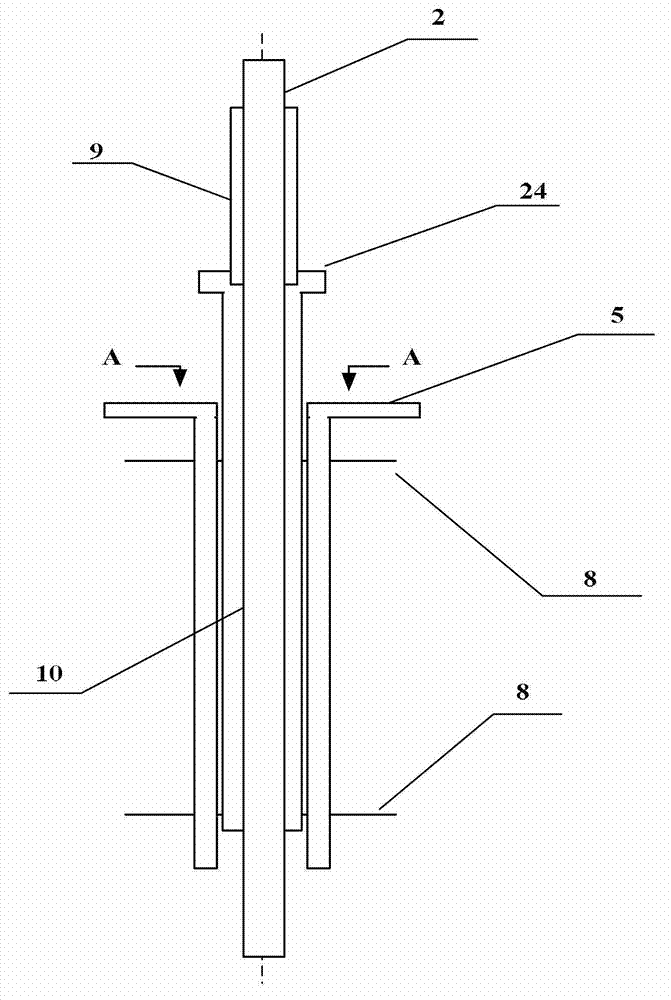

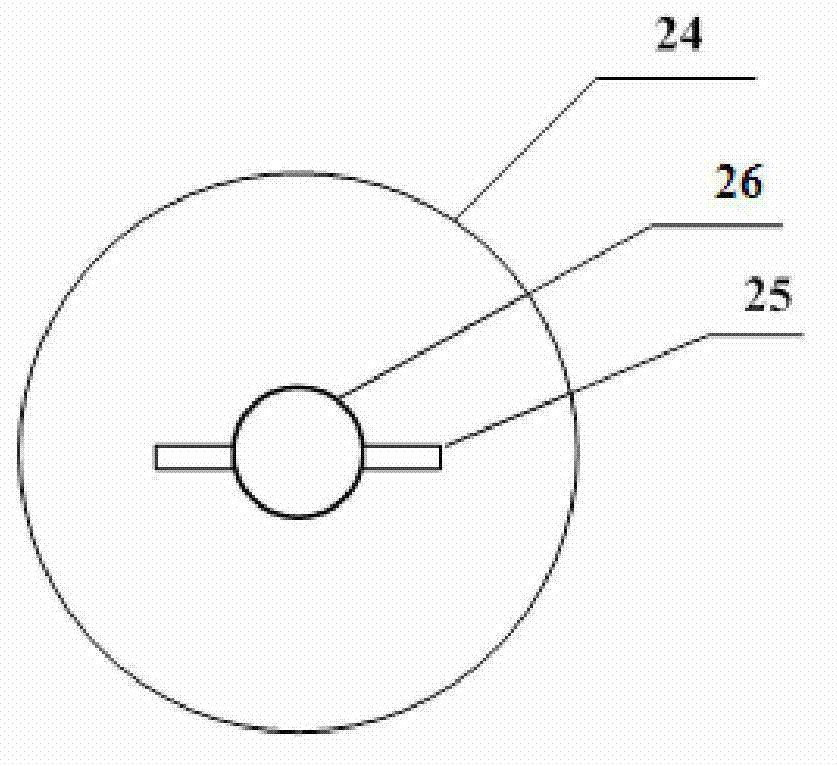

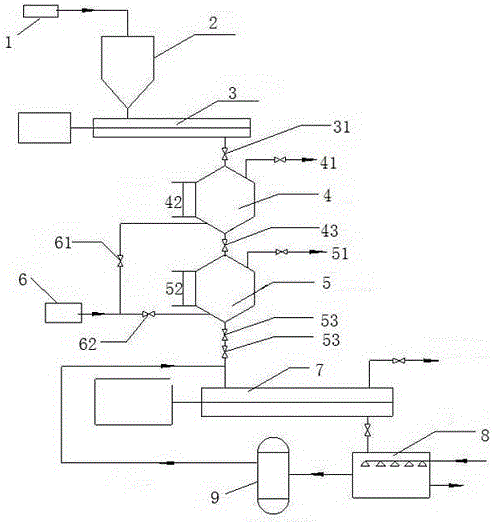

The invention provides a method for preparing 4-amino diphenylamine by catalytic hydrogenation. The method adopts two sections of hydrogenation reaction processes, and comprises the following steps: performing the condensation reaction of condensation solution formed by the condensation reaction of nitrobenzene and aniline which serve as raw materials under an alkaline condition by using using a noble metal hydrogenation catalyst and a nickel catalyst sequentially so as to make the conversion rate of 4-nitroso diphenylamine, 4-nitro diphenylamine and azoxybenzene achieve 100 percent; and separating the noble metal hydrogenation catalyst and the nickel catalyst by using a two-stage membrane separation component system to avoid the loss of small particles of catalyst. At the same time, the method has high degree of automation and can easily realize the continuous hydrogenation process.

Owner:JIANGSU YANGNONG CHEM GROUP +1

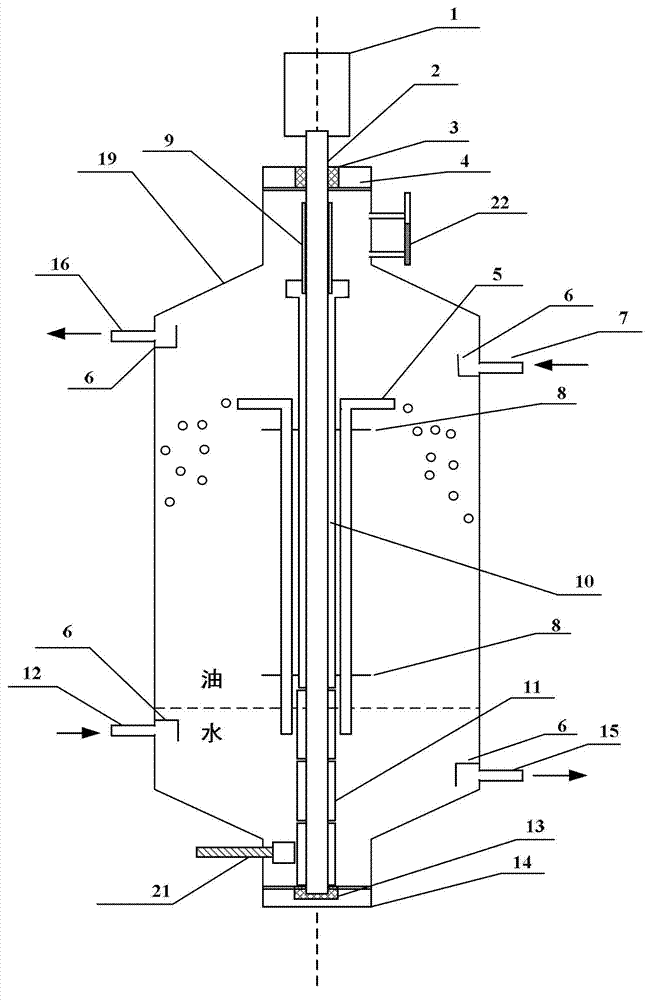

Large phase ratio liquid-liquid two-phase continuous extraction apparatus

ActiveCN102512848APrevent backmixingImproved stage efficiency for unit mass transfer heightsLiquid solutions solvent extractionPhase ratioEngineering

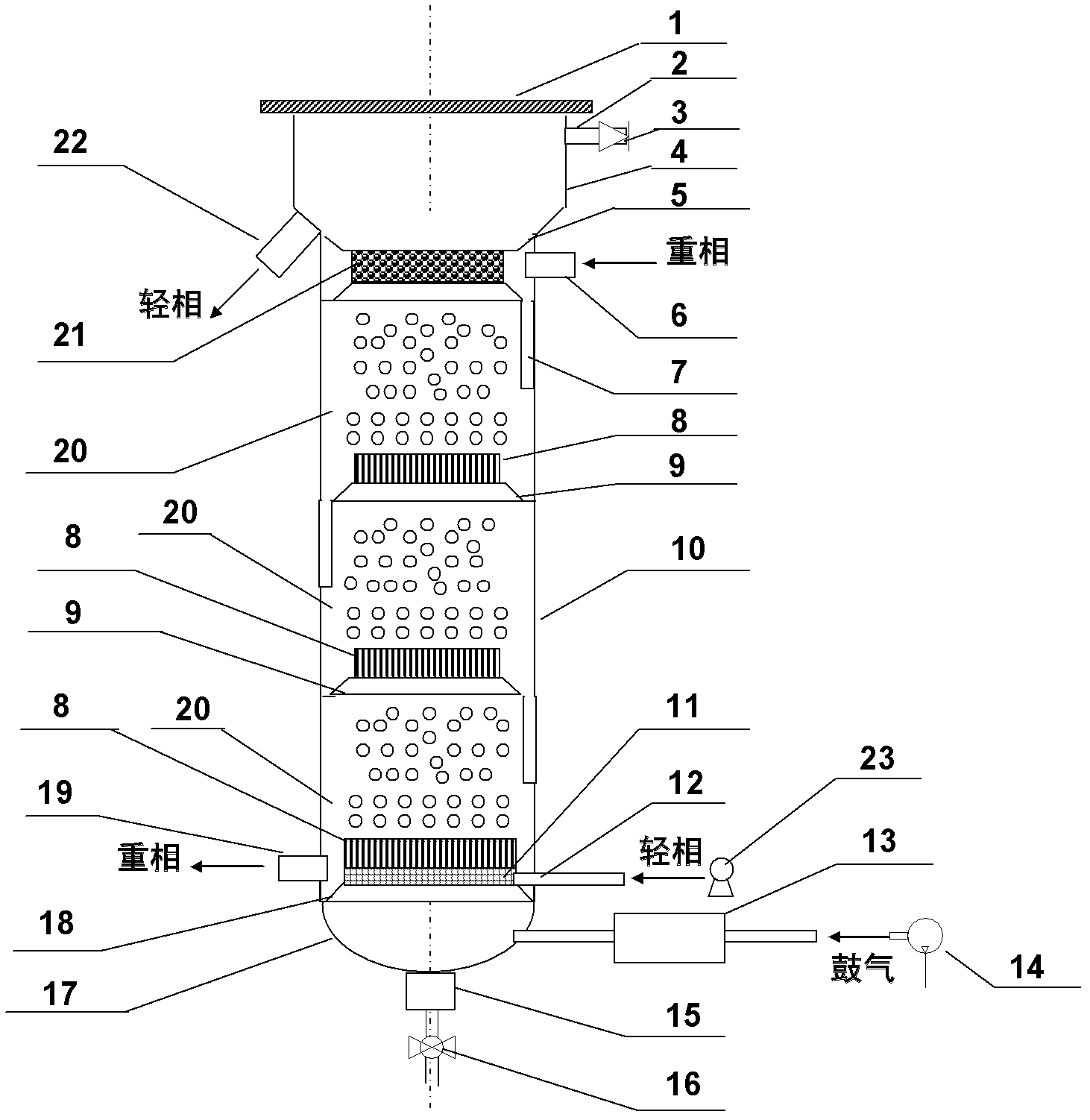

A large phase ratio liquid-liquid two-phase continuous extraction apparatus belongs to the field of liquid-liquid extraction and separation. The apparatus contains a tower body, a gas buffer chamber, a liquid film aggregation device, liquid film dispersers, a liquid film distributor, an air-pressure chamber and the like. The liquid film dispersers and the liquid film distributor can be combined together to realize dispersion of small-volume organic phase by the use of tiny bubbles, thus solving the problem that it is not easy to fully disperse small-volume organic phase by a traditional stirring mode. The phase ratio of a light phase to a heavy phase flowing upstream in the tower body can be adjusted by the interlayer gap of the liquid film distributor. The light phase and the heavy phase can be operated by counter current under the condition of super-large phase ratio. A liquid film disperser and a bubble connection cap are arranged at intervals in the tower body, so as to realize repeated coagulation and dispersion of rising bubbles and achieve high stage efficiency of height of mass transfer unit. A liquid film aggregation device on the top of the tower can be used for bubble coagulation and demulsification and is suitable for extraction operation of an easily-emulsified system. The apparatus provided by the invention is applicable to continuous countercurrent operation under the condition of multi-stage series connection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

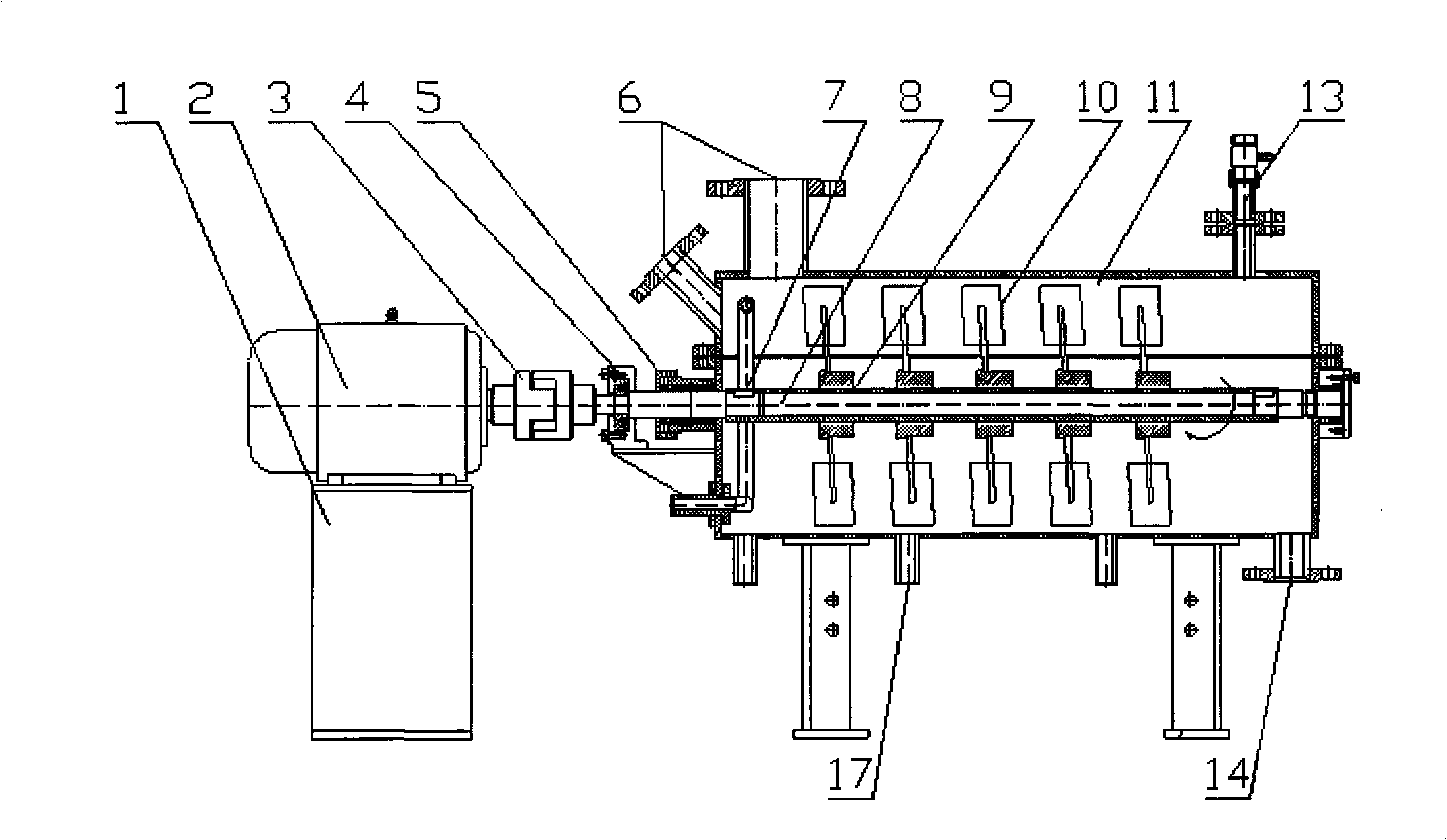

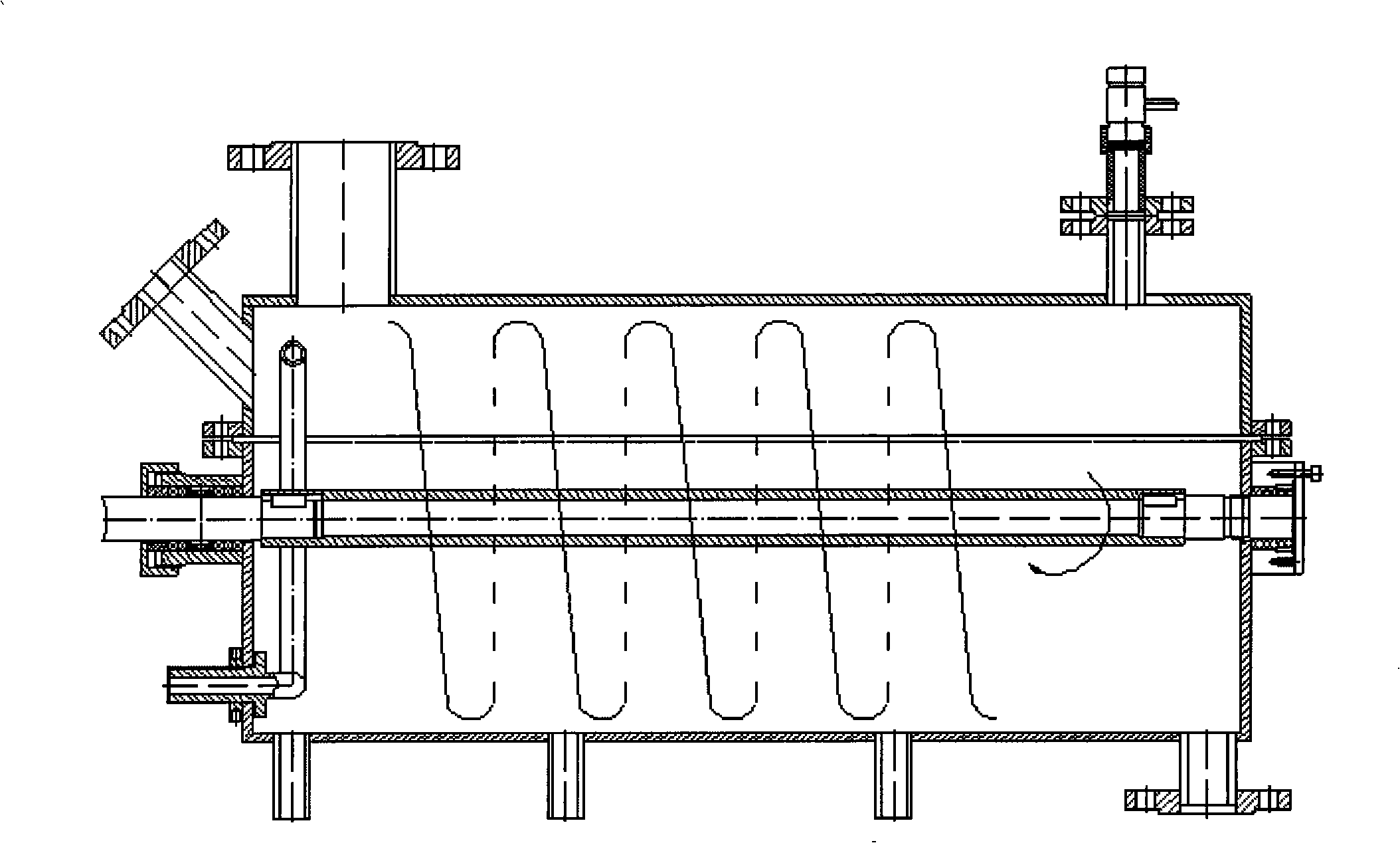

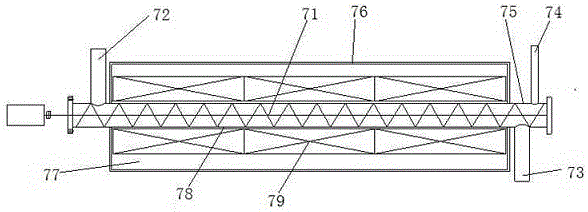

Horizontal helix solid-liquid mixing apparatus

InactiveCN101402025AImprove mixing efficiencyFast mixingRotary stirring mixersMixing methodsContinuous operationMotor drive

The invention discloses a horizontal helical solid-liquid mixing unit, which comprises a speed regulating motor, a bearing pedestal and a cylindrical mixing chamber, wherein the feeding end of the mixing chamber is provided with a solid feed opening and a liquid feed opening, and the discharging end of the mixing chamber is provided with a discharge opening and an exhaust opening; the bottom of the mixing chamber is provided with a cleaning opening; the center of a cylinder is provided with a stirring shaft both ends of which are connected with the bearing pedestal through a rotating shaft respectively; the speed regulating motor drives the rotating shaft to rotate; a helical pitched turbine paddle is fixed on the stirring shaft, and the angle of the helical pitched turbine paddle which is inclined to the stirring shaft is between 2 and 6 DEG; and the inclination angle of a blade of the helical pitched turbine paddle and a disc surface is between 3 and 9 DEG. Compared with the prior art, the mixing unit has high mixing efficiency, high speed and uniform mixing of materials, does not leave dead angle, and is suitable for continuous operation. Moreover, the device has a simple overall structure, and is convenient to assemble, disassemble and clean.

Owner:ZHEJIANG UNIV

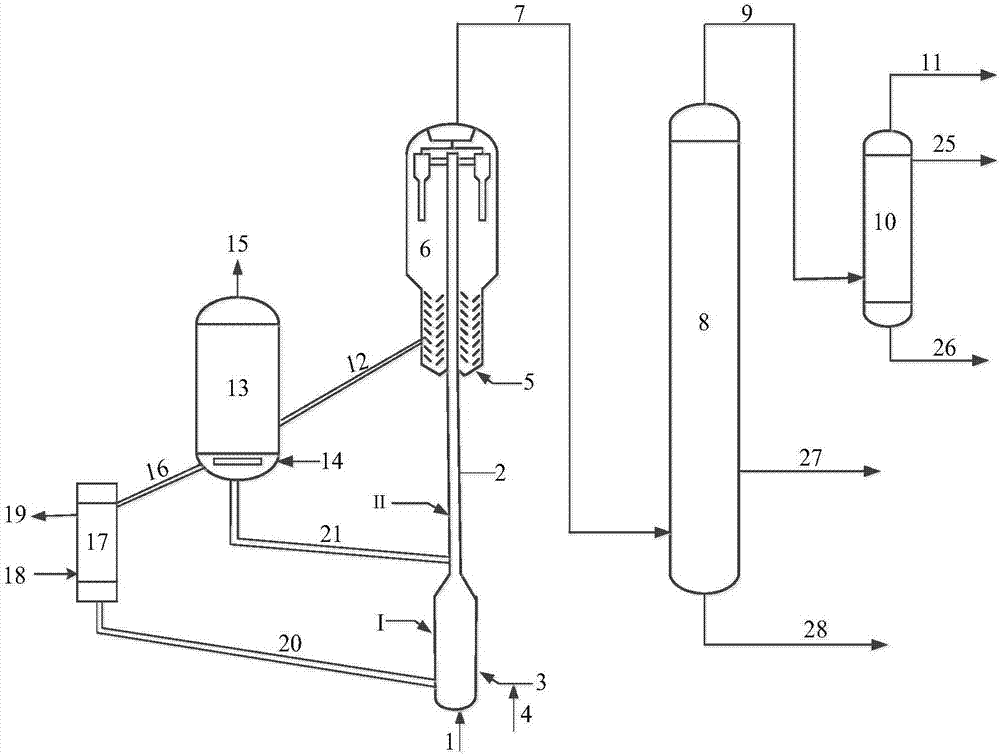

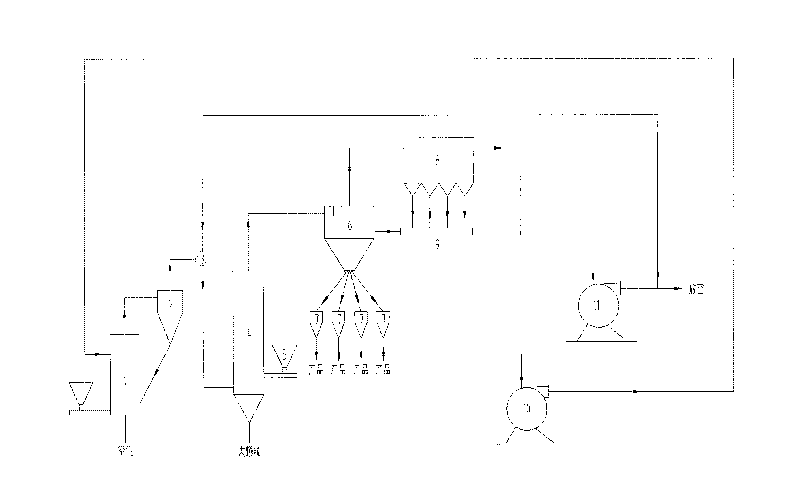

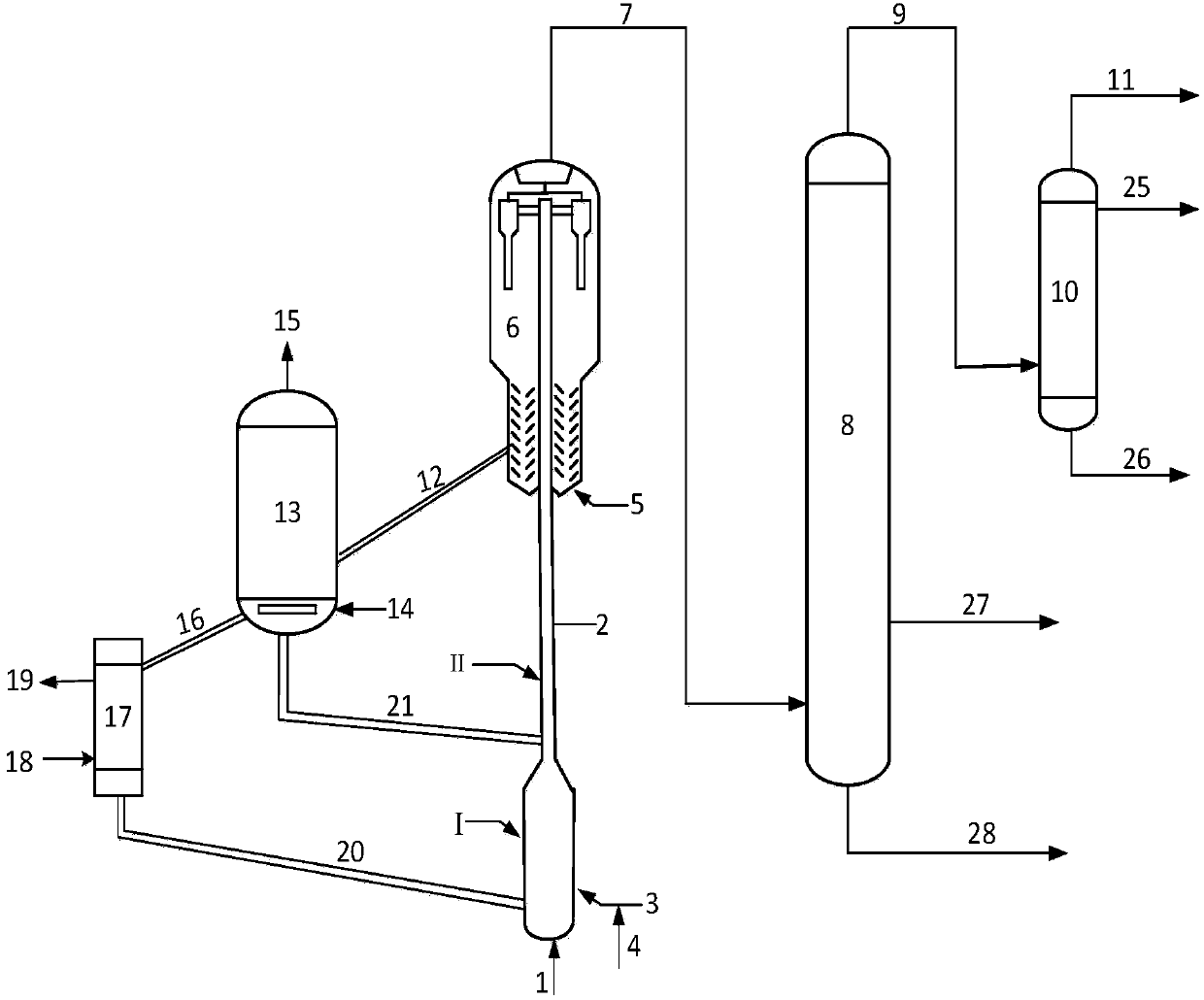

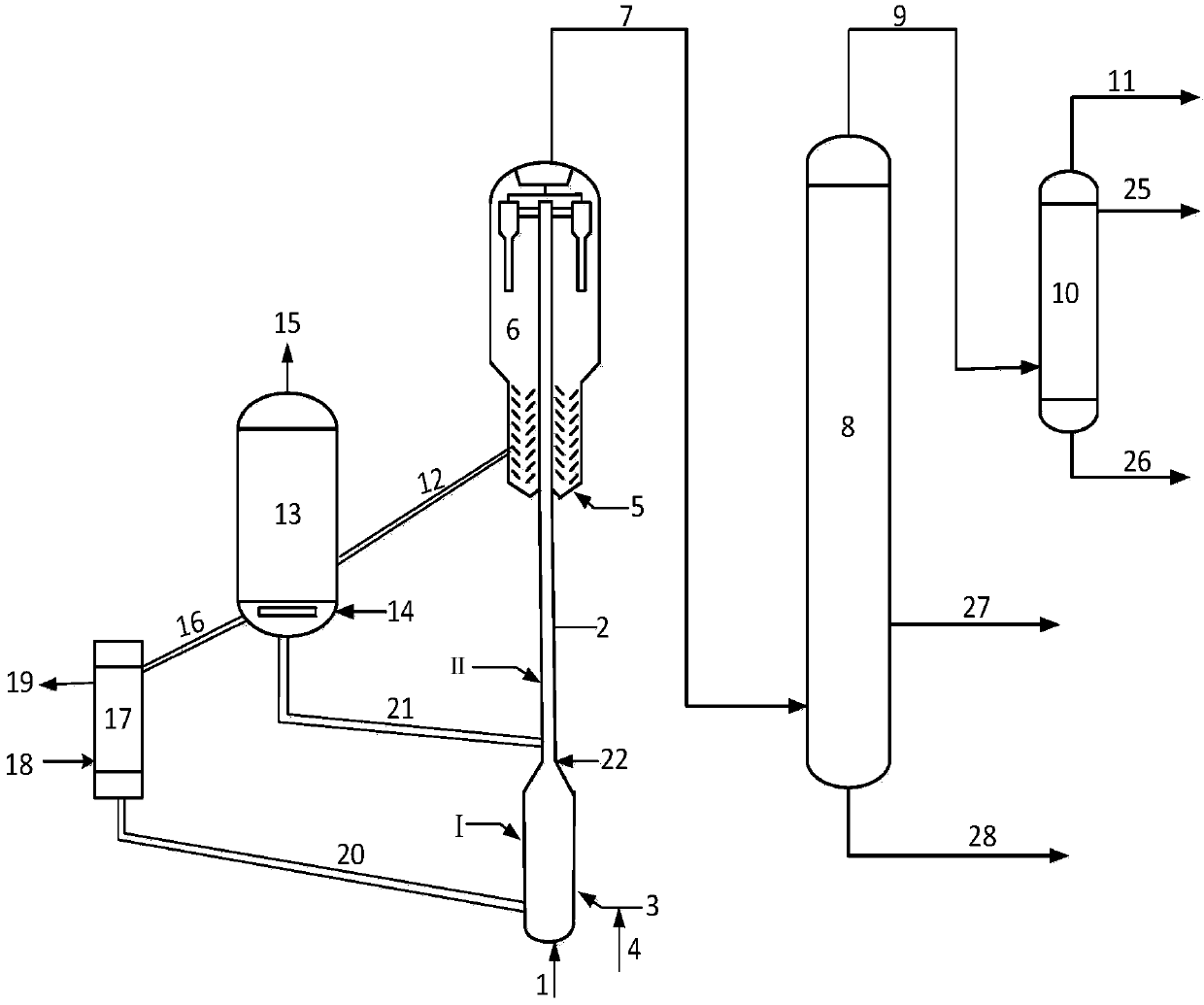

Processing method and system for inferior crude oil

ActiveCN107267211AEliminates rich gas compressorReduce device energy consumptionTreatment with hydrotreatment processesChemistryDry gas

The invention discloses a processing method and system for inferior crude oil. The method comprises the steps as follows: a, feeding hydrogen-containing gas and the inferior crude oil into a fluidized bed hydrogen absorption zone (I) of a fluidized bed riser reactor for contact with a first catalytic cracking catalyst and a hydrogen adsorption reaction to obtain a hydrogen absorption product; b, feeding the hydrogen absorption product obtained in the step a into a riser cracking zone (II) of the fluidized bed riser reactor for contact with a second catalytic cracking catalyst and a catalytic cracking reaction to obtain catalytic cracked oil-gas. The inferior crude oil processed by the system with the method has the advantages that the conversion rate of the inferior crude oil can be increased substantially, the yield of dry gas and coke is reduced, and accordingly, clean and efficient use of the inferior crude oil is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

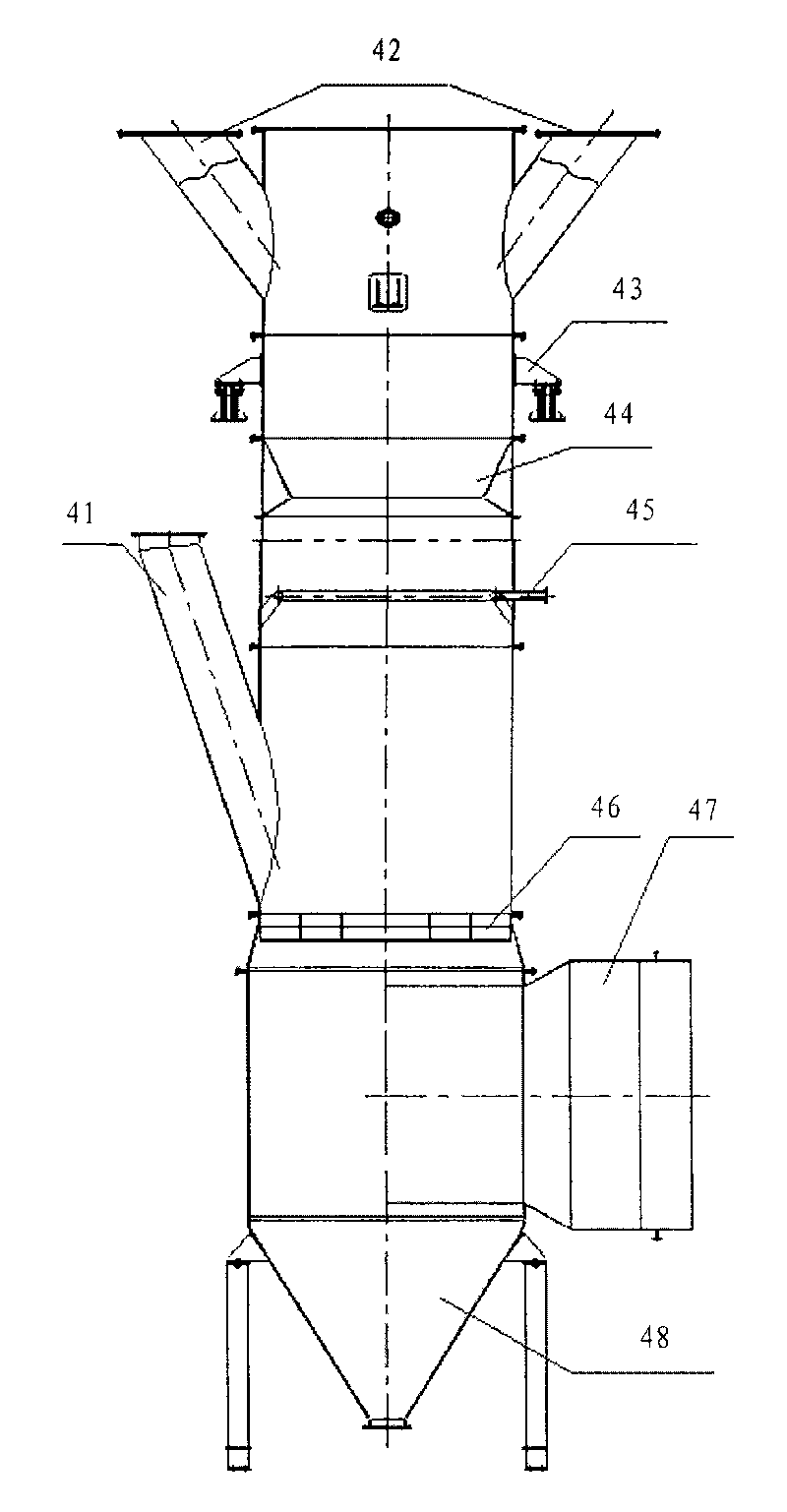

Smoke semi-closed circulating lignite straight pipe type airflow drying method

ActiveCN101726167AGood dispersionImprove dry strengthDrying solid materials with heatDrying gas arrangementsAir volumeDirect combustion

The invention relates to a smoke semi-closed circulating lignite straight pipe type airflow drying method, which ensures the safety and reliability of a device and makes the maximization of the device possible through direct combustion of lignite to generate smoke, once drying of a straight pipe type airflow dryer to meet the moisture requirement of a product, large-grain inertia setting, collection of a fine grain bag type dust collector, even blending of large grains and fine grains through a blending device, emptying and air quantity control through a mixed temperature fan and a booster fan.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

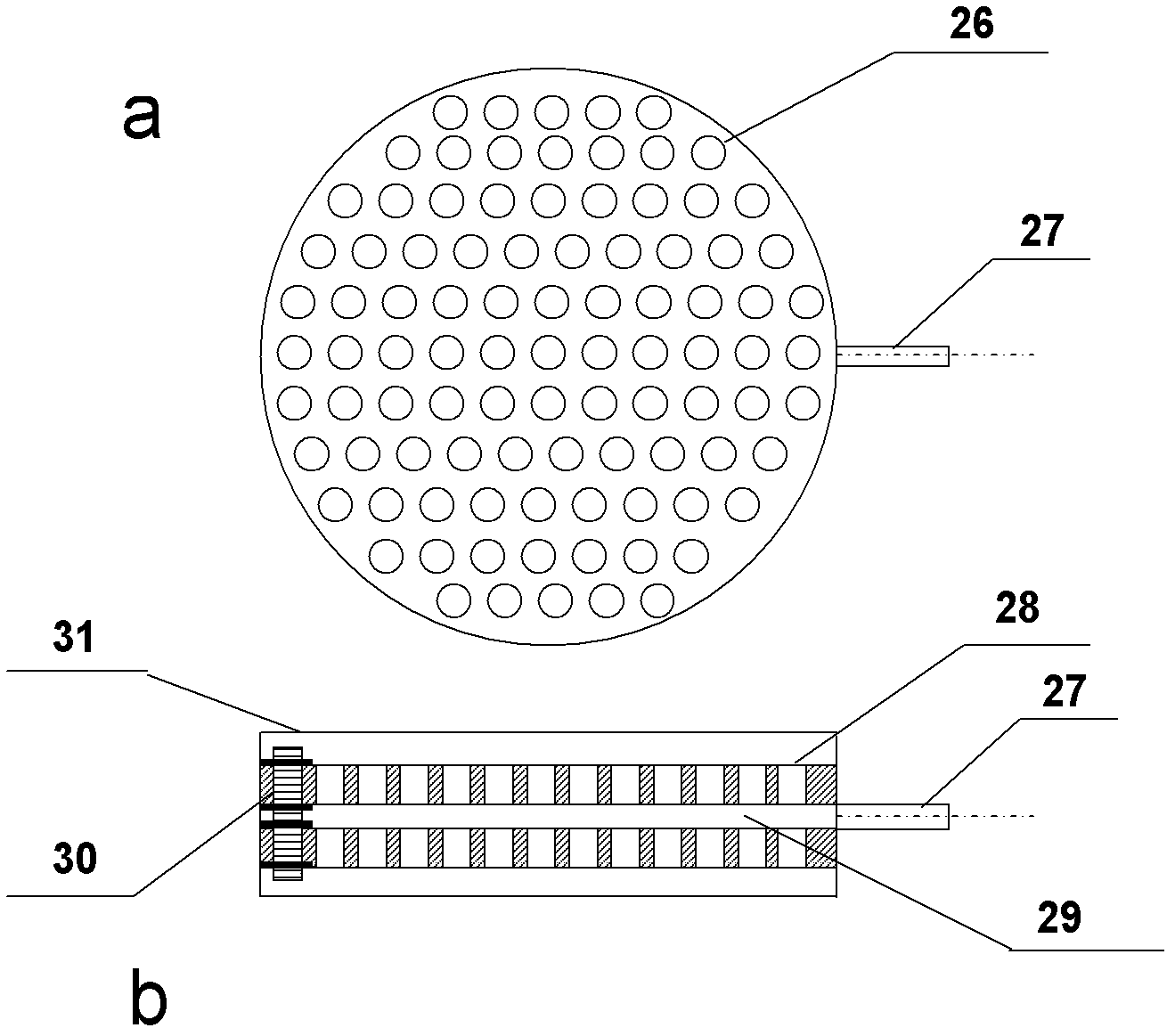

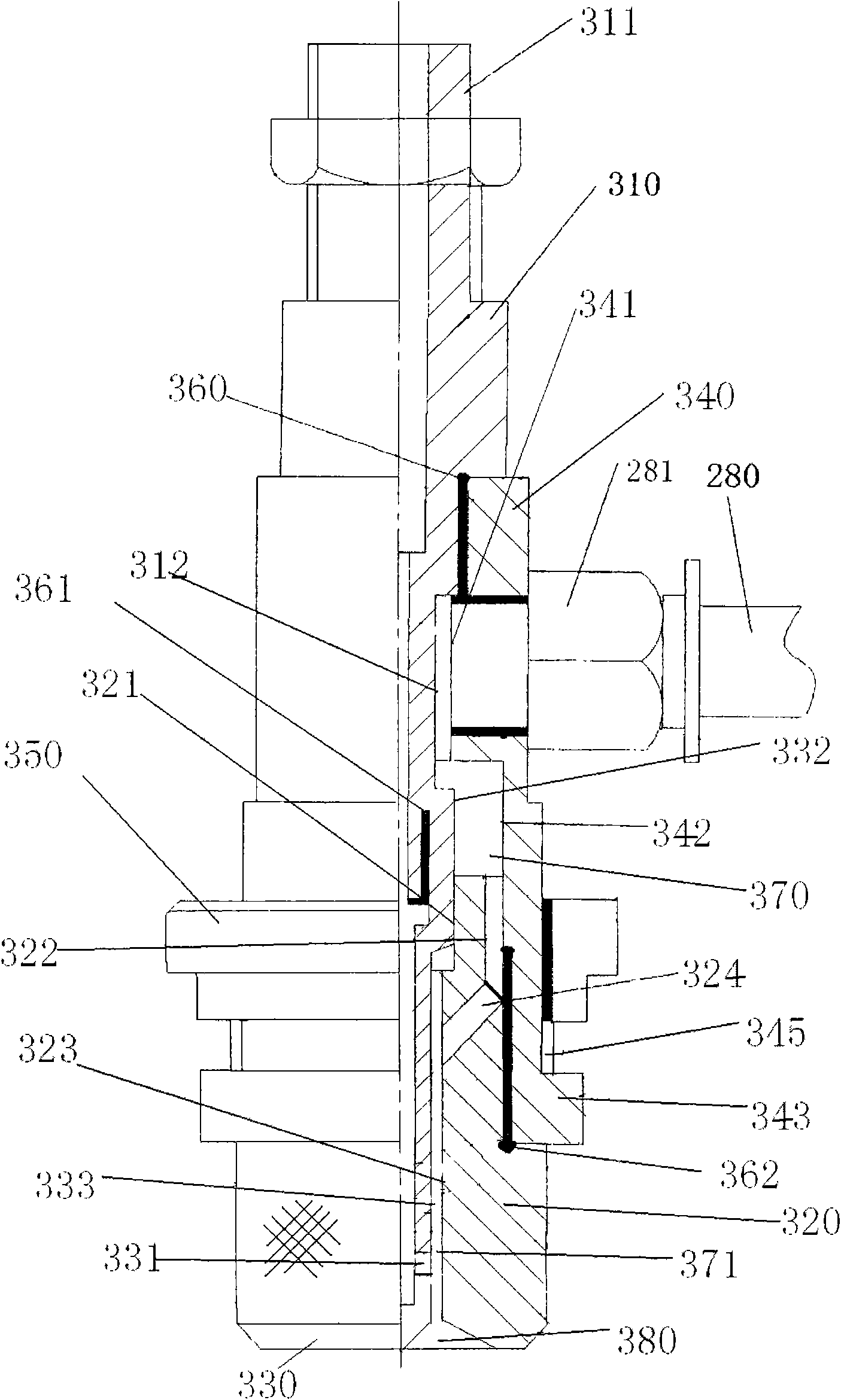

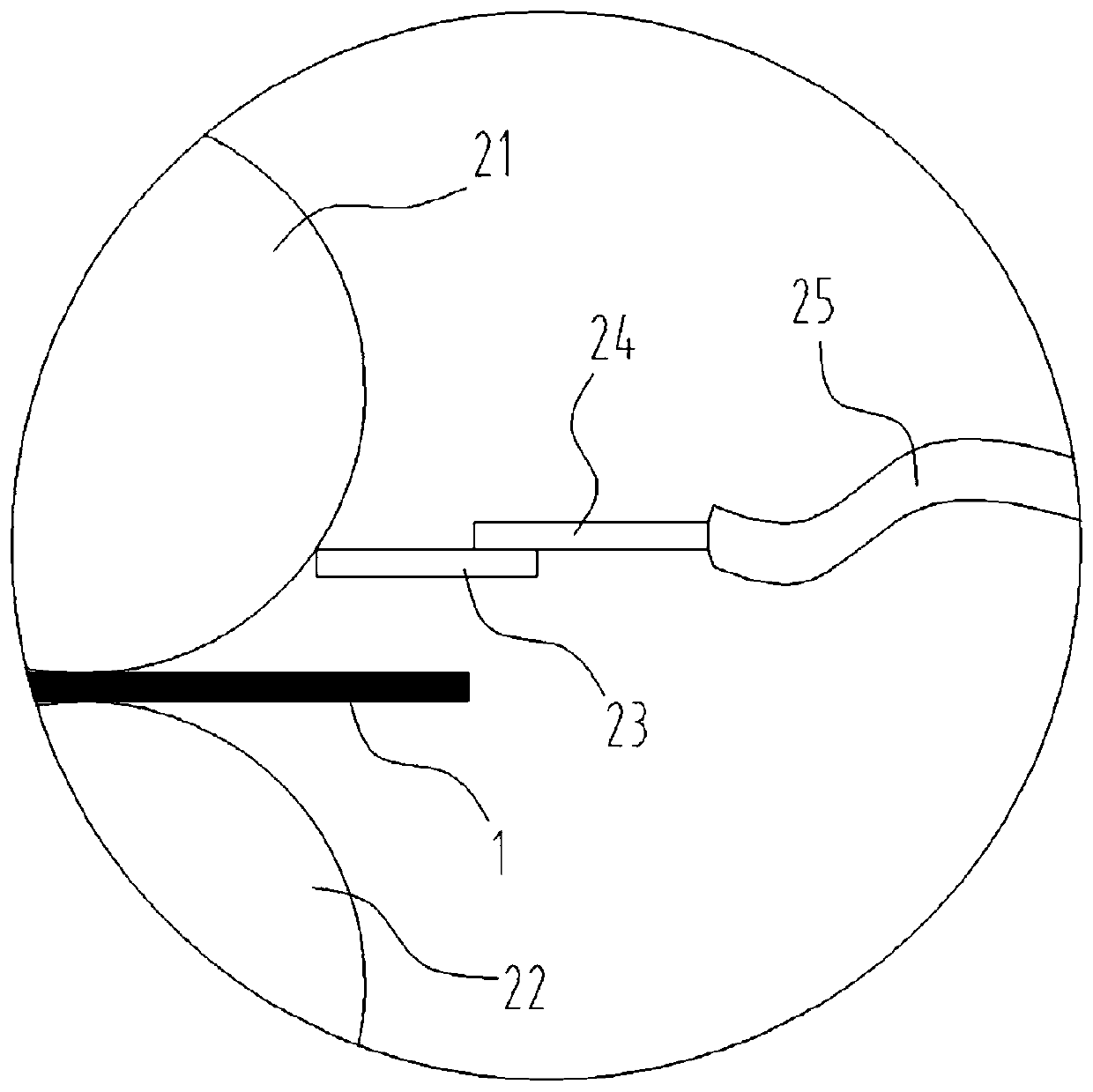

Column type extraction device for pipe bundle multi-channel phase-dispersing and extraction method thereof

InactiveCN102772913ALess prone to turbulenceSuitable for extraction operationLiquid solutions solvent extractionStraight tubeOil phase

The invention relates to a column type extraction device for pipe bundle multi-channel phase-dispersing; a main shaft is arranged inside the column type extraction device; two or at least three hollow thin tubes in parallel to the main shaft are distributed on the outer circumference of the main shaft; one end of each hollow thin tube is provided with a straight tube, and the other end of the hollow thin tube is bent to form a flanged bend; the bending direction of the flanged bend is the remote direction of a mounting shaft; the main shaft is connected with an electric motor, and drives the hollow thin tubes to carry out motion at a same speed with the main shaft when the main shaft rotates. The column type extraction device disclosed by the invention solves the difficult problems that a water phase or an oil phase with relatively small volume is difficult to disperse completely in the conventional mechanical stirring manner when the volume ratio of the water phase to the oil phase in an extraction process is large; and the difficult problems that the water phase and the oil phase are difficult to clarify and separate in an extraction system and the like caused by easy emulsification are also solved when the flow-rate ratio of the water phase to the oil phase is large.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

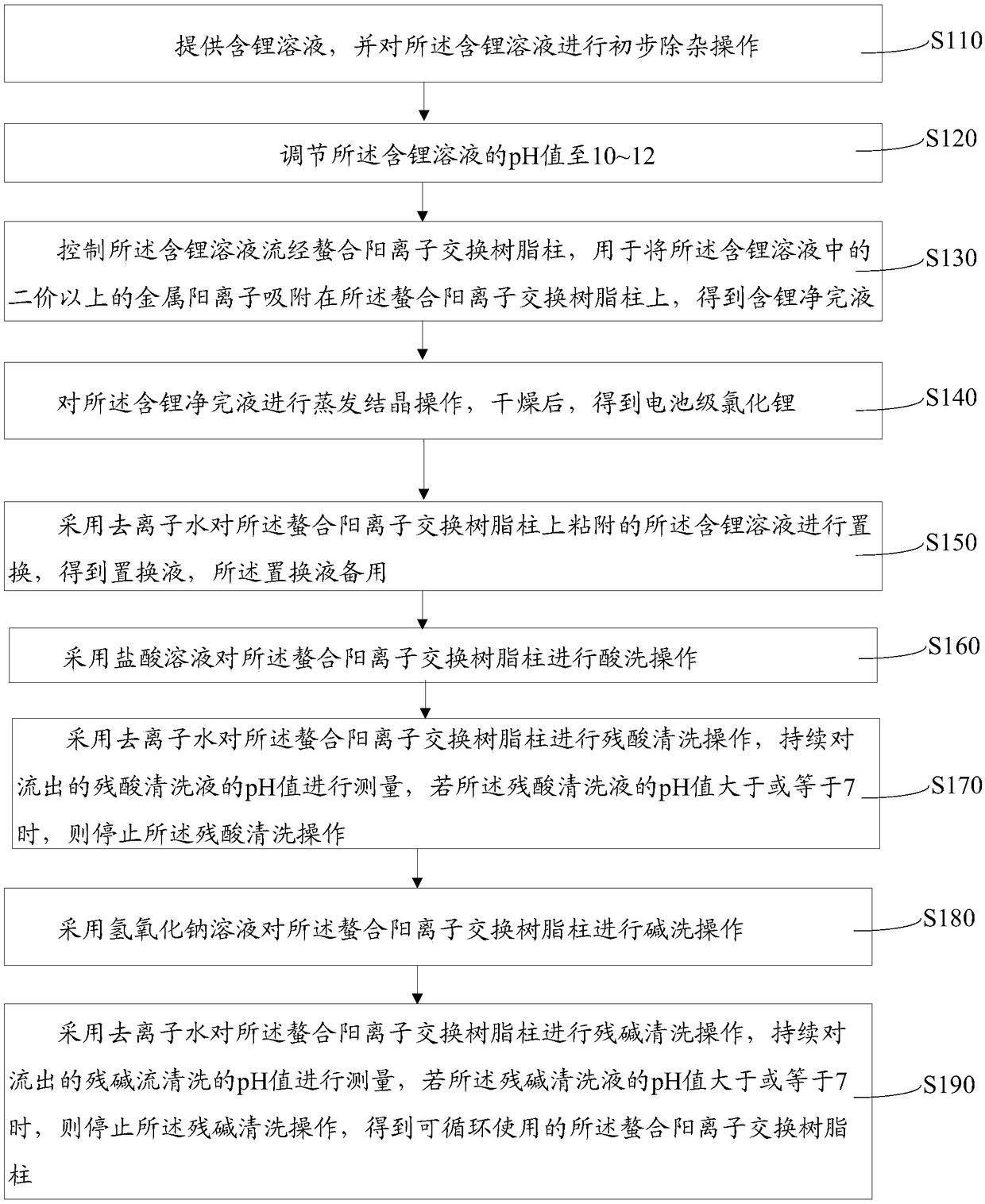

Deep impurity removal method for cell-grade lithium chloride

The invention provides a deep impurity removal method for cell-grade lithium chloride. The method comprises the following steps: a lithium-containing solution is subjected to preliminary impurity removal, then pH is regulated to 10-12, the solution passes through a chelating cation exchange resin column, so that bivalent or higher metal cations in the lithium-containing solution are adsorbed, a lithium-containing purified liquid is obtained and is evaporated, crystallized and dried, and cell-grade lithium chloride is obtained; then the chelating cation exchange resin column is replaced with deionized water, pickled with a hydrochloric acid solution and subjected to reacted acid washing with deionized water, alkaline washing with a sodium hydroxide solution and residual alkali washing withthe deionized water sequentially, and the recyclable chelating cation exchange resin column is obtained. According to the deep impurity removal method for cell-grade lithium chloride, deep impurity removal of cell-grade lithium chloride can be completed once, cell grade is reached, precipitates cannot be produced, impurity removal cost and environmental protection risks are reduced, lithium recovery rate is increased, and the chelating cation exchange resin column is recyclable, so that the impurity removal cost is saved.

Owner:湖北金泉新材料有限公司

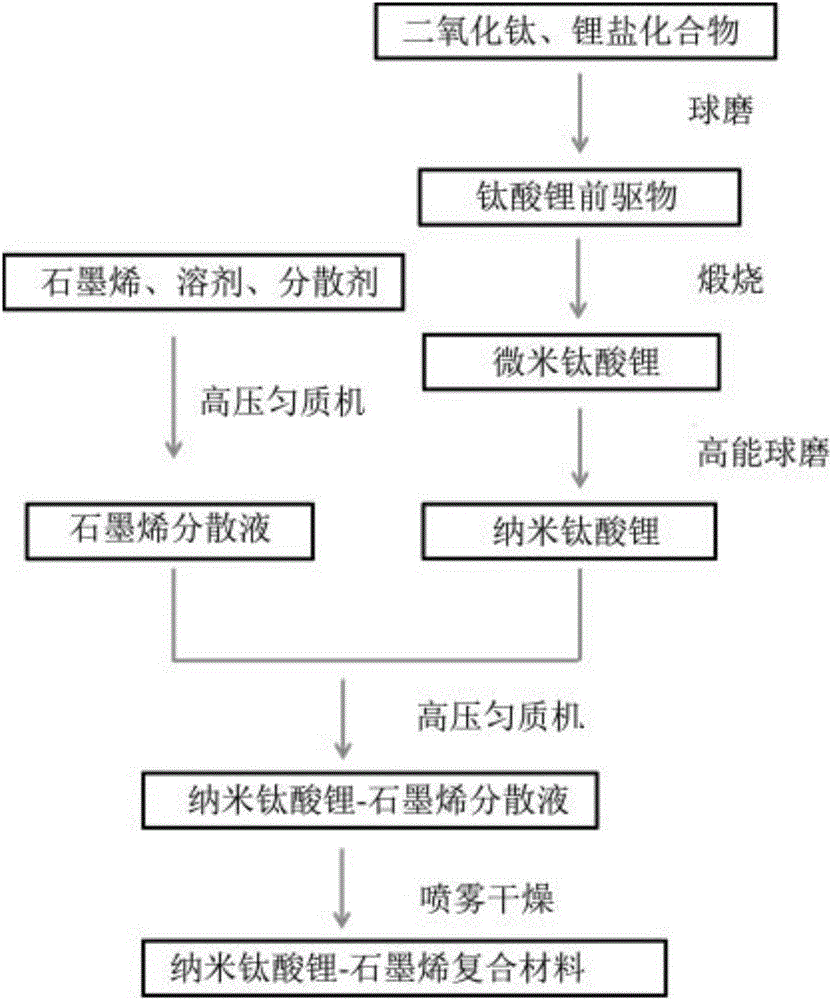

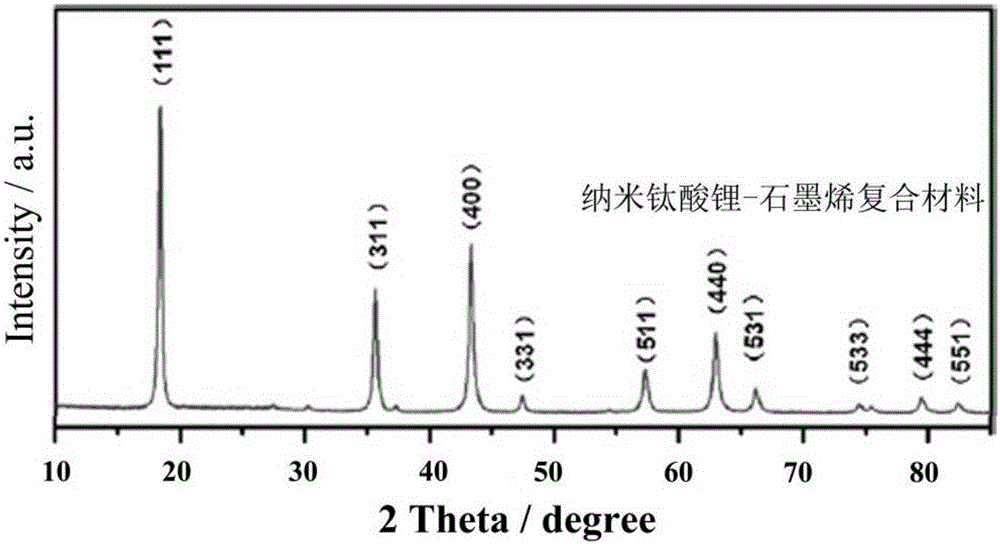

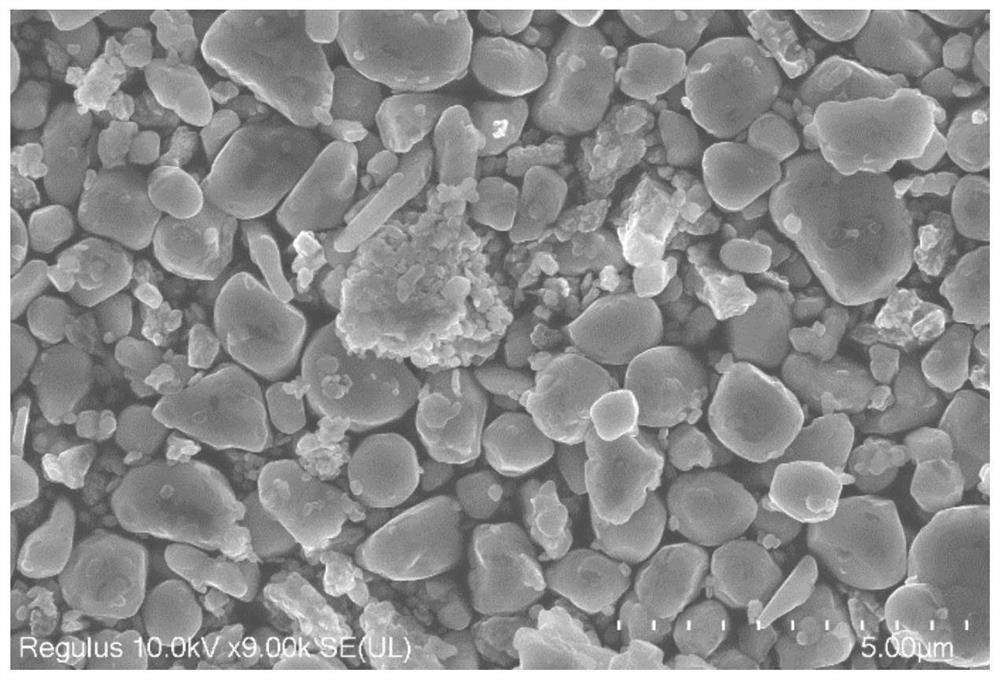

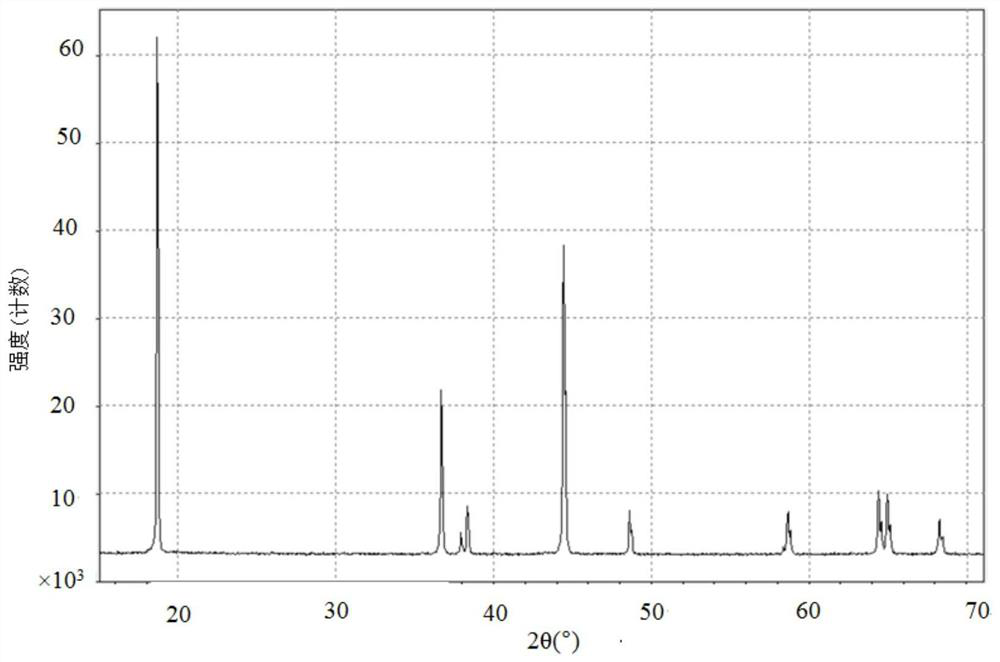

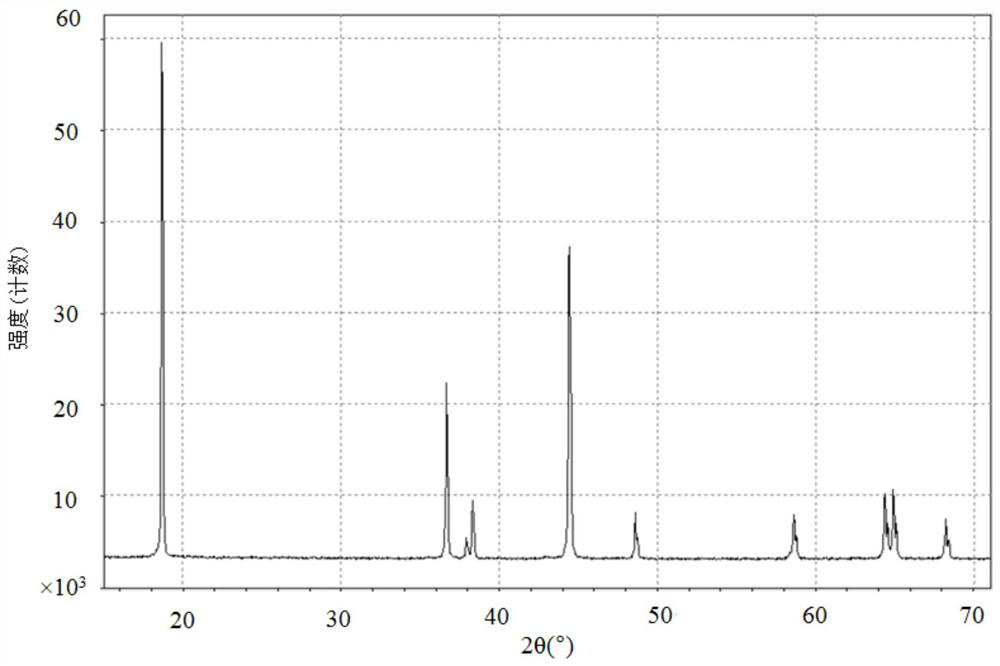

Nano lithium titanate-graphene composite material and preparation method therefor

ActiveCN106374086AShorten the diffusion distanceImprove conductivityMaterial nanotechnologyCell electrodesHigh pressureCvd graphene

The invention discloses a nano lithium titanate-graphene composite material and a preparation method therefor. A graphene material is prepared into a graphene super-dispersion liquid firstly; ball-milled super-lithium titanate nano powder is mixed through a high-voltage micro-jet-flow technology to obtain the nano lithium titanate-graphene composite material; and next, a step of spraying and drying is performed to prepare the spherical lithium titanate-graphene composite material. The invention also relates to the nano lithium titanate-graphene composite material prepared by the abovementioned preparation method.

Owner:温州弘德仪器科技有限公司

Facility cultivation technique for crop rotation of stropharia rugosoannulata and rice

InactiveCN108990697AUniform fruitingThe fruiting rate is stableCultivating equipmentsPlant protectionNutrientHyphomycetes

The invention discloses a facility cultivation technique for crop rotation of stropharia rugosoannulata and rice, and belongs to the technical field of edible mushroom cultivation. The facility cultivation technique includes the steps of fermentation of a culture material, construction of a mushroom shed, construction of a ridged bed, seeding, mycelium management and protection, mushroom cultivation and harvesting, and rice planting and harvesting. After the components of the culture material are subjected to composting and fermentation separately, layered laying is adopted, so that nutrient and oxygen supply in the development process of mycelia and fruiting bodies is ensured, the whole fruiting is uniform, the fruiting rate is stable, the total yield is high, the quality is good, the planting cycle is short, and the continuous cropping obstacles can be solved by crop rotation of the stropharia rugosoannulata and rice.

Owner:湖北省曙骧生态农业有限公司

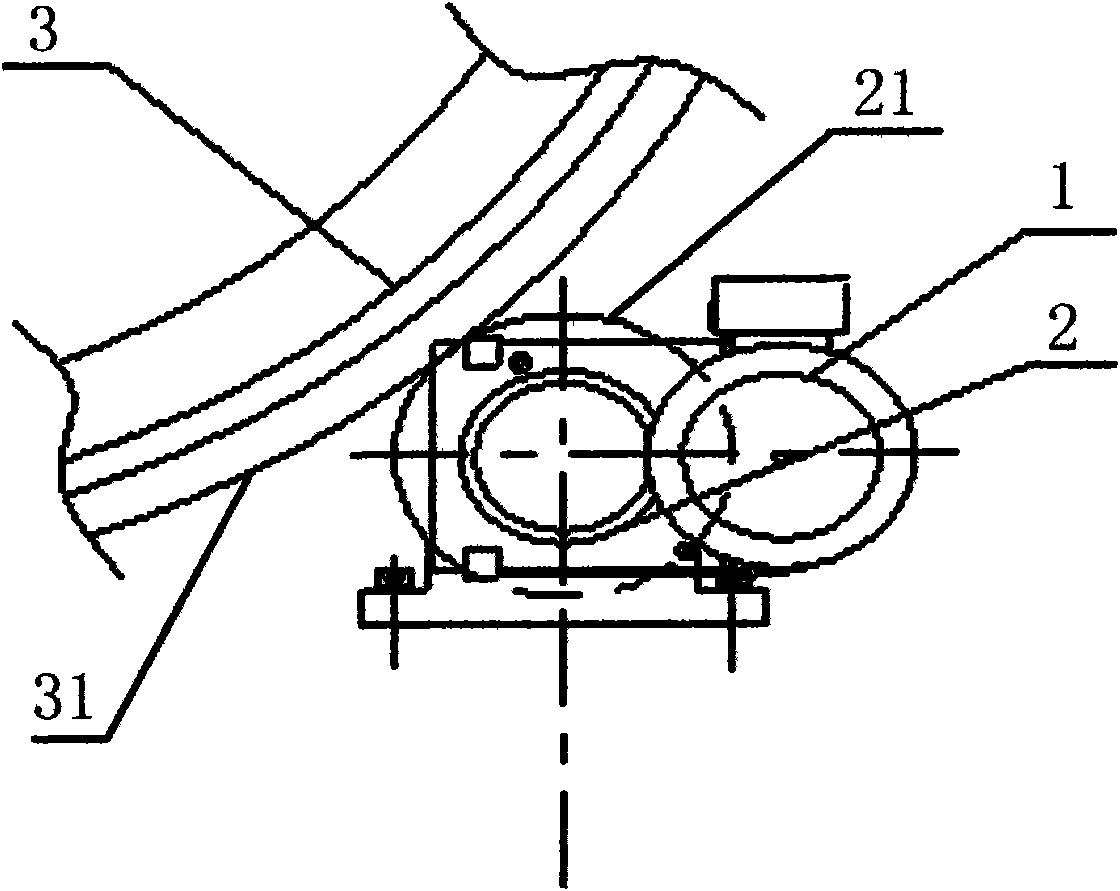

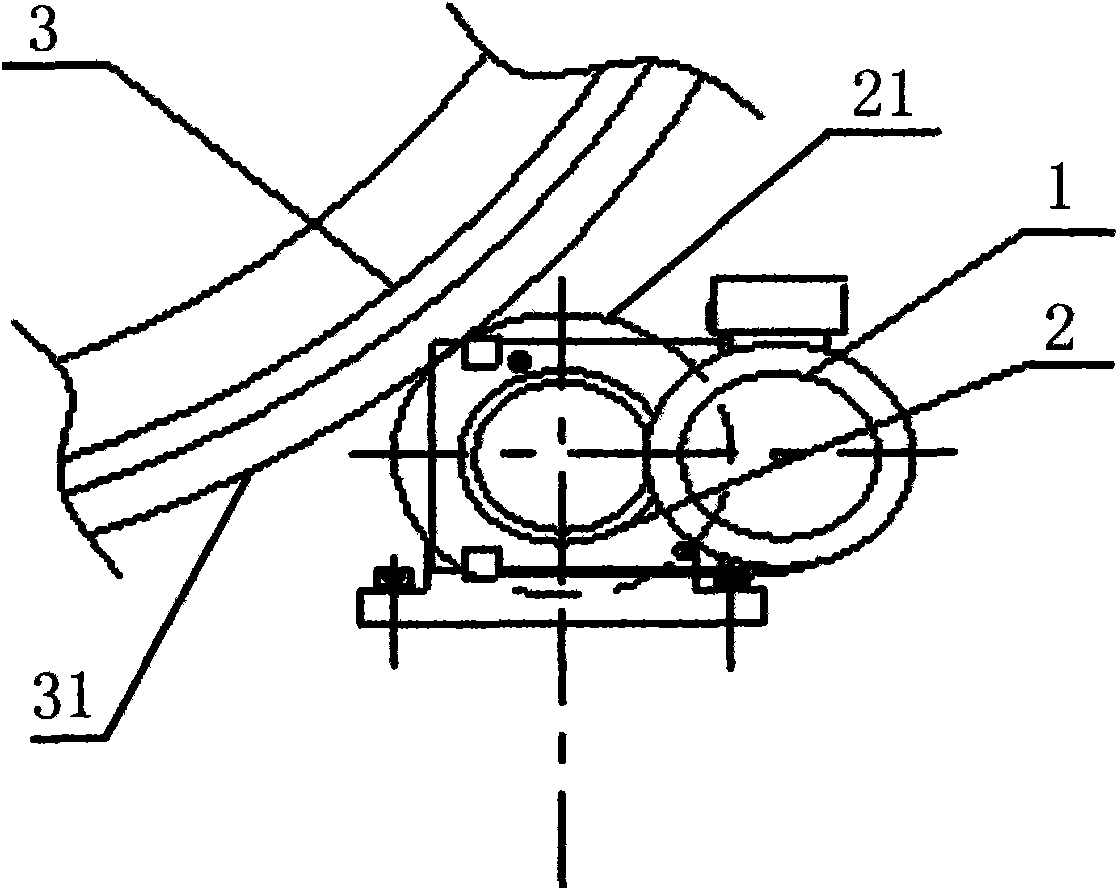

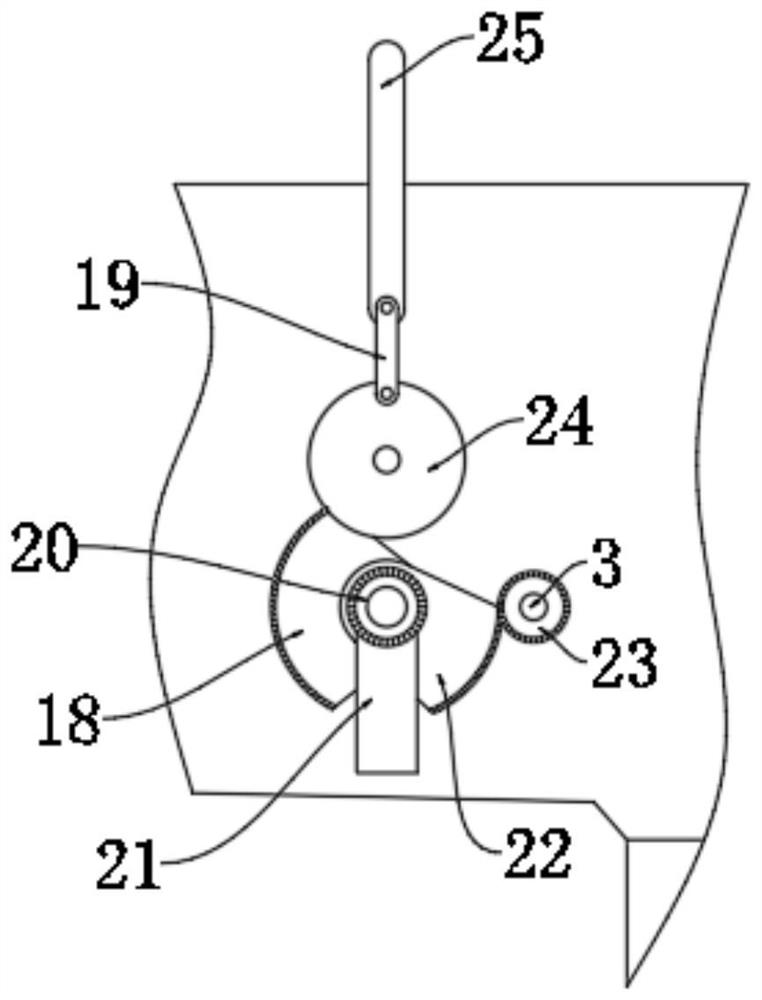

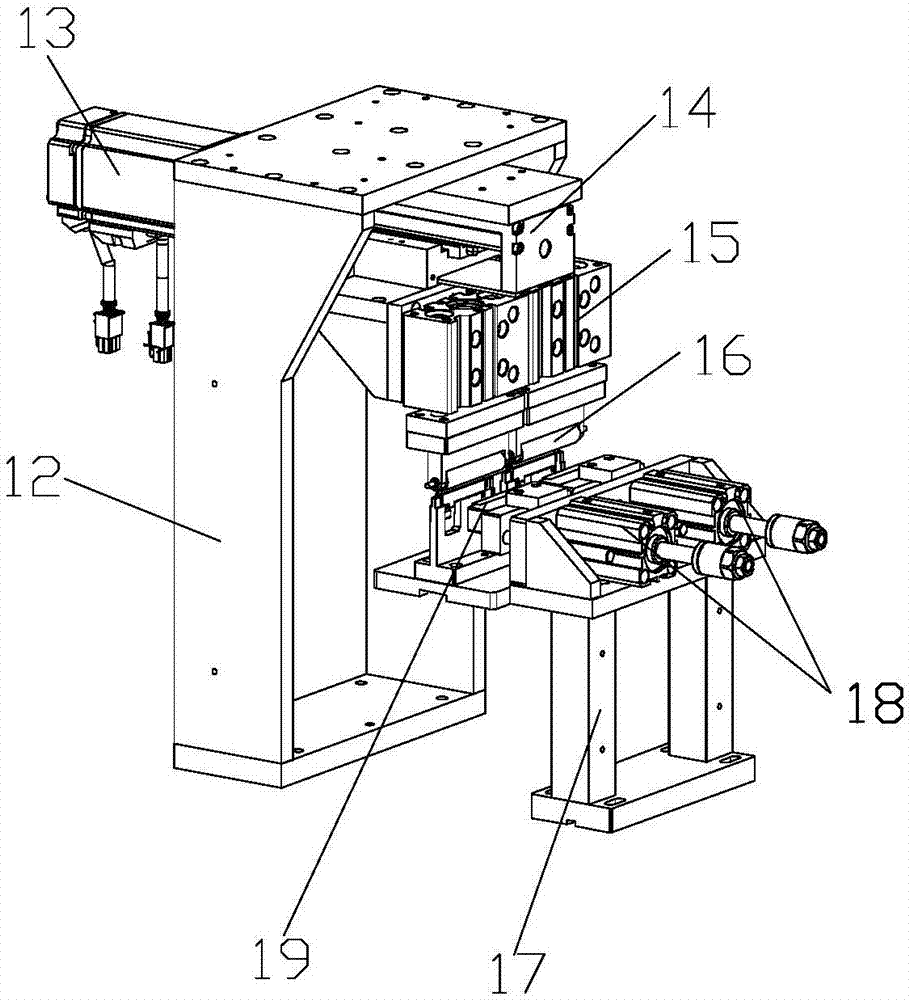

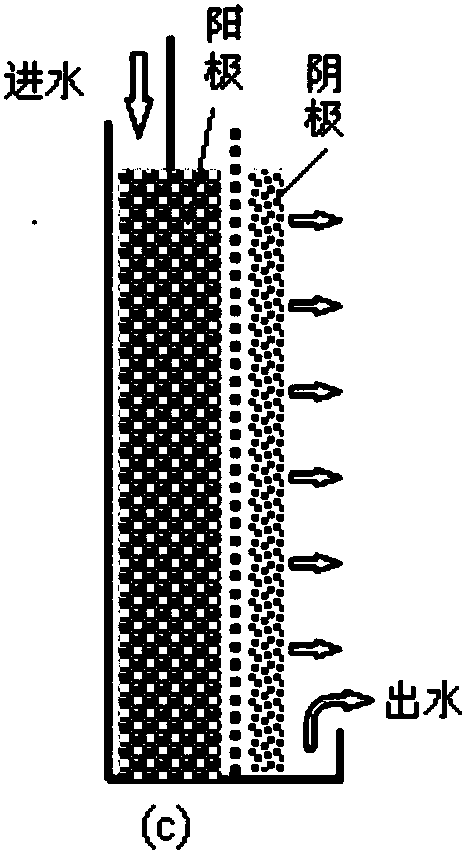

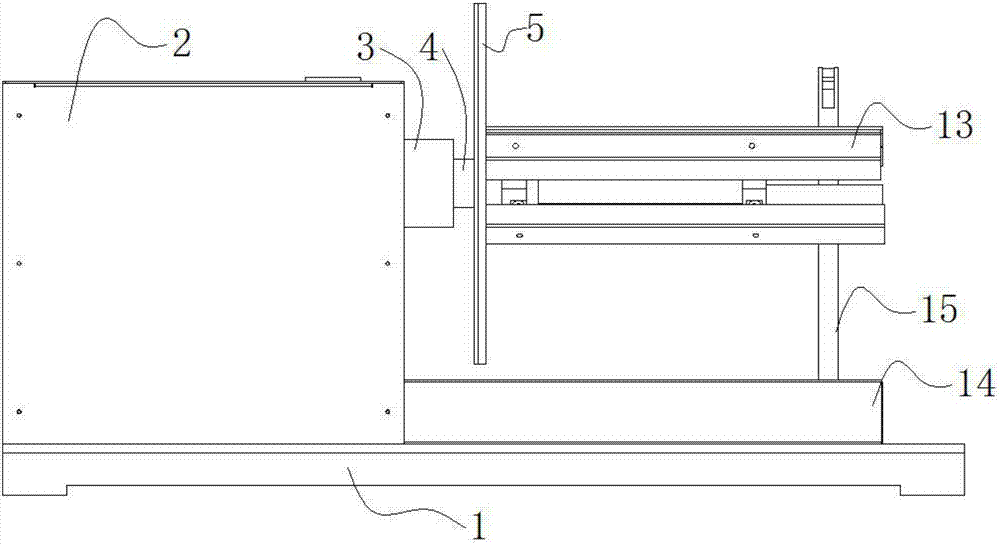

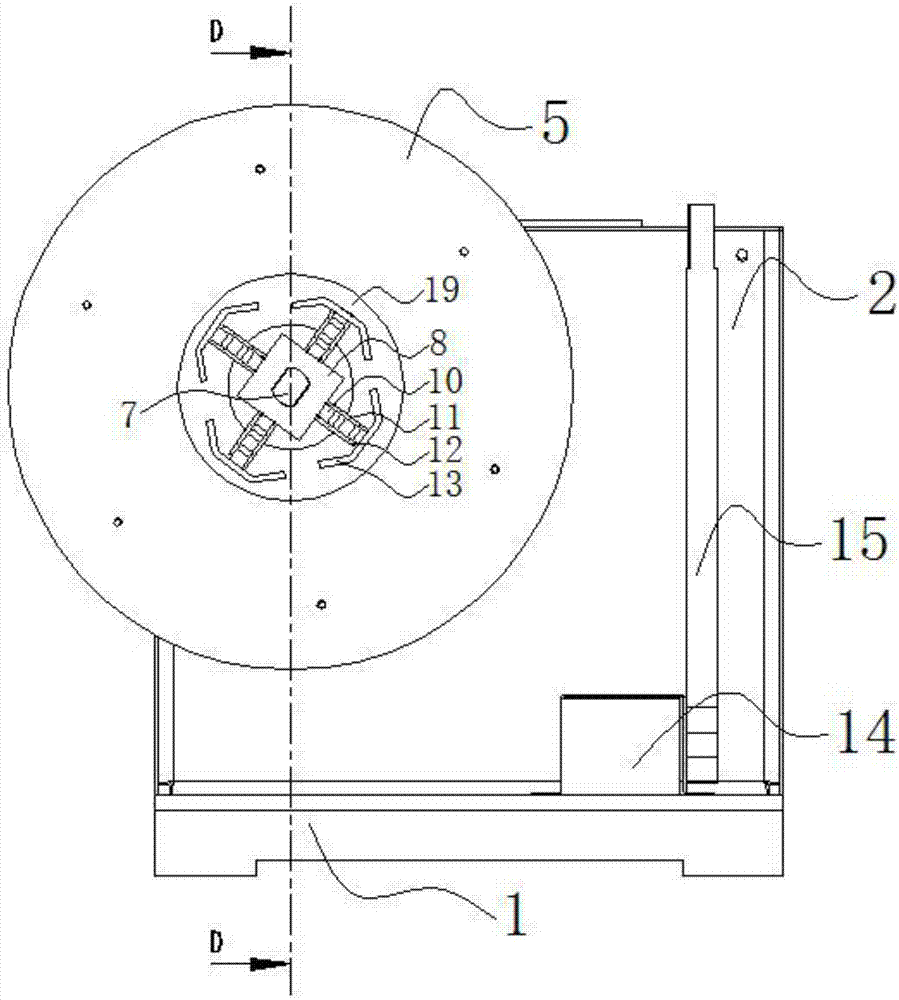

Sand box turning mechanism

InactiveCN102019364AAvoid getting stuck easilyAvoid the lack of pauseMoulding machinesAutomatic controlElectric machinery

The invention relates to a sand box turning mechanism, which comprises a friction wheel and a box turning machine wheel, wherein the friction wheel is driven by a motor; the box turning machine wheel is connected with a turned sand box; and the friction acting surface of the outer rim of the friction wheel and the outer rim surface of the sand box machine wheel form a group of interactional friction surfaces. A frictional transmission mechanism is driven by the motor, so that the automatic control performance of the box turning mechanism is improved.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

UV-curable strippable ink as well as production method and construction method of UV-curable strippable ink

ActiveCN104327593ALow viscosityReduce thixotropyInksPrinting after-treatmentScreen printingHazardous substance

The invention relates to the technical field of chemical engineering and particularly relates to an UV-curable strippable ink as well as a production and construction methods of the UV-curable strippable ink. The UV-curable strippable ink disclosed by the invention has the advantages of low viscosity, good thixotropy, short curing time and no need of high temperature baking during the curing process, can improve the curing efficiency and is suitable for continuous operation; since the UV-curable strippable ink contains no volatile substances, such substances harmful to human bodies and the device as HCl and oil fume cannot be produced and the UV-curable strippable ink is in full compliance with requirement for environment protection; the production method of the UV-curable strippable ink is simple in process and low in cost; according to the construction method of the UV-curable strippable ink, the UV-curable strippable ink is not adhered to a board during the screen printing process and is easy to strip in the later manufacturing procedure, does not pollute a substrate and has good toughness and acid-alkali resistance, and the yield rate in the manufacturing procedure can be preferably improved.

Owner:GUANGZHOU SHUANGKE NEW MATERIAL

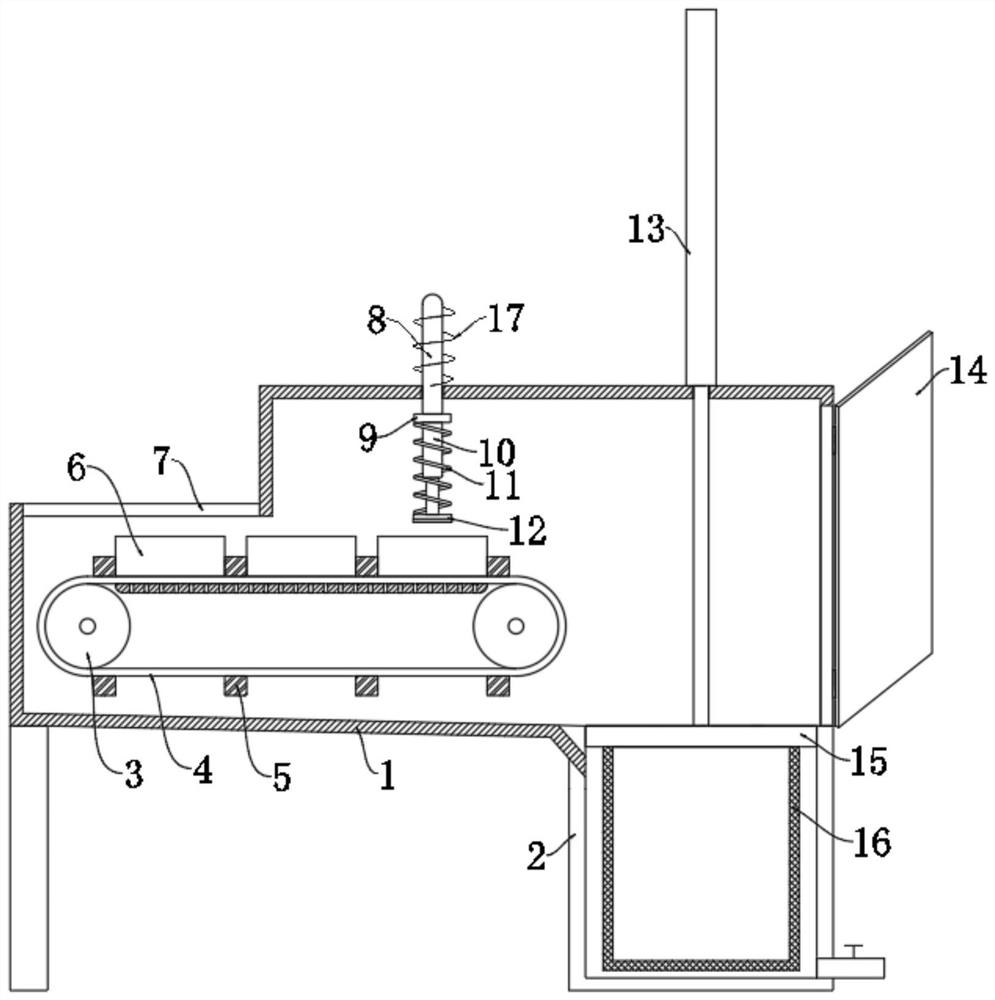

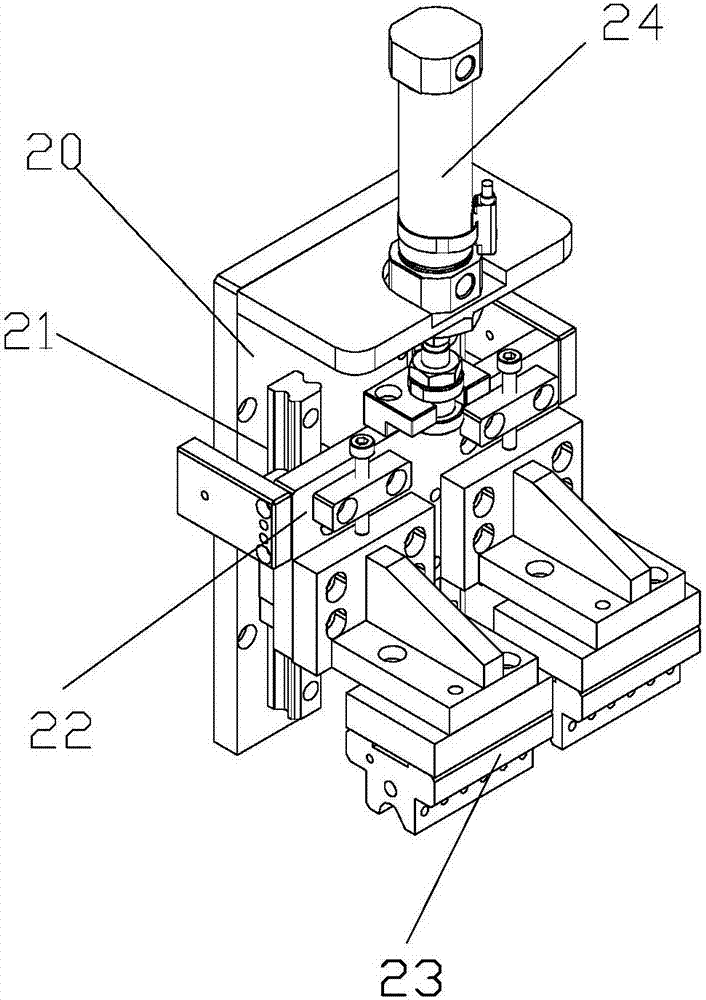

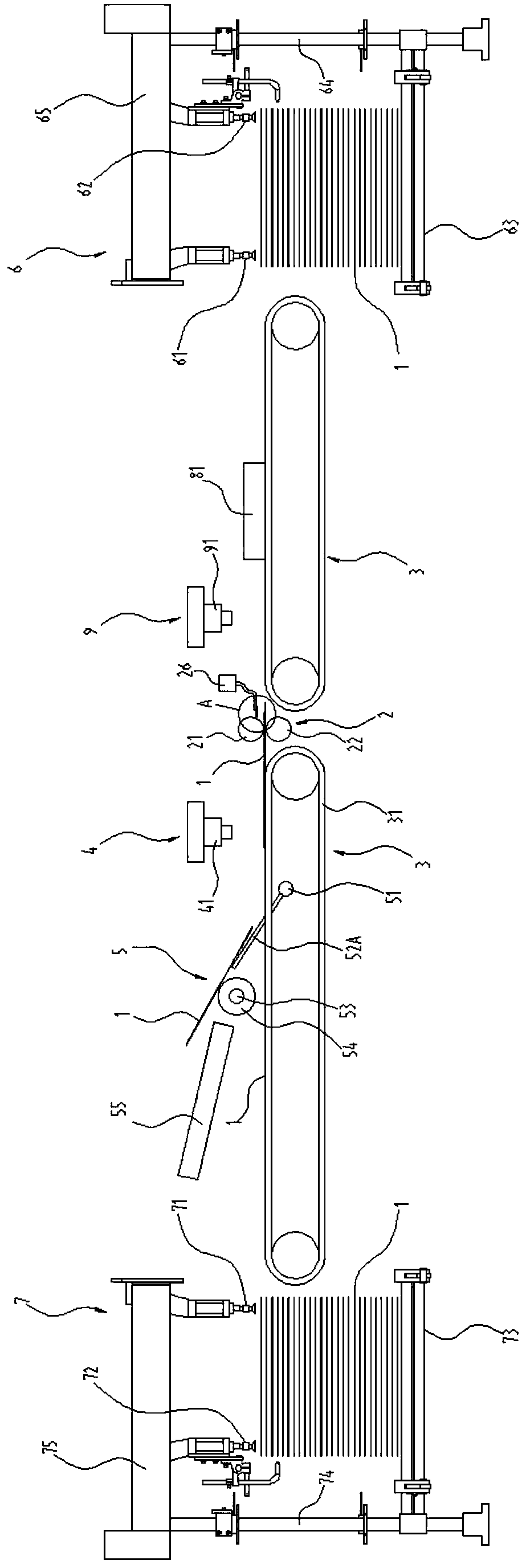

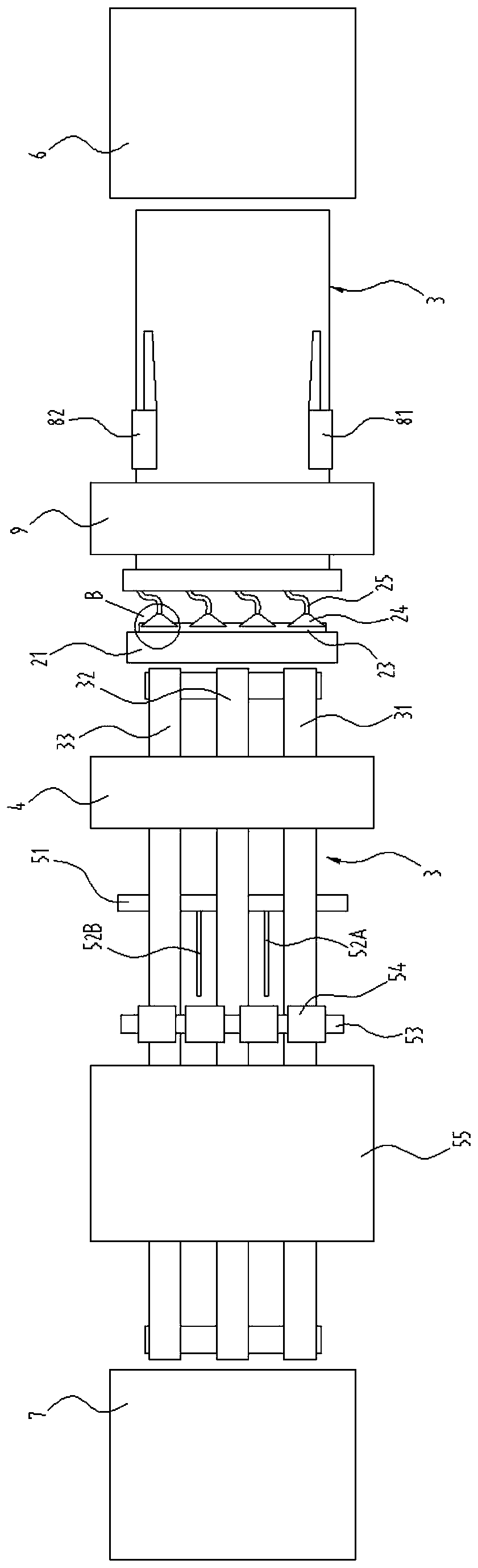

Puncture discharge equipment for new energy automobile lithium battery recycling

ActiveCN112510283AImprove efficiencySuitable for continuous operationBatteries circuit arrangementsWaste accumulators reclaimingNew energyGear wheel

A puncture discharging equipment for new energy automobile lithium battery recycling comprises a puncture box, two transmission rollers are installed on the puncture box in the horizontal direction, aconveying belt is connected to the two transmission rollers, the ends of the transmission rollers penetrate out of the puncture box and are fixedly connected with first driven gears, the puncture boxis provided with a feed port above one side of the conveyor belt, the puncture box is provided with a discharge box below the other side of the conveyor belt, discharge liquid is stored in the discharge box, the inner top of the puncture box is provided with a puncture mechanism above the conveyor belt, a driving mechanism used for driving the first driven gear and the puncturing mechanism is arranged on the outer wall of the puncturing box, a temporary storage mechanism used for storing punctured batteries is arranged in the discharge box, and a material taking door is arranged on the side wall of the puncture box. According to the invention, lithium battery feeding and puncturing can be automatically and intermittently completed, full immersion discharge is realized, the operation efficiency is greatly improved, and the equipment is suitable for continuous operation.

Owner:伟源科技有限公司

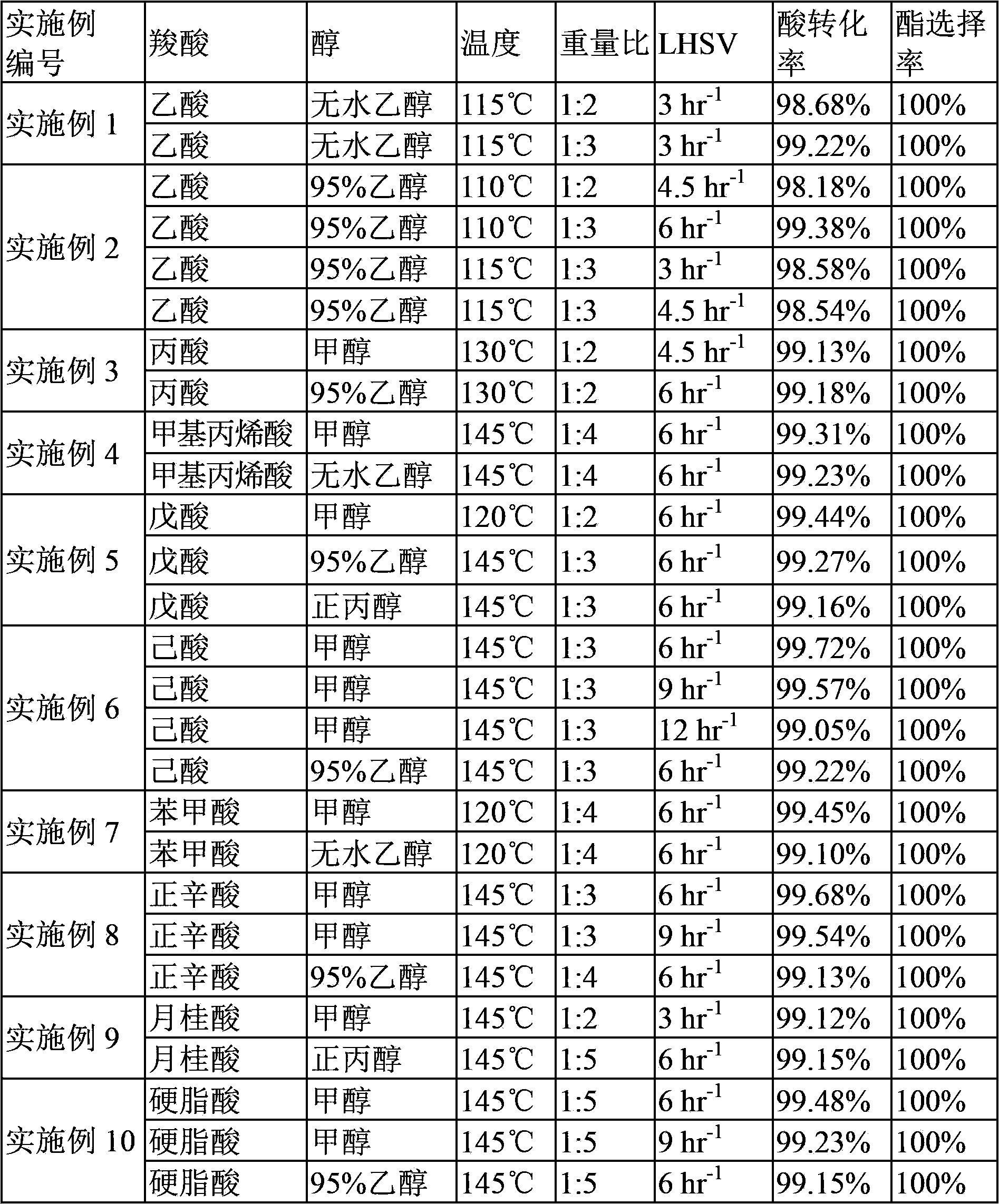

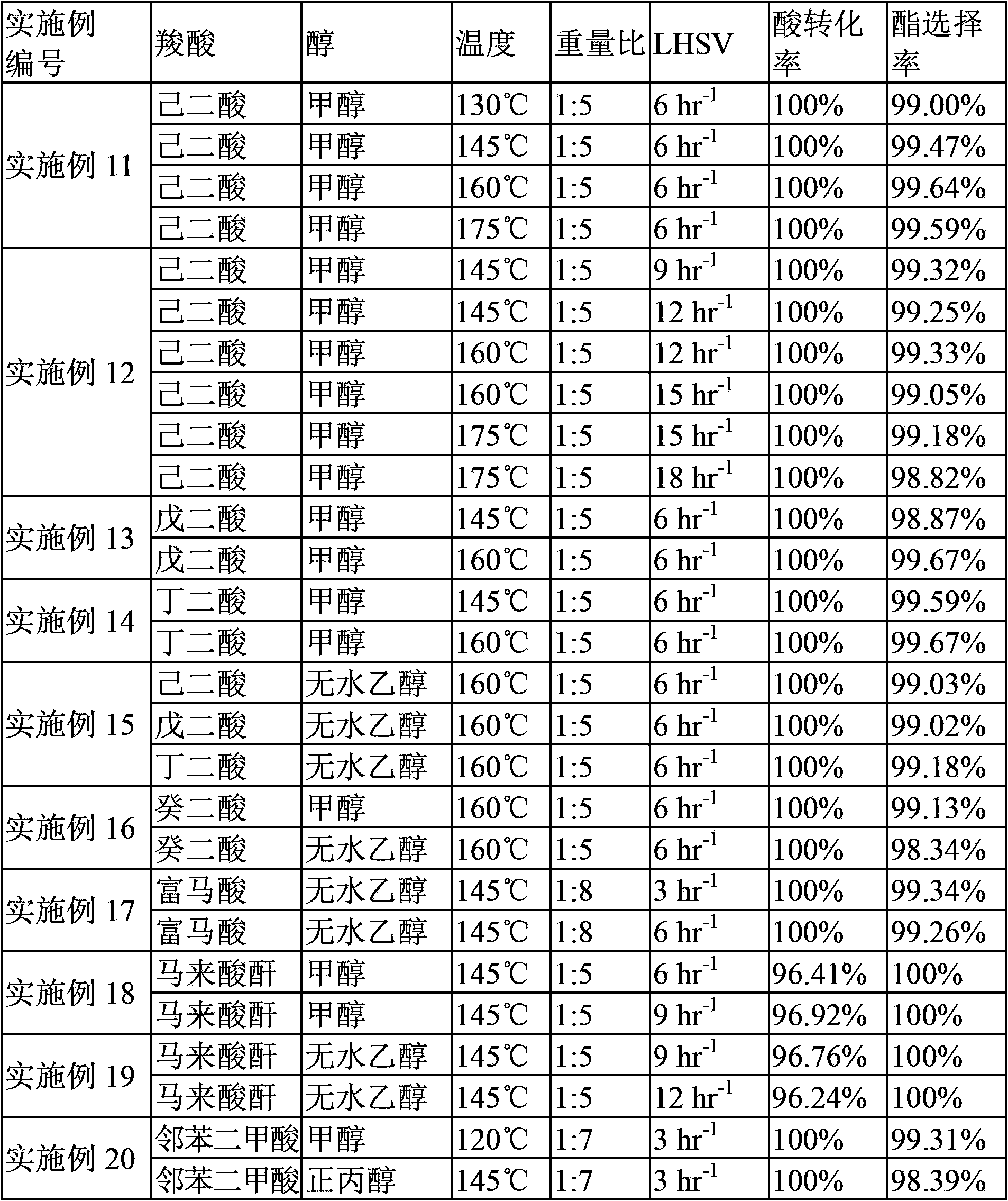

Method for continuously preparing carboxylic acid ester

InactiveCN103387495ASuitable for continuous operationSimple methodOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

A method for continuously preparing a carboxylic acid ester is disclosed. In the method of the present invention, a vertical reactor is filled with a solid catalyst, a carboxylic acid and an alcohol are introduced into a lower part of the vertical reactor, esterification is performed to form an esterized mixture, the esterized mixture is output from an upper part of the vertical reactor, and distillation is performed to isolate the carboxylic acid ester. The method of the present invention is simple, easily controlled and environmental friendly, and has significantly high conversion rate and selectivity.

Owner:CHINA PETROCHEM DEVMENT

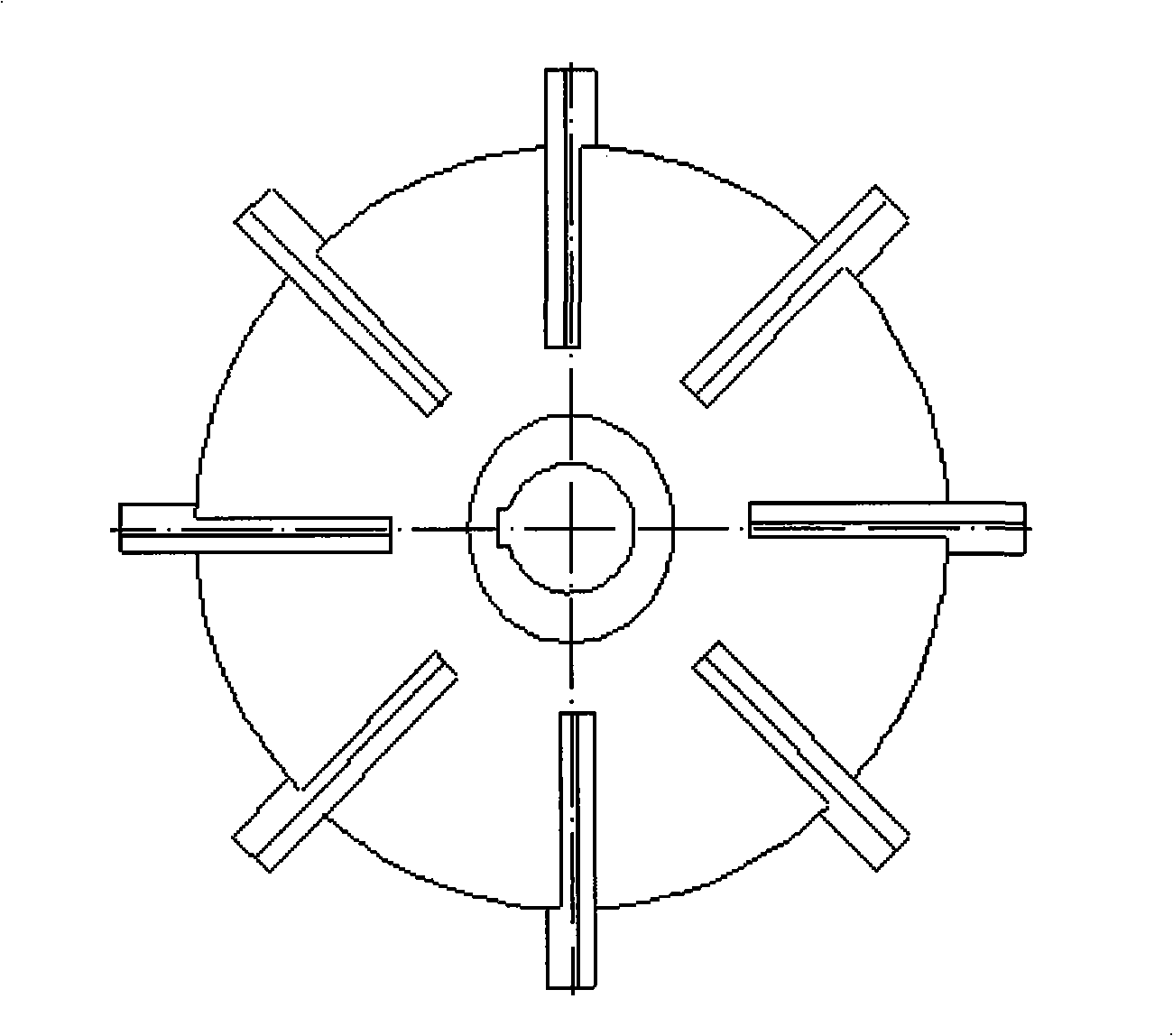

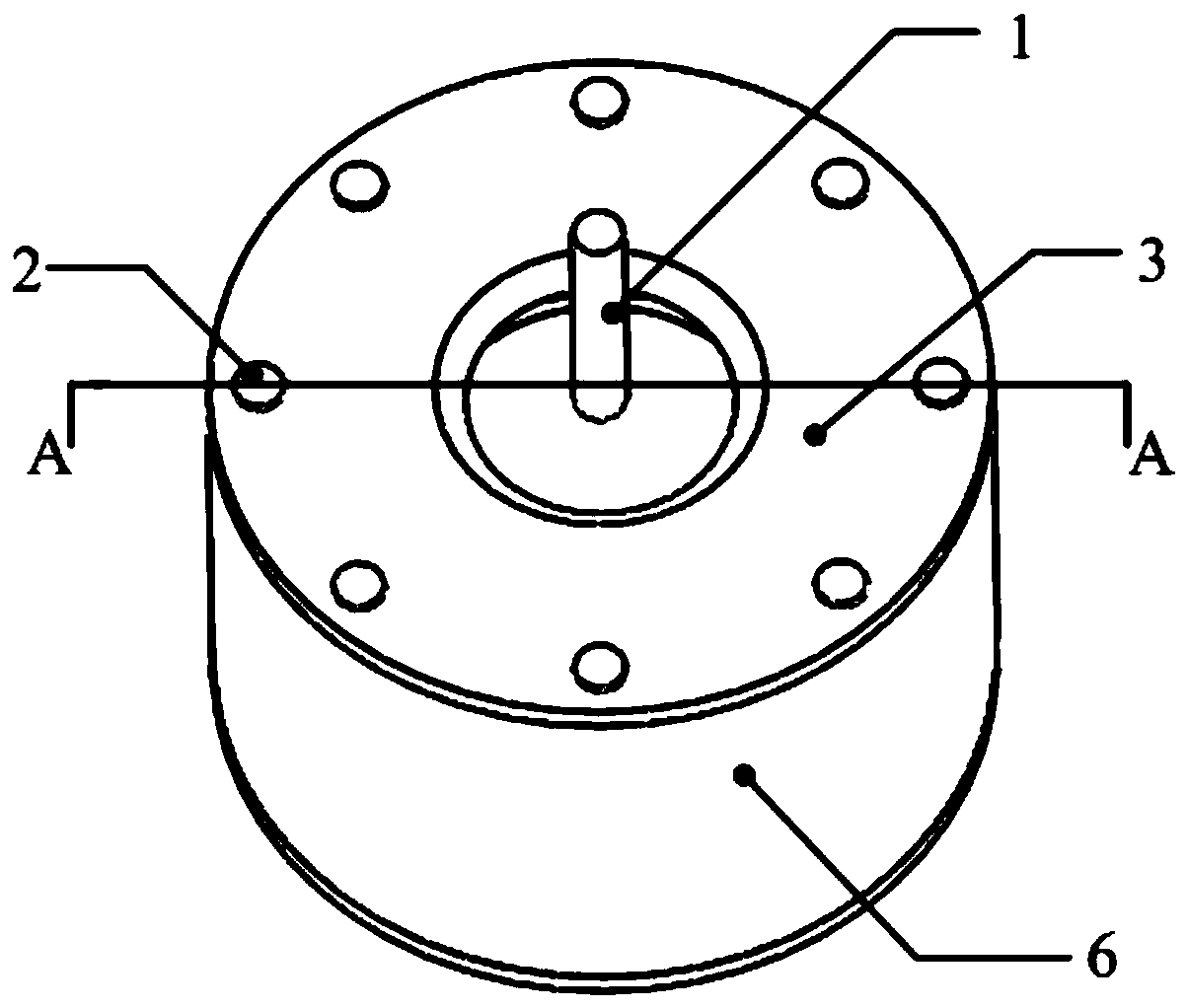

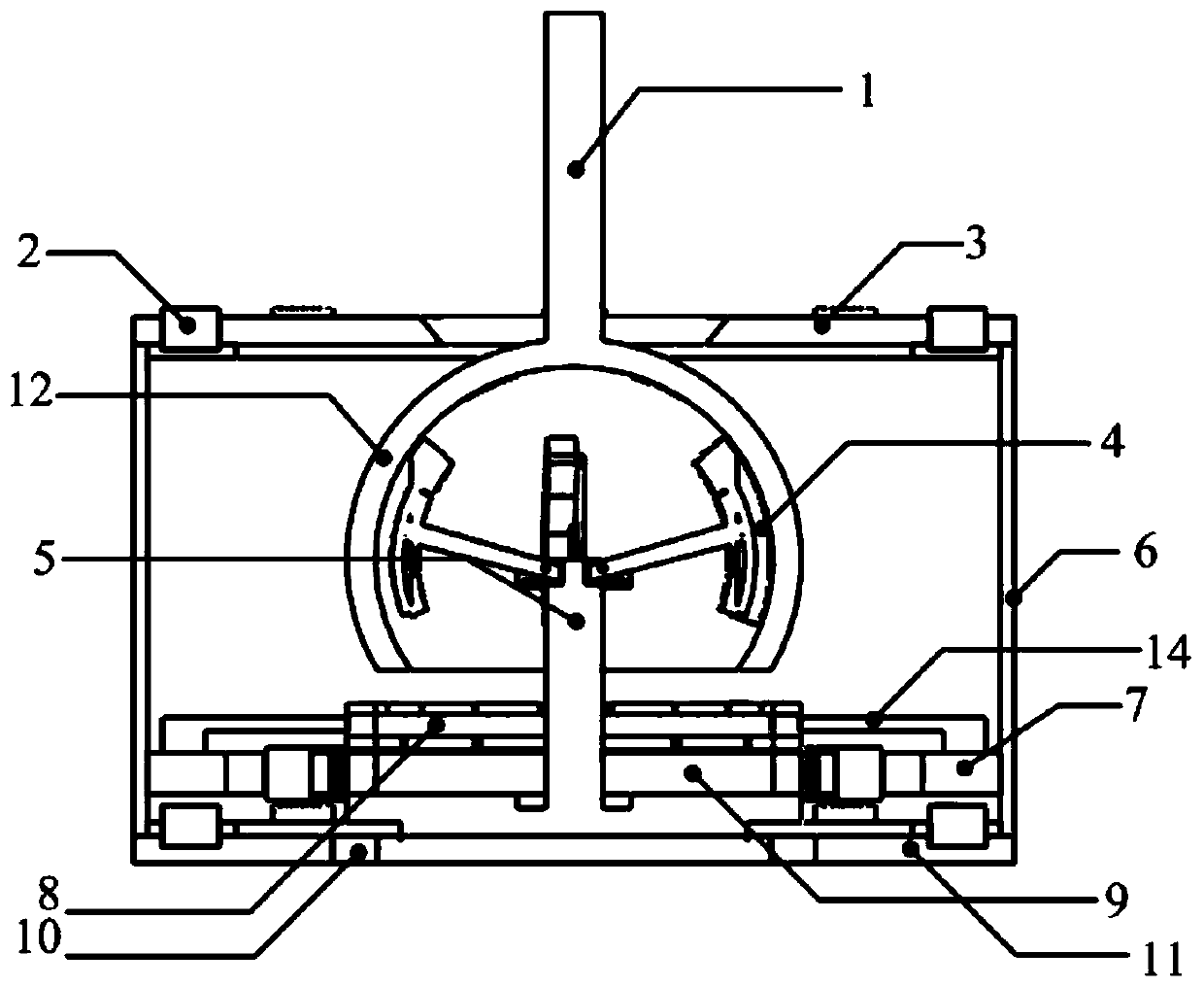

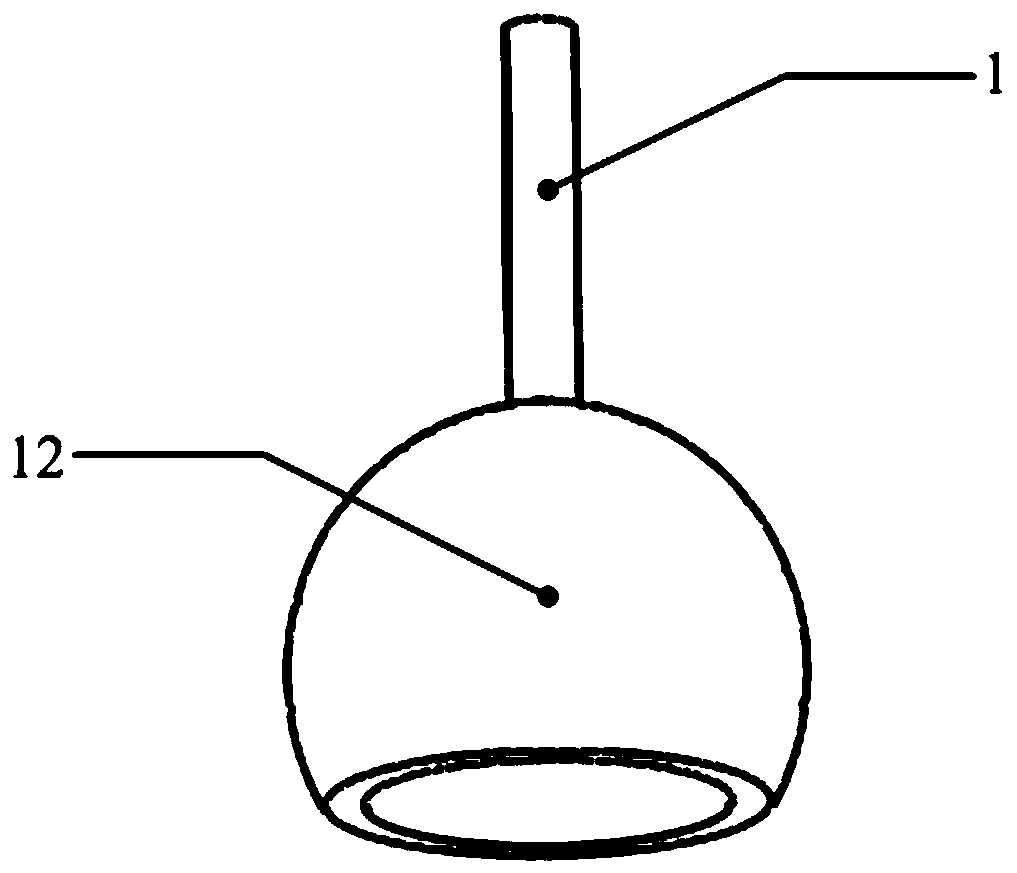

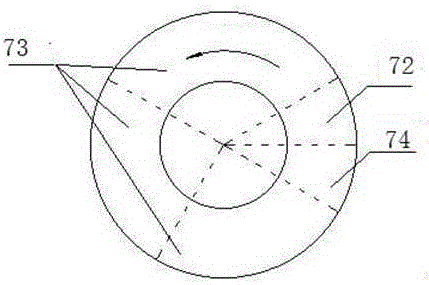

Deflection piezoelectric driving type multi-degree-of-freedom motor

ActiveCN109802596ASmall and flexibleHigh control precisionPiezoelectric/electrostriction/magnetostriction machinesMiniaturizationMulti degree of freedom

The invention provides a deflection piezoelectric driving type multi-degree-of-freedom motor, and relates to the technical field of multi-degree-of-freedom motors. A rotor comprises a spherical-crown-shaped shell on which an output shaft is fixed. A stator comprises a rotor stand column and a deflection piezoelectric driving device. A plurality of deflection piezoelectric driving devices are arranged above the rotor stand column. Each deflection piezoelectric driving device comprises a top pressing type pre-pressure mechanism in contact with the inner side of the spherical-crown-shaped shell,wherein the top pressing type pre-pressure mechanism has a pre-pressure. The technical problems that in the prior art, an existing electromagnetic driving structure is complex, the miniaturization isdifficult to achieve and the like are mainly solved. The deflection piezoelectric driving type multi-degree-of-freedom motor is small in size, flexible, high in control precision, high in response speed, capable of realizing the passive self-locking, convenient to use and wide in application range. The autorotation and the deflection can be separated. The mutual influence of the autorotation control and the deflection control is avoided. The motor is suitable for continuous operation.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

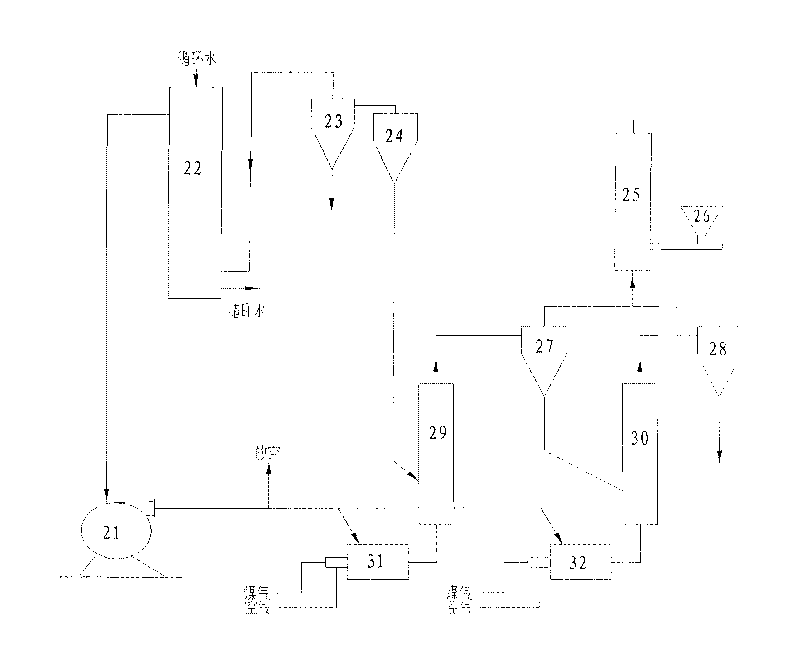

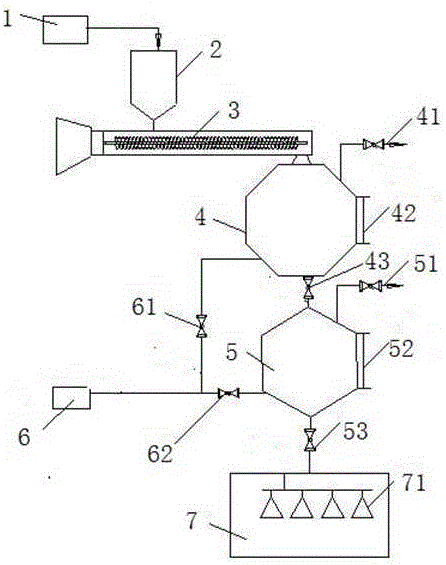

Feeding and discharging system and method for electronic waste pyrolysis

PendingCN106494908AAtmosphere has no effectSuitable for continuous operationConveyorsIncinerator apparatusSlagCooling chamber

The invention provides a novel feeding and discharging system and method for electronic waste pyrolysis in order to overcome the defects in the prior art. The system comprises a feeding device, a material bin, a middle storage tank, a reactor, a cooling chamber and a gas and water separator, wherein the feeding device is located above the material bin and is connected with a feeding port of the material bin; an inlet of the middle storage tank is connected with a discharging port in the lower portion of the material bin; a lower portion outlet of the middle storage tank is connected with a feeding port in the upper portion of the reactor; a slag material outlet in the lower portion of the reactor is sequentially connected with the cooling chamber and the gas and water separator; and a gas outlet of the gas and water separator is connected with a feeding port of the reactor. Thus, the system can achieve feeding and discharging under the condition that atmosphere fluctuation in the reactor is not caused and has the beneficial effects of being high in pyrolysis efficiency, capable of achieving continuous feeding and discharging, high in automation degree, easy and convenient to operate, stable in heat resource, pressure and atmosphere in the whole system, remarkable in energy saving effect and the like.

Owner:SHENWU TECH GRP CO LTD

Clean process method for synthesizing trimethylaluminum

InactiveCN111116625AGood material fluidityImprove liquidityGroup 3/13 element organic compoundsResidual chlorineEnvironmental chemistry

The invention relates to a clean process method for synthesizing trimethylaluminum. A trace amount of dimethyl aluminum chloride is generated in a reaction product of the following formula: 2Al + 3CH3Cl = CH3AlCl2.(CH3)2AlCl, a compound of formula MAl(CH3)4 is used to reduce the chlorine content of the trimethylaluminum, M is a Group IA element including lithium, sodium, and potassium; NaAl(CH3)4tetramethylaluminum sodium is adopted, and the dimethyl aluminum chloride is eliminated. Through removing the residual chlorine in the trimethylaluminum by using the tetramethylaluminum sodium, and recovering the tetramethylaluminum sodium, and converting the tetramethylaluminum sodium into methylaluminum chloride to be used as an initial raw material, the clean process method for synthesizing thetrimethylaluminum is a green process without three wastes.

Owner:南京奥格美化学研究所有限公司

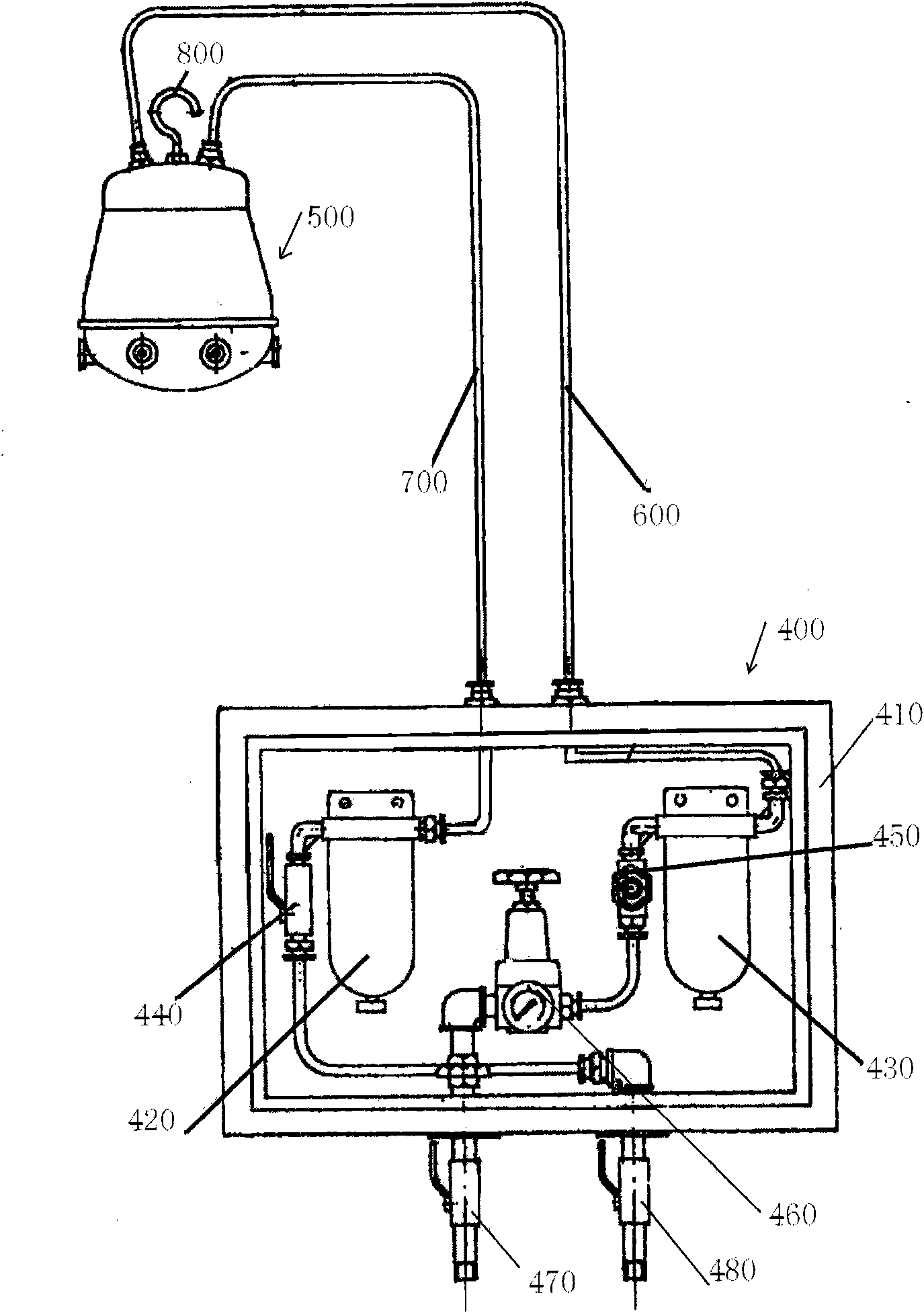

Dust removing sprayer for mine

InactiveCN101649748AGood application of dust suppression works wellLess gas consumptionDust removalFire preventionWater sourceSprayer

The invention discloses a dust removing sprayer for a mine, which comprises a shell. The shell is provided with a suspender used for suspending the whole dust removing sprayer for the mine; a distributor is arranged in the shell; one end of a header water inlet pipe is connected with a water inlet end of a water flow distribution passage in the distributor, and the other end of the header water inlet pipe is extended out of the shell and connected with a water source; one end of the header water inlet pipe is communicated with an air inlet end of a compressed air distribution passage in the distributor, and the other end of the header water inlet pipe is extended out of the shell and connected with a compressed air source; a plurality of ends are communicated with a water distribution endof the water flow distribution passage in the distributor, and the other ends are extended to a nozzle outside the shell; and the nozzle is provided with an air inlet connector which is communicated with the compressed air distribution passage of the distributor through an air distribution pipe. The sprayer can achieve good application effect of reducing the dust by adopting the mass transfer of fog droplets under high-speed airflow acceleration, has the advantages of gas consumption economization, little used water, fine and even fog droplets, large diffusion area, no spraying dead angle, safety, and explosion prevention, and is suitable for continuous operation under severe environment.

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

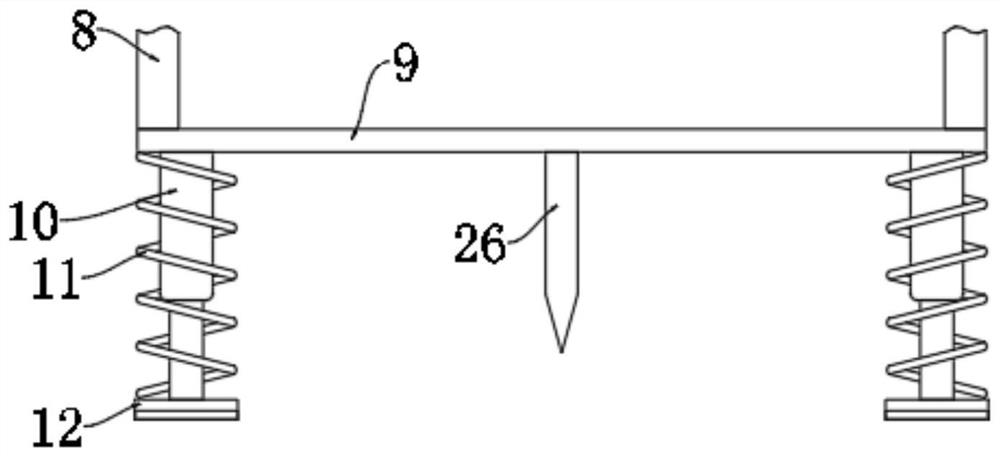

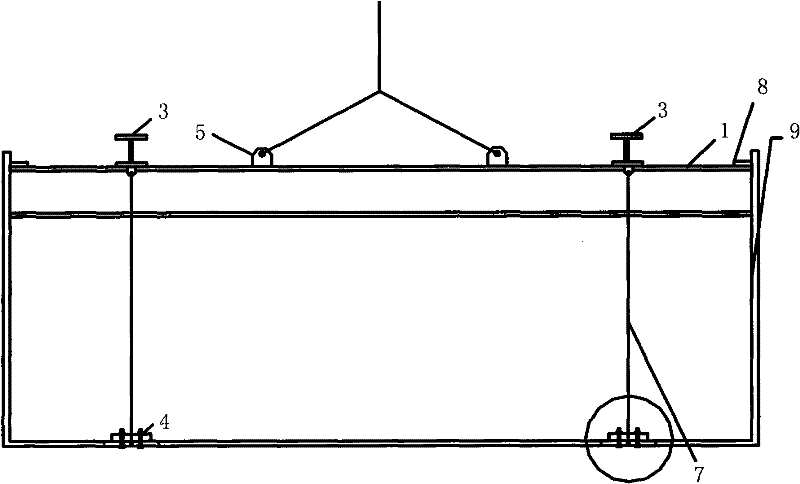

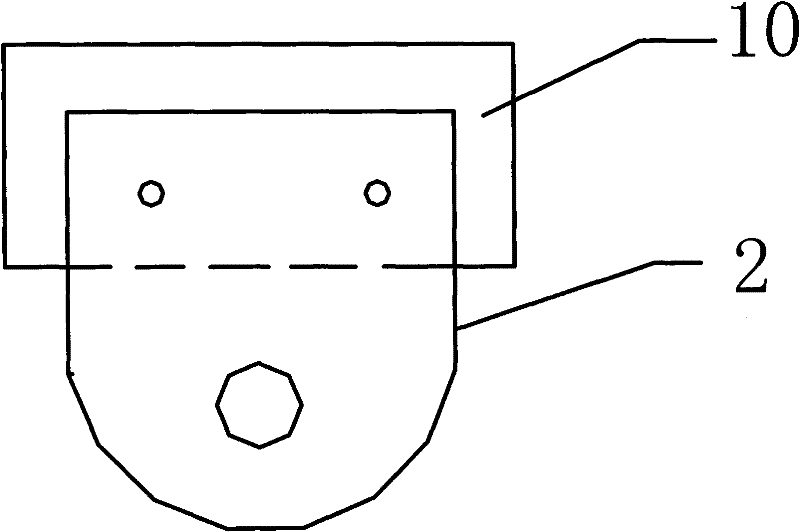

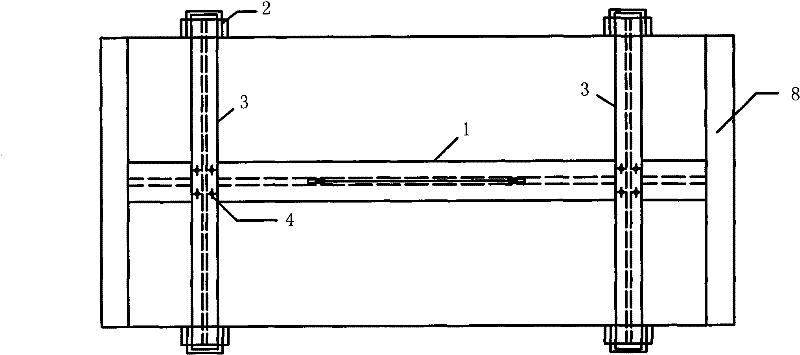

Method for hoisting open type groove body with large volume and small rigidity

The invention relates to a method for hoisting an open type groove body with large volume and small rigidity, which is characterized by comprising the following steps of: a, providing a longitudinal beam (1); b, providing two transverse beams (3); c, correspondingly manufacturing four lifting eye plates (2) by using four connecting plates (10) of a base of the groove body per se, and connecting the four lifting eye plates (2) to the connecting plates (10) of the base of the groove body by using bolts, to be used as hoisting points outside the groove body; d, providing four steel wire ropes (7); e, hoisting with a crane, wherein two lifting eyes (5) on the longitudinal beam (1) are used as main hoisting points of the crane and the four lifting eye plates (2) on the base of the groove body are used as auxiliary hoisting points, the main hosting points and the auxiliary hoisting points jointly form a stress system to ensure that the groove body can be uniformly stressed; and f, after thegroove body (9) is hoisted in place, disassembling the longitudinal beam (1), the two transverse beams (3) and the four lifting eye plates (2), and continuing to carry out the hoisting on the next groove body.

Owner:MCC5 GROUP CORP SHANGHAI

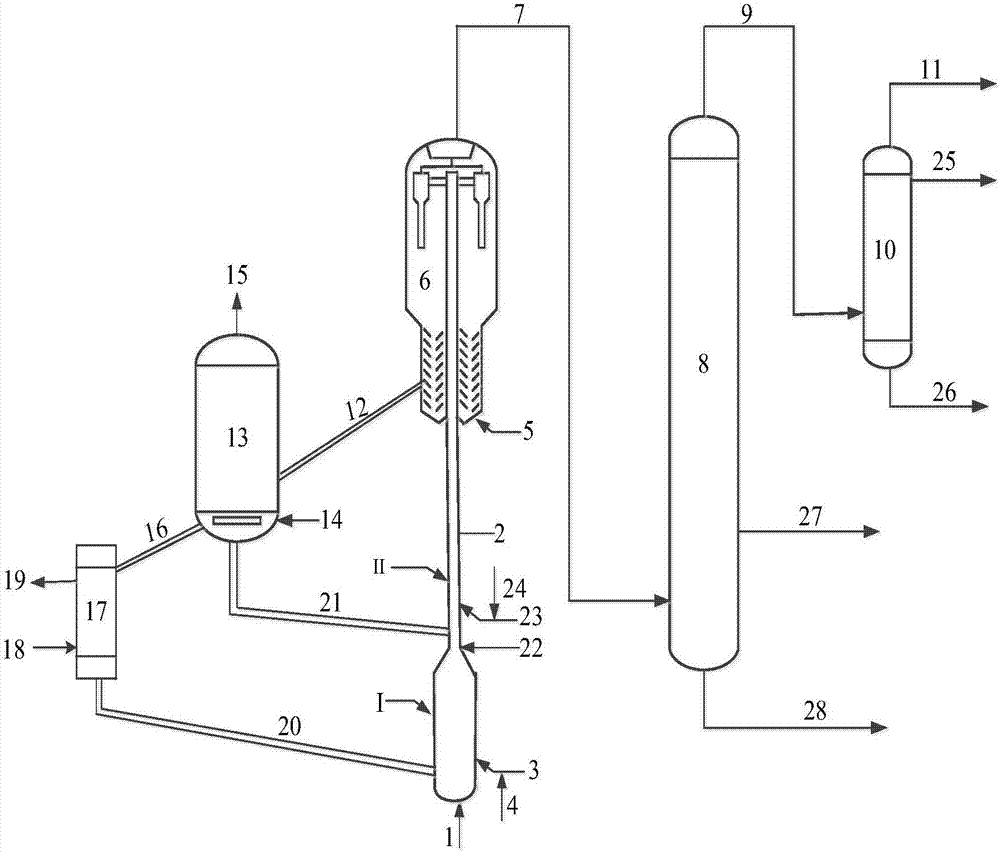

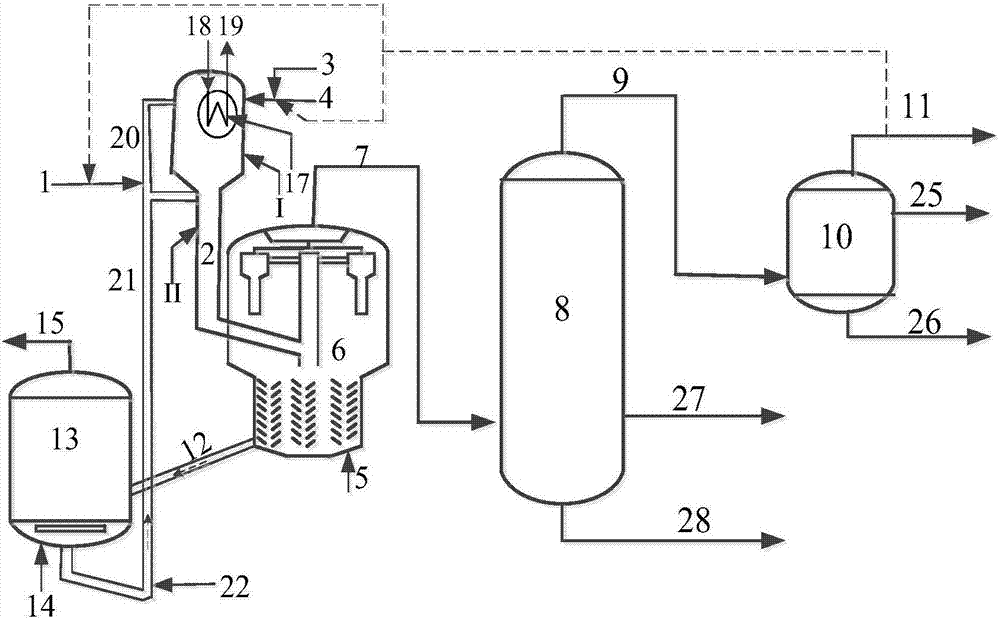

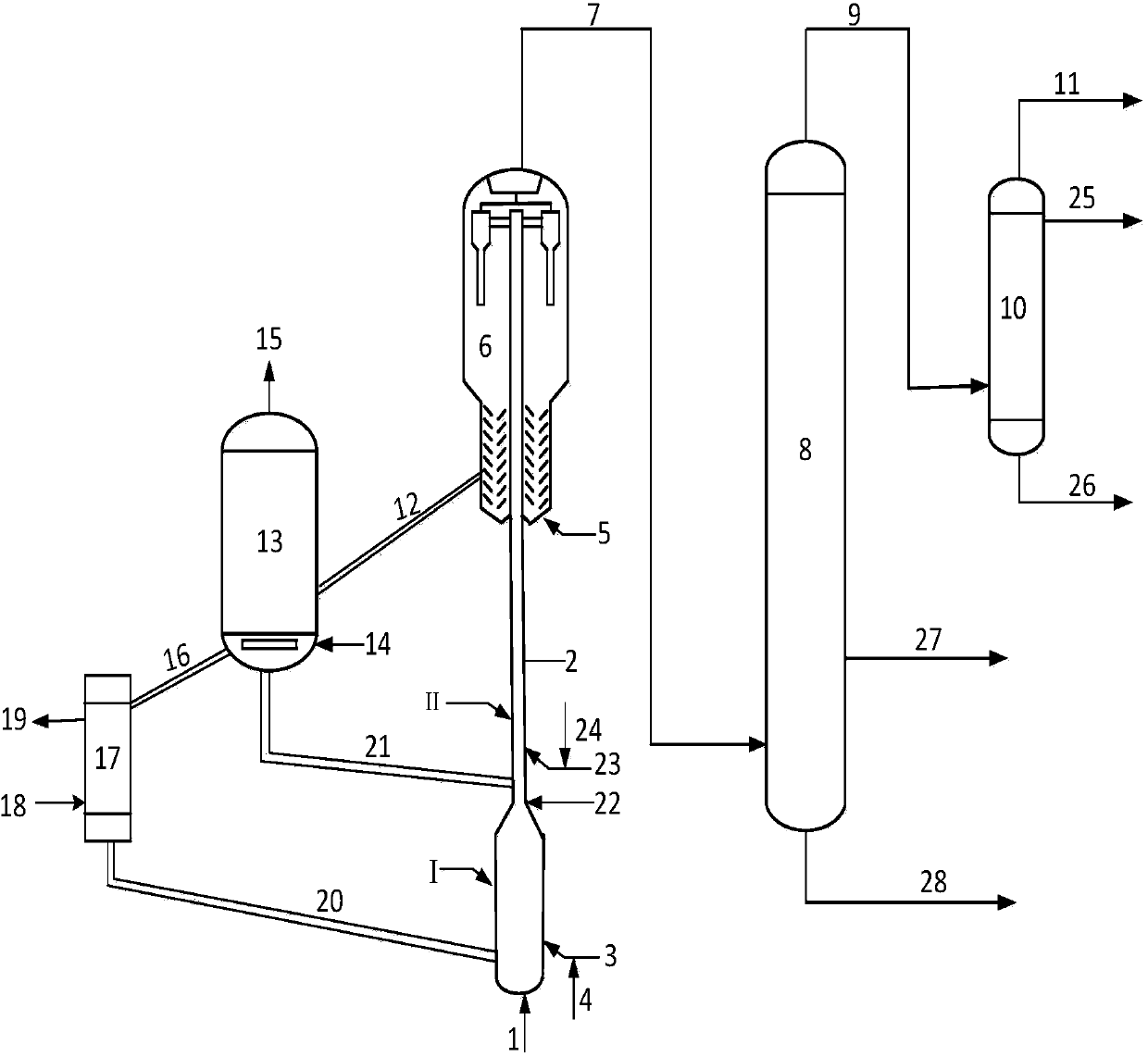

Fluid catalytic cracking method of shale oil

ActiveCN105505454AShort processNo hydrogen consumptionTreatment with plural serial stages onlyHeavy metalsFluid catalytic cracking

The invention discloses a fluid catalytic cracking method of shale oil. By introducing a low temperature catalyst, the reactor area is divided into a fluidized bed adsorption area and a riser cracking area. In a non-hydrogen atmosphere, shale oil enters the fluidized bed adsorption area with a lower temperature, impurities such as alkaline nitrides, colloids, heavy metals, and the like are removed through adsorption, then shale oil is introduced into the riser cracking area, and in the riser cracking area, shale oil is contacted with a reclaiming agent with a high temperature and high activity to carry out catalytic cracking reactions. The provided method has the advantages that the shale oil conversion performance is strong, the yield of dry gas and coke is low, and the yield of liquid product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

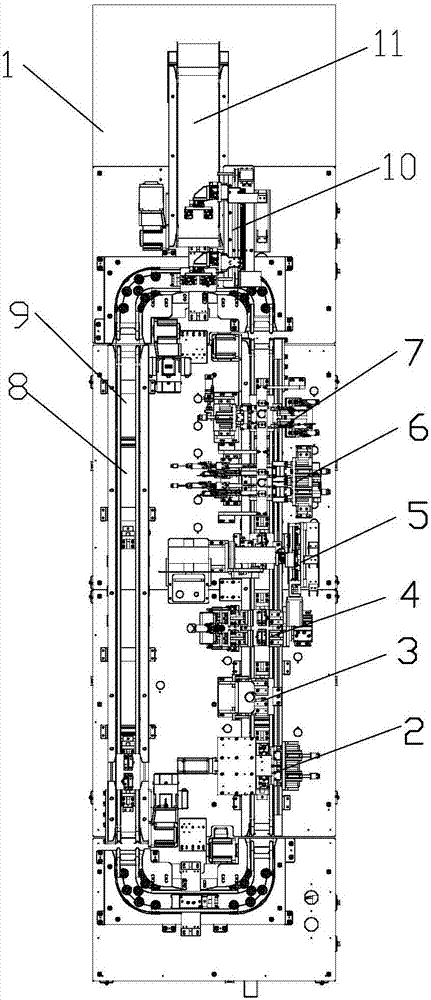

Automatic mounting and bending forming machine of emitting sheet

The invention discloses an automatic mounting and bending forming machine of an emitting sheet. The automatic mounting and bending forming machine of the emitting sheet comprises a machine frame. A rolling mounting mechanism, an upper thermal pressure maintaining mechanism, a lateral thermal pressure maintaining mechanism, a first thermal bending mechanism and a second thermal bending mechanism are lined up on the machine frame and arranged at equal intervals. The machine frame is provided with a round belt ring circulation line penetrating through all the mechanisms. The round belt ring circulation line is provided with multiple jigs arranged at equal intervals. The distance between every two adjacent jigs is equal to the distance between every two adjacent mechanisms. The machine frame is further provided with an automatic product fetching mechanism and a discharging conveyer belt which are located on the side face of the round belt ring circulation line. According to the automatic mounting and bending forming machine of the emitting sheet, except that jig feeding needs manual operation, all the other operations are automatic, and the automatic mounting and bending forming machine of the emitting sheet is suitable for continuous operation and high in production efficiency, greatly improves productivity and efficiency, greatly lowers the demand for operators and reduces the labor cost.

Owner:苏州钧鼎自动化设备有限公司

Press key film tearing-off machine

PendingCN105775279AIncrease production capacityImprove efficiencyArticle unpackingDrive shaftPerpendicular direction

The invention discloses a press key film tearing-off machine. The press key film tearing-off machine comprises a base plate, a supporting seat, line body racks, a line body bottom plate, a driving shaft, a driven shaft, synchronous belts, a direct current motor, an upper clamping jaw, a lower clamping jaw, a lifting air cylinder, an inclined supporting plate, a film tearing-off air cylinder and a film separating air cylinder. The two line body racks and the line body bottom plate are disposed in front of the base plate; the driving shaft and the driven shaft provided with the synchronous belts are disposed at the two ends of the line body bottom plate correspondingly; the driving shaft is in shaft connection with the direct current motor; the supporting seat and the inclined supporting plate are mounted on the rear portion of the base plate; the film tearing-off air cylinder and a film tearing-off guide way are mounted on the inclined supporting plate; film separating guide ways and the film separating air cylinder are disposed at the lower ends of reinforcing plates; and the lifting air cylinder is disposed under the line body bottom plate, and the upper clamping jaw and the lower clamping jaw are disposed on the front sides of the line body racks in the perpendicular direction. According to the press key film tearing-off machine, the upper clamping jaw and the lower clamping jaw are adopted; fixing and alignment are achieved through the lifting air cylinder; film separation is achieved by means of the film separating air cylinder; film tearing-off is performed through the inclined film tearing-off air cylinder; and the press key film tearing-off machine is applicable to film tearing-off of press keys with different sizes, high in efficiency and suitable for continuous operation.

Owner:KUNSHAN HENGXU AUTOMATION EQUIP CO LTD

System and method for feeding and discharging materials for coal pyrolysis

PendingCN106398734AAtmosphere has no effectSuitable for continuous operationSpecial form destructive distillationLoading/unloadingEngineeringCoal pyrolysis

The invention, aiming at the defects of the prior art, provides a system and a method for feeding and discharging materials for coal pyrolysis. The system comprises a feeding device, a storage bin, a middle storage tank and a reactor, wherein the feeding device is positioned above the storage bin and is connected with a feed port of the storage bin; an inlet of the middle storage tank is connected with a discharge port at the lower part of the storage bin; a lower outlet of the middle storage tank is connected with a feed port at the upper part of the reactor; and the reactor is a closed reactor and is used for performing sweeping displacement by use of a gas. Therefore, the system can achieve material feeding and discharging without causing atmosphere fluctuation in the reactor, and has the advantages of being high in pyrolysis efficiency, feeding and discharging materials continuously, being high in automation degree and simple and convenient in operation, having stable heat source, pressure and atmosphere in the whole system, and being significant in energy-saving effect.

Owner:SHENWU TECH GRP CO LTD

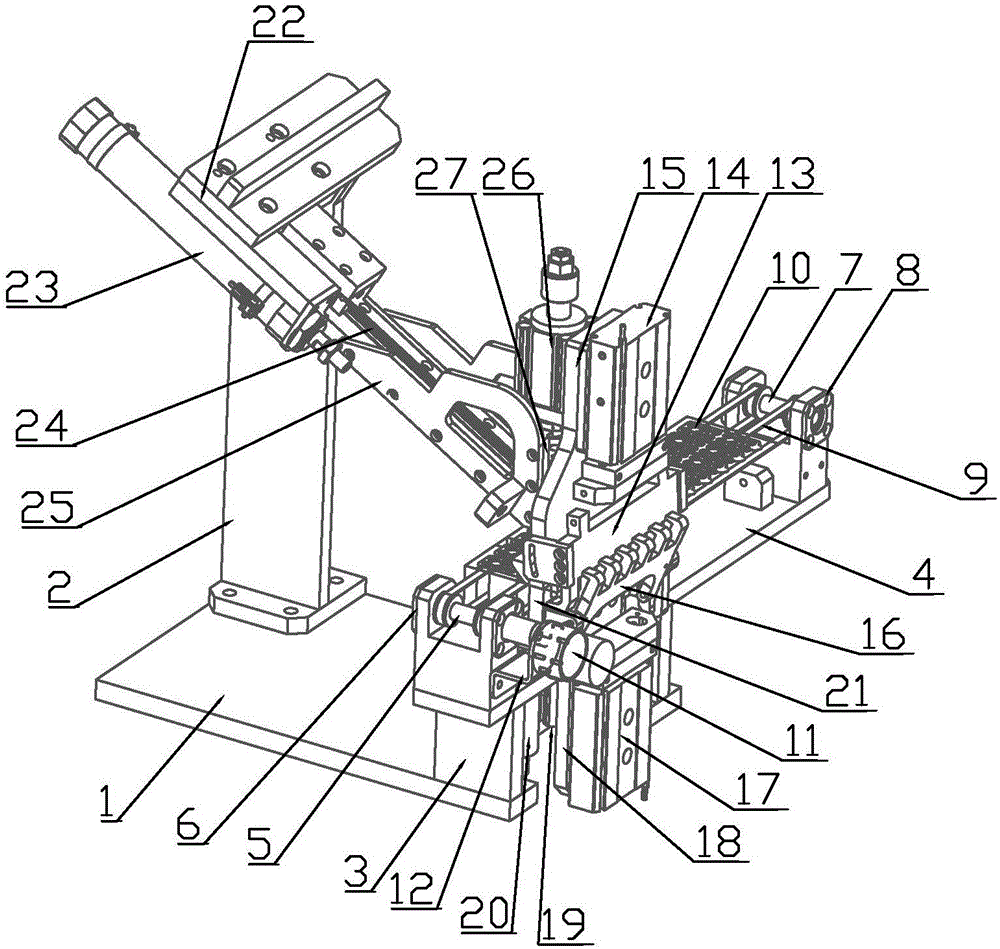

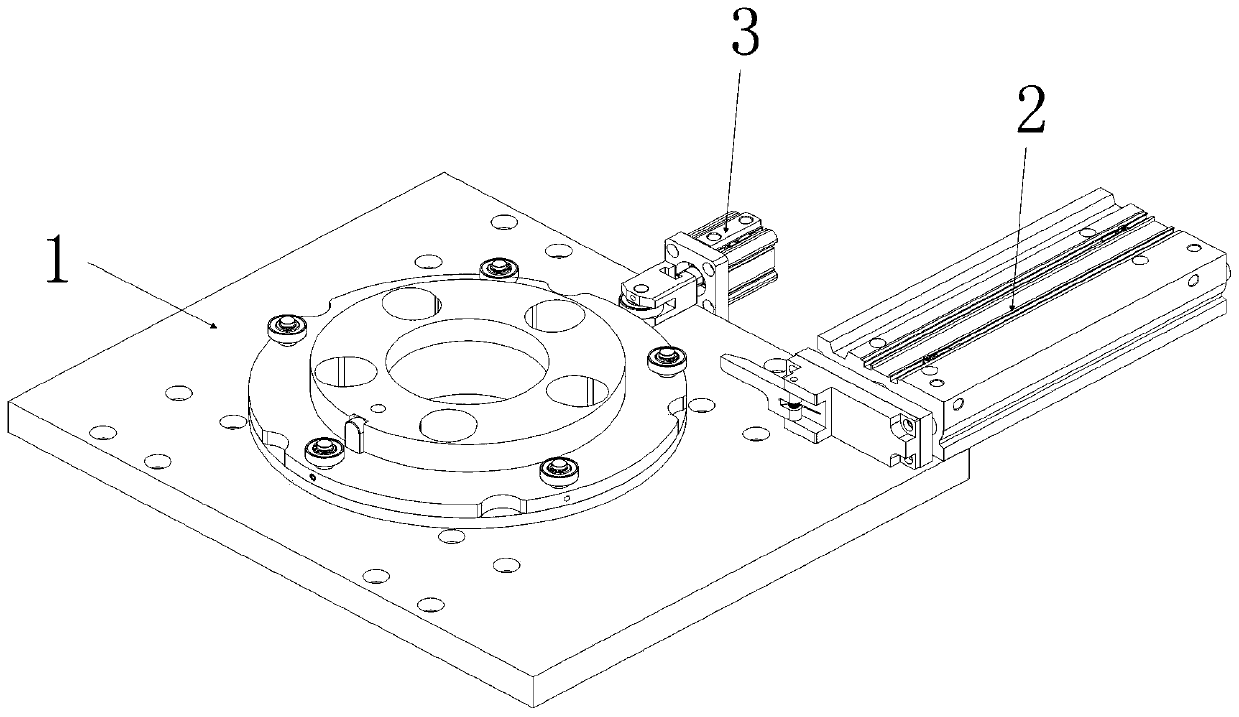

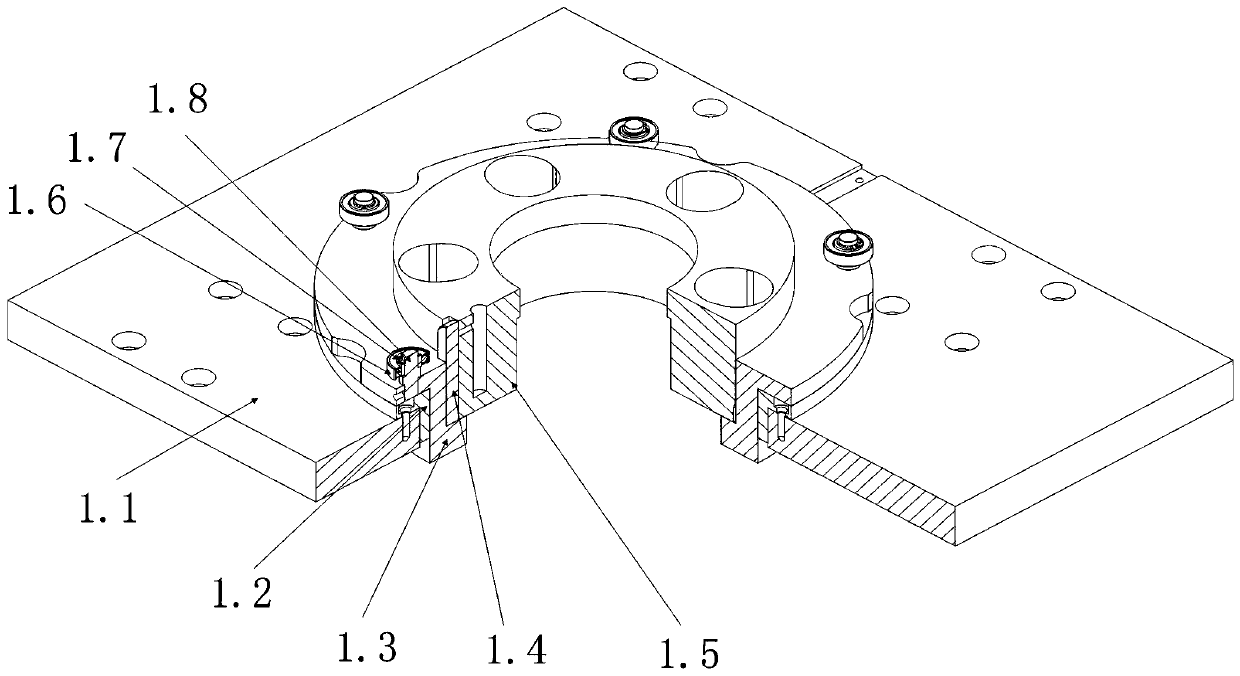

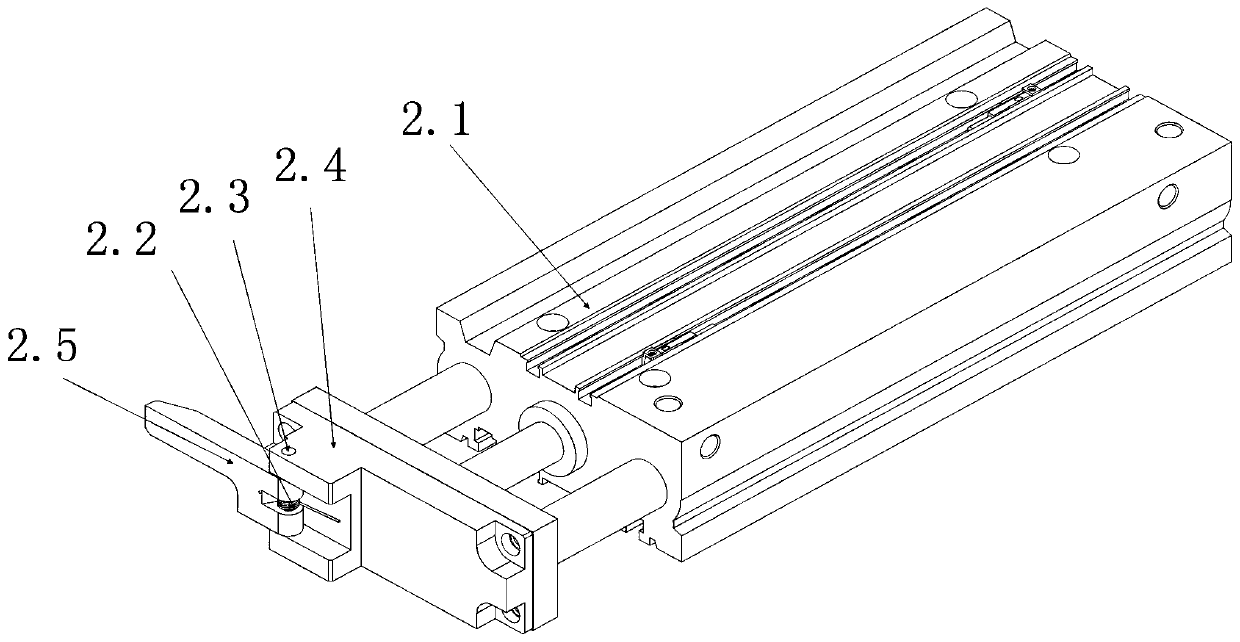

Simple circle equal-division indexing device capable of continuously rotating

InactiveCN109940454ASimple structureSuitable for continuous operationPrecision positioning equipmentRolling-element bearingTorsion spring

The invention relates to the technical field of circle equal-division indexing, in particular to a simple circle equal-division indexing device capable of continuously rotating. The device comprises arotating module, a pushing module and a positioning module; the rotating module comprises a substrate, a wear resisting ring, an indexing ring, a fixed key, a revolving base, a rolling bearing, an elastic retainer ring and a pin shaft; the pushing module comprises a pushing cylinder, a torsion spring mounting base, a torsion spring shaft, a torsion spring and a pallet; and the positioning modulecomprises a positioning cylinder, an indexing circle pressure block, a positioning bearing, a bearing pin, a guide key, a cylinder mounting base and a cylinder joint. The device has the following beneficial effects: the structure is relatively simple; no complicated driving element is provided; when the circle equal-division indexing is realized, the one-way peripheral rotation is realized to meetthe working condition of continuous operation; and the driving and the positioning are realized through the cylinder to provide high-precision circle equal-division indexing, so that no person needsto participate in the process, the device can be suitable for bad working conditions incapable of being operated by persons, and the application range is wider.

Owner:安徽航大智能科技有限公司

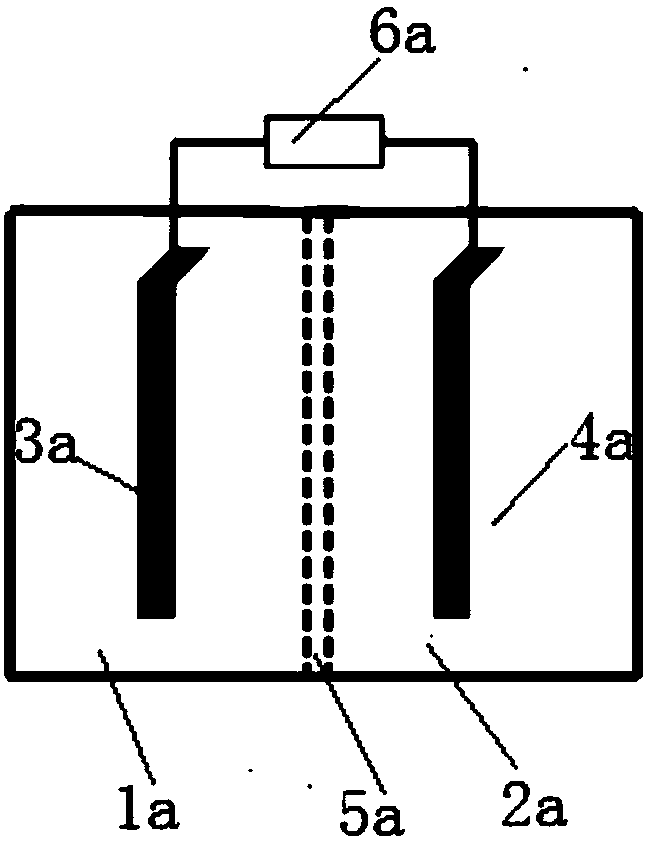

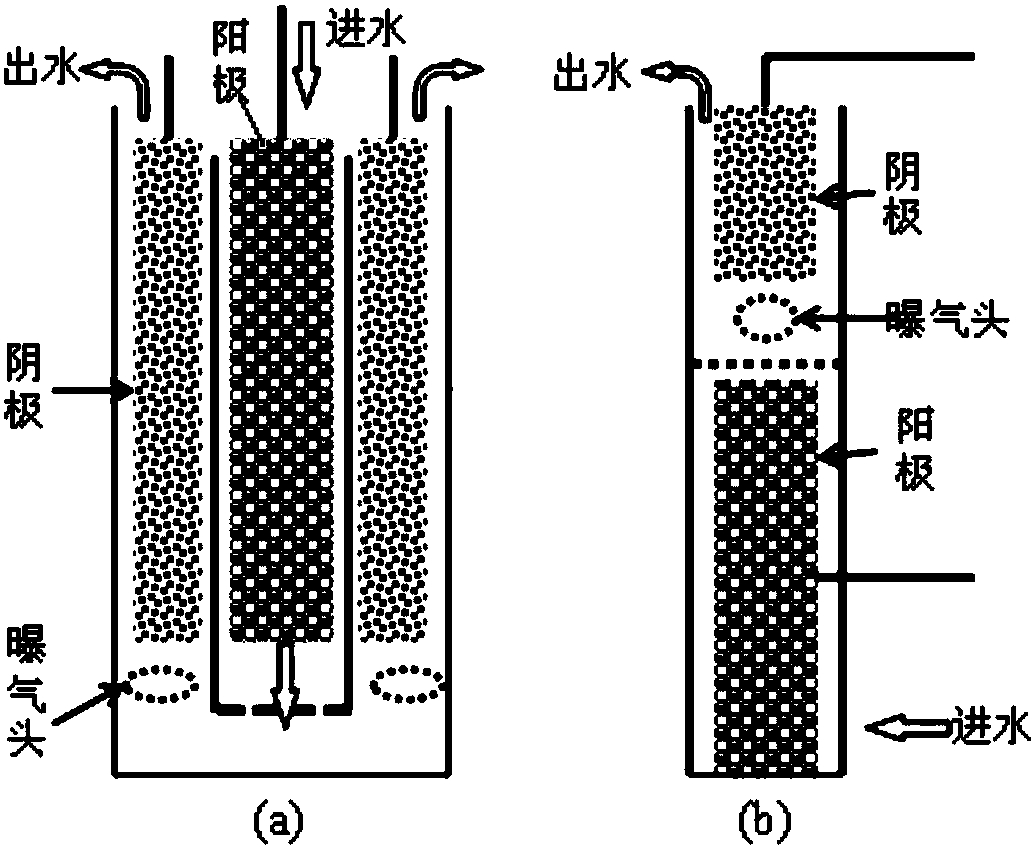

Large-diameter porous spacing structure used in biological-cathode microorganism electrochemical system

ActiveCN108206288AAdjust seepage capacityRegulated conduction capabilityBiochemical fuel cellsMicrometerProton

The invention provides a large-diameter porous spacing structure used in a biological-cathode microorganism electrochemical system, and relates to a large-diameter porous spacing structure in an electrochemical system. The invention aims to solve the problem of high cost of a spacing material in an existing microorganism electrochemical system. The porous spacing structure main body is in a plateshape or a cylindrical shape and comprises at least one layer of large-diameter porous spacing material, at least one layer of insulation material is arranged in the large-diameter porous spacing material in the structure main body, holes of the large-diameter porous spacing material are opened holes, and the diameters of the holes are 0.1 micrometer to 5 millimeters. The spacing structure is usedfor partitioning a cathode chamber and an anode chamber, the structure has seepage water through capability, and oxygen dissolution between the cathode and the anode at two sides, COD gradient and negative / positive ion conduction capability are maintained; compared with an ion / proton exchange membrane, the structure has the advantage that very low cost can be achieved; and the large-diameter porous spacing structure is suitable for the biological-cathode microorganism electrochemical system.

Owner:HARBIN INST OF TECH

Novel cloth wind-up device

PendingCN107187913AImprove coordinationSuitable for continuous operationWebs handlingPhysicsElectric machinery

The invention discloses a novel cloth wind-up device which comprises a base and a box body arranged on one side above the base. The device further comprises a rotating mechanism, a bent plate expansion and retraction mechanism and a guide mechanism. A sliding shaft on the bent plate expansion and retraction mechanism controls four sets of bent plates to be retracted and expanded, so that the cloth wind-up start state and the cloth wind-up end state are easily switched, the production efficiency is higher, and the device is applicable to continuous operation. The guide mechanism is located on the other side of the bent plate expansion and retraction mechanism and comprises a guide rod box and a guide rod. A lead screw is arranged in the guide rod box. The bottom of the guide rod is movably connected with the lead screw. The guide rod does reciprocating motion on the lead screw during forward and reverse rotation of the lead screw. The lead screw is driven by a motor. According to the technical scheme, reciprocating motion of the guide rod is ensured, the cloth wind-up working coordination is improved, continuous operation is achieved, and the production efficiency is improved.

Owner:安徽省根银机电设备有限公司

Surface treatment method of carbon fiber composite

The invention relates to a surface treatment method of carbon fiber reinforced epoxy resin or phenolic resin composite being low in surface free energy and high in quantity of silicon mold release agents. The method comprises the following steps: (1) primarily grinding the surface of a base carbon fiber composite material through waterproof abrasive paper with 300-1000 meshes so as to remove mostof silicon mold release agent containing components and low-activity components on the surface as well as expose some functional groups with high hydrophilia; (2) dipping degreasing cotton into 1-5% by concentration of mixed solution prepared through NaF and HCOOH based on the ratio of 0.1-0.01; wiping the grinded surface of the base material for 5-10min to completely remove the rest silicon moldrelease agents; and slightly swelling the surface of the base carbon fiber composite material; and (3) coating the surface without the mold release agent with a high-activity and high-compatibility resin transition layer being 10-40 microns in thickness; naturally drying for 3-5h; and then correspondingly coating. The method is simple in processes, and low in cost; and the adhesion of the carbon fiber composite surface and the coating can be greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

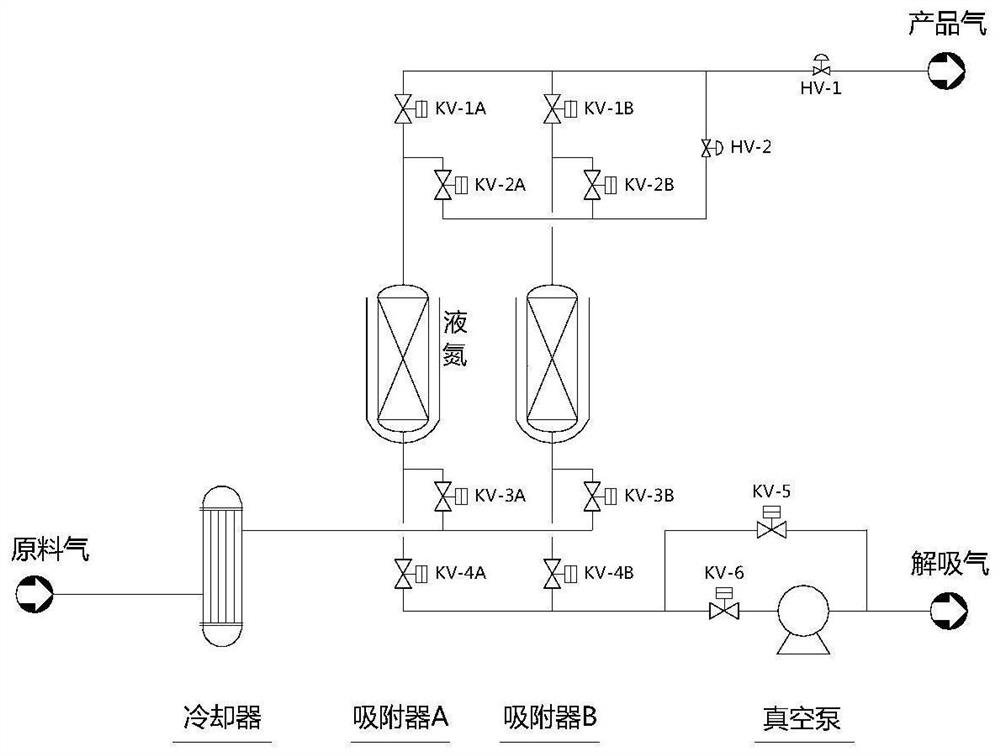

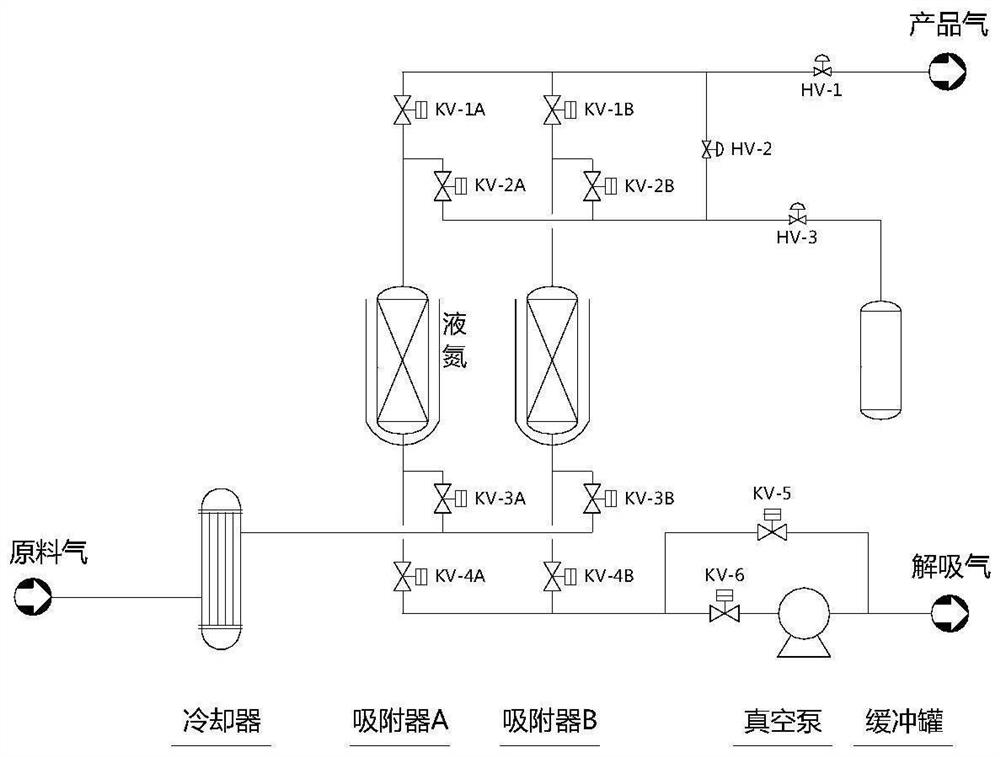

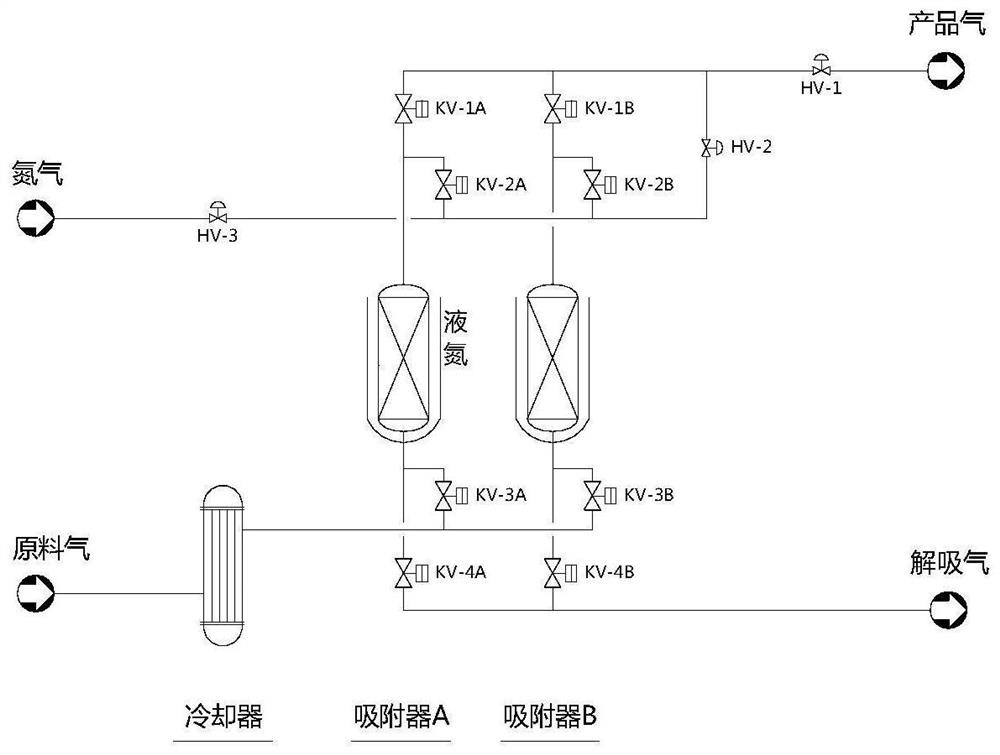

Method for low-temperature adsorption refining of high-purity and ultra-pure gas

ActiveCN114130155AAvoid consumptionReduce energy consumptionGas treatmentDispersed particle separationSorbentProcess engineering

The invention discloses a method for low-temperature adsorption and refining of high-purity and ultra-pure gas, which comprises the following steps: adsorbing and removing impurity gas in raw material gas at low temperature, preparing high-purity and ultra-pure product gas with the purity of higher than 99.99%, vacuumizing an adsorber by using a vacuum pump during regeneration, and feeding the high-purity and ultra-pure product gas into the adsorber while vacuumizing, thereby obtaining the high-purity and ultra-pure product gas with the purity of higher than 99.99%. A small amount of gas with low impurity component content is introduced into the adsorber to regenerate the adsorbent, and the temperature of the adsorber is not obviously increased during regeneration. According to the low-temperature adsorption method, the adsorber does not need to be deliberately heated in the regeneration process, consumption of a large amount of energy and materials caused by frequent heating and cooling of the adsorber is avoided, and the low-temperature adsorption method has the advantages that operation is easy, energy consumption is low, and the device is suitable for long-time continuous operation.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

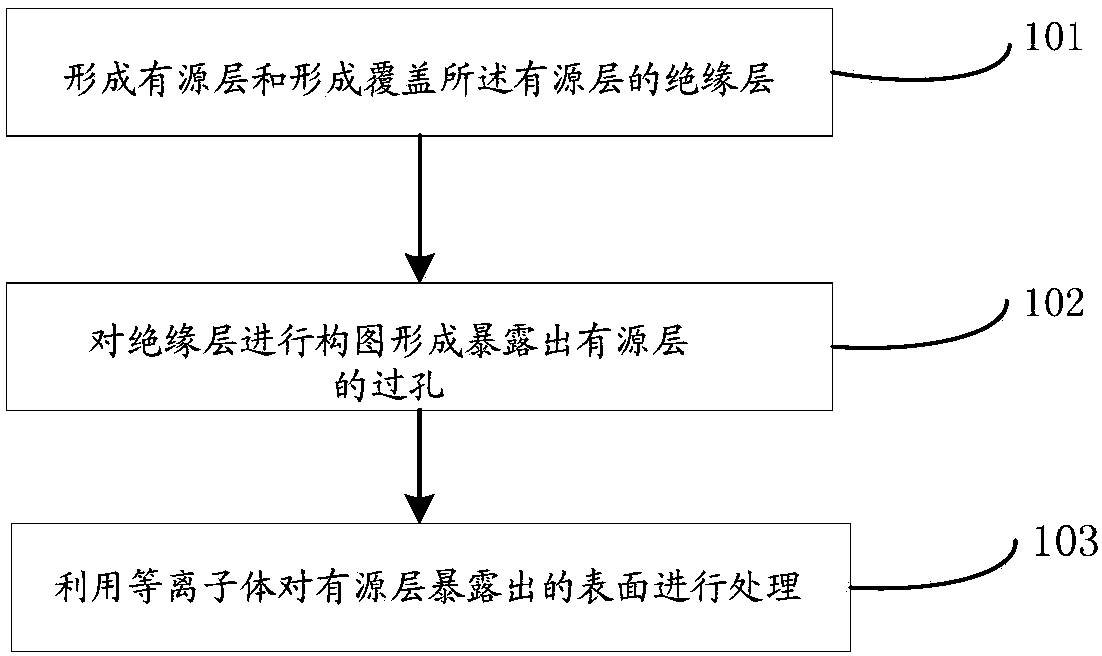

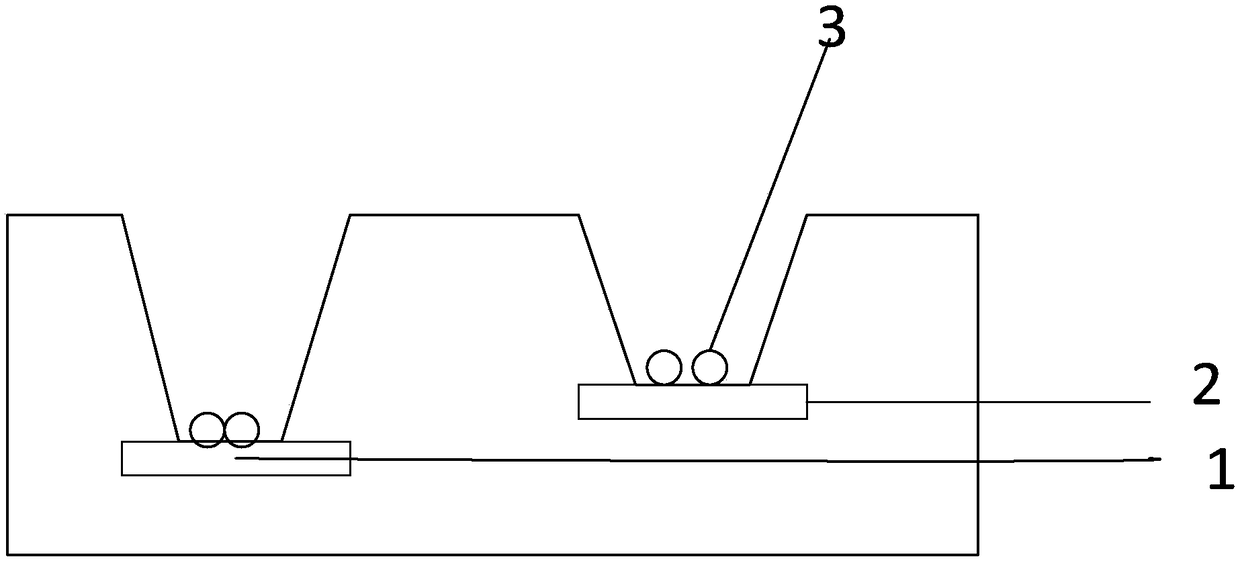

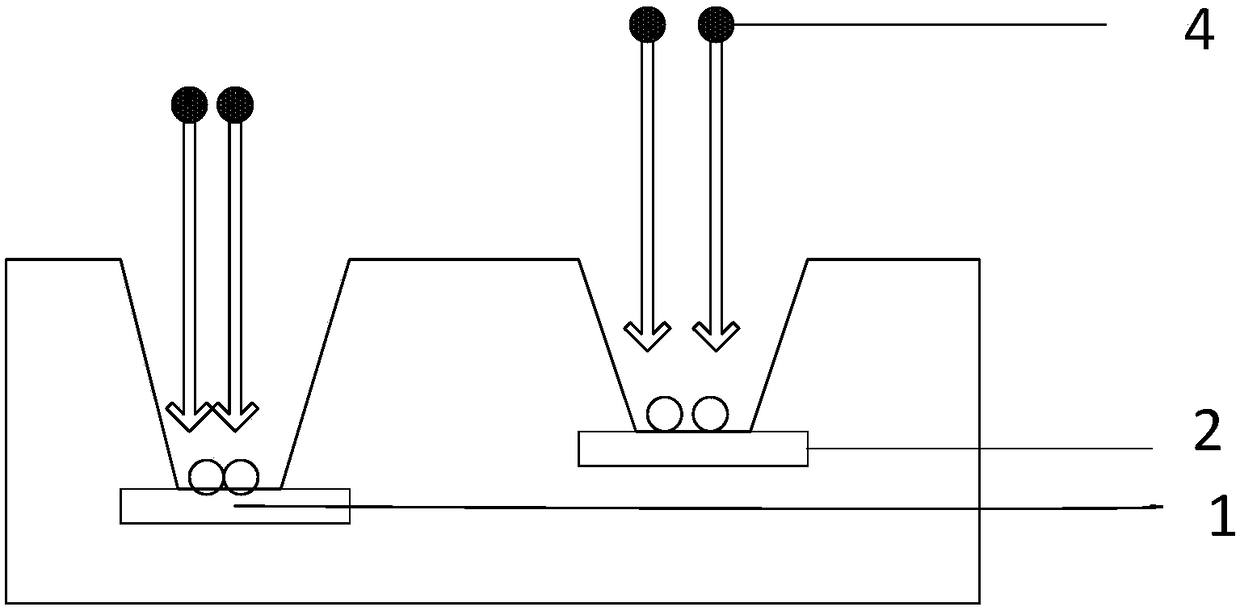

Manufacturing method of thin film transistor and manufacturing method of display substrate and display device

ActiveCN108336024AAvoid damageInhibitory concentrationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxide

The invention relates to the field of display, and particularly relates to a method manufacturing for a thin film transistor, a manufacturing method for the display substrate and a display device. Themanufacturing method of the thin film transistor comprises the steps of forming an active layer and forming an insulating layer covering the active layer, after the insulating layer is patterned, thethrough-hole of the active layer is exposed, treating the exposed surface of the active layer with plasma to remove organic impurities and / or oxides on the surface of the active layer. The manufacturing method of the thin film transistor adopts a dry method to process organic impurities on the surface of the active layer, avoids the pollution of the liquid medicine and improves the stability of the performance of the product. For the thin film transistor with the metal oxide as the active layer, the damage to the metal oxide can be avoided, and the management and the control of the product can be completed under the small uniformity variation.

Owner:MIANYANG BOE OPTOELECTRONICS TECH CO LTD +1

Full-automatic laser coding line

PendingCN110977158ARealize automatic alignmentImprove efficiencyLaser beam welding apparatusEngineeringComputer science

The invention discloses a full-automatic laser coding line. A plate is placed on a conveying belt for conveying; left and right side gauges are arranged at the left and right sides of the feeding endof the conveying belt respectively; a laser coding machine is arranged above the conveying belt and on the rear side of the left and right gauges, and a laser head of the laser coding machine faces the conveying belt; a detection device is arranged on the rear side of the laser coding machine, the detection device comprises a front detection camera arranged above the conveying belt, and the frontdetection camera faces the conveying belt; a defective product tray is arranged above the conveying belt and behind the detection device; and a guide rotating shaft links a guide supporting rod to swing and ascend when driven to rotate by a guide driving device, so that the plate on the conveying belt is guided by the guide supporting rod during conveying to enter the defective product ray. According to the full-automatic laser coding line, full-automatic alignment, coding, detection and screening are realized, and the efficiency is extremely high.

Owner:广东金亨制罐有限公司

Recycling method of lithium ion battery positive electrode material fine powder

ActiveCN112838205AIncrease gram capacityImprove cycle stabilitySecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention belongs to the field of powder recovery, and relates to a recovery method of lithium ion battery positive electrode material fine powder. The method comprises: carrying out ball milling on lithium ion battery positive electrode material fine powder, polyurethane and a grinding aid until the particle size D50 is less than or equal to 1.0 [mu]m; uniformly mixing the obtained fine powder with a dispersing agent, a cosolvent and water; separating the obtained mixed slurry into a large-particle-size positive electrode material, a small-particle-size positive electrode material and a suspension containing a plurality of elements; washing and drying a large-granularity positive electrode material, testing the ICP content, supplementing lithium salt and a coating additive according to a test value, and carrying out coating sintering in an oxygen atmosphere; washing and drying a small-particle-size positive electrode material, testing the ICP content, supplementing lithium salt and a doping additive according to a test value, and carrying out high-temperature sintering in an oxygen atmosphere; and drying and screening the turbid liquid. When the method provided by the invention is used for recovering the fine powder of the positive electrode material of the lithium ion battery, the gram volume and the cycling stability of the regenerated positive electrode material are very good.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com