Method for hoisting open type groove body with large volume and small rigidity

A hoisting method and bulky technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve problems such as inconvenience, weld cracking, tank body deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

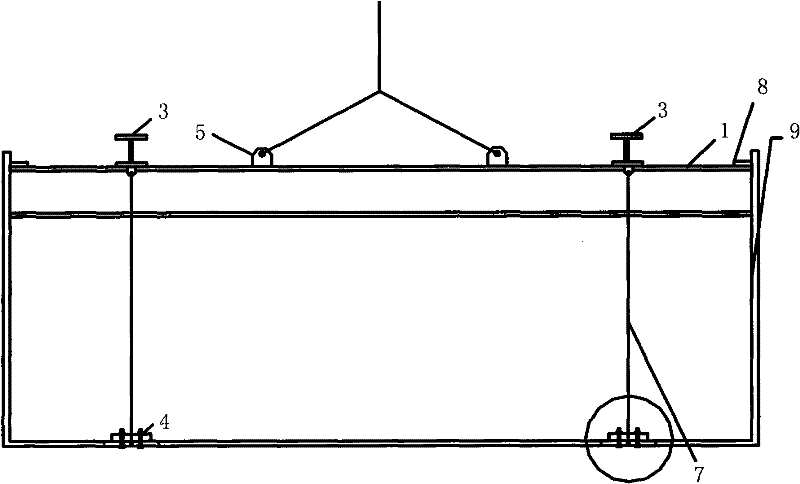

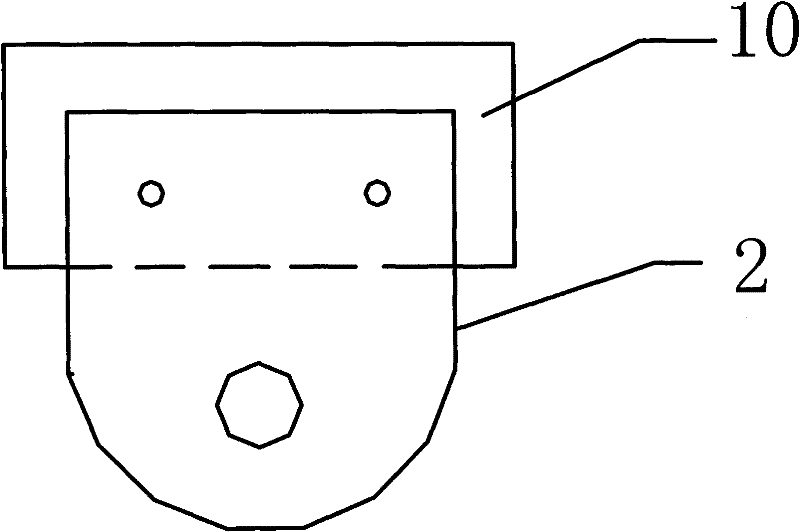

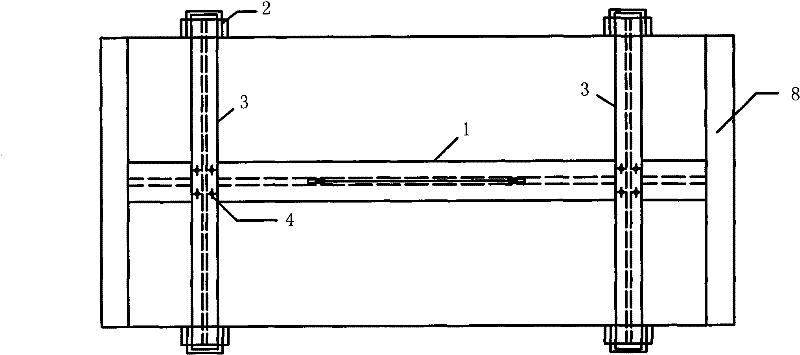

[0025] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0026] The hoisting method of the large-volume, low-rigidity open tank body of the present invention has been successfully applied in the engineering pickling tank hoisting of Baosteel's stainless steel cold-strip annealing pickling unit. There are 10 pickling tanks in the pickling section of the project. The body is made of pp (plastic) material, the tank body is 9m long, weighs 5 tons, and the tank wall δ=25mm. The tank body is welded by the bottom plate and the side plate. The hoisting method of the large-volume, low-rigidity open tank body of the present invention not only ensures that the 9m-long tank body is evenly stressed during the hoisting process, without deformation and cracking, but also because the sling is easy to disassemble and assemble, the pickling section The 10 tanks were continuously operated, and the hoisting was completed in 3 days, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com