Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Increased hydrogenation conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

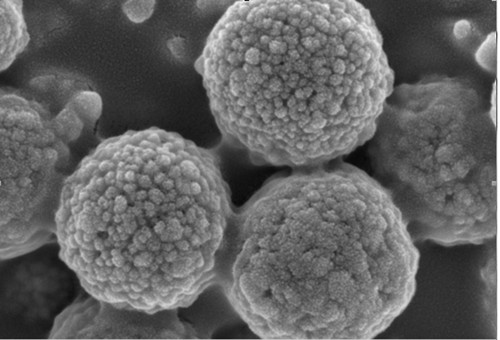

Oil solubility compound-type suspended bed hydrocracking catalyst as well as preparation method thereof

ActiveCN103977822AImprove catalytic performanceReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSolubilityReaction temperature

The invention discloses an oil solubility compound-type suspended bed hydrocracking catalyst, wherein the catalyst is prepared by the following steps: 1) enabling compounds of metal elements in the VIB family, the VIIB family or the VIII family in a periodic table of elements as metal sources with alkali metal sulfide or alkali metal hydrosulfide according to the mole ratio of (0.5 to 1)-(2 to 1), thereby obtaining a metal element compound at a reduction state; 2) adding the metal element compound at the reduction state and amine substances into a reaction medium according to the mole ratio of (1:0.6)-(1 to 2), and meanwhile dropwise adding carbon disulfide with the corresponding quantity into the reaction medium according to the mole ratio of (1 to 1)-(2 to1) with the metal element compound at the reduction state, warming to react at the reaction temperature of 30-110 DEG C for 2-10 hours; 3) filtering and washing the product obtained by the step 2) so as to obtain the oil solubility compound-type suspended bed hydrocracking catalyst. The catalyst prepared by the invention can inhibit the coke yield, and improve the light oil yield.

Owner:CCTEG CHINA COAL RES INST

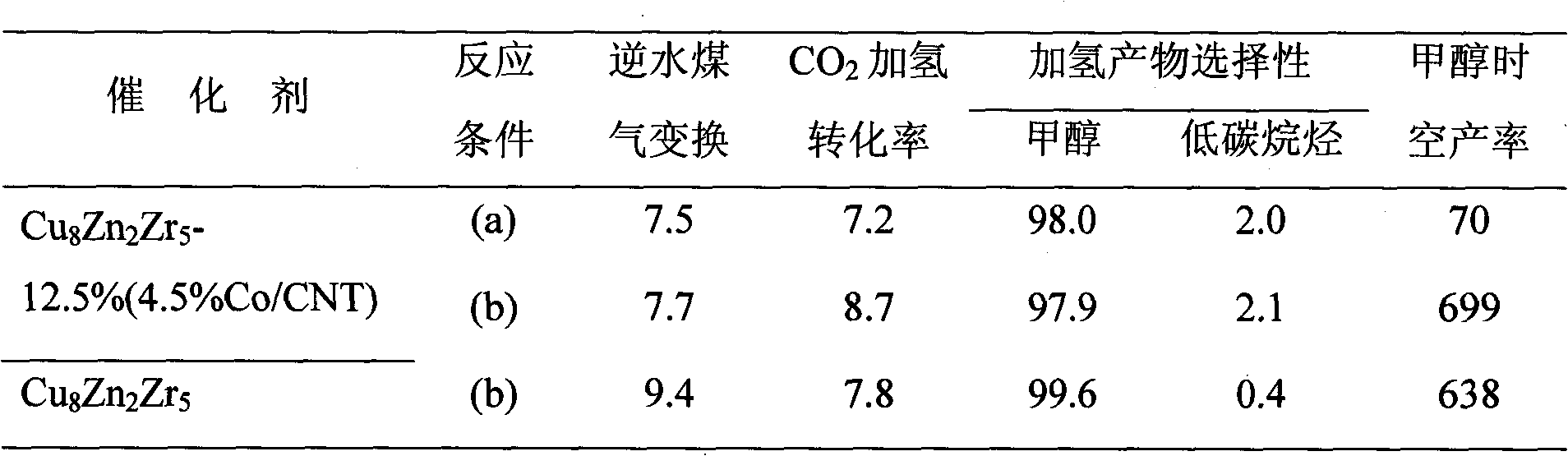

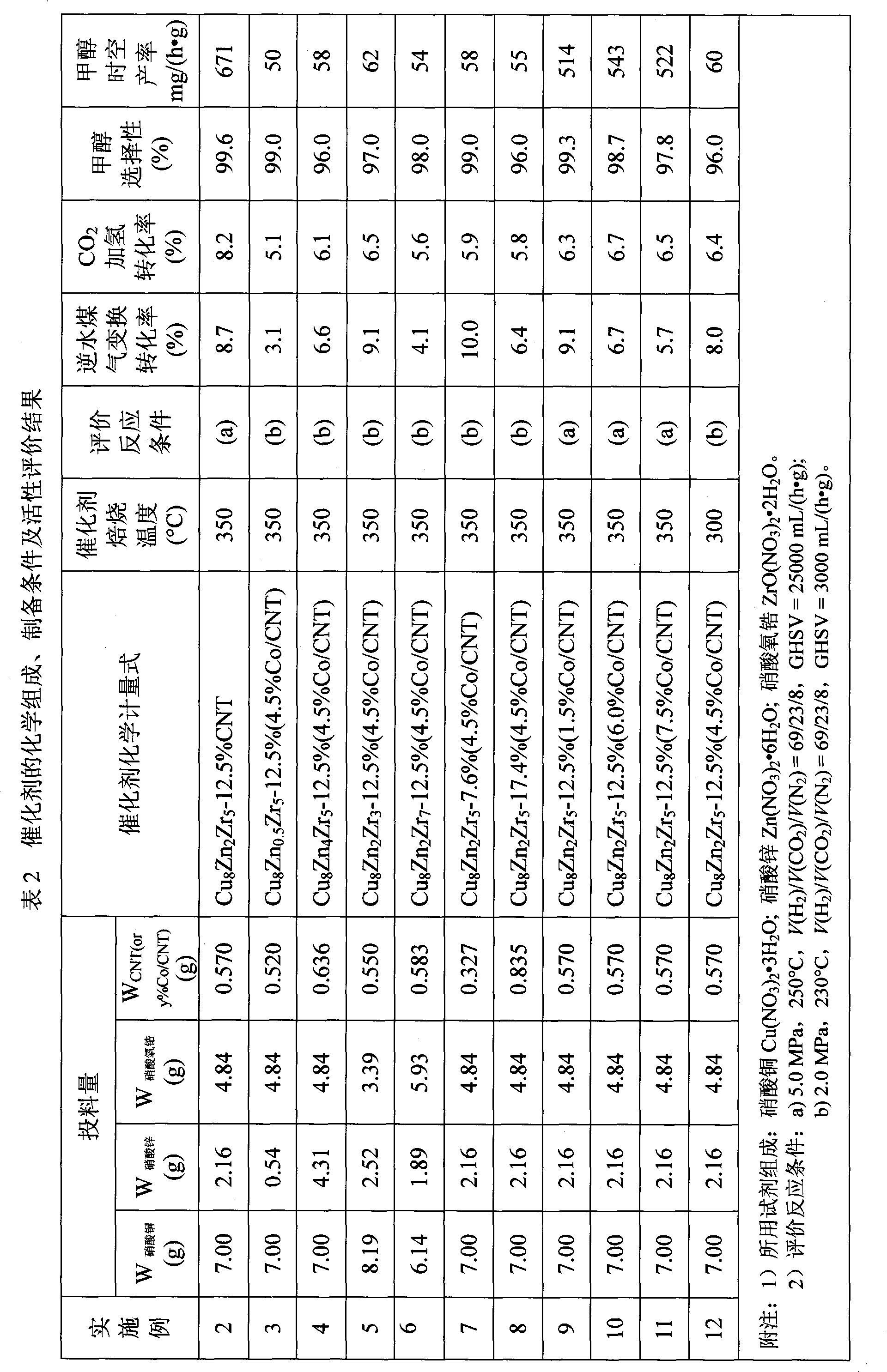

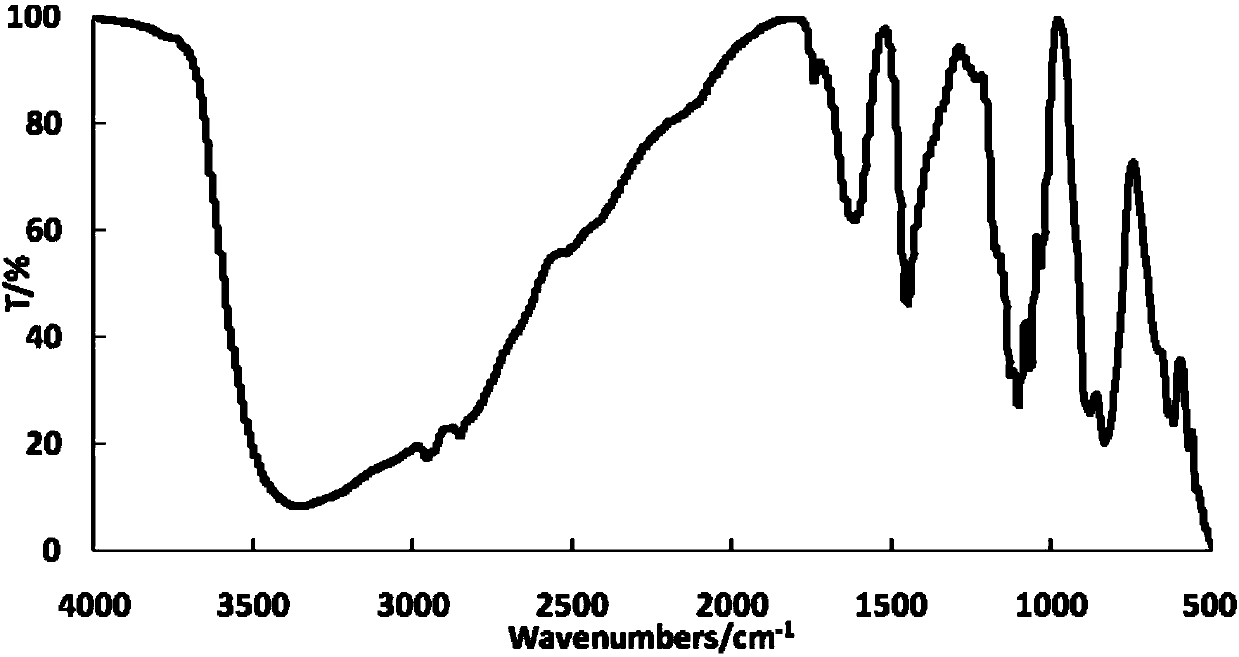

Catalyst for hydrogenation of carbon dioxide to generate methanol and preparation method thereof

InactiveCN101786001AIncreased hydrogenation conversionHigh productivity per passOrganic compound preparationHydroxy compound preparationCarbon nanotubeMetal

The invention relates to a catalyst, in particular to the catalyst for hydrogenation of carbon dioxide to generate methanol and a preparation method thereof. A carbon nanotube-based material is adopted as an accelerating agent. When being used for the catalytic hydrogenation of the carbon dioxide to generate the methanol, the catalyst can effectively increase the hydrogenation converting rate of the carbon dioxide and the one-path yield rate of the methanol. The catalyst comprises main metal components and the accelerating agent of the carbon nanotube-based material. The main metal components include Cu, Zn and Or. The accelerating agent of the carbon nanotube-based material means CNT or y% Co / CNT, and the chemical formula is CuiZnjZrk-x% (CNT or y% Co / CNT). The mass percent of each component is as follows: Zn: 5 to 20%; Zr: 25 to 50%; the accelerating agent of the carbon nanotube-based material: 1 to 18%; and the rest is Cu. The catalyst is prepared through coprecipitation. A multi-wall carbon nanotube modified by metal cobalt is prepared by utilizing liquid-phase microwaves of polyalcohol to assist in chemical reduction and deposition.

Owner:XIAMEN UNIV

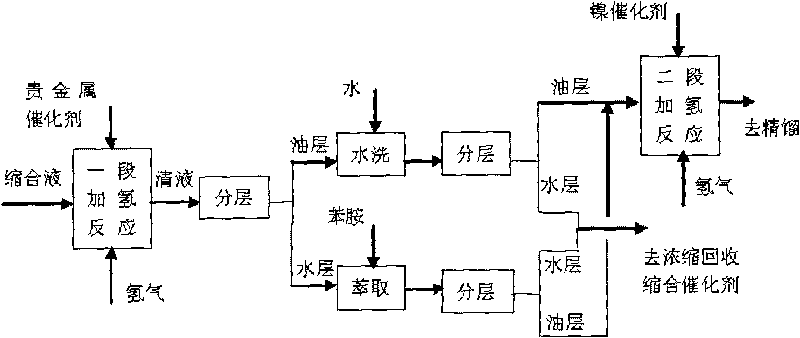

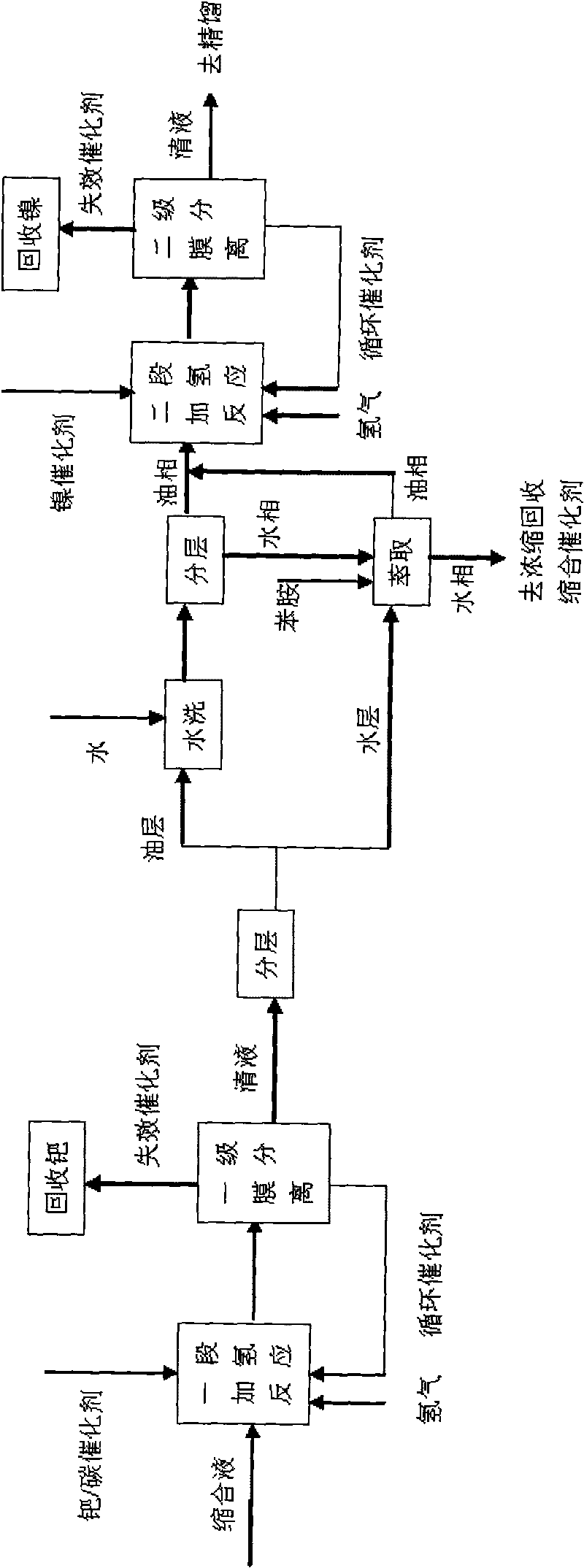

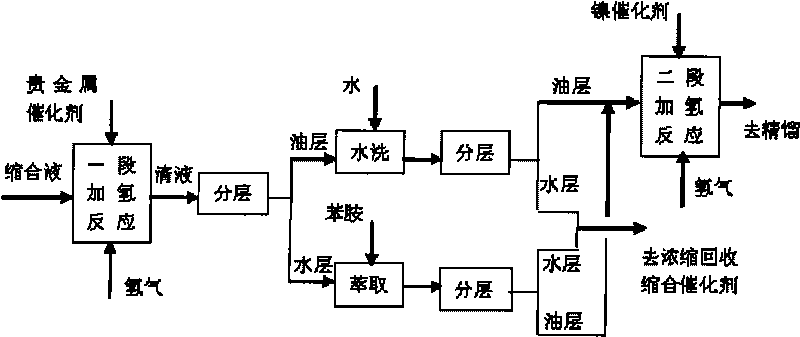

Method for preparing 4-amino diphenylamine by catalytic hydrogenation

ActiveCN101691332AEasy to cleanImprove regenerative abilitySemi-permeable membranesAmino compound purification/separationNitrosoNitrobenzene

The invention provides a method for preparing 4-amino diphenylamine by catalytic hydrogenation. The method adopts two sections of hydrogenation reaction processes, and comprises the following steps: performing the condensation reaction of condensation solution formed by the condensation reaction of nitrobenzene and aniline which serve as raw materials under an alkaline condition by using using a noble metal hydrogenation catalyst and a nickel catalyst sequentially so as to make the conversion rate of 4-nitroso diphenylamine, 4-nitro diphenylamine and azoxybenzene achieve 100 percent; and separating the noble metal hydrogenation catalyst and the nickel catalyst by using a two-stage membrane separation component system to avoid the loss of small particles of catalyst. At the same time, the method has high degree of automation and can easily realize the continuous hydrogenation process.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Catalyst composition for hydrogenation and their use for hydrogenation conjugated diene polymer

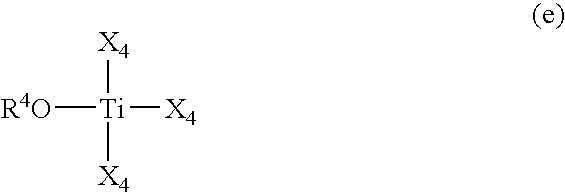

InactiveUS20100137525A1Low costIncreased hydrogenation conversionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsSilyleneHydrogen pressure

The present invention provides a process for hydrogenation of a conjugated diene polymer comprising hydrogenating said polymer in the presence of hydrogen and a hydrogenation catalyst composition, wherein the catalyst composition comprising a titanium compound (A), a silyl hydride (B) selected from the group having a Si—H group and consisting of a monomeric silyl hydride, a polymeric silyl hydride, and a cyclic silyl hydride; and a compound (C), and conducting the hydrogenation in a middle to larger sized reactor having a capacity of 25 liters, with a temperature of 50° C. to 150° C., and a hydrogen pressure of 1 kg / cm2 to 20 kg / cm2.

Owner:CHI MEI CORP

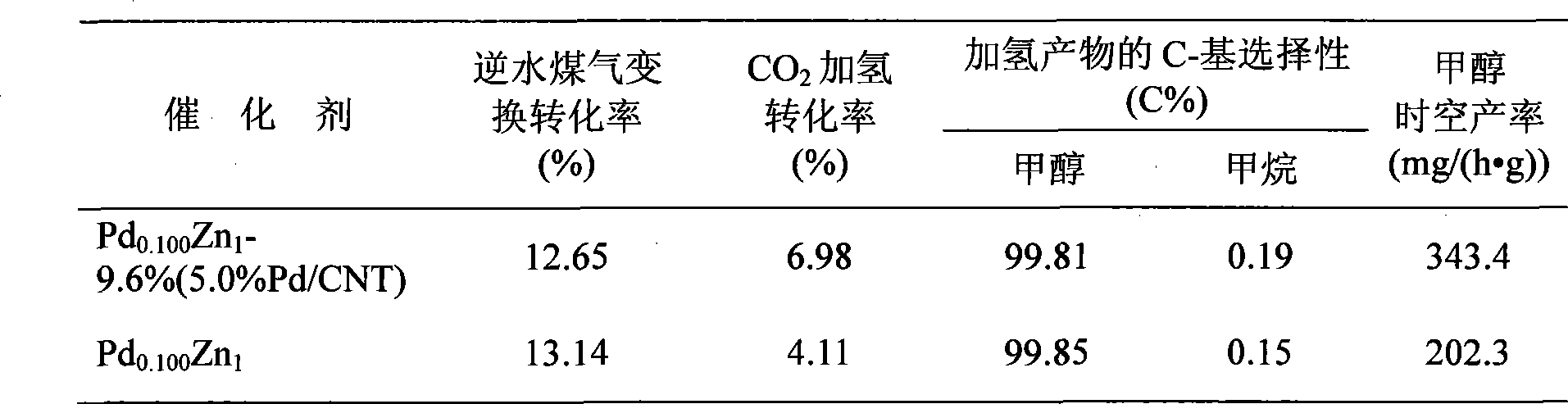

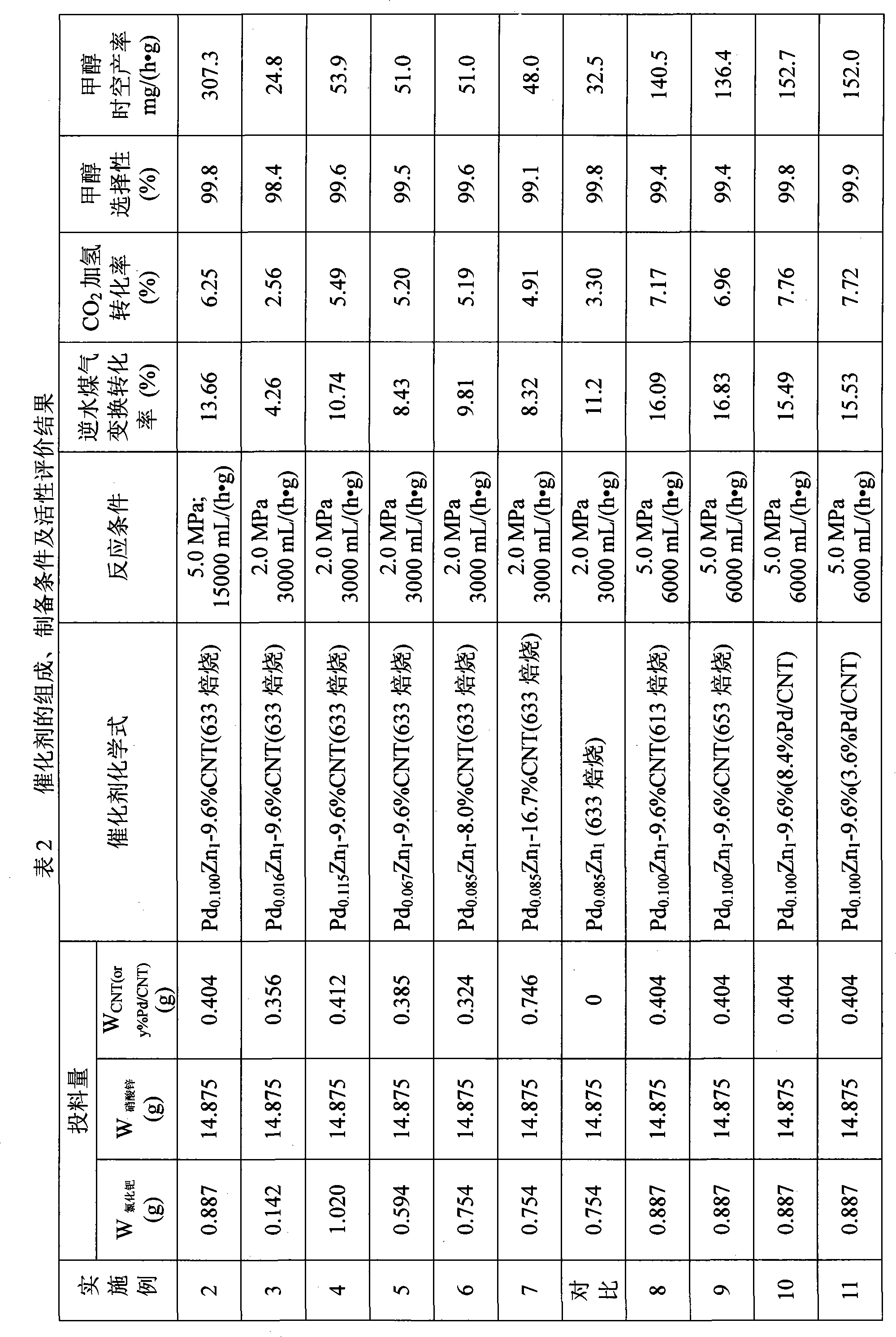

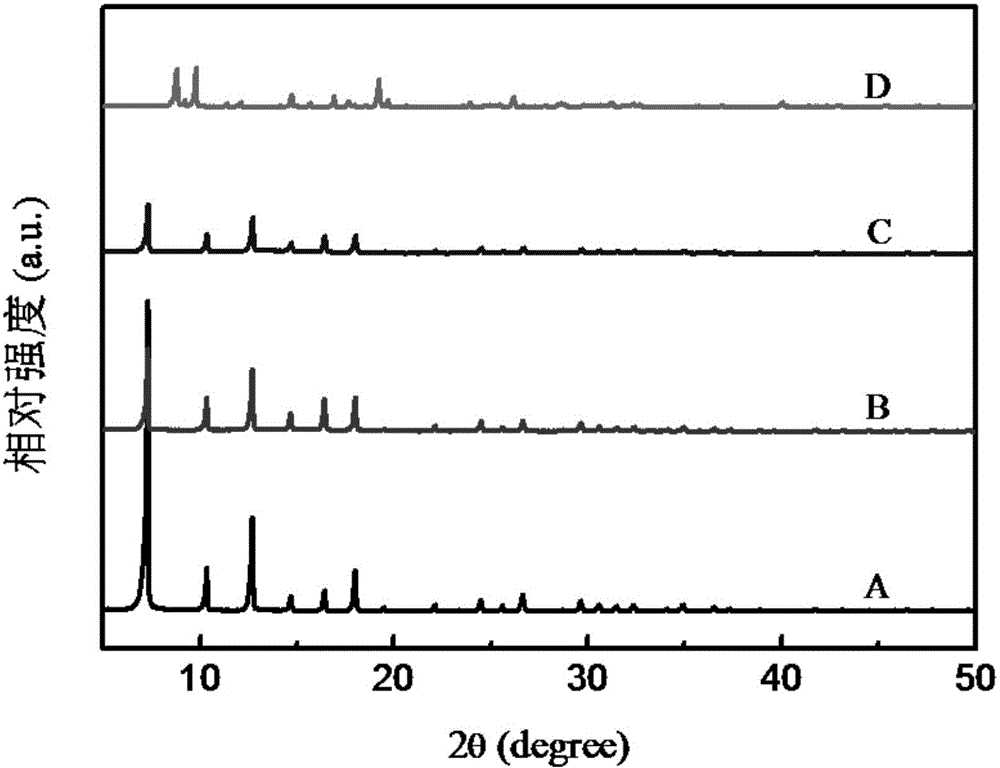

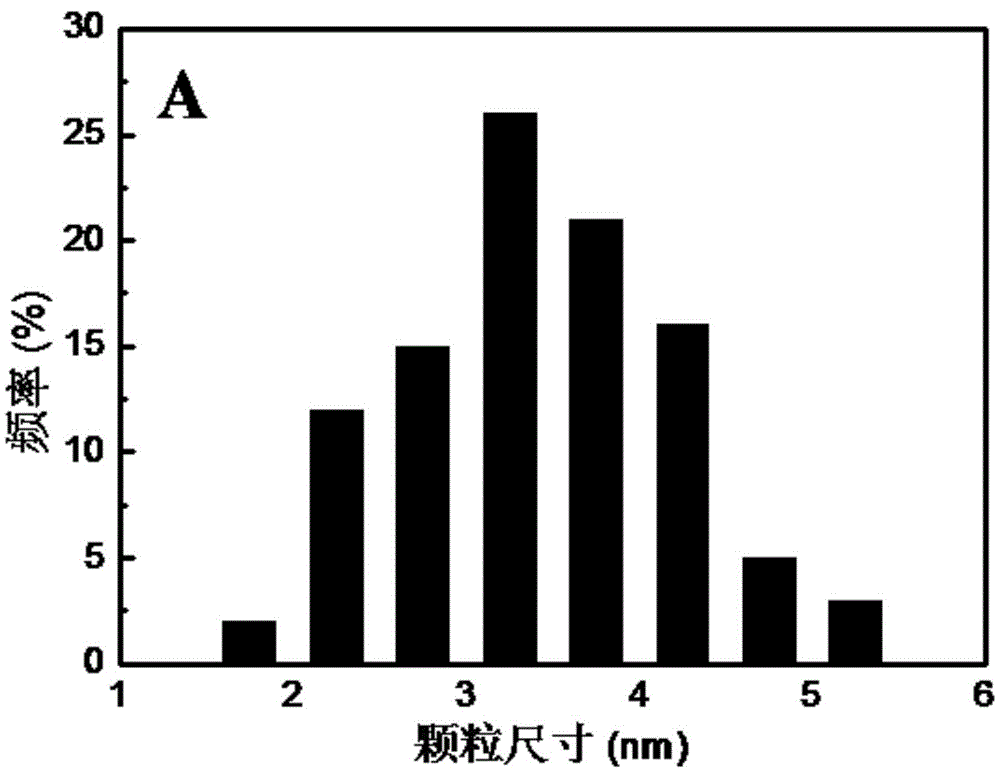

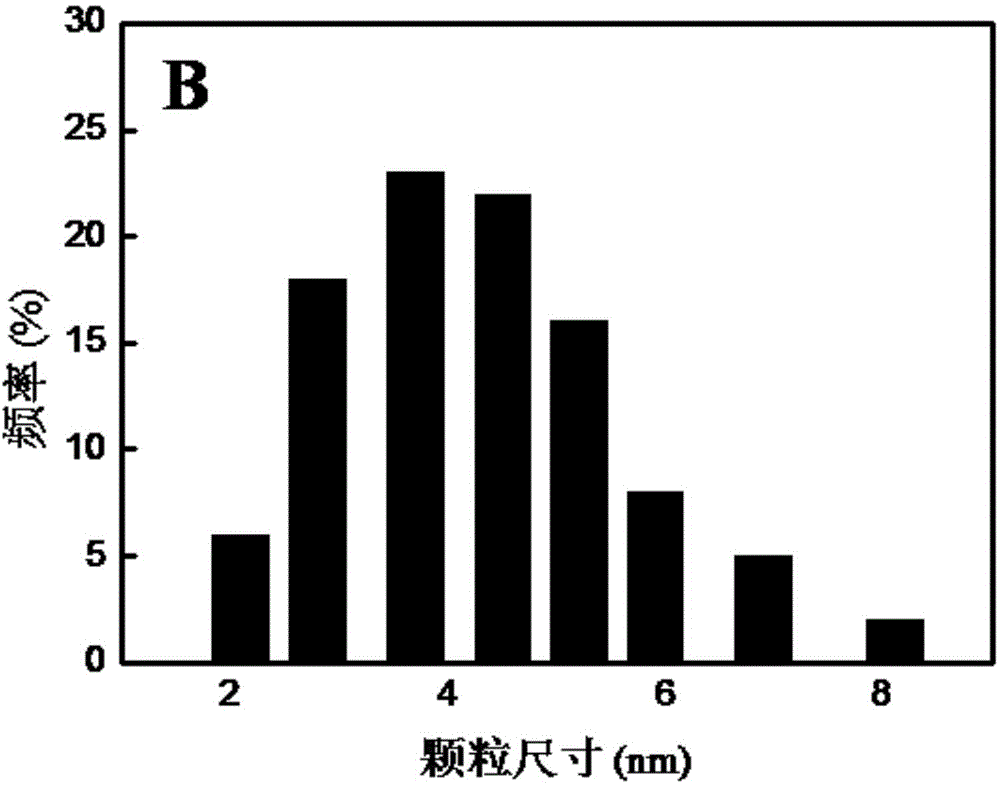

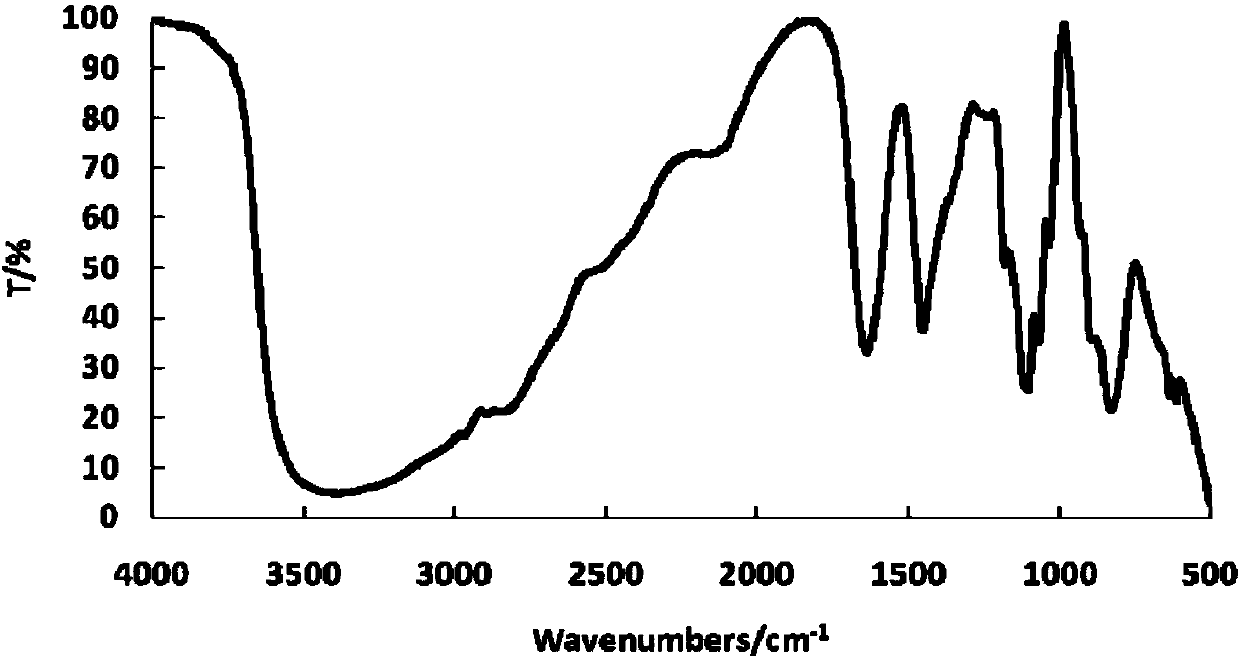

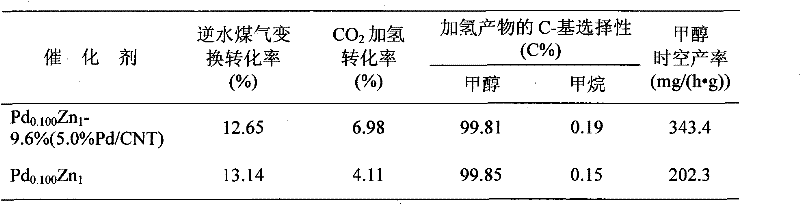

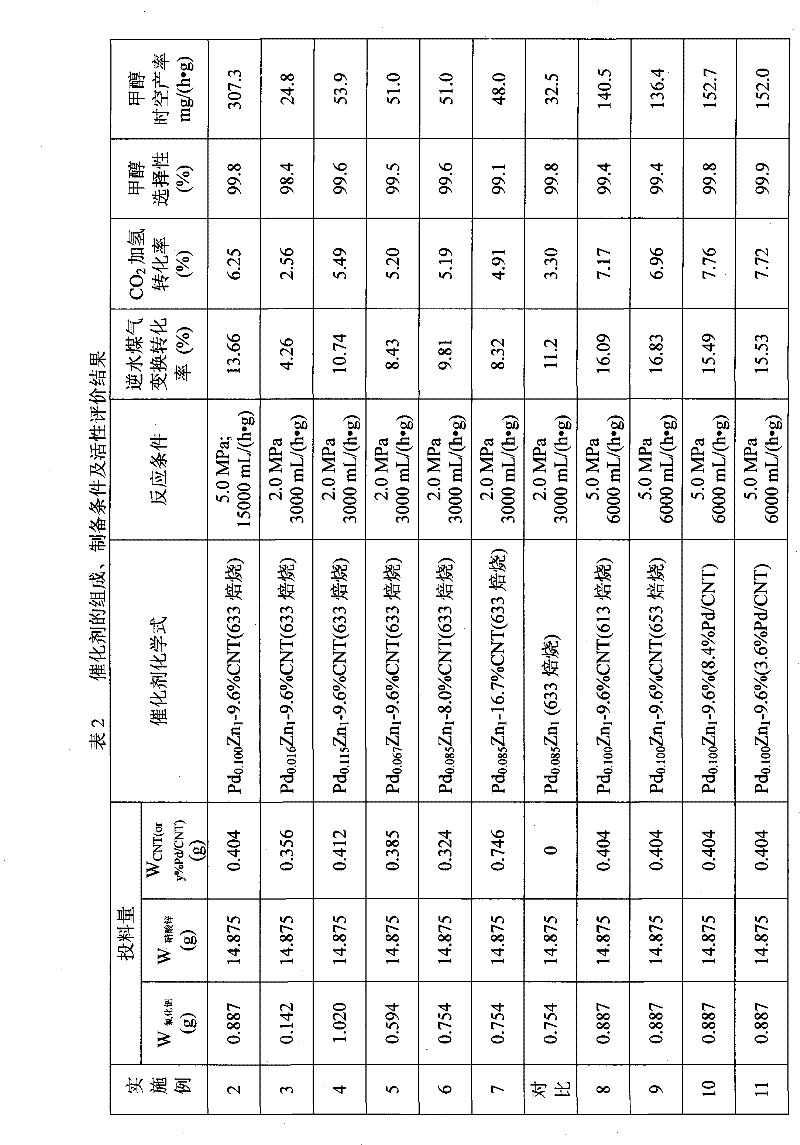

Catalyst used for preparing methanol by hydrogenation of carbon dioxide and a preparation method thereof

InactiveCN101444731AHighly active and stableHigh selectivityOrganic compound preparationHydroxy compound preparationCarbon nanotubeZinc

The invention discloses a catalyst used for preparing methanol by hydrogenation of carbon dioxide and a preparation method thereof, relating to a palladium-zinc catalyst which takes a carbon nanotube base material as an accelerating agent and a preparation method thereof; the catalyst contains main components of Pd and Zn and an accelerating agent of the carbon nanotube base material, the chemical formula is PdiZnj-x percent (CNT or y percent of Pd / CNT), and in the formula, i and j are mole ratio coefficients of relevant metallic elements in the main components of Pd-Zn, and x percent is mass percent of the accelerating agent of carbon nanotube base material in the catalyst; and the mass percentage of all the components is as follows: 2 percent to 25 percent of Pd, 55 percent to 90 percent of Zn and 6 percent to 20 percent of the accelerating agent of the carbon nanotube base material. During the preparation, the main components of Pd and Zn and the accelerating agent are coprecipitated and react and are dried and roasted so as to prepare the methanol. The activity of the catalyst is high and stable; the selectivity of the product of methanol is high; the conversion rate of hydrogenation of CO2 and space time yield of the methanol are obviously higher than the existing similar catalyst; the manufacturing is simple and convenient and the repetitiveness is good.

Owner:XIAMEN UNIV

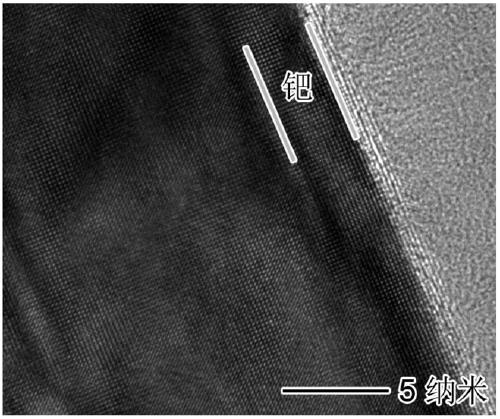

Alkadiene selective hydrogenation catalyst as well as preparation method and application thereof

ActiveCN104399529AGood dispersionIncreased hydrogenation conversionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationActive componentReaction temperature

The invention provides an alkadiene selective hydrogenation catalyst and a preparation method thereof. The carrier of the catalyst adopts carboxyl-functionalized step hole FZIF-8; active components adopts palladium; the active component palladium accounts for 0.1 to 10 percent on the basis of the total weight of the carrier of the catalyst. The invention further provides the preparation method of the alkadiene selective hydrogenation catalyst. A step hole structure is formed in the carrier of the alkadiene selective hydrogenation catalyst, so that carboxyl groups have accessibility, and the active components and the carboxyl groups can interact mutually; the carboxyl groups are contained in the carrier of the catalyst, can anchor the active components, realize high dispersion of the active components, meanwhile prevent agglomeration and drain of the active components during the process, and ensure that the catalyst is high in activity. The catalyst can be applied to the hydrogenation upgrading of FCC petrol, removal of alkadiene in the petrol, and is mild in reaction condition, low in reaction temperature and pressure, and good in selective hydrogenation effect of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for refining terephthalic acid

InactiveCN101607202AHigh porosityIncrease the speed of hydroconversionChemical industryMetal/metal-oxides/metal-hydroxide catalystsFiberCarbon fibers

The invention discloses a catalyst using a structuring nano carbon fiber as a carrier and a method for preparing the same. The catalyst can be applied to hydrofinishing in the production process of catalytic refining of terephthalic acid.

Owner:LINDE AG

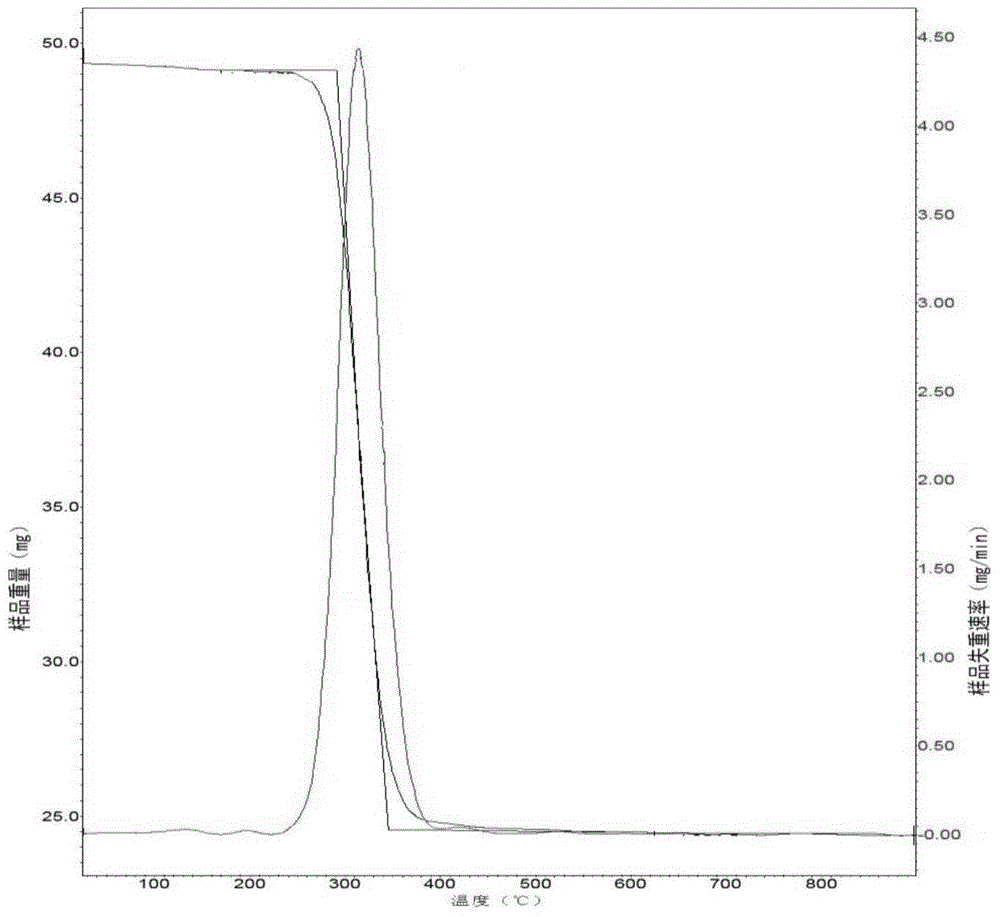

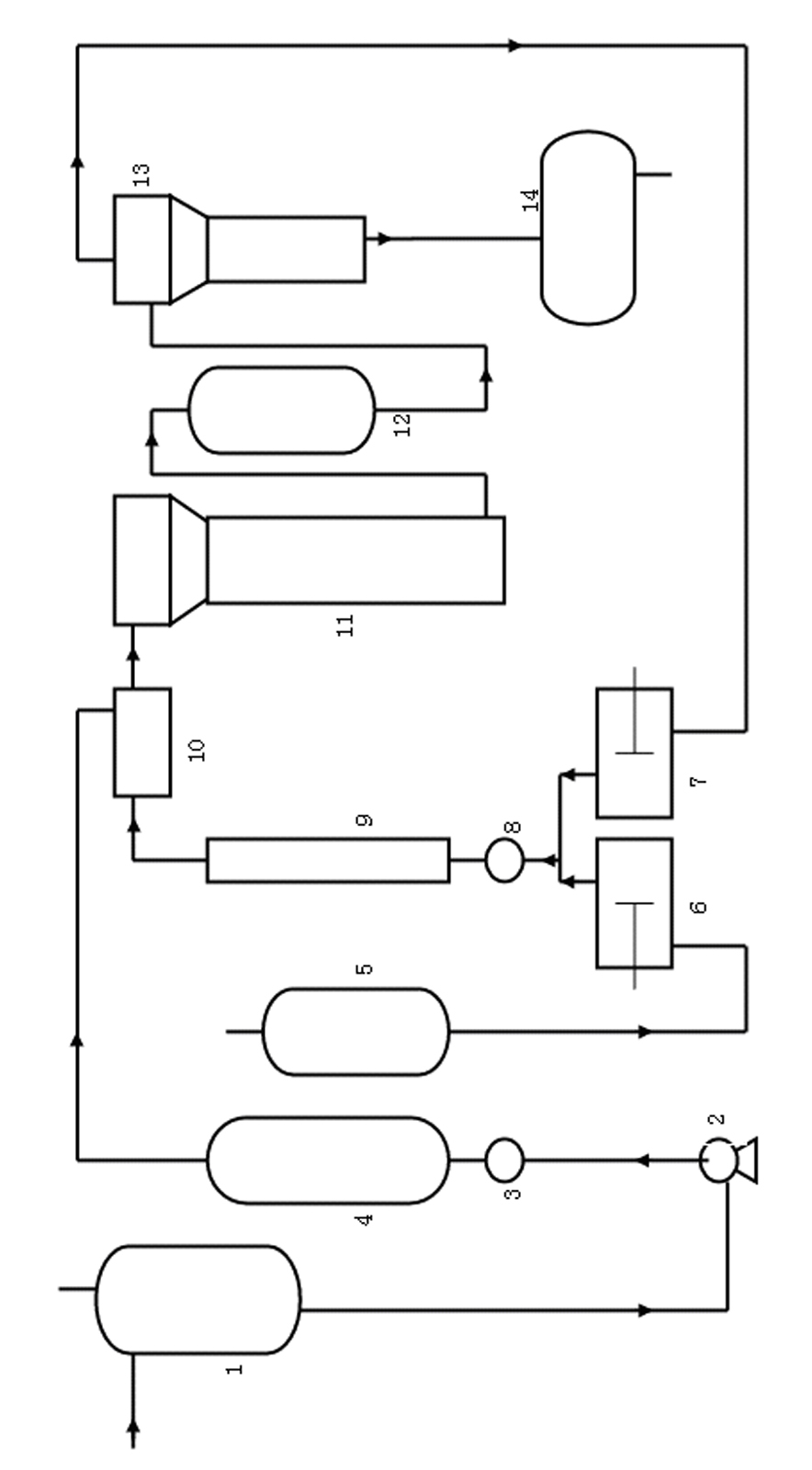

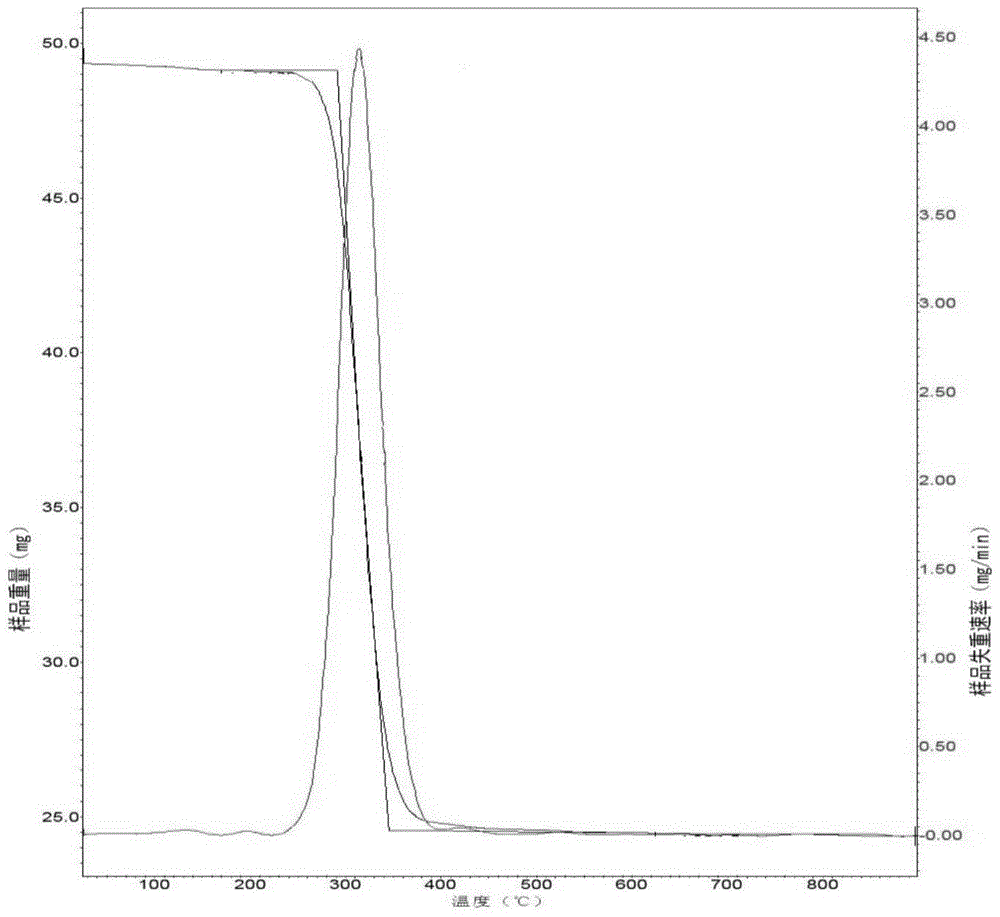

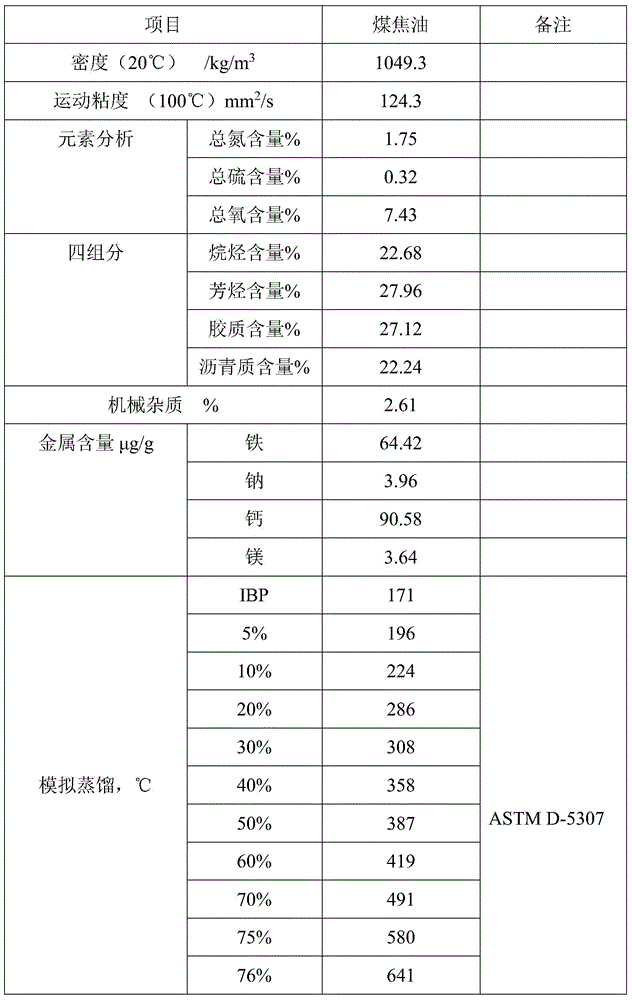

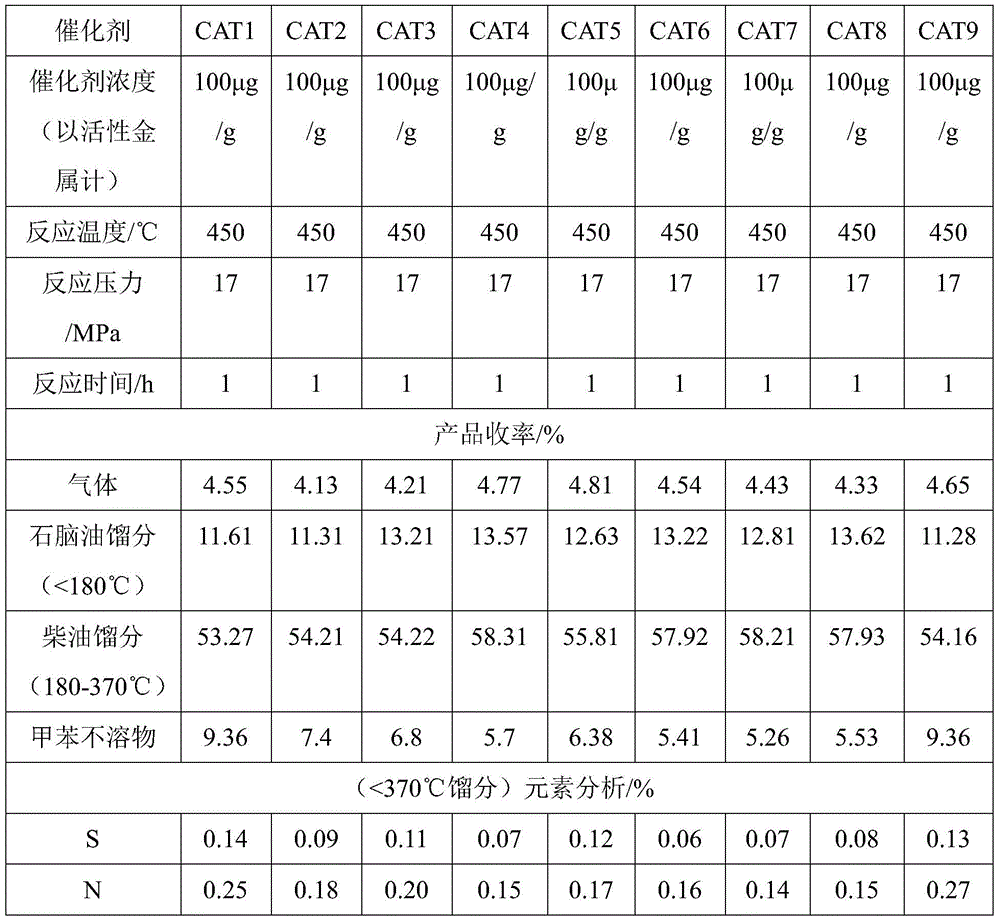

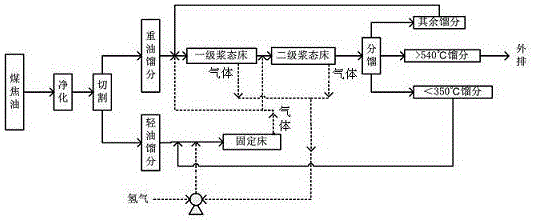

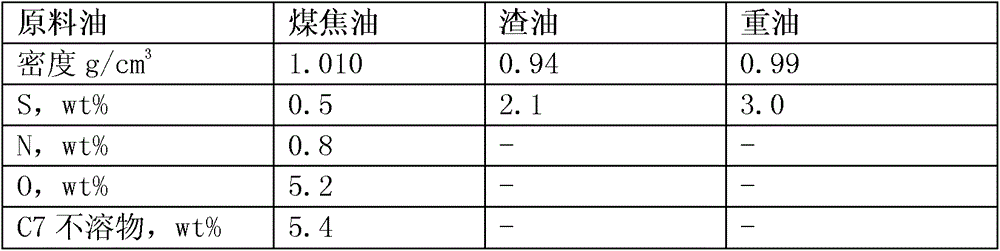

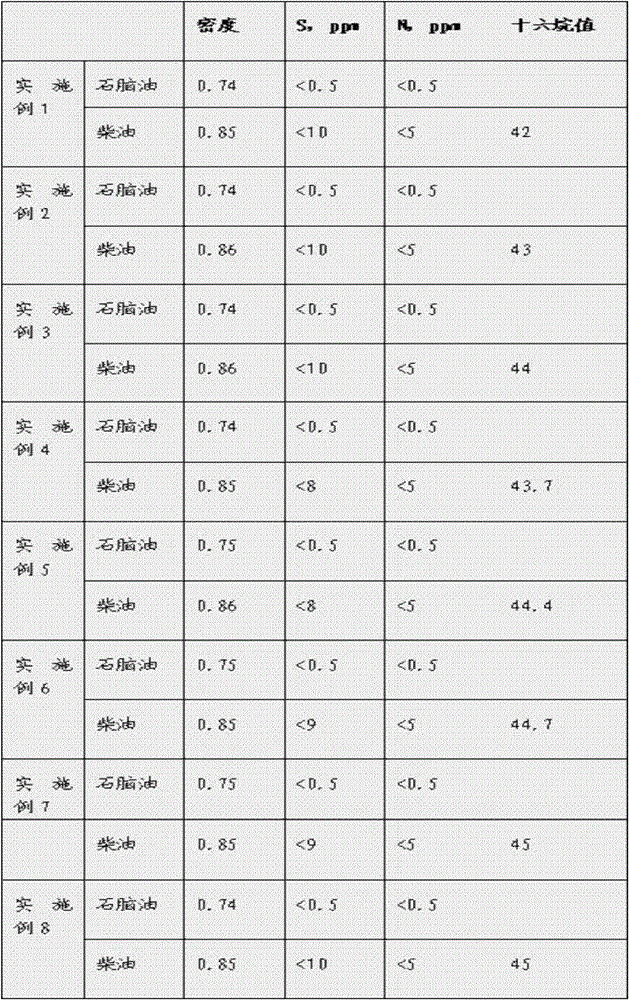

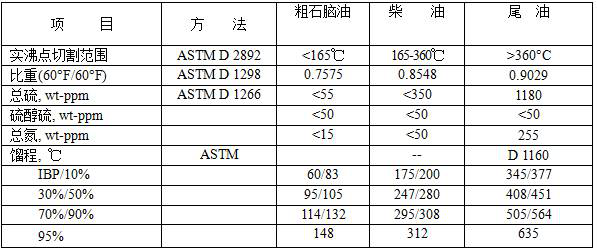

Two-stage slurry bed hydrogenation process of medium and low temperature coal tar

ActiveCN104277879AIncreased hydrogenation conversionReduce hydrogen consumptionTreatment with hydrotreatment processesChemistryCoal tar

The invention provides a two-stage slurry bed hydrogenation process of medium and low temperature coal tar, and the a two-stage slurry bed hydrogenation process comprises the following steps: (1) performing purification on the medium and low temperature coal tar; (2) performing decompression or atmospheric distillation on the medium and low temperature coal tar purified by the step (1) for cutting into light oil fractions and heavy oil fractions, wherein the cutting point temperature range is 320 to 380 DEG; (3) mixing the heavy oil fractions higher than the cutting point of the step (2) with a hydrocracking catalyst and H2, mixing evenly, and in turn getting into a first stage slurry bed and a second slurry bed for two-stage hydrocracking reaction, processing the prepared hydrocracking products by fractionation, performing fractional distillation on the hydrocracking products by the cutting point temperature range in the step (2) to distil off fractions lower than the cutting point; discharging 3-8% fractions higher than 540 DEG C out, and recycling the rest fractions back to a first stage slurry bed reactor. A liquid fuel prepared by the process has the advantages of low hydrogen consumption and high product yield.

Owner:任相坤

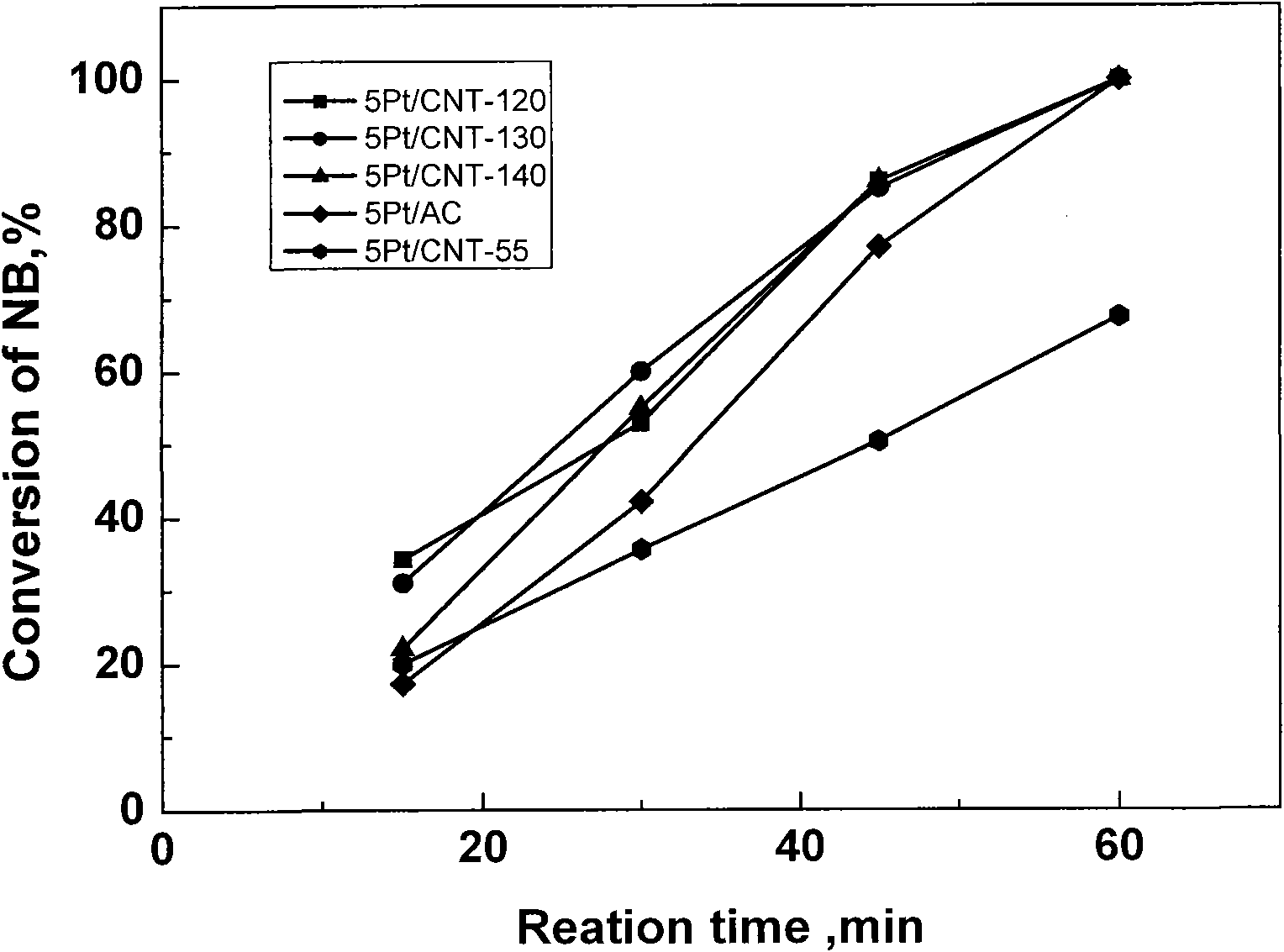

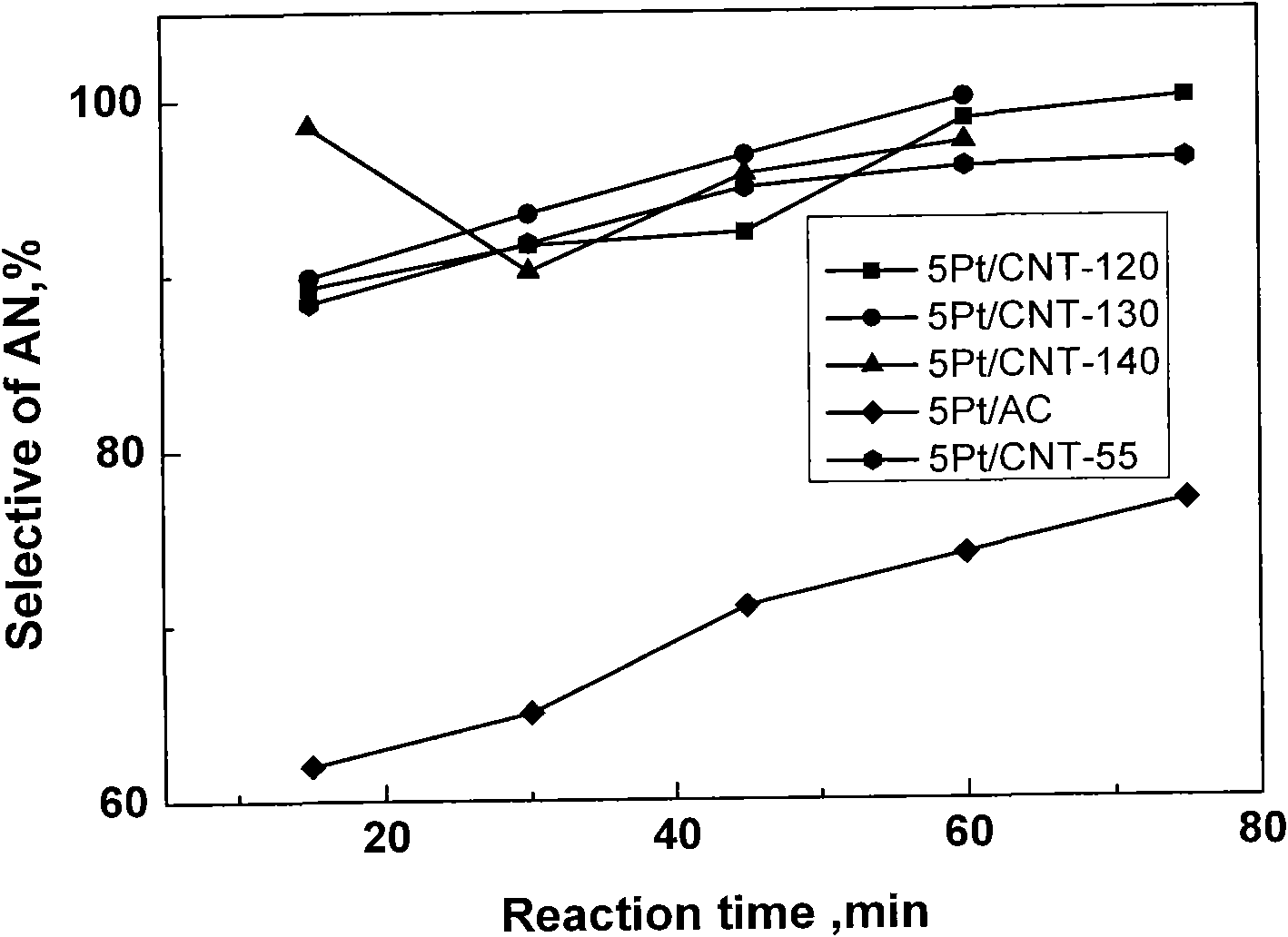

Method for preparing high-strength carbon nano tube supported platinum catalyst

InactiveCN102211023AIncreased hydrogenation conversionGood choiceOrganic compound preparationAmino compound preparationRotary evaporatorCarbon nanotube

The invention provides a method for preparing high-strength carbon nano tube supported platinum catalyst applicable to industrial application, comprising the following steps: preprocessing, namely heating and refluxing a protogenic carbon nano tube in mixed acid of 98wt% concentrated sulfuric acid and 60-63wt% concentrated nitric acid at a volume ratio of 3:1 and at a temperature of 100-130 DEG C, then filtering, washing and drying; impregnating, namely mixing the preprocessed carbon nano tube and a chloroplatinic acid solution, standing for 24 hours, adding absolute ethyl alcohol the volume of which is no more than 50% of the total volume, evaporating a solvent by utilizing a rotary evaporator, and smashing to obtain particles with the granularity of 80-100 meshes; and reducing, namely processing in a hydrogen flow at the temperature of 350 DEG C for 2 hours, cooling to room temperature, and passivating in 20% nitrogen-air for 1 hour. The obtained catalyst has good catalytic activity on nitrobenzene hydrogenation reaction, and the crushing strength reaches 20N.mm<-1>.

Owner:BEIJING UNIV OF CHEM TECH

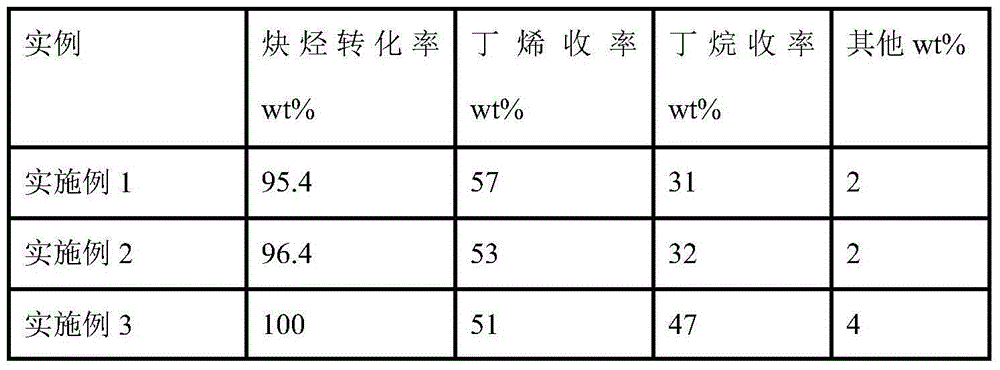

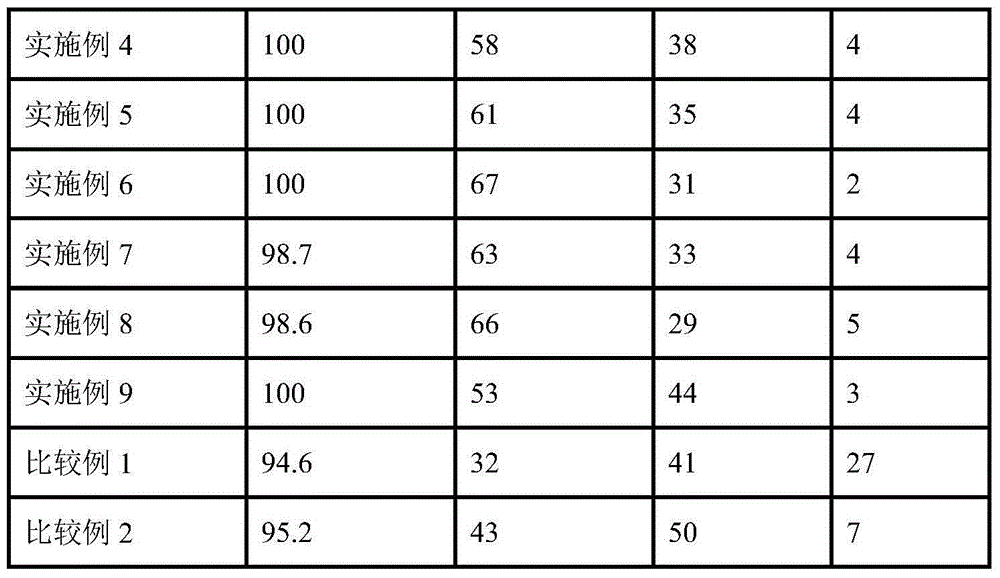

Diacetylene hydrogenation catalyst

ActiveCN105312058AImprove stabilityIncreased hydrogenation conversionHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlkaneAlkaline earth metal

The invention relates to a diacetylene hydrogenation catalyst and mainly solves the technical problems of high catalyst cost and poor stability in the prior art. In the invention, by means of a fixed bed reactor, a material containing the diacetylene and hydrogen are employed as raw materials and are contacted with a catalyst bed layer through the reactor to convert the diacetylene into monoalkene or alkane. The catalyst used in the reactor comprises the following components, on the basis of the weight part of the catalyst: (a) 10-20 parts of metal nickel or an oxide thereof, (b) 0.1-10 parts of at least one element of cerium or lanthanum or an oxide thereof; (c) 0.1-30 parts of zinc or an oxide thereof, (d) 0-2 parts of alkali metal or alkali earth metal, and (e) 38-90 parts of aluminum oxide. The technical scheme solves the technical problem well. The diacetylene hydrogenation catalyst is used in industrial production of high-order acetylene hydrogenation in a device of partially oxidizing natural gas to produce acetylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst composition for hydrogenation and their use for hydrogenation conjugated diene polymer

InactiveUS20080171653A1Low costIncreased hydrogenation conversionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsSilyleneTitanium

The present invention provides a catalyst composition for hydrogenation comprising: (1) a titanium compound (A) represented by the following formula (a):(2) a silyl hydride (B); and (3) a compound (C) represented by the following formula (e):The catalyst composition for hydrogenation can maintain activity longer and improve hydrogenation conversion of the conjugated diene polymers, particularly of the trans structure. The conjugated diene polymers produced according to the present invention can further perform good thermal stability and odorless.

Owner:CHI MEI CORP

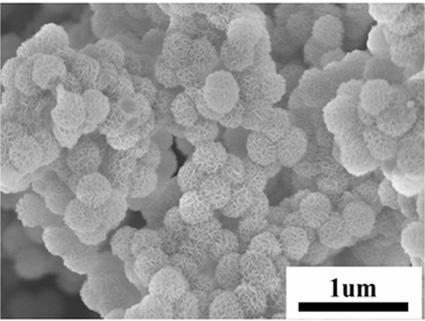

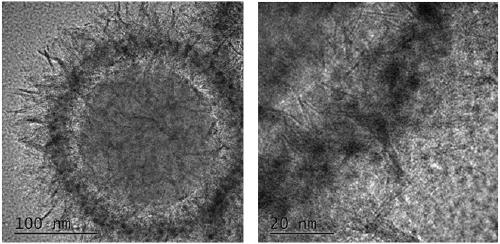

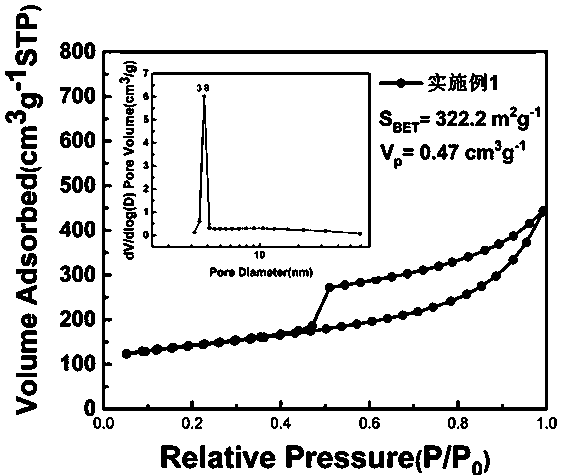

Preparation method of supported nickel-based catalyst and application of catalyst in catalytic hydrogenation of C5/C9 petroleum resin

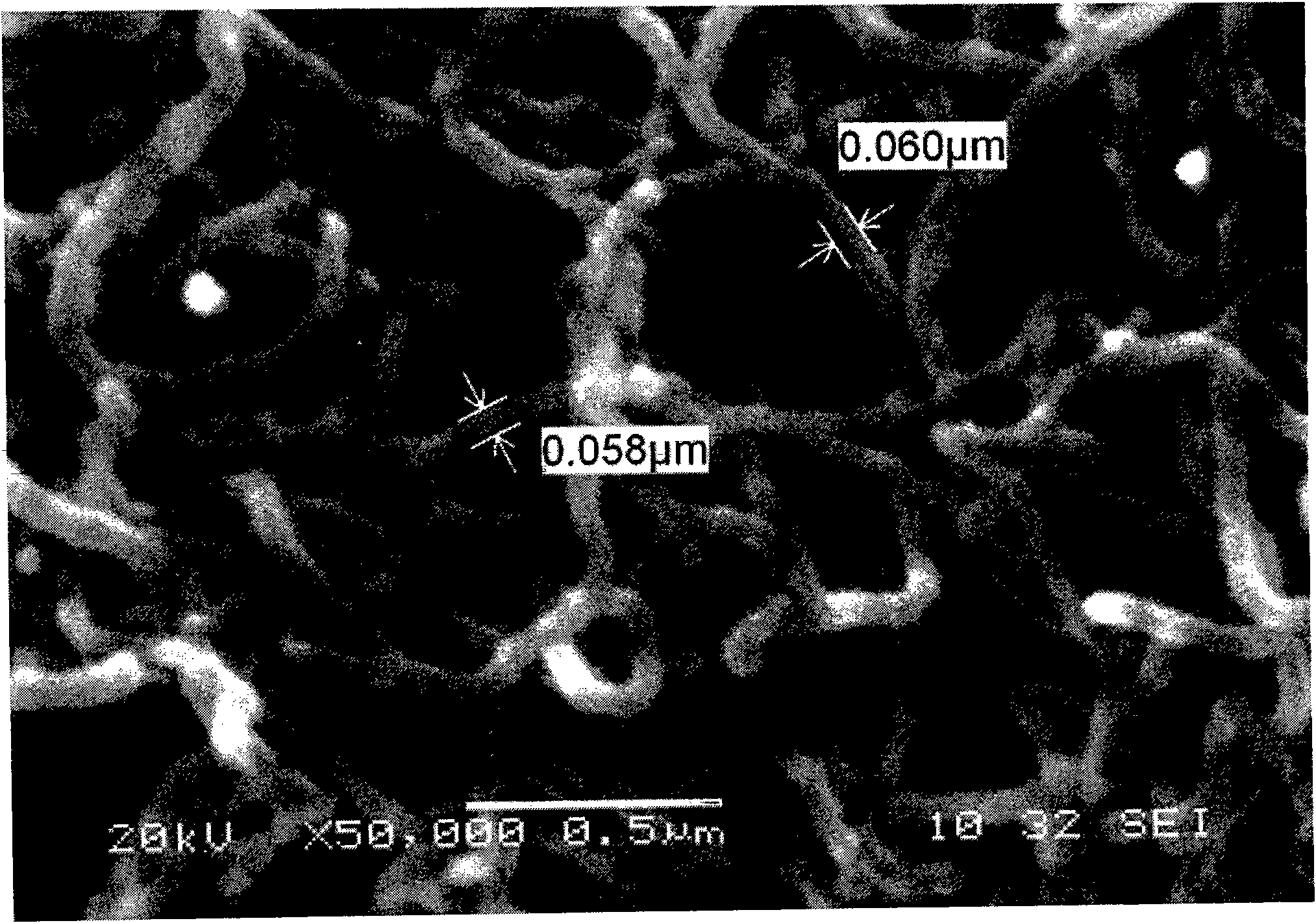

ActiveCN110013854ALarge specific surface areaSmall particlesSilicaMetal/metal-oxides/metal-hydroxide catalystsMetal particleBinding force

The invention discloses a supported nickel-based catalyst, a preparation method thereof, and an application of the catalyst in catalytic hydrogenation of C5 / C9 petroleum resin. The catalyst is a mesoporous hollow nanosphere catalyst Ni-M-SiO2 prepared by taking SiO2 as a carrier, taking Ni as a main active metal center, and adding an assistant metal M (M=Cu / Co / Mg). The prepared catalyst has a relatively large specific surface area, the particle size of active metal particles is small, dispersion is uniform, the binding force with the carrier is strong, and loss and agglomeration do not occur easily in a reaction process. When being applied to a hydrogenation reaction of C5 / C9 petroleum resin, the catalyst not only has relatively high catalytic hydrogenation activity and decoloring performance, but also can effectively inhibit great reduction of the softening point, and is suitable for preparing high-quality hydrogenated petroleum resin. The obtained product is low in bromine price (smaller than 1.2 g Br2 / 100 g), small in color scale (Gardner color scale smaller than 0.6), and is high in softening point (larger than 84 DEG C).

Owner:FUZHOU UNIV

Method for continuously producing pinane by pinene and device therefor

InactiveCN101962310AIncreased hydrogenation conversionGood choiceHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAutomatic controlChemistry

The invention relates to a method for continuously producing pinane by pinene and a device therefor. The method comprises the following steps: (1) placing catalyst into a fixed bed reactor, replacing air with nitrogen, then preheating hydrogen before feeding the hydrogen into a gas and liquor mixer; preheating the pinene by a liquor preheater and then feeding the preheated pinene into the gas and liquor mixer; evenly mixing the preheated pinene with hydrogen in the gas and liquor mixer and then feeding the mixture into the fixed bed reactor to carry out hydrogenation; (2) cooling the hydrogenated material; (3) carrying out gas-liquid separation on the cooled reaction mass to obtain a menthane liquid product, returning the separated hydrogen to the fixed bed reactor. The invention also relates to a device for continuously producing pinane by pinene. The method and the device of the invention facilitate the improvement of the unstable state in the hydrogenation production of the pinane by the pinene, improve production efficiency, promote convenient utilization of the automatic control system in the production process and facilitate the reduction of human operational errors; in addition, the invention features stable quality of the product, safe operation, high efficiency and low energy consumption and convenient expansion of production scale.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Organic molybdenum salt and preparation method thereof

ActiveCN107868108AEvenly dispersedAvoid gatheringOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOil additiveHydrogenation process

The invention relates to an organic molybdenum salt and a preparation method thereof. The organic molybdenum salt is a molybdenum amine complex containing Mo<+6>, an acyl group bound with the molybdenum ion and an amine group combined with a hydrocarbon group in the acyl group, wherein molybdenum accounts for 10%-30% by mass of the organic molybdenum salt. The provided organic molybdenum salt is used as a catalyst precursor of a residual oil hydrogenation process, and has high hydrogenation conversion rate; meanwhile, the compound has excellent antiwear and antifriction properties and good metal corrosion inhibition performance, and can be used as a water-soluble lubricating oil additive. The preparation method of the water-soluble organic molybdenum salt is simple, the synthesis route isnon-toxic and environmentally friendly, and product separation is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

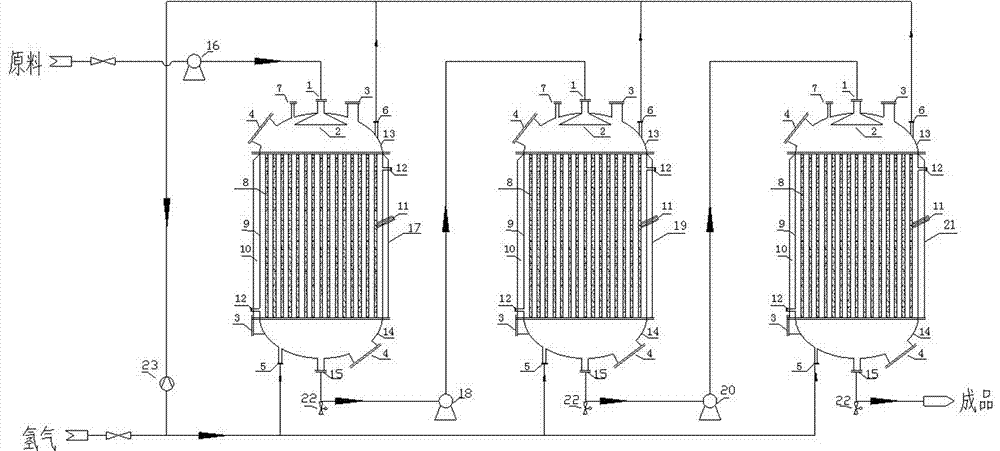

Method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation

ActiveCN107089961AWell distributedImprove conversion rateOrganic chemistryChemical/physical processesThree levelFixed bed

The invention discloses a method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation and belongs to the field of organic chemicals. A three-level split-tube fixed bed reactor is adopted for circularly continuous hydrogenating; a split-tube type structure is adopted in the split-tube fixed bed reactor; a solid catalyst is arranged between tube passes; a heat medium is arranged in a shell pass; hydrogen respectively enters from the bottom of each level of split-tube fixed bed reactor in parallel; unreacted hydrogen passes by each split tube and then returns to a hydrogen compressor from the upper part of the reactor; the raw material, methyltetrahydrophthalic anhydride, gradually passes by a high pressure pipe pump, is conveyed to the upper part of the split-tube reactor and is sprayed by a distributor located at the top in the reactor so as to be uniformly distributed on the surface of the solid catalyst and react with hydrogen; after circular reaction through the three-level reactor, the hydrogenating conversion rate is close to 100%. According to the method, the production of methylhexahydrophthalic anhydride by means of continuous hydrogenation is realized, the technical process is clean and the catalyst is reused.

Owner:河南惠成新材料有限公司

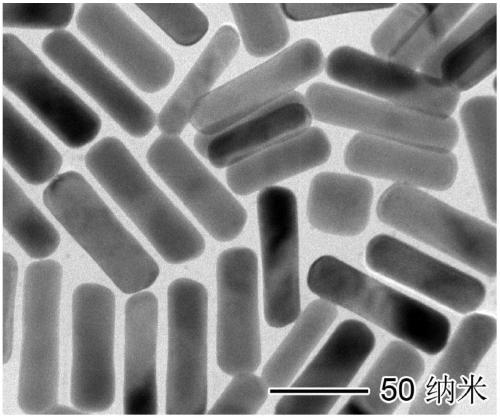

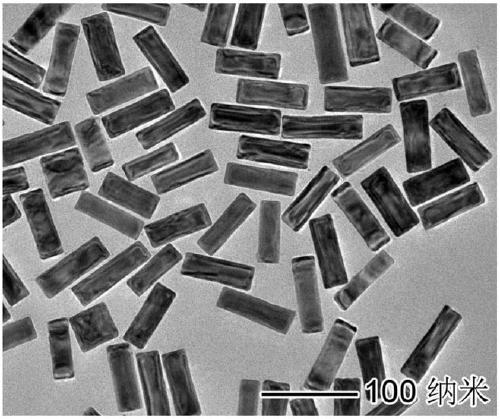

Catalyst for alkyne hydrogenation reaction and preparation method thereof

ActiveCN108993597AEfficient hydrogenation reactionHydrogenation reaction promotionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenation reactionMetal-organic framework

The invention provides a catalyst for an alkyne hydrogenation reaction. The catalyst comprises a gold-palladium bimetallic nanomaterial and a ZIF metal organic framework material coated on the surfaceof the gold-palladium bimetallic nanomaterial. The invention also provides a preparation method of the catalyst, and the method comprises the step of performing a reaction on the gold-palladium bimetallic nanomaterial, imidazole compounds and a zinc source in a solvent so as to obtain the catalyst for the alkyne hydrogenation reaction. Through coordination of central zinc metal ions with the imidazole compounds, coating on the surface of the gold-palladium bimetallic nanomaterial is achieved so as to prepare the catalyst with the metal organic framework material-coated bimetallic nanomaterial; and the catalyst is applied to photo-driven alkyne hydrogenation reactions, and exhibits excellent hydrogenation activity and excellent selectivity to olefin products.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of oil-soluble composite suspension bed hydrocracking catalyst and preparation method thereof

ActiveCN103977822BImprove catalytic performanceReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSolubilityReaction temperature

The invention discloses an oil solubility compound-type suspended bed hydrocracking catalyst, wherein the catalyst is prepared by the following steps: 1) enabling compounds of metal elements in the VIB family, the VIIB family or the VIII family in a periodic table of elements as metal sources with alkali metal sulfide or alkali metal hydrosulfide according to the mole ratio of (0.5 to 1)-(2 to 1), thereby obtaining a metal element compound at a reduction state; 2) adding the metal element compound at the reduction state and amine substances into a reaction medium according to the mole ratio of (1:0.6)-(1 to 2), and meanwhile dropwise adding carbon disulfide with the corresponding quantity into the reaction medium according to the mole ratio of (1 to 1)-(2 to1) with the metal element compound at the reduction state, warming to react at the reaction temperature of 30-110 DEG C for 2-10 hours; 3) filtering and washing the product obtained by the step 2) so as to obtain the oil solubility compound-type suspended bed hydrocracking catalyst. The catalyst prepared by the invention can inhibit the coke yield, and improve the light oil yield.

Owner:CCTEG CHINA COAL RES INST

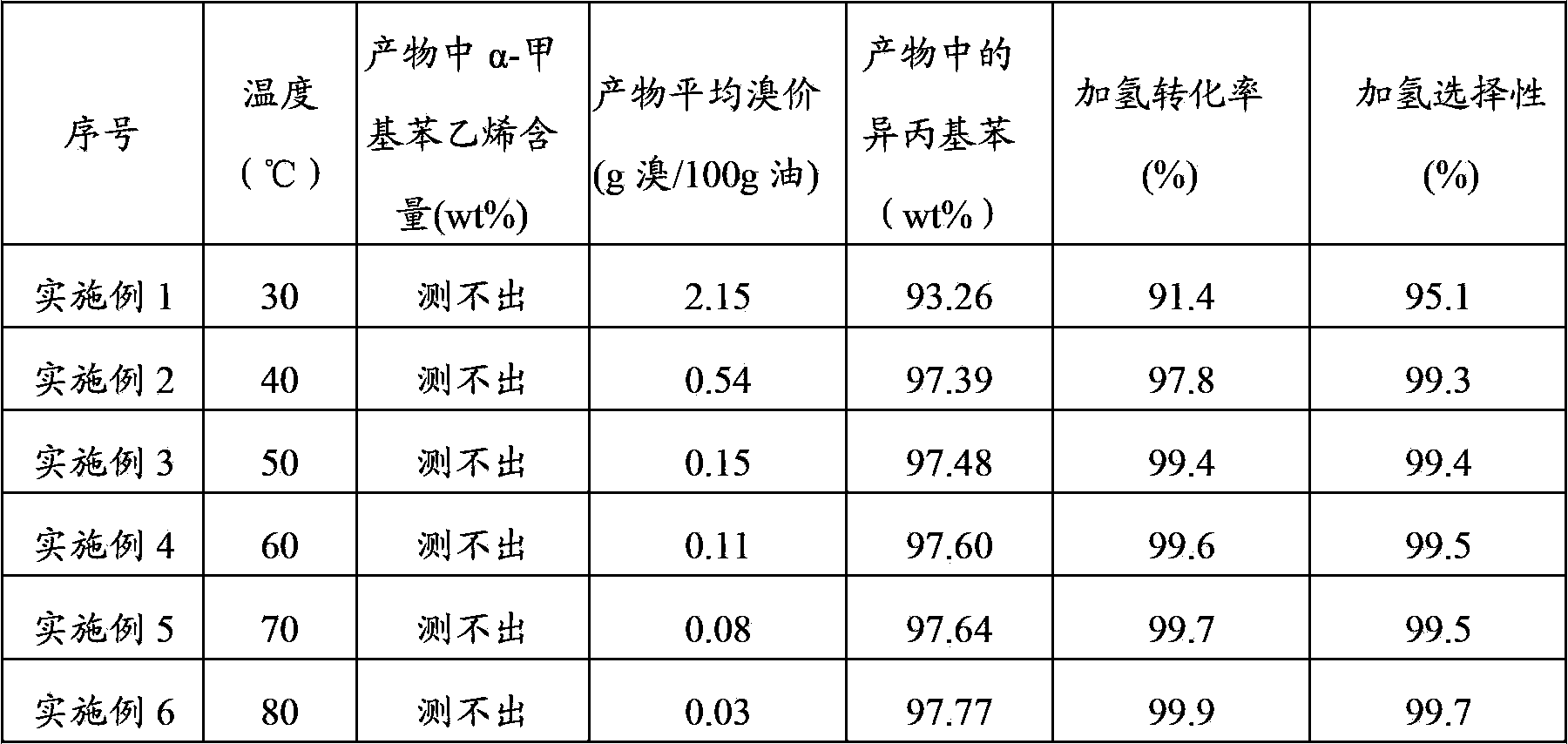

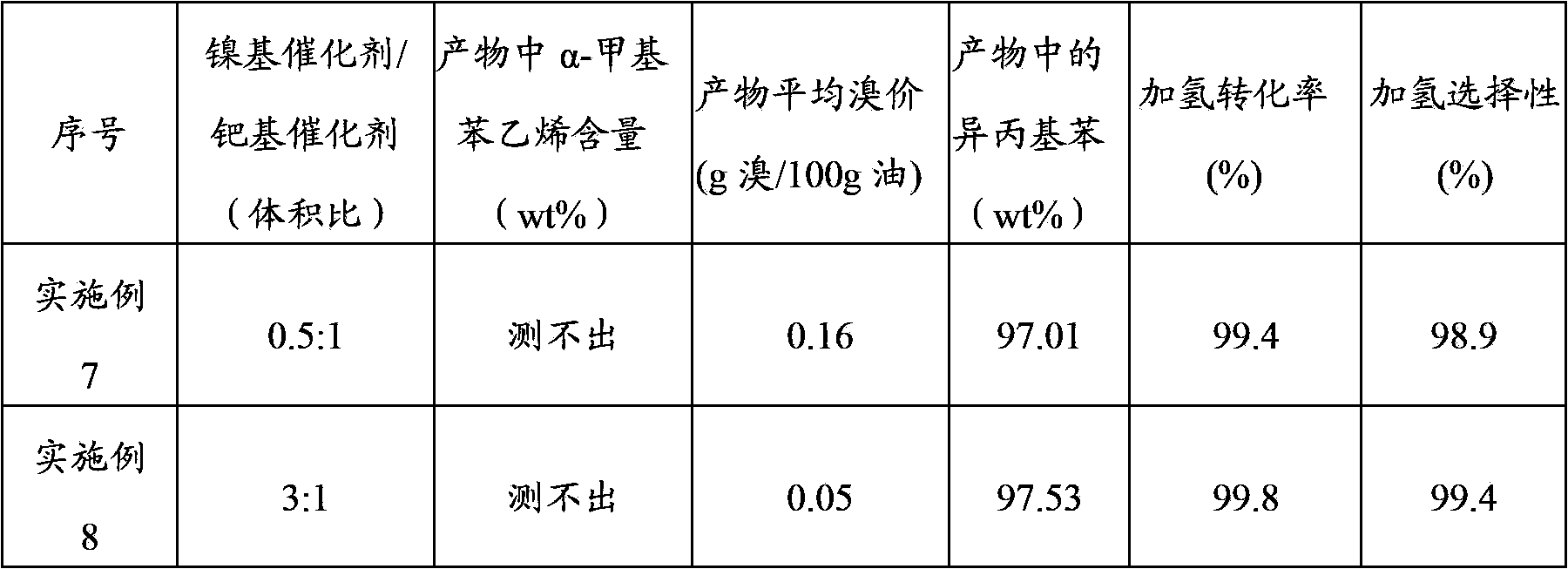

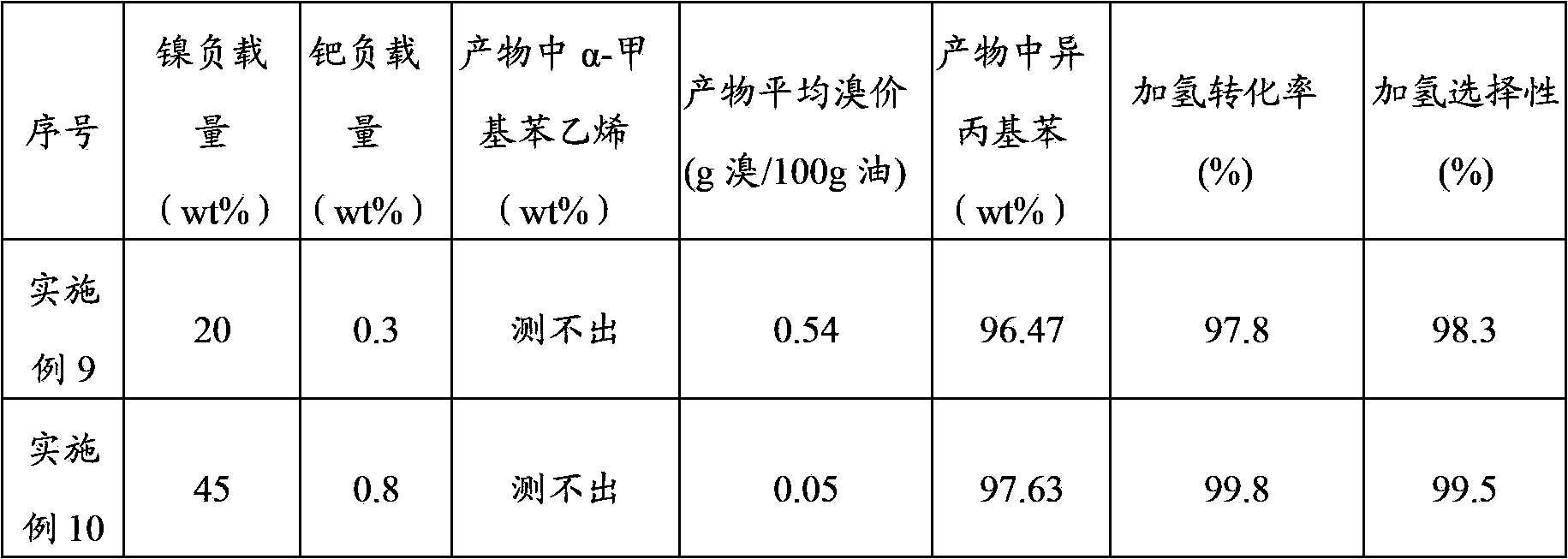

Selective hydrogenation method for alpha-methyl styrene

ActiveCN103724153AImprove hydrogenation performanceLow costHydrocarbon by hydrogenationChemical recyclingHydrogenation reactionPalladium

The invention provides a selective hydrogenation method for alpha-methyl styrene, which comprises: alpha-methyl styrene-containing raw material circulation pass through nickel-based catalyst and palladium-based catalyst with hydrogen in sequence, after one-step hydrogenation, the alpha-methyl styrene is converted into isobutylbenzene. Optimally, nickel-based catalyst and palladium-based catalyst are contacted directly. According to the hydrogenation method provided by the invention, the reaction material circulation continuously passes through different catalysts, thereby realizing one-step hydrogenation, and simplifying reaction equipment and reaction technology, and saving cost. In addition, according to the invention, the hydrogenation reaction condition is mild, and the catalyst activity is high, and the hydrogenation conversion rate and hydrogenation selectivity are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

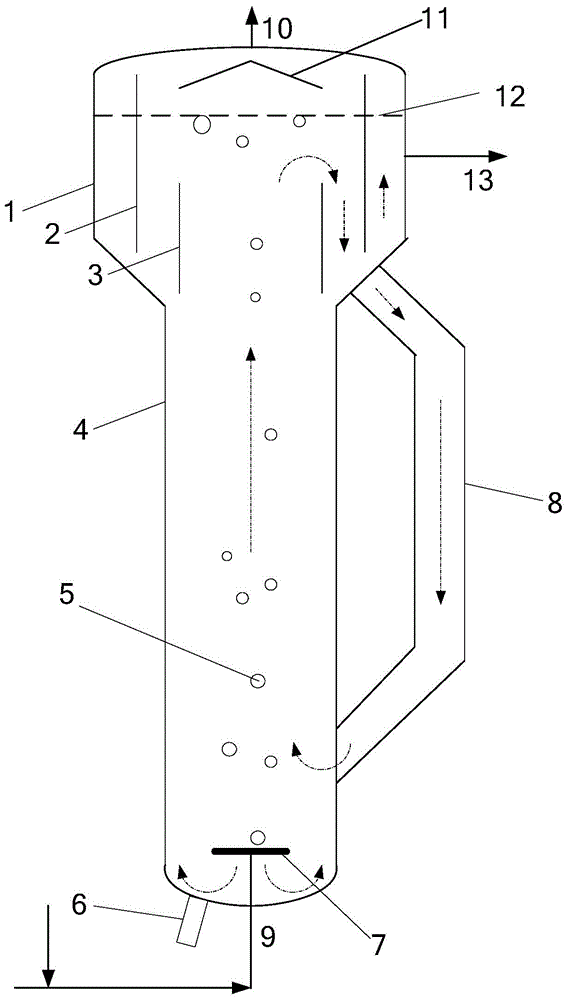

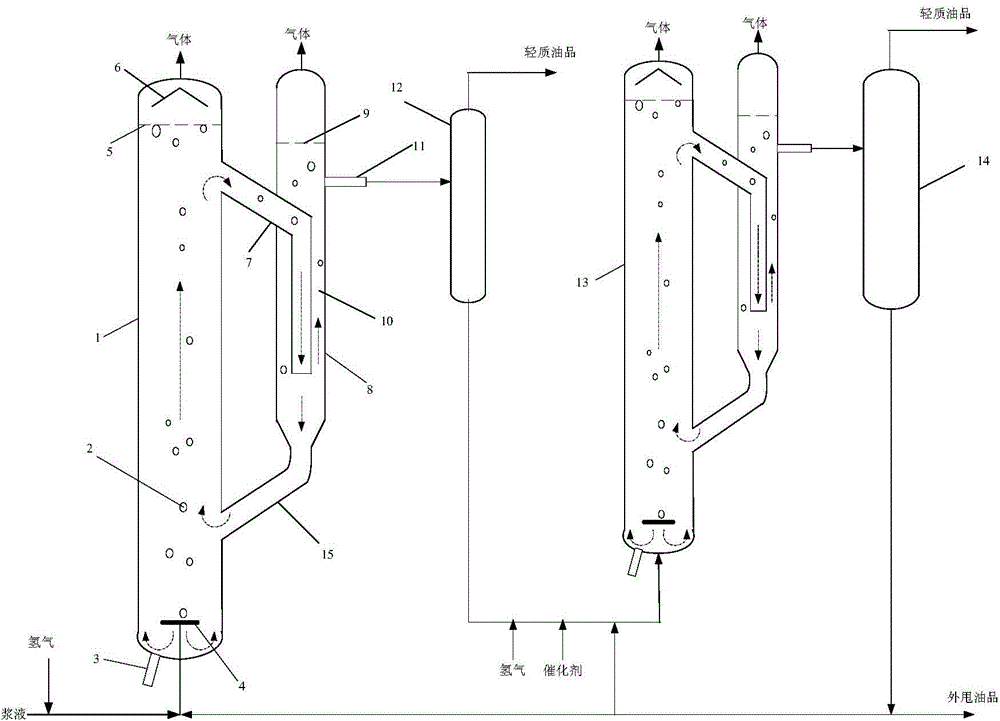

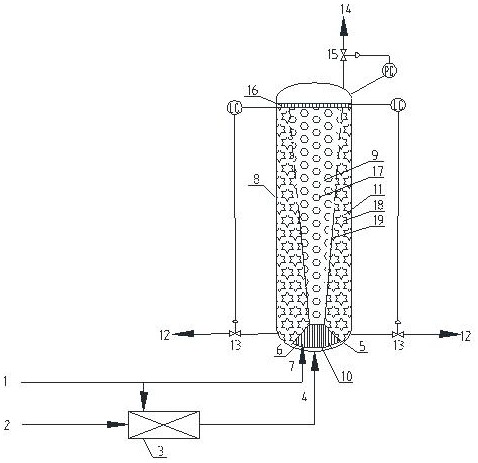

Heavy oil hydrogenation slurry bed reactor and heavy oil hydrogenation method

InactiveCN104549062ASimple structureExtended operating cycleHydrocarbon oil crackingChemical/physical processesGas phaseHydrogenation reaction

The invention relates to a heavy oil hydrogenation slurry bed reactor and a heavy oil hydrogenation method. The heavy oil hydrogenation slurry bed reactor comprises a riser (4), an expansion section (1) at the top of the riser and a downcomer (8), wherein the expansion section (1) is communicated with the upper part of the downcomer (8), the lower part of the riser (4) is communicated with the bottom of the downcomer (8), a slurry phase separator is arranged in the expansion section (1), the slurry phase separator is of a sleeve structure comprising an inner cylinder (3) and an outer cylinder (2), a mist eliminator (11) is arranged at the upper part of the slurry phase separator, a gas phase outlet (10) is formed in the top of the expansion section, a material outlet (13) is formed in the side wall of the expansion section, a fluid distributor (7) is arranged at the bottom of the riser (4), and a raw material outlet (9) is formed in the bottom of the riser (4). The heavy oil hydrogenation slurry bed reactor provided by the invention can realize hydrogenation reaction to separate a light oil product and an unreacted heavy oil product. The heavy oil hydrogenation slurry bed reactor provided by the invention can also inhibit the generation of coke particles of a heavy oil reaction system and effectively prolong the operation period of the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

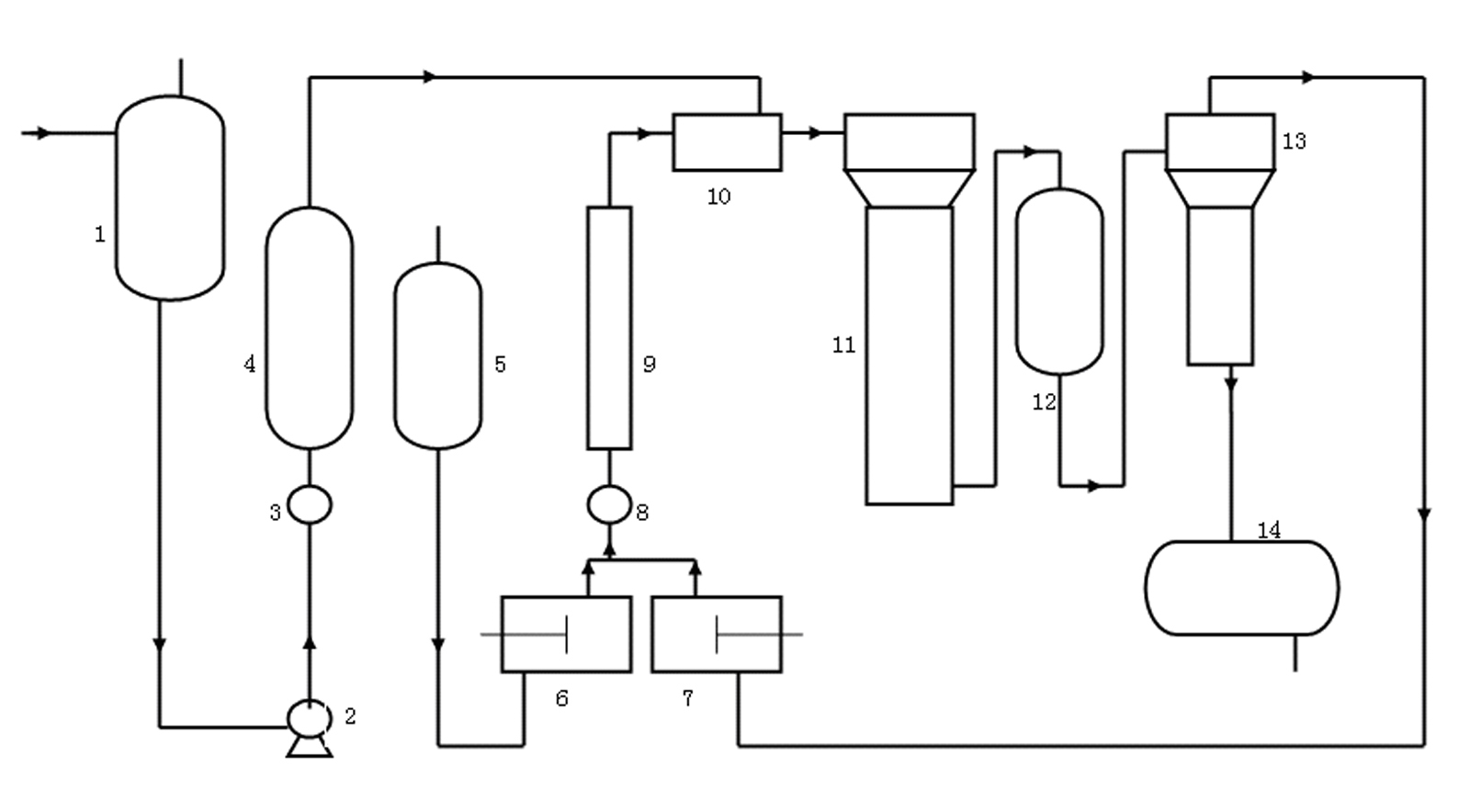

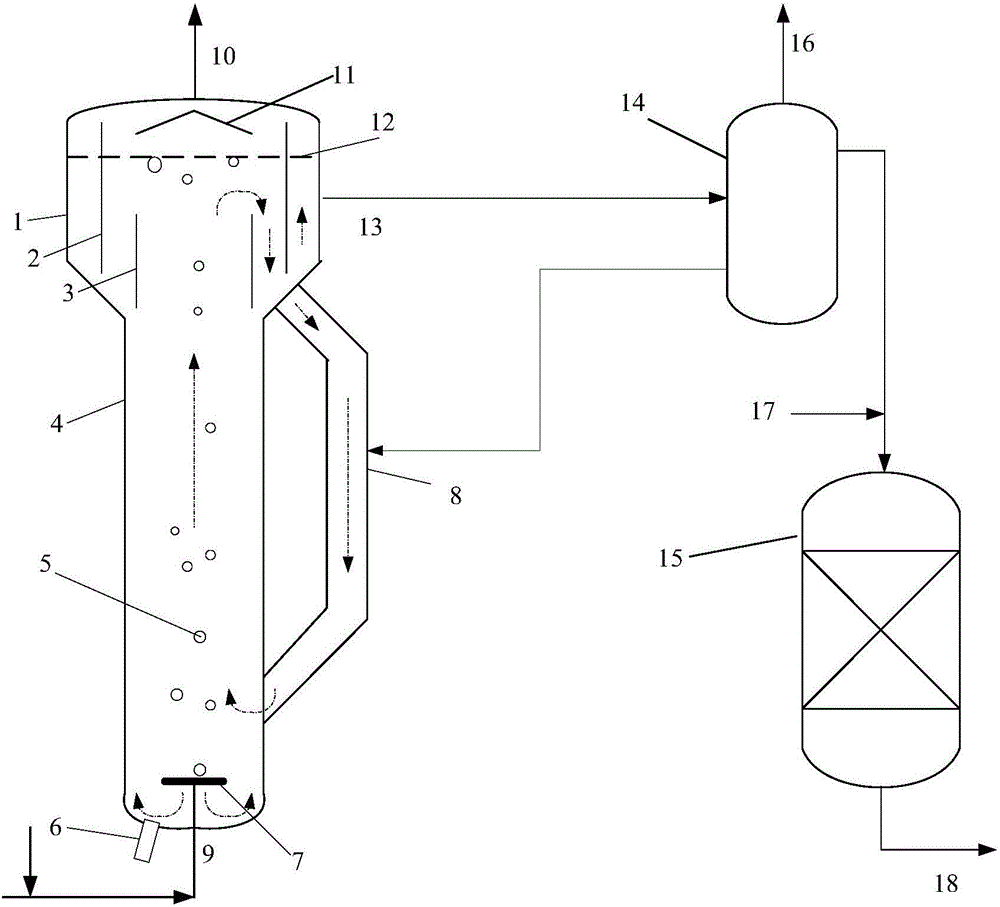

Heavy oil slurry reactor hydrogenation reaction device and application method

ActiveCN106147850AAvoid depositionInhibition of adhesionTreatment with hydrotreatment processesSlurry reactorBuffer tank

The invention discloses a heavy oil slurry reactor hydrogenation reaction device and an application method. The device comprises a slurry bed circulation flow reactor, a buffer tank connected with the slurry bed circulation flow reactor and a fixed bed hydrogenation reactor communicated with the upper portion of the buffer tank. The slurry bed circulation flow reactor comprises an ascending pipe (4), an enlarging section (1) on the top of the ascending pipe and a descending pipe (8). The enlarging section (1) is communicated with the upper portion of the descending pipe (8). The lower portion of the ascending pipe (4) is communicated with the bottom of the descending pipe (8). A slurry phase separator is arranged inside the enlarging section (1). The slurry phase separator is a sleeve structure with an inner cylinder (3) and an outer cylinder (2). A foam remover (11) is arranged at the upper portion of the slurry phase separator. A gas outlet (10) is arranged on the top of the enlarging section. A material outlet (13) is arranged on the side wall of the enlarging section. A raw material inlet (9) is formed in the bottom of the ascending pipe (4). According to the slurry reactor hydrogenation reaction device and application method, long-term operation of the reactor is convenient, the heavy oil hydrogenation conversion rate is increased, and slurry processing of follow-up equipment is convenient.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for Claus tail gas hydrohydrolysis and preparation method and application thereof

ActiveCN108246303BRaise the ratioIncreased hydrogenation conversionGas treatmentHeterogenous catalyst chemical elementsPtru catalystAluminium oxides

The invention discloses a catalyst for hydrogenation hydrolysis of Claus tail gas, a preparation method and applications thereof, and belongs to the technical field of Claus tail gas treatment. The catalyst uses active alumina as a carrier, wherein cobalt oxide, cesium oxide and molybdenum oxide are supported on the active alumina, the active alumina accounts for 77-85% of the total weight of thecatalyst, the cobalt oxide accounts for 3-4% of the total weight of the catalyst, the cesium oxide accounts for 0.5-1.0% of the total weight of the catalyst, and the molybdenum oxide accounts for 12-18% of the total weight of the catalyst. According to the present invention, under the premise of the ensuring of the high hydrogenation conversion rate of sulfur dioxide, the disadvantage of the pooractivity of the hydrolysis on organic sulfur at the low temperature through the existing catalyst is overcome, and the hydrolysis on organic sulfur is increased so as to reduce the emission concentration of sulfur dioxide and meet the national standard requirement.

Owner:PETROCHINA CO LTD

Two-stage heavy oil slurry-bed reactor hydrogenation equipment and method

InactiveCN105623729AImprove conversion rateImprove stabilityTreatment with hydrotreatment processesFuel oilProcess engineering

Two-stage heavy oil slurry-bed reactor hydrogenation equipment and a method thereof are disclosed. The equipment comprises a first slurry-bed reactor, a first separating unit communicated with the first slurry-bed reactor, a second slurry-bed reactor communicated with a discharge port of the first separating unit, and a second separating unit communicated with the second slurry-bed reactor. The first and second slurry-bed reactors comprise a riser tube (1) and a downcomer (8). Upper parts and lower parts of the riser tube (1) and the downcomer (8) are respectively communicated through connecting pipes. An opening of the upper connecting pipe (7) extends into the lower part of the downcomer (8). The bottom of the riser tube (1) is provided with a raw material inlet. Tops of the riser tube (1) and the downcomer (8) are respectively provided with gas outlets. The middle upper part of the downcomer (8) is provided with a product outlet. The two-stage heavy oil slurry-bed reactor hydrogenation equipment and the method are convenient for long-term operation of the reactors, hydrogenation conversion rate of heavy oil is raised, and slurry processing of subsequent equipment is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

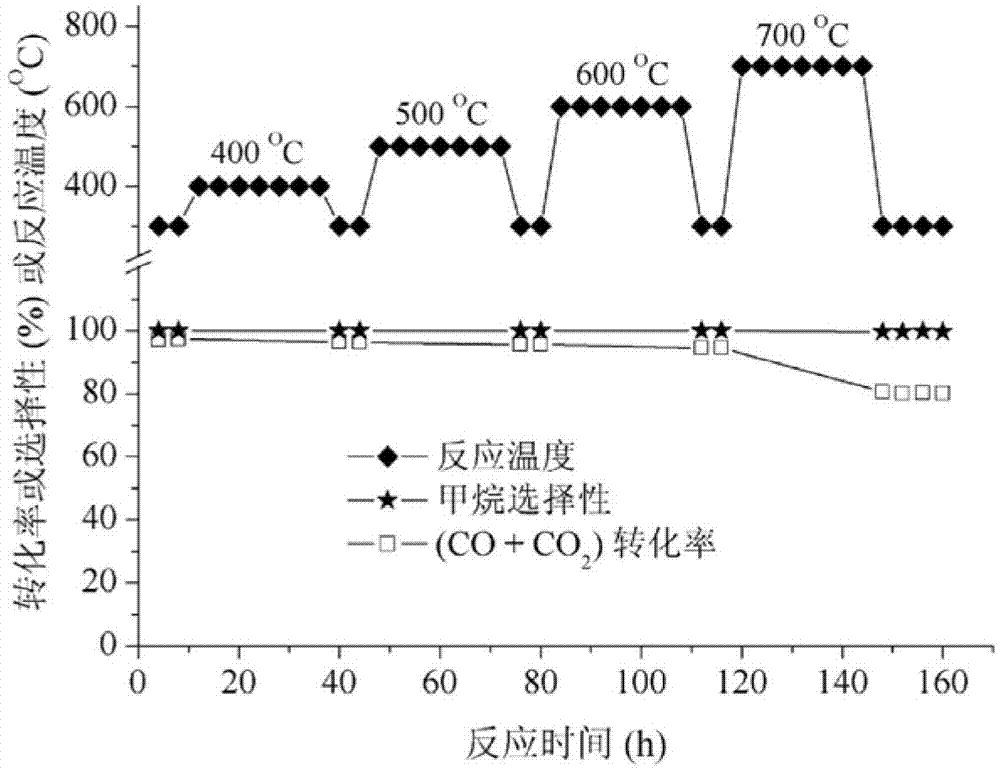

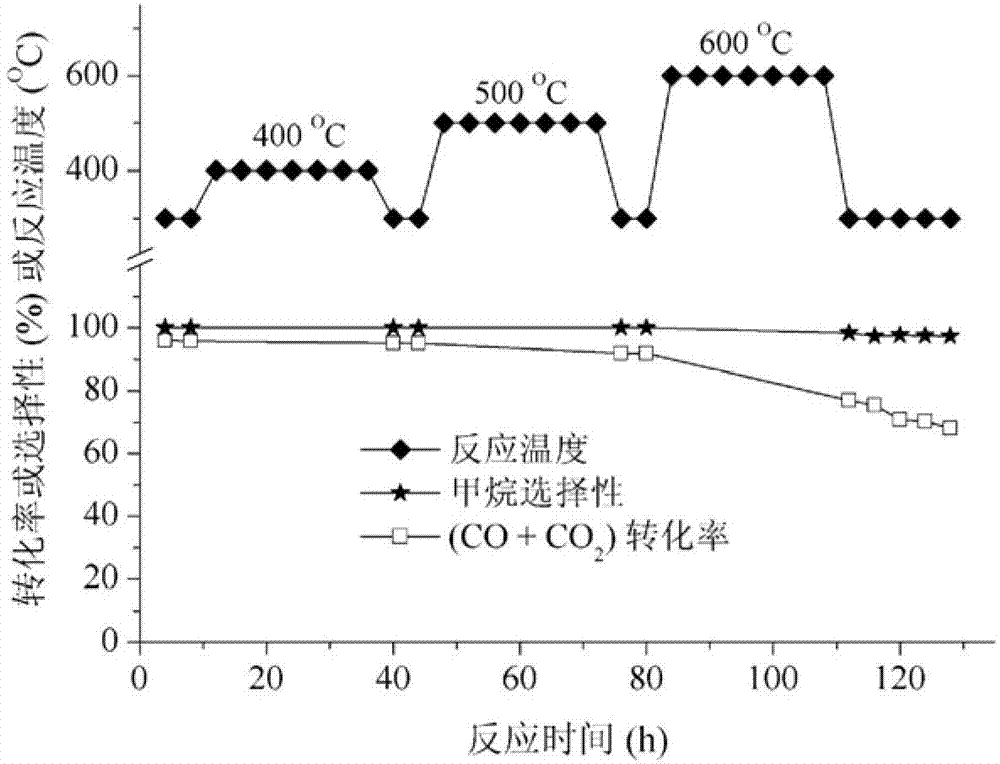

Catalyst for preparing synthetic natural gas and preparation method thereof

InactiveCN103170340AHighly active and stableImprove heat resistanceGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsMethanationHeat resistance

The invention discloses a catalyst for preparing synthetic natural gas and a preparation method thereof, and relates to a catalyst. The catalyst is scandium-enhanced coprecipitation type nickle-cobalt-based catalyst, the chemical formula is NiiZrjSck, wherein the subscripts i, j and k in the formula are the molar ratio factor of Ni, Zr and Sc in the catalyst; the catalyst comprises the following components in percent by weight: 48%-62% of Ni, 3%-25% of Sc and the balance of Zr. The preparation method comprises the following steps of: mixing and preparing metered Ni(NO3)2.6H2O, Zr(NO3)4.3H2O and Sc(NO3) into aqueous solution, carrying out coprecipitation reaction with K2CO3 aqueous solution, filtering feed liquid after reaction, cleaning, drying and roasting on filtered cakes, and then obtaining the NiiZrjSck catalyst for methanation of coal or biomass-based synthetic natural gas. The catalyst disclosed by the invention has the advantages that the activity is high and stable, the heat resistance is good, the conversion rate of hydrogenated methanation of CO and CO2 and the per pass yield of a product (methane) can be effectively improved.

Owner:XIAMEN UNIV

Catalyst used for preparing methanol by hydrogenation of carbon dioxide and a preparation method thereof

InactiveCN101444731BHighly active and stableHigh selectivityOrganic compound preparationHydroxy compound preparationCarbon nanotubeZinc

Owner:XIAMEN UNIV

Preparation method used for cyanobenzene direct atmospheric hydrogenation catalyst

InactiveCN108276291AEasy to prepareLow costOrganic compound preparationCatalyst activation/preparationPrecipitationMetal

The invention discloses a preparation method used for a cyanobenzene direct atmospheric hydrogenation catalyst. The preparation method is characterized in that a cyanobenzene hydrogenation reduction catalyst is prepared from 10-55 parts by weight of Co, 5-50 parts by weight of Ni and 5-30 parts by weight of metal element M, wherein the metal element M is one or a mixture of multiple of Cu, Mn, Cr,Zn, Fe, Mo or Mg in any proportion. The catalyst is prepared through a simple co-precipitation method. The catalyst has the advantages of being simple in preparation method, low in cost, high in catalytic activity, good in stability, relatively long in service life, and high in cyanobenzene hydrogenation conversion rate.

Owner:LANZHOU UNIVERSITY

Two-stage slurry bed hydrogenation process of high temperature coal tar

ActiveCN104277878AImprove conversion rateReduce hydrogen consumptionTreatment with hydrotreatment processesDistillationFractionation

The invention provides a two-stage slurry bed hydrogenation process of high temperature coal tar, and belongs to the coal chemical technical field. The two-stage slurry bed hydrogenation process comprises the following steps: (1) performing purification on the high temperature coal tar; (2) performing decompression or atmospheric distillation on the high temperature coal tar purified by the step (1) for cutting into light oil fractions lower than 350DEG C and heavy oil fractions higher than 350 DEG C; (3) mixing the heavy oil fractions higher than 350 DEG C of the step (2) with a hydrocracking catalyst and H2, mixing evenly, and in turn getting into a first stage slurry bed and a second slurry bed for two-stage hydrocracking reaction, and processing the prepared hydrocracking products by fractionation. A liquid fuel prepared by the two-stage slurry bed hydrogenation process of the high temperature coal tar has the advantages of low hydrogen consumption and high product yield.

Owner:任相坤

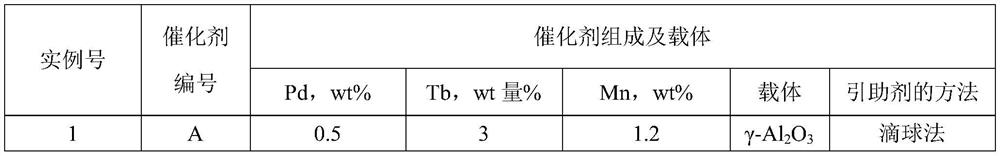

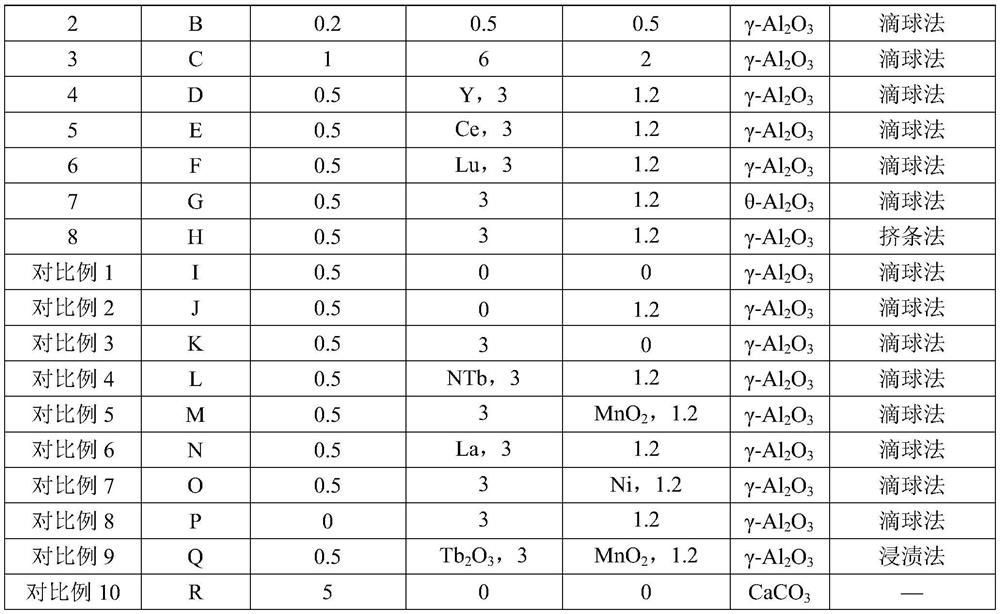

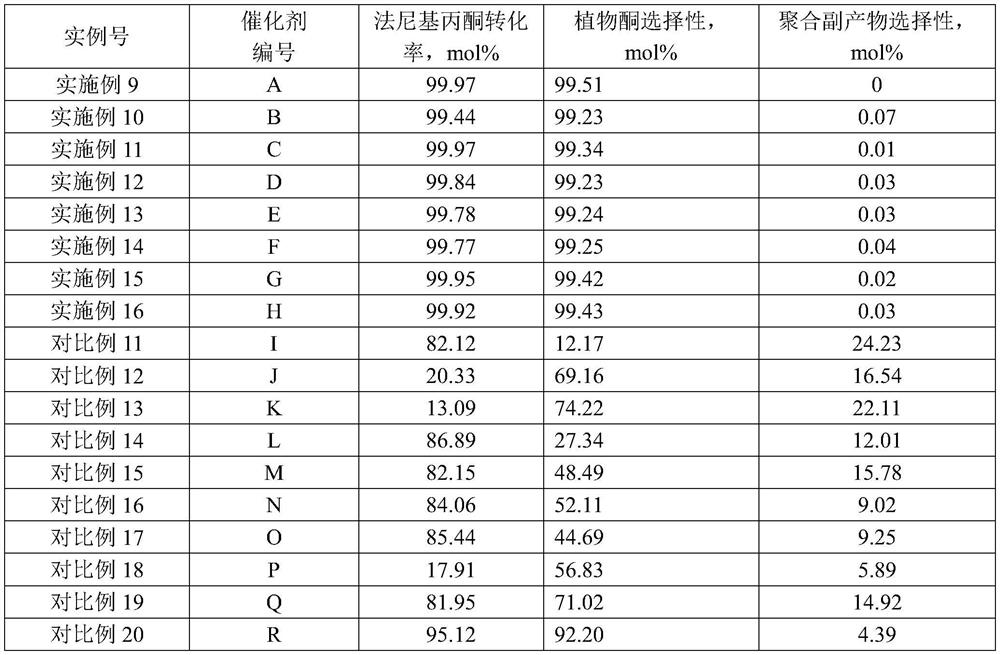

Kenone selective hydrogenation catalyst, and preparation method and application thereof

ActiveCN113786862AInhibition of polymerizationHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystLutetium

The present invention provides a ketene selective hydrogenation catalyst, and a preparation method and application thereof. The catalyst comprises an alumina carrier and active components, and the active components comprise 0.2-1 wt% of palladium, 0.5-2 wt% of manganese nitride (in terms of manganese element), and 0.5-6 wt% of hydride of at least one of terbium, cerium, yttrium and lutetium (in terms of metal element) based on the mass of the carrier. The catalyst is low in palladium content, is used for preparing corresponding saturated ketones through selective hydrogenation of ketene, has higher activity, and can inhibit ketene polymerization and reduce side reaction selectivity.

Owner:WANHUA CHEM GRP CO LTD

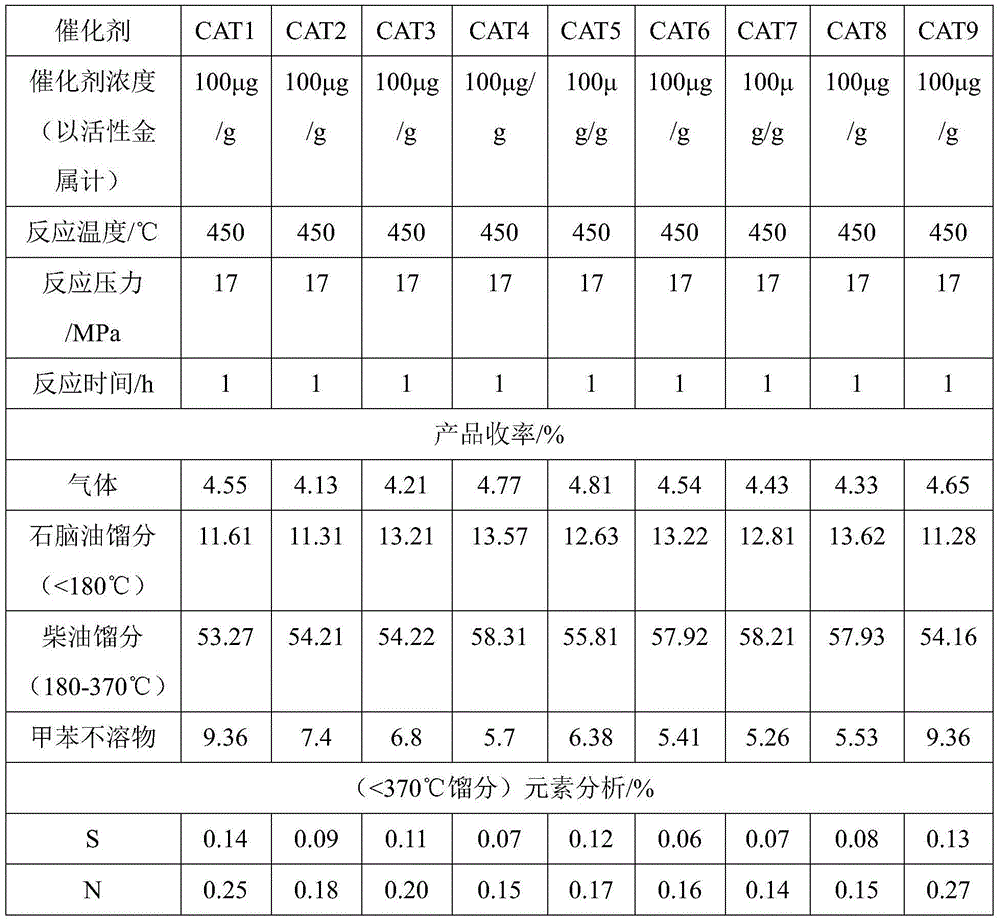

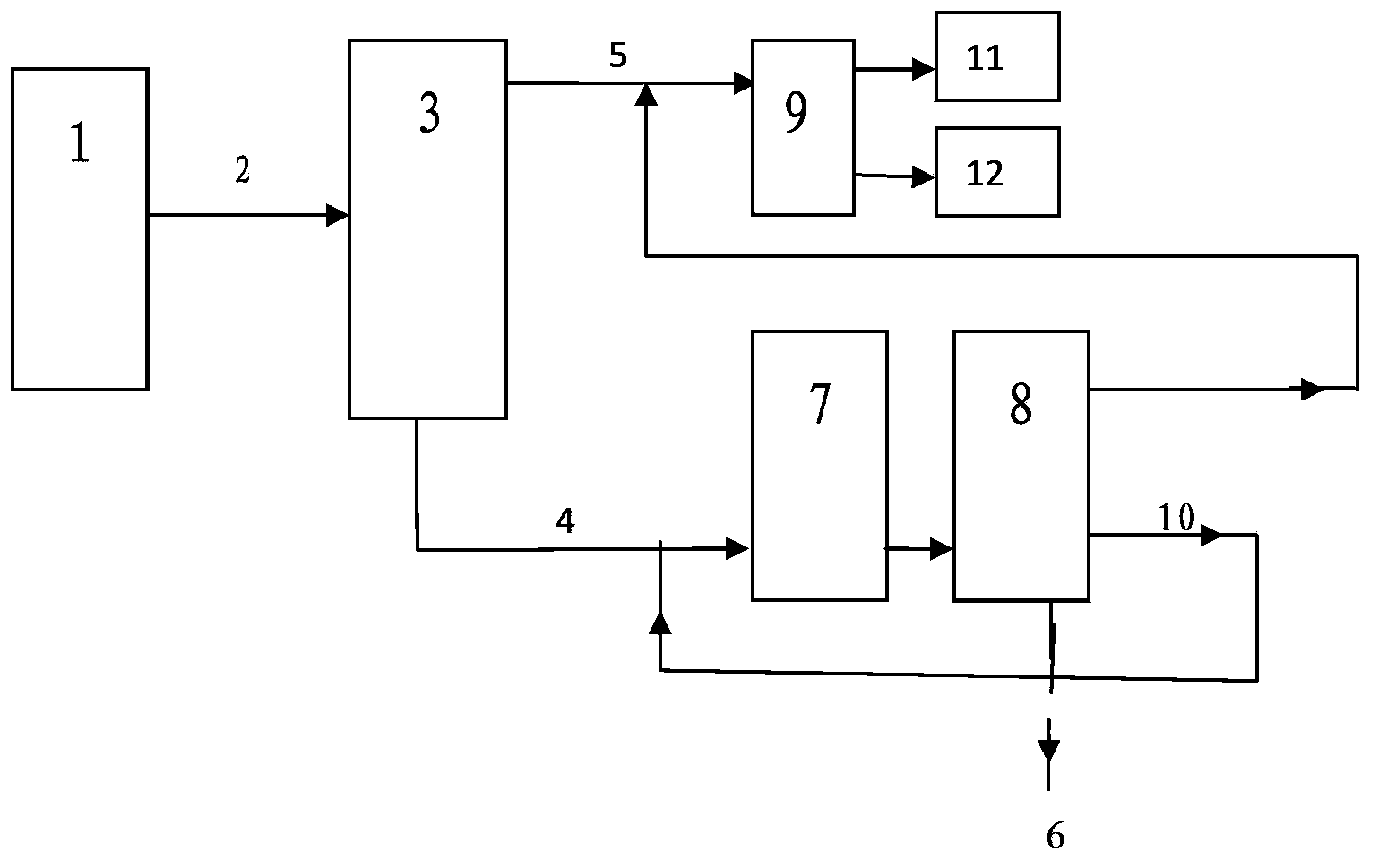

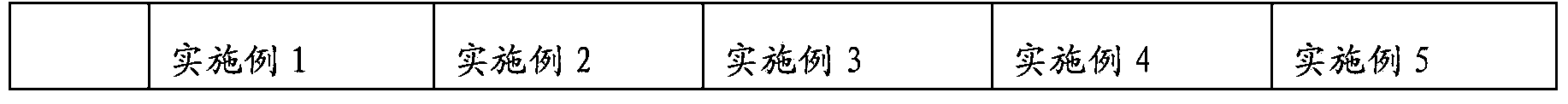

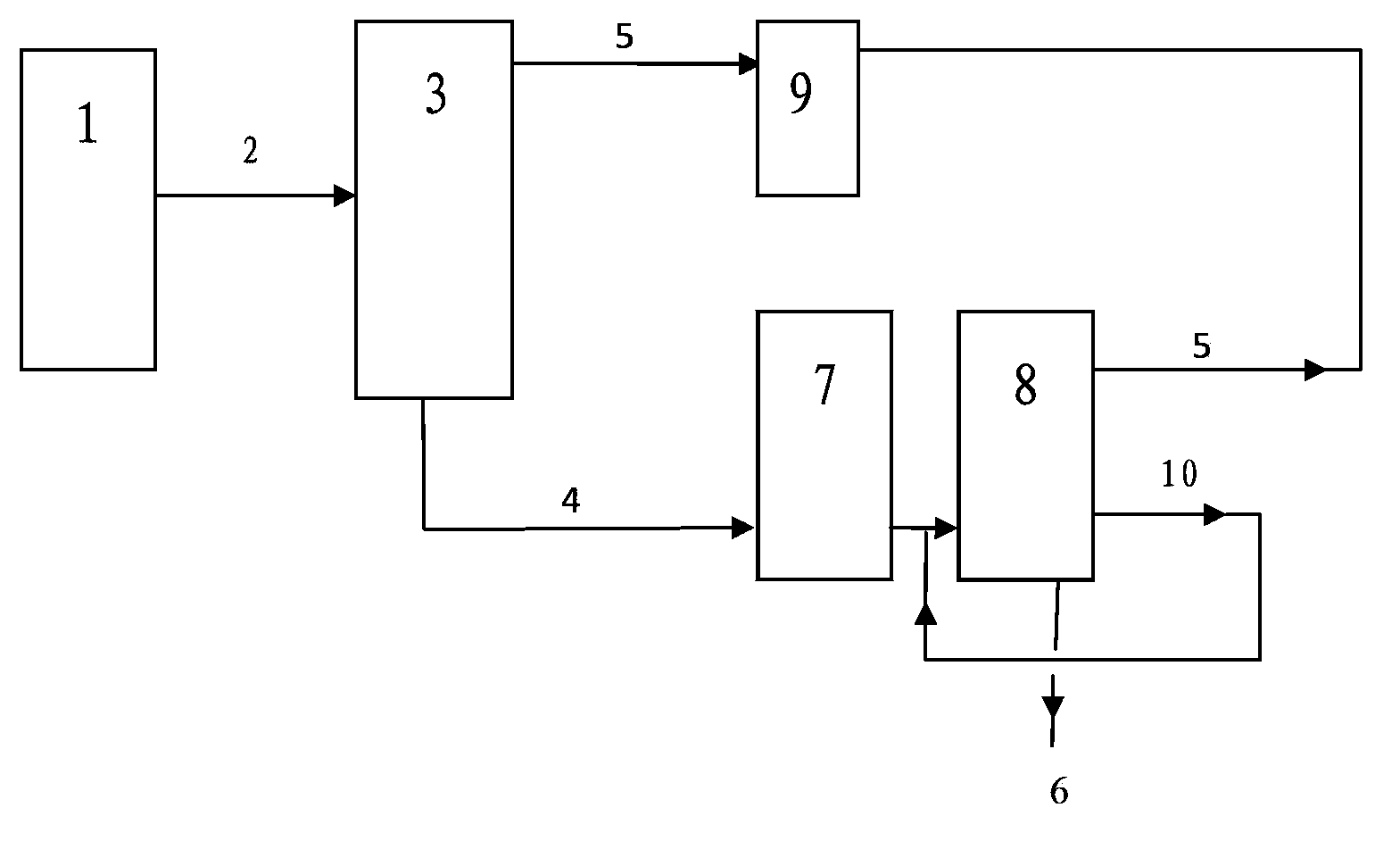

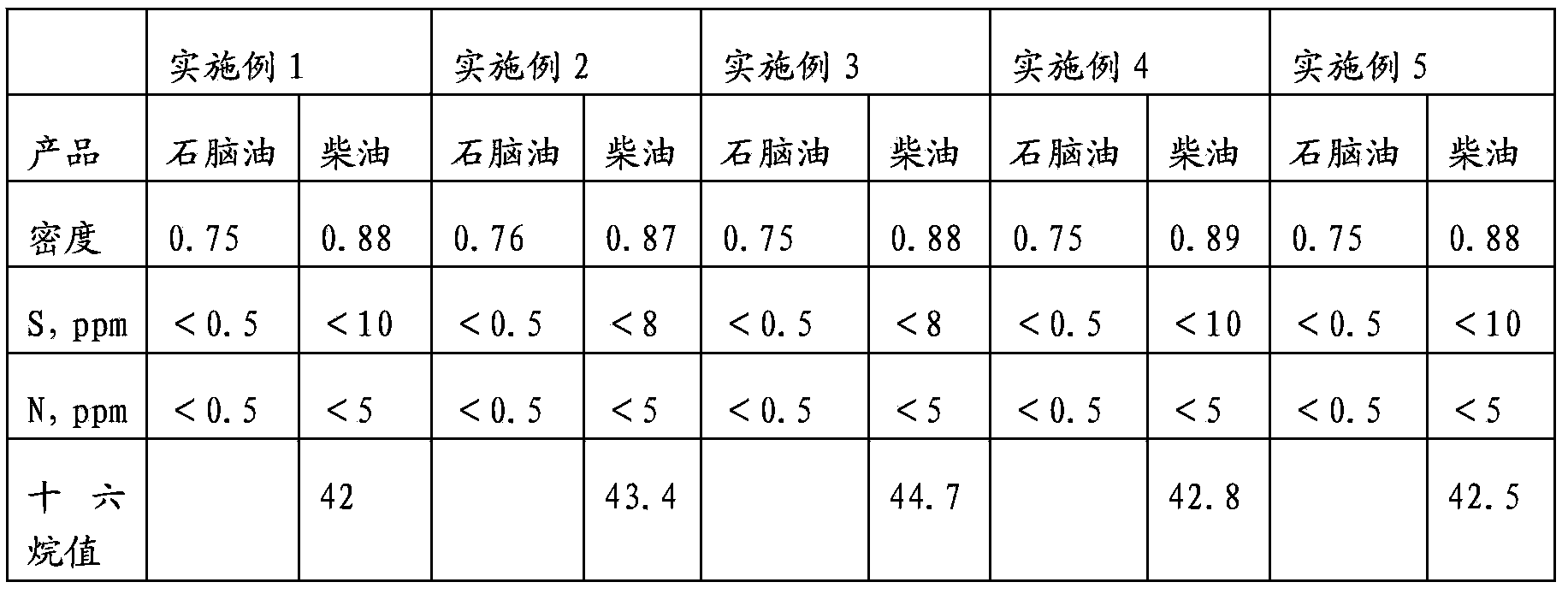

A slurry bed and fixed bed serial hydrogenation process of coal tar

ActiveCN104419461BImprove qualityIncrease cetane numberTreatment with hydrotreatment processesDistillationFixed bed

The present invention provides a coal tar slurry bed and fixed bed series connection hydrogenation process, which comprises: (1) carrying out a purification treatment; (2) carrying out pressure reducing or normal pressure distillation on the purified coal tar, and cutting into the light oil distillate and the heavy oil distillate, wherein the cutting point of the light-heavy oil distillate is 220-370 DEG C; (3) mixing the light oil distillate and H2, uniformly mixing, conveying the obtained material into a fixed bed, and carrying out hydrorefining under the hydrorefining catalyst effect to prepare a hydrorefining product; and (4) mixing the heavy oil distillate, a hydrocracking catalyst and H2, uniformly mixing, sequentially conveying the obtained material into a first-stage slurry bed and a second-stage slurry bed to carry out a double-stage hydrocracking reaction, and carrying out a fractionation treatment on the prepared hydrocracking product, wherein the distillate with the boiling point of more than 540 DEG C is externally discharged, the distillate with the boiling point of less than 350 DEG C is recycled as part of the fed material of the fixed bed, and the remaining components return to the first-stage slurry bed inlet. With the method of the present invention, the sulfur content and the nitrogen content in naphtha and diesel fuel are reduced, and the cetane number in the diesel fuel is substantially improved.

Owner:任相坤

Heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116AReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesMaterials scienceCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

Layered composite material as well as preparation method and application thereof

PendingCN112156784AIncreased hydrogenation conversionHigh selectivityHydrocarbon from carbon oxidesCatalyst activation/preparationWater-gas shift reactionHydrogenation reaction

The invention relates to a layered composite material as well as a preparation method and application thereof, in particular to a Fe-based material for high-selectivity preparation of alpha-olefin. Acatalyst provided by the invention can inhibit secondary hydrogenation reaction of primary olefinand water gas shift reaction WGS, thereby improving olefin selectivity, effectively reducing CO2 generation, regulating and controlling product distribution with high added value, especially improving the yield of alpha olefin, and having significant industrial application value.

Owner:NINGXIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com