Preparation method of supported nickel-based catalyst and application of catalyst in catalytic hydrogenation of C5/C9 petroleum resin

A catalyst, supported technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of small external specific surface area, large particles of nickel active components, The problems of low hydrogenation degree of unsaturated hydrocarbon bonds in petroleum resins can achieve the effect of high hydrogenation conversion rate, long service life and high degree of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

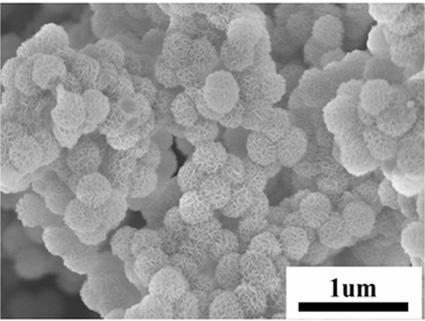

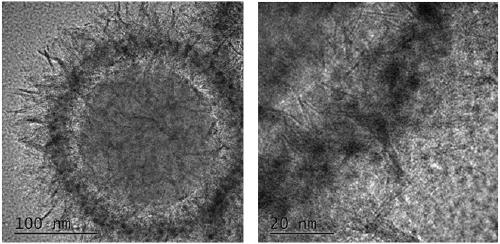

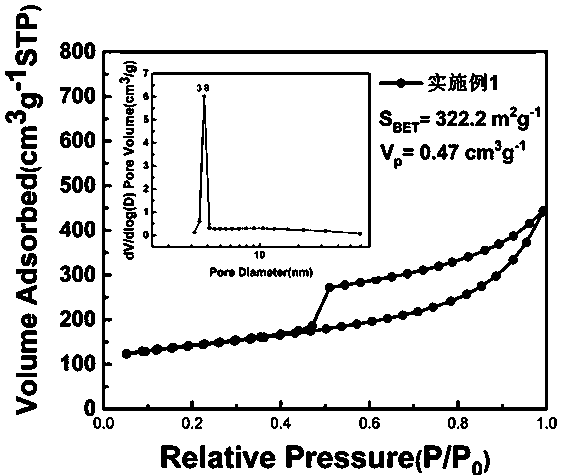

[0041] Take 0.2g SiO 2 Add to 50 ml deionized water, ultrasonically disperse for 40 min to form solution A, weigh 0.25 gNiCl 2 •6H 2 O, 0.02 g CuCl 2 • 2H 2 O was dissolved in 40 ml of deionized water, 2 ml of 25-28 vol% ammonia solution (the molar ratio of ammonia to silica was 6:1) was added dropwise, and 0.5 g of NH 4 After Cl, stir for 5 min to obtain metal ammonia solution B, add solution B to solution A and continue stirring for 5 min, then transfer to a stainless steel reaction kettle with polytetrafluoroethylene lining, and place it in an oven at 150 °C for 12 After h, cool to room temperature, filter under reduced pressure and wash with deionized water and ethanol several times, and then dry in an oven at 70 °C to constant weight to obtain a green powder, which is placed in a tube furnace under a reducing atmosphere at 850 °C Reduction at lower temperature for 6 h, the supported nickel-based catalyst Ni-Cu-SiO 2 .

[0042] Take 3.5g (2.5 ml) of the 20-40 mesh ca...

Embodiment 2

[0047] Take 0.2g SiO 2 Added into 50 ml deionized water, ultrasonically dispersed for 40 min to form solution A, weighed 0.3 g Ni(NO 3 ) 2 •6H 2 O, 0.02 g Co(NO 3 ) 2 • 2H 2 O was dissolved in 40 ml deionized water, 1.5 ml, 25-28 vol% ammonia solution (molar ratio of ammonia to silica was 5:1) was added dropwise, and 0.5 g NH 4 After Cl, stir for 5 min to obtain metal ammonia solution B, add solution B to solution A and continue stirring for 5 min, then transfer to a stainless steel reaction kettle with polytetrafluoroethylene lining, and place it in an oven at 120 °C for 10 After h, cool to room temperature, filter under reduced pressure and wash with deionized water and ethanol several times, and then dry in an oven at 70 °C to constant weight to obtain a green powder, which is placed in a tube furnace under a reducing atmosphere at 800 °C Reduction at lower temperature for 6 h, the supported nickel-based catalyst Ni-Co-SiO 2 .

[0048] Take 3.5g (2.5 ml) of the 20-4...

Embodiment 3

[0050] Take 0.2g SiO 2 Add it into 50 ml deionized water, ultrasonically disperse for 40 min to form solution A, weigh 0.25 g Ni(OAC) 2 •6H 2 O, 0.02 g Mg(NO 3)2 • 2H 2 O was dissolved in 40 ml deionized water, 1.0 ml, 25-28 vol% ammonia solution (molar ratio of ammonia to silica was 3:1) was added dropwise, and 0.5 g NH 4 After Cl, stir for 5 min to obtain metal ammonia solution B, add solution B to solution A and continue stirring for 5 min, then transfer to a stainless steel reaction kettle with polytetrafluoroethylene lining, and place it in an oven at 120 °C for 10 After h, cool to room temperature, filter under reduced pressure and wash with deionized water and ethanol several times, and then dry in an oven at 70 °C to constant weight to obtain a green powder, which is placed in a tube furnace under a reducing atmosphere at 800 °C Reduction at lower temperature for 6 h, the supported nickel-based catalyst Ni-Mg-SiO 2 .

[0051] Take 3.5g (2.5 ml) of the 20-40 mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com