Method for low-temperature adsorption refining of high-purity and ultra-pure gas

It is an adsorption refining and gas technology, which is applied in the direction of separation methods, gas treatment, chemical instruments and methods, etc. It can solve the problems of low efficiency of adsorbent recycling, difficulty in large-scale continuous production, and long-term heating and cooling, so as to avoid A large amount of energy and material consumption, high recycling efficiency, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

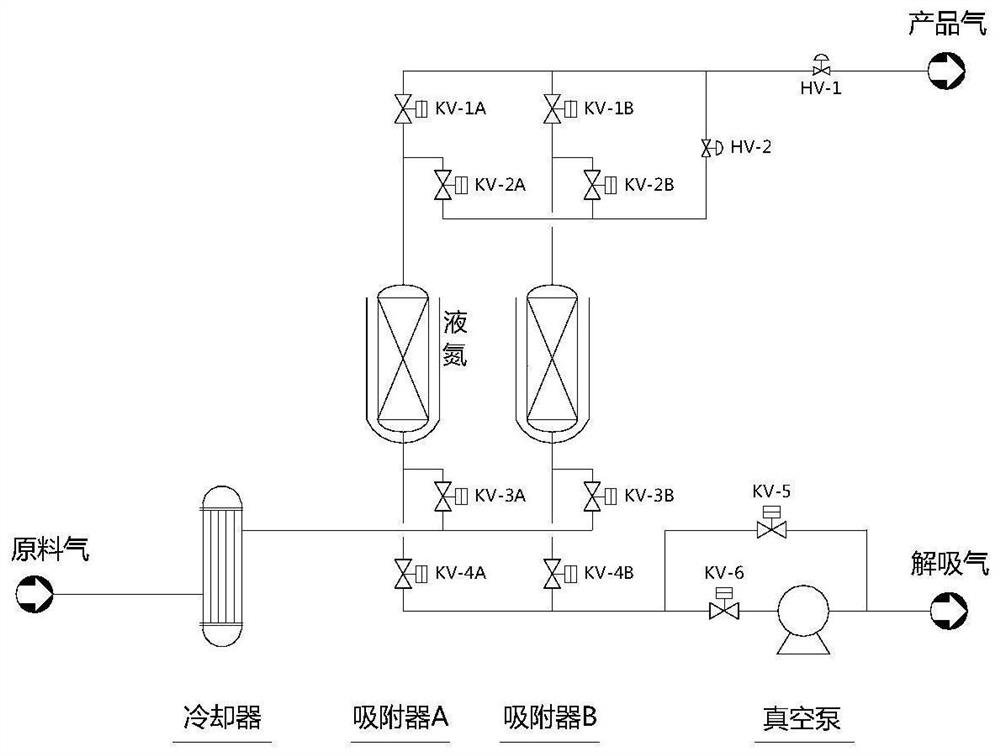

[0050] The method for the low-temperature adsorption and purification of ultrapure gas in this embodiment, the process flow chart is shown in figure 1 , the specific method steps are as follows:

[0051] The raw material gas mainly consists of helium, whose volume content of helium is 99%, the volume content of nitrogen is 1%, the gauge pressure is 1.0MPa, and the temperature is normal temperature. First, it is cooled to about -180°C by a cooler, and then enters a low-temperature adsorption device including two adsorbers. The adsorbent filled in the adsorber is activated carbon, and the adsorber is always immersed in a liquid nitrogen container. When regenerating, there is no need to remove the liquid The nitrogen container does not need to remove liquid nitrogen, nor does it need to add materials and energy to heat up the adsorber.

[0052] Taking adsorber A as an example, when adsorber A is adsorbing, open the valves KV-1A and KV-3A, and the cooled raw gas enters the adsorb...

Embodiment 2

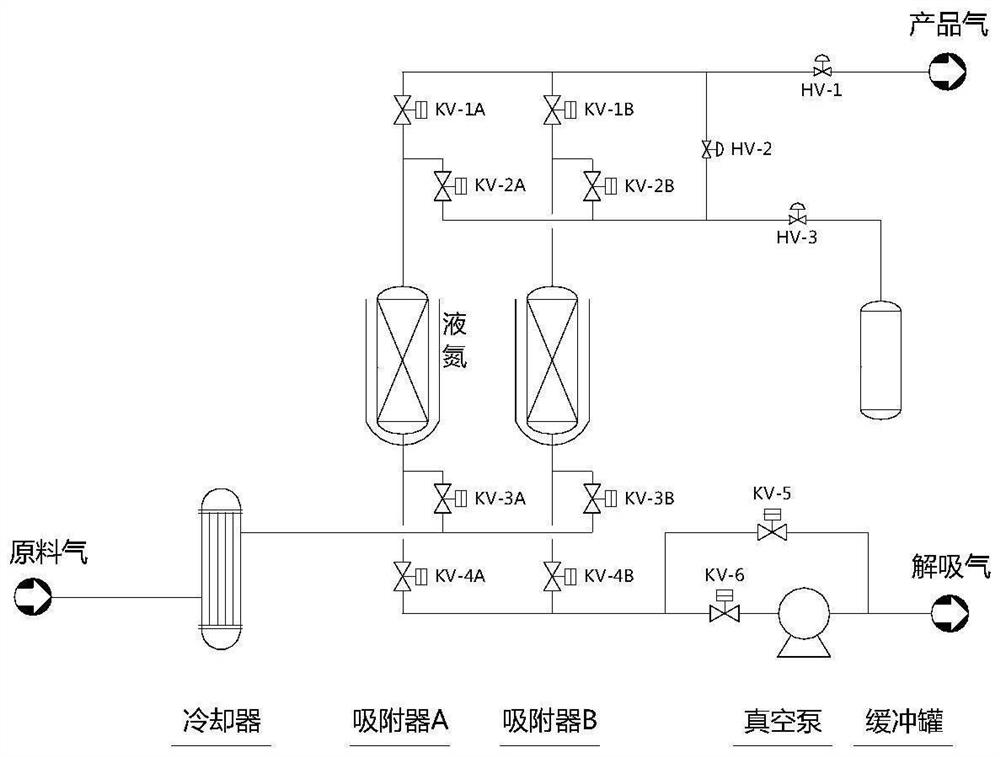

[0059] The method for low-temperature adsorption and purification of high-purity gas in this embodiment, the process flow chart is shown in figure 2 , the specific method steps are as follows:

[0060] The hydrogen-based raw material gas has a volume content of hydrogen of 95%, a volume content of nitrogen of 5%, a gauge pressure of 1.0 MPa, and a temperature of normal temperature. First, it is cooled to about -180°C by a cooler, and then enters a low-temperature adsorption device including two adsorbers. The adsorbent filled in the adsorber is 5A molecular sieve, and the adsorber is always immersed in a liquid nitrogen container. It does not need to be removed during regeneration. The liquid nitrogen container does not need to remove the liquid nitrogen, nor does it need to add materials and energy to increase the temperature of the adsorber.

[0061] Take the adsorber A as an example, when the adsorber A is adsorbing, open the valves KV-1A and KV-3A, the cooled raw materia...

Embodiment 3

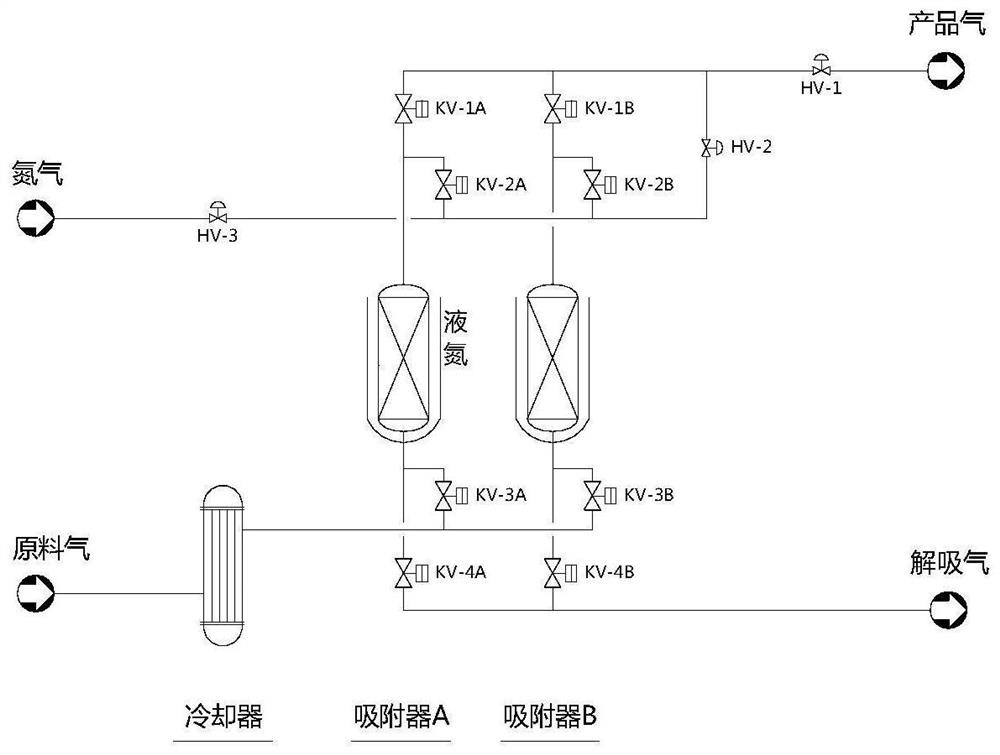

[0068] The method for low-temperature adsorption and purification of high-purity gas in this embodiment, the process flow chart is shown in image 3 , the specific method steps are as follows:

[0069] The raw material gas mainly consists of helium, whose volume content of helium is 99%, the volume content of nitrogen is 1%, the gauge pressure is 1.0MPa, and the temperature is normal temperature. First, it is cooled to about -180°C by a cooler, and then enters a low-temperature adsorption device including two adsorbers, and the adsorbent filled in the adsorbers is activated carbon.

[0070] Taking adsorber A as an example, when adsorber A is adsorbing, the liquid nitrogen jacket outside the adsorber is filled with liquid nitrogen, and the valves KV-1A and KV-3A are opened, and the cooled raw material gas enters the adsorption from the bottom of adsorber A. device. During regeneration, the temperature of the adsorber is at room temperature. During adsorption, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com