Nano lithium titanate-graphene composite material and preparation method therefor

A composite technology of nano-lithium titanate and graphene, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the complex synthesis process, limit the wide application of composite materials, and is difficult to achieve large-scale production. and other problems, to achieve the effect of simple process, excellent electrochemical performance, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

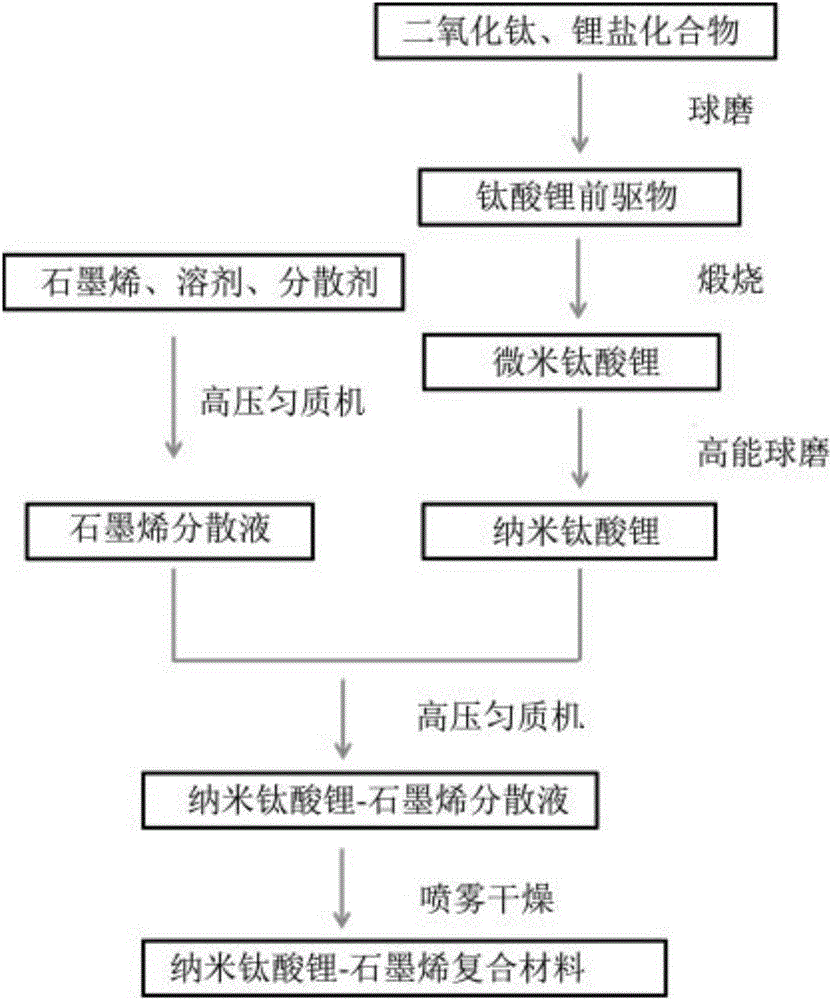

[0028] Please refer to figure 1 , the embodiment of the present invention provides a preparation method of nano-lithium titanate-graphene composite material, comprising the following steps:

[0029] (1) Preparation of nano-lithium titanate: uniformly mix titanium dioxide and lithium source according to the molar ratio of lithium to titanium of 0.8 to 0.9:1, and perform wet ball milling for 1 to 48 hours. Calcined at 500-1100°C for 1-36 hours in a neutral atmosphere to obtain micron lithium titanate powder, then put the micron lithium titanate powder into a grinder, and wet ball mill at a speed of 800-12000 rpm 30 to 240 minutes, after drying, nano lithium titanate powder is obtained;

[0030] (2) Preparation of graphene dispersion liquid: disperse graphene in solvent, and add a certain amount of dispersant, open Microfluidizer M-110L high-pressure micro-jet homogenizer, adjust pressure to be 400-10000 pounds / square inch PSI, in The basis of the emulsification of the dispersant...

Embodiment 1

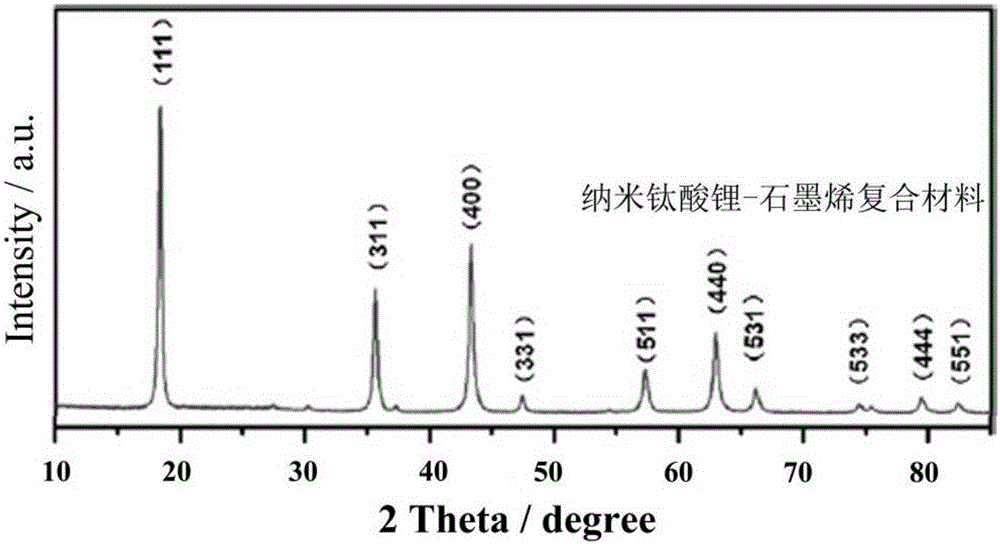

[0038] The preparation process of nano-lithium titanate-graphene follows the process flow figure 1 conduct. First prepare the nano-lithium titanate material, choose lithium carbonate as the lithium source, mix lithium carbonate and titanium dioxide uniformly according to the molar ratio of lithium to titanium 0.82:1, add absolute ethanol and ball mill, and control the solid content at 35wt%, on the planetary ball mill Ball milling at a speed of 400 rpm for 12 hours to obtain a lithium titanate precursor mixture. After drying at 120°C, it was calcined at 800°C for 12 hours under an argon atmosphere, cooled at room temperature to below 100°C, and taken out to obtain micron lithium titanate. Put the above-mentioned micron lithium titanate powder into a high-energy ball mill, add absolute ethanol for ball milling, control the solid content to 30wt%, ball mill at a speed of 2000 rpm for 120 minutes, and then dry the ball mill tank at 120°C to obtain nanometer lithium titanate . ...

Embodiment 2

[0045] Nanoscale lithium titanate was prepared in the same manner as in Example 1.

[0046] The difference from Example 1 is that the graphene content in the composite material is controlled at 1 wt%, and the lithium titanate is about 99 wt% in the total weight of the composite material. The prepared composite material dispersion was rotary evaporated to obtain composite material powder.

[0047] The obtained composite material powder was calcined in an argon atmosphere, the temperature was adjusted to 400° C., kept for 20 hours, and naturally cooled to room temperature to obtain a nano-lithium titanate-graphene composite material.

[0048] Electrochemical tests were carried out on the prepared composite material, and the mixture ratio of the pole piece smear was: composite material: conductive carbon black: PVDF=60:30:10. After testing, the battery shows excellent cycle stability. At 1C rate, the ultra-high specific capacity reaches 165mAh / g; at 10C rate, the specific capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com