Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "Fast mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

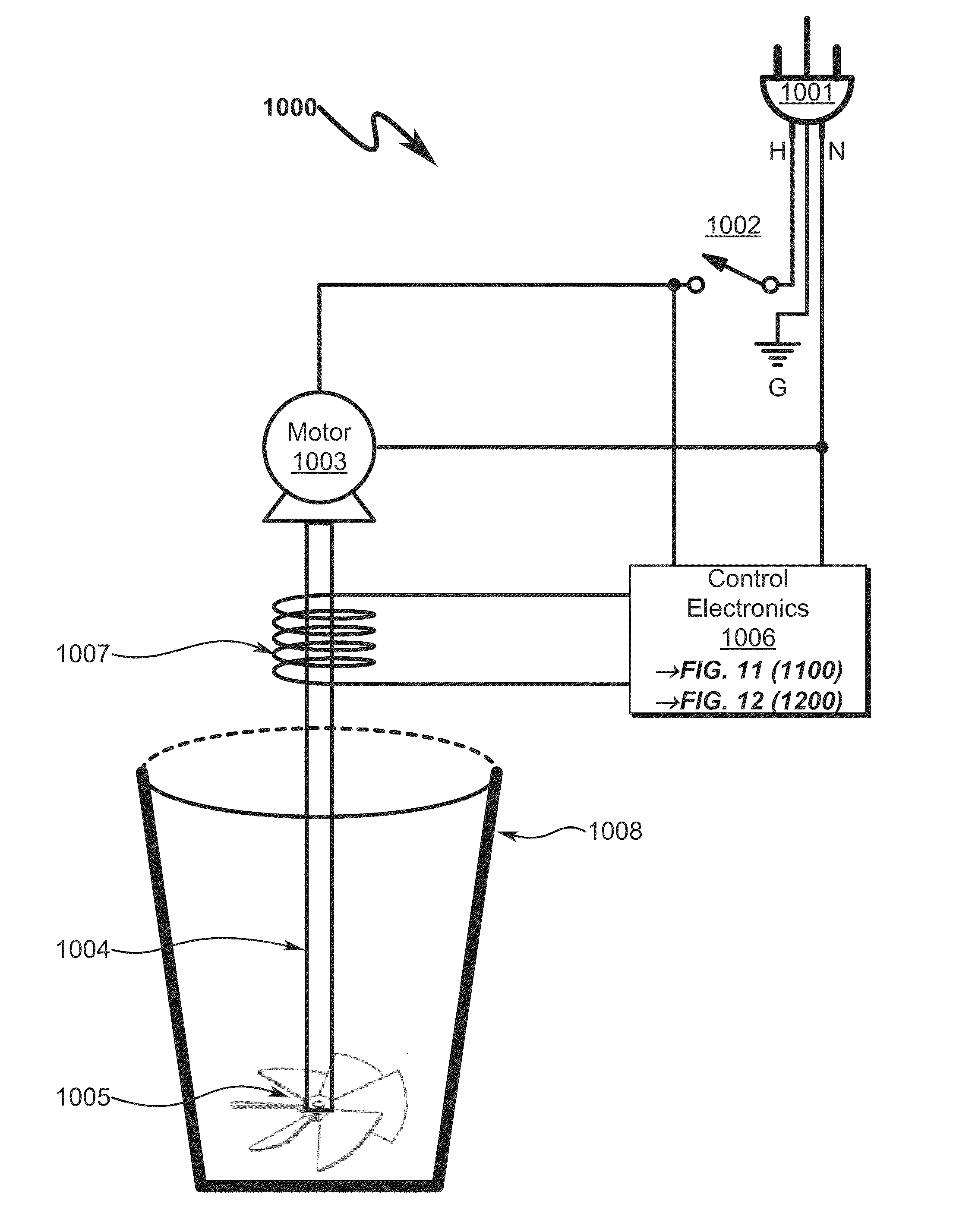

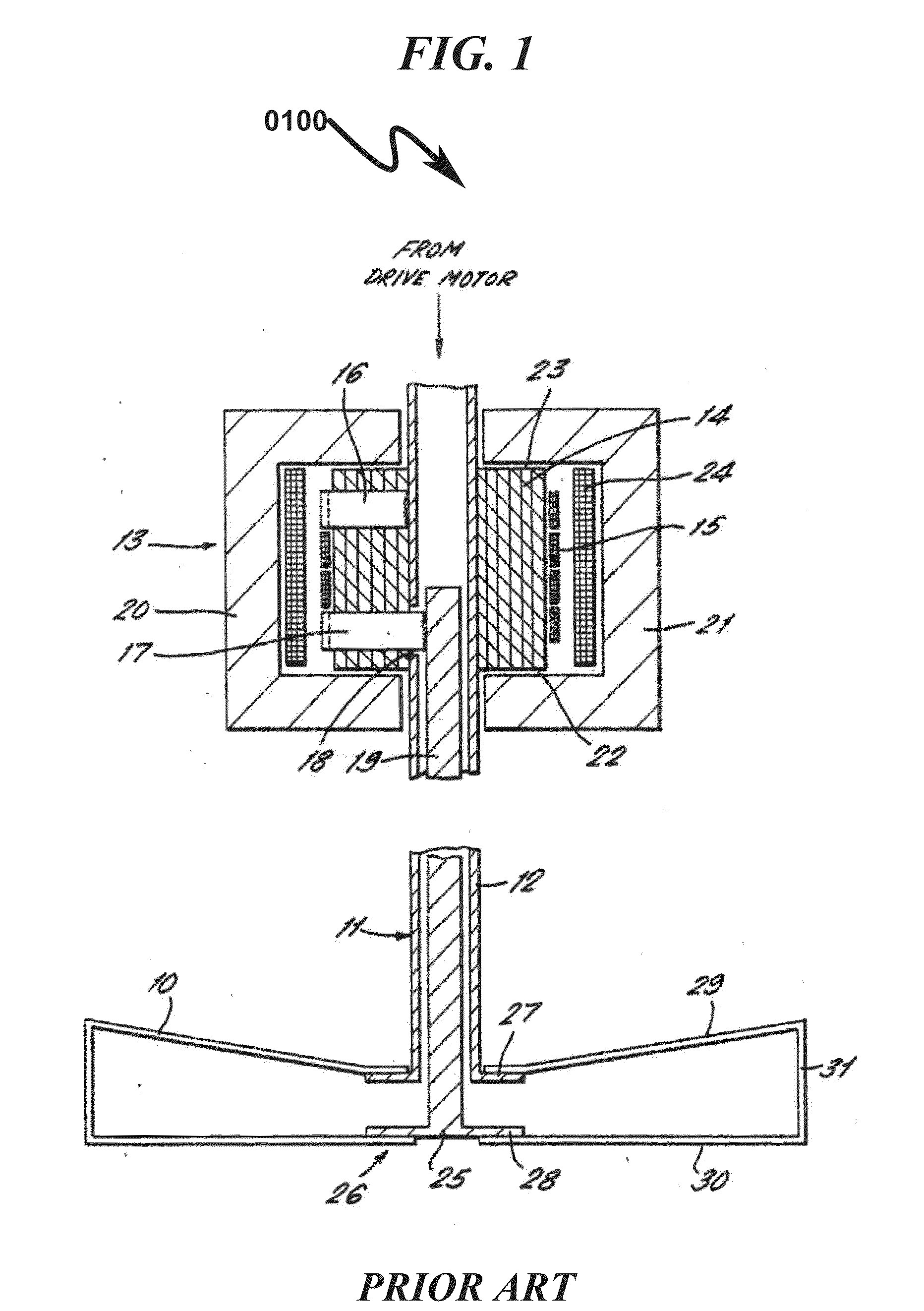

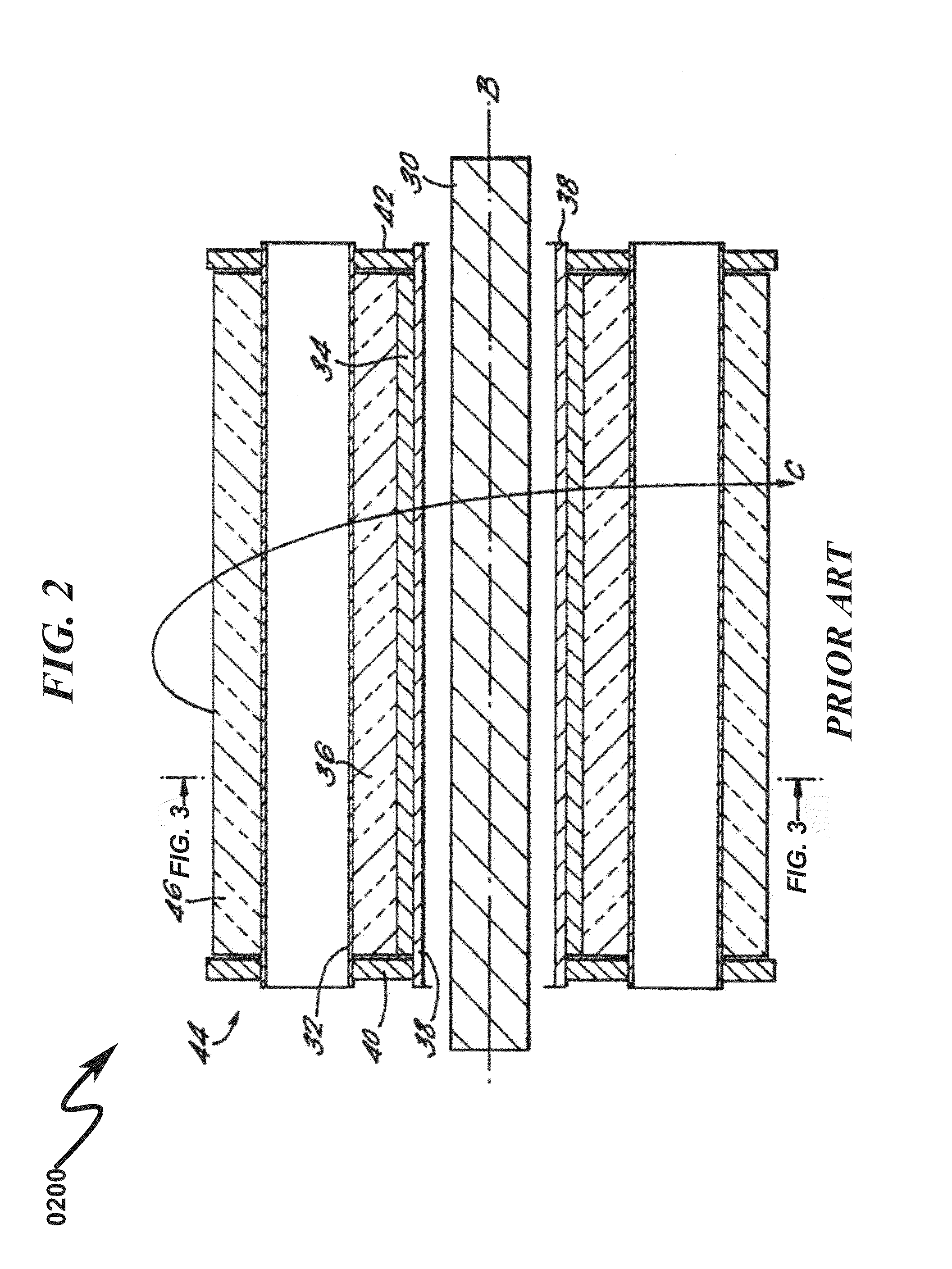

Beverage Mixing System and Method

ActiveUS20130344204A1Fast mixingDough treatmentRotary stirring mixersPerformance improvementHybrid system

A beverage mixing system / method allowing faster mixing / blending of frozen beverages is disclosed. The system / method in various embodiments utilizes inductive coupling to introduce heat into the frozen beverage during the mixing / blending process via a rotating driveshaft and attached mechanical agitator to speed the mixing / blending process. Exemplary embodiments may be configured to magnetically induce heat into the driveshaft and / or mechanical agitator mixing blade to affect this mixing / blending performance improvement. This heating effect may be augmented via the use of high power LED arrays aimed into the frozen slurry to provide additional heat input. The system / method may be applied with particular advantage to the mixing of ice cream type beverages and other viscous beverage products.

Owner:QDOT ENGINEERS LLC

Rapid gas hybrid reactor for high temperature cracking and application thereof

ActiveCN101982227ALittle resistance lossFast mixingFlow mixersGas-gas reaction processesFriction lossProduct gas

The invention relates to a rapid gas hybrid reactor for high temperature cracking and an application thereof. Two types of gases are transported by a concentric bilayer circular tube, one type of the gas is transported by an inner tube, the other type of the gas is transported by a tube annular space between an outer tube and the inner tube, and the two types of the gases can be subject to mutualtemperature regulation in the transportation process, the gases are pre-tempered; and one type of the gas is transported to the inner turbine of a mixing nozzle by the inner tube, the other type of the gas is transported to the annular turbine of the mixing nozzle by the tube annular space between the outer tube and the inner tube, the rotation direction of the turbine blades of the inner turbineand the annular turbine are opposite so as to lead the rotation direction of the two types of the gases to be opposite, thus generating a huge velocity difference to cause large shear force, intensive turbulence, small resistance loss and high hybrid speed, and enabling the two types of the gases to be evenly mixed instantly and then enter in a reaction tube for reaction immediately. The gases are mixed in the mixing nozzle and directly enter the reactor for reaction, thus a mixing section is not required to be additionally arranged.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

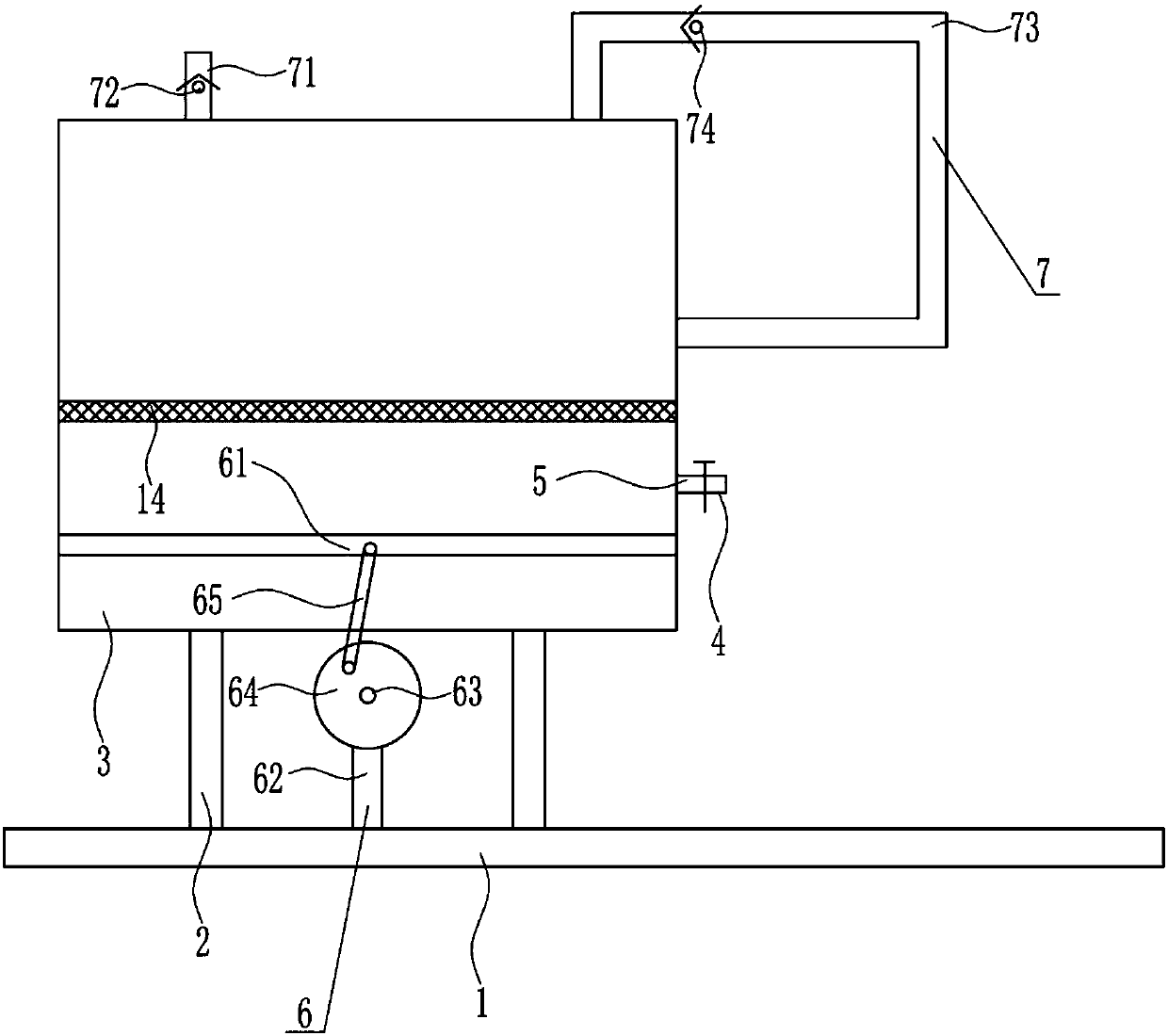

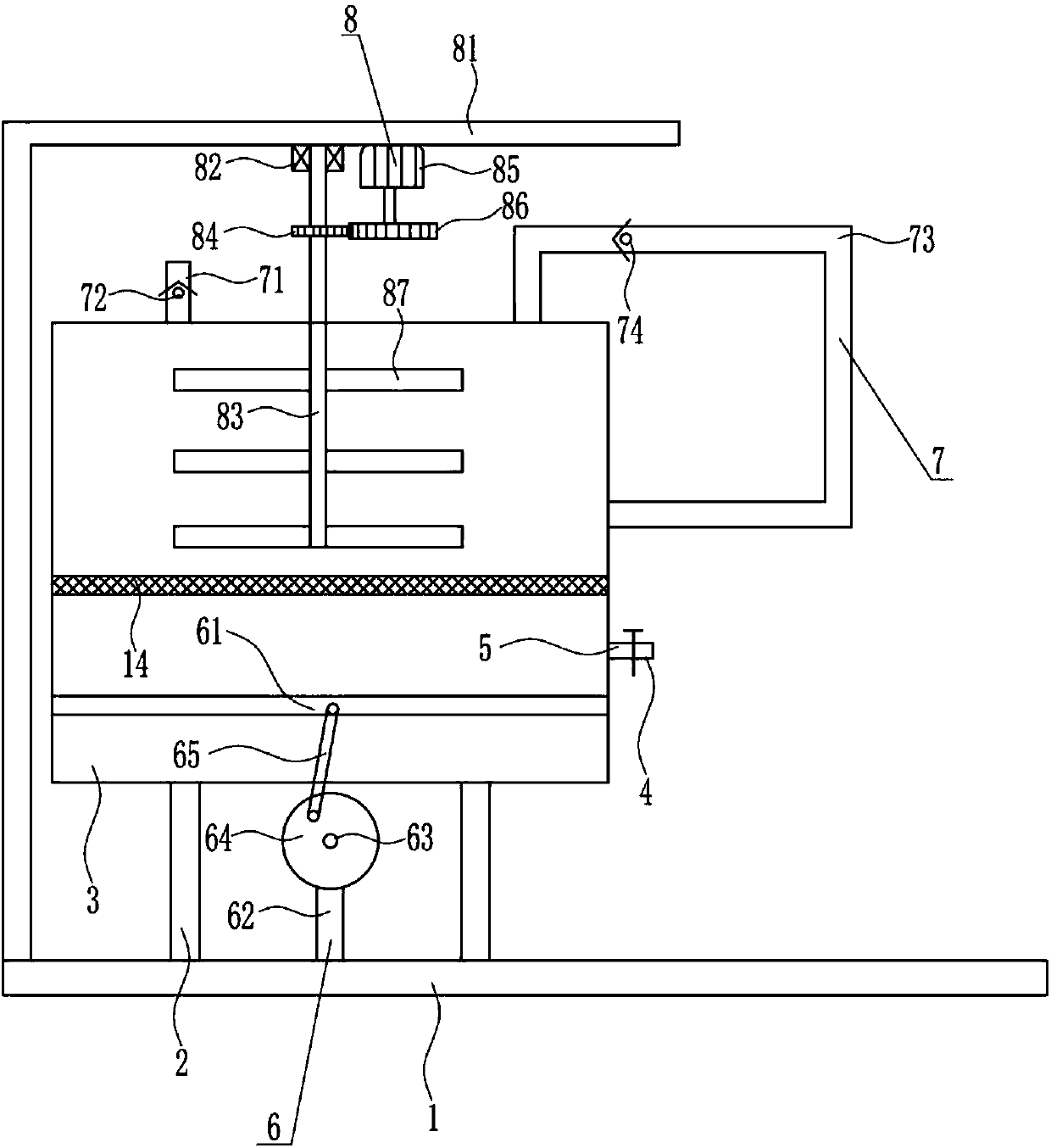

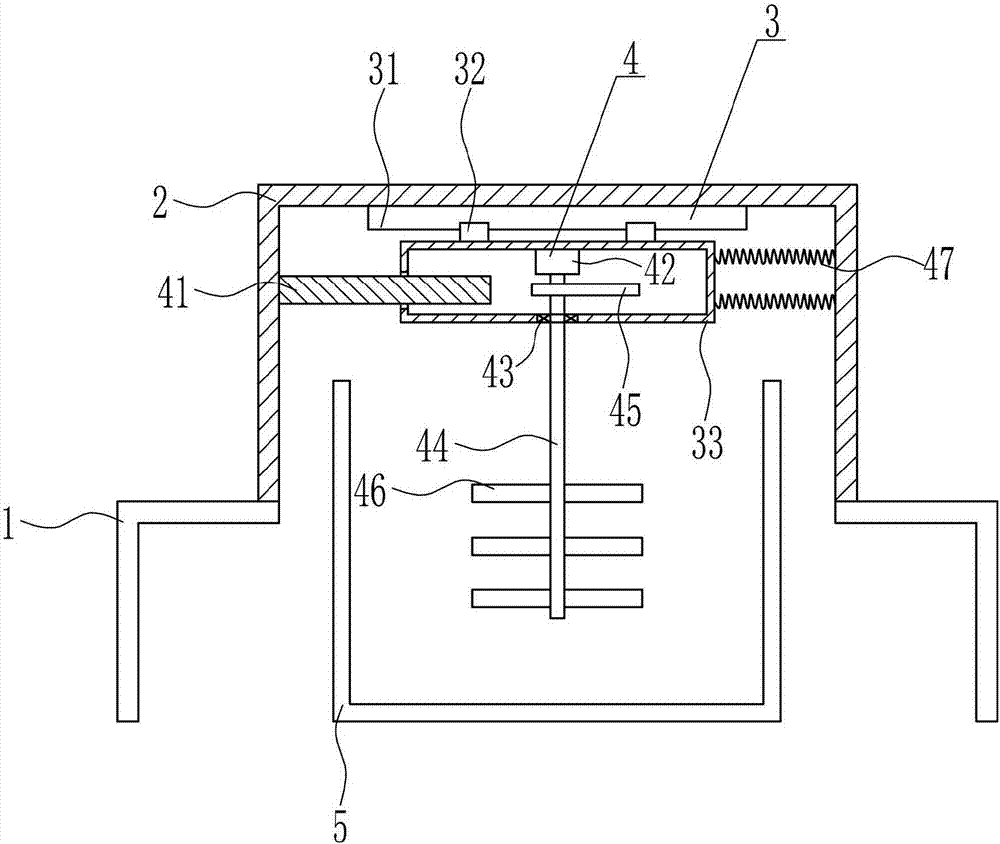

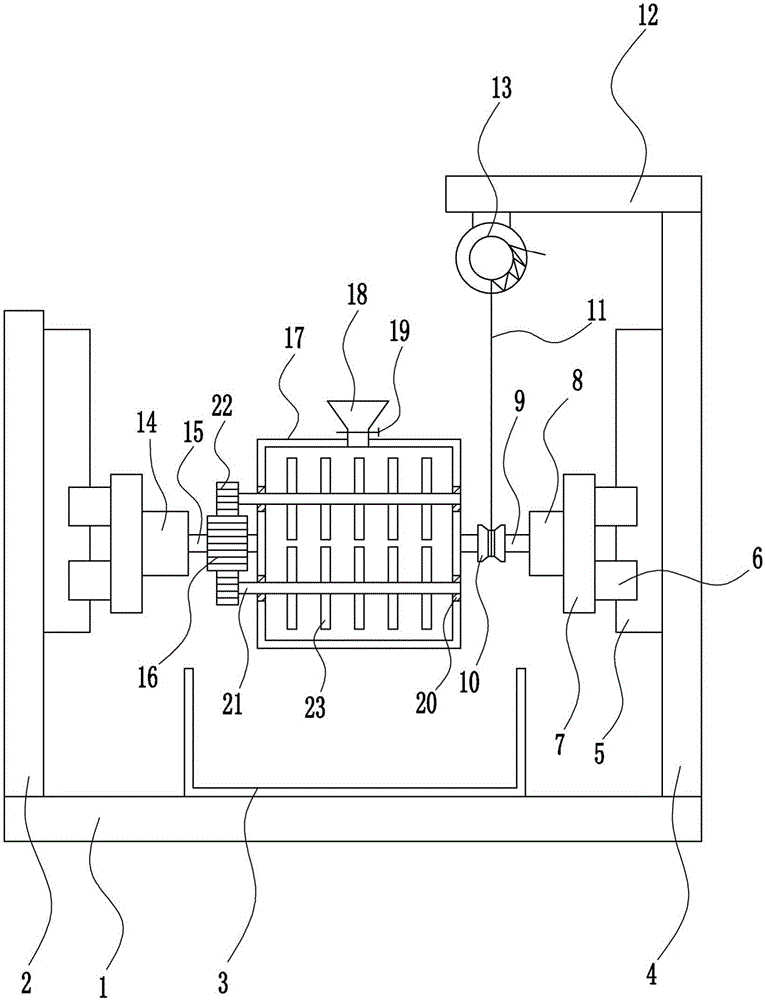

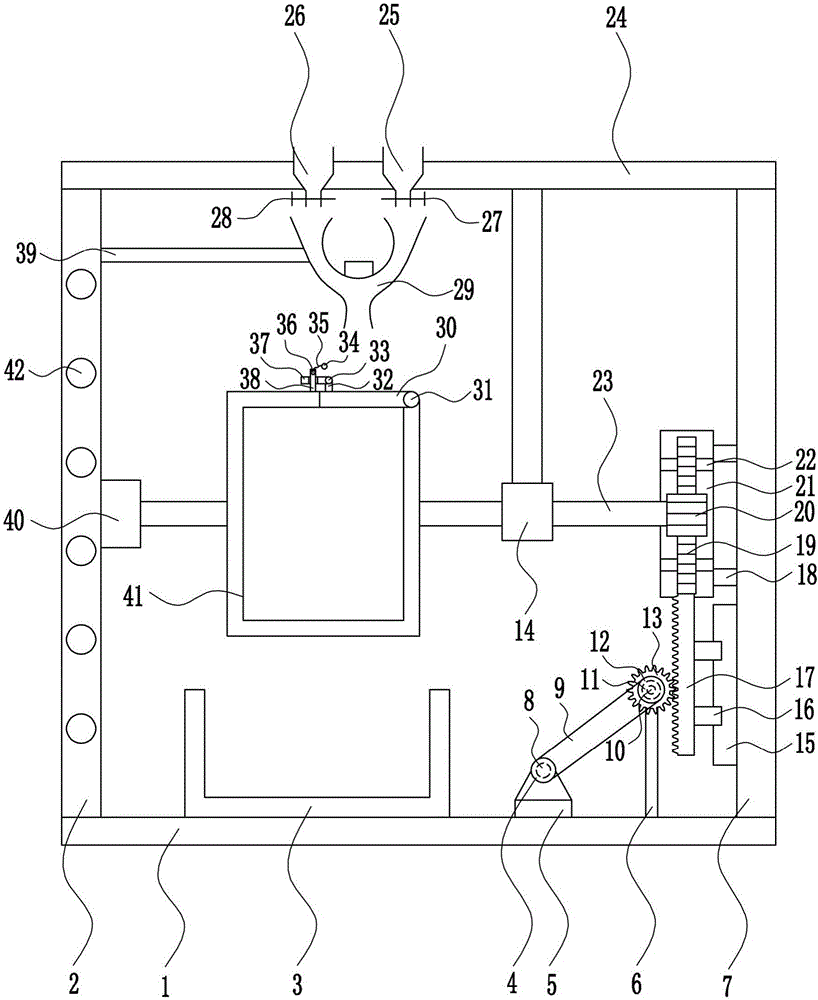

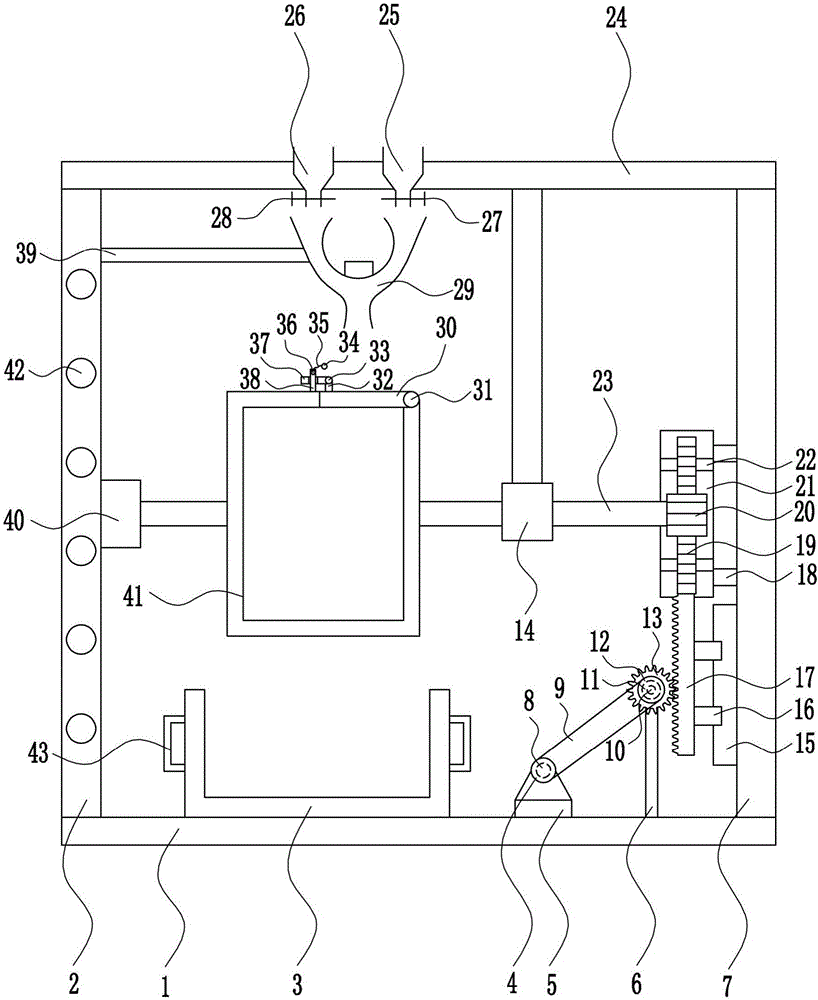

High-efficiency mixing device for raw material for producing brake clutch disc

InactiveCN107855065AImprove mixing efficiencyIncrease the mixing areaFlow mixersTransportation and packagingEngineeringUltimate tensile strength

The invention relates to a mixing device for a raw material, and particularly relates to a high-efficiency mixing device for a raw material for producing a brake clutch disc. The invention aims at solving the technical problem of providing a high-efficiency mixing device for the raw material for producing the brake clutch disc, which is uniform in mixing, low in labor intensity and quick in mixingspeed. In order to solve the technical problem, the invention provides such a high-efficiency mixing device for the raw material for producing the brake clutch disc. The high-efficiency mixing devicecomprises a bottom plate, supporting rods, a first box body, a first discharge pipe, a valve and the like, wherein the left and right sides of the bottom left side of the bottom plate are both provided with the supporting rods through a bolt connection way; the first box body is arranged at the tops of the supporting rods; the lower part of the right side of the first box body is provided with the first discharge pipe; the first discharge pipe is provided with the valve; the middle part in the first box body is provided with a reticular plate. The high-efficiency mixing device is used for realizing the effect of the high-efficiency mixing device for the raw material for producing the brake clutch disc, which is uniform in mixing, low in labor intensity and quick in mixing speed.

Owner:闫梦蝶

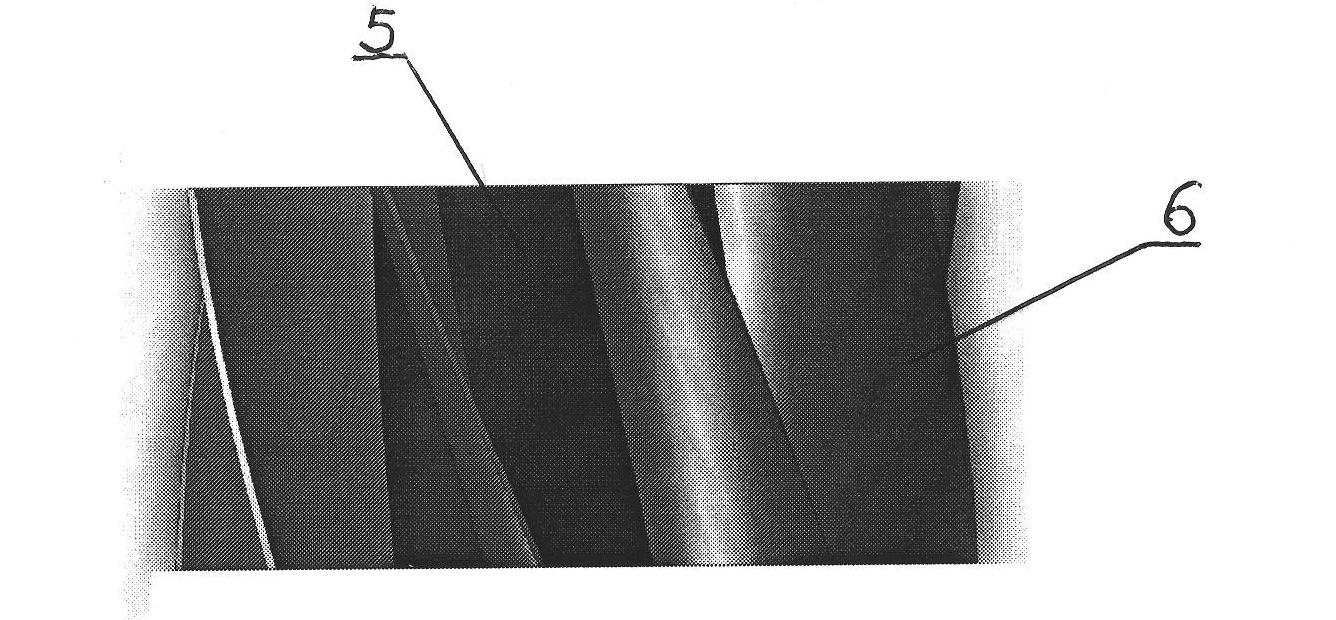

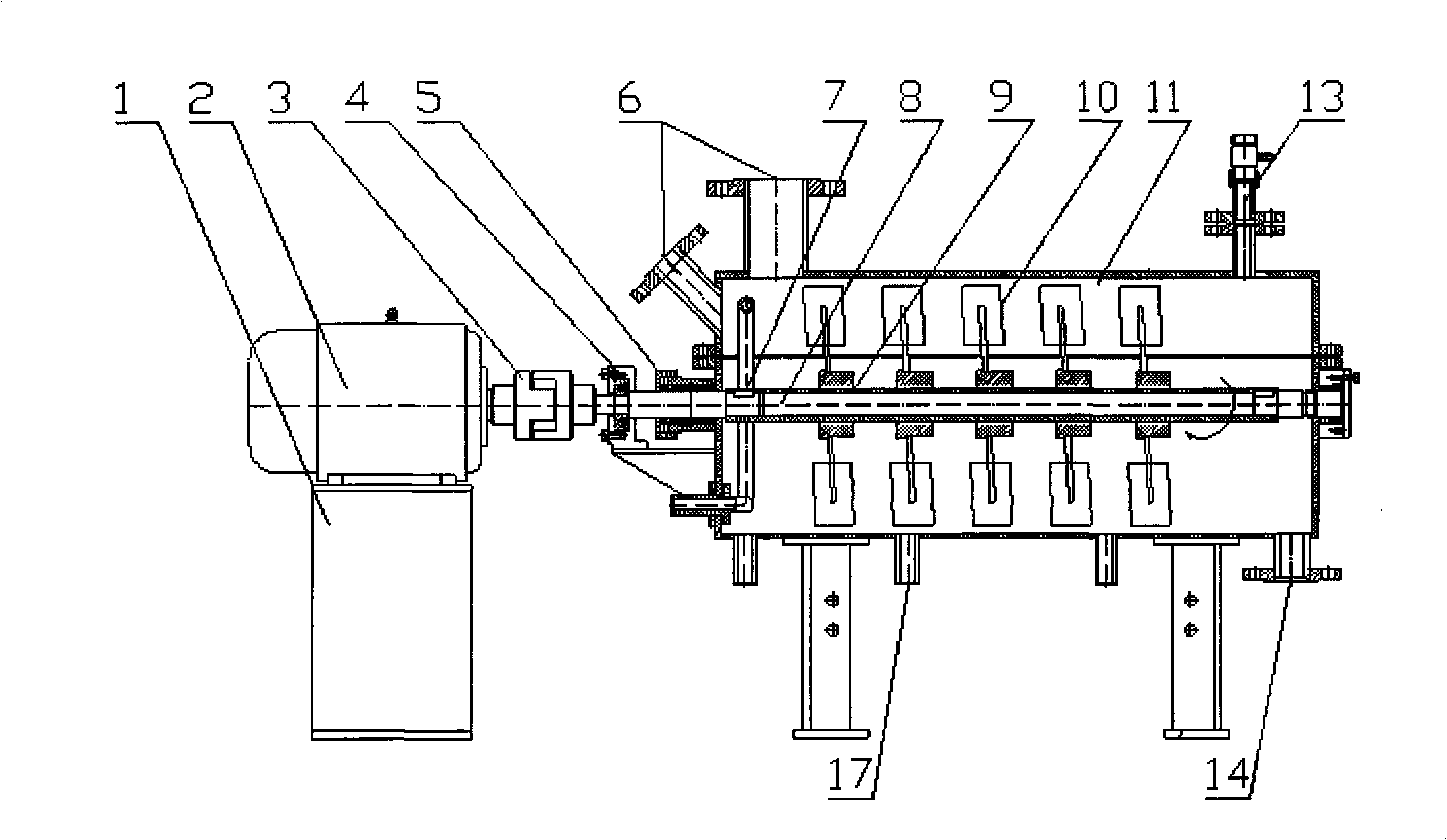

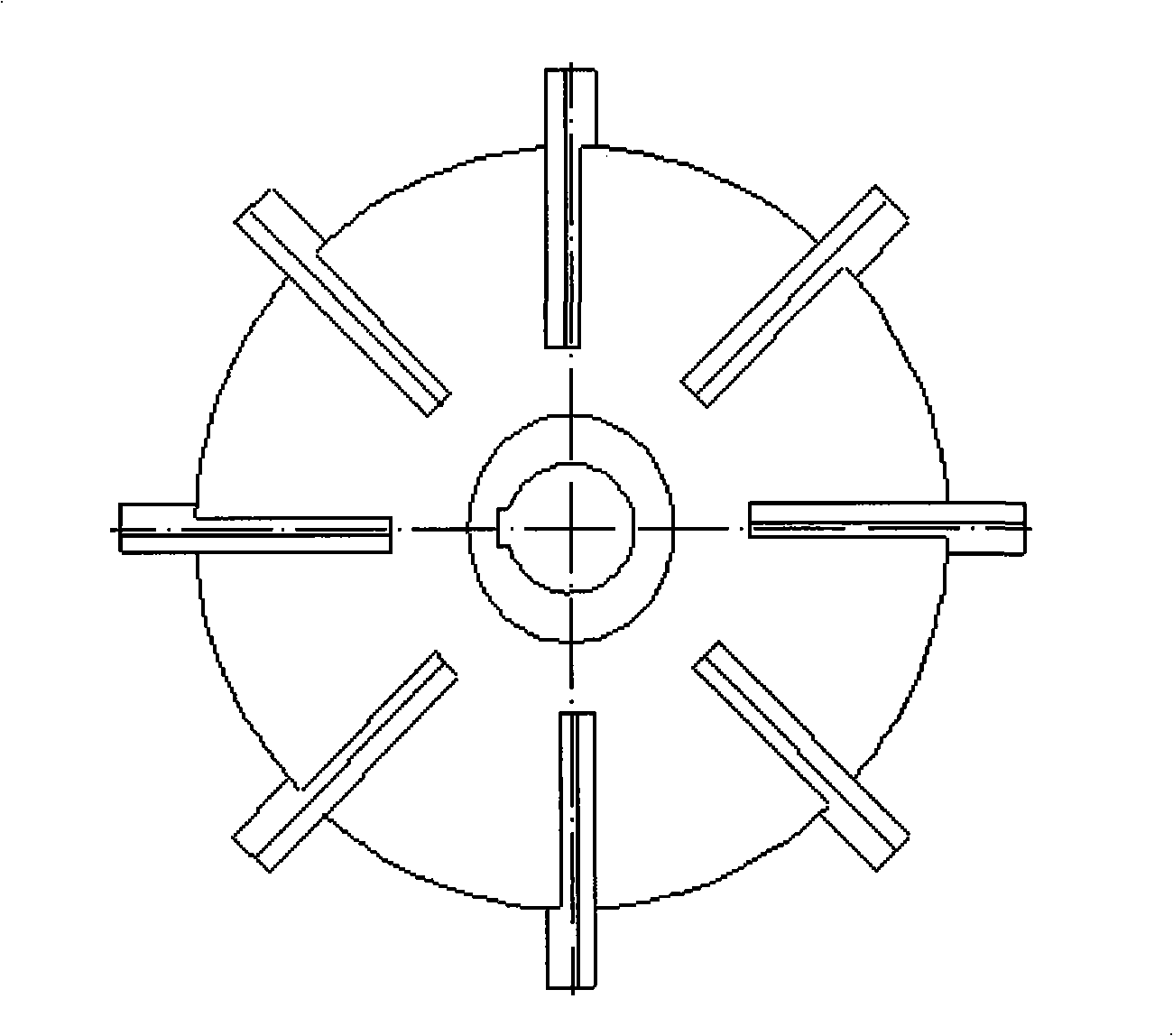

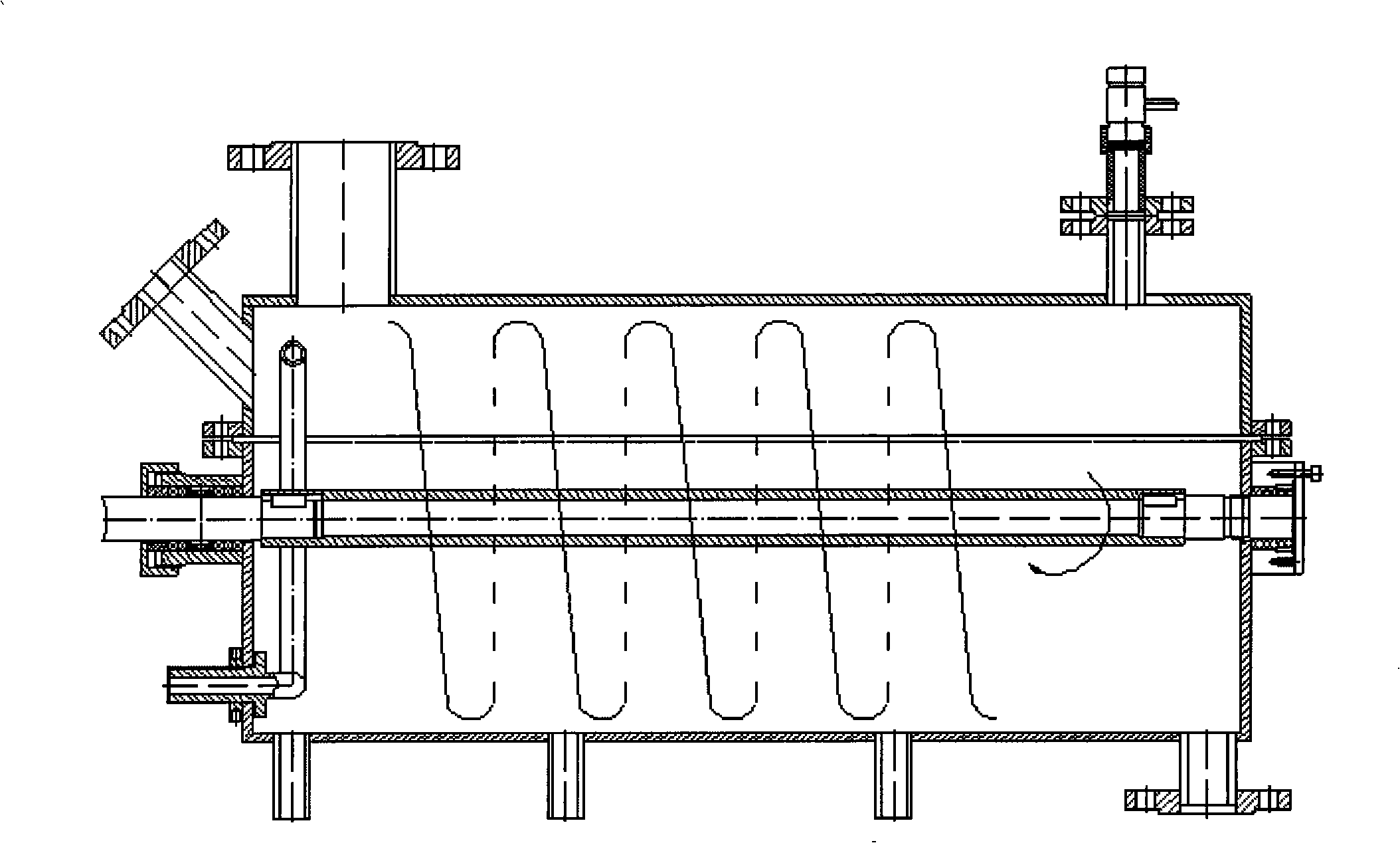

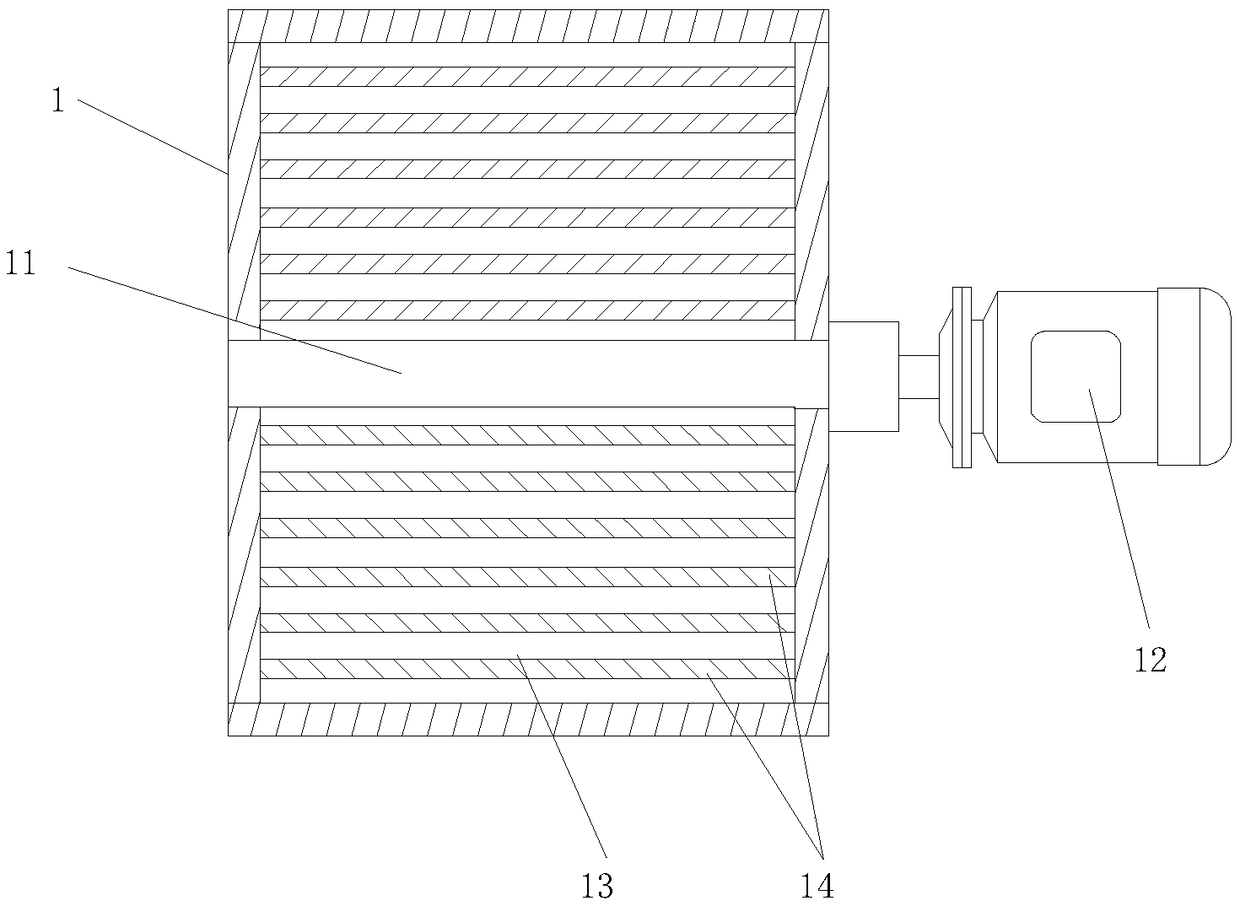

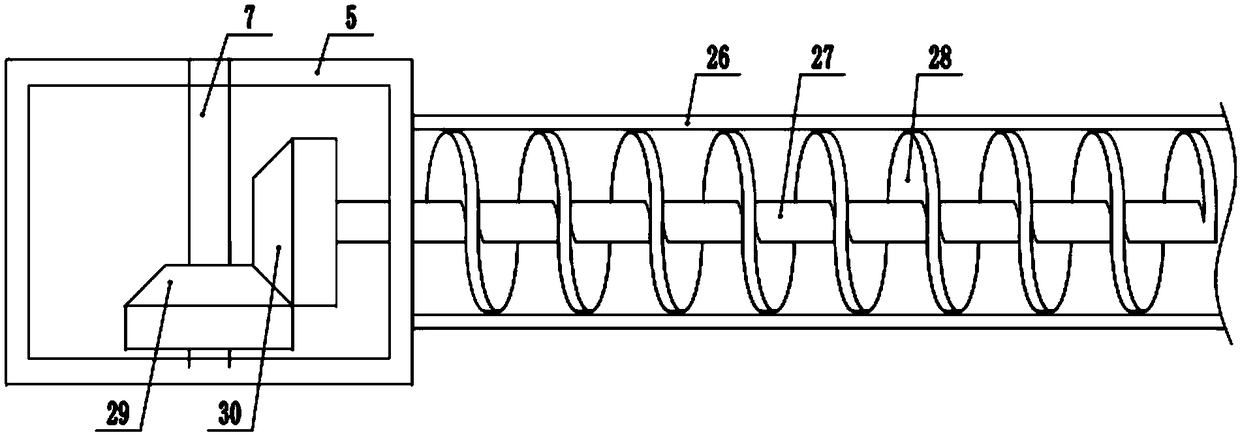

Horizontal helix solid-liquid mixing apparatus

InactiveCN101402025AImprove mixing efficiencyFast mixingRotary stirring mixersMixing methodsContinuous operationMotor drive

The invention discloses a horizontal helical solid-liquid mixing unit, which comprises a speed regulating motor, a bearing pedestal and a cylindrical mixing chamber, wherein the feeding end of the mixing chamber is provided with a solid feed opening and a liquid feed opening, and the discharging end of the mixing chamber is provided with a discharge opening and an exhaust opening; the bottom of the mixing chamber is provided with a cleaning opening; the center of a cylinder is provided with a stirring shaft both ends of which are connected with the bearing pedestal through a rotating shaft respectively; the speed regulating motor drives the rotating shaft to rotate; a helical pitched turbine paddle is fixed on the stirring shaft, and the angle of the helical pitched turbine paddle which is inclined to the stirring shaft is between 2 and 6 DEG; and the inclination angle of a blade of the helical pitched turbine paddle and a disc surface is between 3 and 9 DEG. Compared with the prior art, the mixing unit has high mixing efficiency, high speed and uniform mixing of materials, does not leave dead angle, and is suitable for continuous operation. Moreover, the device has a simple overall structure, and is convenient to assemble, disassemble and clean.

Owner:ZHEJIANG UNIV

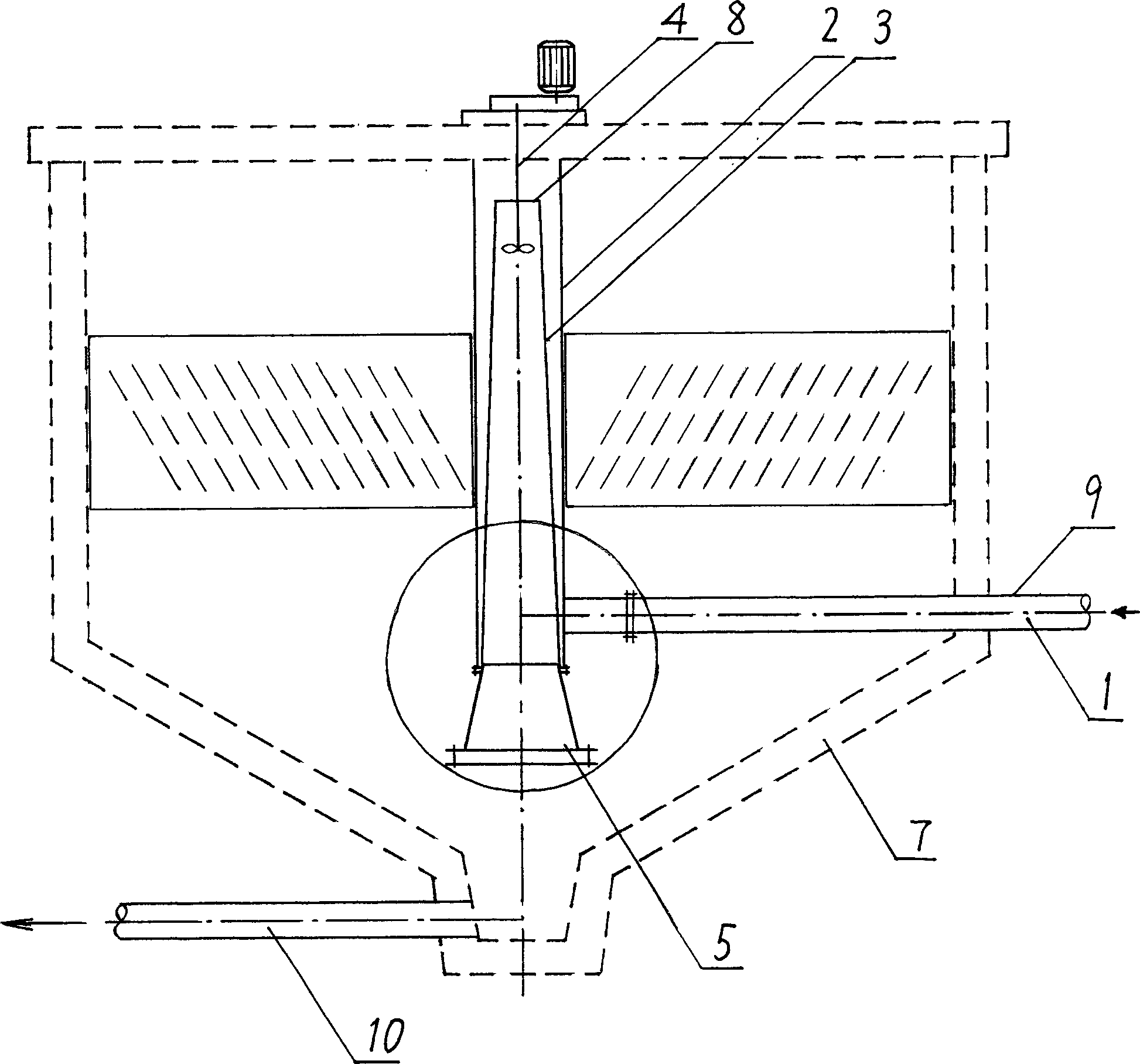

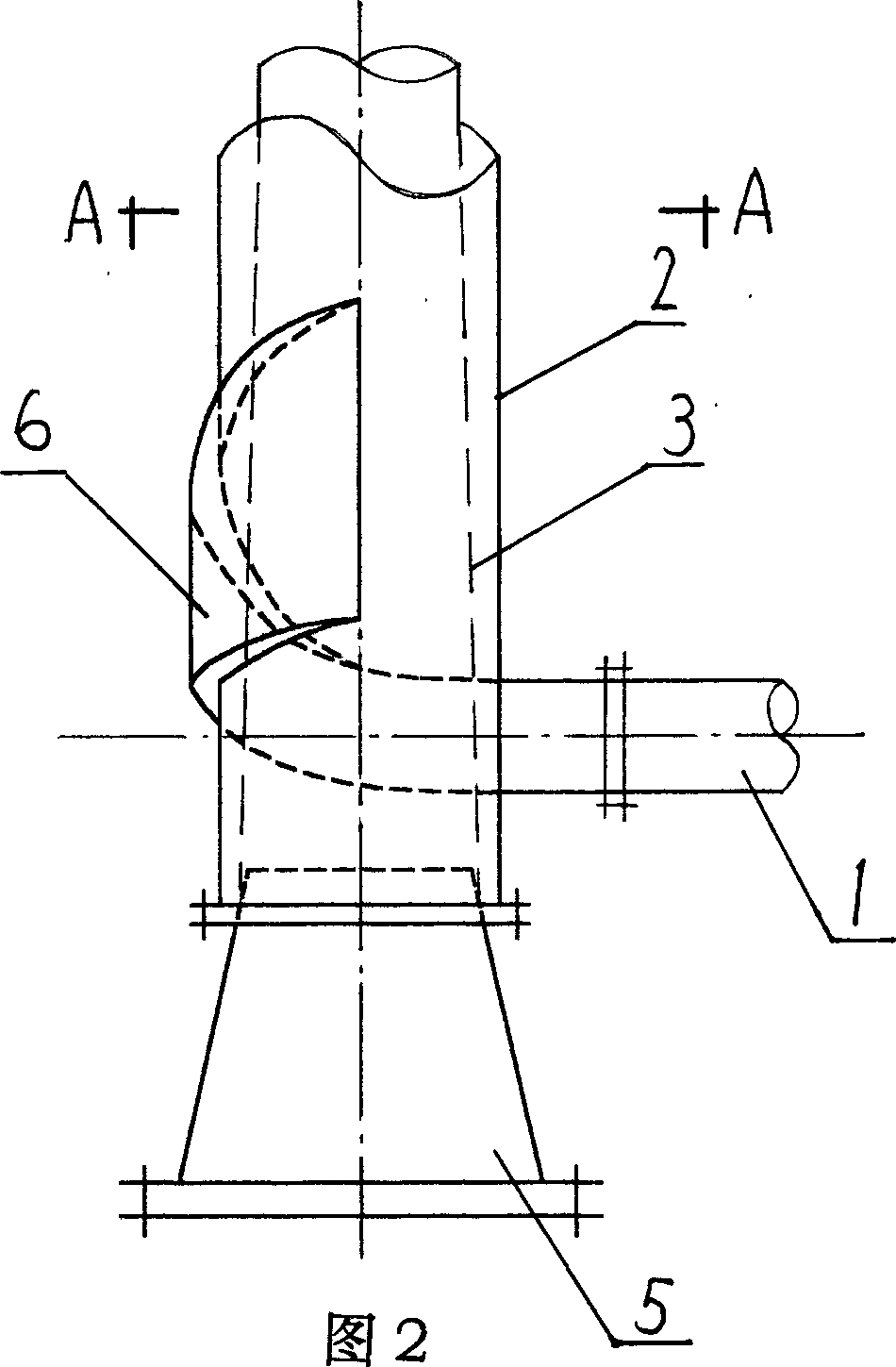

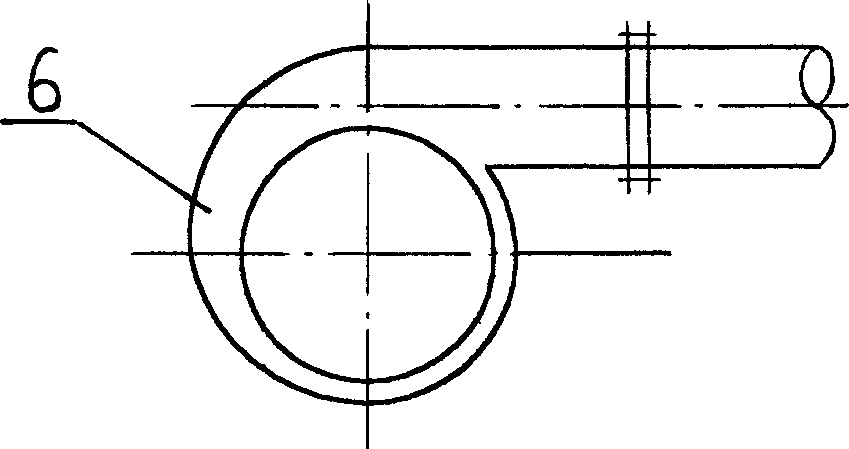

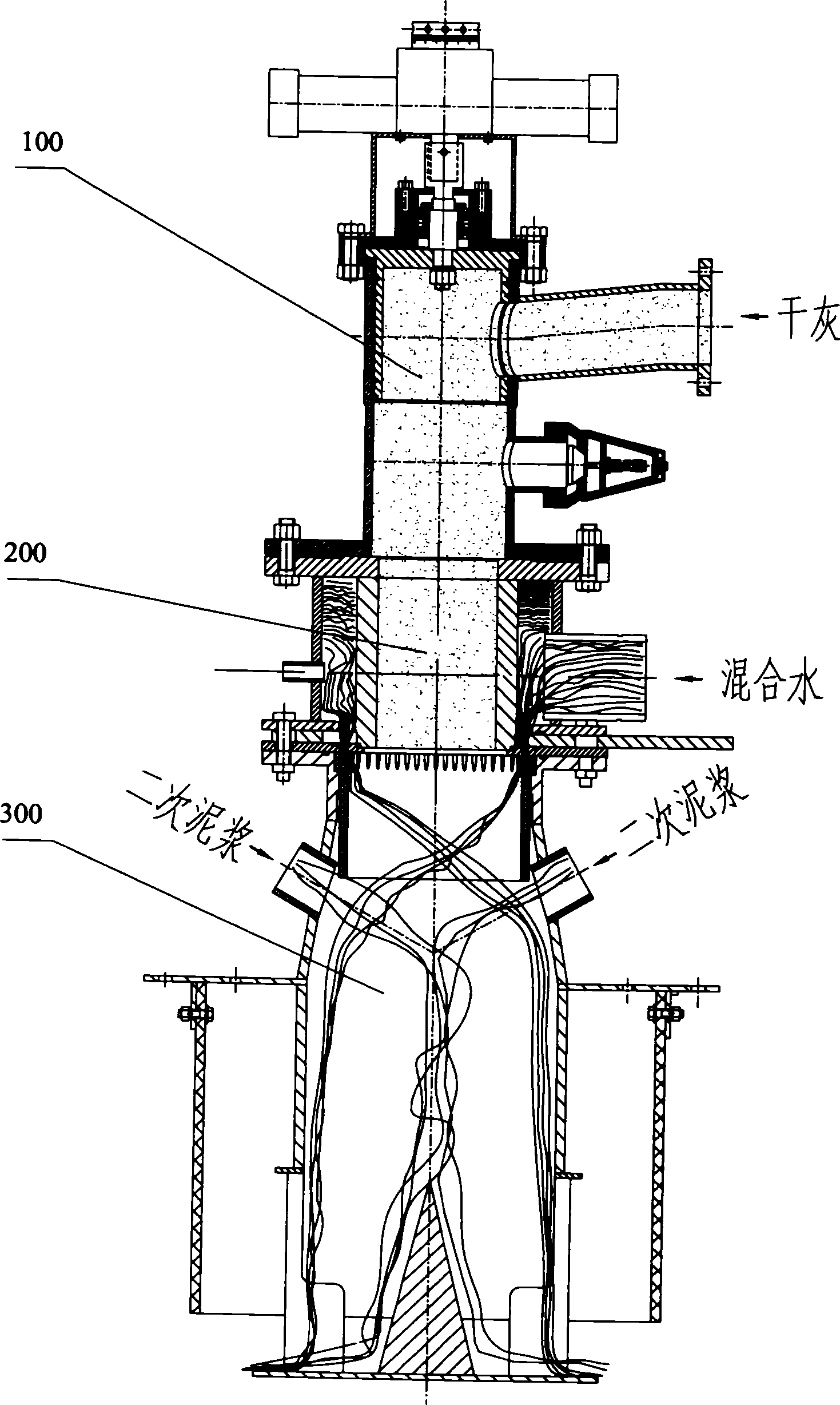

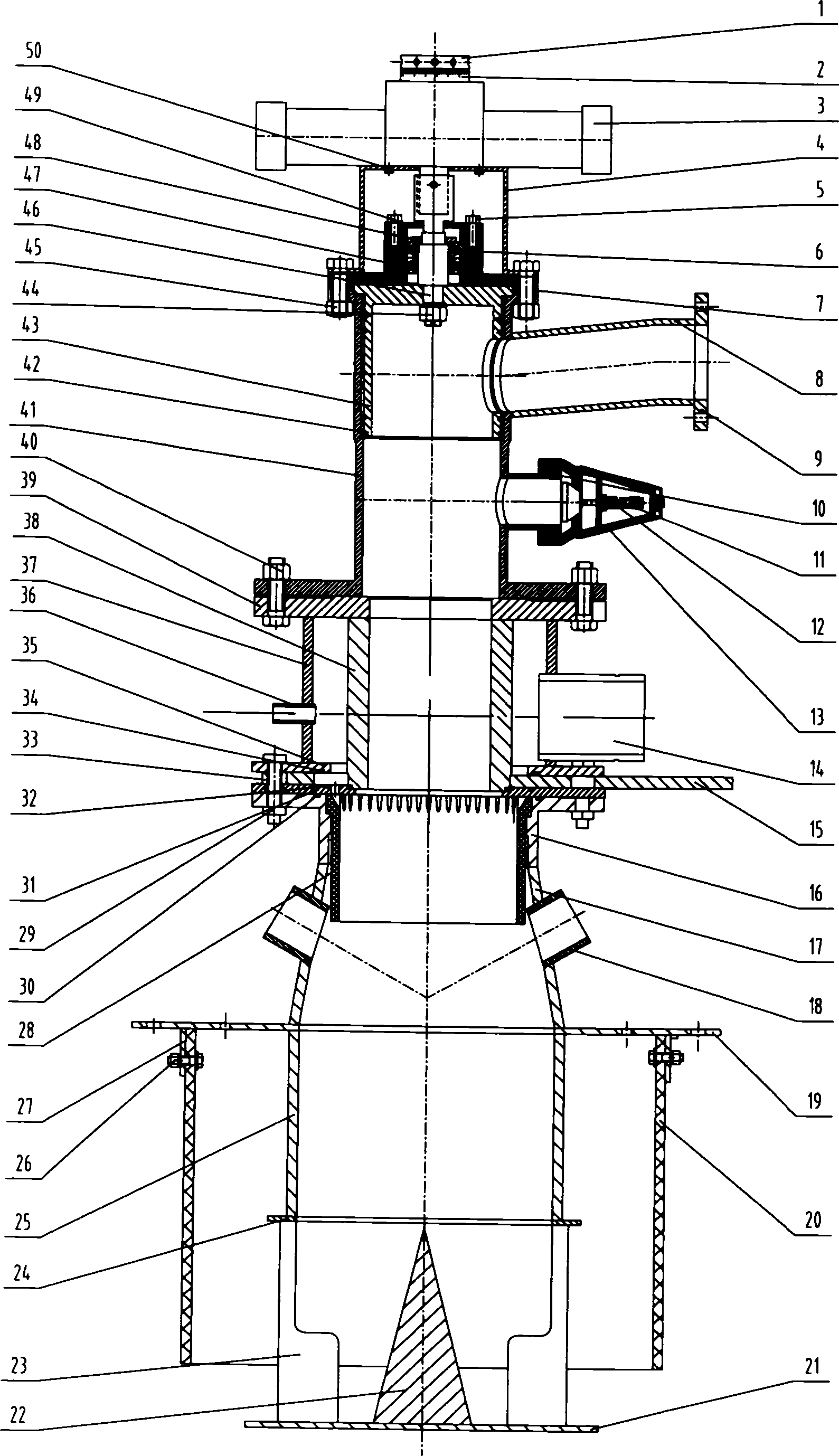

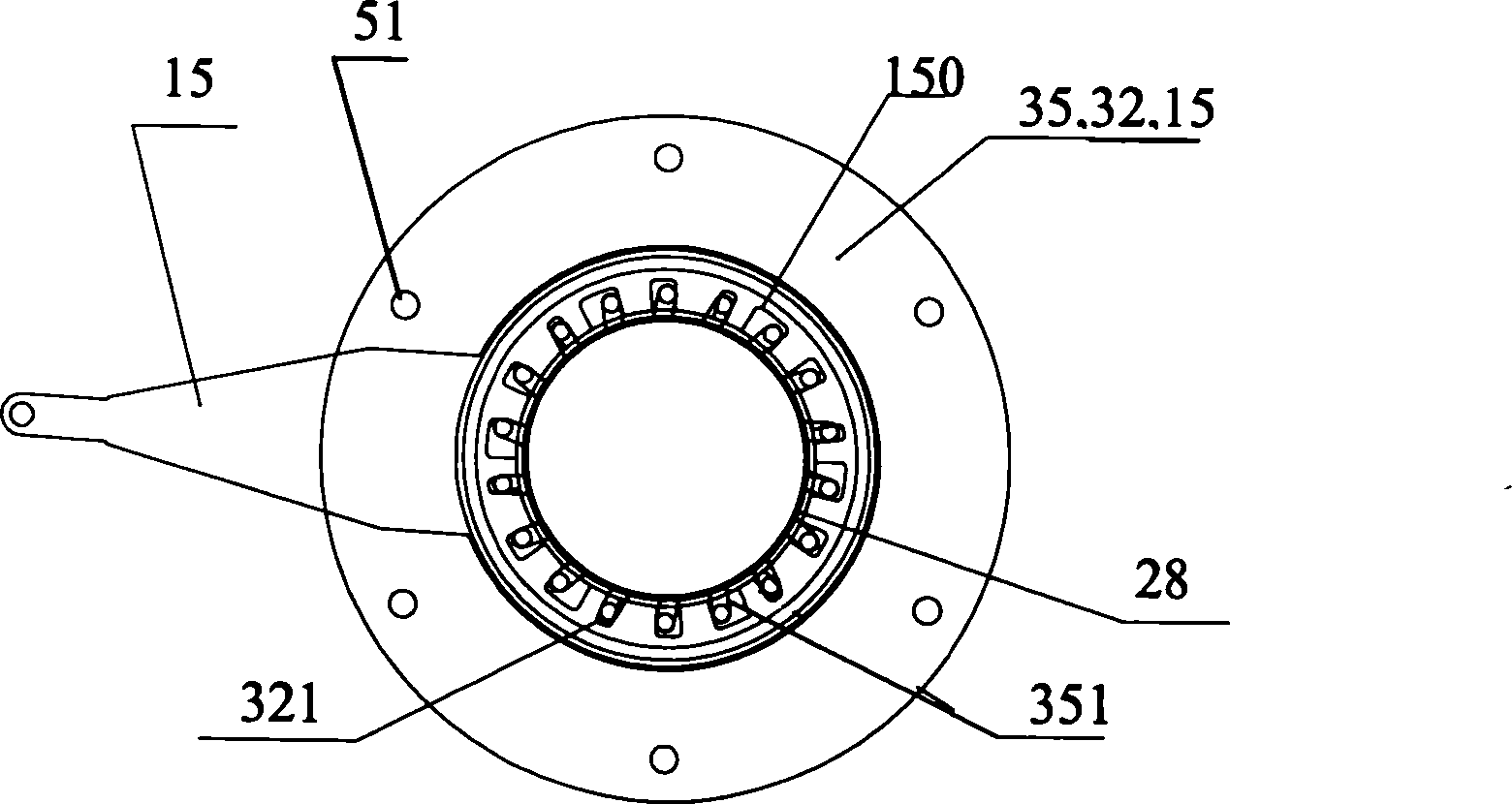

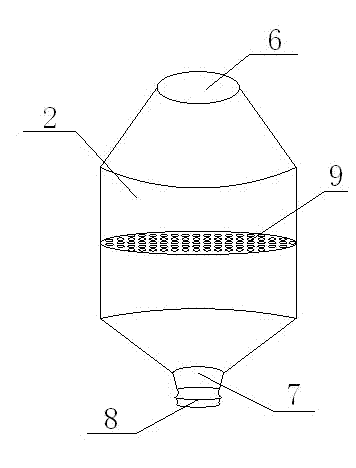

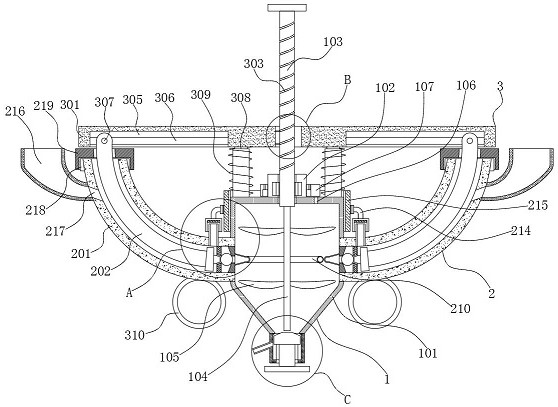

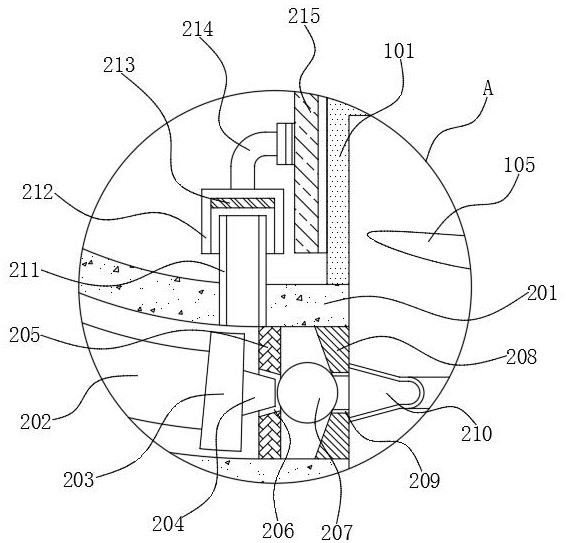

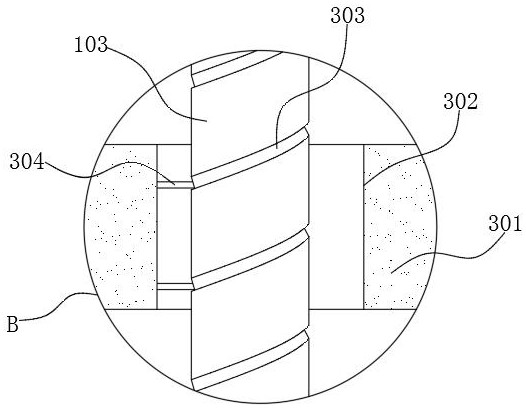

Sleeve type flow speed changing swirling flow composite reactor and high efficiency composite precipitation tank

ActiveCN1559648AReduce volumeReduce energy consumptionCentrifugal force sediment separationSludgeReclaimed water

An efficient depositing pool for cleaning sewage and reclaimed water has an upper water outlet bath, a middle clarifying area, a lower sludge area connected to mud draining pipe, and a cental vertical sleeve pipe type combined reactor with the speed-variable cyclone. Said combined reactor consists of external cylindrical pipe, internal conic pipe with stirrer and cyclone guide pipe. It has also water inlet pipe and chemical applying pipe.

Owner:BEIJING ENFI ENVIRONMENTAL PROTECTION CO LTD

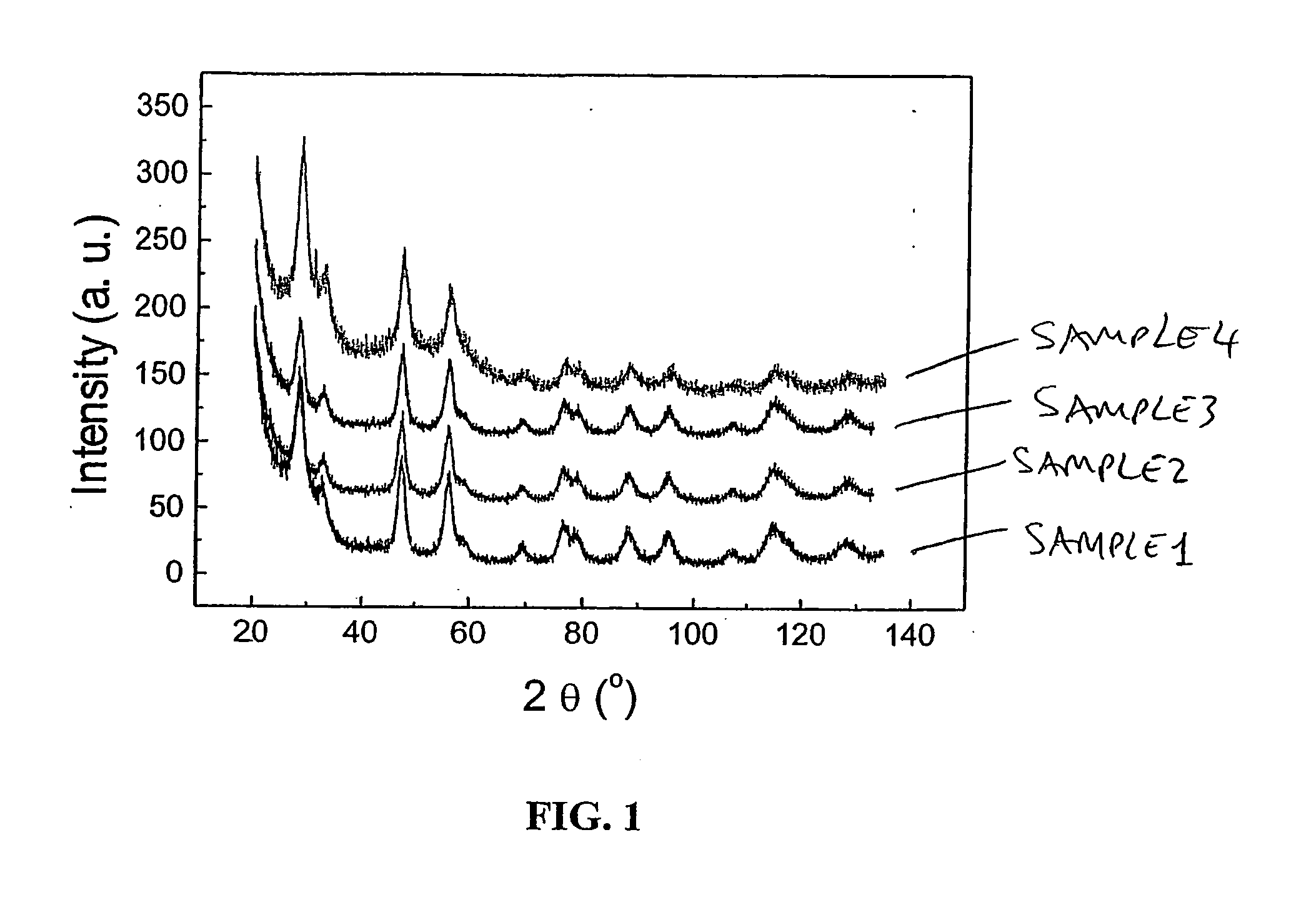

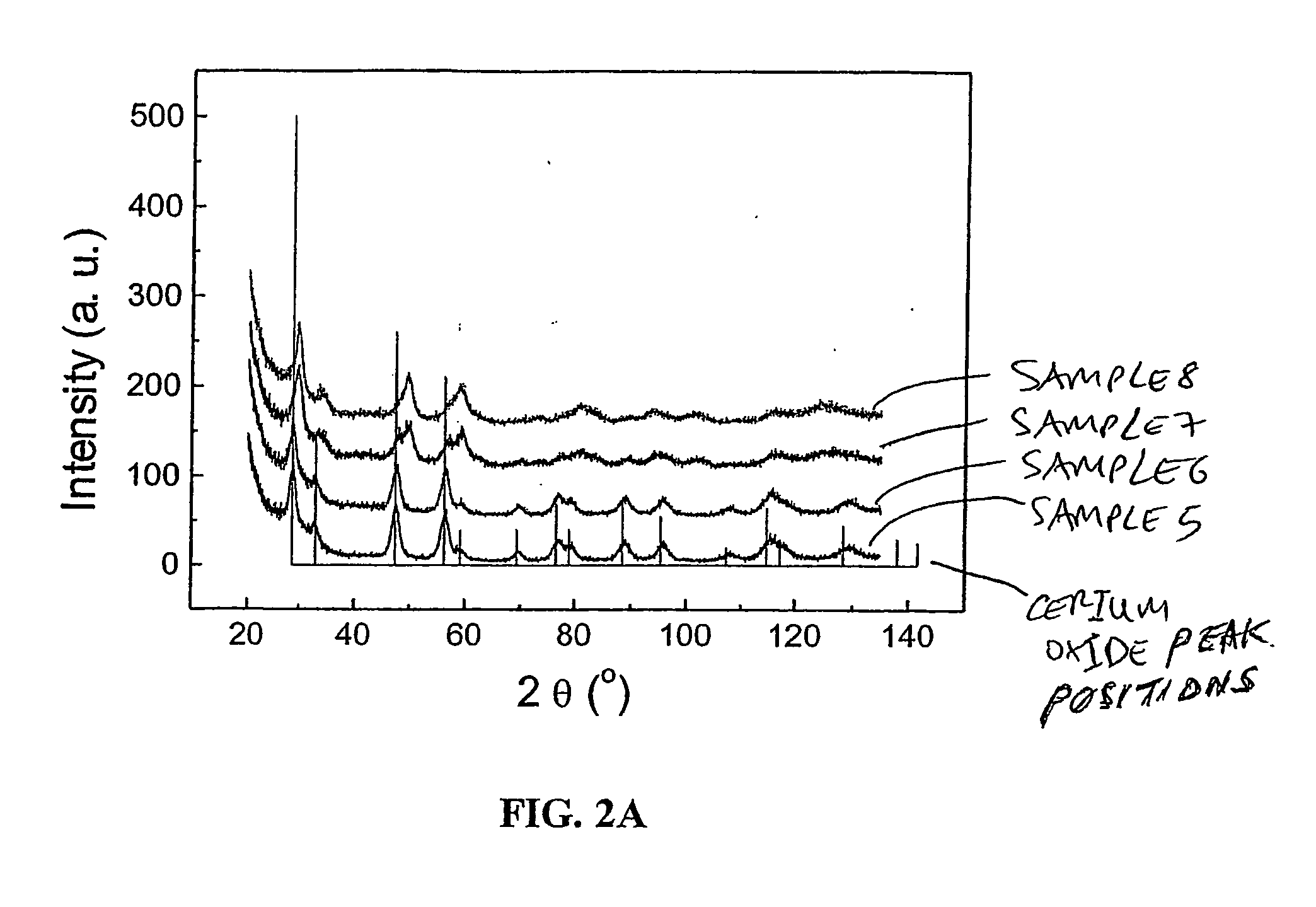

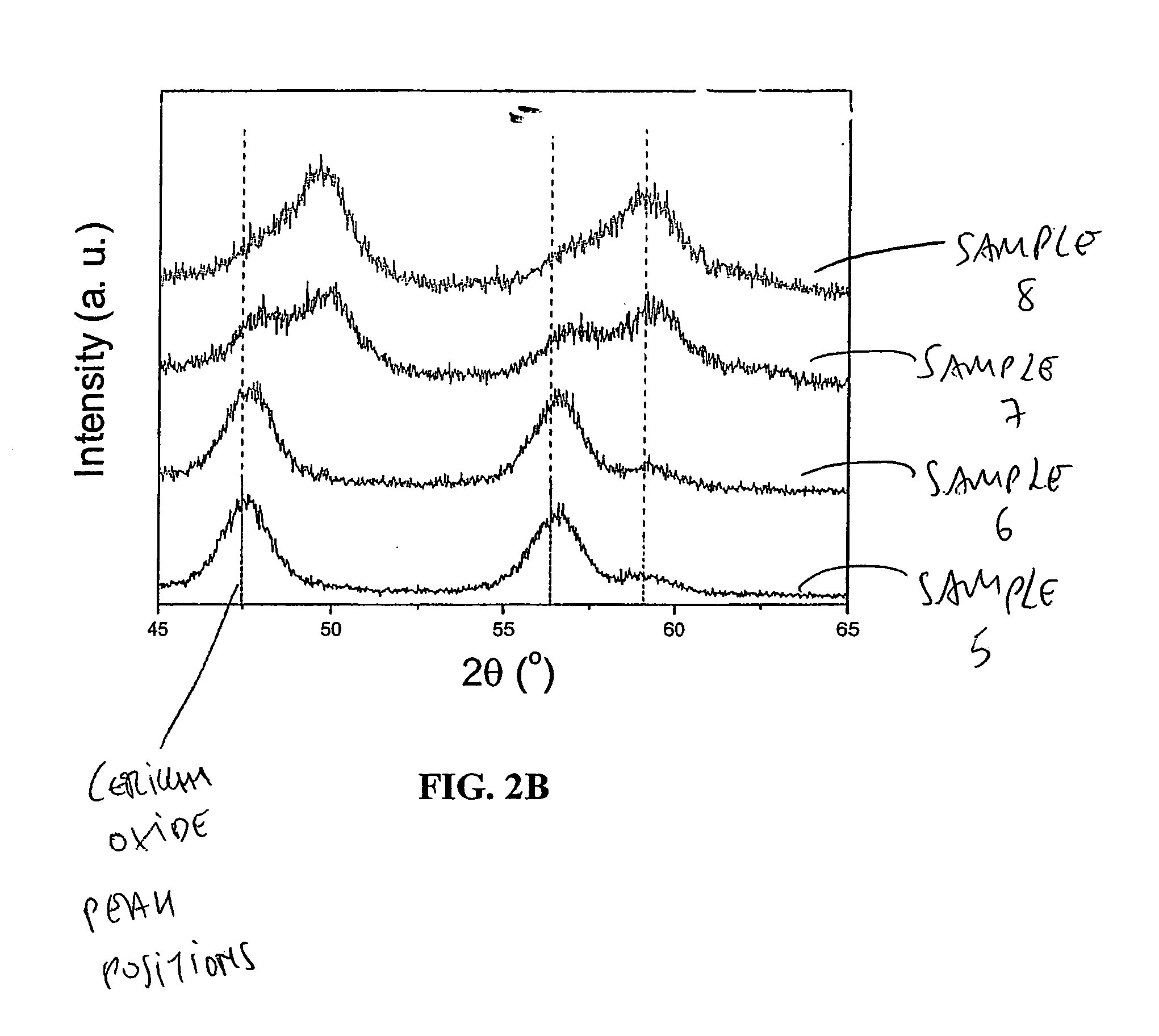

Method for preparing nanoparticles comprising cerium oxide and zirconium

InactiveUS20060057048A1Fast initial mixing rateReaction time is thus limitedMaterial nanotechnologyRare earth metal compoundsCerium nitrateHexamethylenetetramine

This invention provides a method for preparing nanoparticles comprising cerium oxide and zirconium and having a narrow size distribution. The method comprises providing a first aqueous solution comprising zirconium oxychloride and providing a second aqueous solution comprising a first component which is either cerium nitrate or hexamethylenetetramine. The second aqueous solution is added to the first aqueous solution to form a first mixture. A third aqueous solution comprising a second component which is either cerium nitrate or hexamethylenetetramine, and which is different from the first component, is added to the first mixture to form a second mixture. The second mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles are then separated from the second mixture and sintered in air at a temperature ranging between about 500° and about 1100° C. The nanoparticles obtained by the method of the invention are at least in part crystalline.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

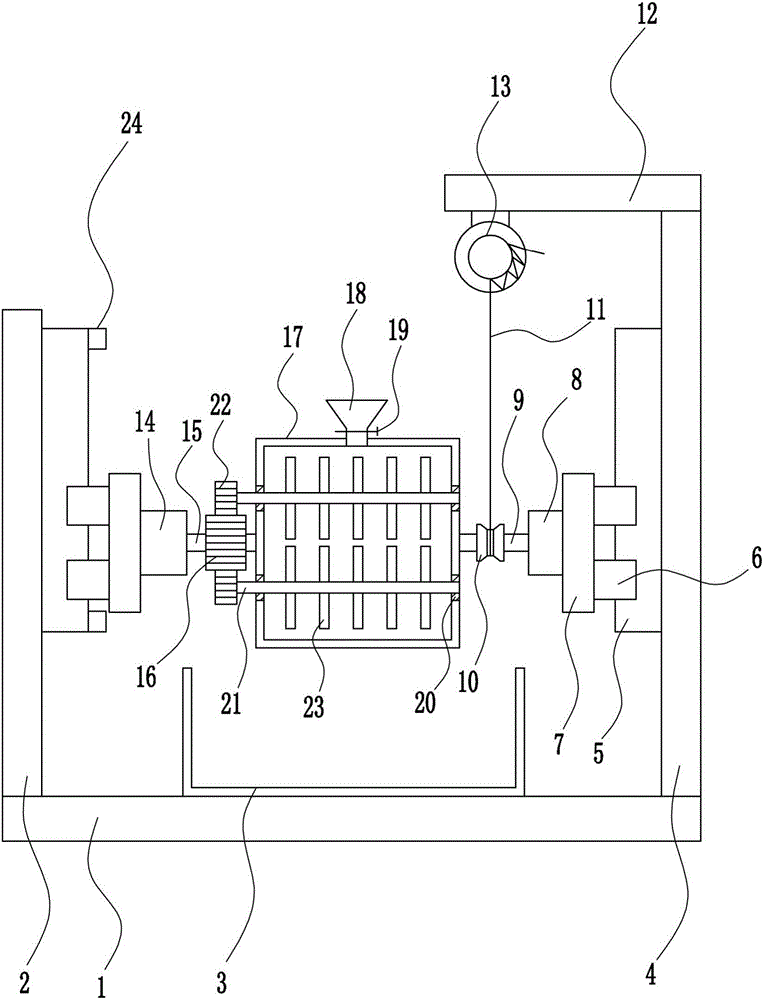

Leather shoe paint spraying pigment mixing device

InactiveCN106964289ADoes not affect the effect of spray paint effectFast mixingRotating receptacle mixersShaking/oscillating/vibrating mixersMixing effectPigment

The invention relates to a mixing device, in particular to a leather shoe paint spraying pigment mixing device, and aims to provide a leather shoe paint spraying pigment mixing device which has the effects that time and labor are saved, the mixing speed is rapid, a good mixing effect is achieved, and furthermore the shoe paint spraying effect is not affected. To solve the technical problem, the invention provides the leather shoe paint spraying pigment mixing device which comprises a bottom plate and the like, wherein a support plate is mounted on the right side of the top of the bottom plate in a bolt connection mode; a rotating device is arranged between the support plate and the top of the bottom plate; a holding frame is connected with a rotating part of the rotating device; a uniform mixing device is arranged at the upper part of the left side surface of the support plate; a uniform mixing part of the uniform mixing device is positioned inside the holding frame. The leather shoe paint spraying pigment mixing device has the effects that the time and the labor are saved, the mixing speed is rapid, a good mixing effect is achieved, and furthermore the shoe paint spraying effect is not affected.

Owner:湖州娇斯登鞋业有限公司

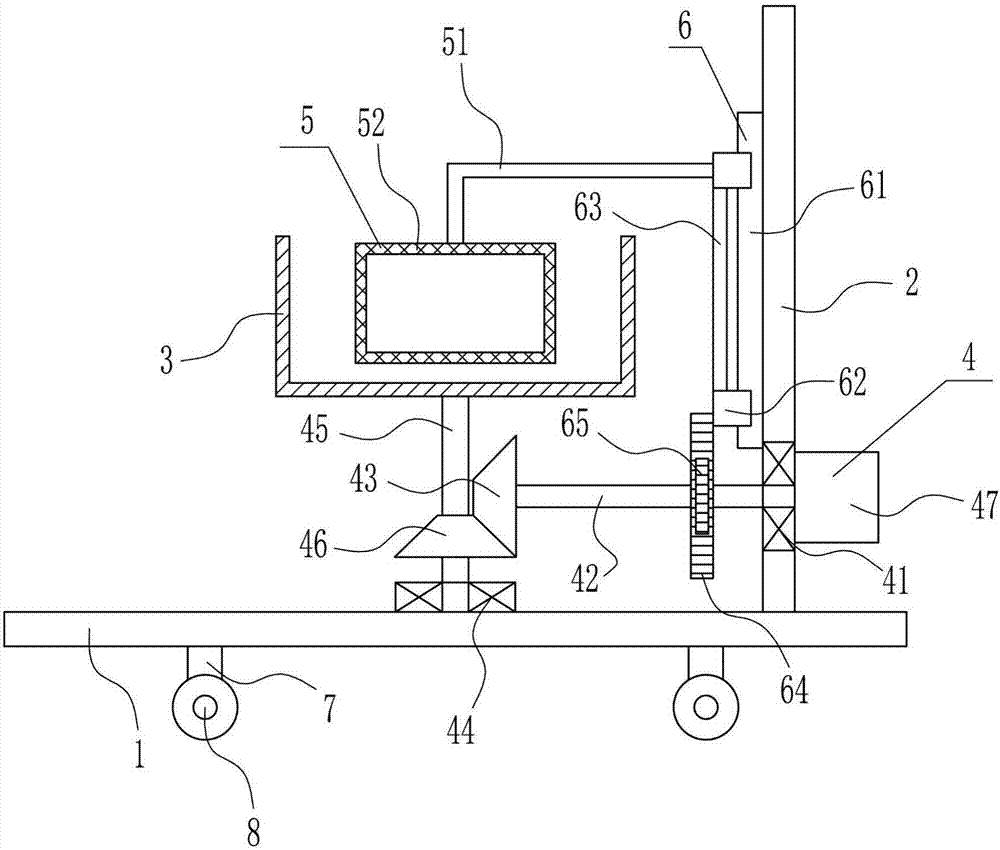

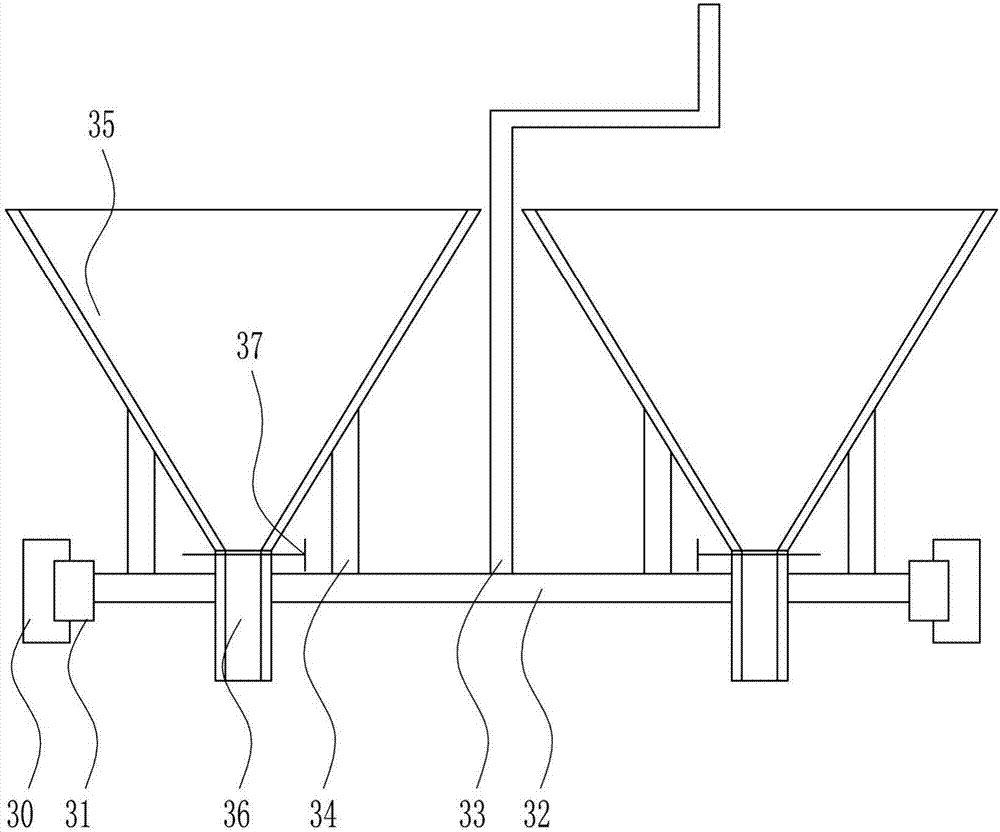

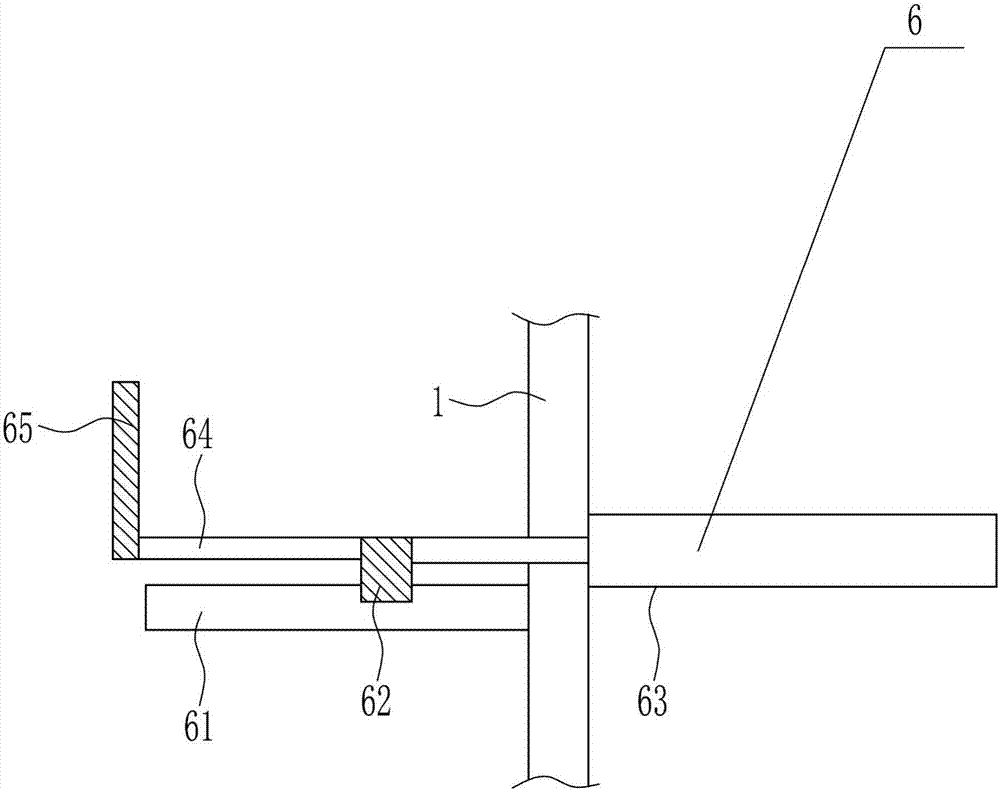

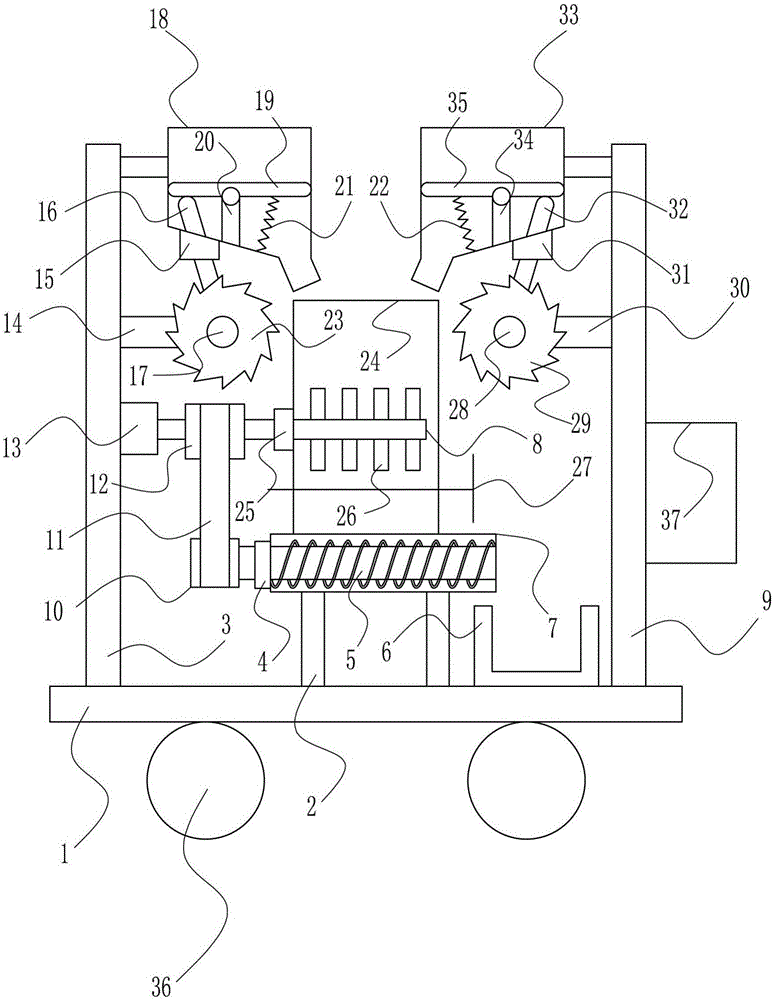

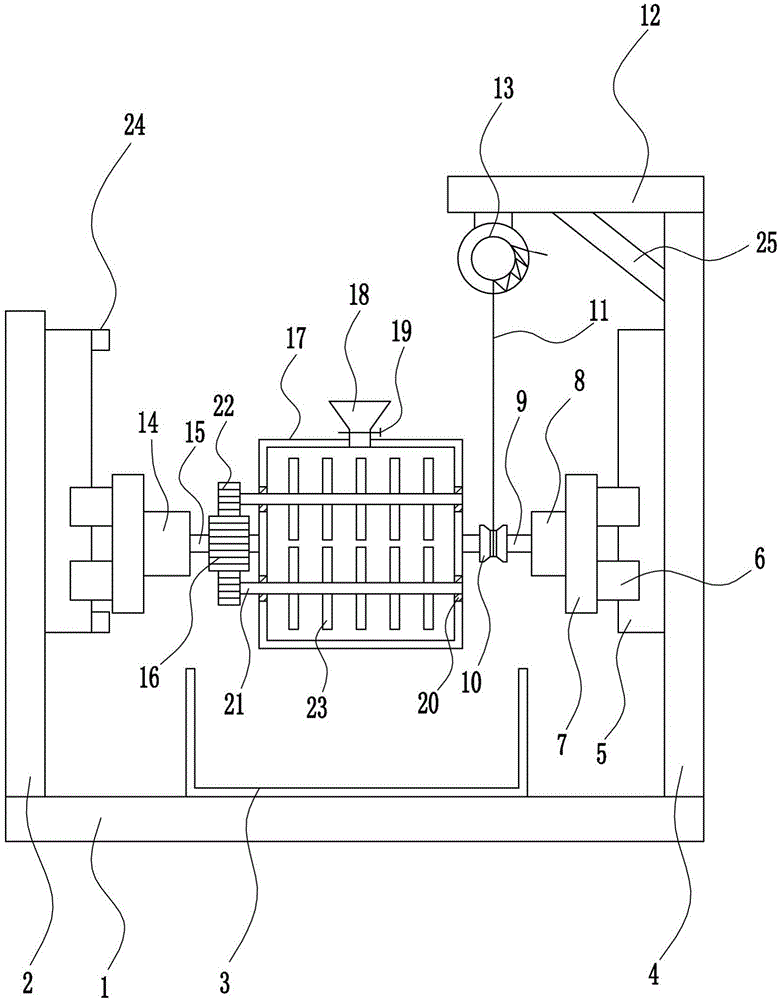

Feed-and veterinary-drug fast mixing device for chicken farms

InactiveCN106345336AWell mixedFast mixingTransportation and packagingRotary stirring mixersDrive wheelEngineering

The invention relates to a fast mixing device for chicken farms, in particular to a feed-and veterinary-drug fast mixing device for the chicken farms with an aim to technically obtain the chicken-farm feed-and veterinary-drug fast mixing device uniform in mixing, fast in mixing and simple in structure. The feed-and veterinary-drug fast mixing device comprises a bottom plate, a left frame, an electric wheel, a first slider, a second slide rail, a second slider, a driven wheel, a first retaining plate, a fixed pulley, a first slide rail, a sliding shaft and the like; first springs are symmetrically arranged on the left top side of the bottom plate, a mixing frame is arranged at tops of the first springs, and bearing seats are symmetrically arranged on the middle portion of the left wall and the right wall of the mixing frame. By the arrangement, effect of even mixing, high mixing speed and simple structure is achieved, and the feed-and veterinary-drug fast mixing device is low in manufacturing cost, reasonable in structure, easy to maintain and repair, convenient in use, low in investment of manpower and material resources and low in cost.

Owner:邵鹏程

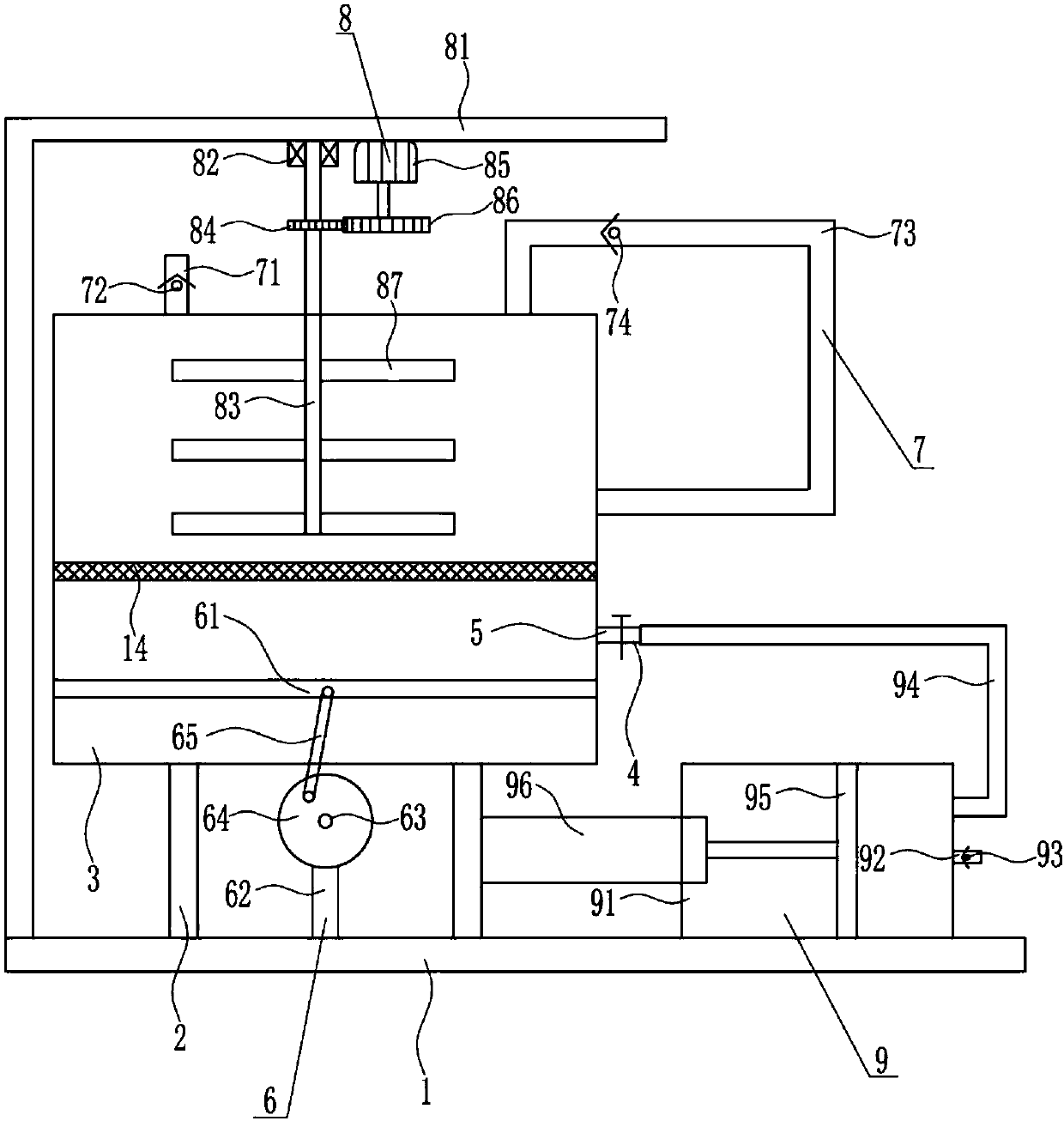

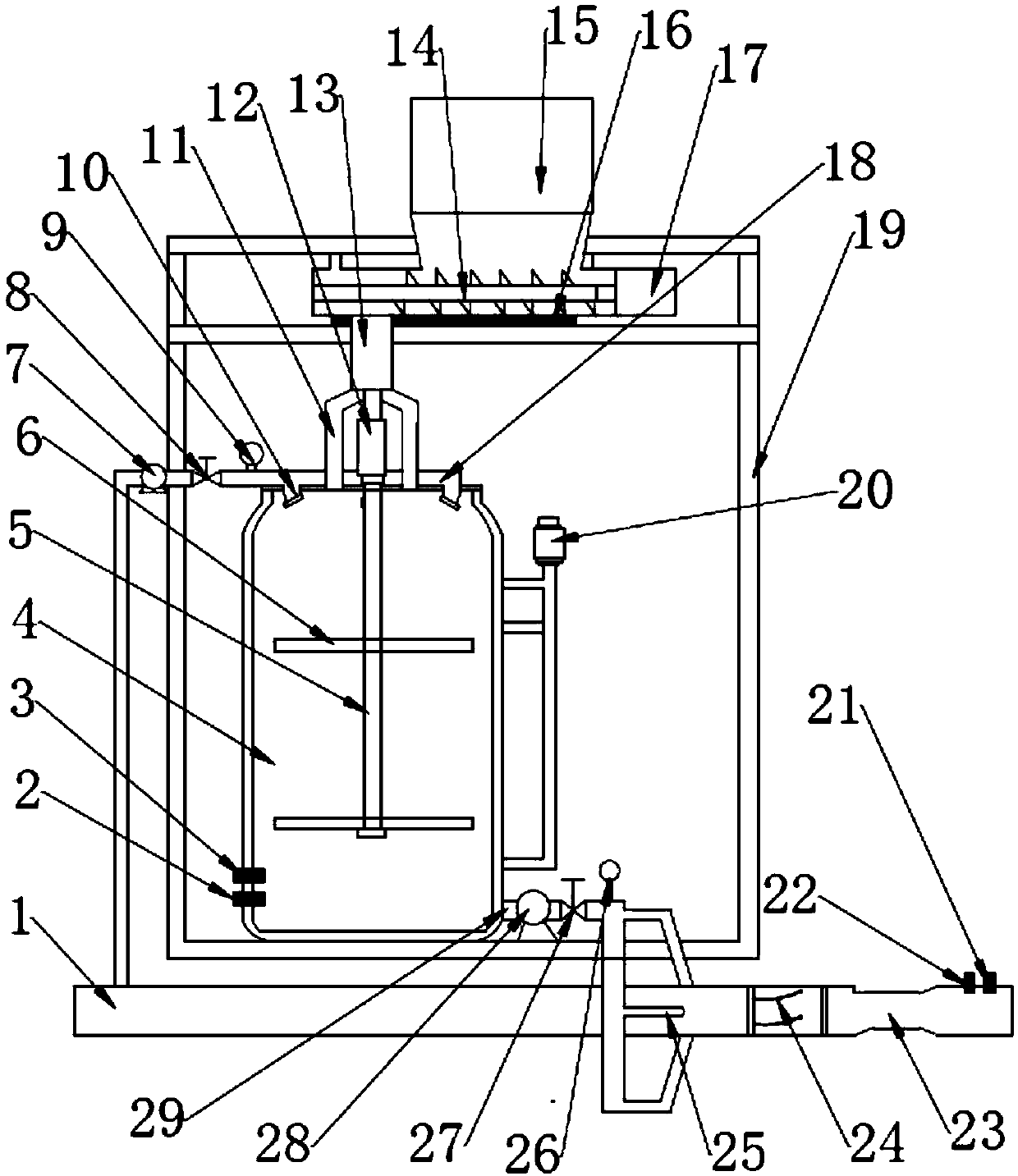

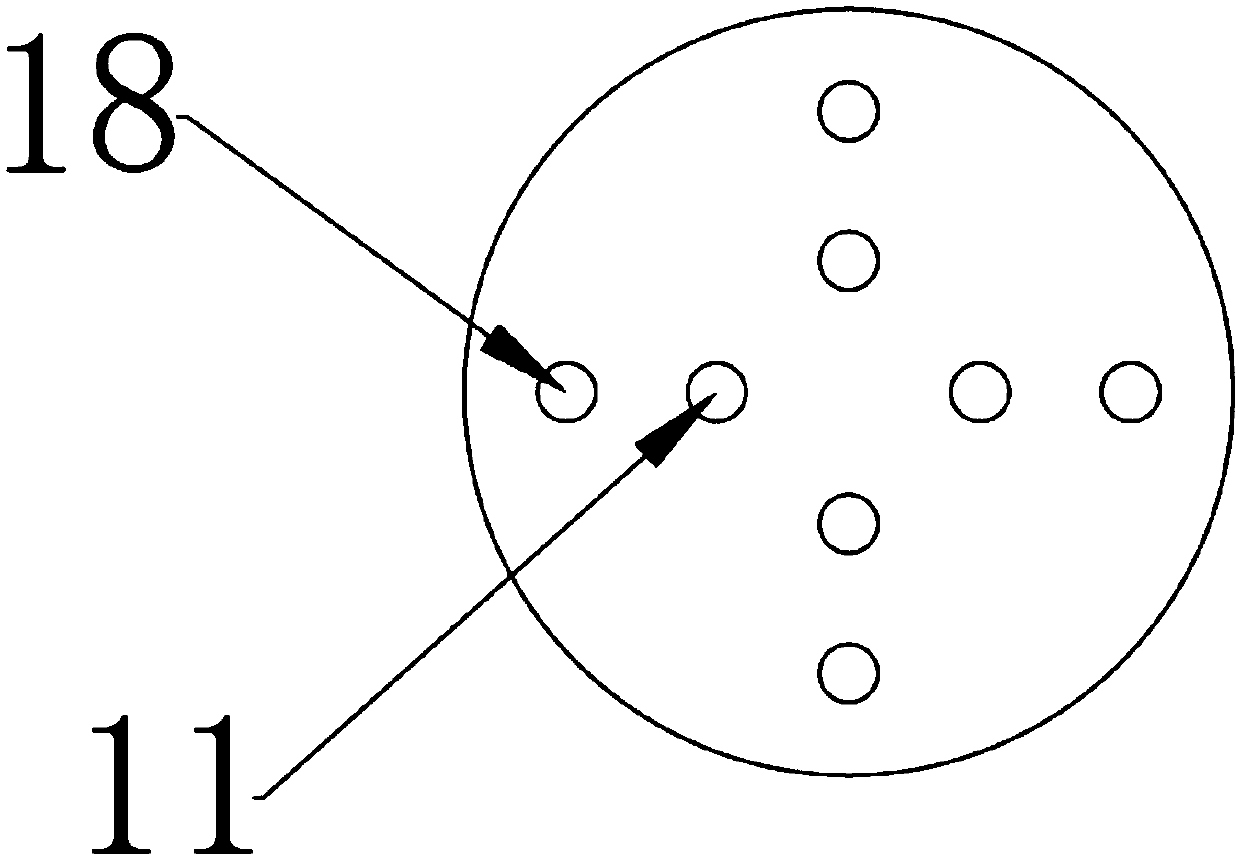

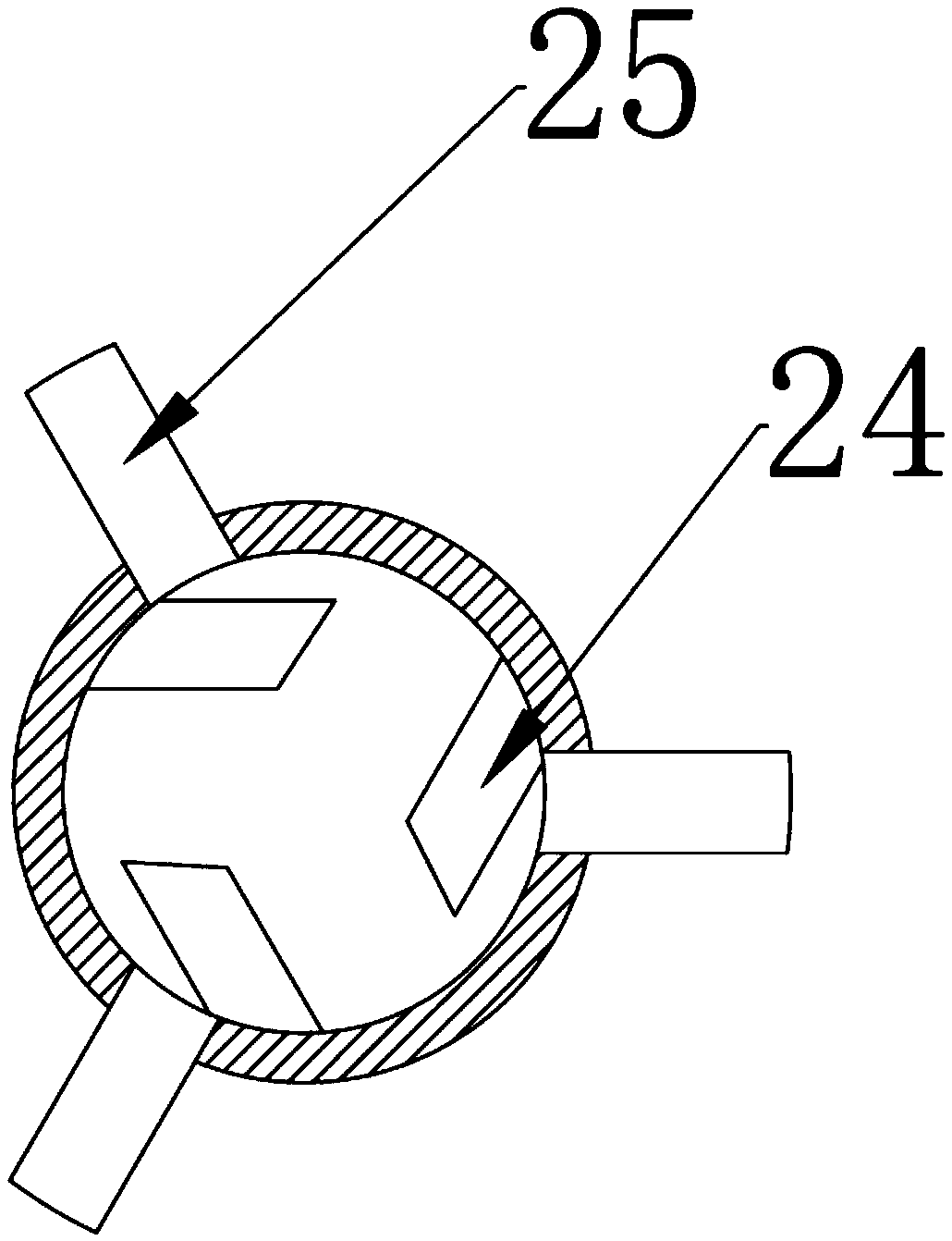

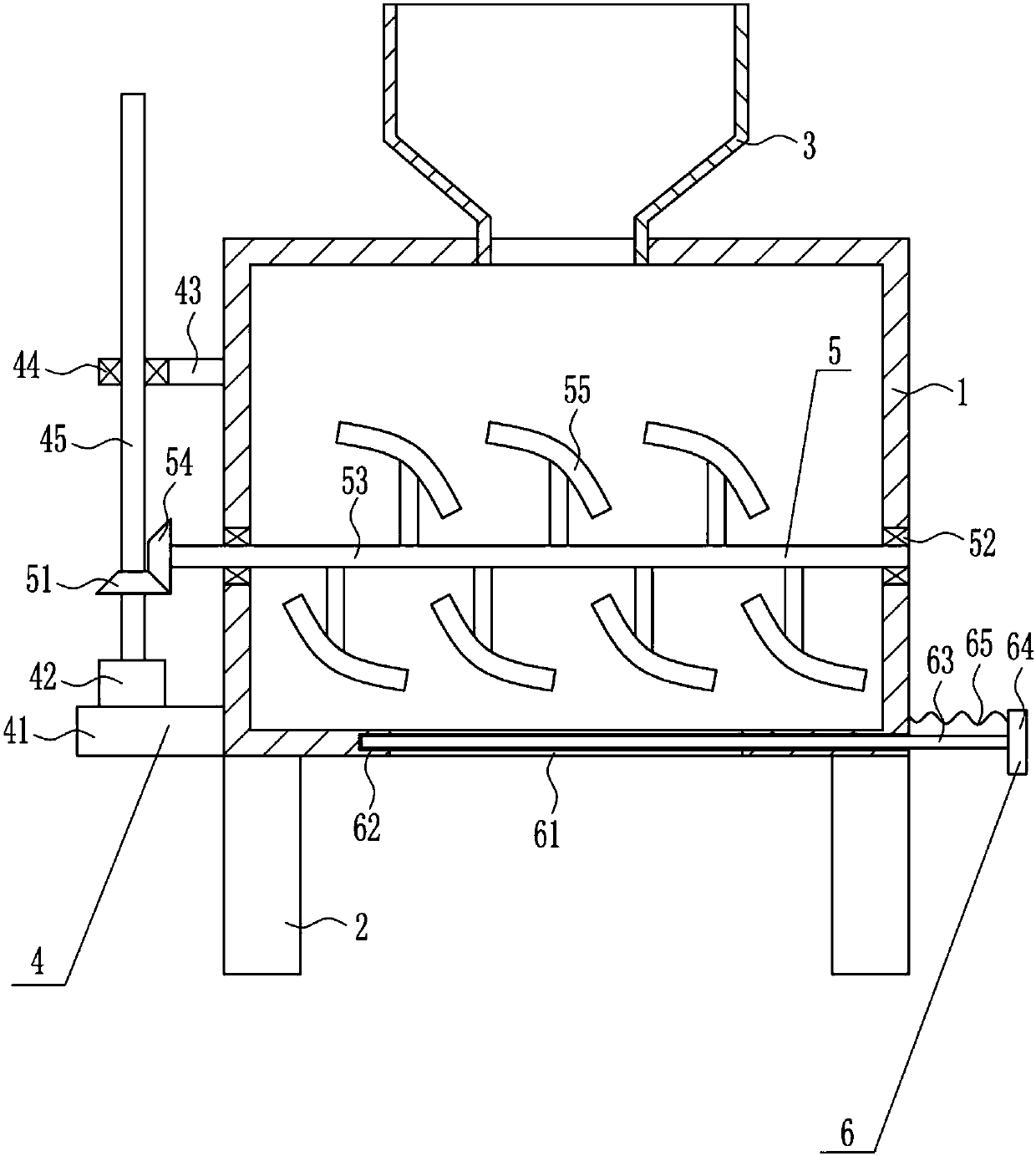

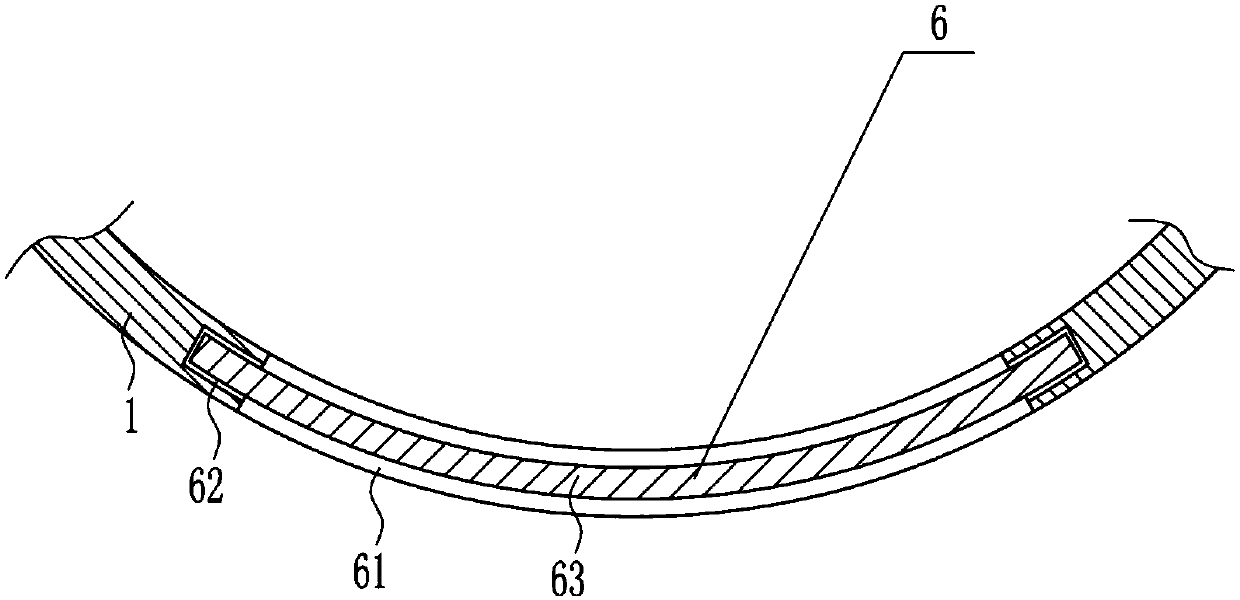

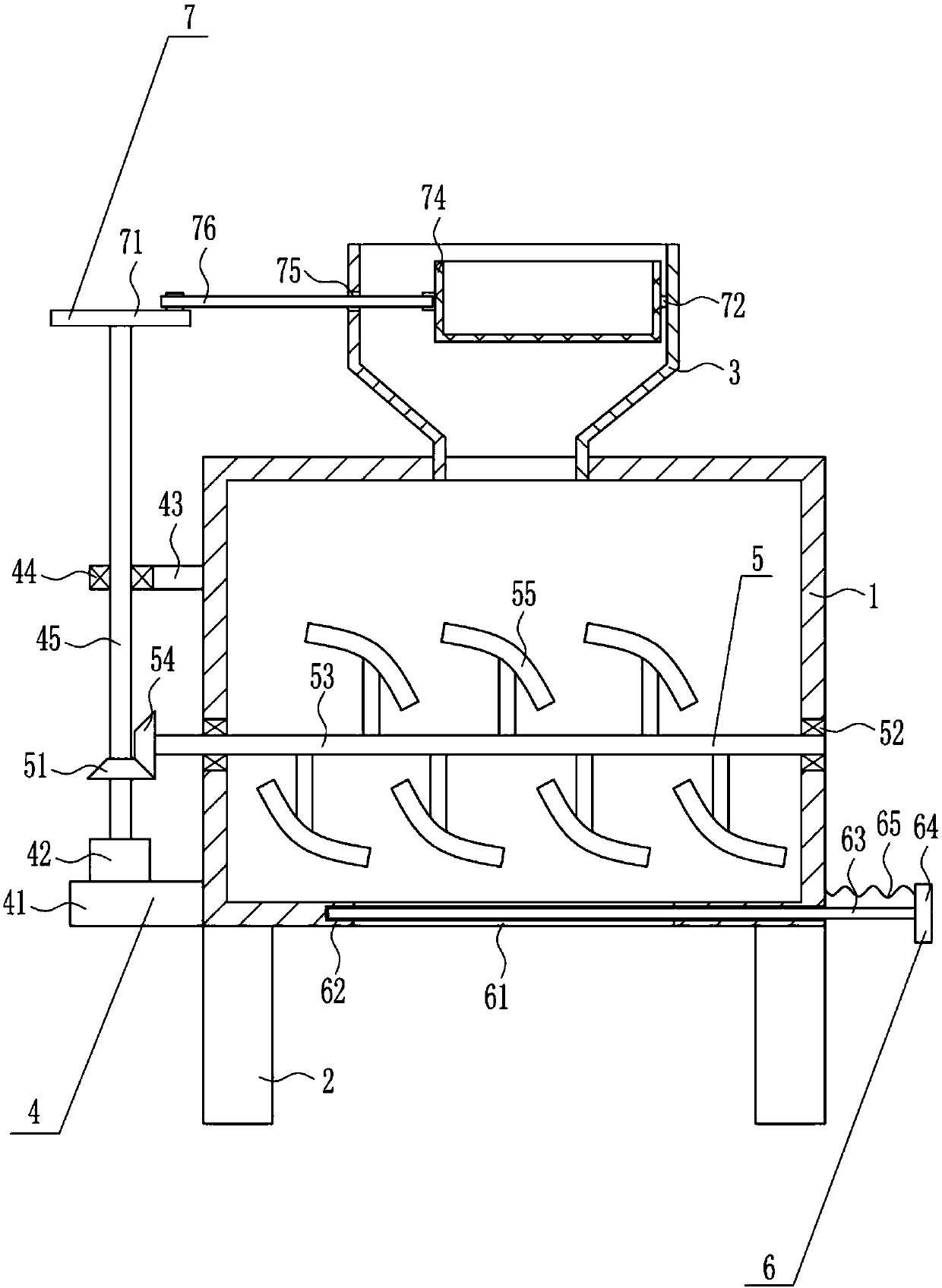

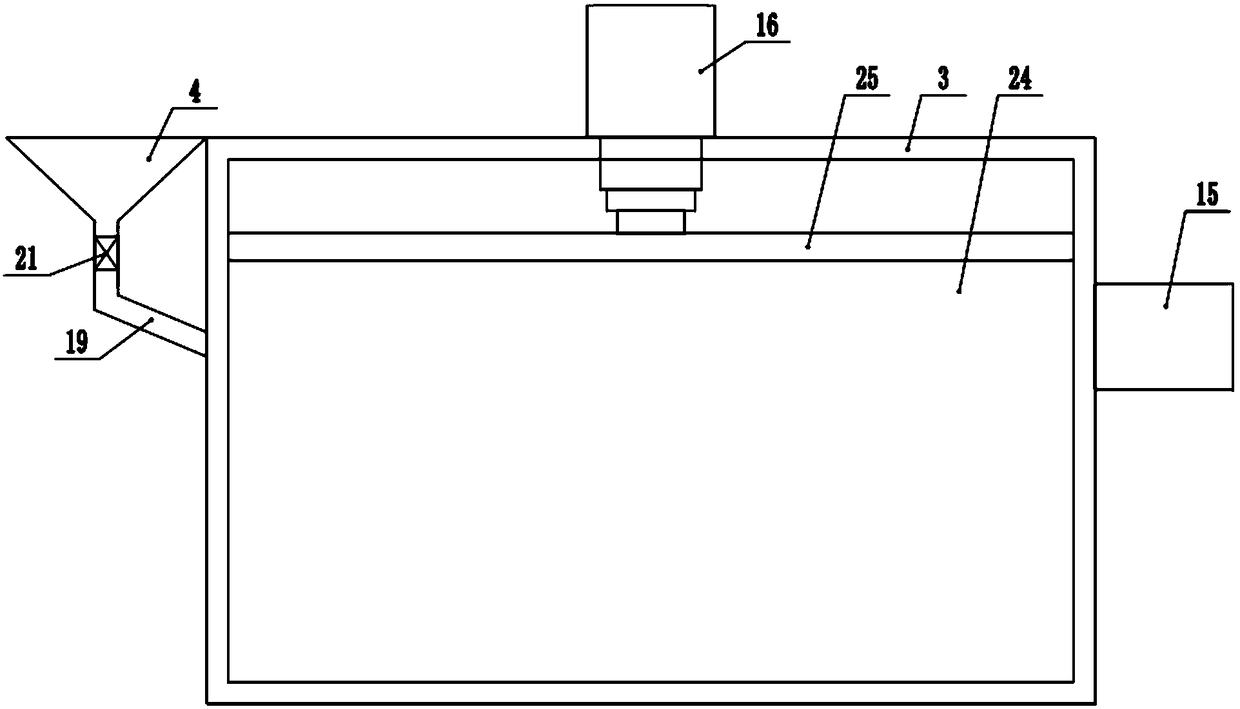

Continuous water-fertilizer-integrated solid fertilizer applying device

PendingCN109618634AFast dissolutionIncreased turbulenceRotary stirring mixersTransportation and packagingFertilizerMother liquor

The invention relates to a continuous water-fertilizer-integrated solid fertilizer applying device. The device comprises a fertilizer adding device, a mother liquor tank, an irrigation water pipe, a fertilizing pipe, a water inlet pipe, a bracket and a control system, wherein a fertilizer discharging port of the fertilizer adding device is connected with the top of the mother liquor tank through afertilizer adding pipe, the fertilizer adding pipe is connected with the top of the mother liquor tank through a plurality of fertilizer branch pipes, the water inlet pipe is communicated with a plurality of sprayers arranged on the top of the mother liquor tank, the fertilizing pipe is sequentially provided with a fertilizing pump, a fertilizing electromagnetic valve and a fertilizing flowmeter,and the fertilizing branch pipes are uniformly communicated with the irrigation water pipe. The continuous solid fertilizer applying device has the advantages that the speed of dissolving and mixingthe solid fertilizer is high, fertilization liquid is uniformly mixed with irrigation water, and the mixing speed is high; by directly detecting the concentration of the fertilizer in the water afterfertilization, fertilization control is more accurate, adjustment is more rapid, and the precision of fertilization and irrigation can be effectively improved.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

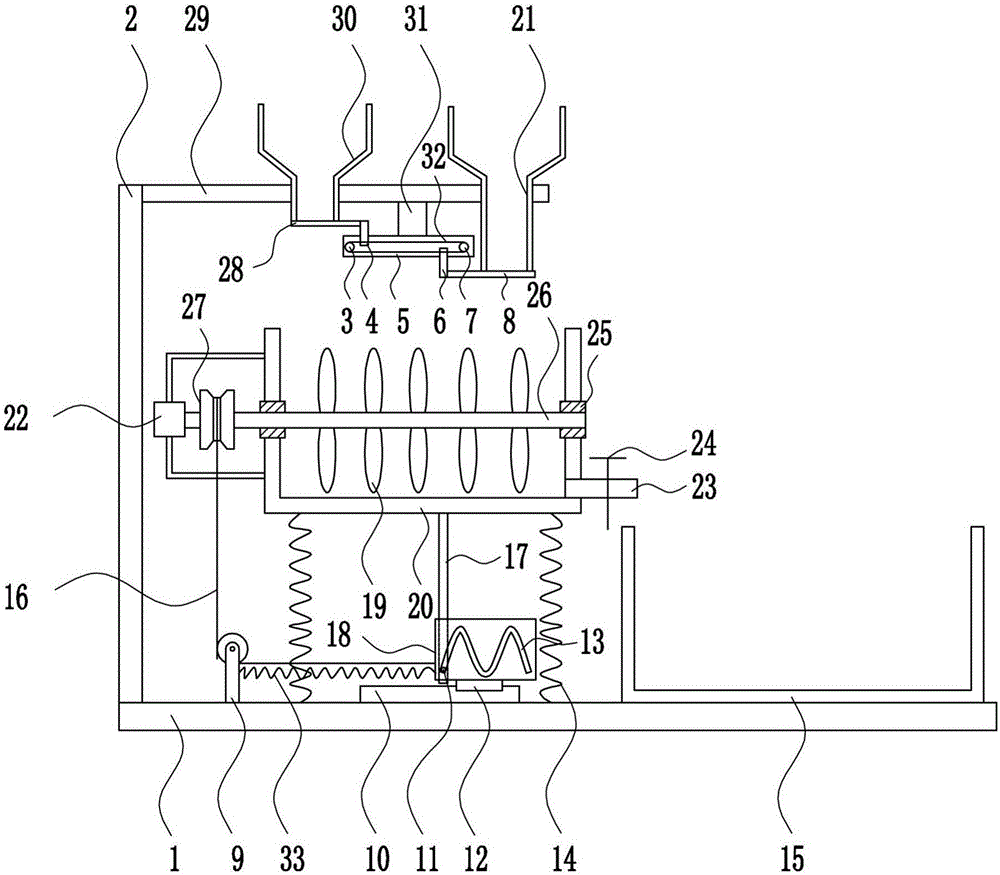

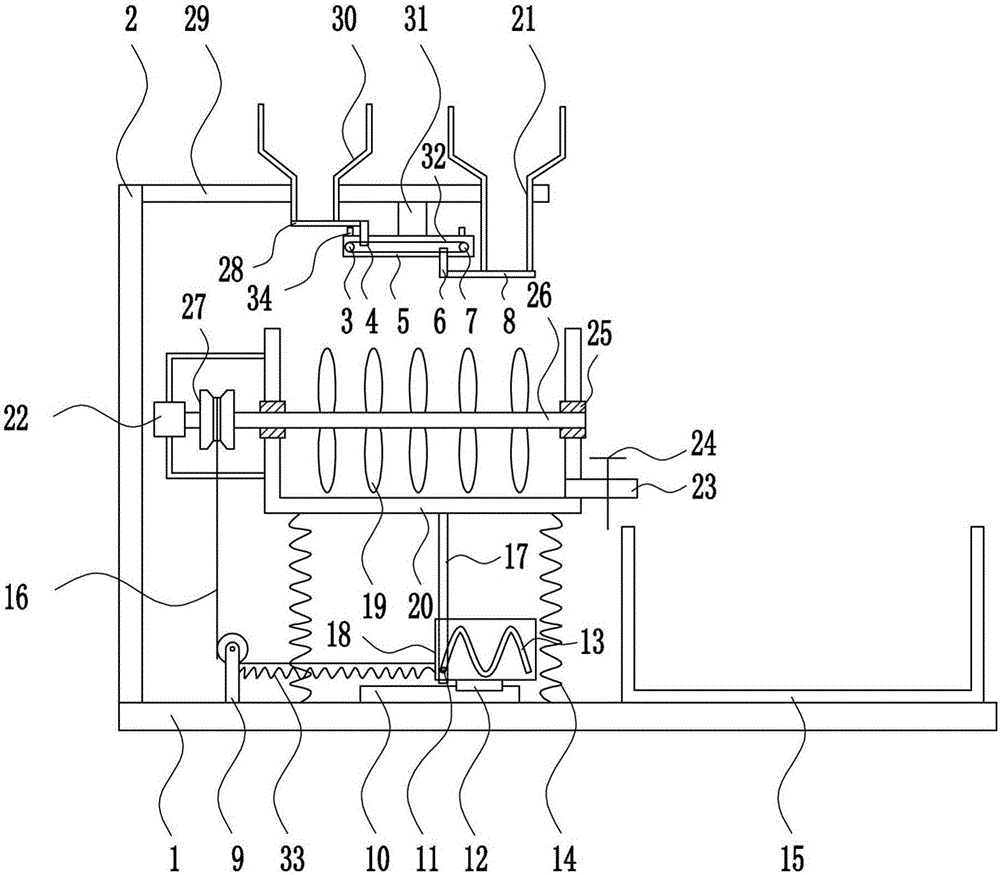

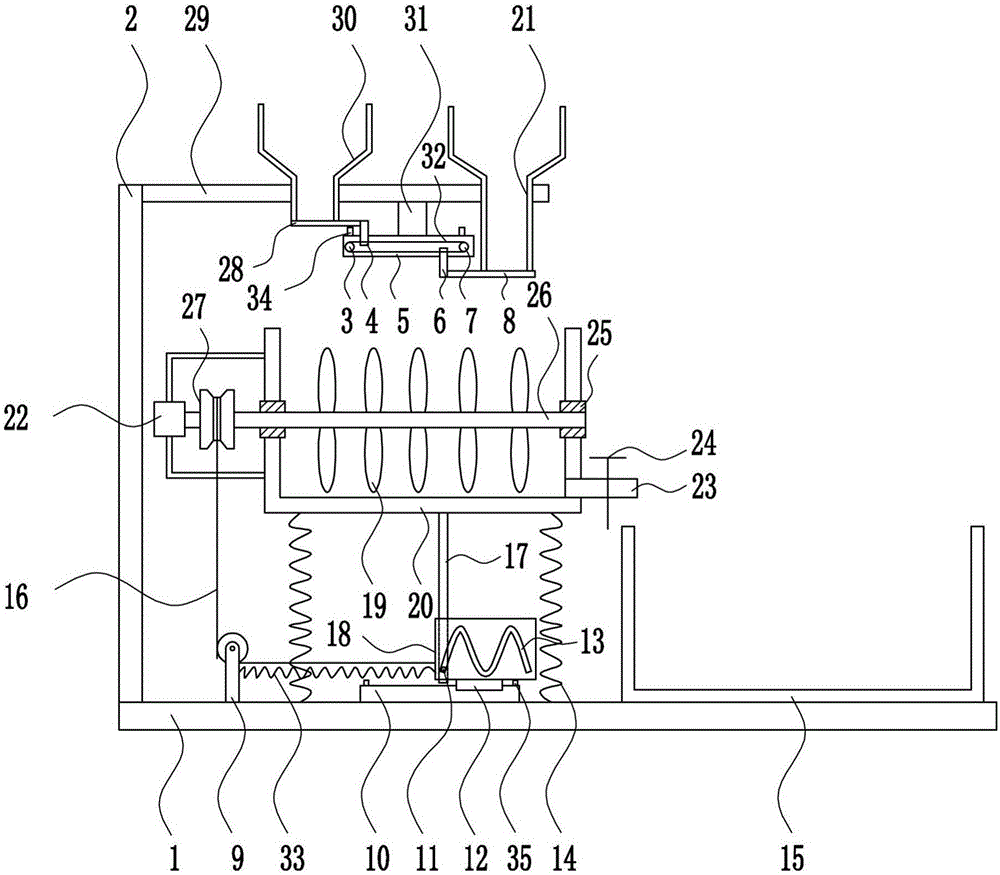

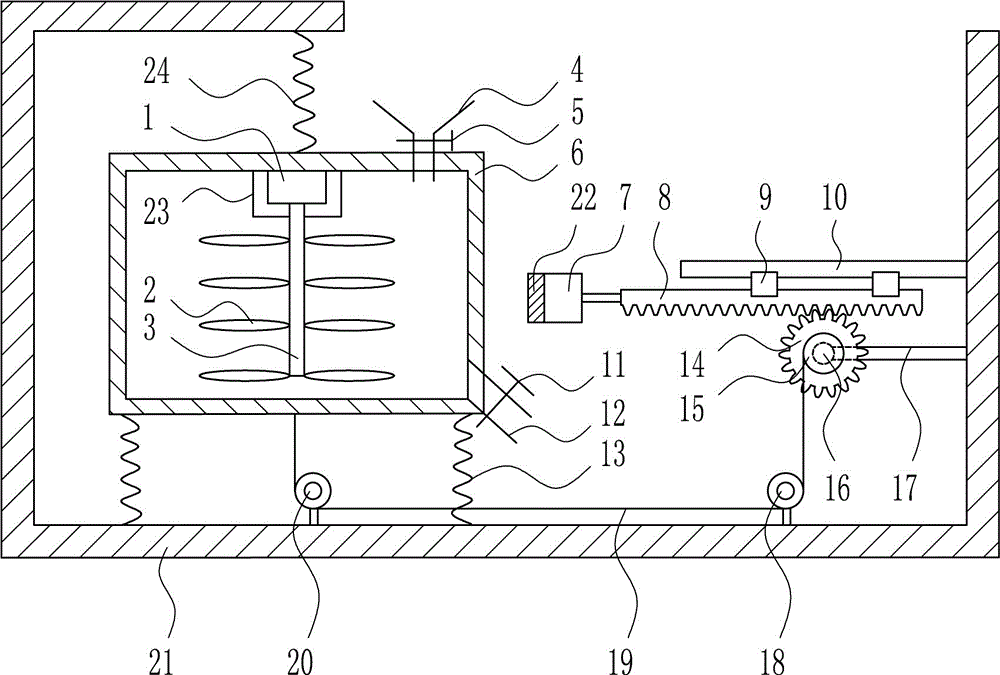

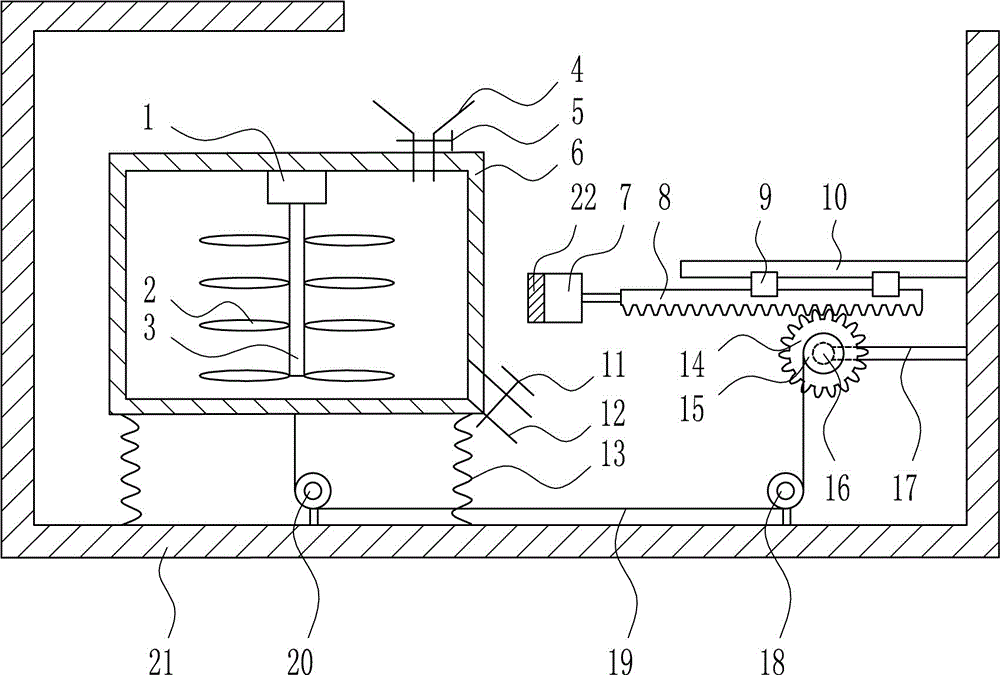

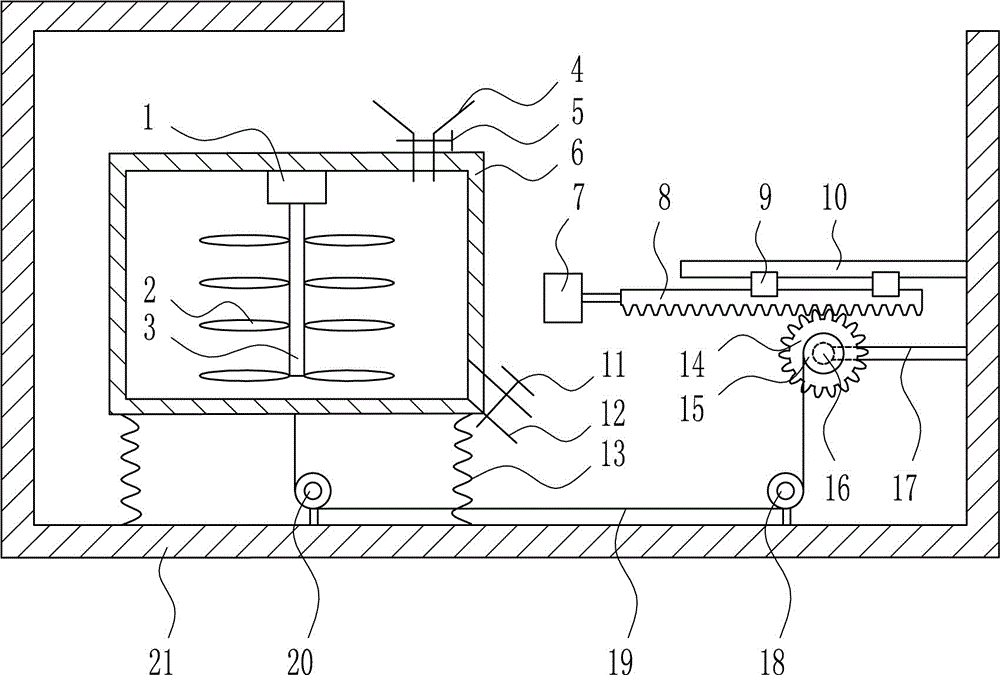

Rare earth raw material high-accuracy uniform mixing device

InactiveCN106732091AWell mixedFast mixingShaking/oscillating/vibrating mixersTransportation and packagingMetallurgyRare earth

The invention relates to a uniform mixing device, in particular to a rare earth raw material high-accuracy mixing device, and aims to solve the technical problem to provide the rare earth raw material high-accuracy mixing device which is in uniform mixing. The rare earth raw material high-accuracy uniform mixing device comprises a first motor, rotating blades, a rotating shaft, a feed hopper, a first electric control valve, a material mixing box, a knocking block, a gear rack, sliding blocks, a sliding rail, a second electric control valve, a material outlet valve, a first spring, a gear, a winding wheel, a second motor, a supporting rod, a first fixed pulley, a bracing wire, a second fixed pulley and a support, wherein the first spring, the second fixed pulley and the first fixed pulley are arranged at the inner bottom part of the support. According to the rare earth raw material high-accuracy uniform mixing device provided by the invention, the effects of uniform mixing, time and labor saving and simpleness in operation are achieved; the material mixing box can be shaken left and right and can move up and down, so that rare earth can be uniformly mixed, the mixing speed is fast, a large amount of manpower and material resources can be saved, and the mixing efficiency of a rare earth raw material is increased.

Owner:邱艳

Fodder mixing device for livestock raising

The invention relates to a mixing device, in particular to a fodder mixing device for livestock raising and aims to provide a fodder mixing device for livestock raising. For solving the technical problem, the fodder mixing device for livestock raising comprises a fodder mixing box and the like. A fodder mixing box is arranged at the top of a first support, a first through hole is formed in the bottom of the fodder mixing box, a feeding device is arranged at the top of the fodder mixing box, and a stirring device is arranged in the fodder mixing box. The fodder mixing device achieves the effects of even mixing, higher mixing speed and convenient mixing. When a user needs to take out mixed fodders, and an air cylinder is started firstly, stretches to drive a first sliding block to move up.

Owner:谢陈钗

Preparation method of powdered oil feed

The invention relates to a feed, in particular to a preparation method of a powdered oil feed. The preparation method mainly solves the technical problems that the powdered oil feed in the prior art is easy to melt, oxided and deteriorated and is difficult to preserve, a carrier of the traditional oil powder is a non-nutritive substance such as furfur, corn (cob) flour, modified starch, powder fiber and the like, only fat is provided, other nutritional ingredients are low, and the powdered oil feed can only serve as energy feed on an aspect of animal demand. By a special method, the carrier in the oil powder is replaced to animal and vegetable protein from the non-nutritive substance. The method comprises the following steps of: adding and mixing animal fat and vegetable fat according to proportion; adding an emulsifier into a mixture according to proportion, and performing high-speed emulsification; homogenizing the emulsified mixture by a homogenizing machine; and adding animal protein, vegetable protein, vitamin, mineral substances and trace elements into the homogenized mixture according to proportion, mixing in a solid-liquid stirring and mixing machine; and packaging.

Owner:HANGZHOU XIANGBAO FEED

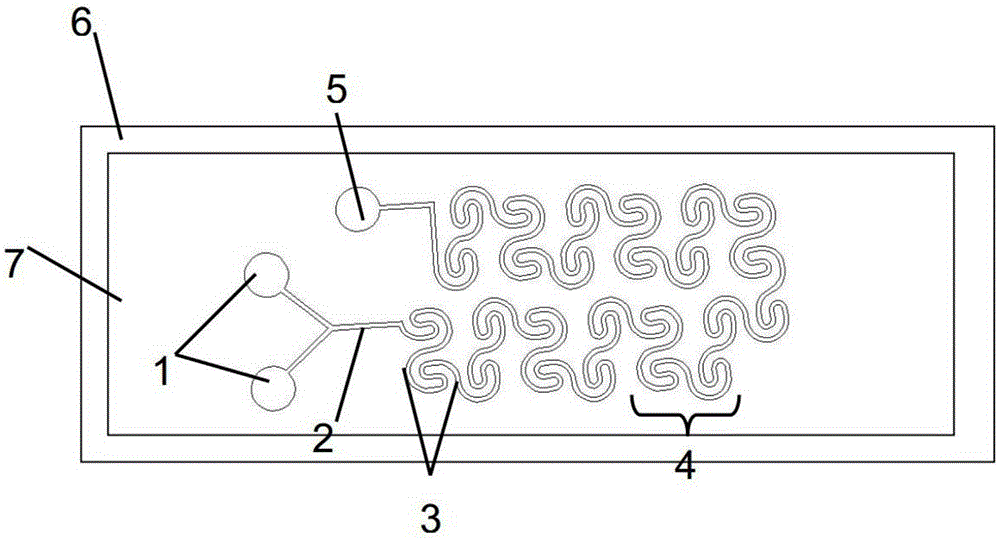

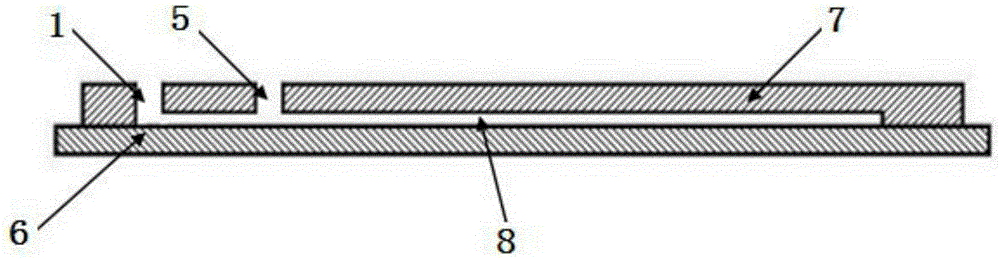

Distorted arc-shaped micro mixer based on enhanced secondary flow effect

The invention provides a distorted arc-shaped micro mixer based on an enhanced secondary flow effect. The micro mixer comprises a plurality of inlets, a mixing pipeline, an arc-shaped bend hybrid matrix and an outlet, wherein the inlets are communicated with one end of the arc-shaped bend hybrid matrix through the mixing pipeline, the other end of the arc-shaped bend hybrid matrix is communicated with the outlet, and the arc-shaped bend hybrid matrix comprises a plurality of arc-shaped bend mixing units which are sequentially communicated. Compared with a common S-type mixing pipeline, the mixing speed of the mixer is increased in a nonlinear mode along with mixing length increase.

Owner:SHANGHAI JIAO TONG UNIV

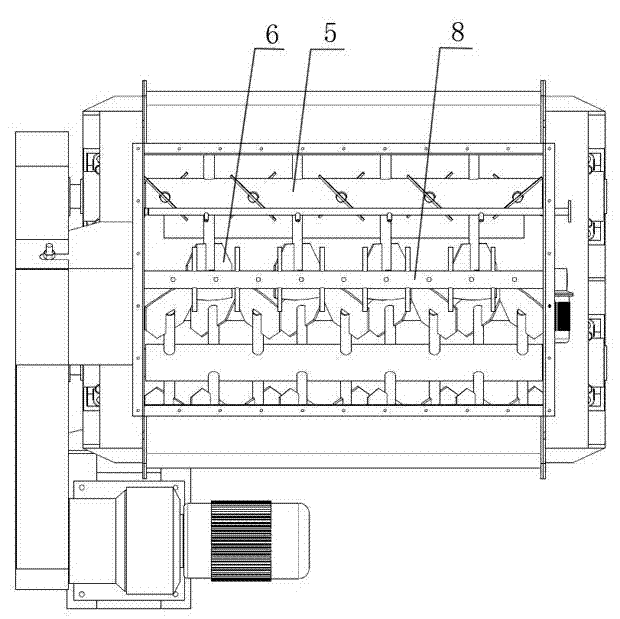

Mixing device for producing fermented feed

InactiveCN107930438AShorten the timeImprove the mixing effectFeeding-stuffRotary stirring mixersTime efficientEngineering

The invention relates to a mixing device, and particularly relates to a mixing device for producing a fermented feed. The invention aims to solve the technical problem and provide a time-saving mixingdevice for producing the fermented feed with a good mixing effect and rapid mixing speed. In order to solve the technical problem, the invention provides such a mixing device for producing the fermented feed. The mixing device comprises a box and the like, wherein support legs are vertically mounted at four corners of the bottom of the box; a blanking hopper is mounted at the middle part of the top of the box, and is communicated with the box; a driving device is arranged on the left side face of the box; a stirring device is arranged at the lower part of the inside of the box; the driving device is matched with the stirring device; a discharging device is arranged at the bottom of the box. According to the mixing device for producing the fermented feed, the driving device is used for driving the stirring device to stir raw materials of the feed, and the discharging device is used for discharging the stirred raw materials of the feed, so that the effects of saving time and achieving the good mixing effect and rapid mixing speed are achieved.

Owner:张景云

Blast-injecting forced-advancing full pre-mixing energy-saving combustor

The invention provides a blast-injecting forced-advancing full pre-mixing energy-saving combustor which comprises a main cavity, a blast pipe, a fuel gas pipe, a nozzle, a fire distributor and a firing needle, wherein the blast pipe and the fuel gas pipe are connected with the main cavity; the nozzle is connected with the fuel gas pipe; and the fire distributor and the firing needle are arranged at the top of the main cavity. The blast-injecting forced-advancing full pre-mixing energy-saving combustor is characterized in that a screen, a flow fixer and a gas flow mixer are sequentially arranged between the fire distributor and the nozzle in the main cavity; the caliber of the gas outlet end of the flow fixer is smaller than the caliber of a gas inlet end of the flow fixer; the flow mixer is a cylinder of which the diameter corresponds to the internal diameter of the main cavity; and a plurality of gas mixing holes are arranged vertically along the cylinder and the calibers of all gas outlet ends of the gas mixing holes are smaller than the calibers of all gas inlet ends of the gas mixing holes. By adopting the structure, the effects of the high efficiency, the energy conservation and the environment protection are achieved.

Owner:何梅顺

Eco-friendly novel pavement brick raw material quick mixing device

InactiveCN106512814AFast mixingMix thoroughlyTransportation and packagingRotary stirring mixersEnvironmental resistanceBrick

The invention relates to a raw material mixing device and especially relates to an eco-friendly novel pavement brick raw material quick mixing device. The mixing device has a fast mixing rate and full mixing effects and can be conveniently operated. The mixing device comprises a bottom plate, a collecting frame, a support rod, a first electric push rod, stirring blades, a rotating shaft, a motor, a left frame, a first spring, a slide rail, a discharge pipe and a second electric push rod. The left end of the top of the bottom plate is welded to the left frame, the left side of the top of the bottom plate is connected to the first electric push rod through a hinge part, and the right side of the top of the bottom plate is welded to the support rod. The mixing device has the effects of fast mixing speed, full mixed effects and operation easiness. The mixing device has good mixing effects and improves the working efficiency and safety.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

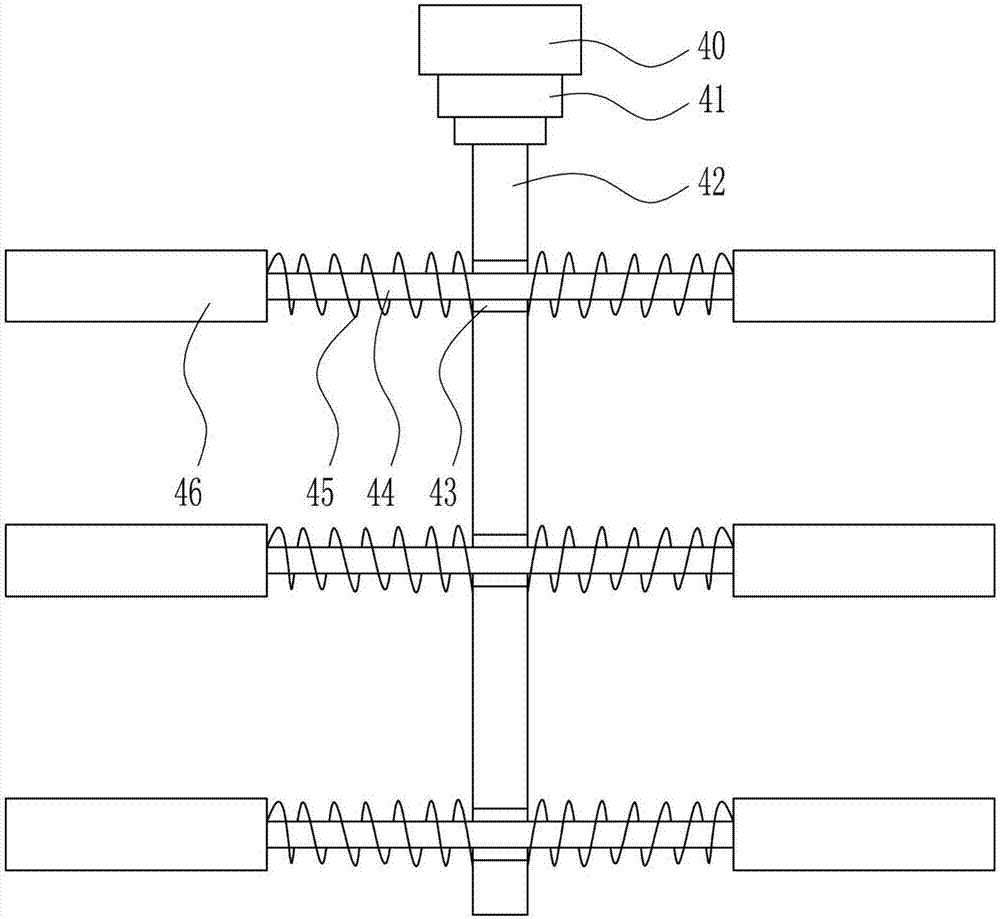

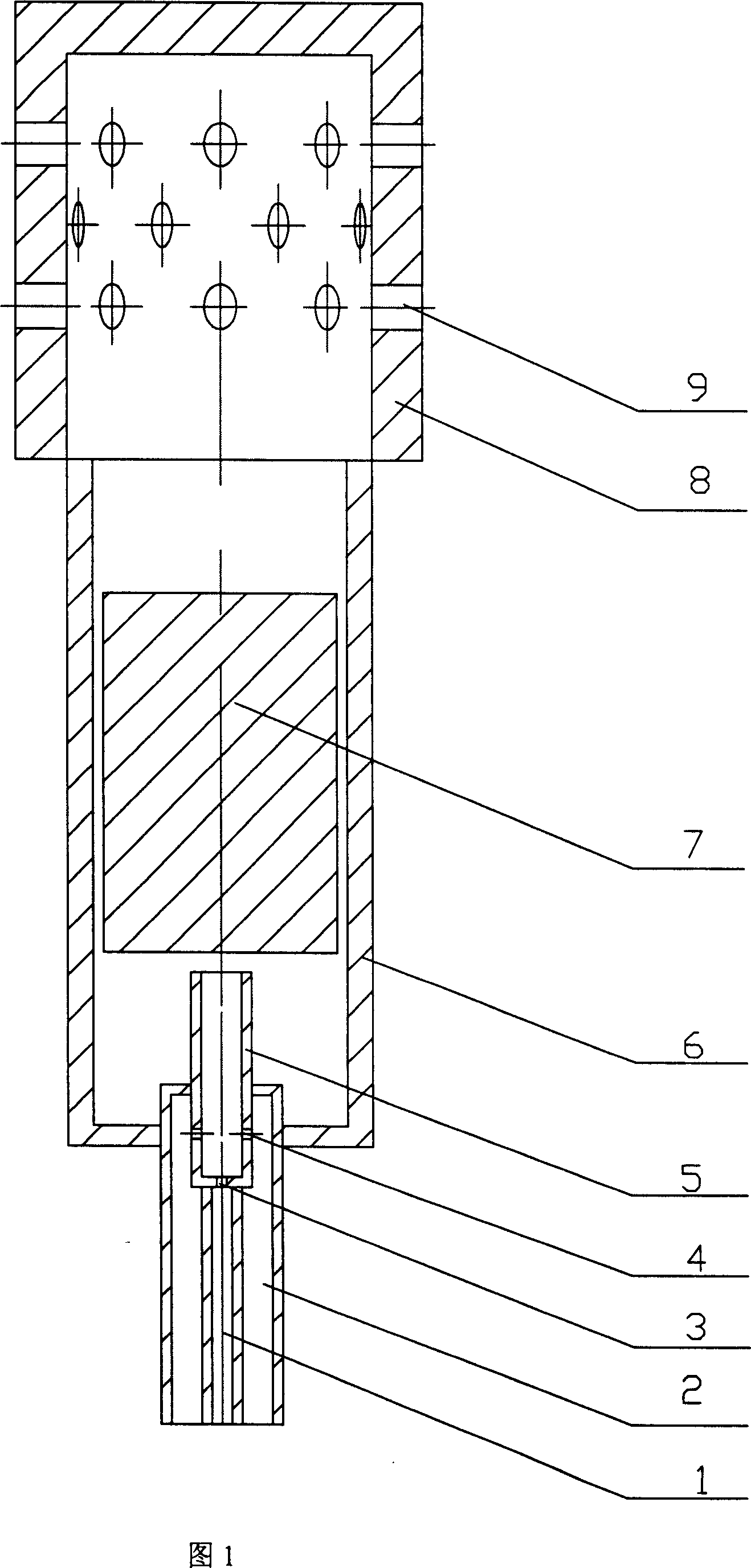

Method for mixing solid powder and liquid and axial flow type mixer therefor

ActiveCN1883907ASpeed up the mixingFast mixingMixing operation control apparatusCement mixing apparatusControl systemVolumetric Mass Density

A process for mixing solid powder and liquid and axial flow mixer therefore are disclosed. The axial flow mixer comprises a solid powder proportioning valve, a liquid proportioning valve, and a mixing head connected together in turn, wherein there are inner chambers in above three parts, and these inner chambers form an vertically-interconnected and hermetic chamber, the solid powder proportioning valve is used for adding the solid powder and adjusting the inlet size; the inner chamber of the liquid proportioning valve is used as a channel for solid powder, and there is another channel to the mixing head from the outside used for adding liquid, and the channel opening size can be adjusted; the mixing head is used for mixing the solid powder and liquid. The process comprises adjusting the valve opening of the solid powder proportioning valve and the liquid proportioning valve, and adding the mixed liquid and solid powder into mixer according to given proportion; mixing firstly in mixing head; spraying the mixed slurry into slurry mixing tank, at the same time, continuously monitoring the density of cement slurry by control system. In the invention, multivariable control can be realized and the solid powder and liquid can be mixed in low energy consumption.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Feed and forage fast mixing equipment for sheep feeding

InactiveCN107006883AWell mixedMix evenly and quicklyFeeding-stuffRotary stirring mixersAnimal ForagingEngineering

The invention relates to feed and forage mixing equipment, in particular to feed and forage fast mixing equipment for sheep feeding. According to the technical aim, manpower can be saved, time can be saved, the mixing speed is high, and even mixing can be achieved. In order to achieve the technical aim, the feed and forage fast mixing equipment for sheep feeding comprises supports and the like; the supports are symmetrically arranged on the left side and the right side, the tops of the two supports are in bolt connection with an N-shaped frame, a guide device is arranged on the top in the N-shaped frame, and a mixing device is arranged on a guide component of the guide device. Forage and feed can be comprehensively, evenly and fast mixed in the mode that blades rotate and move left and right at the same time.

Owner:谢南林

Gas burning premixing high speed burning nozzle

ActiveCN1987199AHigh strengthEasy to adjust combustionGaseous fuel burnerCombustion chamberSolid particle

A high-speed burner with air-gas pre-mixing function for directly heating the fluidized solid particles is composed of the coaxially arranged gas tube, air tube and pre-mixing chamber, a mixing-igniting chamber containing high-temp porous ceramic catalyst, and a combustion chamber with cylindrical cap shape and fume outlet orifices on its side wall.

Owner:中科合肥煤气化技术有限公司

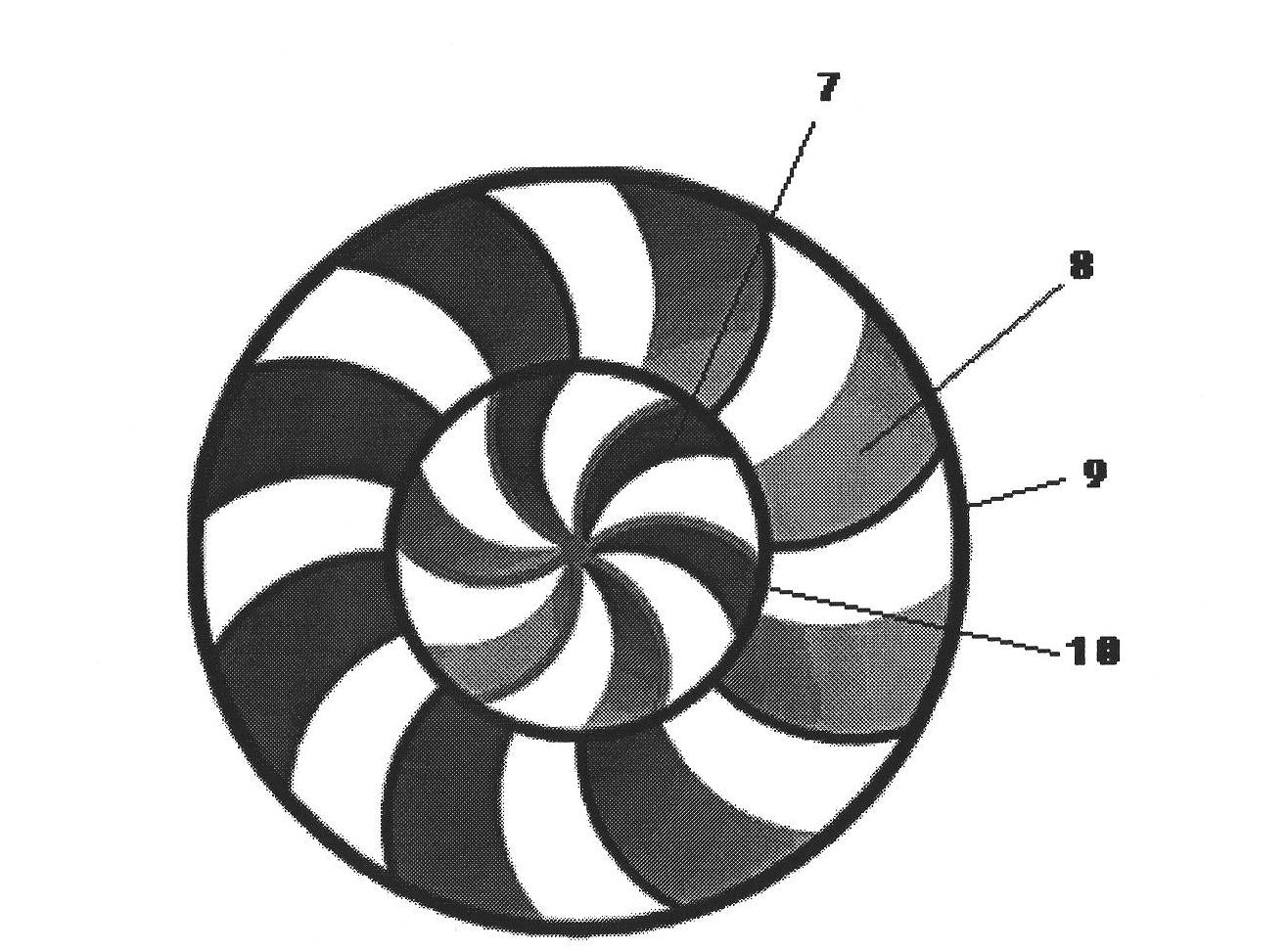

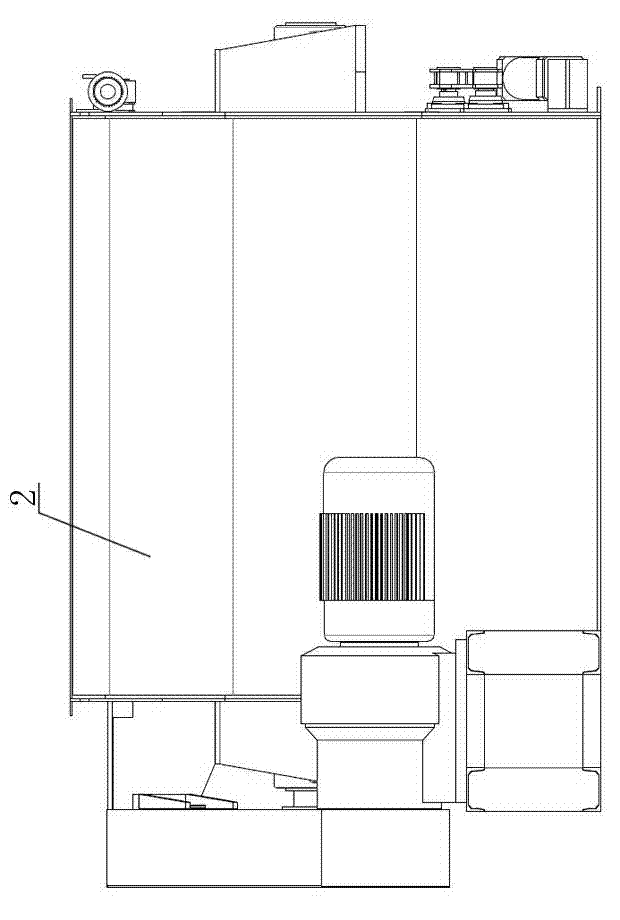

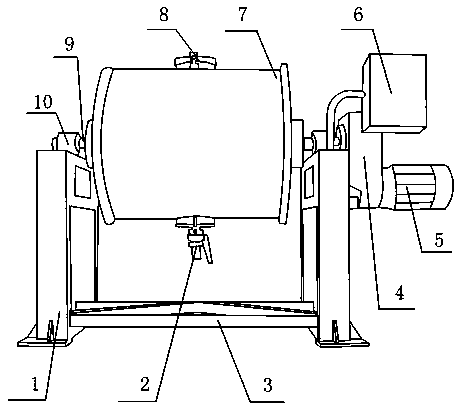

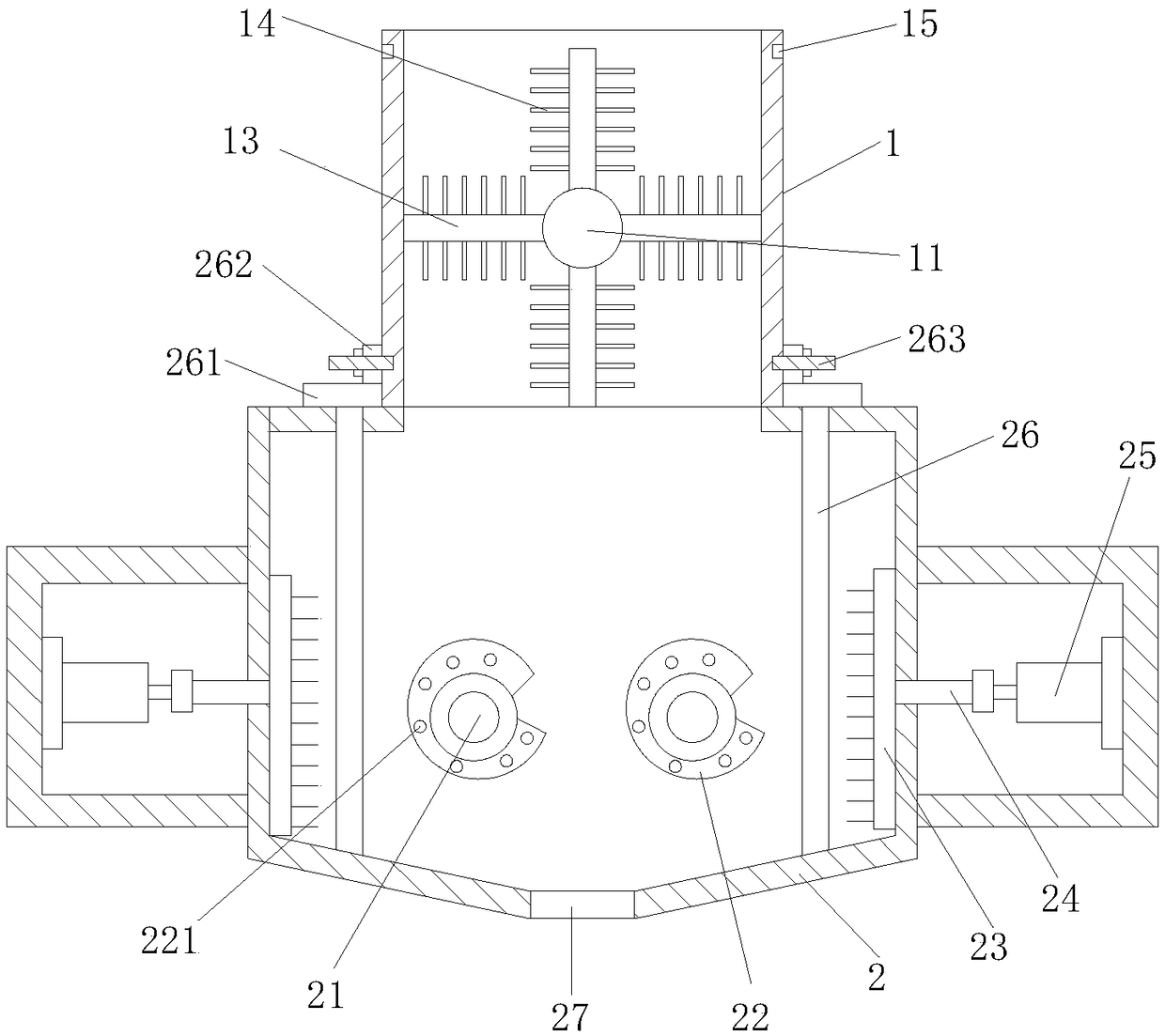

Rotary mixing apparatus

InactiveCN103386272ASimple structureLess maintenance and overhaulRotating receptacle mixersTransportation and packagingEngineeringUniform - quality

The invention discloses a rotary mixing apparatus. The rotary mixing apparatus comprises a support seat, two support frames are arranged over the support seat, a motor is arranged on one of the support frames, a mixer is arranged between the support frames, and the mixer is connected with the motor. The mixing apparatus has the advantages of simple structure, small maintenance amount, low energy consumption, fast mixing speed, and uniform quality, and utilizes the stereo repeated overturning to realize uniform mixing, avoid the deposition of medicinal raw materials on the inner wall and improve the mixing effect.

Owner:SICHUAN HUILI IND

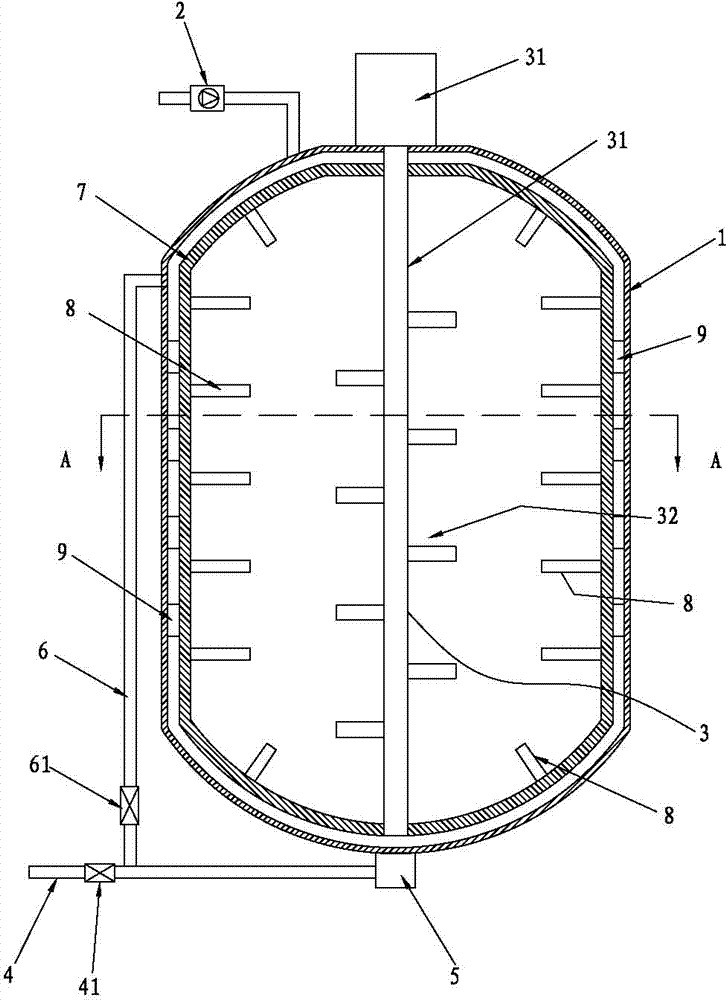

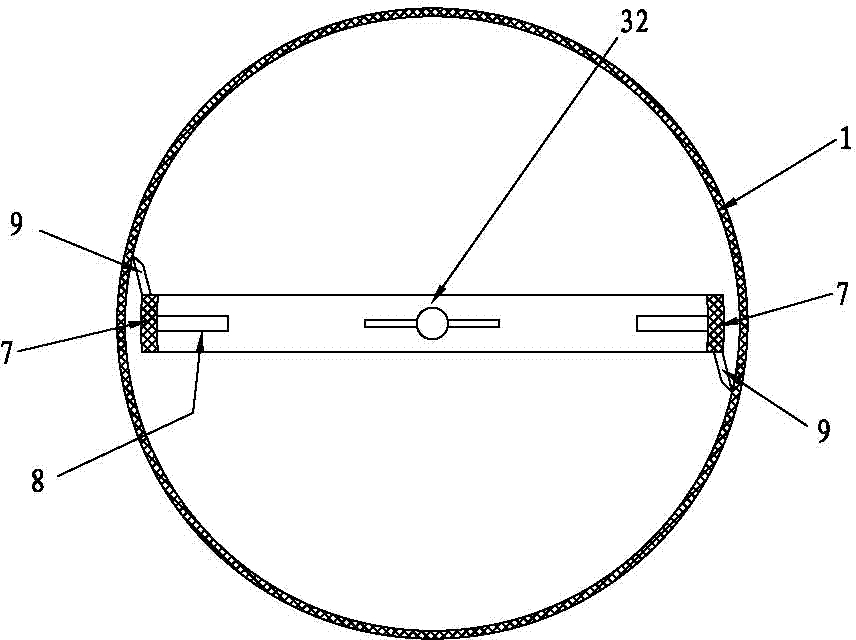

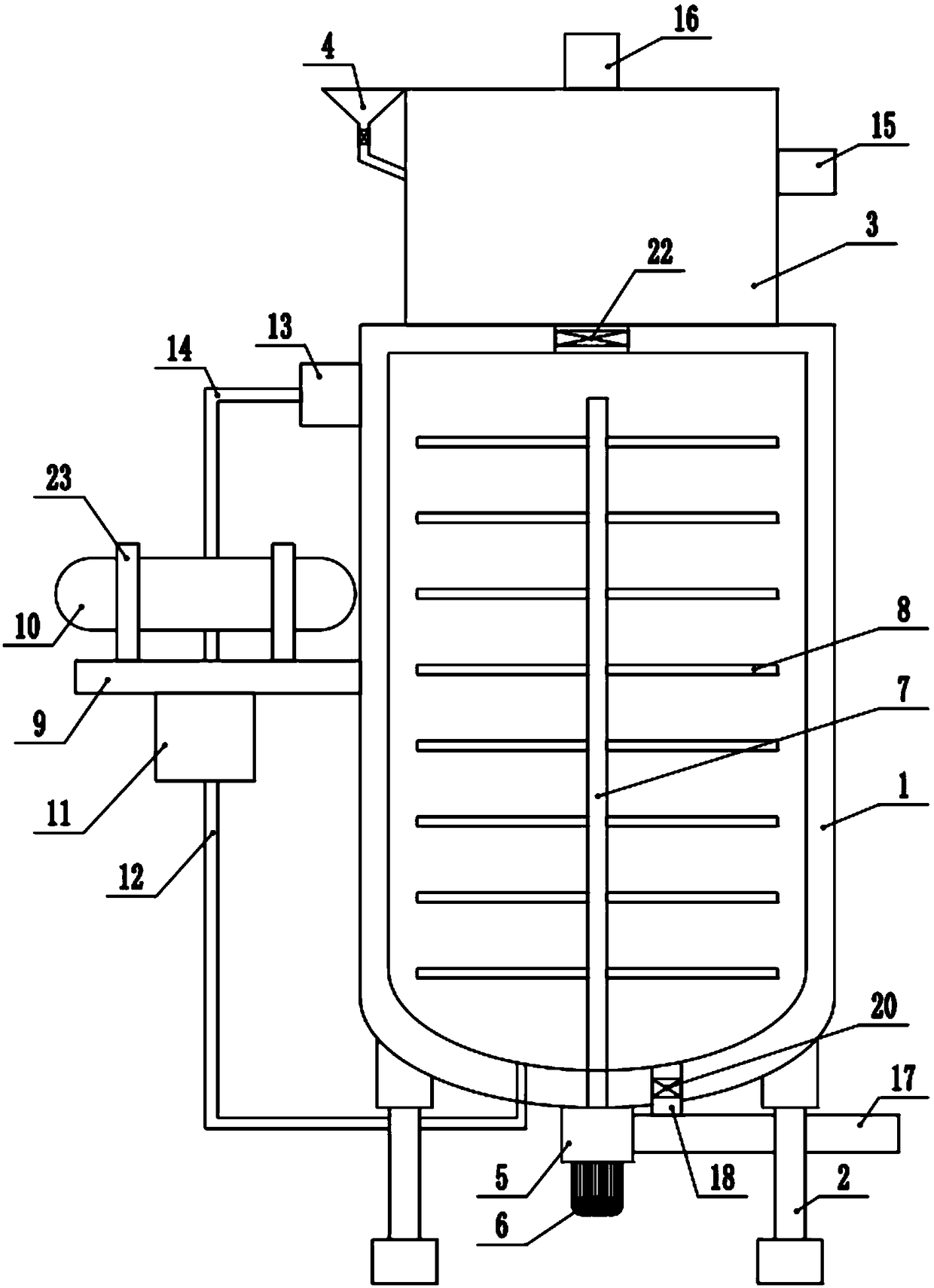

Vacuum emulsifier during cosmetics production

The invention discloses a vacuum emulsifier during cosmetics production. The vacuum emulsifier comprises an emulsifying tank, a vacuum pump and a stirring device, and also comprises a feeding hole and a discharging hole of a homogenizer, wherein the feeding hole is communicated with the bottom of the emulsifying tank, and the discharging hole of the homogenizer is communicated with a discharging pipe. The vacuum emulsifier also comprises a circulating pipe, wherein one end of the circulating pipe is connected with the discharging pipe between a stop valve and the homogenizer, and the other end of the circulating pipe is communicated with the upper part of the emulsifying tank. The vacuum emulsifier also comprises a stirring mechanism, wherein the stirring mechanism comprises an annular frame and a stirring blade arranged on the annular frame, the stirring blade is arranged on the annular frame, middles of a top border and a bottom border of the annular frame are fixedly connected with a shaft of a stirring paddle, the stirring blade and a blade of the stirring paddle are oppositely arranged, and directions of bending angles of the blade and the stirring blade are opposite. Because the directions of the bending angles of the blade and the stirring blade are opposite, raw materials are mixed rapidly; and when stirring inside is carried out, an external circulating device is additionally provided, and thus the raw materials inside the emulsifier and at the upper part and the lower part of the emulsifier are fully stirred, and the mixing speed is high and the raw materials are uniformly mixed.

Owner:NOX BELLCOW COSMETICS CO LTD

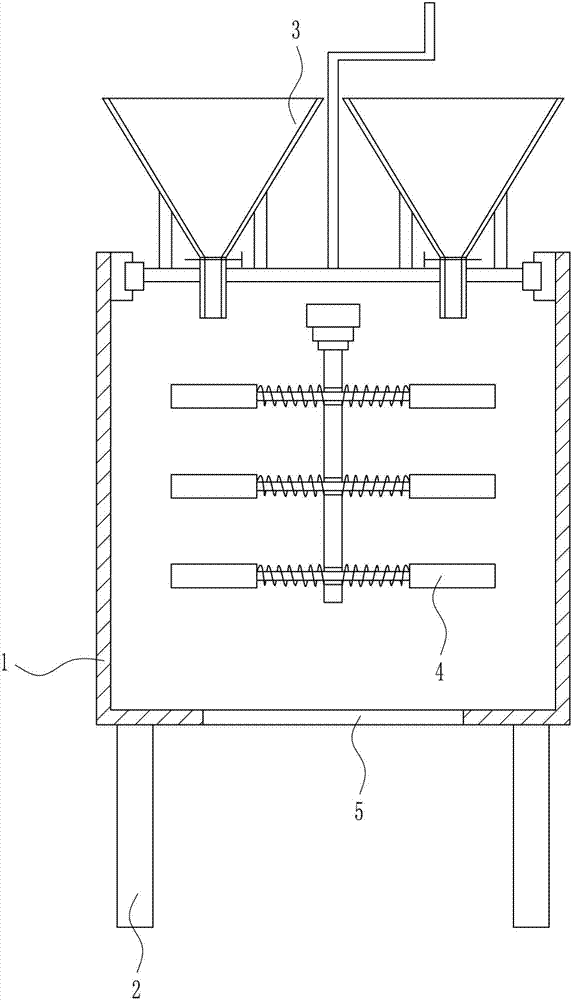

High-efficiency feed mixing device for animal husbandry

The invention relates to a mixing device, in particular to a high-efficiency feed mixing device for animal husbandry. The invention aims to solve the problem of providing the high-efficiency feed mixing device for the animal husbandry, which is simple in framework, high in mixing speed and uniform to mix. In order to solve the problem, the high-efficiency feed mixing device for the animal husbandry provided by the invention comprises a bottom plate, supporting rods, a left frame, a first bearing seat, a screw, a collecting box, a pushing barrel, a rotating shaft, a right frame, a small belt pulley, a flat belt, a large belt pulley, a first motor and the like, wherein the left frame, the supporting rods, the collecting box and the right frame are arranged at the top of the bottom plate from left to right, the pushing barrel is arranged at the upper ends of the supporting rods, and an outlet of the pushing barrel is located above the collecting box. The high-efficiency feed mixing device disclosed by the invention achieves the effects of being simple in framework, high in mixing speed and uniform to mix, operators can rapidly and efficiently mix feeds by operating the device, time can be saved, and the working efficiency can also be improved.

Owner:邵鹏程

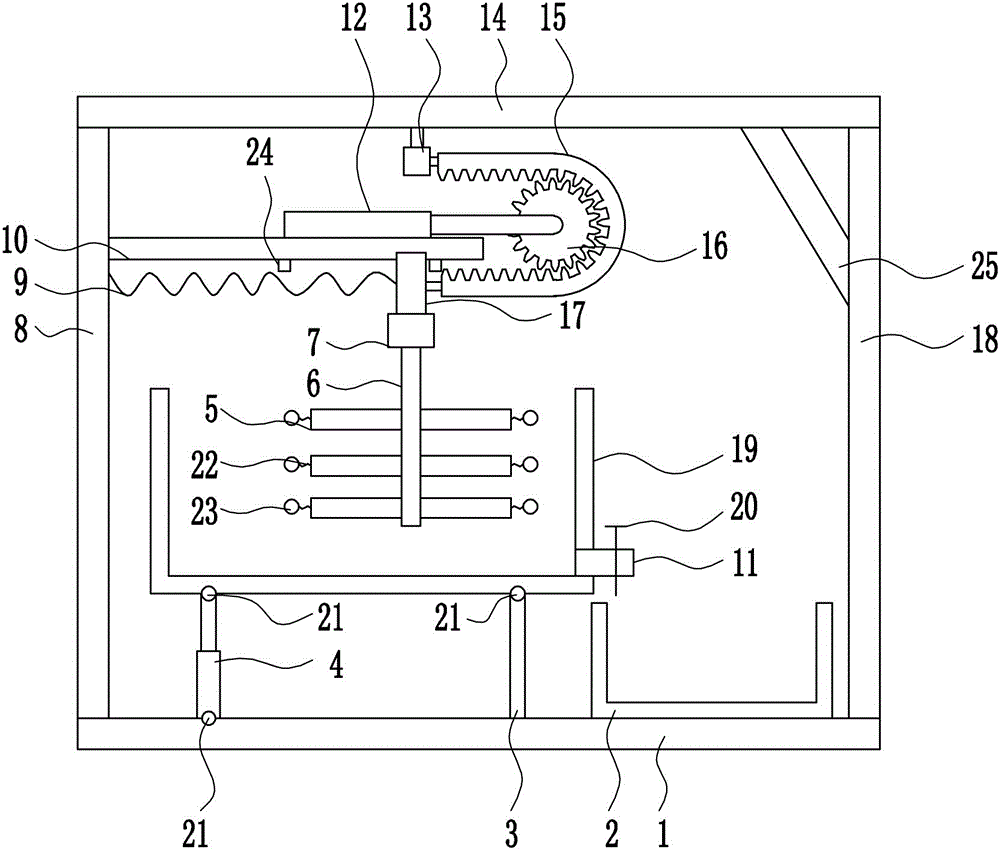

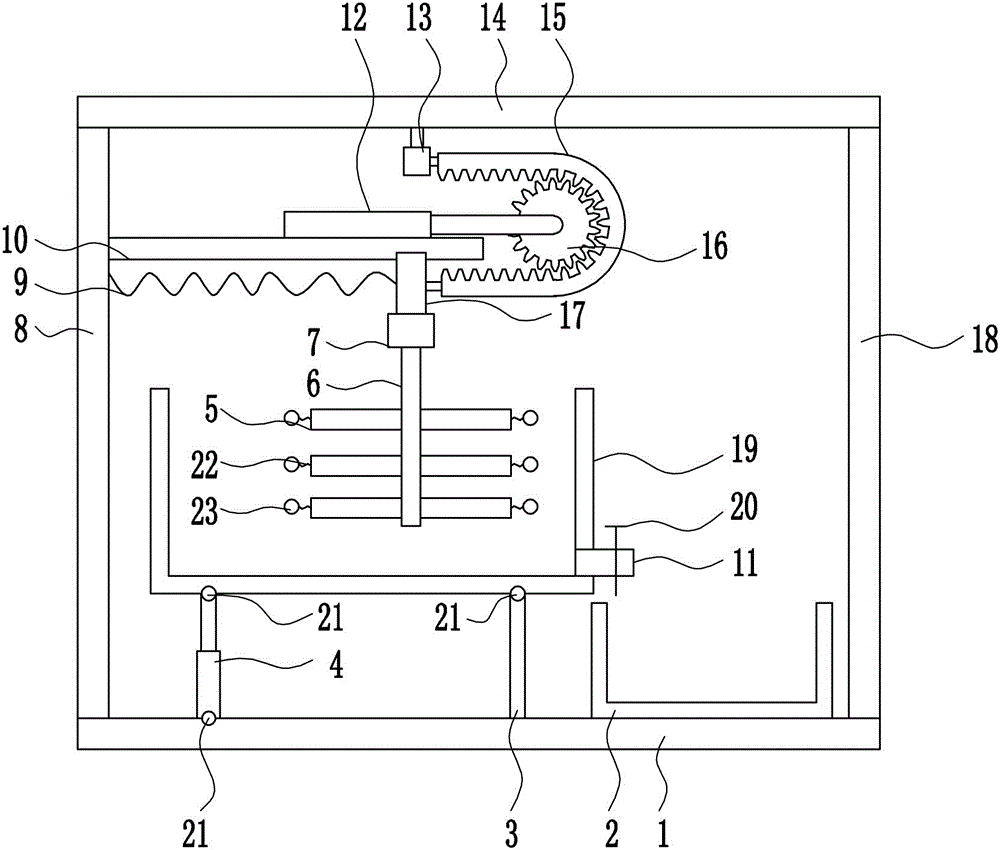

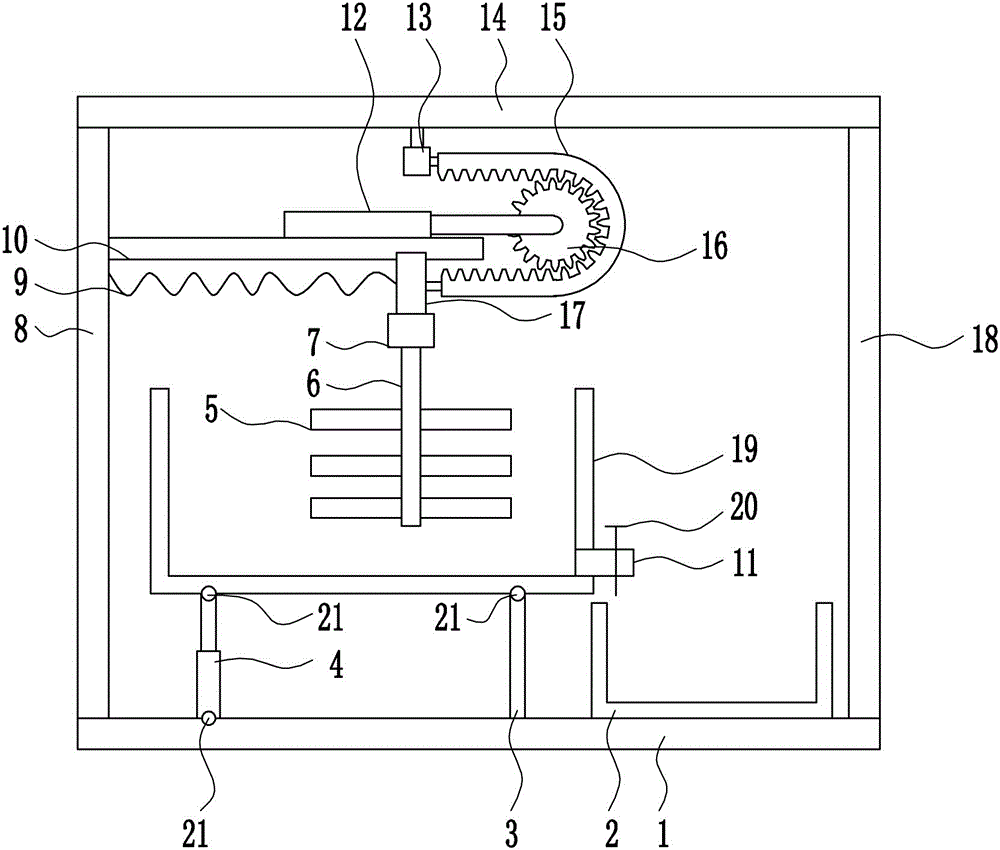

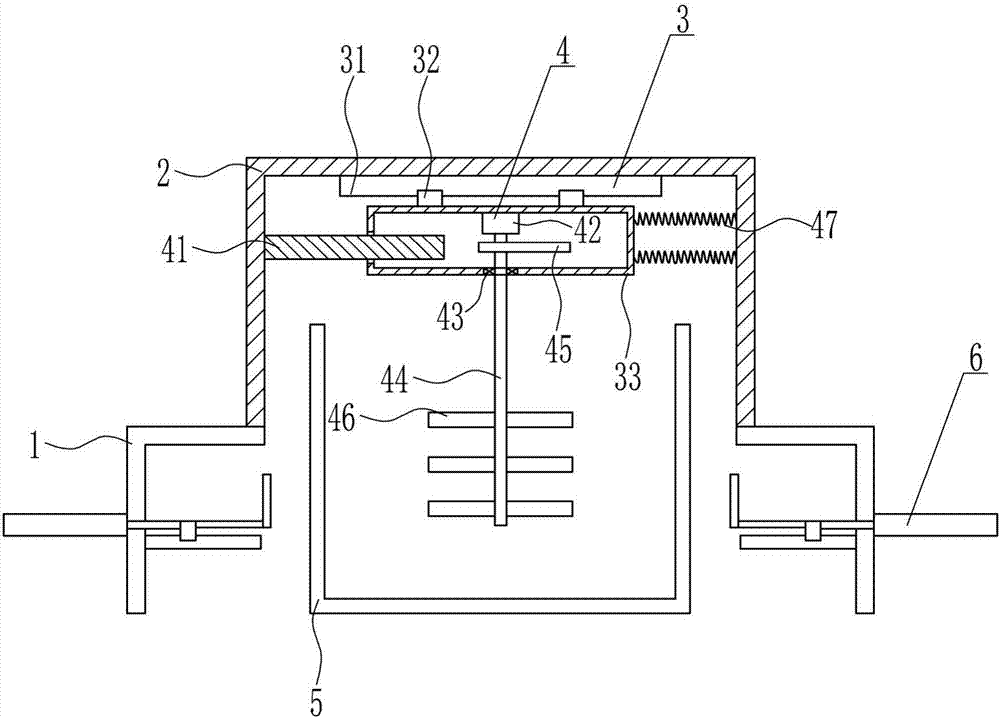

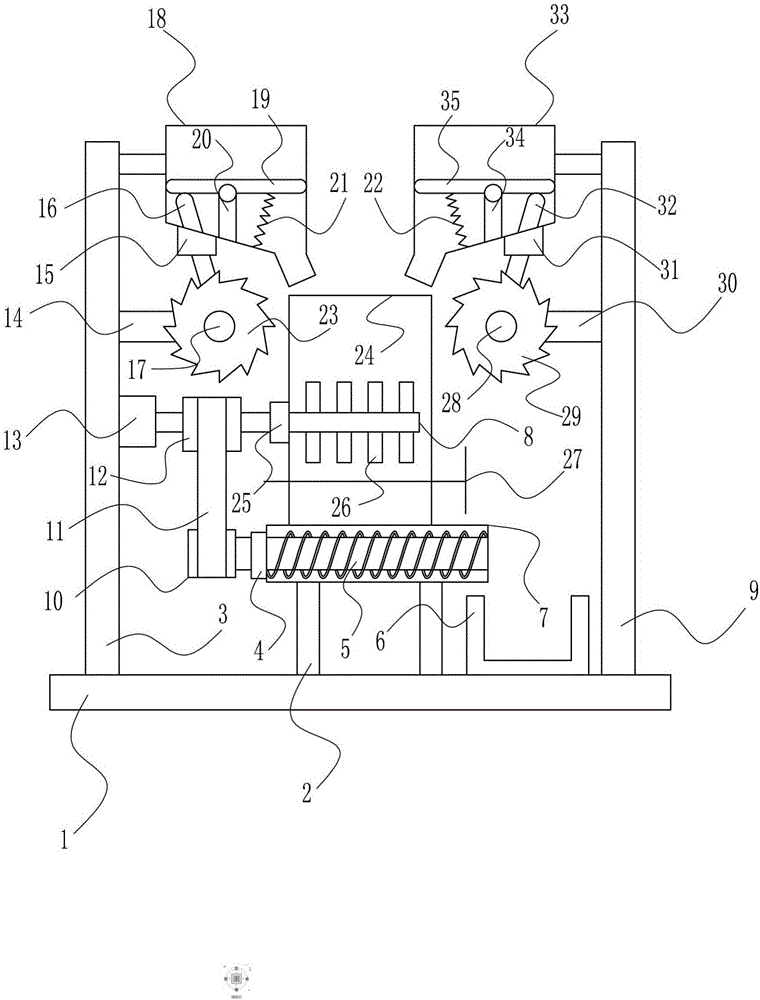

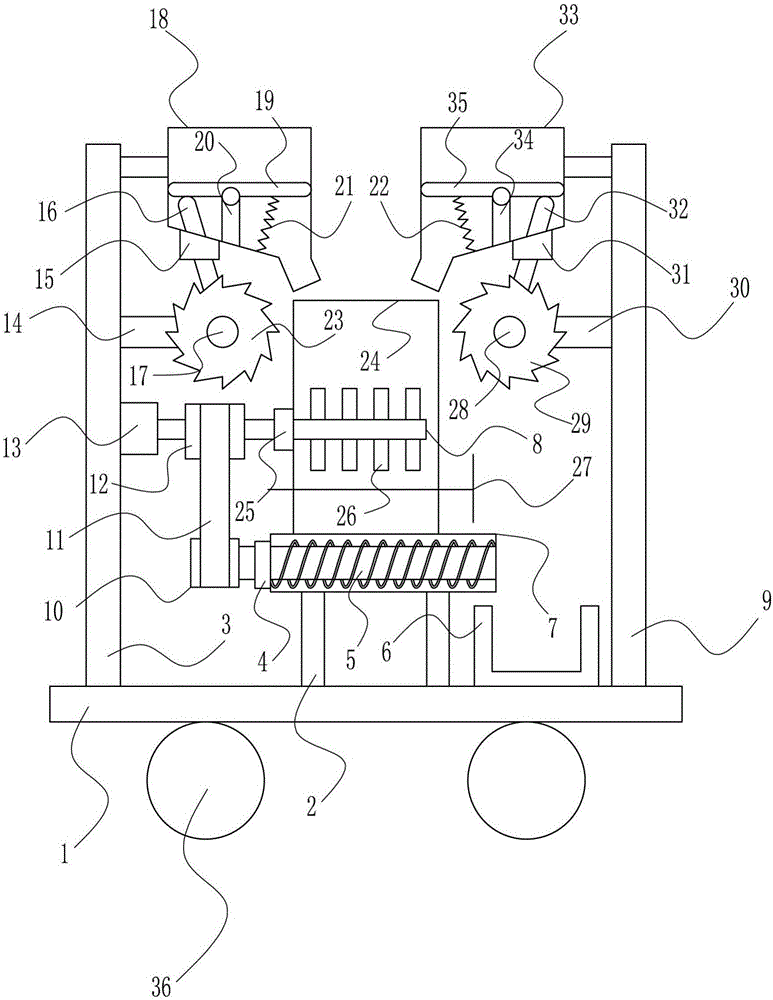

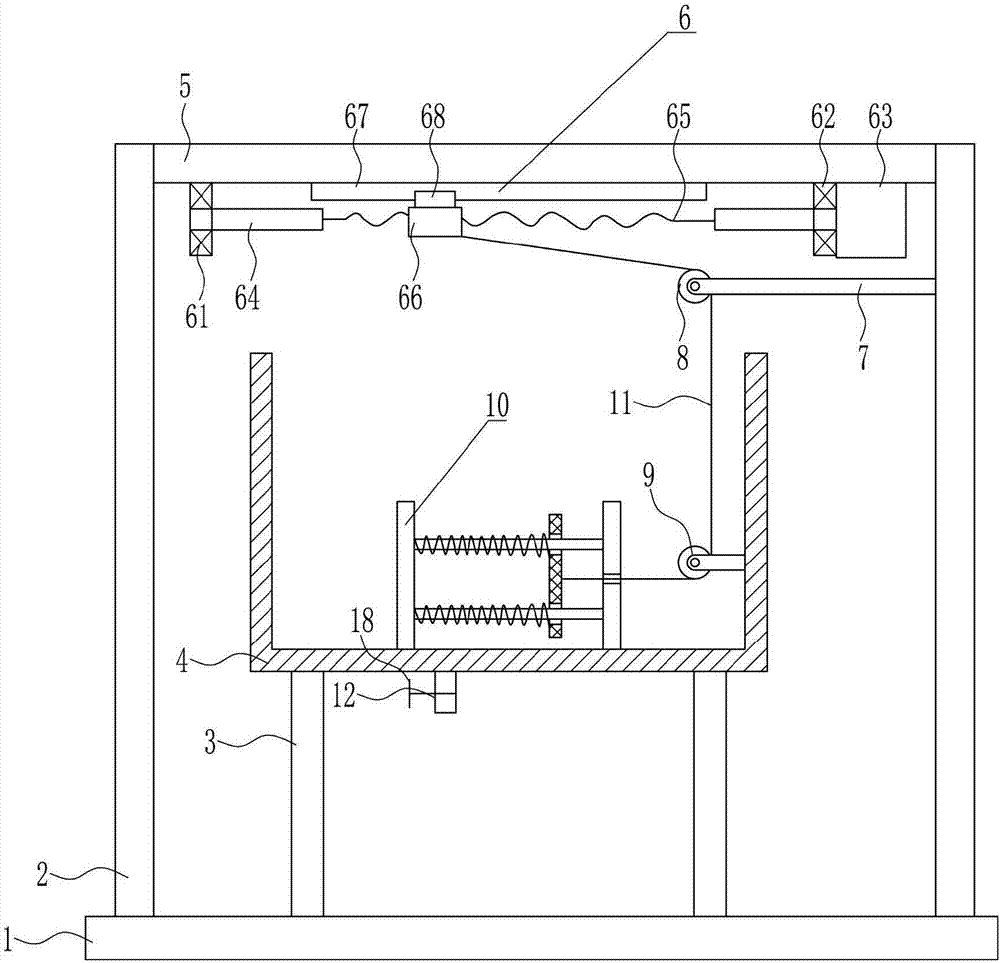

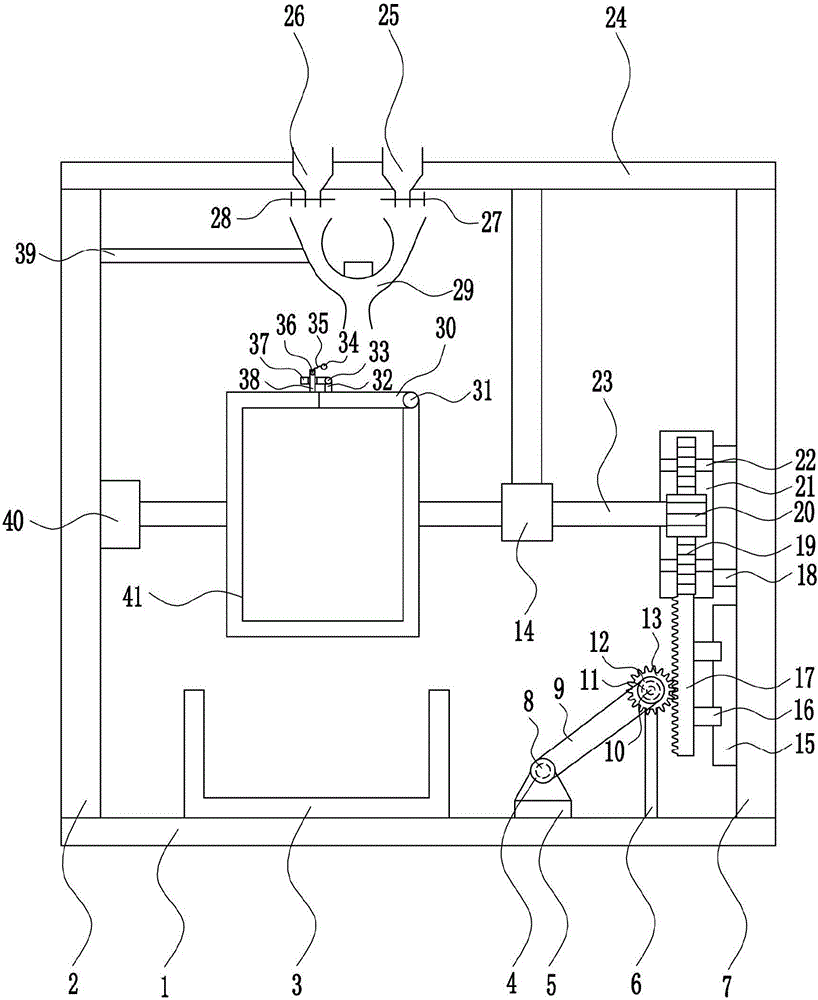

Mixing equipment special for test pieces of rock and soil tests

InactiveCN107351243AImprove the mixing effectControl the output speedDischarging apparatusCement mixing apparatusMixing effectBolt connection

The invention belongs to the technical field of rock and soil tests, and in particular relates to a special mixing equipment for rock and soil tests. The technical problem to be solved by the present invention is to provide a special mixing equipment for rock and soil test specimens with good mixing effect, saving manpower and time, fast mixing speed and high working efficiency. In order to solve the above-mentioned technical problems, the present invention provides such a special mixing equipment for rock and soil test specimens, including a bottom plate, a bracket, legs, a mixing box, a top plate, a left and right moving device, a cross bar, a first pulley, a second Pulleys, mixing devices, pull wires, etc.; the top of the bottom plate is vertically installed with brackets by means of bolt connection, outriggers are installed on the top of the bottom plate between the two brackets, a mixing box is installed on the top of the legs, and the top between the two brackets is passed The way of bolting is installed horizontally with a top plate. The invention achieves the effects of good mixing effect, saving manpower and time, fast mixing speed and high working efficiency.

Owner:向远虎

Short fiber mixing device for silk fabrics

The invention discloses a short fiber mixing device for silk fabrics. The short fiber mixing device for silk fabrics comprises a feeding box, a mixing box is arranged at the outlet of the feeding box,a transverse feeding rod is arranged in the feeding box, the two ends of the feeding rod are rotatably connected with the inner wall of the feeding box, a rotating motor is connected to one end of the feeding rod, and a plurality of feeding plates are arranged on the circumferential surface of the feeding rod; a pair of mixing rollers distributed in parallel left and right are arranged in the mixing box, S-shaped mixing blades are arranged on the circumferential surfaces of the mixing rollers, cleaning brushes in one-to-one correspondence with the mixing rollers are further arranged in the mixing box, driving electric cylinders are connected to the outer side faces of the cleaning brushes through connecting rods, baffles are arranged between the cleaning brushes and the mixing rollers, the lower ends of the baffles abut against the inner bottom wall of the mixing box, and the upper ends of the baffles penetrate out of the top of the mixing box to be up and down slidably connected withthe mixing box; the bottom section of the mixing box is in an inverted cone shape, and the lowermost end of the mixing box is provided with a discharging port. The short fiber mixing device for silkfabrics has the advantages of high mixing speed, good mixing effect and convenient cleaning.

Owner:湖州飞顺丝绸有限公司

Animal husbandry epidemic prevention medicine mixing equipment

InactiveCN106390834AWell mixedReduce laborRotating receptacle mixersFeeding-stuffAnimal husbandryMixing effect

The invention relates to epidemic prevention medicine mixing equipment, in particular to animal husbandry epidemic prevention medicine mixing equipment. Uniform mixing effects can be realized by the animal husbandry epidemic prevention medicine mixing equipment, and the animal husbandry epidemic prevention medicine mixing equipment is high in mixing speed. The animal husbandry epidemic prevention medicine mixing equipment comprises a bottom plate, a left rack, a collecting frame, a right rack, slide rails, sliders, movable plates, a first bearing block, a first rotary shaft, a reel, a stay, a top plate, a fixing ring and the like. The left rack is welded at the left end of the top of the bottom plate, the right rack is welded at the right end of the bottom plate, the slide rails are connected to corresponding positions of the inner sides of the left rack and the right rack by bolts, and the sliders are slidably arranged on the slide rails and are matched with the slide rails. The animal husbandry epidemic prevention medicine mixing equipment has the advantages that the uniform mixing effects can be realized, and the animal husbandry epidemic prevention medicine mixing equipment is high in mixing speed; the animal husbandry epidemic prevention medicine mixing equipment is convenient to operate, accordingly, the amount of labor can be reduced for herdsmen, and medicines and feed can be uniformly mixed with one another.

Owner:吴波

High-efficient blister package material mixing device

The invention relates to a mixing device, in particular to a high-efficient blister package material mixing device. The invention aims to solve the technical problems so as to provide the high-efficient blister package material mixing device with uniformity in discharging, fast mixing speed and uniformity in mixing. In order to solve the technical problems, the invention provides the high-efficient blister package material mixing device which comprises a base plate, a left support, a collecting frame, a small belt pulley, a mounting base, a support rod, a right support, a motor, a flat belt, a first rotary shaft, a first bearing seat, a big belt pulley and the like. The left support is welded to the left-most side of the top part of the base plate; a second bearing seat is connected to the middle part of the right side of the left support through a bolt connection way; a connecting rod is welded to the upper part of the right side of the left support; and a mixing hopper is welded to the right end of the connecting rod. According to the high-efficient blister package material mixing device provided by the invention, raw materials are preliminarily mixed in the mixing hopper and are added into a box body through the mixing hopper, and the motor is controlled to rotate so as to drive the box body to turn over continuously, so that the raw materials in the box body are re-mixed uniformly.

Owner:江苏古柏包装科技有限公司

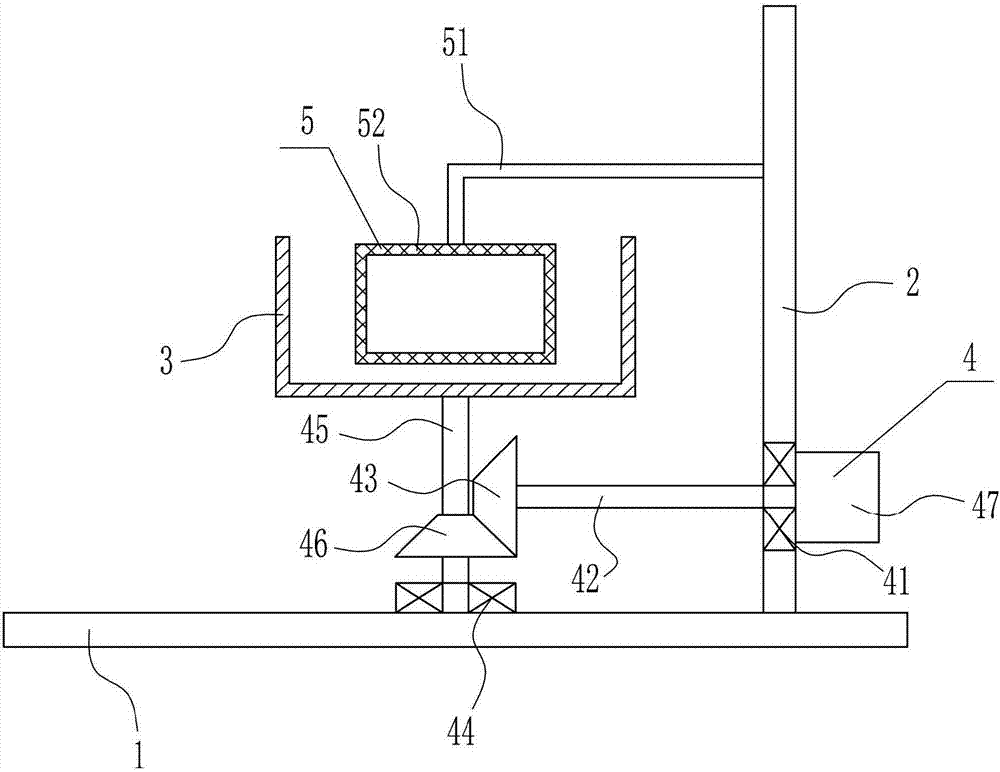

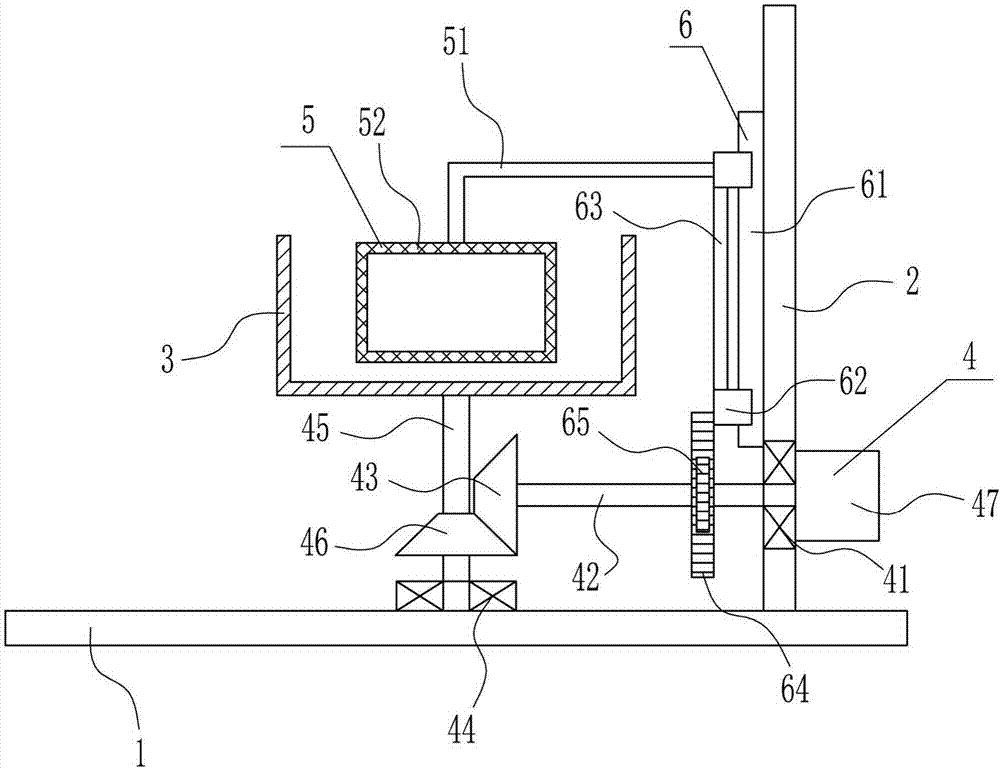

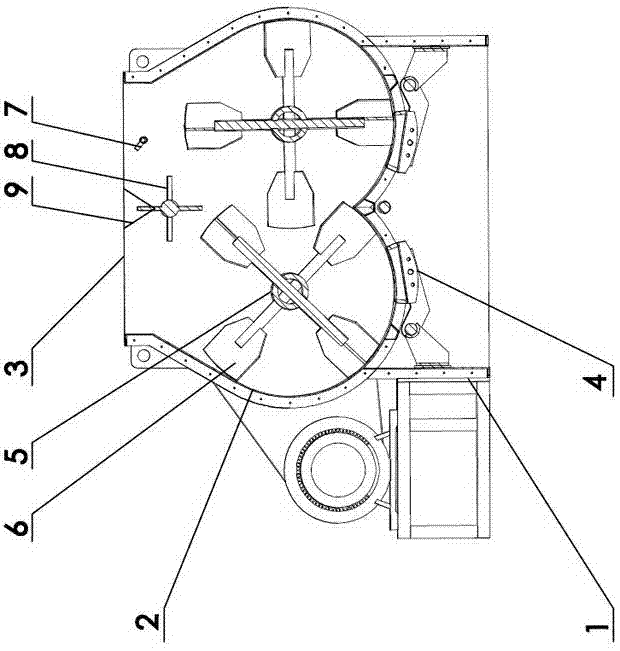

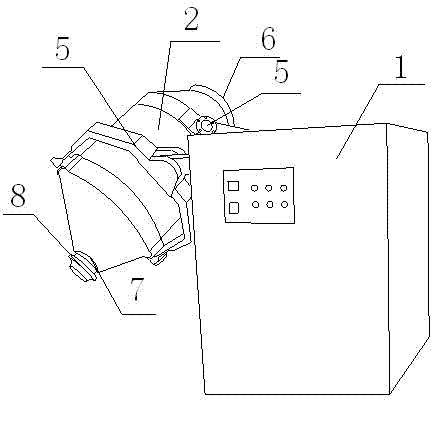

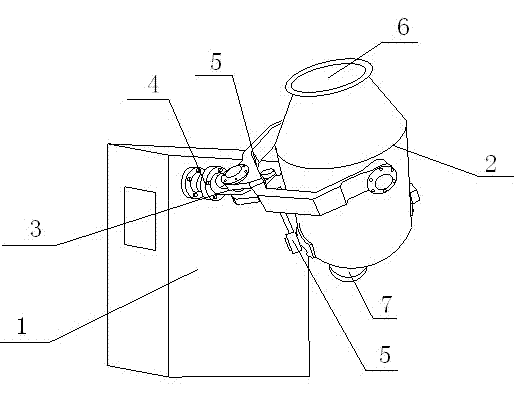

Efficient multi-directional movement mixer

InactiveCN103084098ASpeed up the mixingFast mixingRotating receptacle mixersMixing methodsEngineeringManipulator

The invention discloses an efficient multi-directional movement mixer, comprising an engine base (1), a storage tank (2) and two manipulators (3), wherein each manipulator (3) comprises a rotating shaft (4) and U-shaped clamps (5); the rotating shaft (4) is arranged on the engine base (1); the rotating shaft (4) is also connected to a motor inside the engine base (1); the U-shaped clamps (5) are hinged on the rotating shaft (4); the storage tank (2) is arranged between two arms of the U-shaped clamp (5); two U-shaped clamps (5) are respectively arranged at the upper end and the lower end of the storage tank (2); and at least one filter screen (9) is also arranged inside the storage tank (2). The efficient multi-directional movement mixer has the beneficial effects that two mechanical rotating elements are provided, so that the tank body can move in a plurality of directions; the mixing speed of liquid in the tank body is quickened; the filter screen is added to the inside of the tank body; the liquid mixing speed becomes fast by eddy generated when the liquid passes through the filter screen; and the mixing completeness is increased.

Owner:SICHUAN HUILI IND

Drug mixing device for genetic engineering

PendingCN112316791AWell mixedMix well and easilyRotary stirring mixersTransportation and packagingMedicinePharmaceutical drug

The invention discloses a drug mixing device for genetic engineeringwhich comprises a mixing assembly, feeding assemblies are arranged at the two ends of the mixing assembly respectively, a driving assembly is movably arranged at the top of the mixing assembly, a discharging assembly is fixedly arranged at the bottom of the mixing assembly, the mixing assembly comprises a mixing pipe, and the topof the mixing pipe is fixedly connected with a fixing base. By pushing a movable rod to move downwards, the movable rod drives a rubber piston to collide liquid medicine to the surface of a transmission rod through a first through hole, a fixing ring and a circulating pipe, the structure of the liquid medicine becomes dispersed, and therefore the liquid medicine is easy to mix. The liquid medicinecontinues to be injected into the mixing pipe through the circulating pipe, the pressure of the liquid medicine in the mixing pipe is large, fusion of the liquid medicine is further promoted, the liquid medicine is fully stirred and mixed through cooperation of stirring blades, and therefore the purposes of high mixing speed, uniform mixing and convenience of mixing can be achieved.

Owner:华安庆

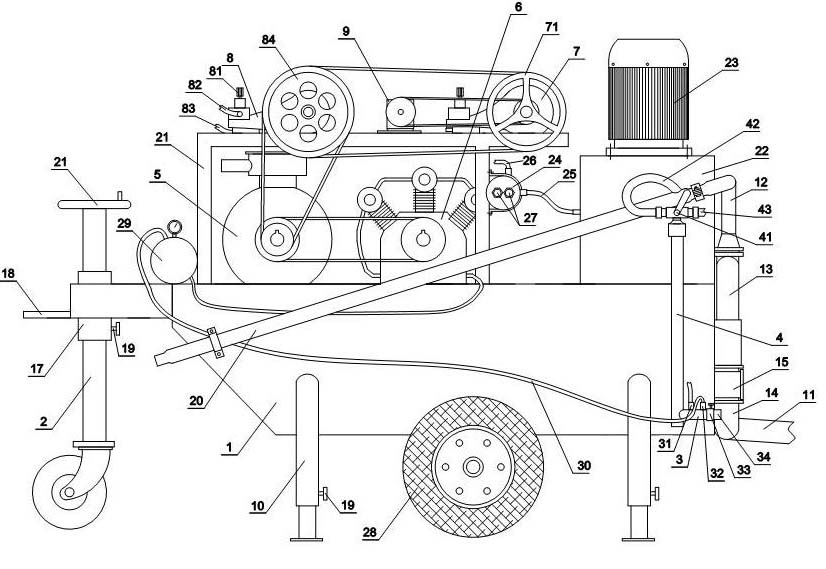

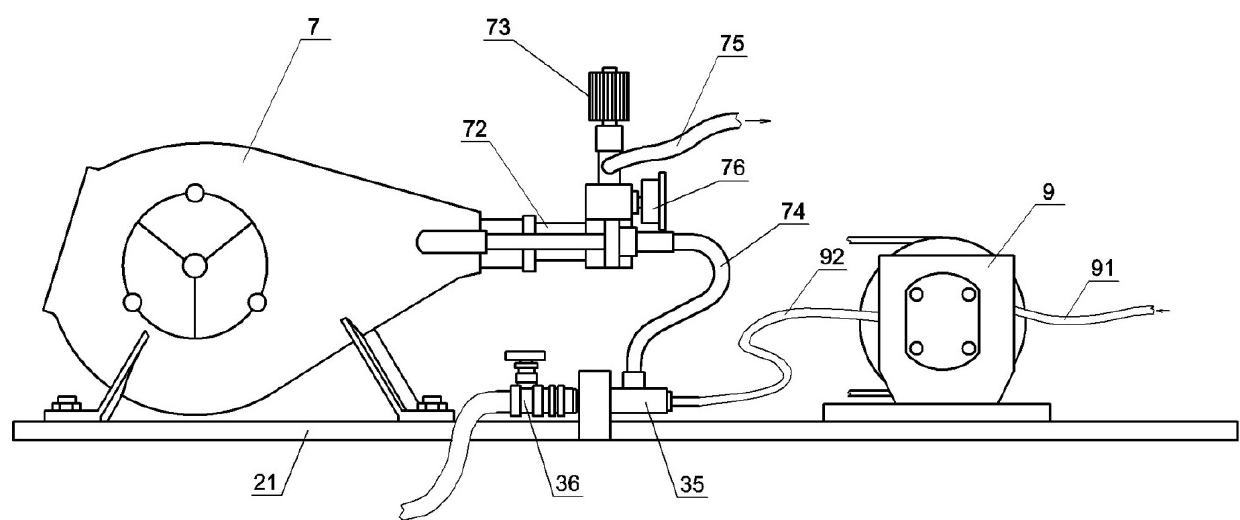

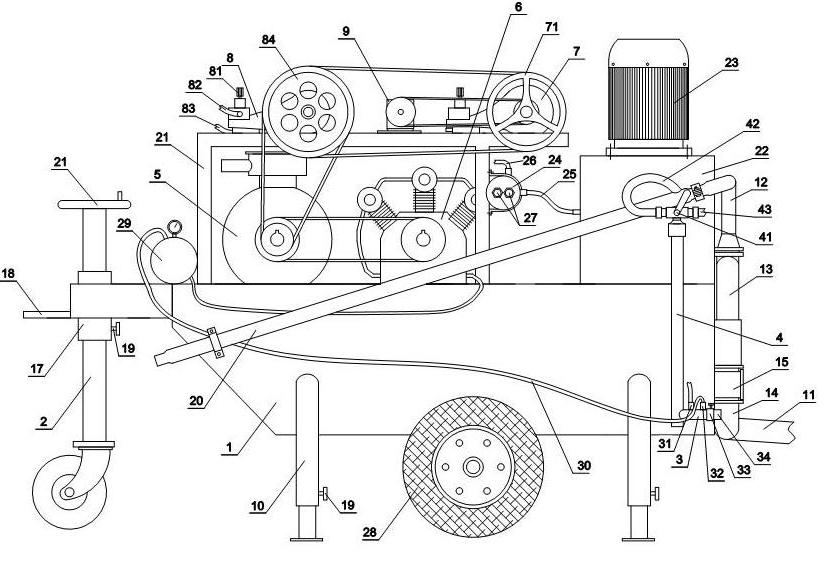

Mine cement foaming machine

InactiveCN101920517AQuick buildImprove work efficiencyCeramic shaping apparatusVehicle frameUnderground tunnel

The invention relates to a mine cement foaming machine which comprises a stand, a cement slurry conveying mechanism and a hydraulic system, wherein an explosion-proof motor is installed on the stand and is used for simultaneously driving a foaming plunger pump and a micropump; an output pipe of the foaming plunger pump is communicated with a foam producing device; an output shaft of the explosion-proof motor is used for also driving an air compressor; an output air pipe of the air compressor is communicated with the foam producing device; and the foam producing device passes through a pipeline and is communicated with the output pipe of the cement slurry conveying mechanism after a valve is installed. The invention can be suitable for mine operation and is capable of rapidly constructing walls in an underground tunnel, such as a windbreak wall, and the like and has time saving, labor saving and high working efficiency. The whole machine adopts a manual control valve or a mechanical control valve, meets the mine working condition, has the advantages of safety, reliability, convenient use and easy manufacture or reformation, is suitable for mass production and is quite beneficial to popularization and construction.

Owner:HENAN FUCHENG ECOLOGICAL ENERGY TECH

Cosmetics raw material agitation device

InactiveCN109351270AFast mixingImprove efficiencyRotary stirring mixersTransportation and packagingBiochemical engineeringDrive motor

The invention discloses a cosmetics raw material agitation device, and relates to the field of production of cosmetics. The cosmetics raw material agitation device comprises an agitation tank, whereinthe bottom end of the agitation tank is fixedly connected with supporting legs, the top end of the agitation tank is fixedly provided with a pretreatment box, the side edge of the pretreatment box isfixedly provided with a feed hopper, the bottom end of the agitation tank is fixedly connected with a bottom block, the bottom end of the bottom block is fixedly connected with a drive motor, an output shaft of the drive motor is fixedly connected with a rotating shaft, the rotating shaft penetrates through the bottom block and is placed in the agitation tank, the rotating shaft is fixedly connected with an agitation paddle, and one side of the agitation tank is fixedly connected with a fixing plate. The cosmetics raw material mixing device has the advantages that through the arrangement of afirst air pump and a second air pump, pneumatic rolling type agitation can be carried out on cosmetics raw materials in the agitation tank, through the arrangement of the agitation paddle, stirring type agitation can be carried out on the cosmetics raw materials in the agitation tank, the cosmetics raw material agitation device has double agitation capacity, the raw materials do not react with air during agitation, the mixing speed of the cosmetics raw materials is quick, and the efficiency is high.

Owner:张玉娥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com