Sleeve type flow speed changing swirling flow composite reactor and high efficiency composite precipitation tank

A combined reactor and variable flow rate technology, used in sedimentation separation, chemical instruments and methods, and sediment separation by centrifugal force, etc., can solve the problems of poor mixing uniformity, low water treatment efficiency, and slow sludge discharge speed. The effect of fast mud speed, improved efficiency, and fast mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

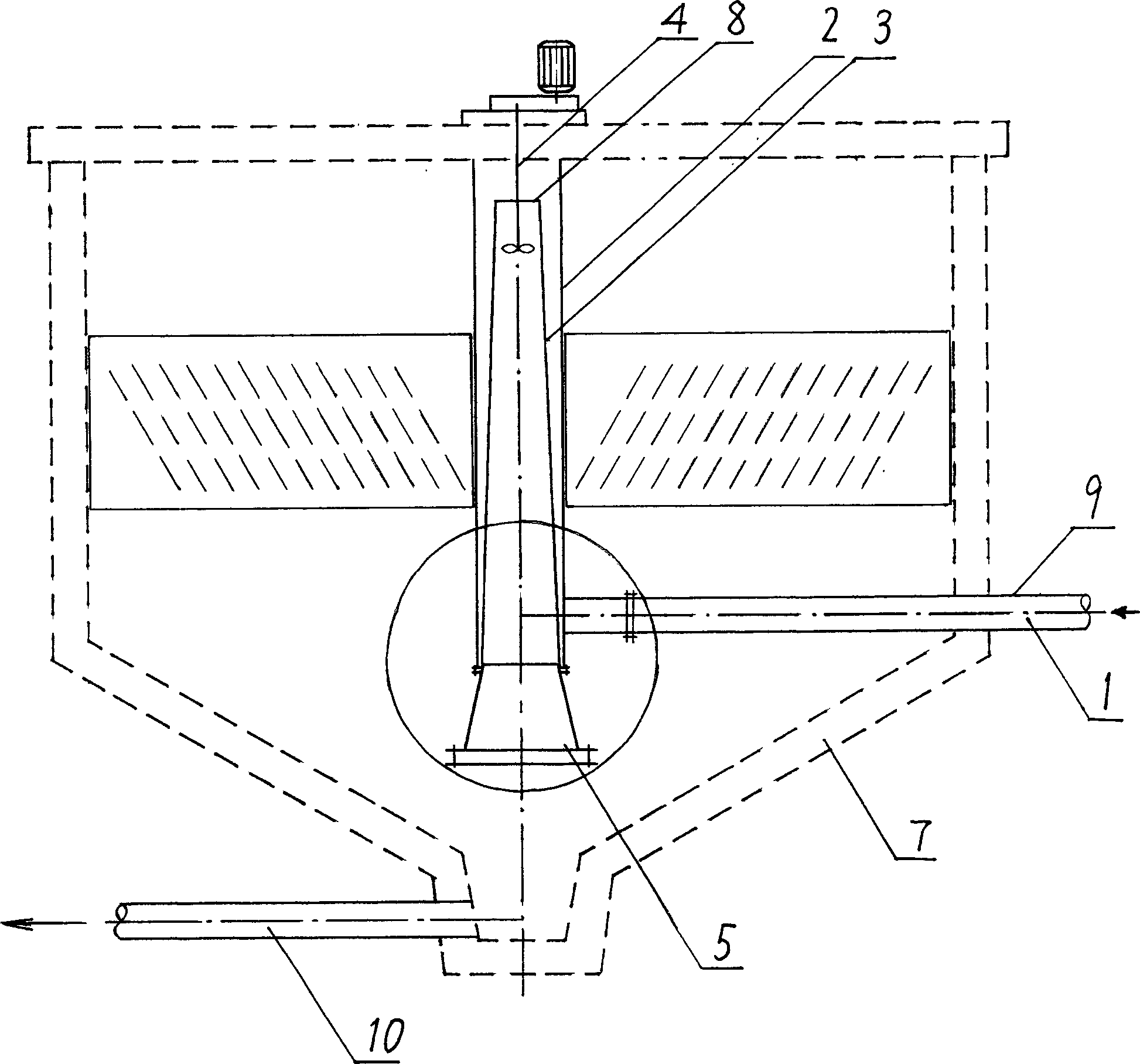

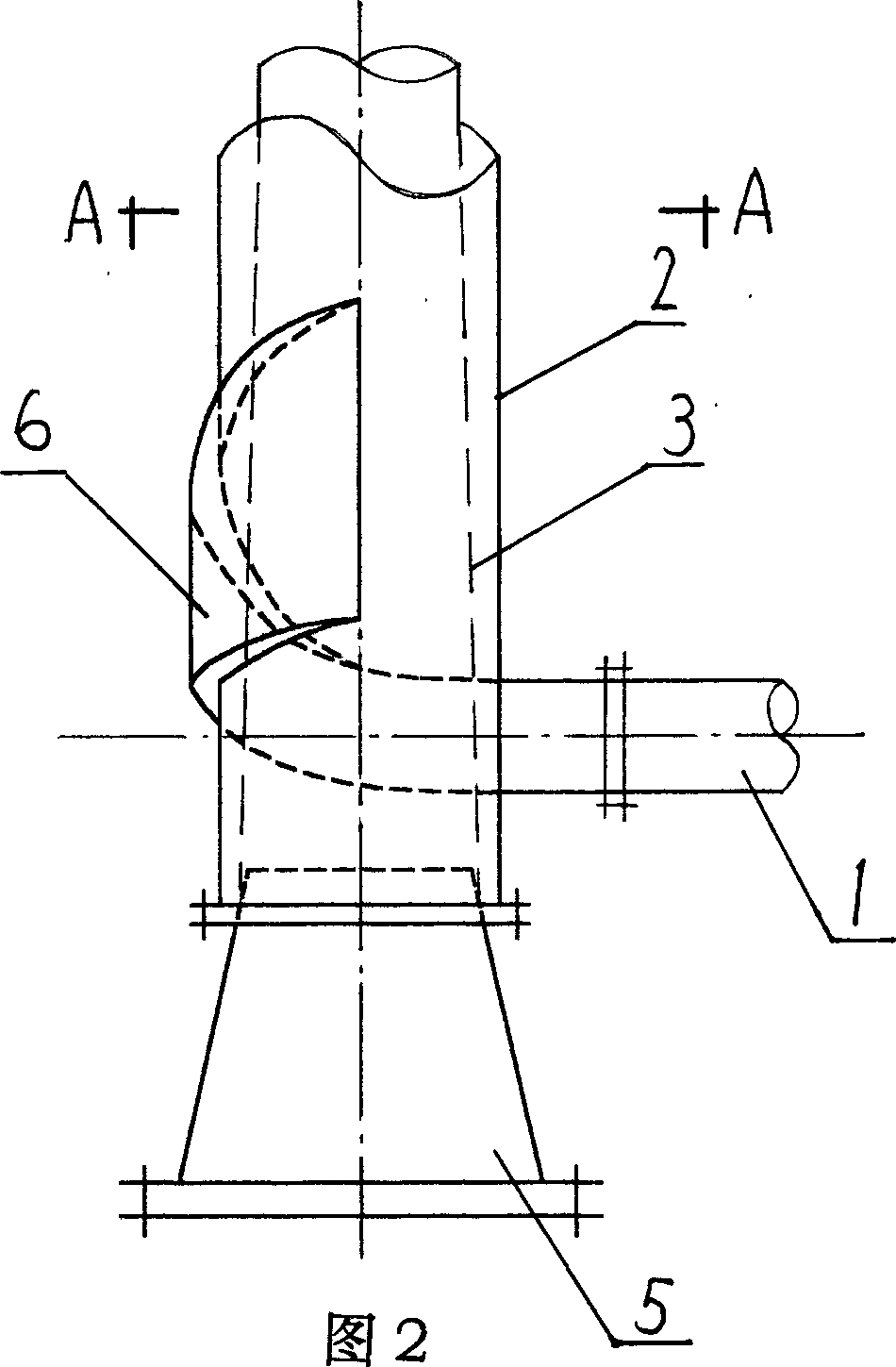

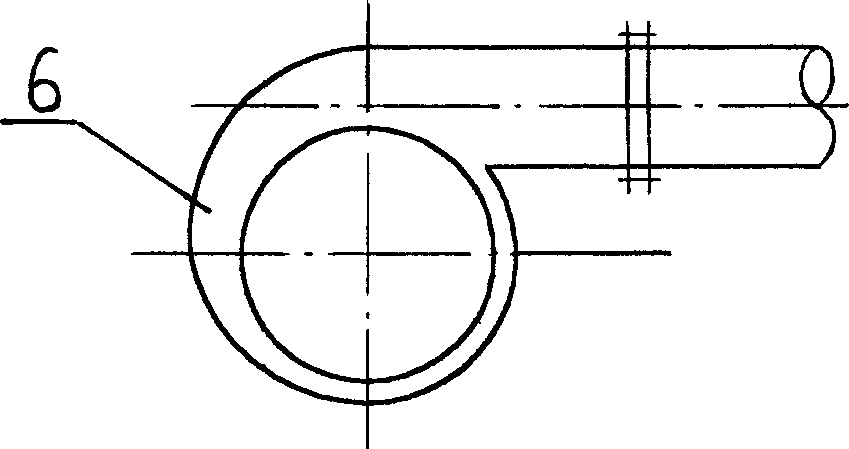

[0022] Example figure 1 , 2, and 3 shown: the sleeve type variable flow rate cyclone combined reactor of the present invention comprises an outer cylinder and an inner cylinder, and a cylindrical outer cylinder and a conical inner cylinder are concentrically sleeved together; The tapered diameter-reducing inner cylinder 3, the lower end of the diameter-reducing inner cylinder is connected with the trumpet-shaped water outlet diffusion pipe 5 protruding from the outer cylinder, the upper end of the diameter-reducing inner cylinder is submerged in the outer cylinder 2, and an inner cylinder agitator 4 is arranged. The upper end of the inner cylinder may have a flocculant dosing port 8, which is connected with a flocculant dosing pipe or a flocculant dosing device; the lower part of the outer cylinder is tangentially connected with the water inlet and dosing pipe 1. The water inlet and dosing pipe 1 may be provided with a coagulant dosing port 9, which is communicated with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com