Mine cement foaming machine

A cement foaming and cement technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of affecting the stability and strength of foam, difficult to control, uneven size of foam, etc., and achieve fast gas-liquid mixing speed, easy manufacturing or The effect of renovation and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

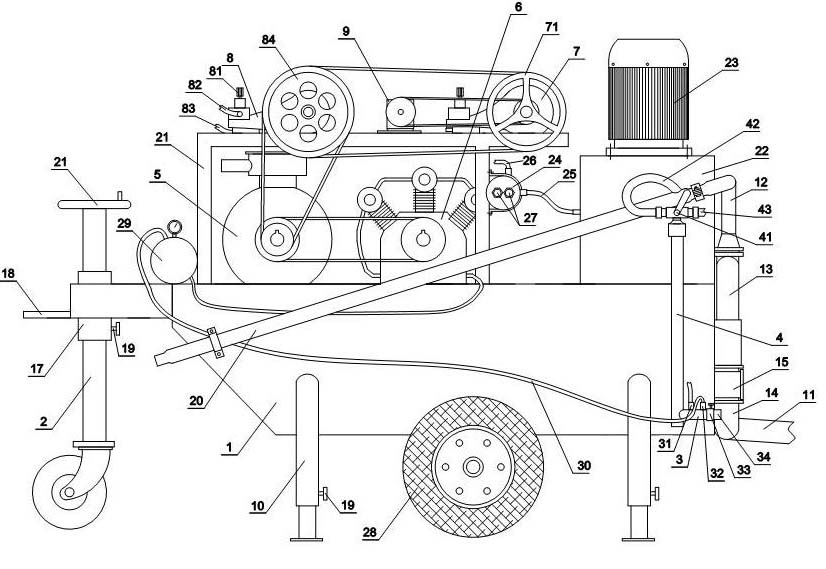

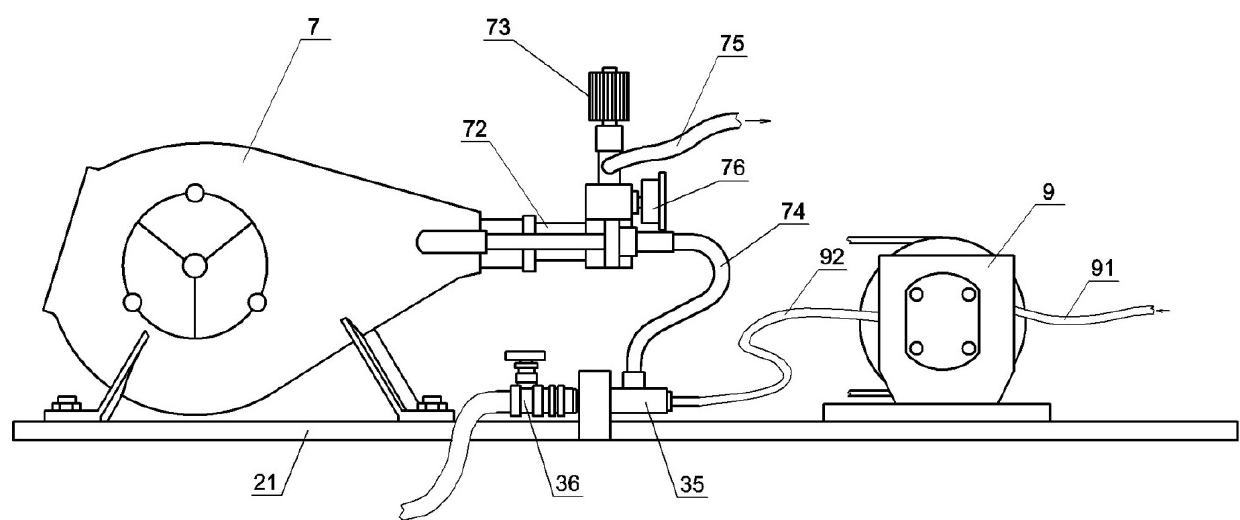

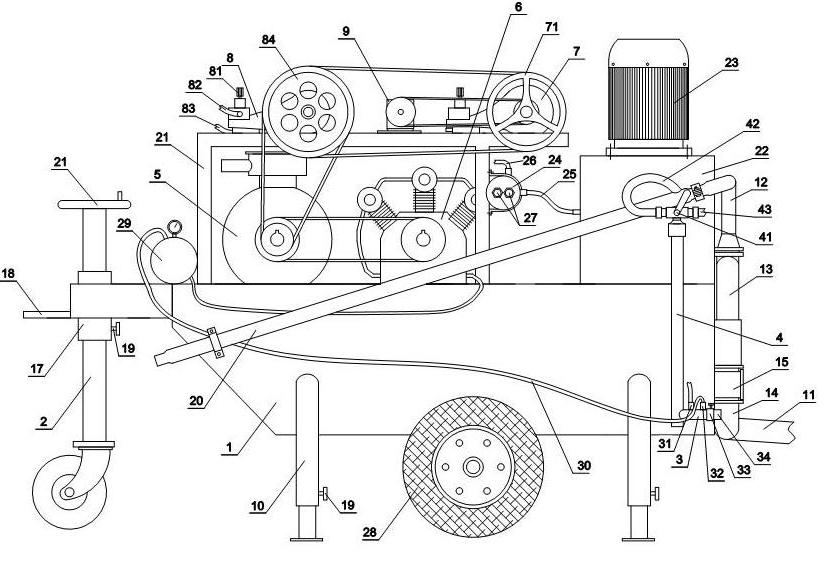

[0025] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , the number 1 in the figure is the frame, 2 is the front side walking wheel, 3 is the horizontal pipe of the foam maker, 4 is the vertical pipe of the foam maker, 5 is the explosion-proof motor, 6 is the hydraulic conveying mechanism, and 7 is the foaming Piston pump, 8 is a quick-setting plunger pump, 9 is a micro pump, 10 is a telescopic outrigger, 11 is a main pipe for suction of cement slurry, 12 is a main pipe for output of cement slurry, 13 is a branch pipe for output of cement slurry, and 14 is for cement slurry Suction pipe, 15 is the support, 16 is the air compressor, 17 is the fixed sleeve, 18 is the pulling arm, 19 is the fastening bolt, 20 is the foam delivery pipe of the cement slurry delivery mechanism, 21 is the rotating wheel, 22 is the oil tank , 23 is a hydraulic pump, 24 is a cooler, 25 is an oil outlet pipe of a fuel tank, 26 is an oil outlet pipe of a cooler, 27 is a cold water inle...

Embodiment 2

[0031] Embodiment 2: The accompanying drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that a plurality of pulleys with different diameters are installed on the rotating shaft of the micropump at the same time, and different pulleys are driven to achieve alignment. Foaming agent should be controlled as much as possible or output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com