Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

372results about How to "Mix thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective catalytic reduction of nox enabled by sidestream urea decomposition

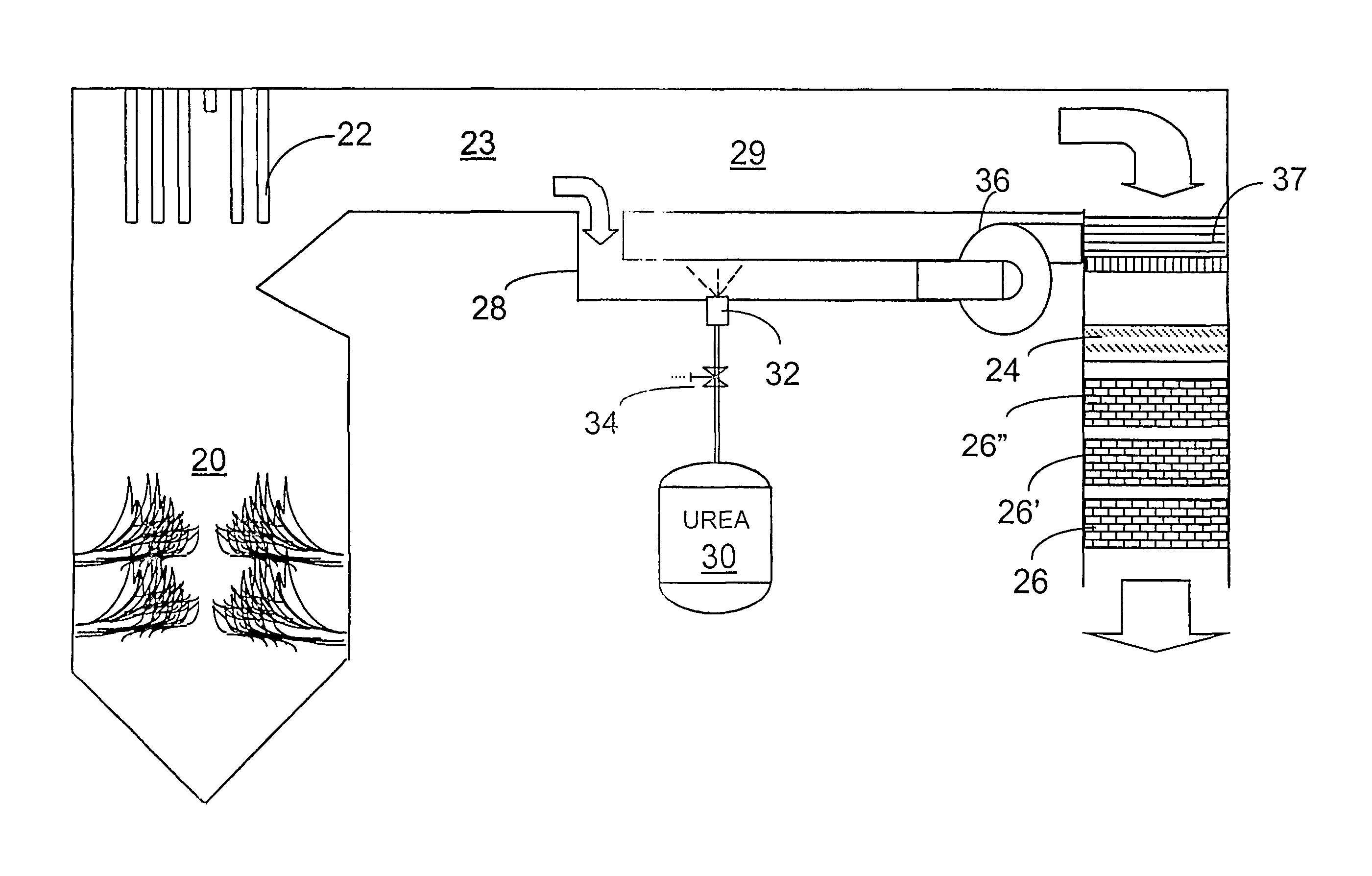

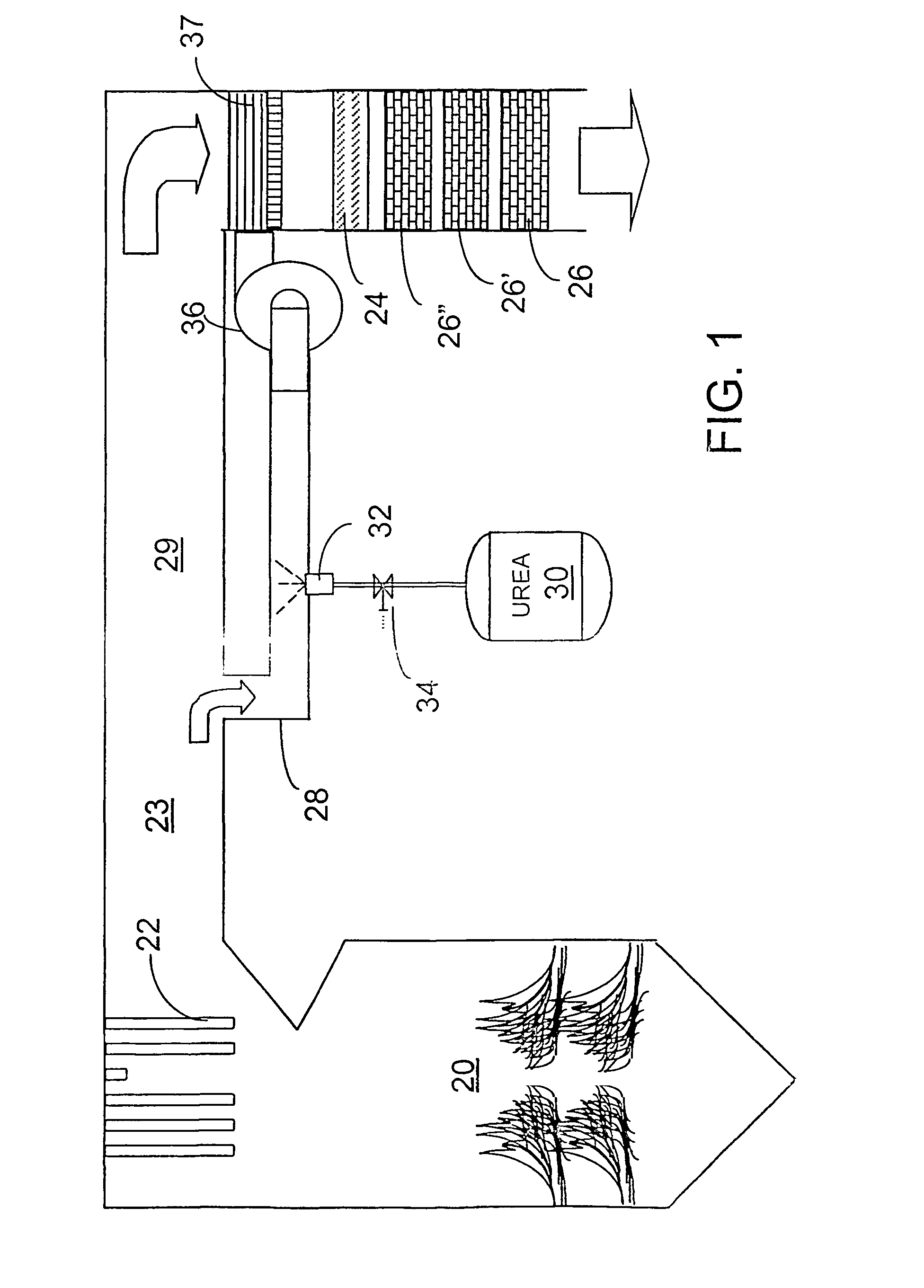

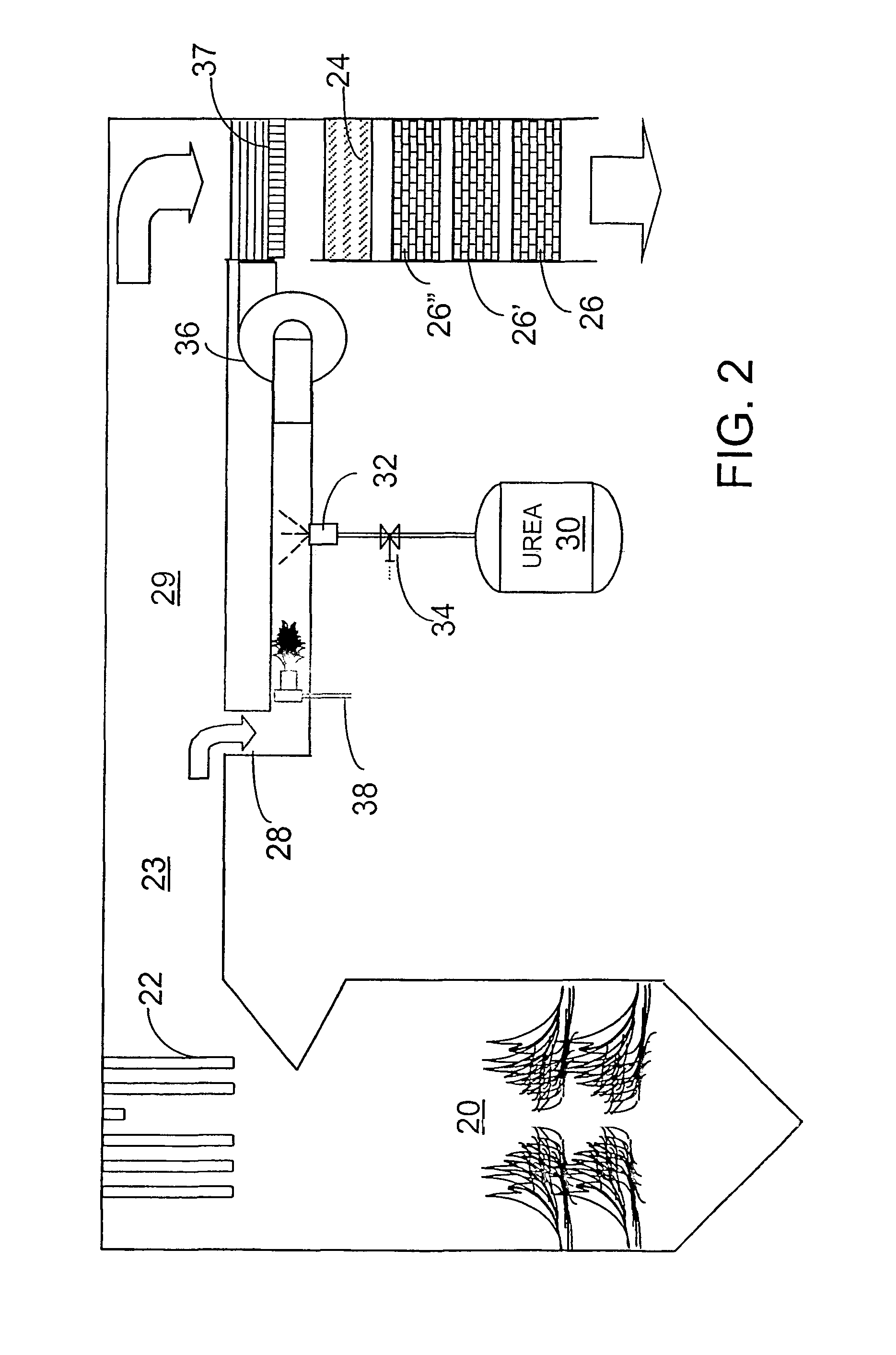

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

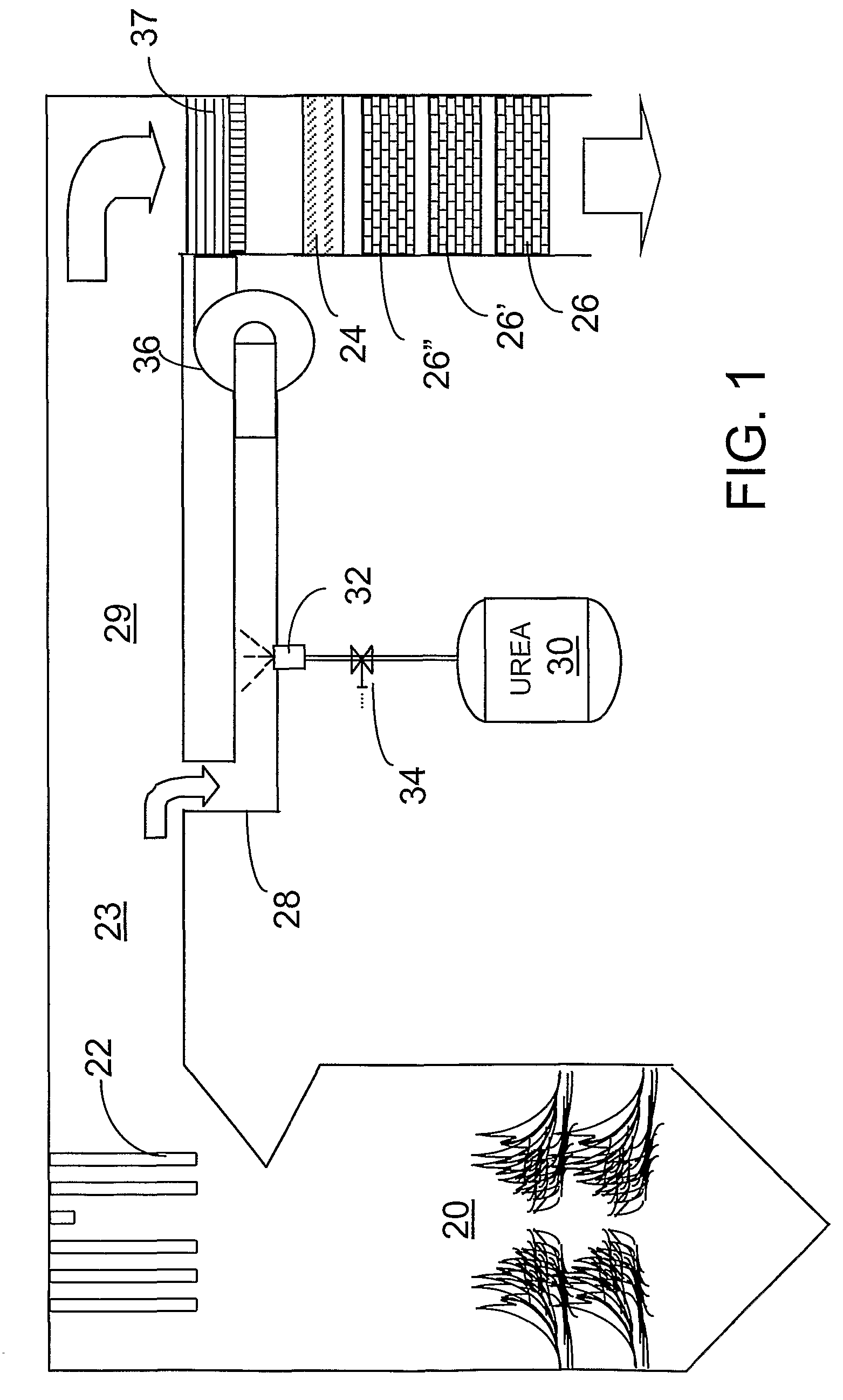

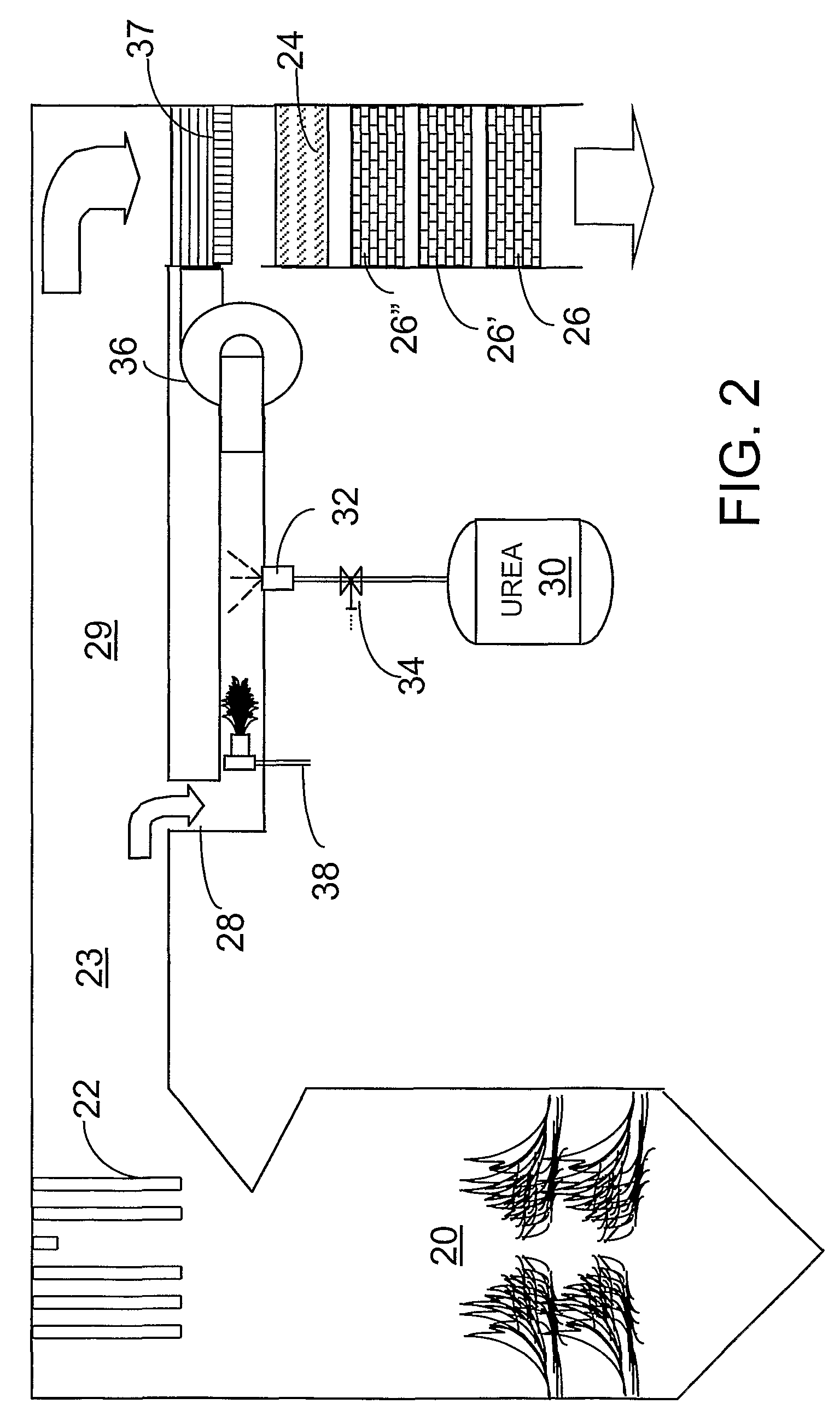

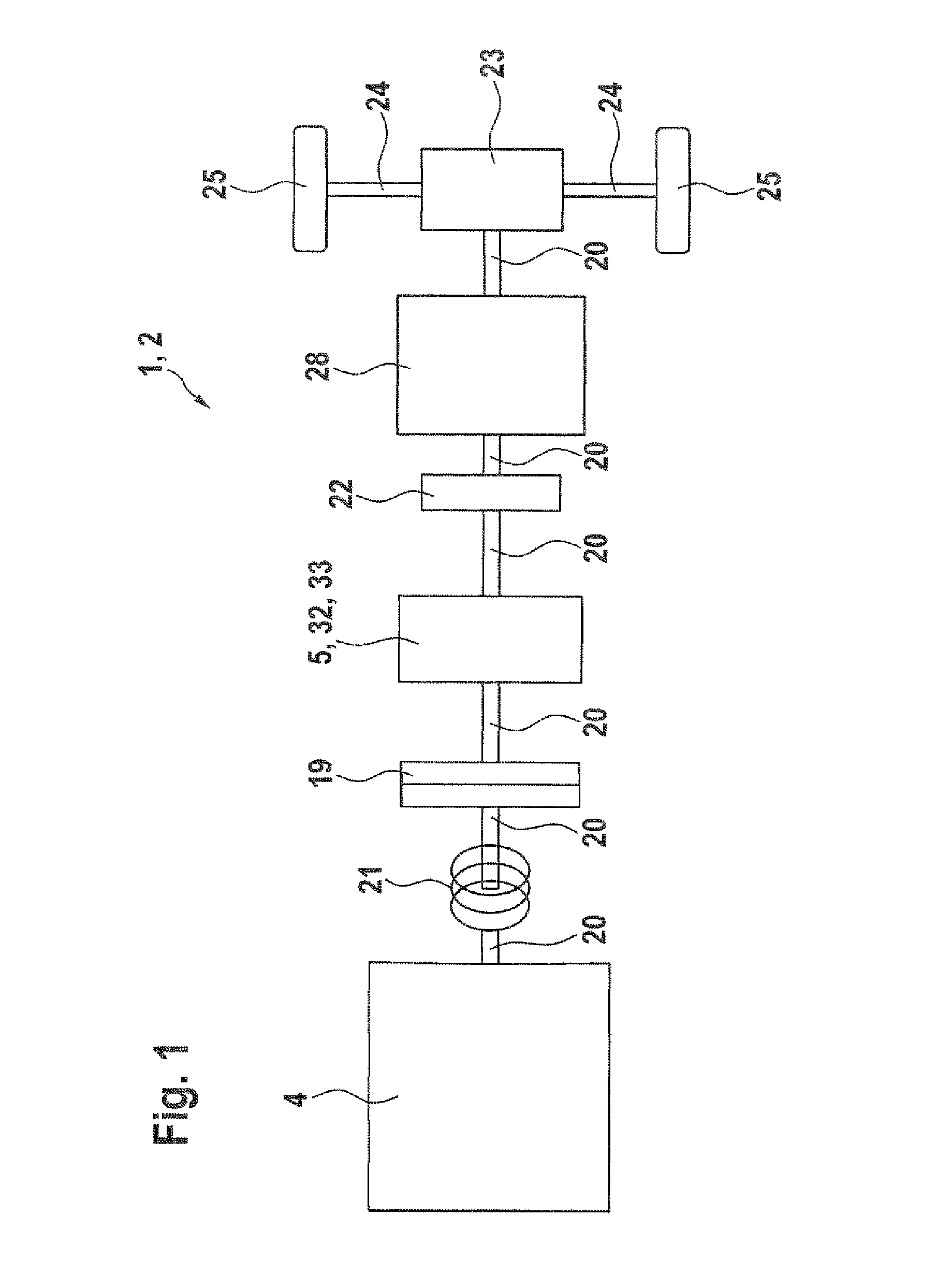

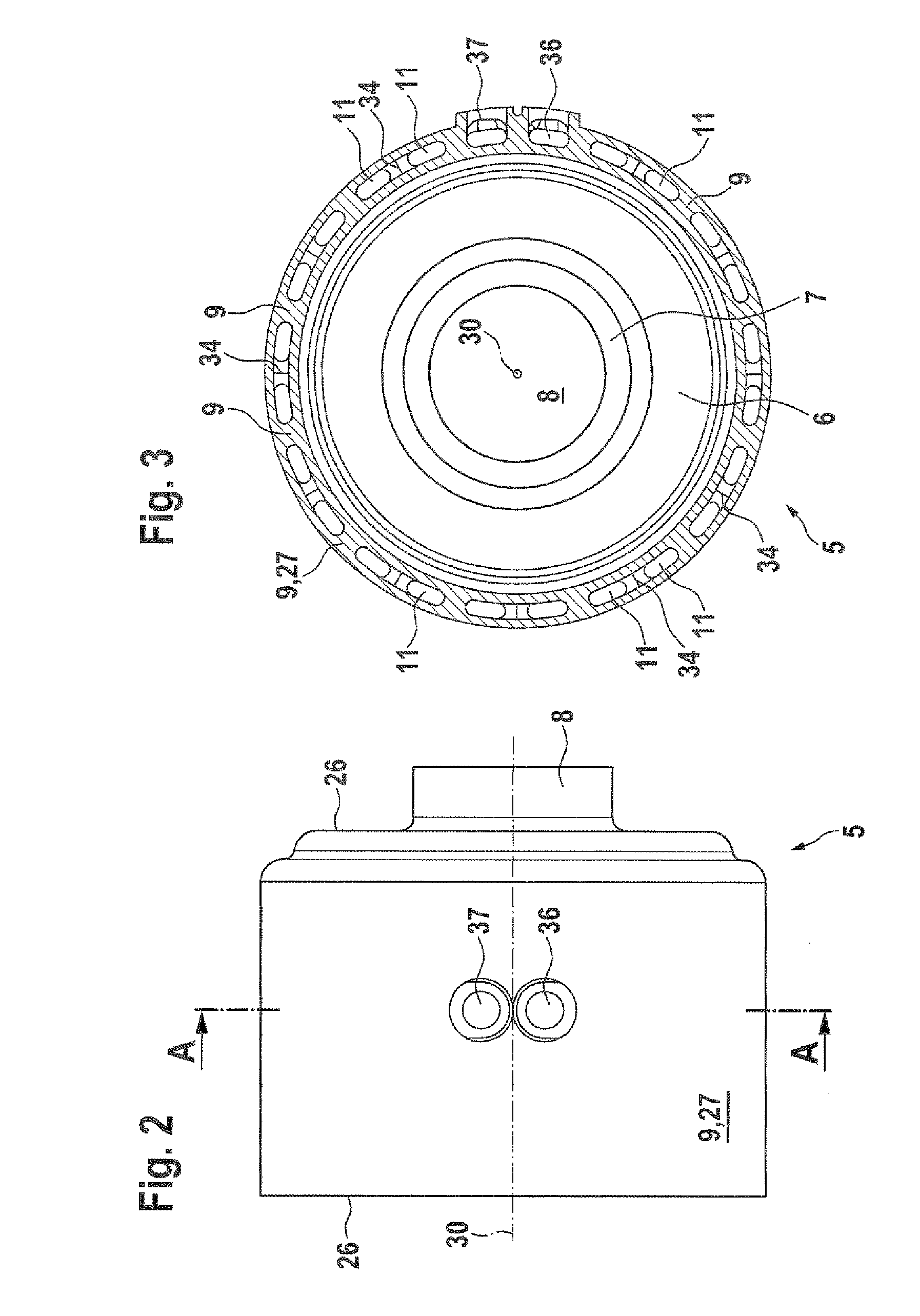

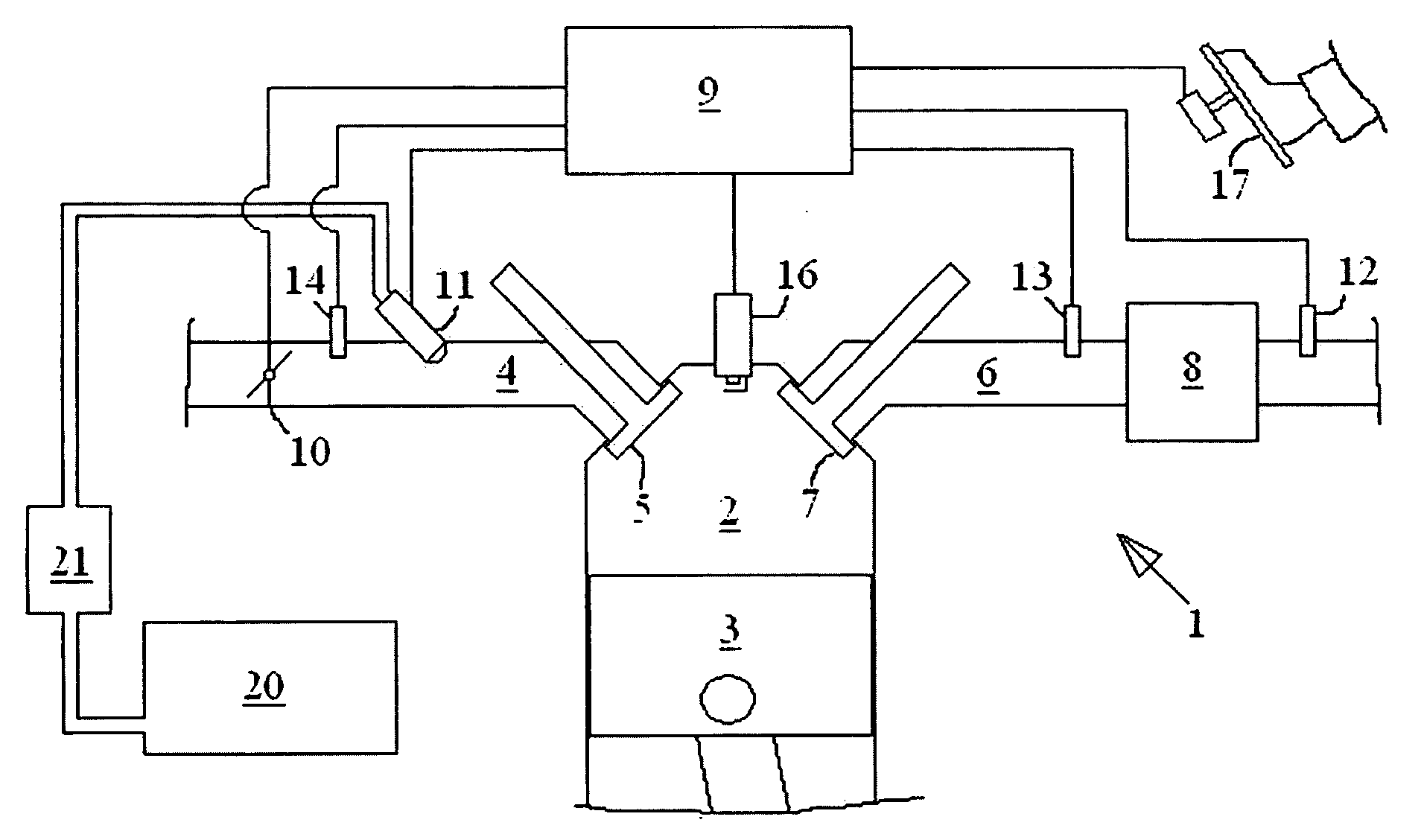

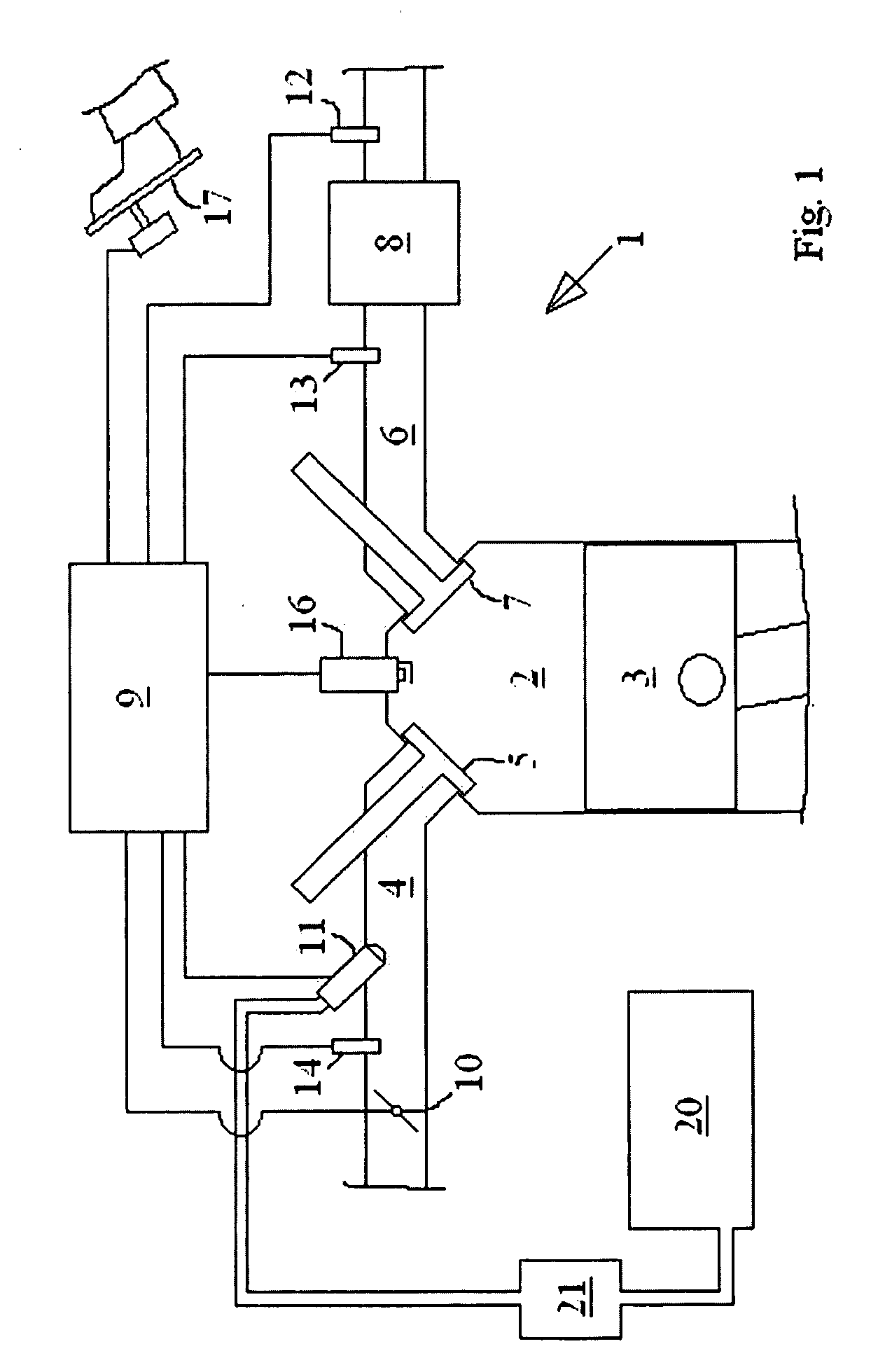

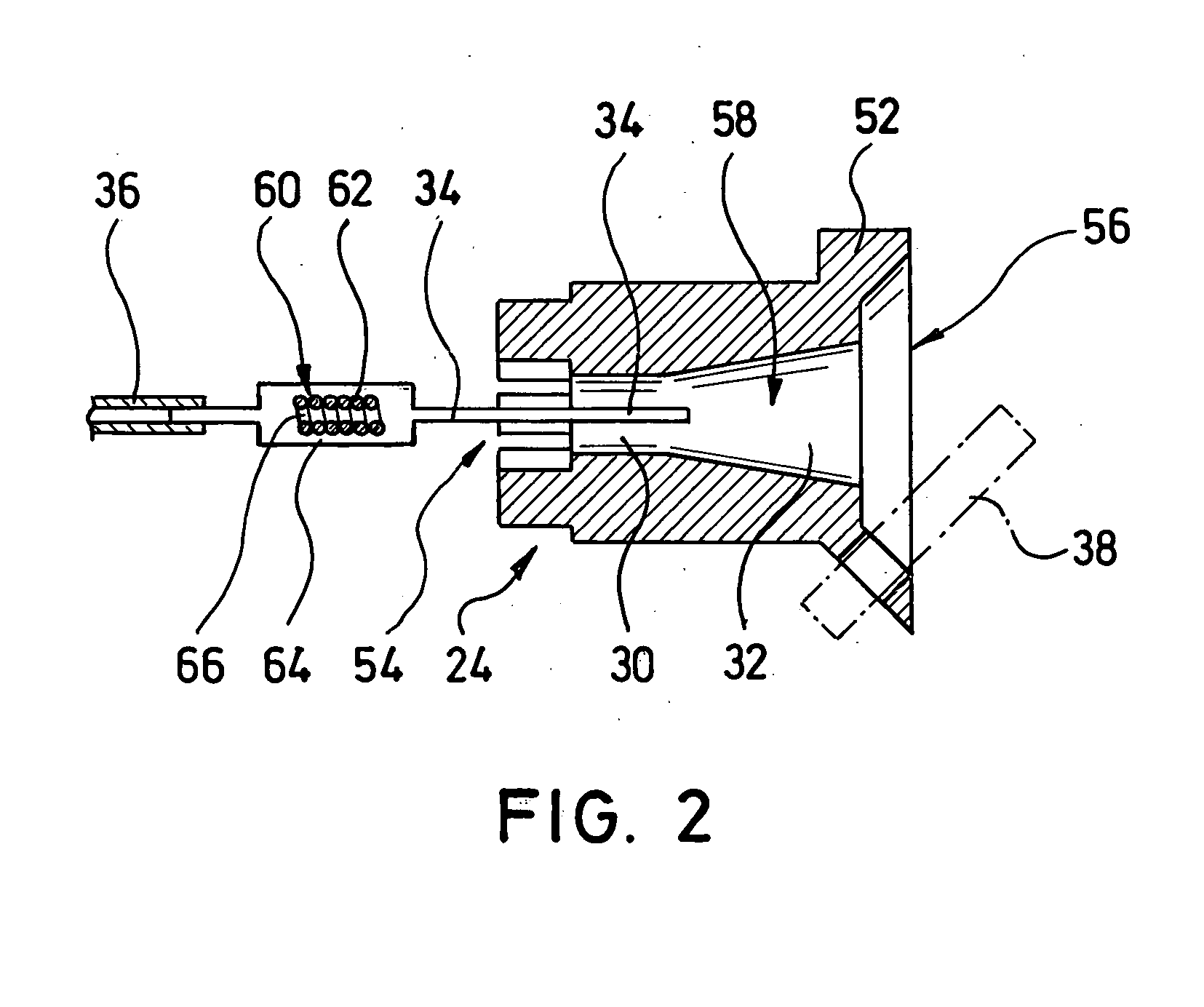

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

Food product comprising a proline specific protease, the preparation thereof and its use for degrading toxic or allergenic gluten peptides

InactiveUS20090304670A1Extended shelf lifeIntense and long interaction periodSpread compositionsPeptide/protein ingredientsProteinase activityWater activity

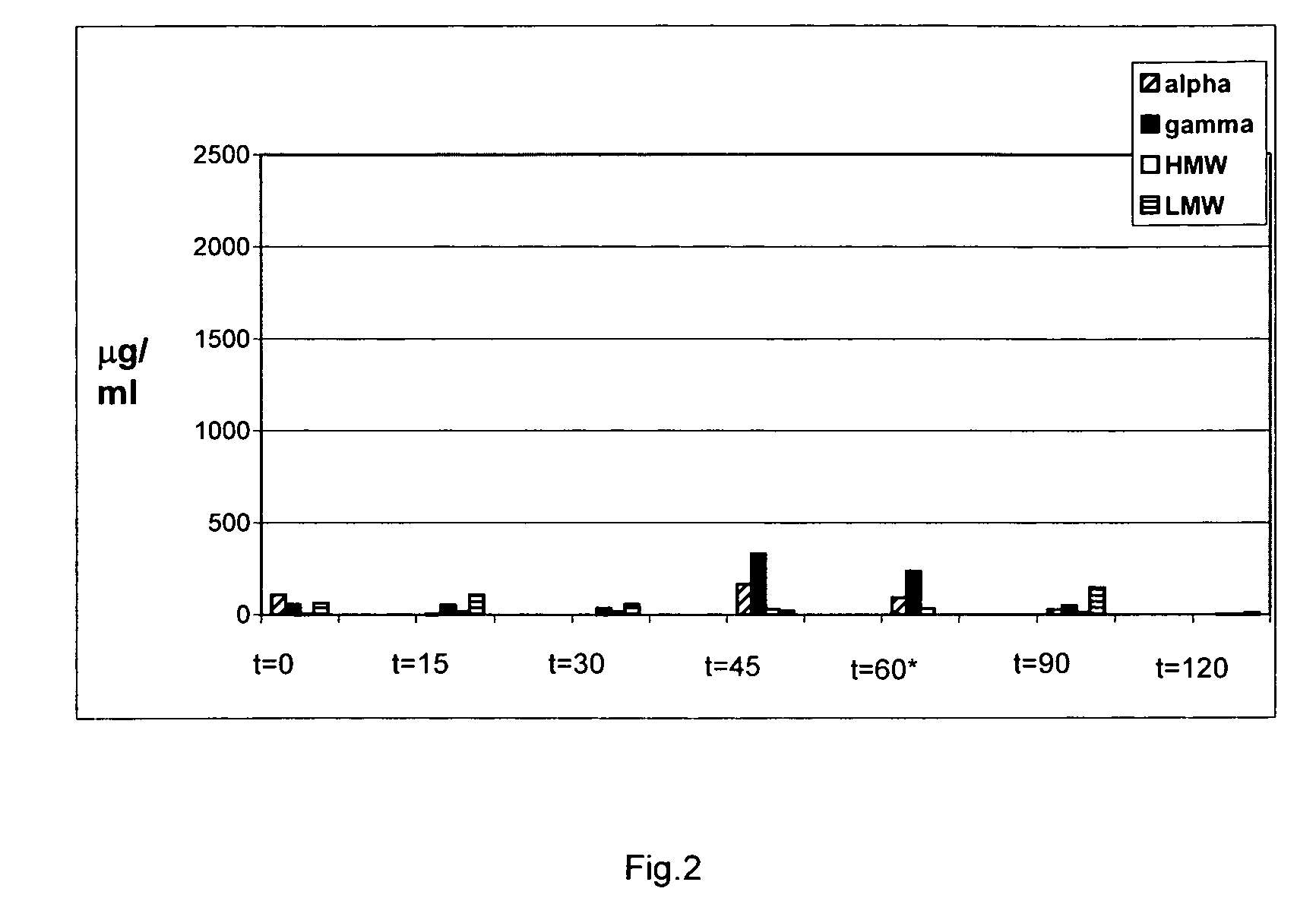

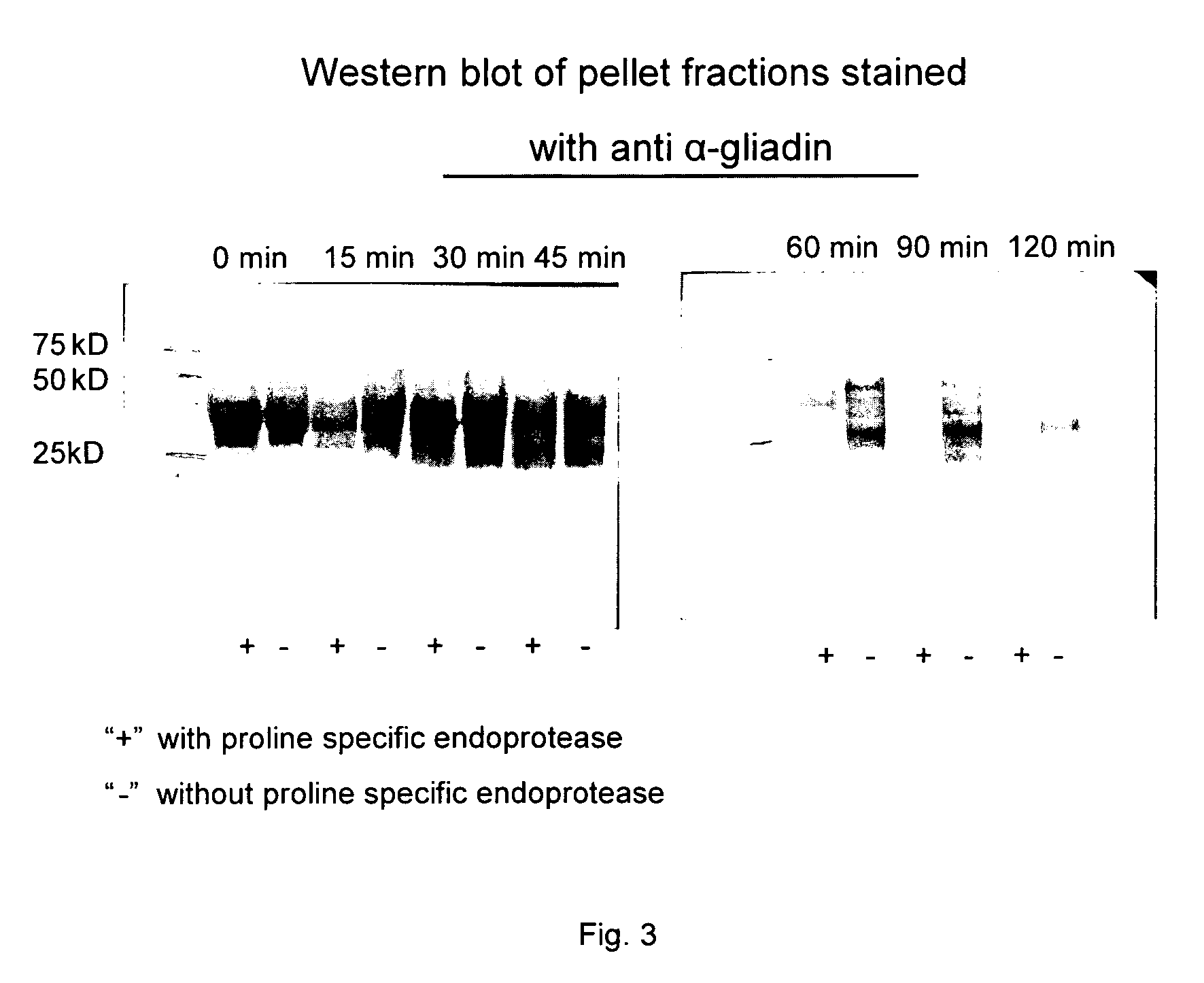

The present invention relates to a pasteurized food product having a water activity of at least 0.80, preferably at least 0.85 and containing a proline specific protease.

Owner:UPONOR INNOVATION AB +1

SELECTIVE CATALYTIC REDUCTION OF NOx ENABLED BY SIDESTREAM UREA DECOMPOSITION

ActiveUS20060115402A1Well mixedAccurate temperatureCombination devicesNitrogen compoundsParticulatesSuperheater

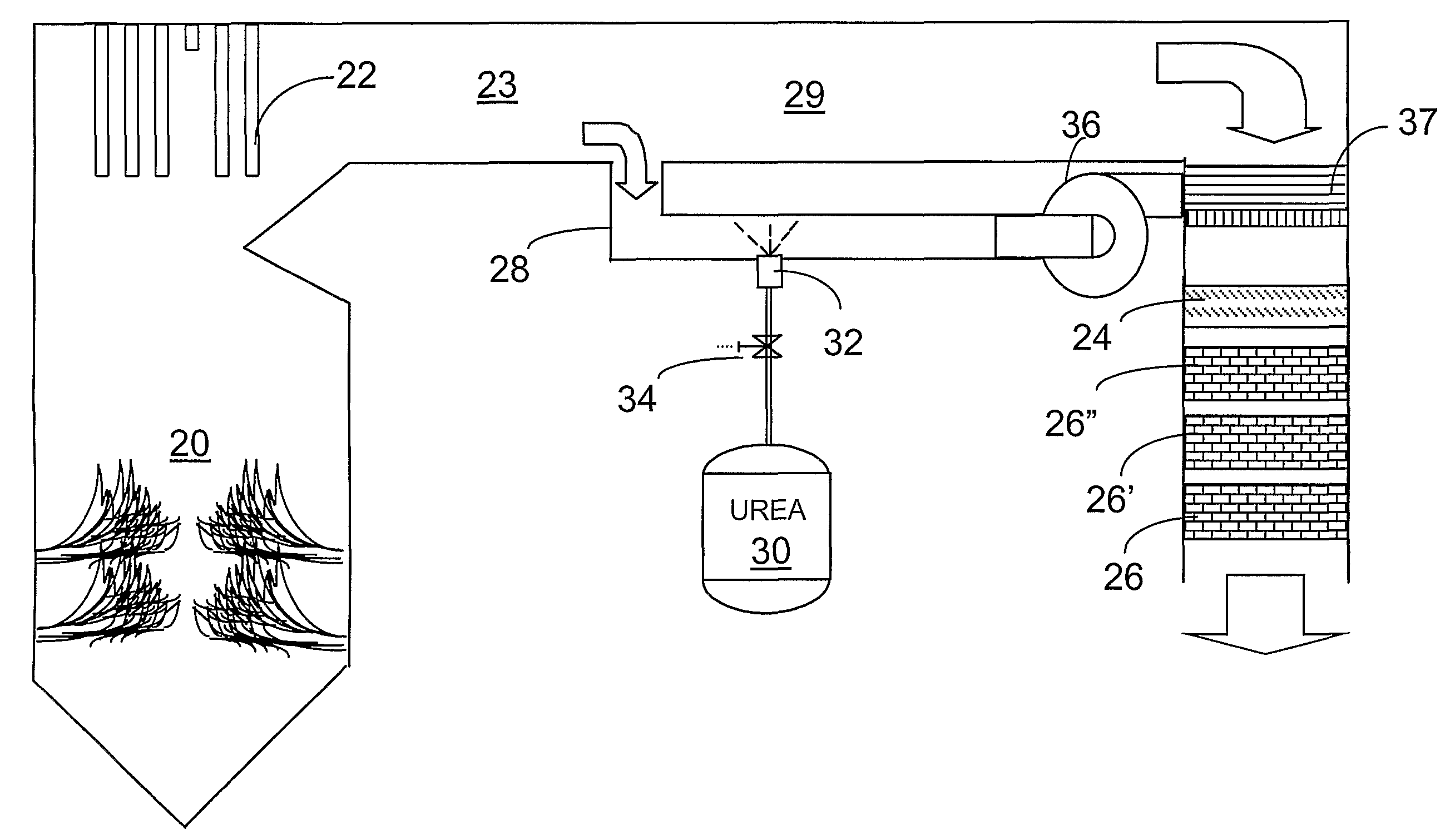

A preferred apparatus arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140.degree. C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

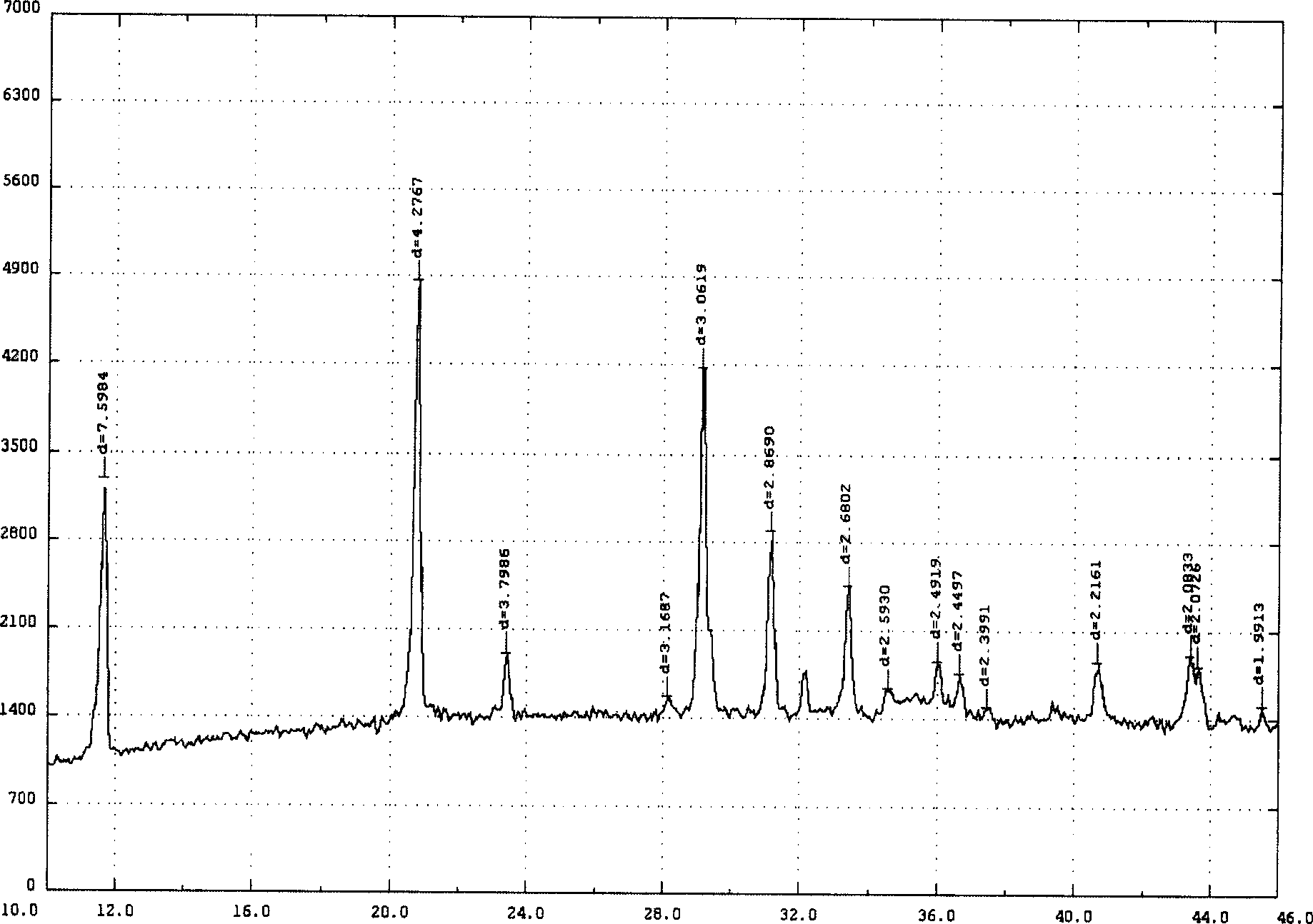

Process for synthesizing LiFePO4 as positive electrode materials of lithium ion cell

InactiveCN1837033AEvenly distributedImprove charging capacityCell electrodesPhosphorus compoundsCompound aPhosphate ion

The invention discloses a Synthesis of lithium ferrous phosphate which is anode material of lithium ion battery. The material synthesis is as follows: geeting lithium salt, malysite and mammonium dihydrogen phosphate, according to the mole ratio of lithium ion: iron ion: phosphate radical ion is (0.8-1.2):(0.8-1.2):(0.8-1.2), getting compound A of equal proportion, joining some compound A in aqueous solution B which contains soluble salt and soluble organic species, putting it in high temperature furnace, then cooling naturely, compounding ferrous phosphate powder containing carbon and adulterating metal ion, milling the synthetical aqueous lithium solution powder, controllong the grain diameter between 1-50 mum. The synthetical material of this invention distribute equally, using this material as positive material can improve batteries' charging capacity effectively.

Owner:SHANDONG UNIV OF SCI & TECH

Orthopaedic cement mixing and dispensing device

InactiveUS6874927B2Mix thoroughlyBetter able to cut through cementSurgical furnitureRotary stirring mixersOrthopedic cementBiomedical engineering

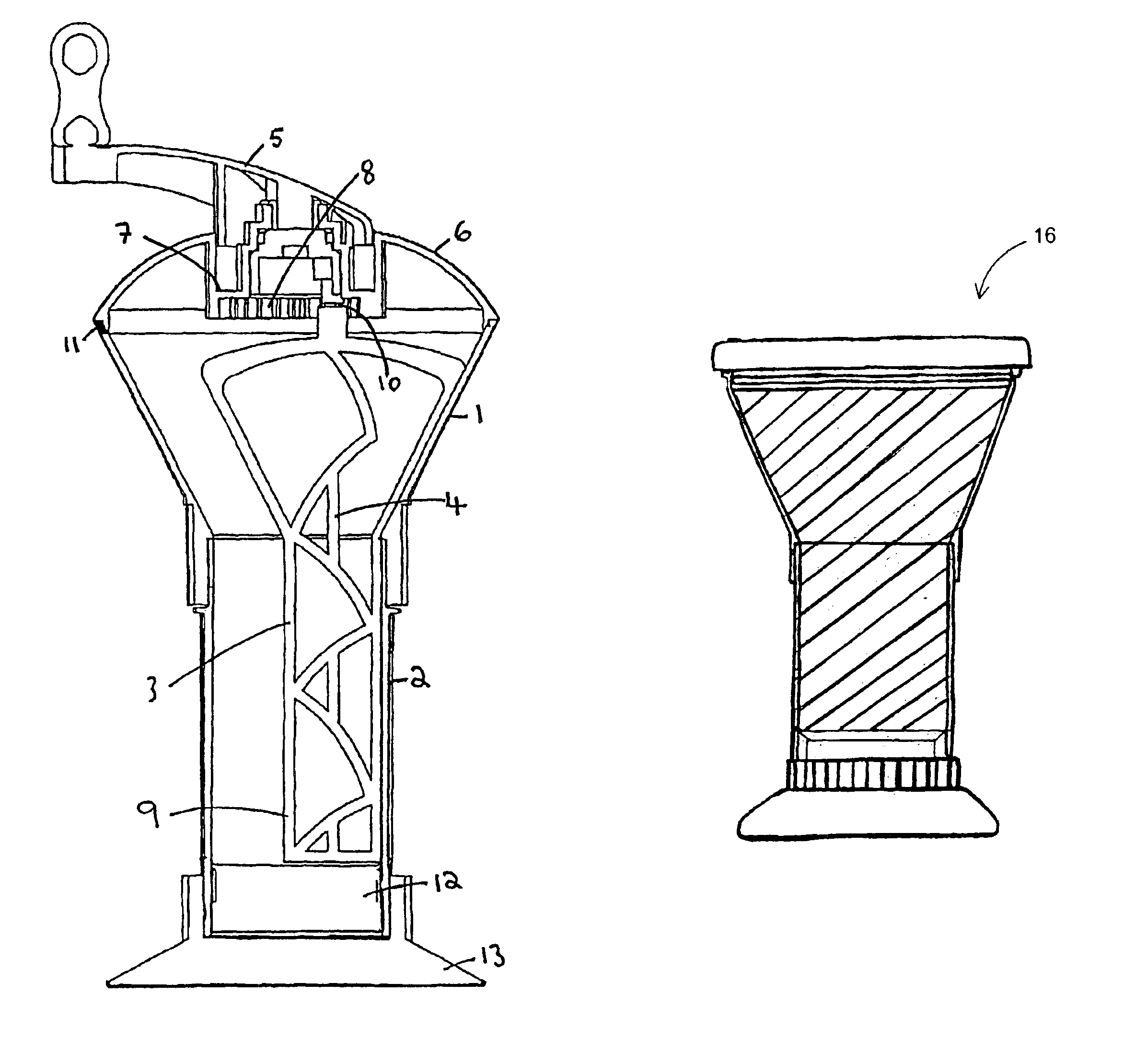

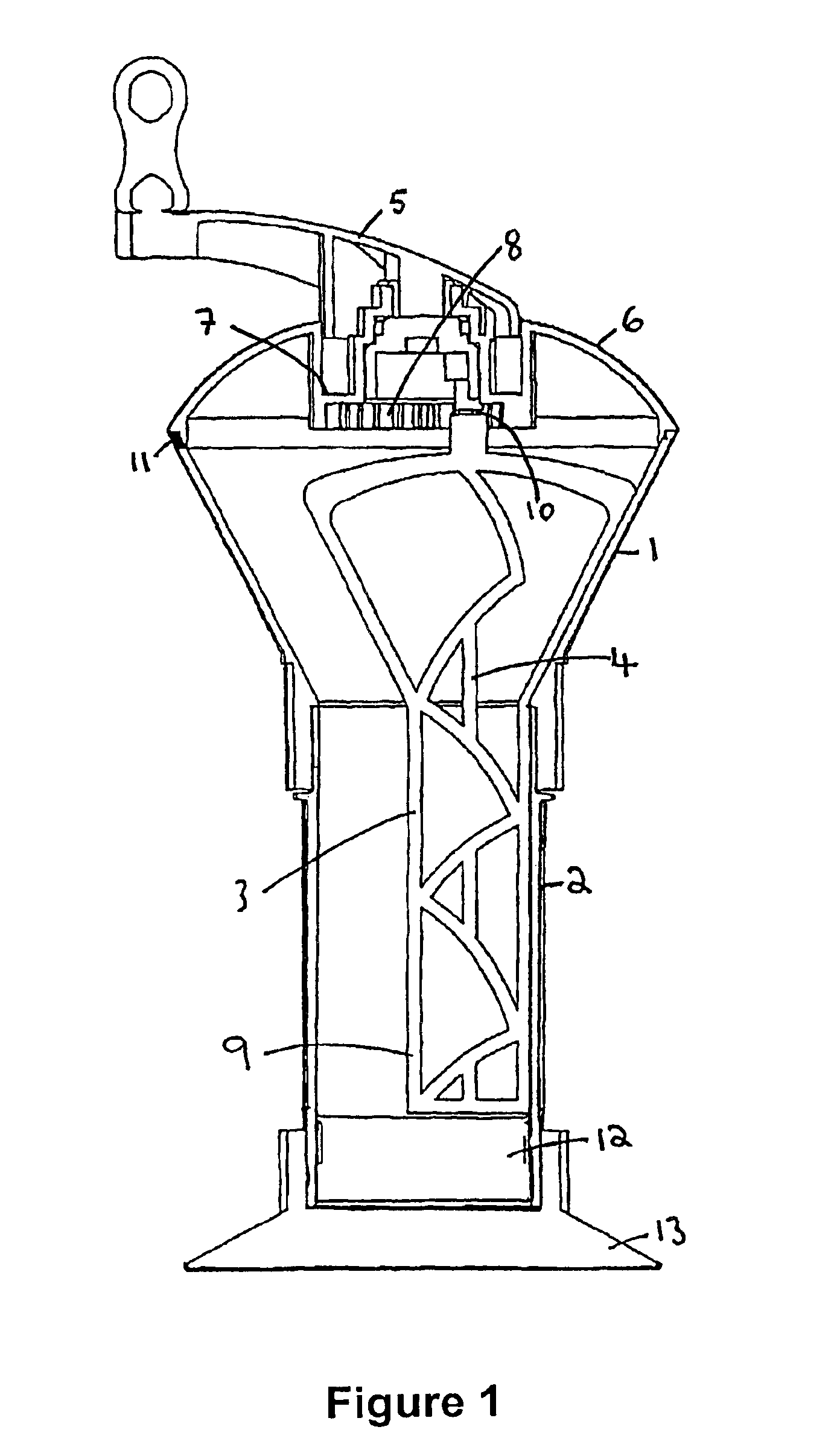

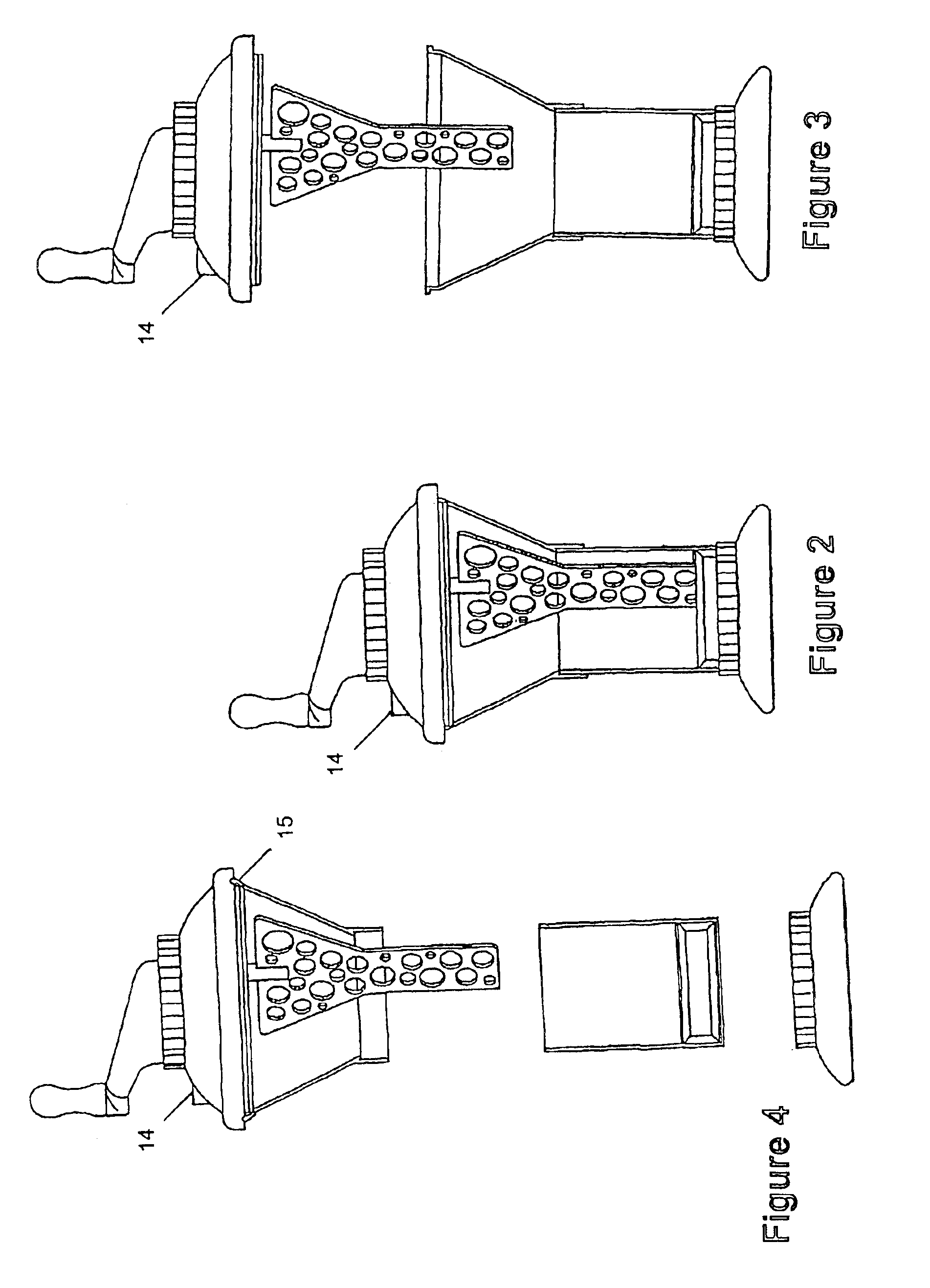

The apparatus is a mixing and dispensing device for orthopaedic bone cement, comprising an introducer funnel and a mixing syringe body. A mixing shaft and paddle arrangement extends through the funnel and mixing chamber, the paddle having a profile matching the shape of the funnel, in the introducer funnel.

Owner:SUMMIT MEDICAL

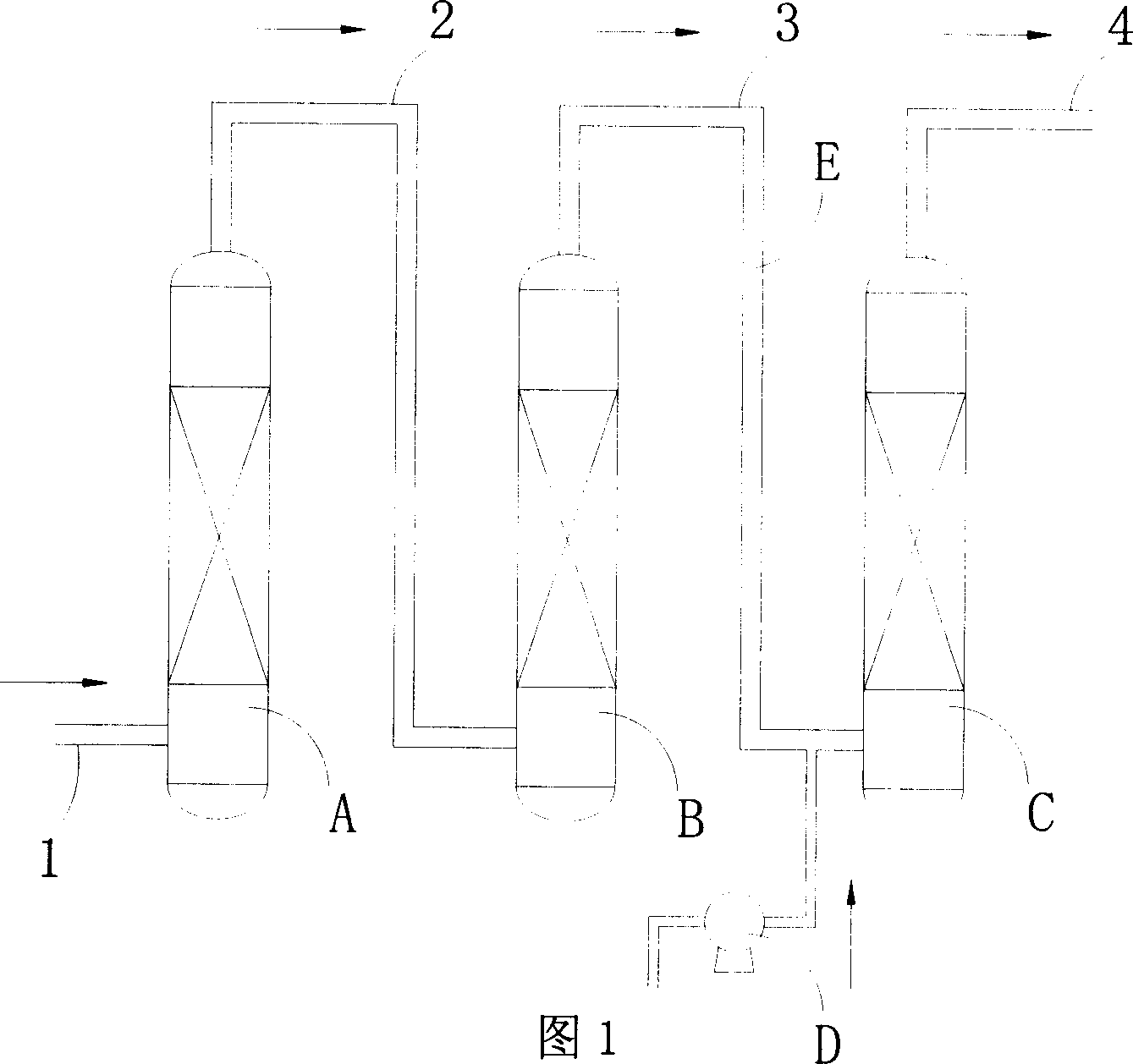

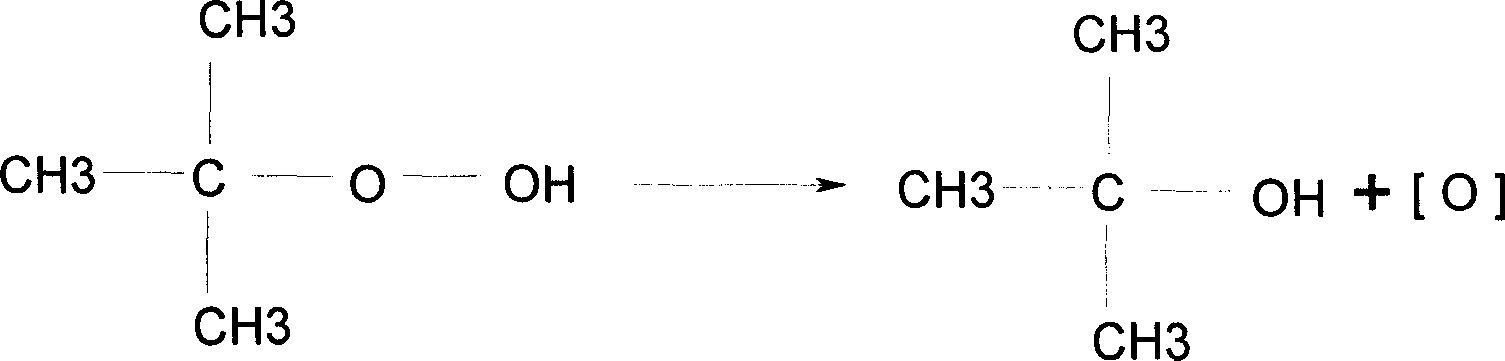

Method for refining catalytic liquefied petroleum gas

The present invention relates to a method for refining catalytic liquefied petroleum gas, in which catalyzed liquefied petroleum gas by alconol-amine method removing hydrogen sulfide process is operated by hydrolysis carbonyl sulfur process by passing through carbonyl sulfur hydrolysis activator bed layer, such that carbonyl sulfur hydrolysis generates sulfureted hydrogen and carbon dioxide; then it passes through the desulfurizer bed layer to operate hydrogen sulfide removing process, the preparation of reaction of the hydrogen sulfide and the desulfurizer is chemically absorbed on the desulfurizer; at last, liquid oxygen supplying agent having effective component of tert-butyl hydroperoxide is applied into the catalyzed liquefied petroleum gas, then it is processed by transformation mercaptan by passing through the double effects activator bed layer, under the effect of the double effects activator, the tert-butyl hydroperoxide is hydrogen peroxide decomposed to release fresh state oxygen, and the mercaptan is oxygenated to bisulfide; the activate component of the double effects activator is compound of manganic.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

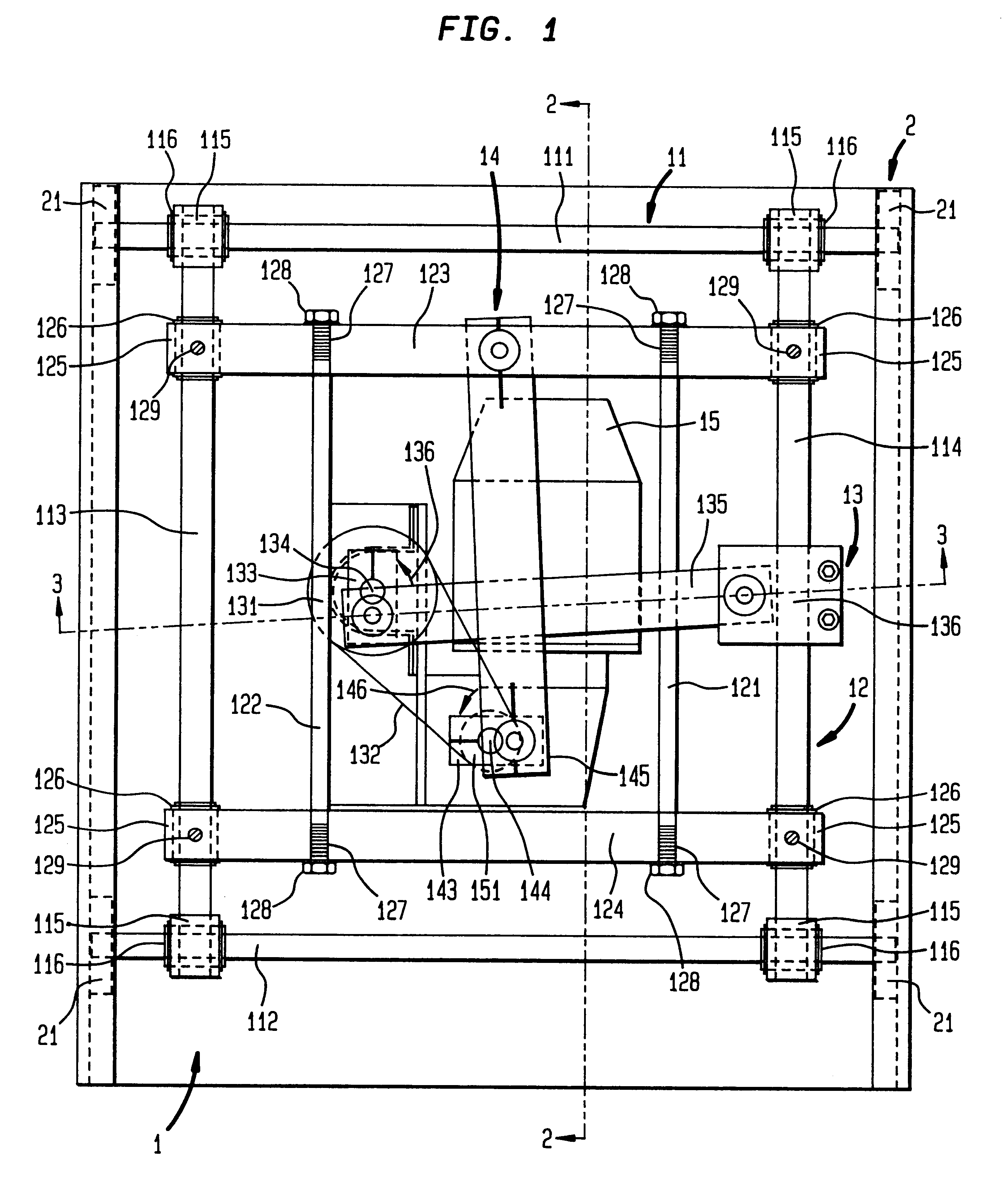

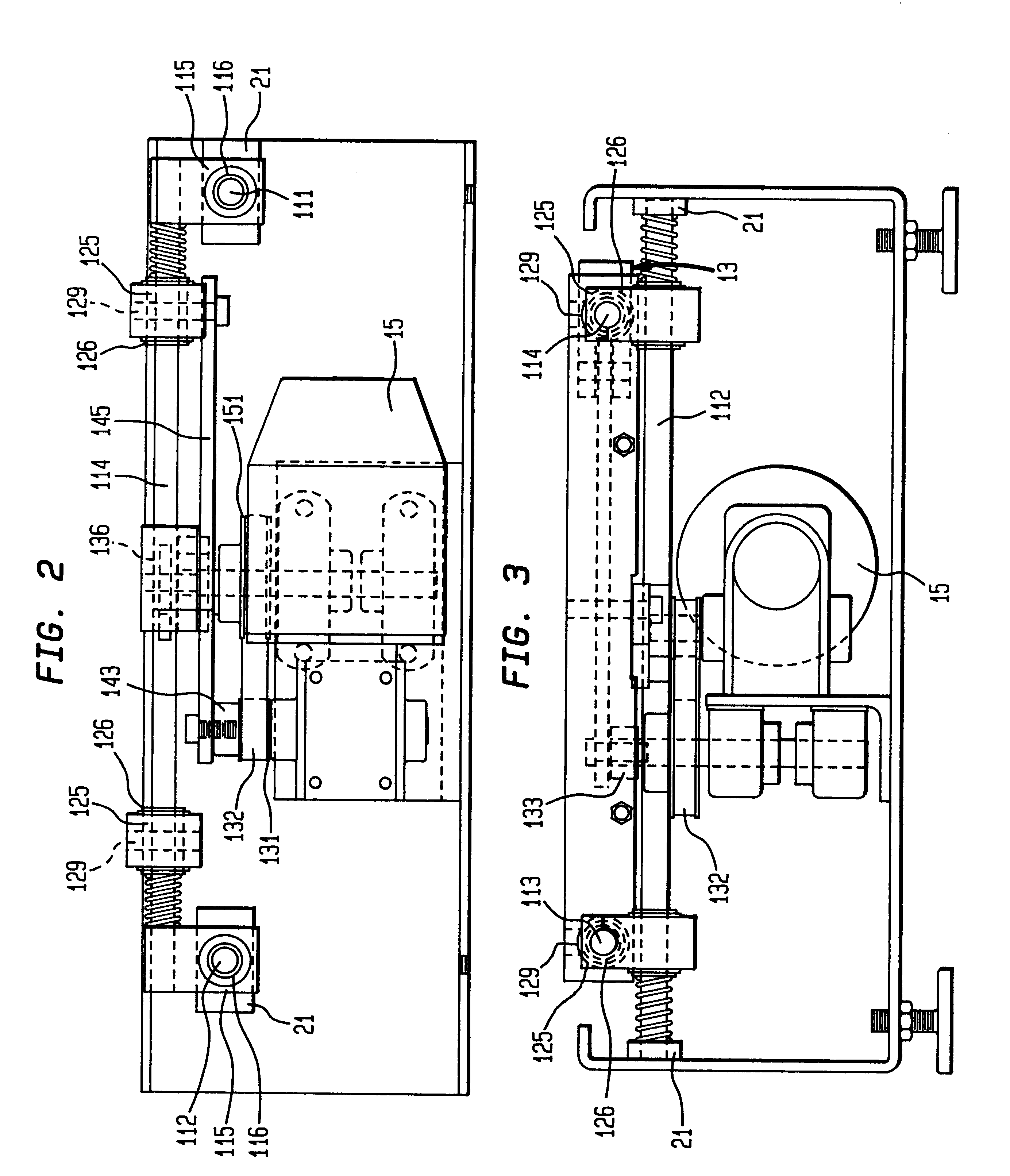

Reversing rotatory shaker movement

InactiveUS6322243B1Well mixedLower energy levelShaking/oscillating/vibrating mixersTransportation and packagingSynchronous motorHigh rate

A shaker movement permits an arbitrary path of motion in a shaker's shaking action. The shaker movement comprises independent control over the "X" and "Y" directions of the shaking actions by a pair of track assemblies, each track assembly comprising a pair of fixed rods and a pair of sliding rods that are interconnected with each other in a rectangular, grid-like pattern. Motion in both directions can be driven by a single motor utilizing independent pulley-and-belt systems or by two synchronized motors which are connected to a sliding rod of each track assembly. By altering the relative amplitude, phase angle, and frequency between the "X" and "Y" directions, the shaking action can follow a desired path. The shaker path can be varied from the traditional circular orbital motion or linear motion, to a new group of shaking patterns in which the direction of the shaking movement can reverse. The new patterns of shaker movement cause the liquid being shaken to be more thoroughly mixed, with less power input, and at a lower angular frequency than is practical with traditional paths of motion. This results in higher rates of gas transfer to and from the liquid, resulting in greater growth of a bacterial culture, and for higher rates of mass transfer at equivalent levels of energy input.

Owner:BULL DANIEL

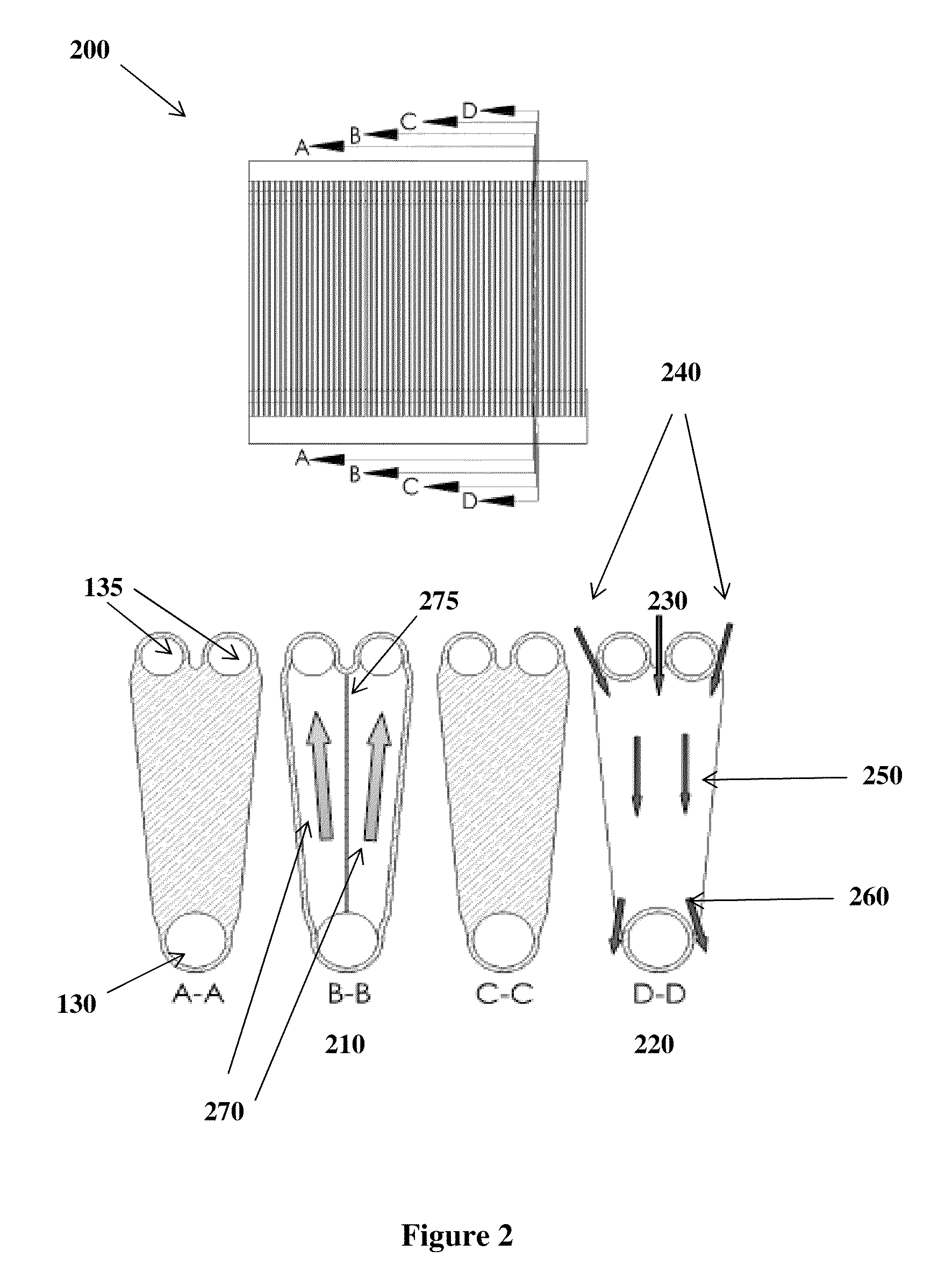

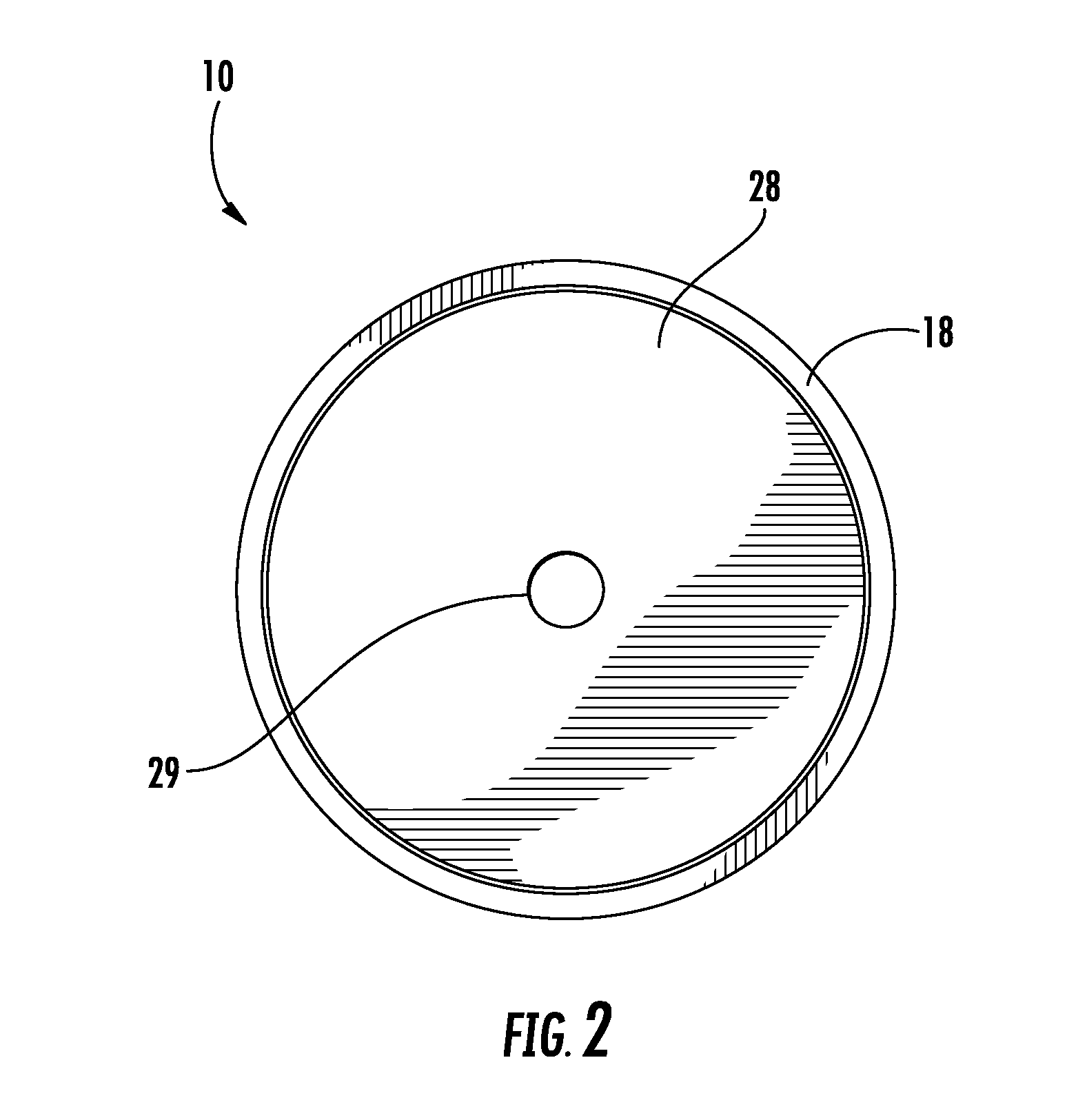

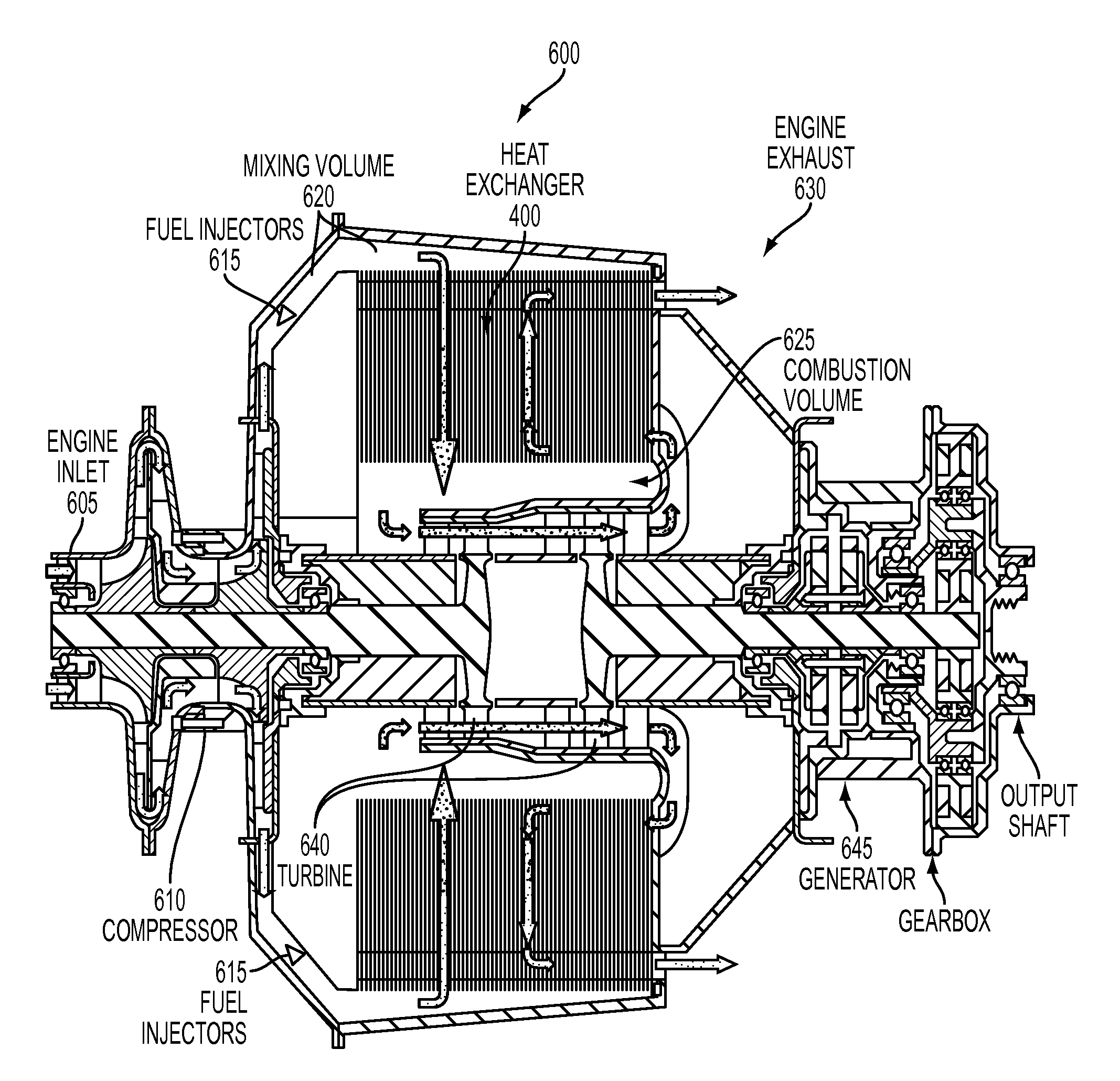

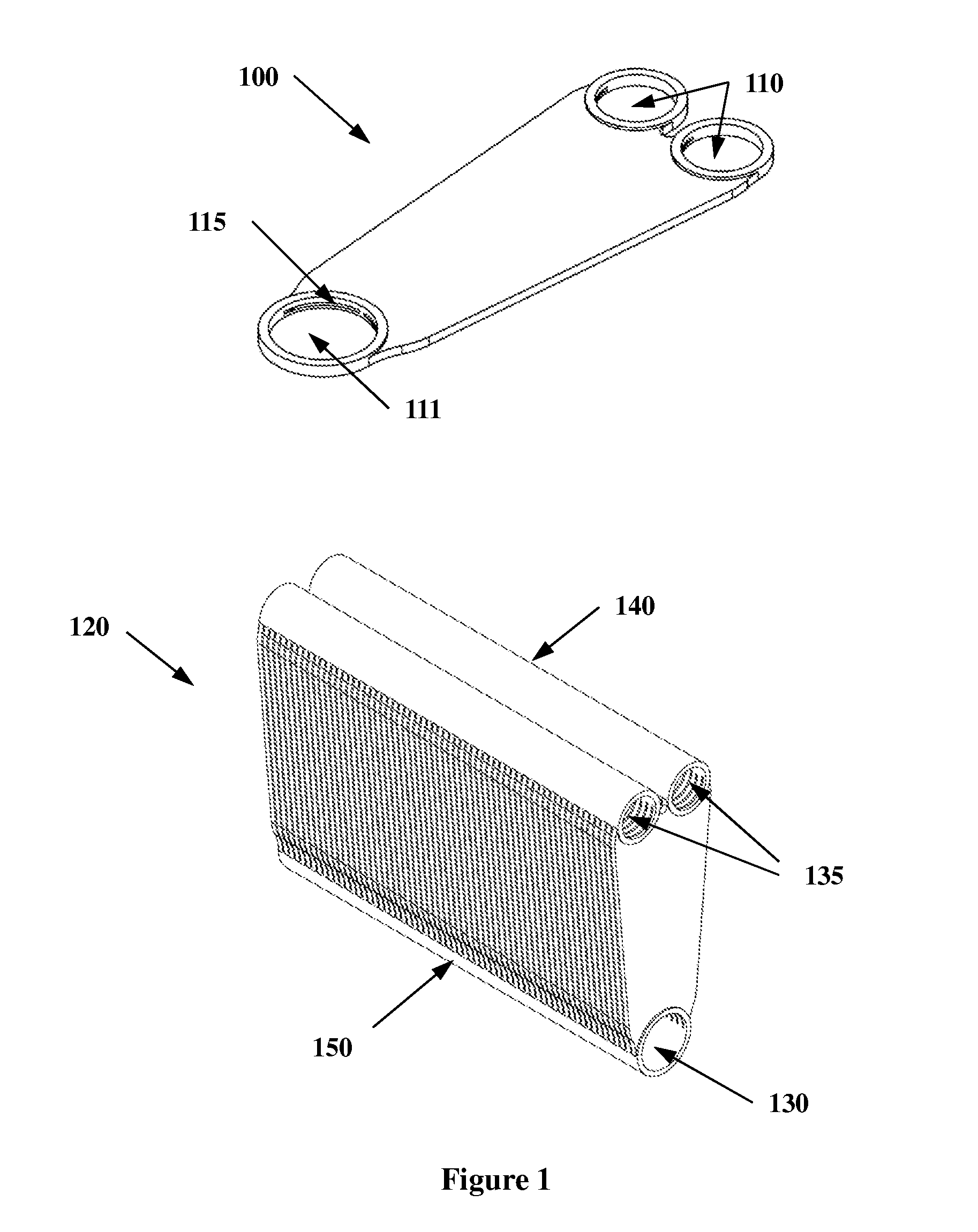

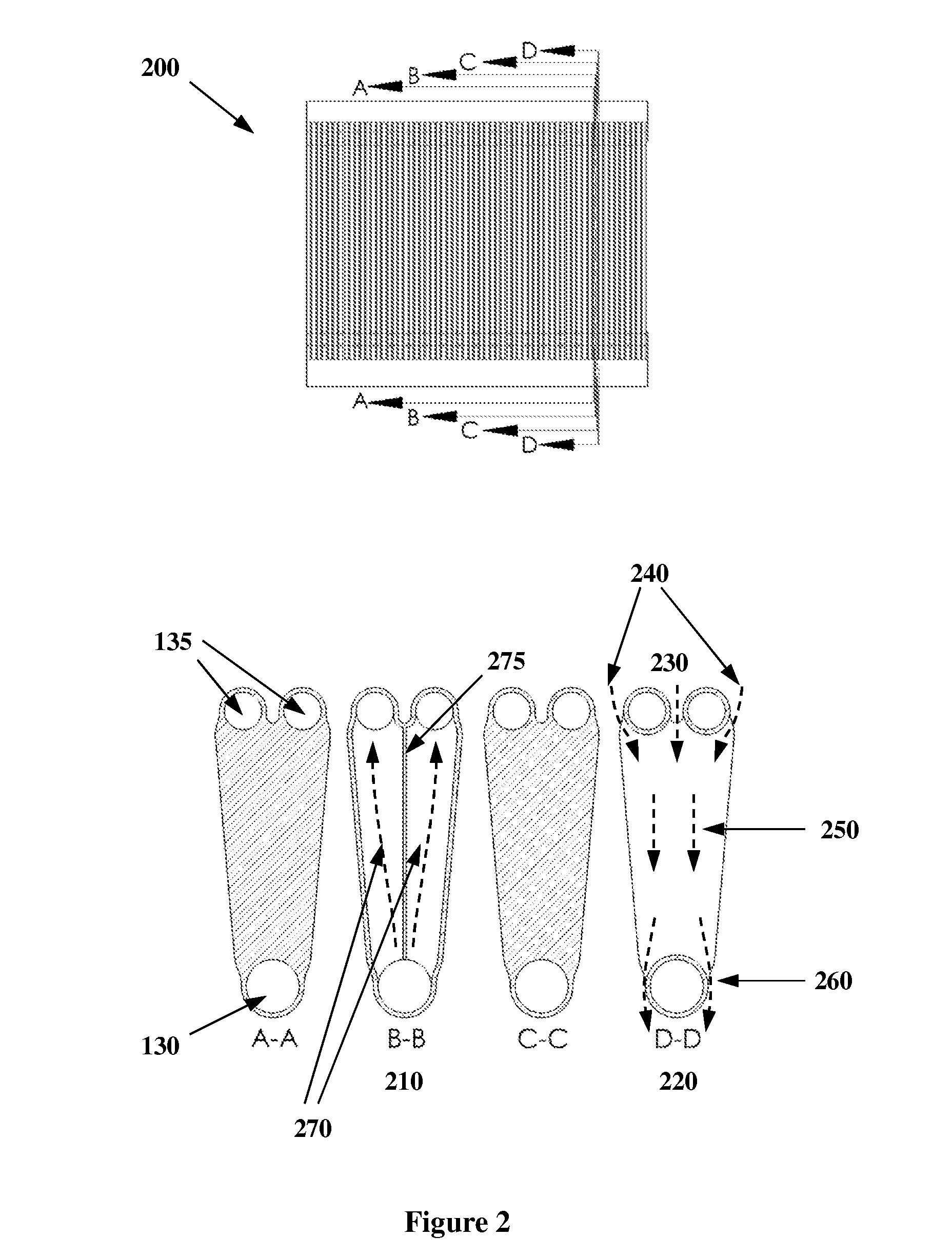

Compact Radial Counterflow Recuperator

ActiveUS20100293946A1Reduce thermal stressReduce manufacturing costRecuperative heat exchangersGas turbine plantsCombustorMechanical engineering

An annular design heat exchanger is formed from an arrangement of wedge-shaped stacks of wafers. Each wafer includes sheets of material separated by peripheral and supporting walls that define interior flow channels through which a first fluid can flow. Holes in the sheets provide inlets and outlets to the channels, and walls surrounding the holes mate with neighboring wafers in the stack, forming integral inlet and outlet manifolds, while ensuring uniform spacing between the wafers. A second fluid can flow around the manifolds and through the spaces between the wafers in a counterflow pattern. In the annular assembly, the manifolds are oriented substantially axially, and the flow channels are oriented substantially radially. The heat exchanger can be formed from a ceramic material, and can be incorporated into an engine assembly or a heat-recirculating combustor.

Owner:UNITED STATES OF AMERICA

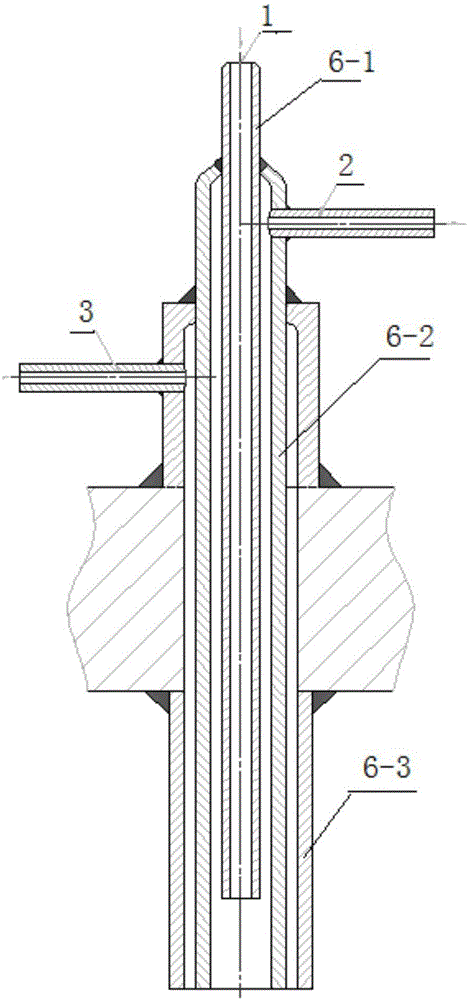

Jet combustion device and method for super-critical water oxidization of organic matter

InactiveCN105782995ARapid temperatureIncrease reaction rateIncinerator apparatusMesosphereInorganic salts

The invention provides a jet combustion device and method for super-critical water oxidization of organic matter. The device comprises an inner sleeve and an outer sleeve which are arranged together in a coaxial sleeving manner; a coaxial jet combustor extending into the reactor inner sleeve is coaxially installed at the top of the reactor inner sleeve; the coaxial jet combustor is of a three-layer coaxial sleeve structure, an auxiliary heat source access channel is located on the innermost layer, an oxidant access annular channel is located on the middle layer, and a waste liquid access annular channel is located on the outermost layer; and a process water jacket region, a super-critical water oxidization region and a subcritical water region capable of dissolving inorganic salt are formed in a reactor.

Owner:SHANDONG UNIV

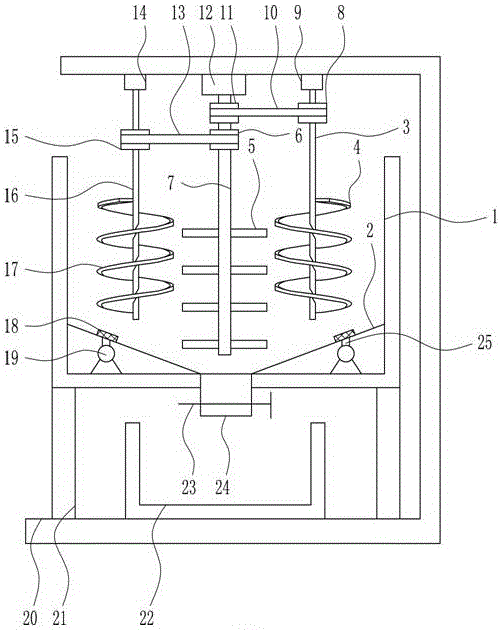

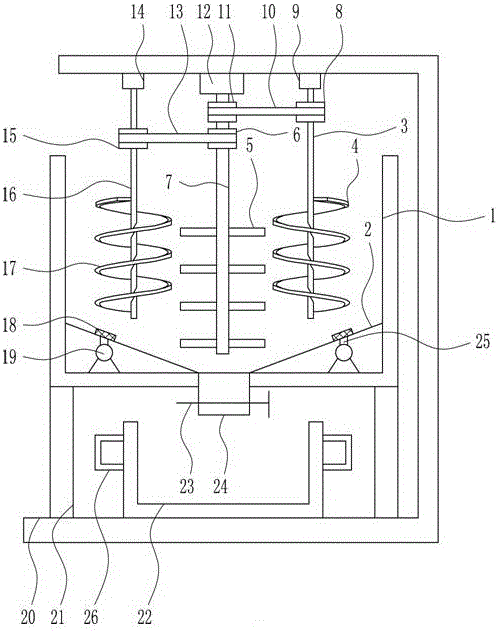

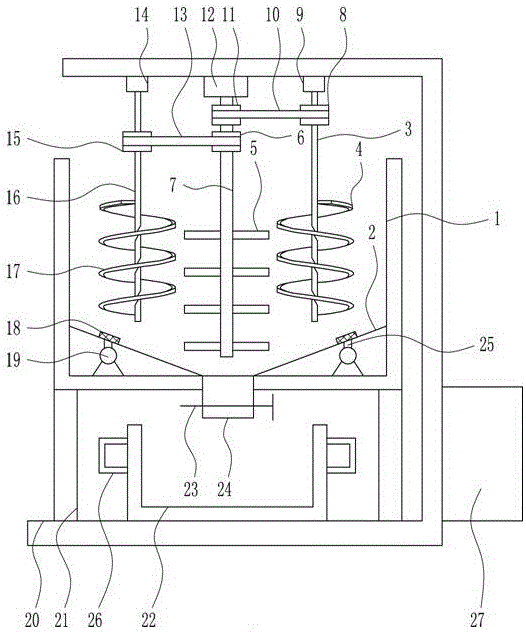

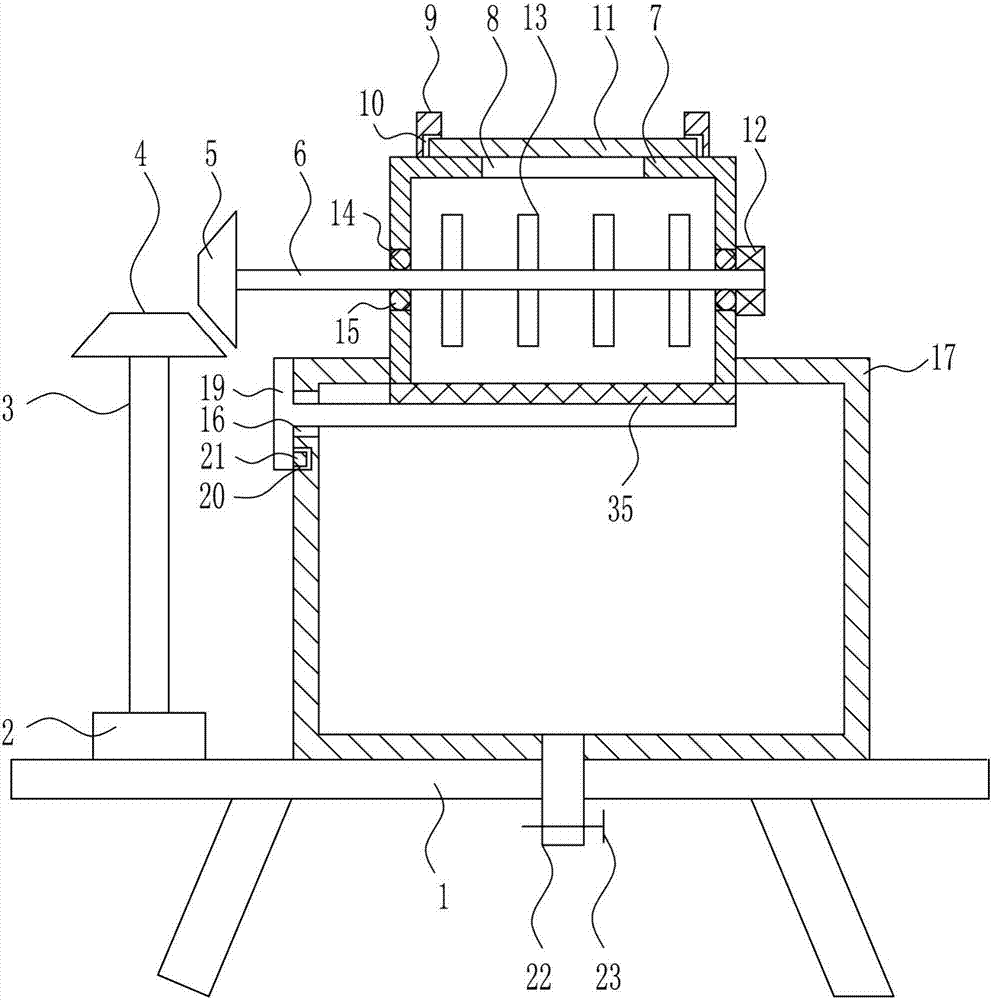

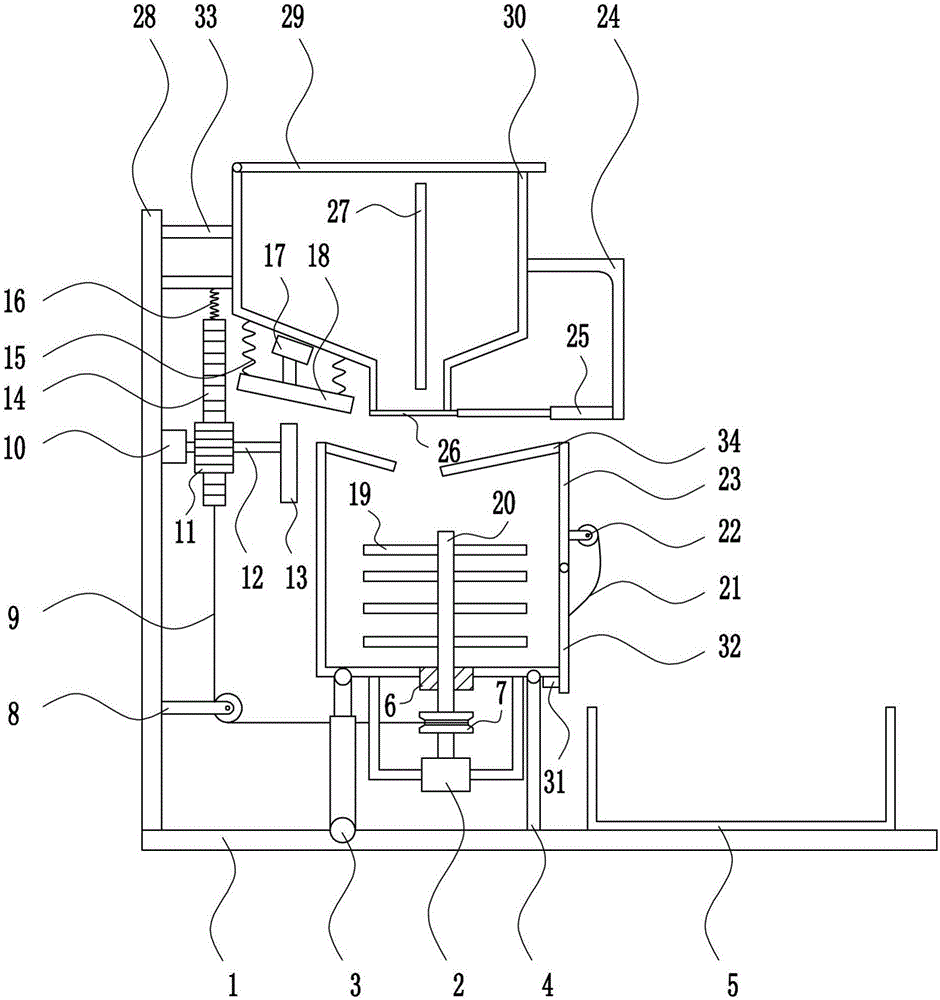

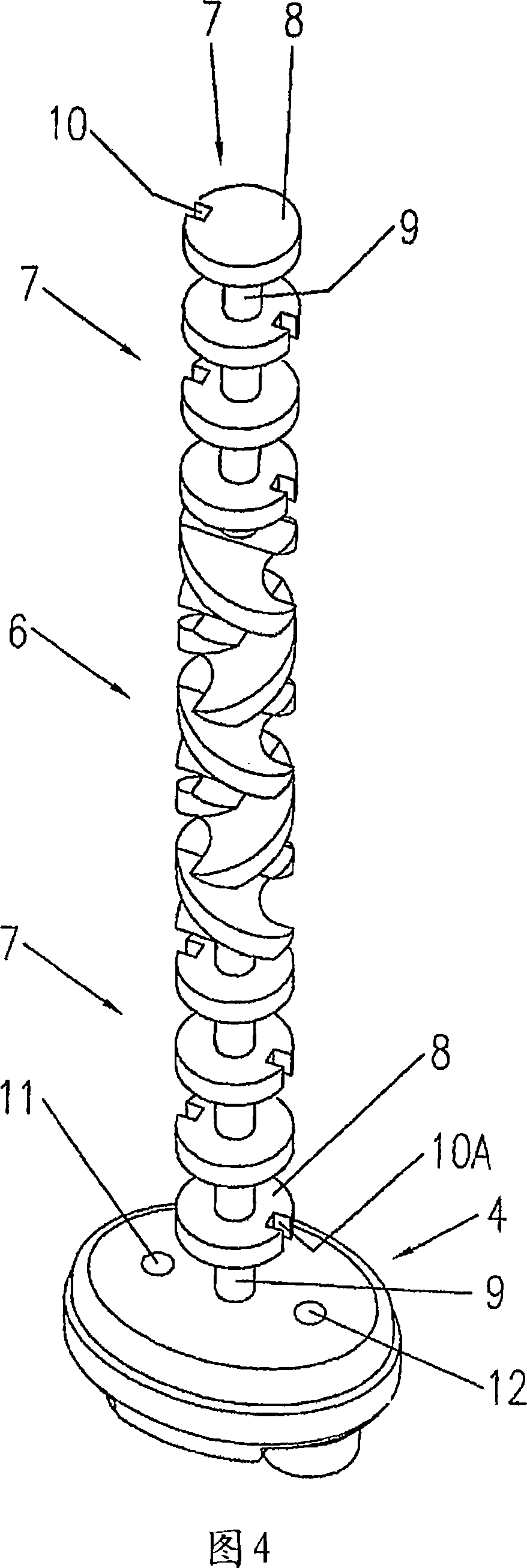

Polyurethane foaming plastic reaction molding device

InactiveCN106478907ANot easy to corrodeExtended service lifeRotary stirring mixersTransportation and packagingSpiral bladePolymer chemistry

The invention relates to a reaction molding device, and particularly relates to a polyurethane foaming plastic reaction molding device. The technical problem to be solved in the invention is to provide a polyurethane foaming plastic reaction molding device with ideal reaction molding and thorough reaction. In order to solve the technical problem, the invention provides the polyurethane foaming plastic reaction molding device. The polyurethane foaming plastic reaction molding device comprises a frame body, a clapboard, a first stirring shaft, a first spiral blade, a stirring blade, a third belt wheel, a second stirring shaft, a first belt wheel, a first bearing base and others; left and right sides of the bottom part in an installing frame are symmetrically welded with supporting rods, and top ends of the supporting rod are welded with the frame body; the center of the bottom part of the frame body is welded with a discharge pipe, and a valve is arranged on the discharge pipe. Through a motor, the stirring blade is driven to rotate, so as to mix raw materials in the frame; meanwhile, the first spiral blade and the second spiral blade are driven to rotate, and thus the raw materials are vertically conveyed.

Owner:WUXI TONGXIN PLASTIC PROD

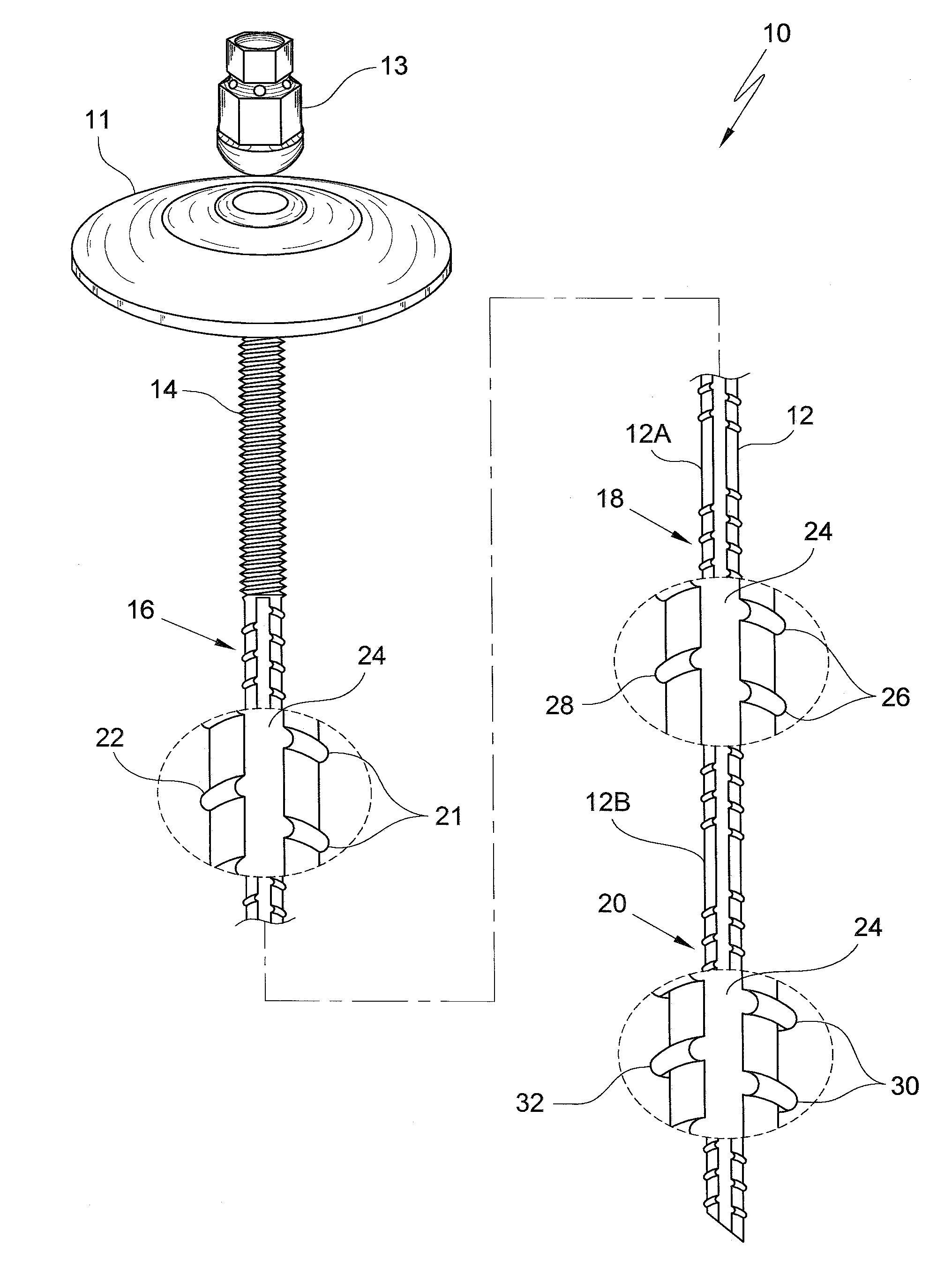

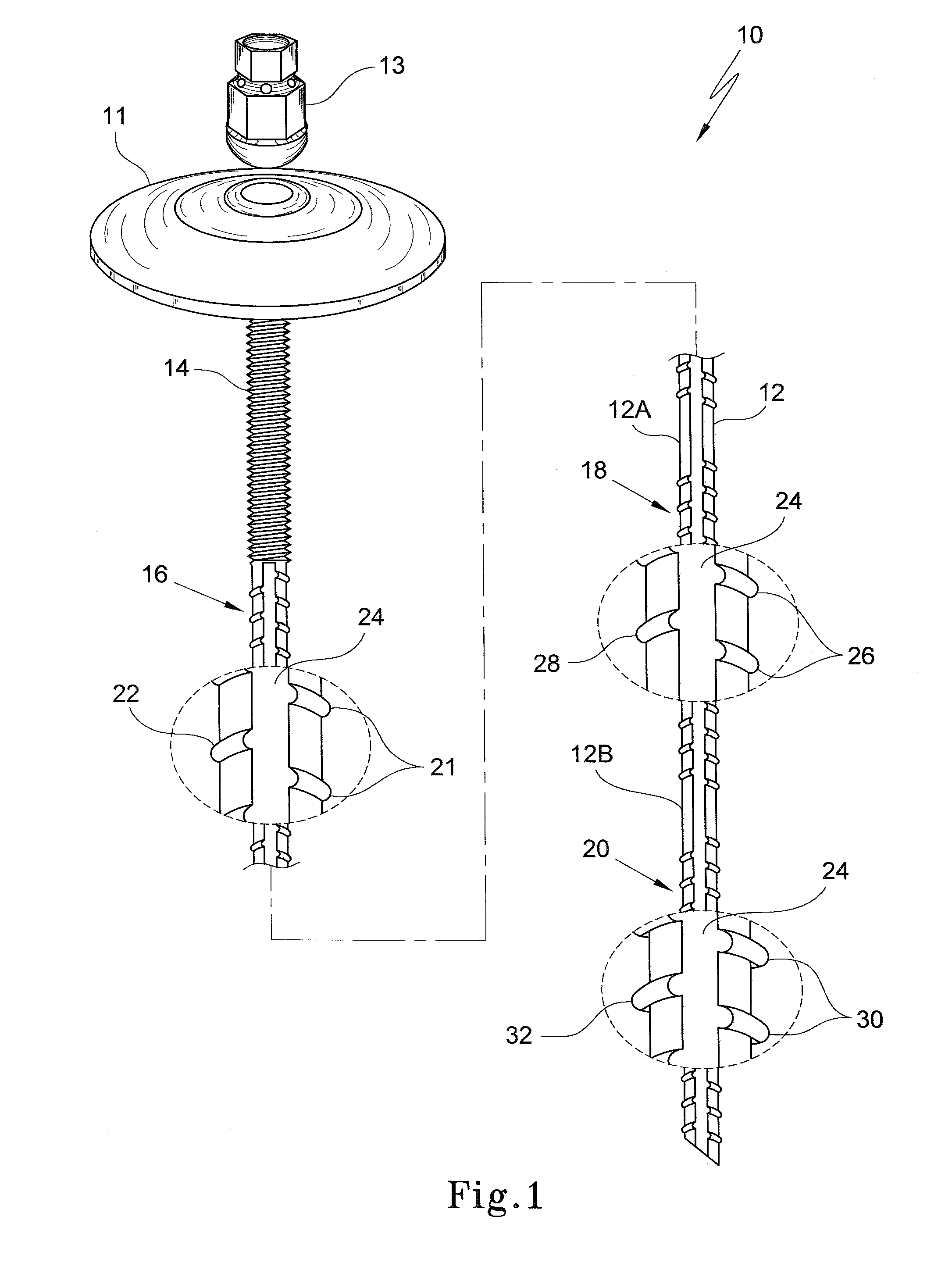

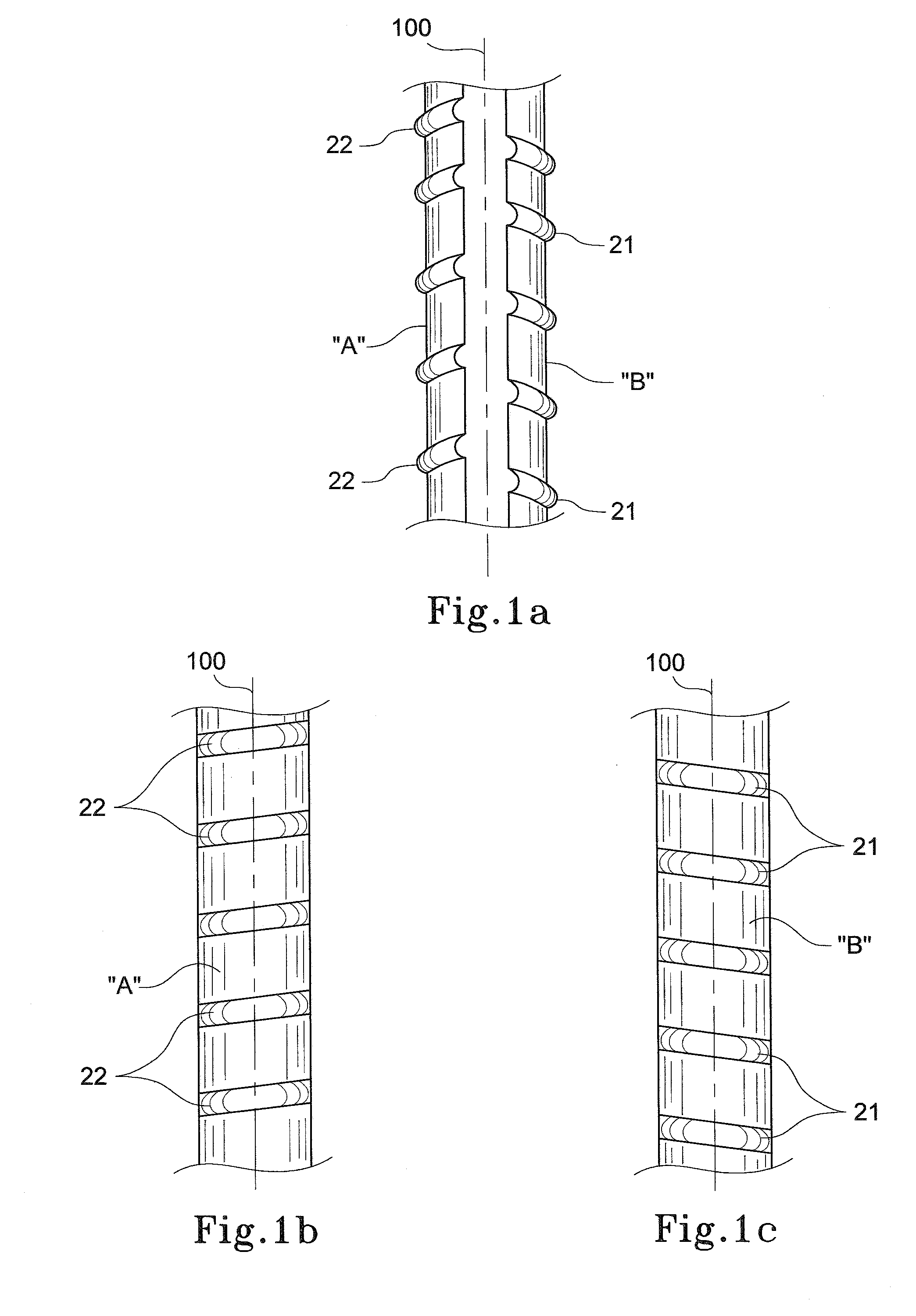

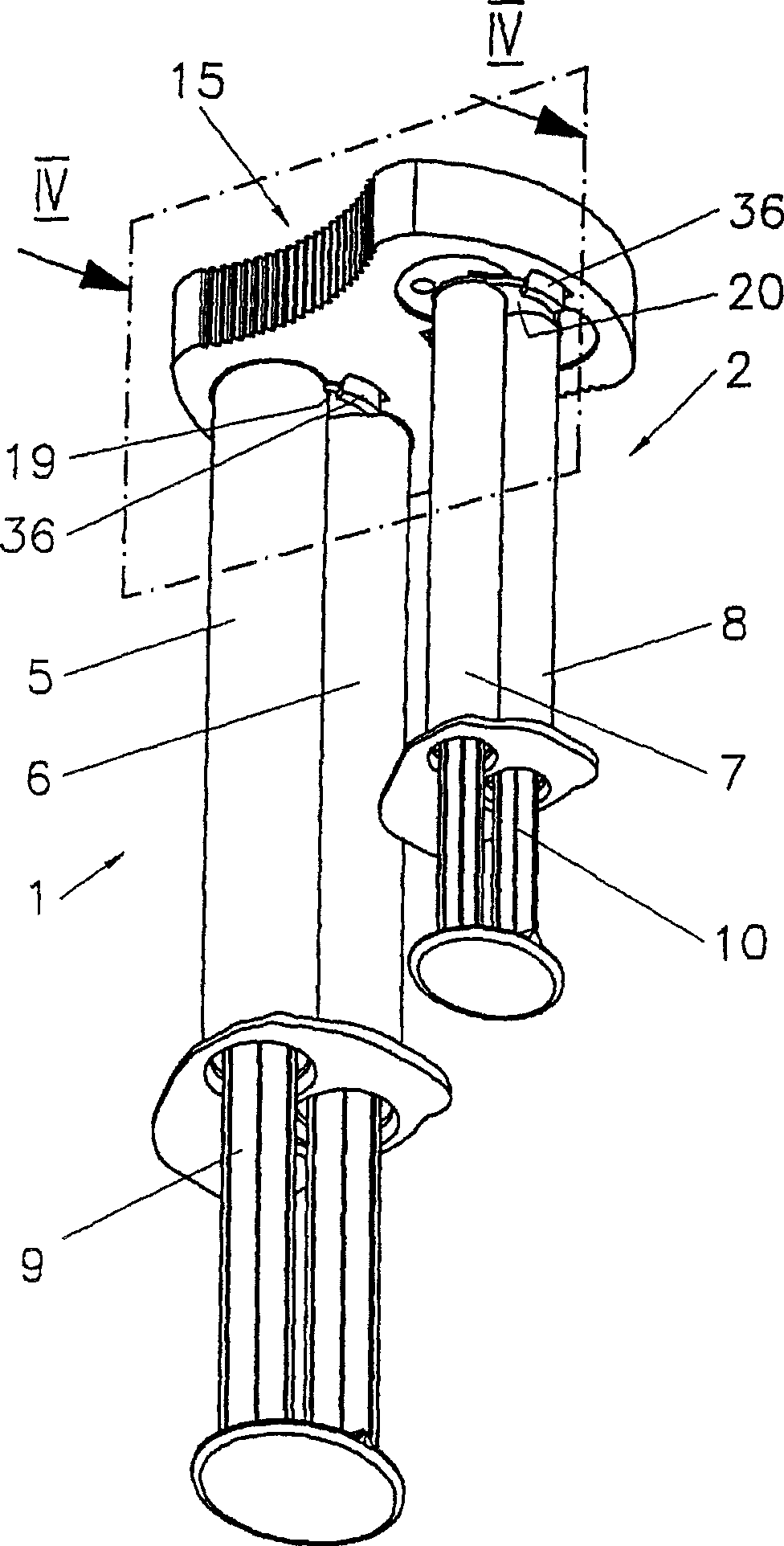

Plastic rock-bolt or dowel

A rock-dowel has a dowel shank has a diameter of about 20-22 mm, and a threaded end at the head or proximal end of the dowel. Three groups of projecting mixing vanes are spaced along the shank. A first group of vanes at the tip project at least 2.5 mm and preferably no more than 4 mm from the shank. The second group of vanes which project from the shank by a lesser degree than the first group, are defined in a central portion of the shank spaced from the first group. The third group of vanes which project from the shank by a lesser degree than the second group, are defined adjacent the threaded portion of the shank spaced from the second group. In use when inserted into a pre-drilled hole containing a two-part encapsulating resin and spun, the rock-dowel can thoroughly mix the two part resin encapsulating resin and force the resin casings into the back of the pre-drilled hole. In particular, the vanes are designed to mix the resin in three stages, the first stage is at the tip of the dowel and these projections are the largest and designed to not only mix the two resins but create a very large “spin diameter” within the pre-drilled hole so that the spinning dowel is presenting to the resin capsule a much larger diameter enabling the two separate capsule casings to be broken. Also disclosed is a nut made from a plastics material defining a first, typically relatively wider, barrel portion and a second, typically relatively narrower, nut portion, the second portion defining a nut section for engagement with a socket, wherein an area of weakness is provided between the first and second portions such that the second portion breaks from the first portion when a particular torque value is applied to the nut, the predetermined torque value being less than the breaking torque of the dowel.

Owner:APPLIED RES OF AUSTRALIA

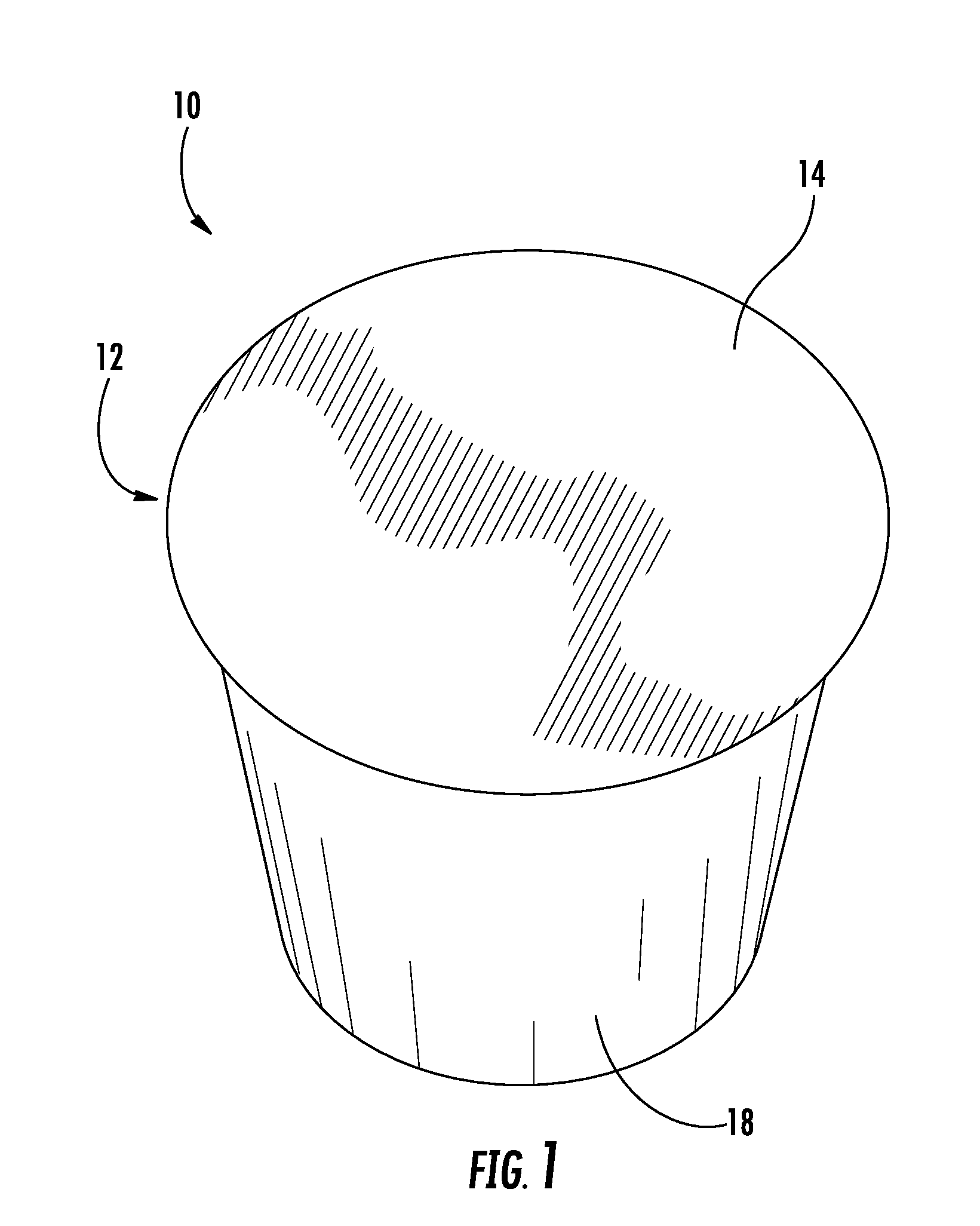

Rust removal preparation device for LED (light-emitting diode) lamp holder manufacture

InactiveCN106902694AImprove liquidityMix thoroughlyTransportation and packagingMixer accessoriesEngineeringLED lamp

The invention relates to a rust removal preparation device, in particular to a rust removal preparation device for LED (light-emitting diode) lamp holder manufacture, and aims to provide a preparation device which can achieve multistage stirring preparation and collect rust removers after rust removal. The rust removal preparation device comprises a working table, a motor, a first rotating rod, a first bevel gear, a second bevel gear, a second rotating rod, a stirring box, a supporting rod, a baffle plate, a first bearing block, a first stirring rod and the like, wherein the motor is mounted on the left side of the top of the working table, the first rotating rod is connected to the output shaft of the motor, and the first bevel gear is connected to the top end of the first rotating rod. The rust removal preparation device is further provided with a third bevel gear, a fourth bevel gear, a second bearing block, a fourth rotating rod and a second stirring rod.

Owner:宁波伍兹光电有限公司

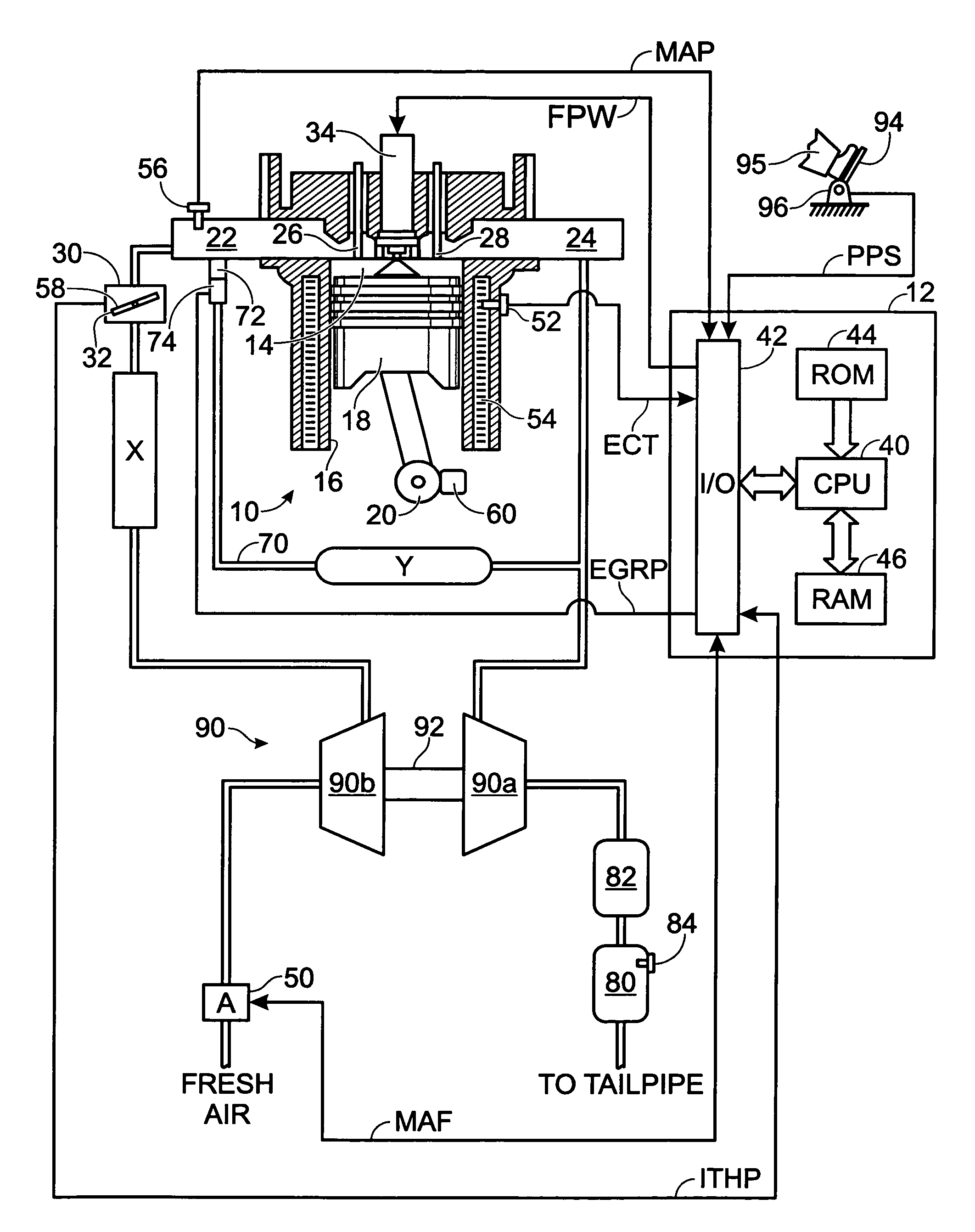

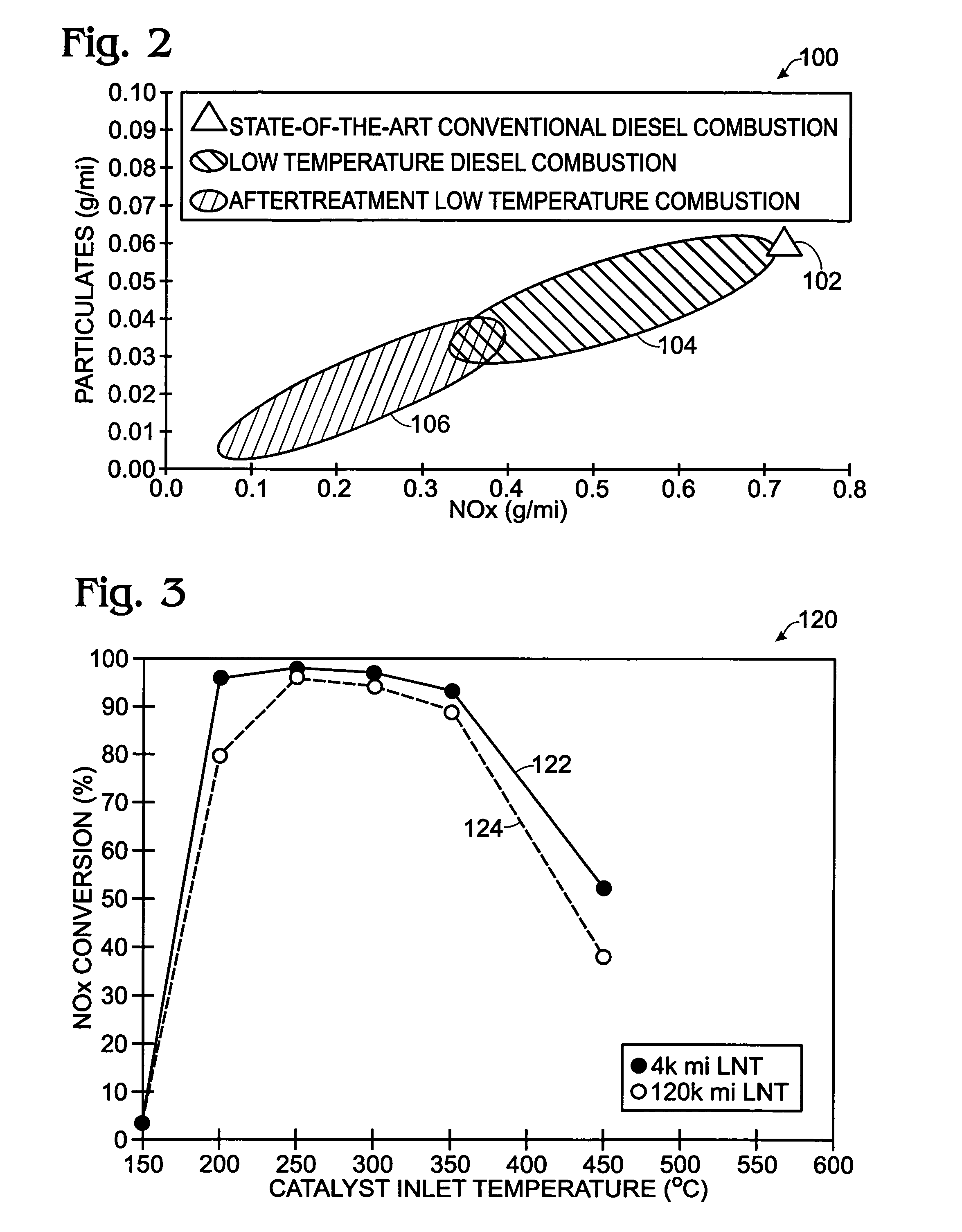

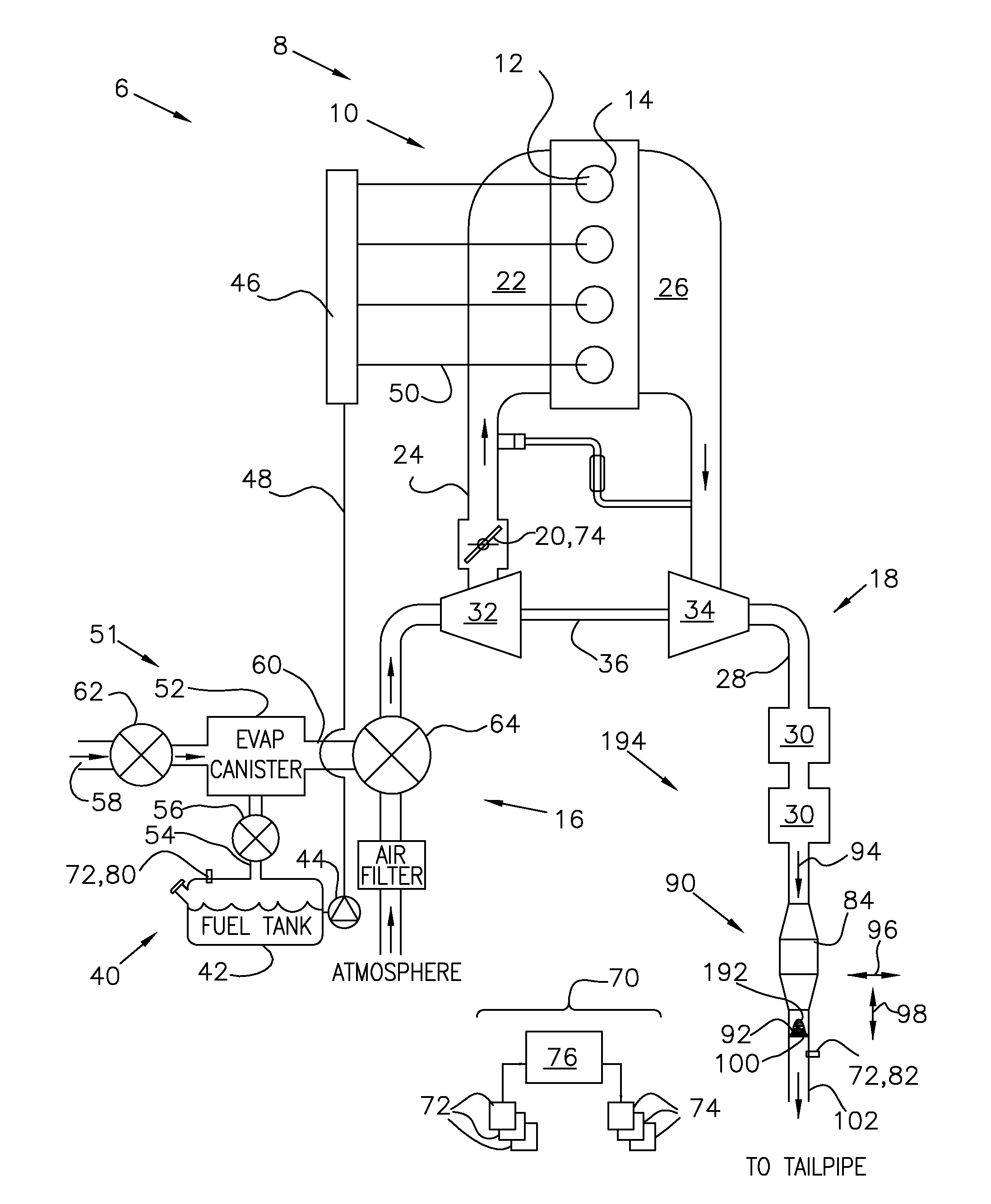

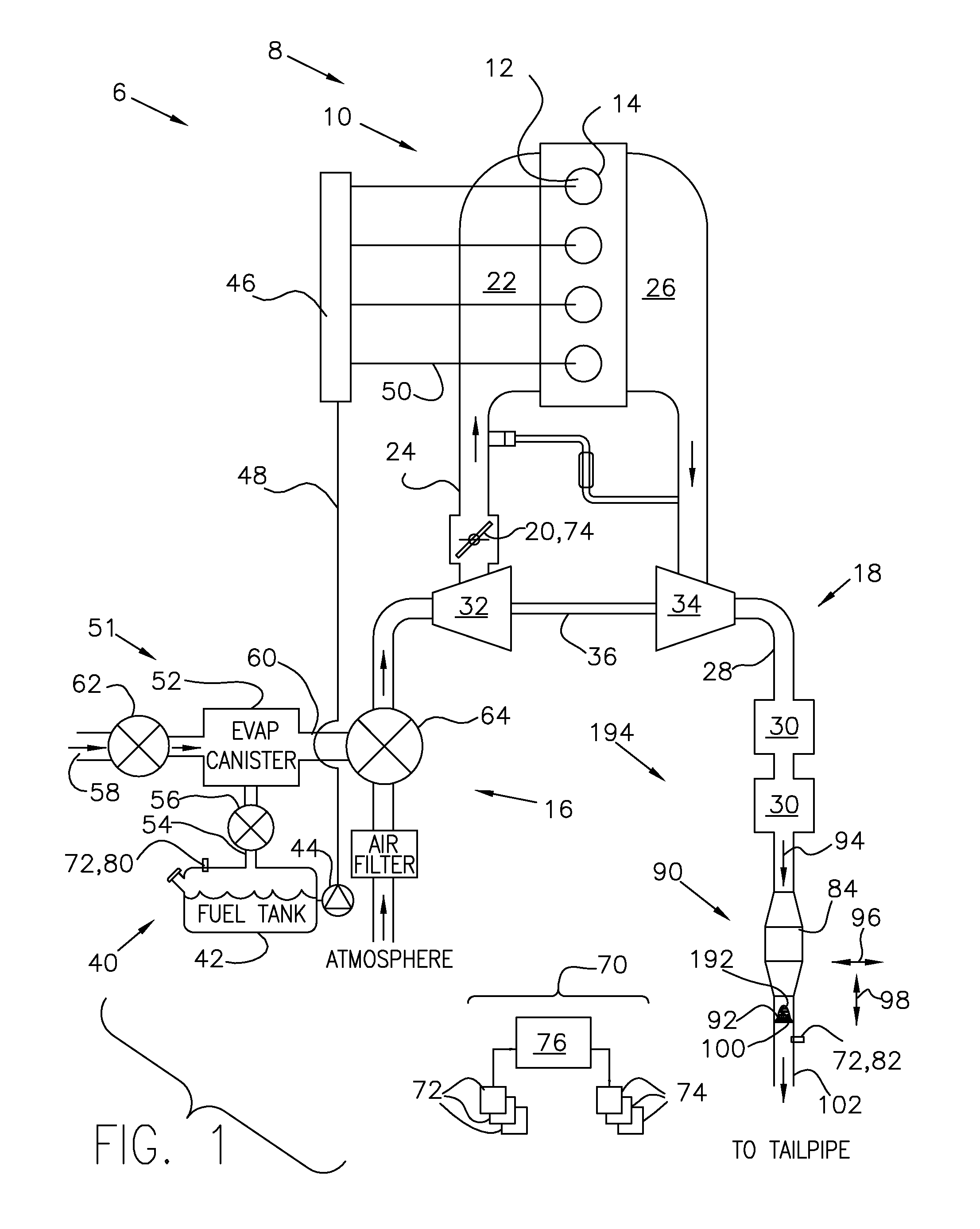

System and method for reducing NOx emissions in an apparatus having a diesel engine

InactiveUS7533518B2Mix thoroughlyLess mixingElectrical controlInternal combustion piston enginesCombustion chamberExhaust fumes

A method of operating a diesel engine in a mechanical apparatus is disclosed, wherein the diesel engine includes a combustion chamber, and wherein the mechanical apparatus also including a catalyst configured to treat NOx emissions from the diesel engine. The method includes performing at least one early homogenization combustion in the combustion chamber, determining a temperature of the catalyst, and if the temperature of the catalyst is equal to or below a preselected temperature threshold, then performing at least one late homogenization combustion or diffusion combustion in the combustion chamber to raise a temperature of exhaust provided to the catalyst.

Owner:FORD GLOBAL TECH LLC

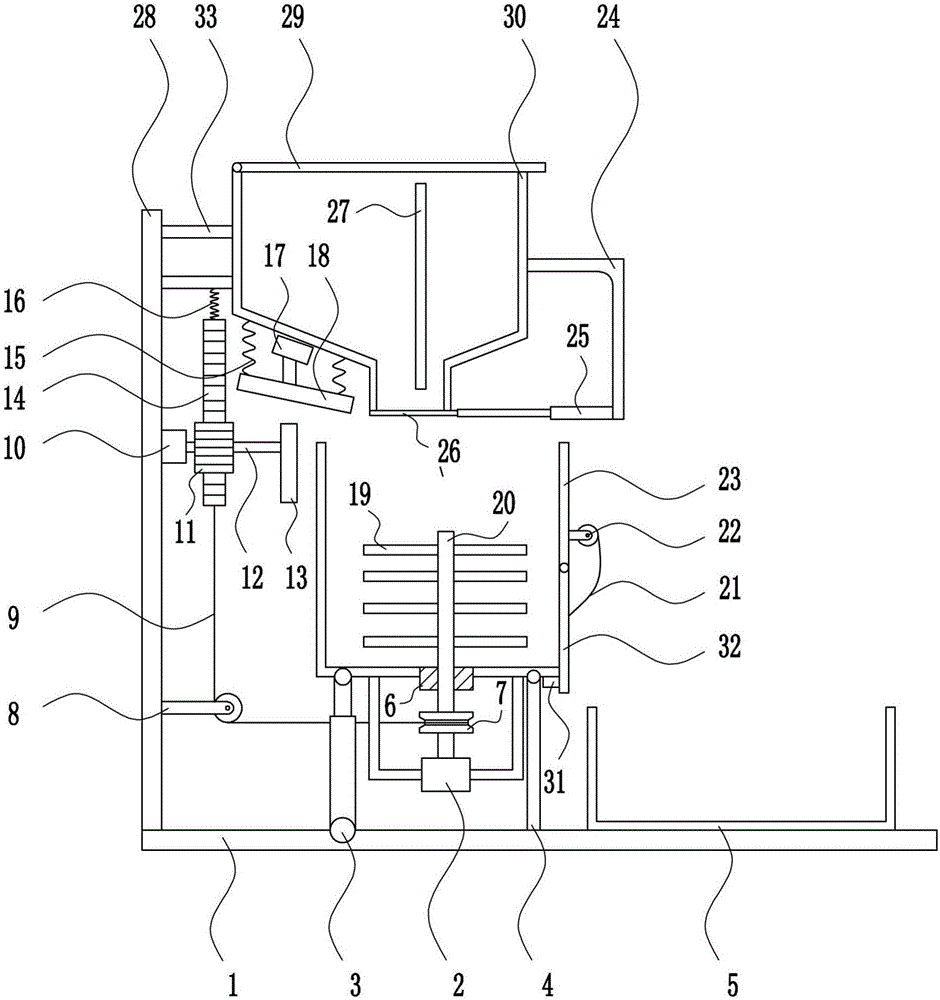

Feed mixing device used in animal husbandry

The invention relates to a mixing device used in animal husbandry, in particular to a feed mixing device used in animal husbandry. The technical problem to be solved by the invention is to provide the feed mixing device used in animal husbandry, which is thorough in mixing, uniform in mixing and simple in structure. In order to solve the technical problem, the feed mixing device used in animal husbandry comprises a base plate, a motor, a cylinder, a first supporting rod, a collecting frame, a first bearing seat, a first reel, a fixed pulley, a first pull rope, a second bearing seat, a gear and the like, wherein a left rack is arranged on the left side of the top of the base plate; second supporting rods are symmetrically arranged on the upper part of the right side of the left rack; a material storage box is arranged at the right ends of the second supporting rods; and the top end of the left side of the material storage box is hinged to and connected with a first box cover. The feed mixing device used in animal husbandry achieves the effects that the device is thorough in mixing, uniform in mixing and simple in structure, the device is low in manufacturing cost, easy to maintain and repair and convenient to use, and the device can provide favorable conditions for workers directly, accurately and quickly.

Owner:邵鹏程

Mild alkaline pretreatment and simultaneous saccharification and fermentation of lignocellulosic biomass into organic acids

InactiveUS20110177567A1Reduced pHHigh activityBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseOrganic acid

The invention relates to a method for the production of a fermentation product from lignocellulosic biomass, to a reactor to carry out the method and to use of the reactor to produce a fermentation product.

Owner:STICHTING DIENST LANBOUWKUNDIG ONDERZOEK

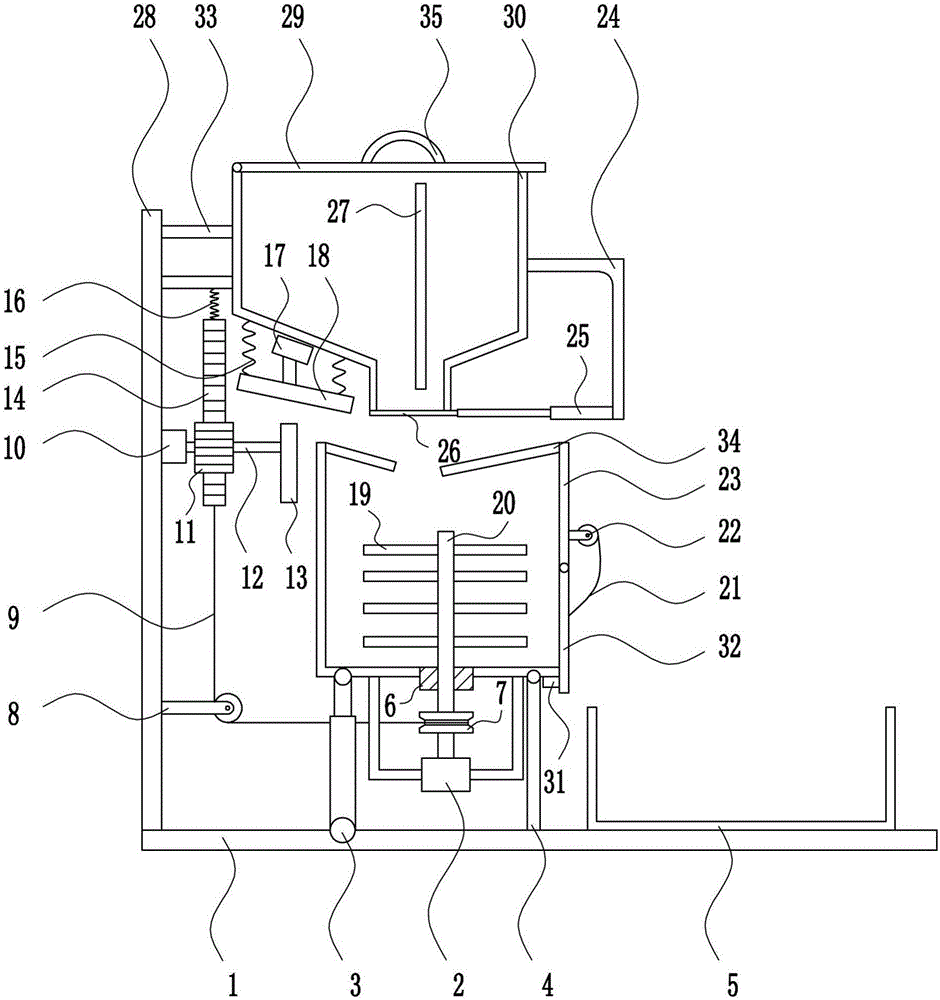

Beverage mixing cartridge and method of using same

InactiveUS20150166258A1Helps to disperseMix thoroughlyReady-for-oven doughsFlow mixersEngineeringInfant formula

An apparatus for preparing a beverage includes a housing, and one or more swirl-inducing sections positioned within the housing. A beverage medium, such as instant infant formula powder or a flavored drink mix, can be contained within the housing. Each swirl-inducing section can include a substantially arcuate channel having an entrance opening and an exit opening. When a liquid, such as water, is introduced into the housing, it can flow into the arcuate channel, which produces a swirling movement of the liquid that helps to thoroughly break up and evenly disperse the beverage medium throughout the liquid to produce a thoroughly mixed beverage that is ready for consumption.

Owner:GRUDER ROBERT

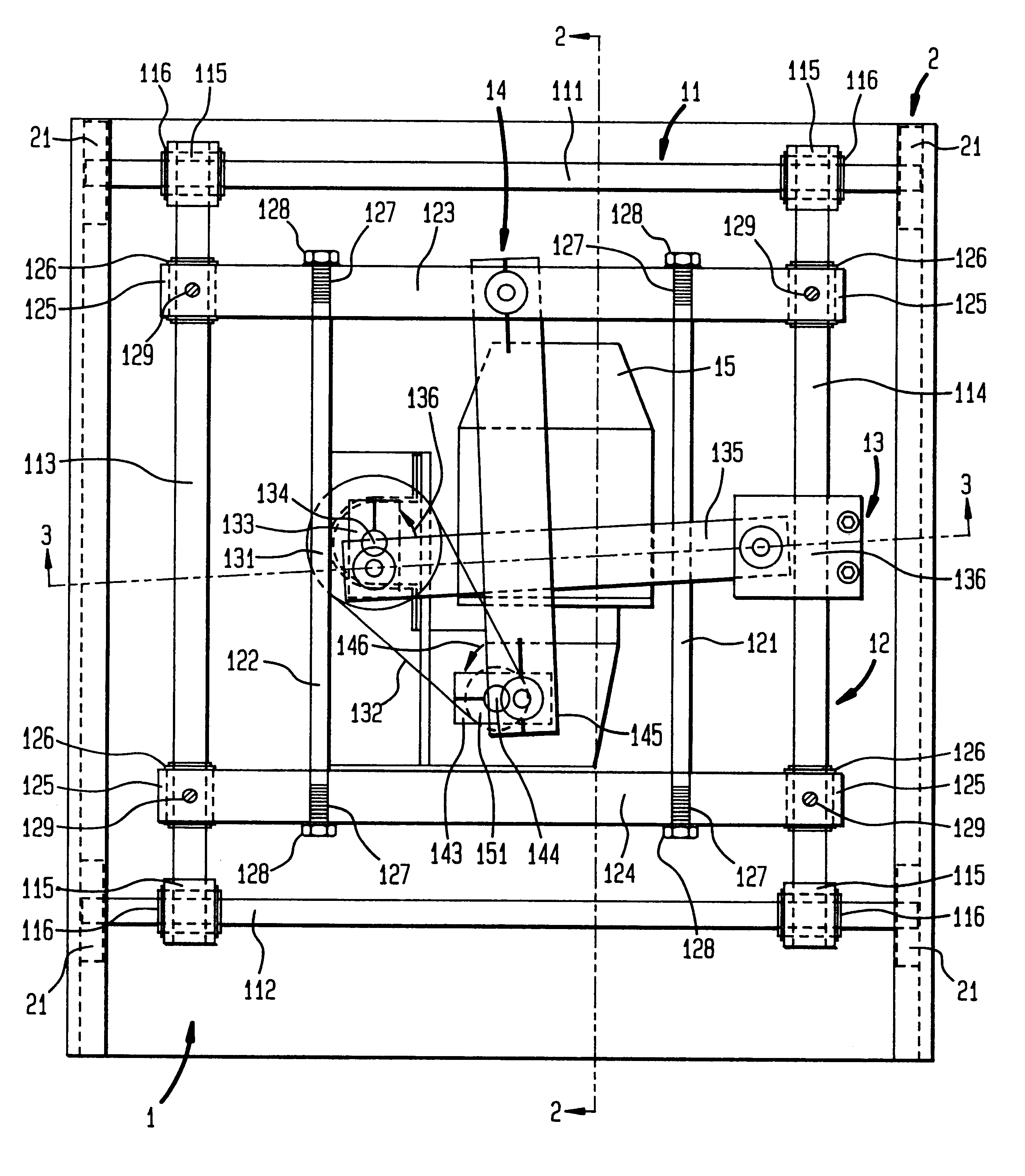

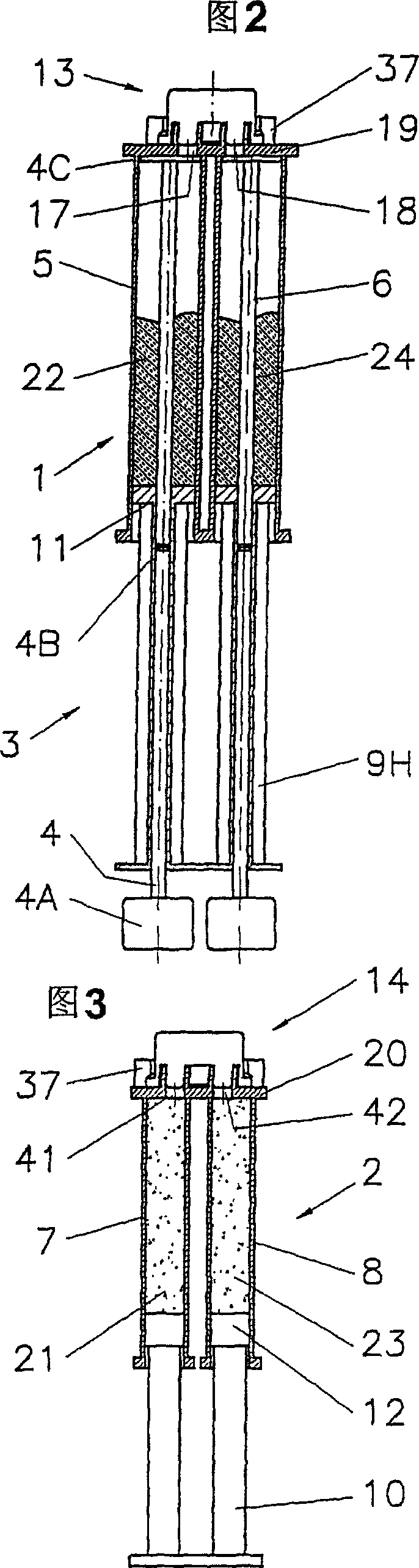

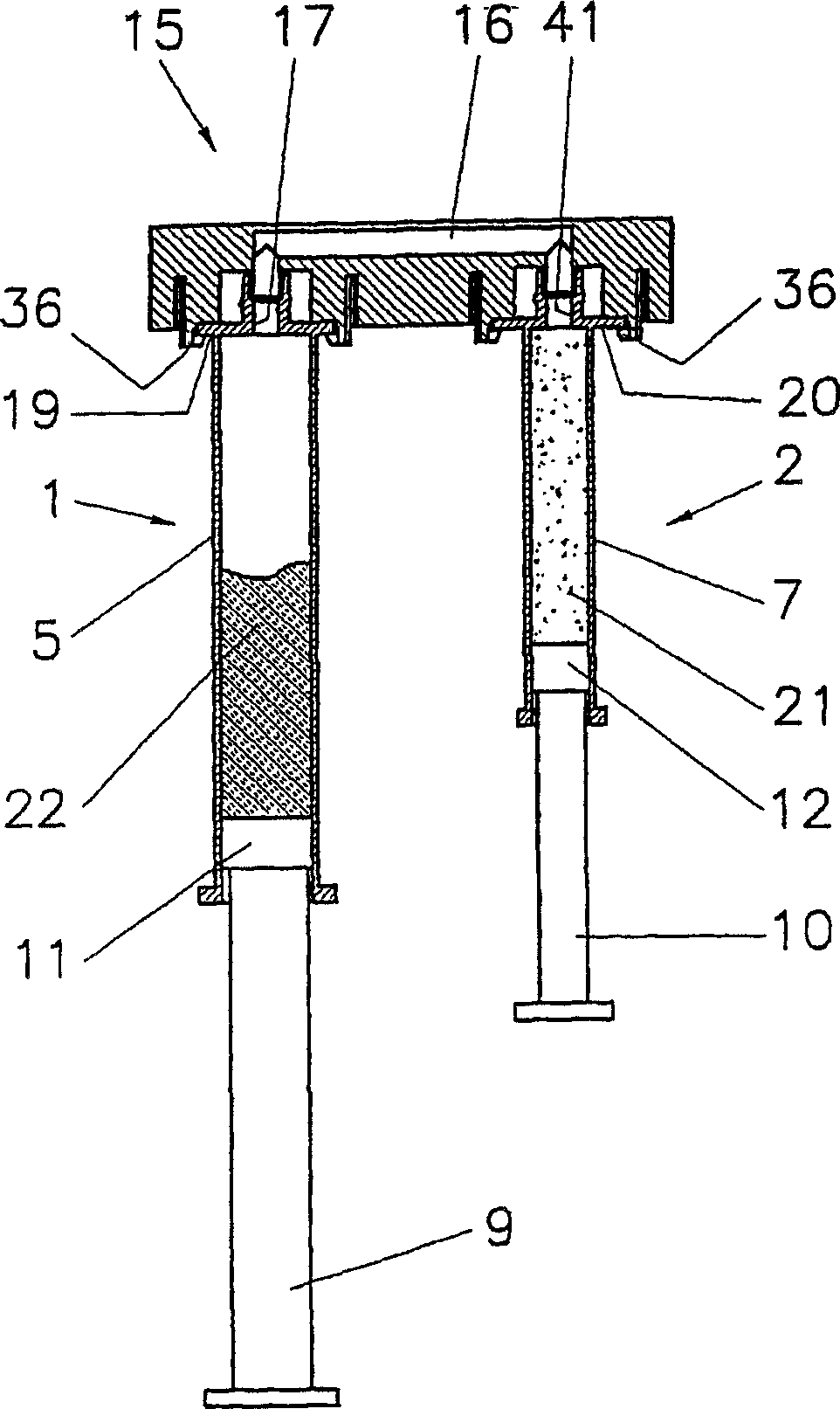

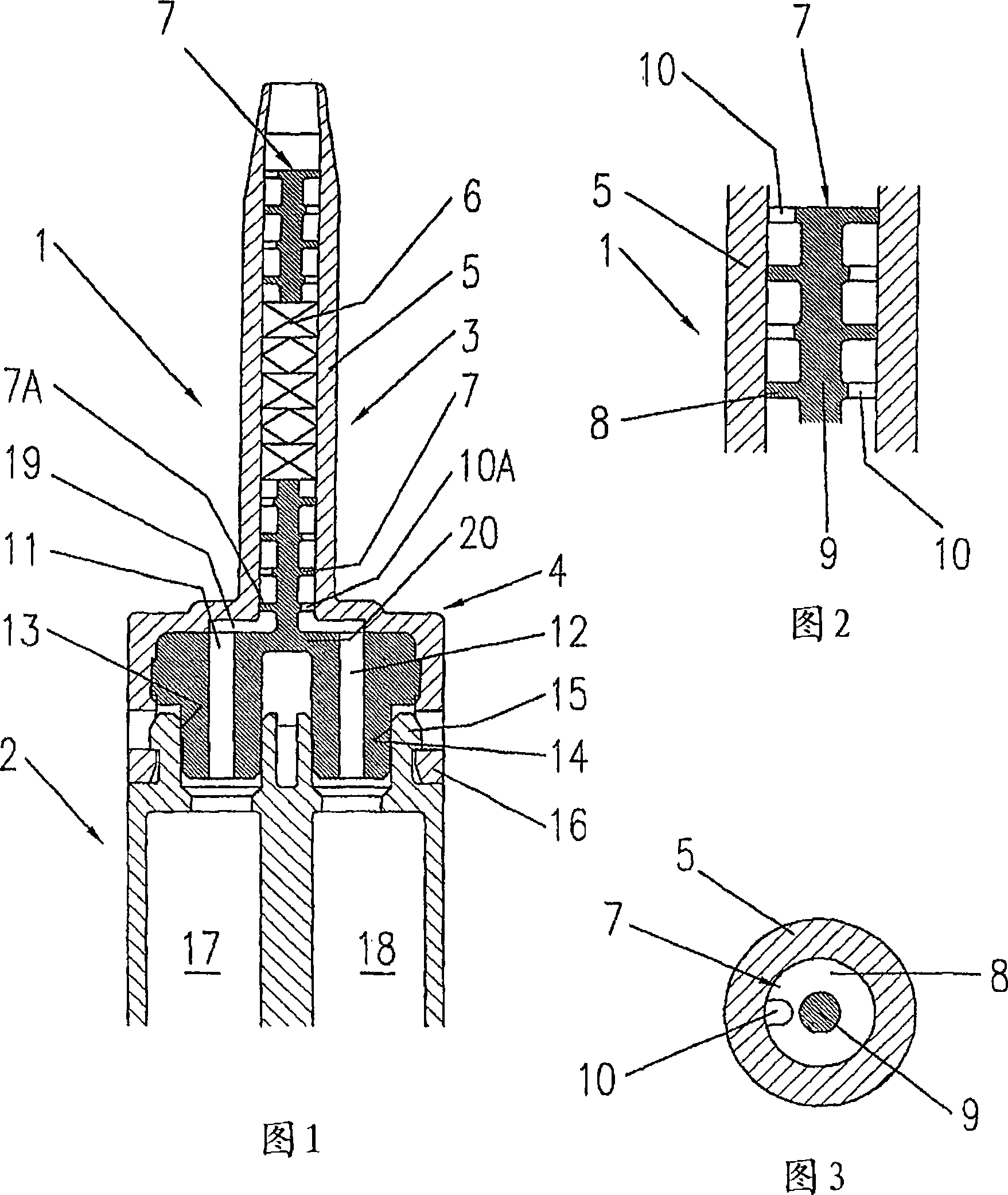

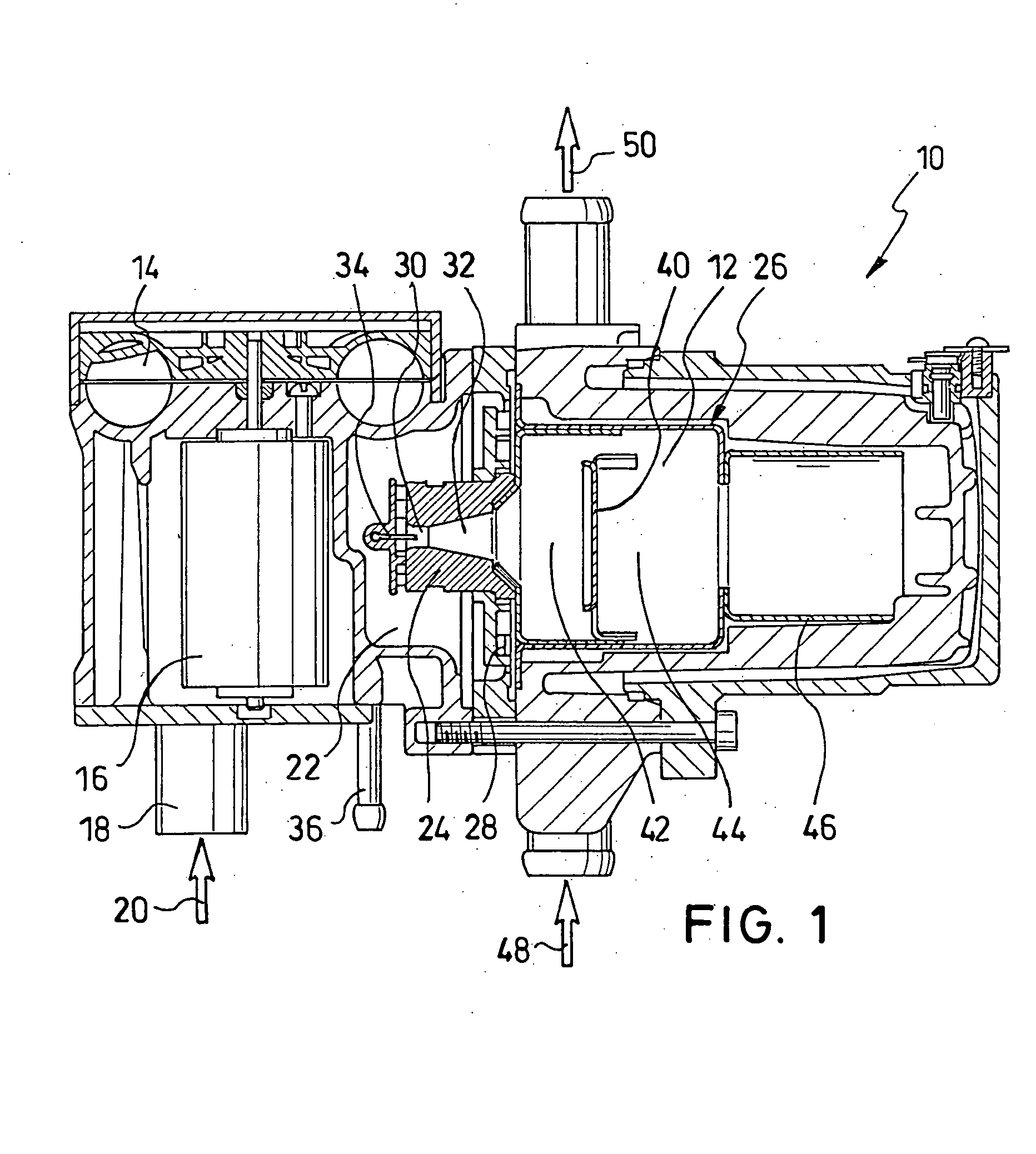

Device and method for transferring, mixing and delivering components

InactiveCN1838997AEasy to operateMix thoroughlyLiquid surface applicatorsShaking/oscillating/vibrating mixersNicrophorus distinctusBone cement

The invention relates to a transferring, mixing and delivering device preferably comprising at least two delivering devices (1, 2) one of which contains liquid components (21, 23) and a transferring unit (15) for connecting said delivering devices (1, 2). The transferring unit comprises connecting channels (16, 38) between outputs (17, 18; 41, 42) for components (21, 23; 22, 24) contained in the reservoirs (5, 6, 7, 8) of the delivering devices (1, 2). The aim of said invention is to increase the reliability of said transferring, mixing and delivering device. For this purpose, the transferring unit (15, 31, 39) is provided with locking elements (36) for receiving the flanges (19, 20) arranged on the delivering devices (1, 2). Such an injection system makes it possible without any problems to store, easily and softly blend and deliver the mixtures by means of double syringes. The inventive device provides exceptional advantages when a powder or granulate material, for example a bone cement or a bone substitute material is contained in the first syringe.

Owner:MEDMIX SYST

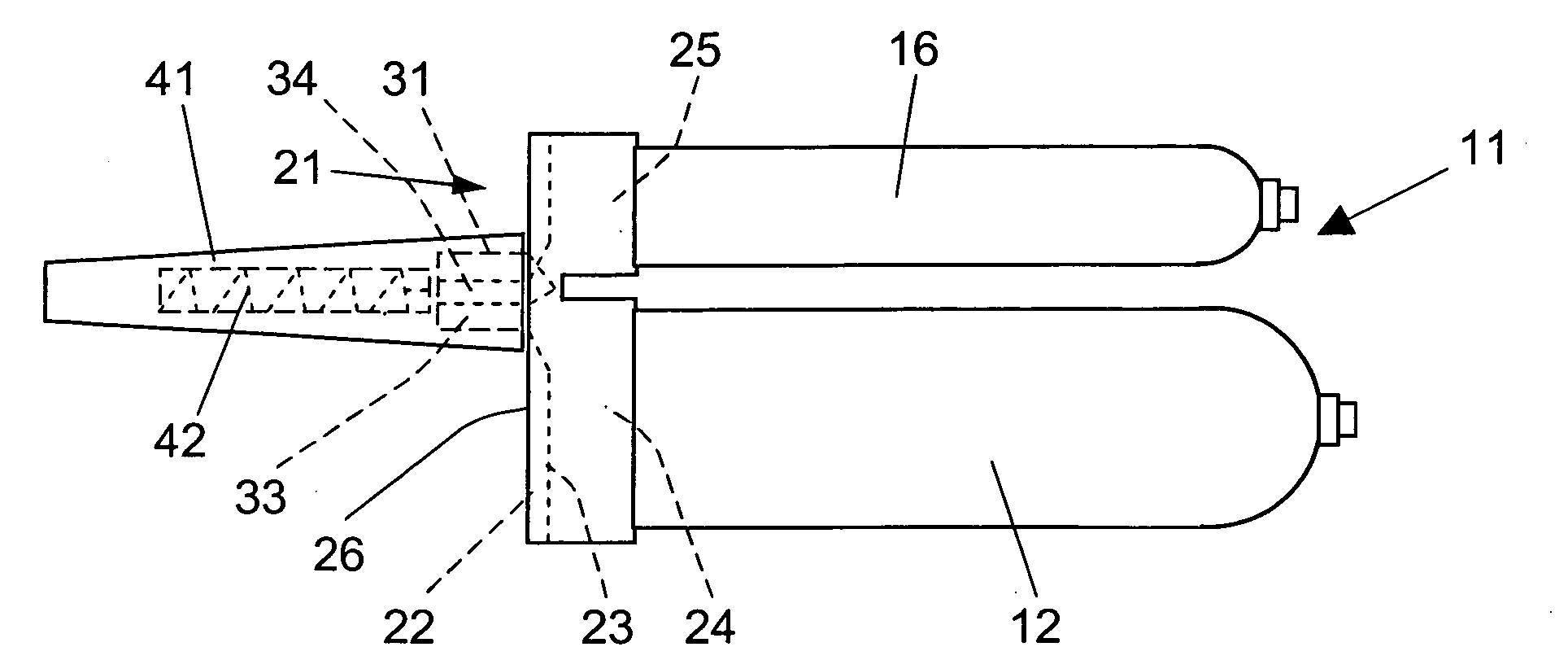

Foil container with foil bag chambers which are arranged next to one another

ActiveUS20090084815A1Lower ejection forceSimple and inexpensive ejectionLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

Owner:HILTI AG

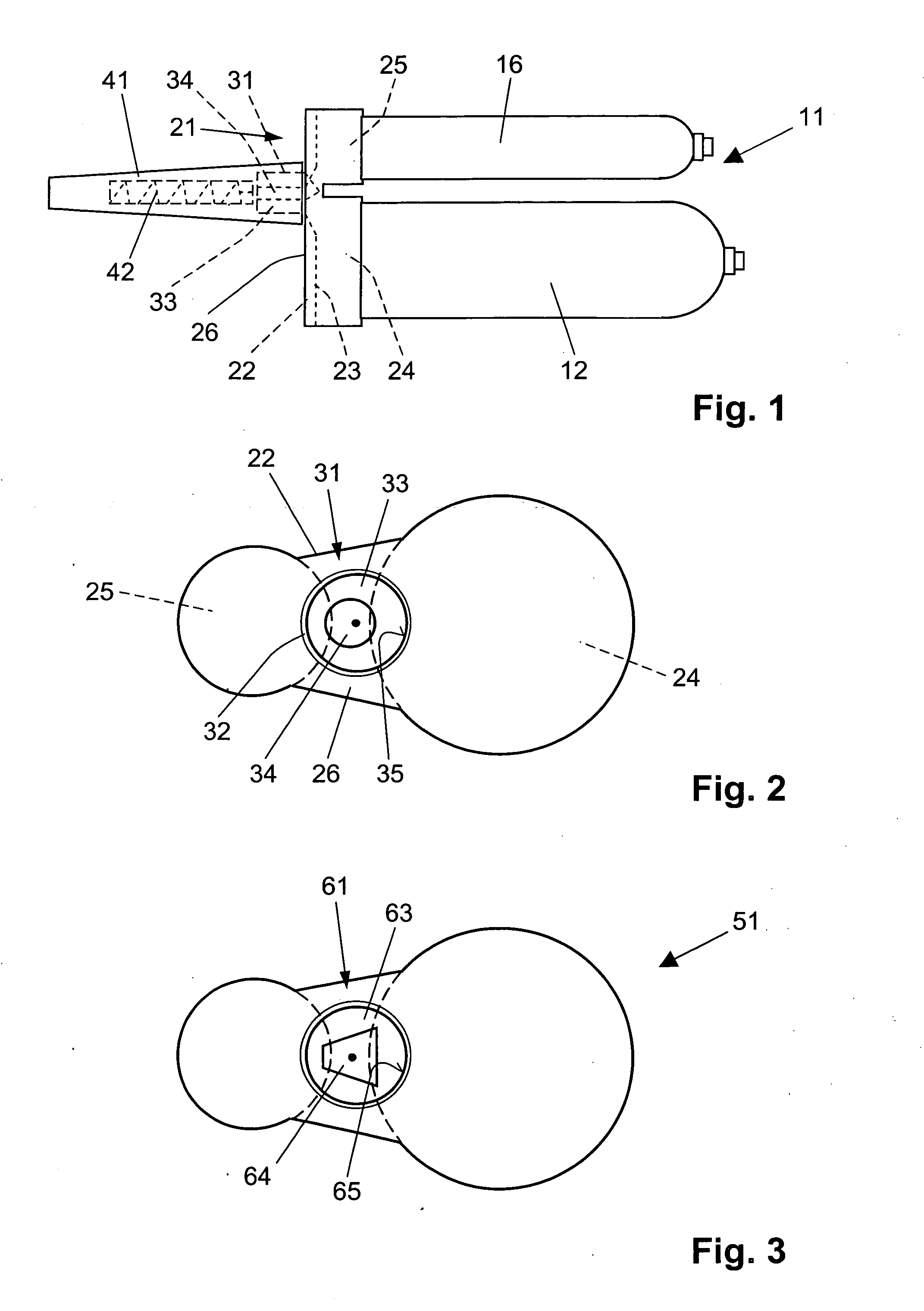

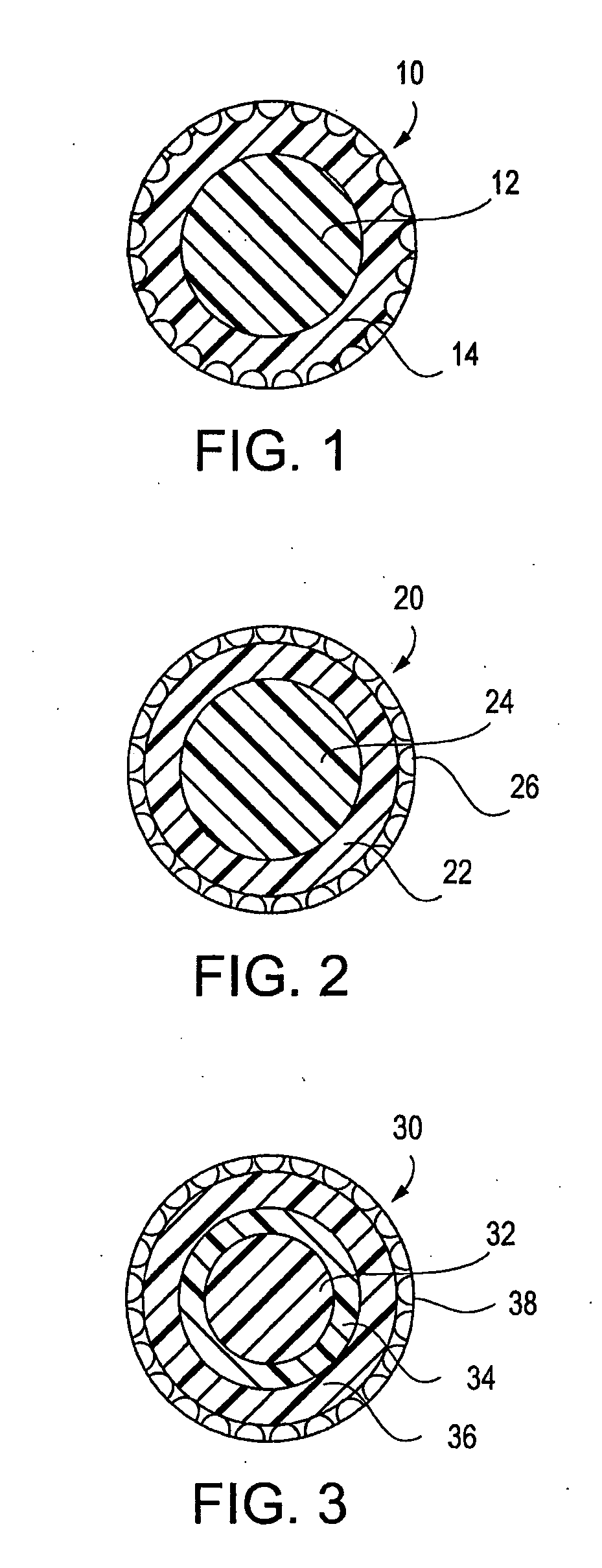

Static mixer

ActiveCN101056697AGuaranteed mixMix to ensure that both substances are thoroughlyRotating receptacle mixersLiquid surface applicatorsEngineeringStatic mixer

The static mixer for two components comprises a housing (3) having an input part (4) and mixing elements disposed inside the housing. Known mixers use mixer helices as the mixing elements. The inventive mixer is characterized in that at least one mixing element is configured as a discoid shear blade (7, 7A) having a passage (10, 10A) on its disk (8). Such shear elements allow to mix even very small quantities, which are delivered dropwise, since higher shearing rates are produced during discharge at the shear blade passages and vortices are produced at the discharge end, which is particularly advantageous for the use of such mixers in the medical field.

Owner:MEDMIX SWITZERLAND AG

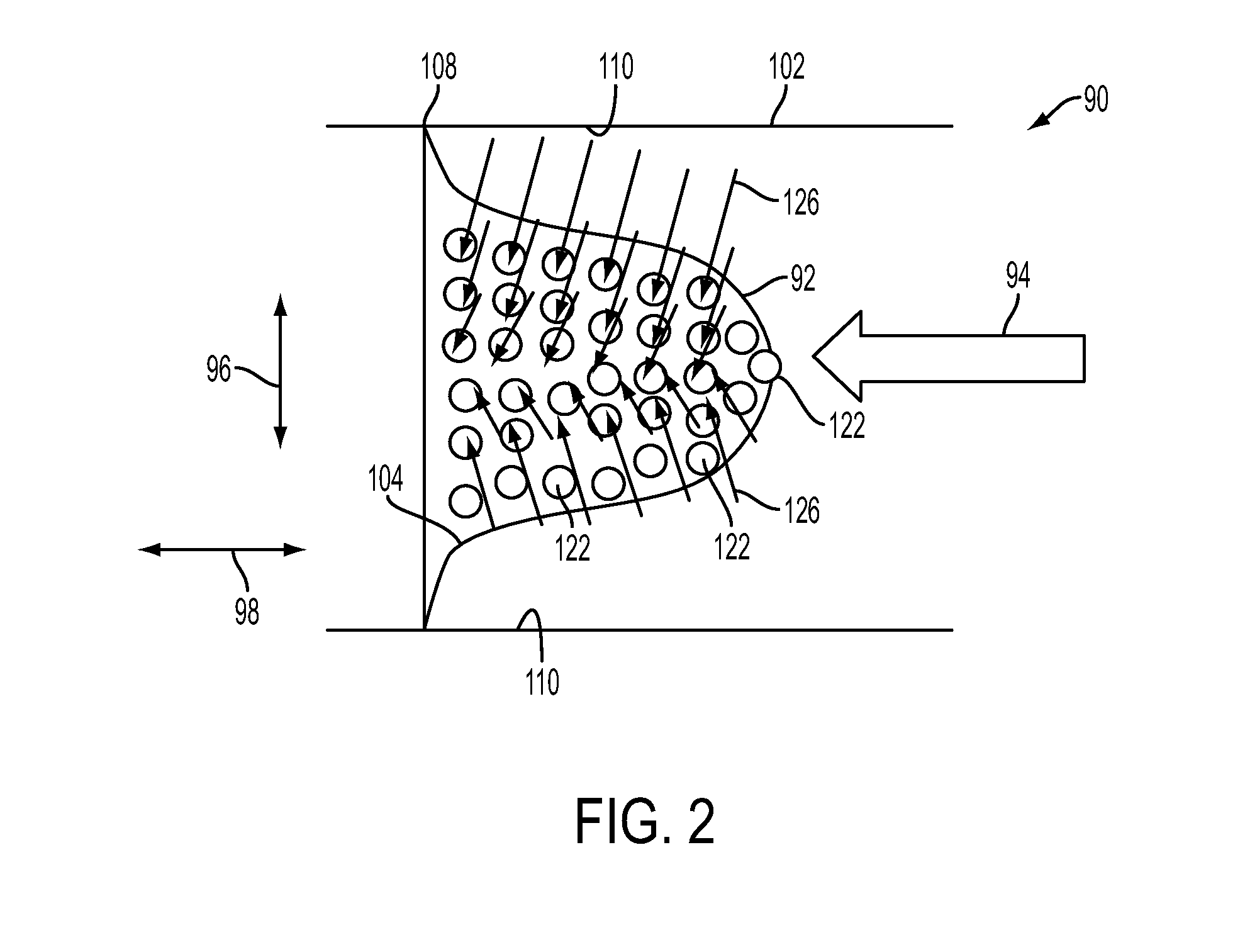

Exhaust gas mixer and system

InactiveUS20150047330A1Accurate readingWell mixedInternal combustion piston enginesExhaust apparatusCombustion chamberExhaust fumes

A device and a system are provided. The system may include a perforated barrier disposed within an exhaust stream downstream from the combustion chamber(s). The barrier may divide the exhaust stream radially and longitudinally. A mixing surface may be coupled with the perforated barrier which may define a path within the exhaust stream to impart a swirl to the exhaust stream.

Owner:FORD GLOBAL TECH LLC

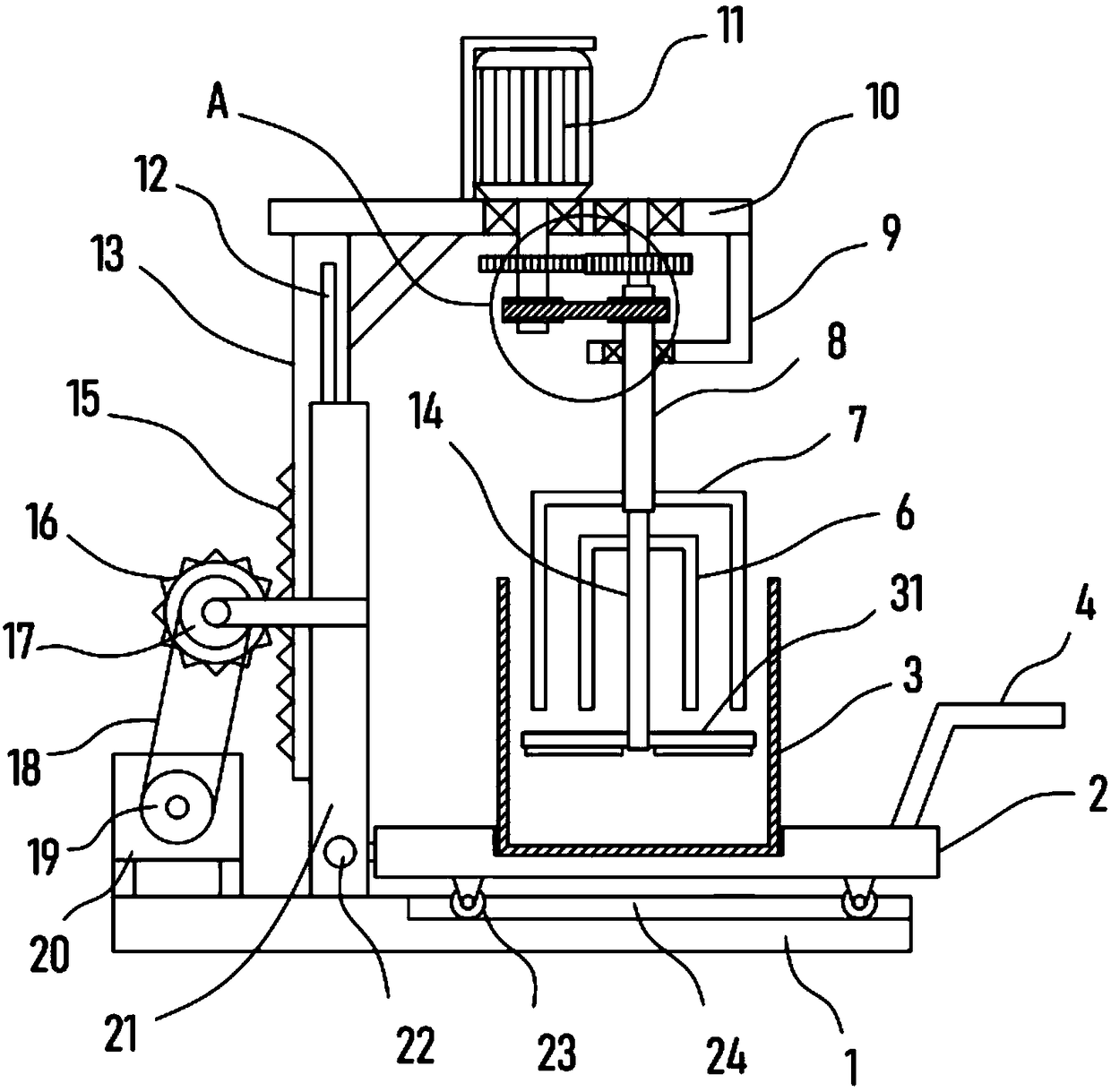

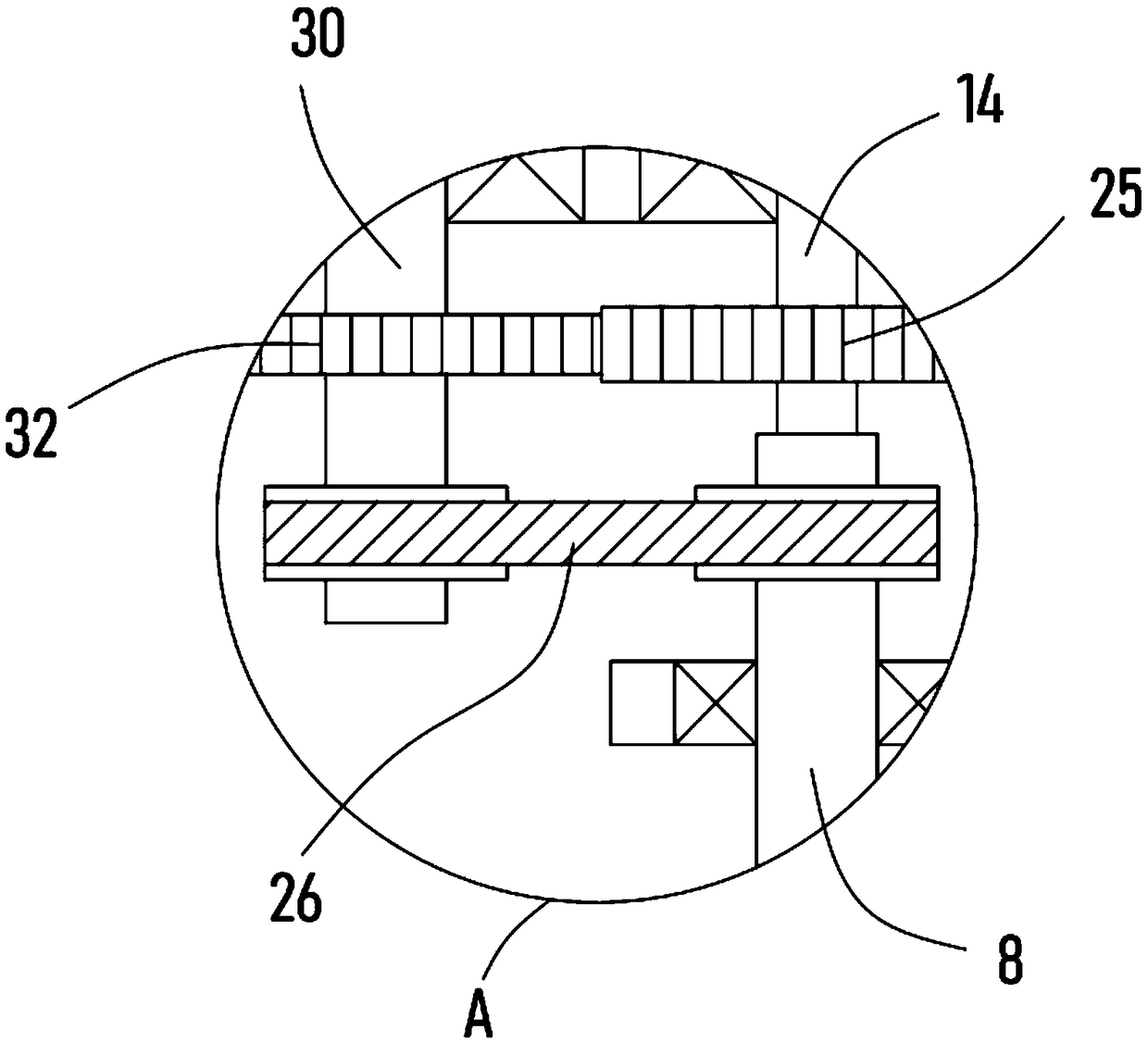

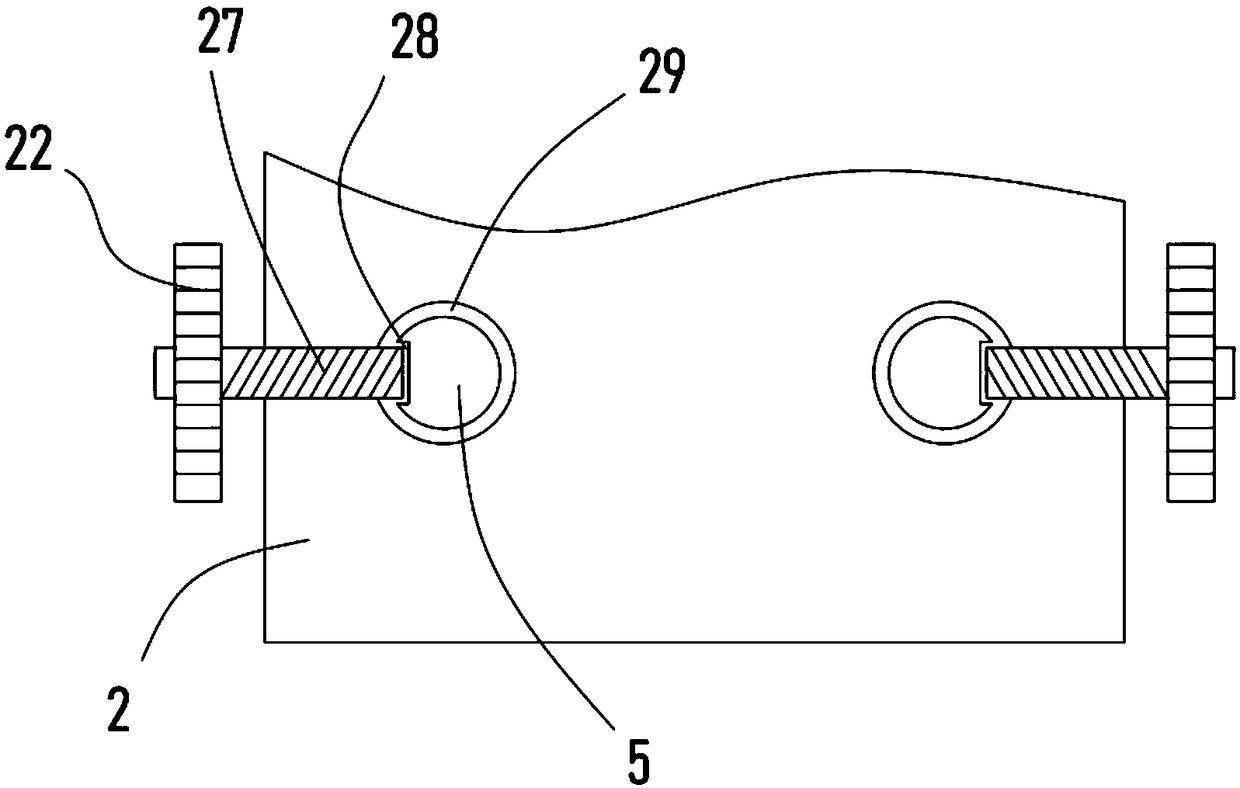

Wall coating stirring and mixing device for civil engineering construction

InactiveCN108970462AEasy and fast mobilityEasy and fast placementRotary stirring mixersTransportation and packagingDrive shaftCoating

The invention discloses a wall coating stirring and mixing device for civil engineering construction, and relates to the technical field of construction machinery. The wall coating stirring and mixingdevice comprises a base plate; a limiting frame is vertically fixed on the base plate; a lifting column is vertically arranged on the limiting frame in a sliding mode; a top plate is horizontally fixed at the upper end of the lifting column; a sliding push plate is arranged on the base plate; a driven gear fixedly sleeves a driven shaft; a driving gear meshing with the driven gear fixedly sleevesa driving shaft; and an outer stirring frame and an inner stirring frame vertically corresponding to a stirring barrel are fixedly arranged on the side wall of a rotary sleeve and the side wall of the driven shaft correspondingly. The wall coating stirring and mixing device has the advantages that a building coating in the stirring barrel can be mixed and stirred through the rotation of the innerstirring frame and the outer stirring frame, the inner stirring frame and the outer stirring frame are opposite in rotating direction, so that the stirring effect of the coating is better, mixing ismore complete and more thorough, meanwhile, the inner stirring frame and the outer stirring frame can be adjusted up and down, so that the mixing range of the coating is widened, the stirring efficiency is greatly improved, and meanwhile, the stirring barrel is more convenient and rapid to move and place.

Owner:郑州靓岛建筑设计有限公司

Wound sterilizing and cleaning device for mixing ozone gas and liquid by applying ultrasonic technique

InactiveCN102861366AWash thoroughlyThoroughly liquid for mixingEnemata/irrigatorsMixing methodsUltrasonic cavitationTransformer

The invention discloses a wound sterilizing and cleaning device for mixing ozone gas and liquid by applying an ultrasonic technique. The wound sterilizing and cleaning device comprises an ozone liquid generator, an ultrasonic generator and a handheld ultrasonic mixer; an infusion tube, an amplitude transformer and a spray nozzle inside the handheld ultrasonic mixer are sequentially connected to form a passage of conveying the ozone liquid; the inside of the amplitude transformer is hollow to form a water channel; and the amplitude transformer is provided with an ultrasonic transducer. According to the wound cleaning device disclosed by the invention, the ozone gas and the liquid are mixed by applying the ultrasonic cavitation effect; moreover, the amplitude transformer is internally provided with the water channel; the mixed liquid of the ozone gas and liquid passes through the water channel in the amplitude transformer; and the ultrasonic oscillation acts better on the mixed liquid of the ozone gas and liquid, so that the ozone gas and liquid are mixed into a creamy-white gas-liquid mixture, and the highly mixed and emulsified purposes can be achieved.

Owner:童自国

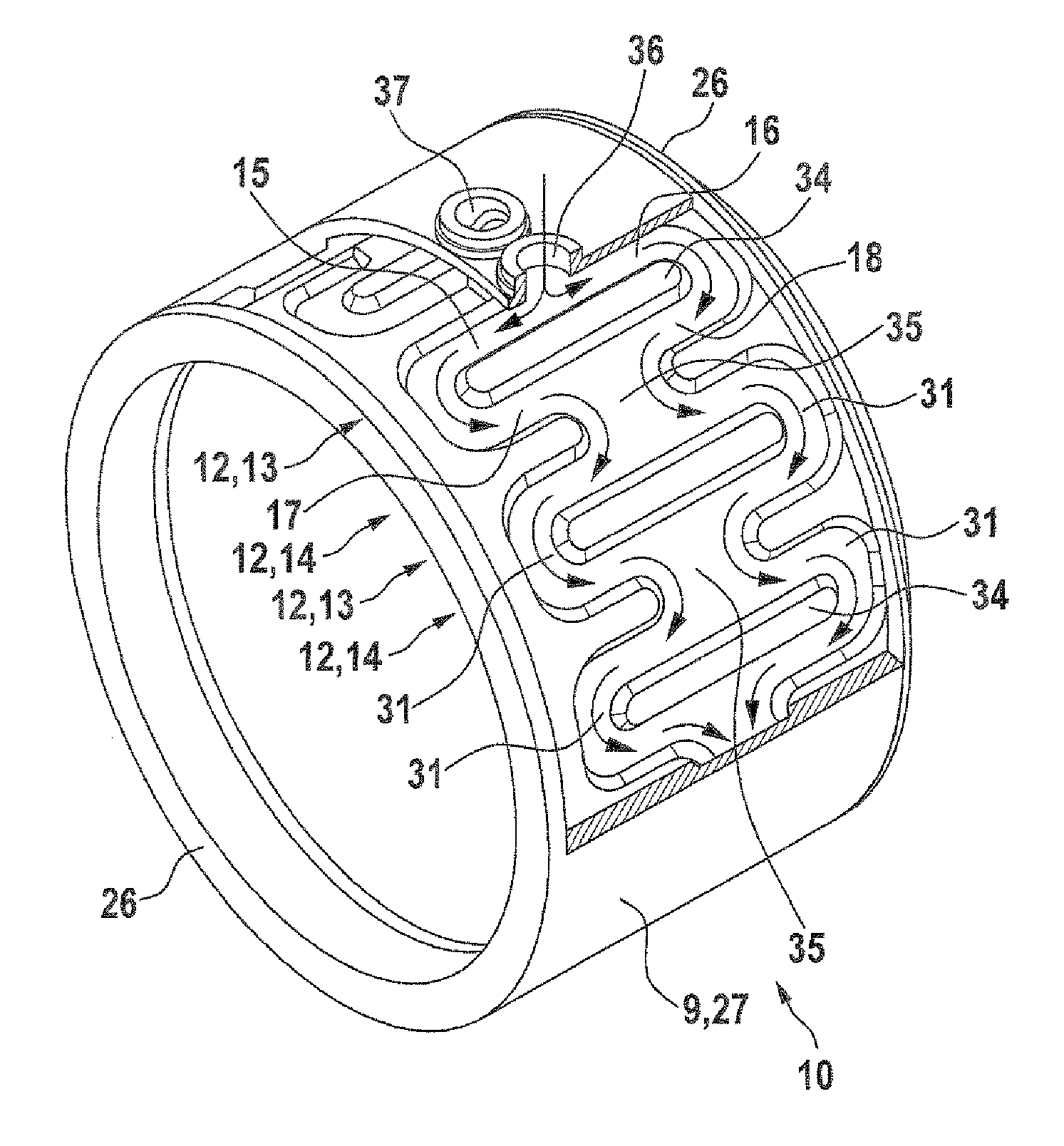

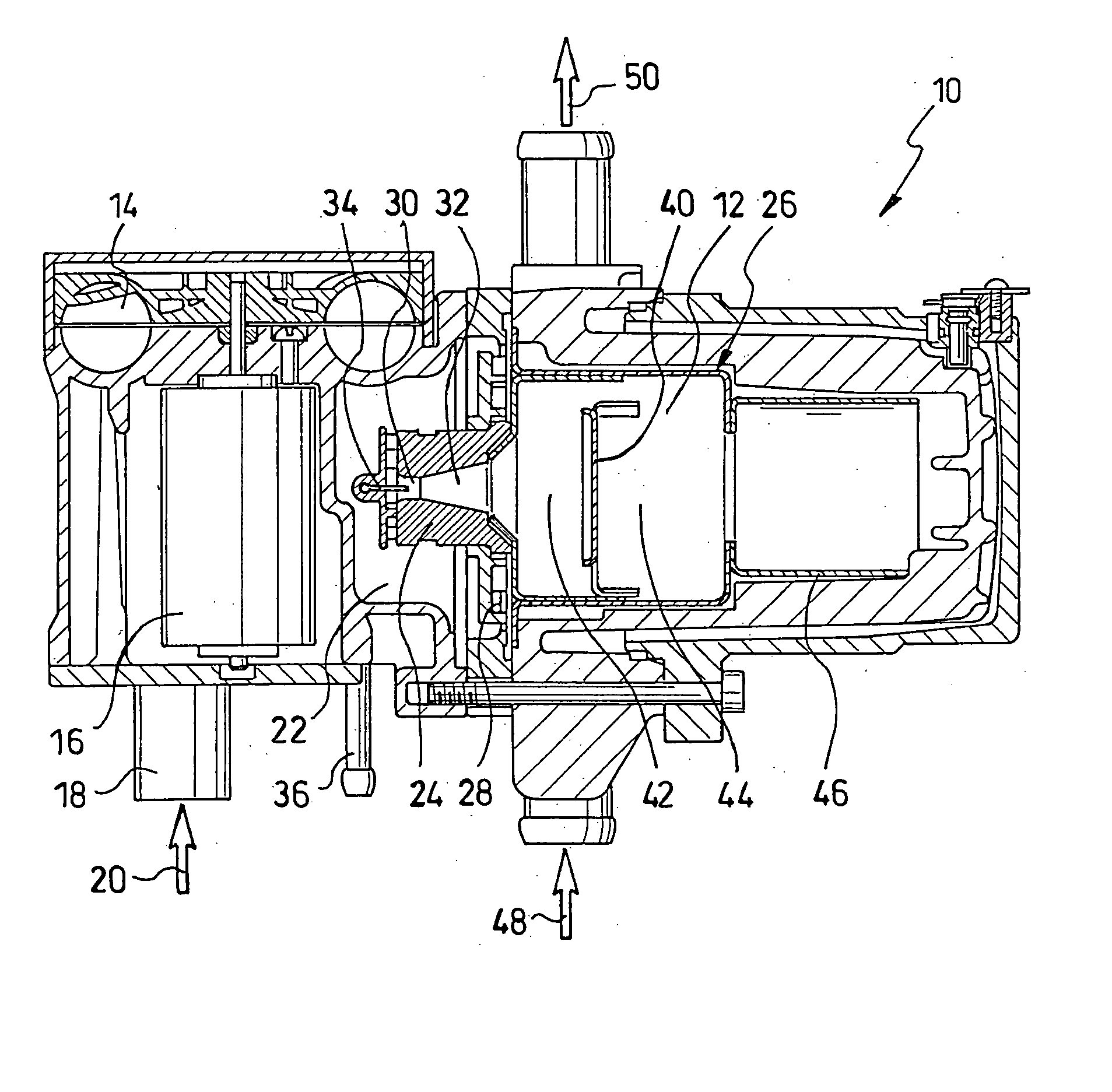

Electrical Machine Comprising Cooling Channels

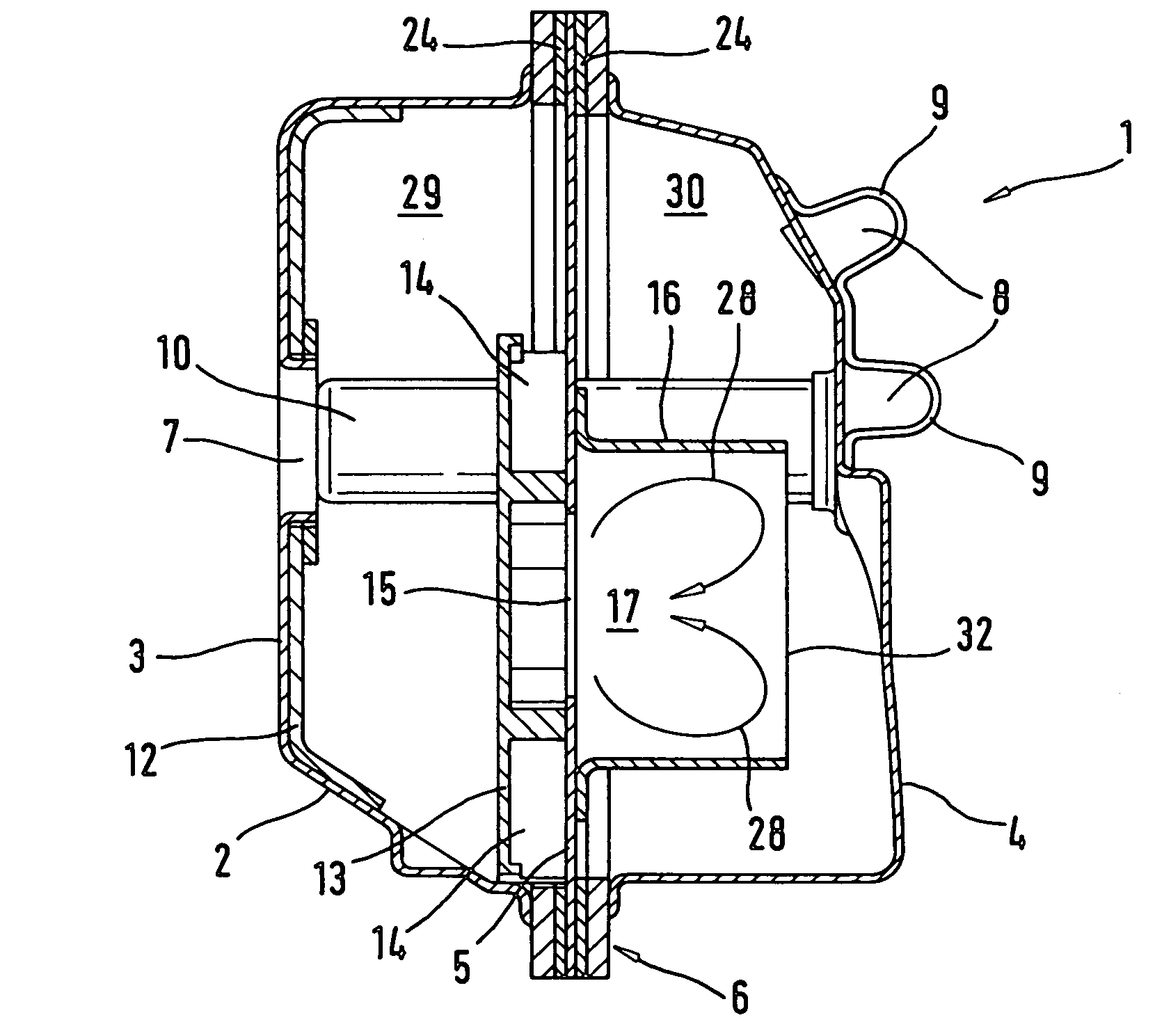

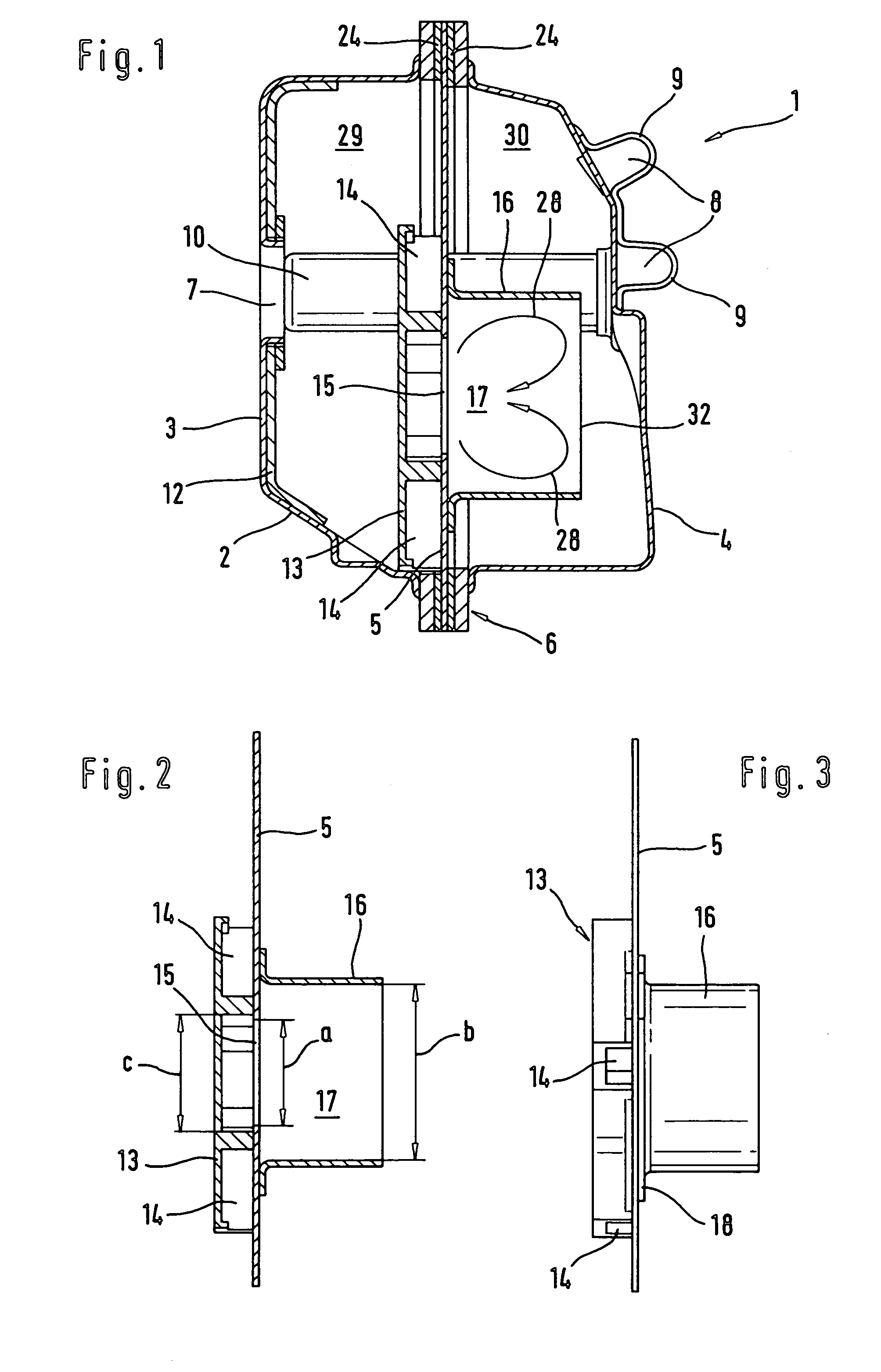

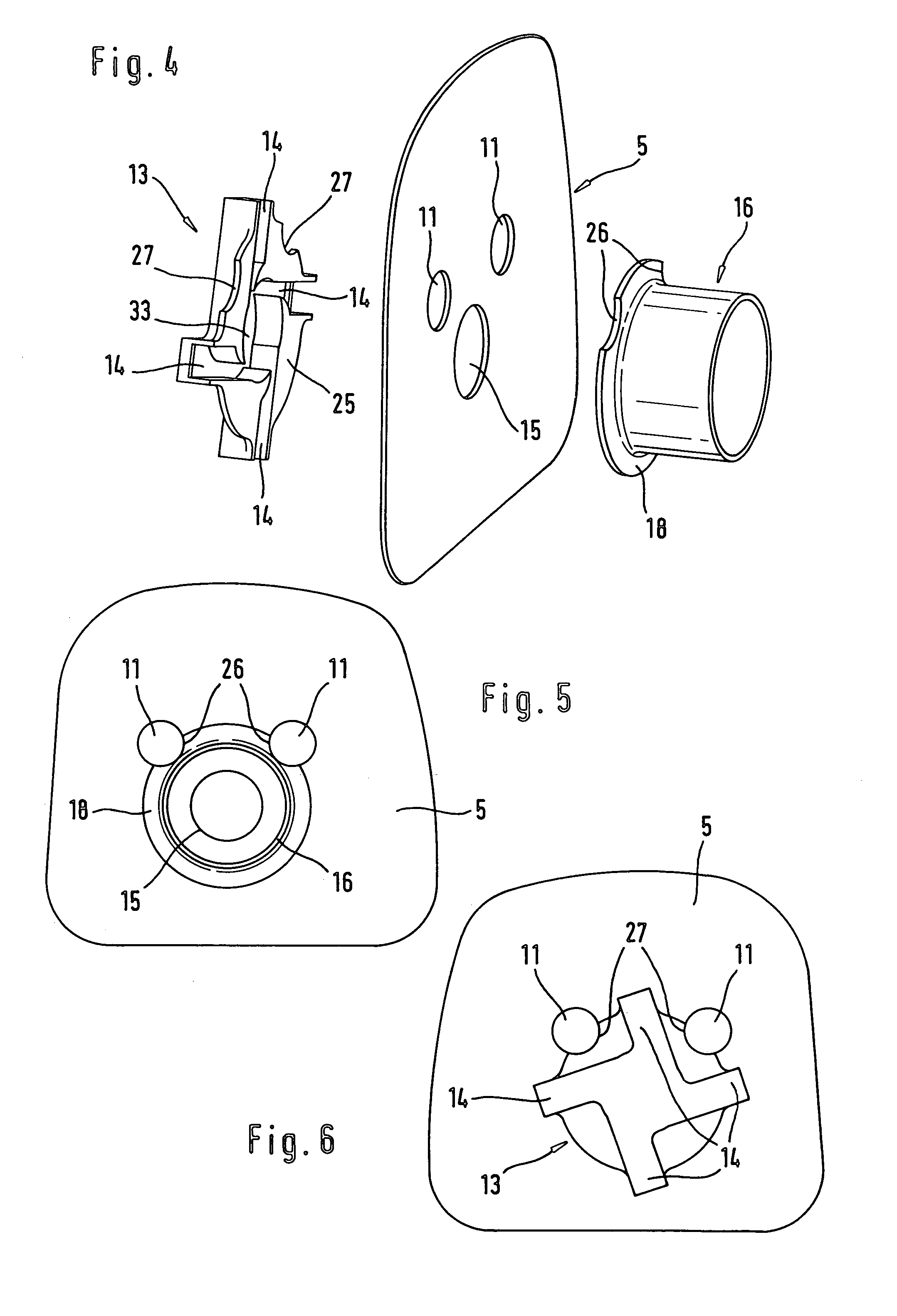

ActiveUS20140069099A1Increase heat absorptionEffective absorptionHybrid vehiclesElectric devicesCooling channelCoolant

The invention relates to an electric motor, in particular for a motor vehicle, comprising a housing (9), a shaft (8) having an axle (30), a stator and a rotor, at least one channel (11) for conducting a coolant for cooling the electric motor (5), wherein the geometry of the alignment of at least one section (12) of the at least one channel (11) is designed such that the coolant flows in the direction of the axle (30) of the shaft (8) through the at least one channel (11), having a deviation of less than 40°.

Owner:ROBERT BOSCH GMBH

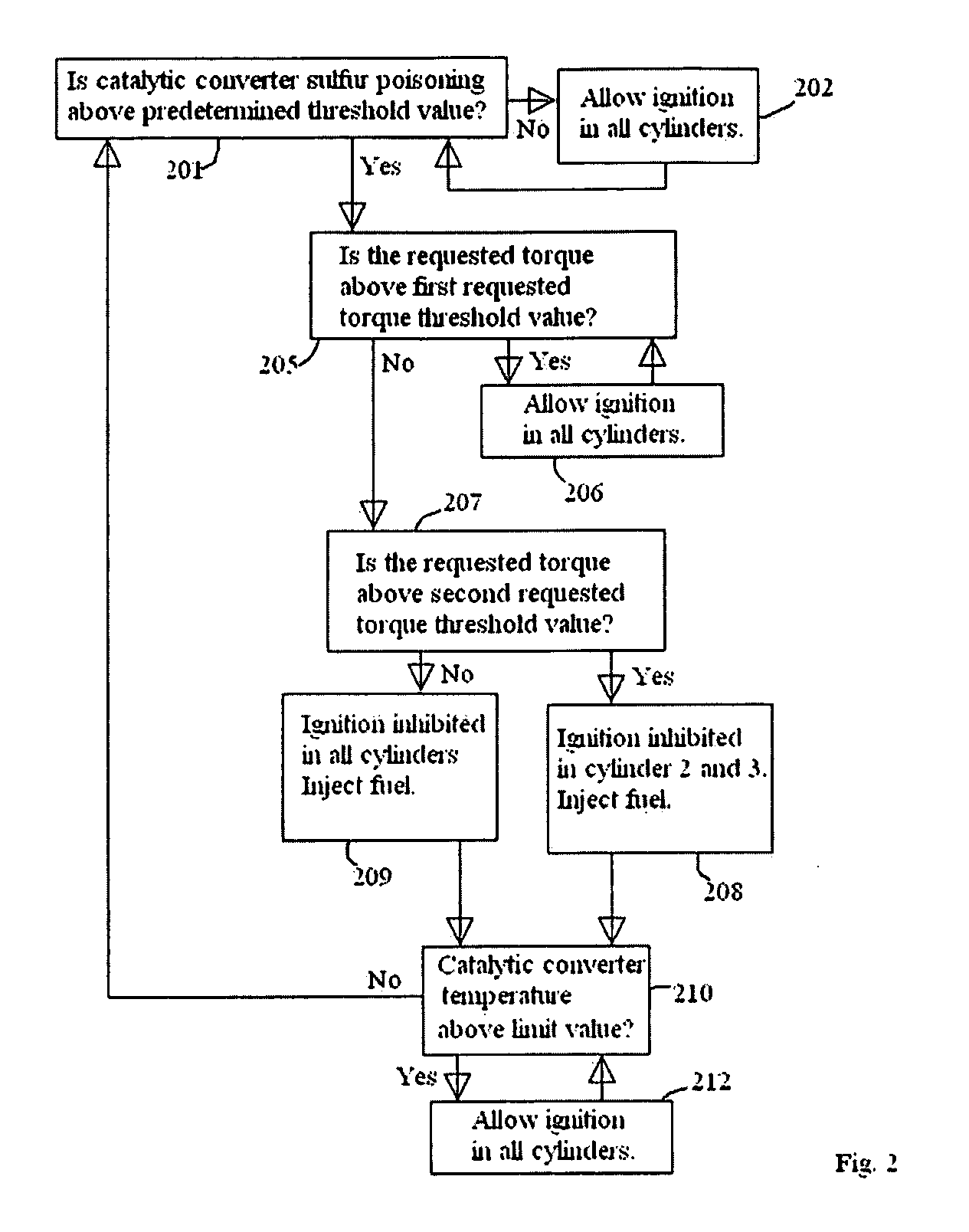

Engine system and a method for a combustion inhibition regeneration of an exhaust gas treatment device in a such system

InactiveUS20080148719A1Quick and accurate controlReduce device temperatureElectrical controlInternal combustion piston enginesCombustionExhaust fumes

A method and a system for regenerating an exhaust gas treatment device in an internal combustion engine having at least one cylinder are presented. The method comprises regenerating the device by inhibiting combustion in at least one of the engine cylinders and controlling the fuel injection system so that fuel is allowed into at least one of the cylinders in which combustion is inhibited.

Owner:FORD GLOBAL TECH LLC

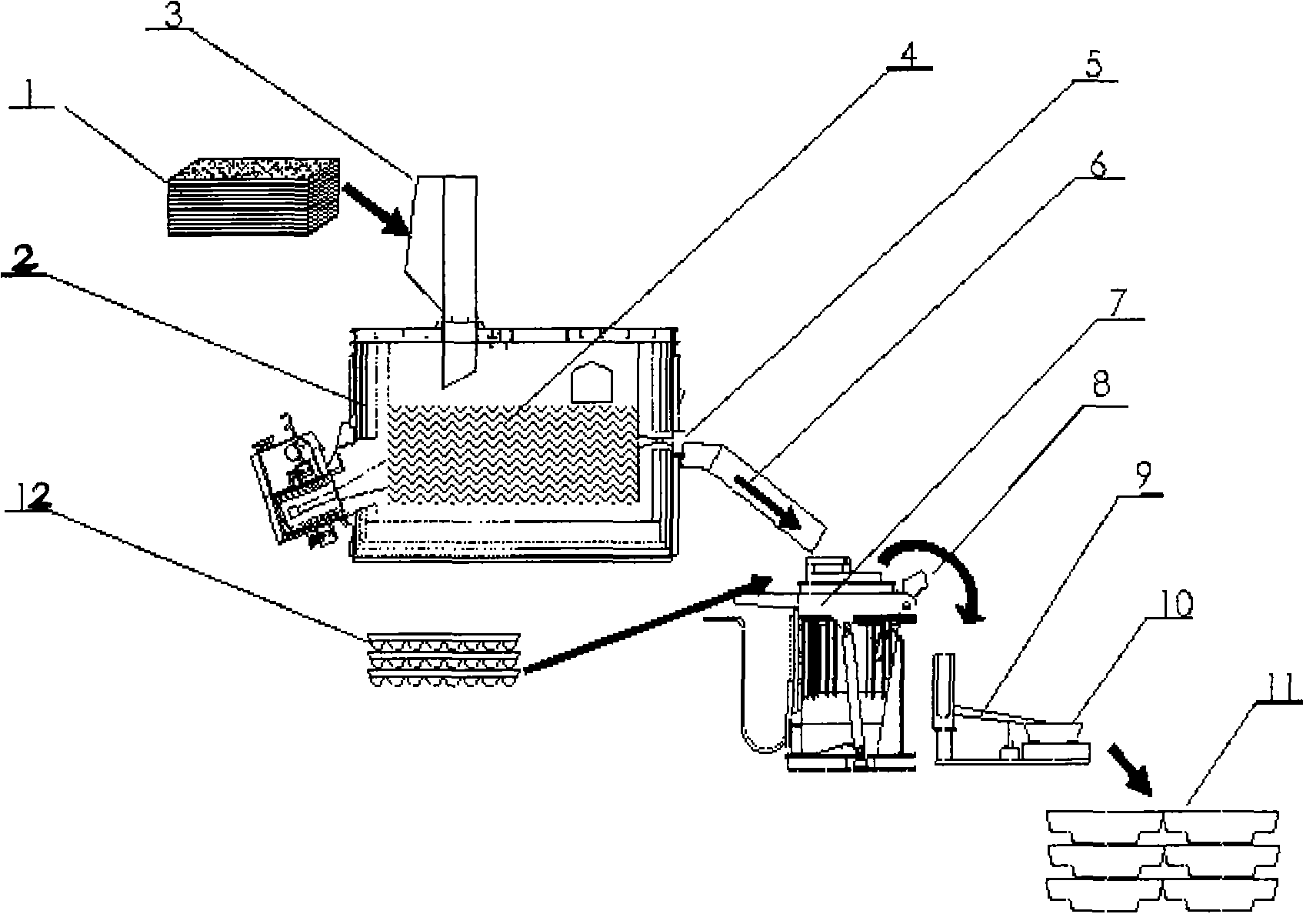

Combination metallurgical furnace for producing zinc alloy and zinc alloy combination producing method

InactiveCN101509727AStrong continuous melting abilityFast heatingIncreasing energy efficiencyCrucible furnacesZinc alloysIngot

The invention provides a combined metallurgical furnace and a combined production method for zinc alloy, comprising a cored line-frequency induction furnace (2) and at least two line-frequency coreless induction furnaces (7) with dumping devices (13); a convertible chute (6) is connected between a liquid outlet of the cored line-frequency induction furnace and a liquid inlet (14) of the line-frequency coreless induction furnaces; and a casting mechanism (9) is arranged correspondingly to a sprue (8) of the line-frequency coreless induction furnaces. The production method comprises the steps as follows: the zinc liquid which is melted in the cored line-frequency induction furnace is injected into each line-frequency coreless induction furnace in turn by the convertible chute and is then mixed with the middle alloy liquid which is smelted in advance in the line-frequency coreless induction furnaces; the non-contact melt mixing is realized by the electromagnetic induction force of the line-frequency coreless induction furnaces, thus preparing the zinc alloy ingot by pouring the zinc alloy liquid. The combined metallurgical furnace and the combined production method have high production efficiency, high yield, good quality of the produced zinc alloy, low energy consumption and small damage to the furnace body.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Liquid lutein and preparation method thereof

InactiveCN101124944AStrong stabilityGood for long-term storageAnimal feeding stuffAccessory food factorsAbsorption rateChemistry

Owner:CHENGDU FENGLAN SCI & TECH

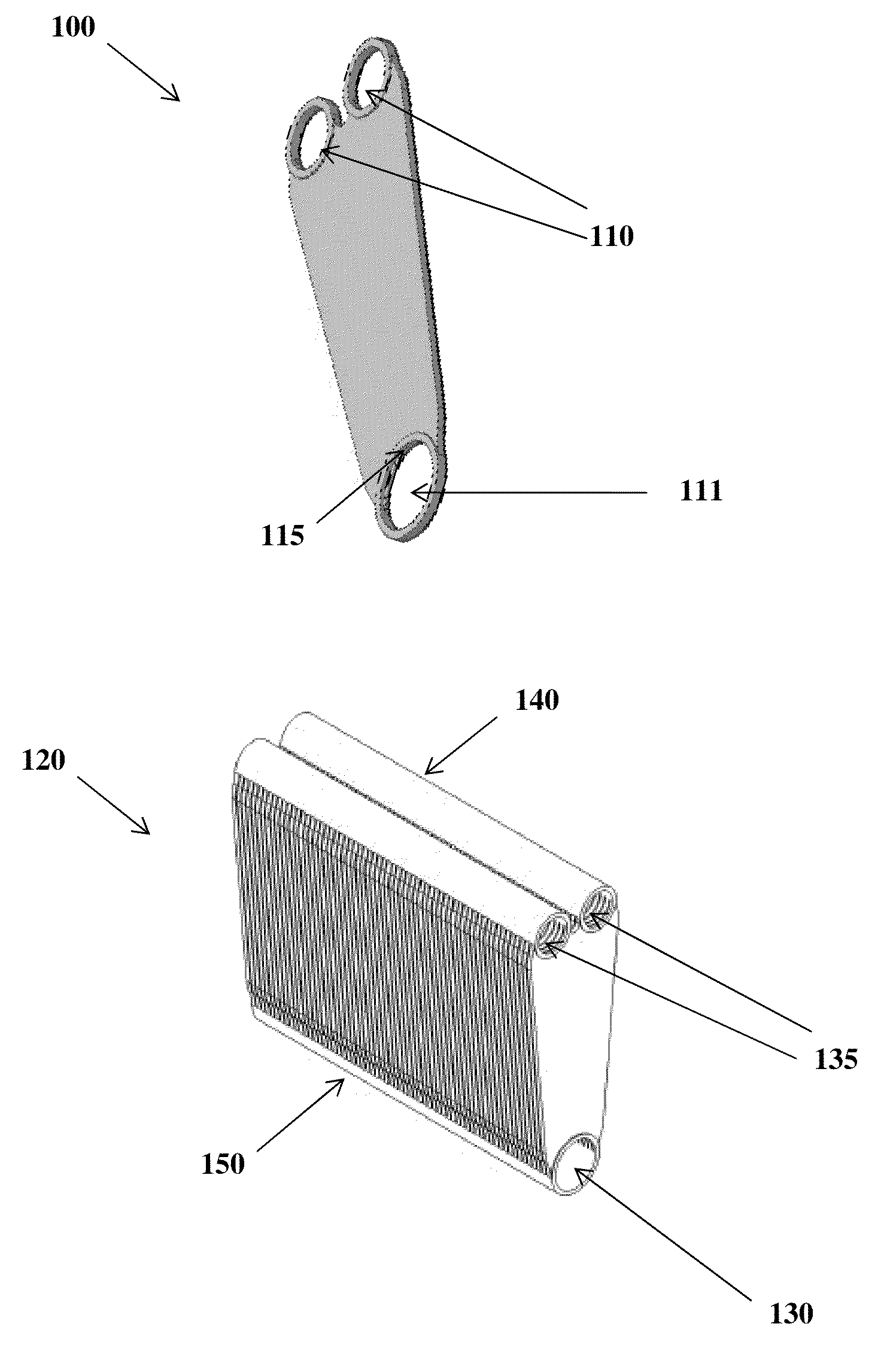

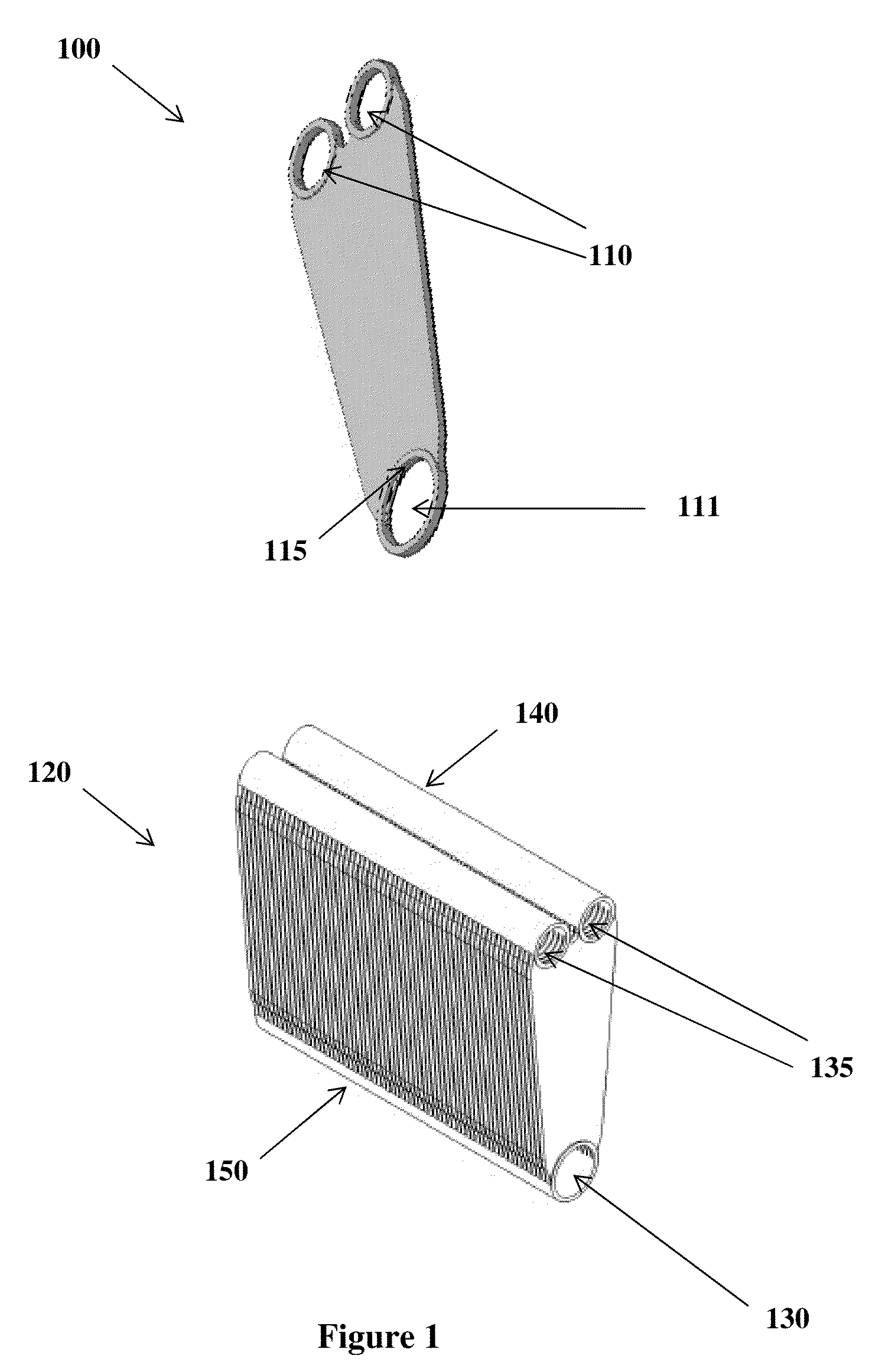

Compact radial counterflow recuperator

ActiveUS8573291B2Reduce manufacturing costLess denseRecuperative heat exchangersEfficient propulsion technologiesCombustorEngineering

An annular design heat exchanger is formed from an arrangement of wedge-shaped stacks of wafers. Each wafer includes sheets of material separated by peripheral and supporting walls that define interior flow channels through which a first fluid can flow. Holes in the sheets provide inlets and outlets to the channels, and walls surrounding the holes mate with neighboring wafers in the stack, forming integral inlet and outlet manifolds, while ensuring uniform spacing between the wafers. A second fluid can flow around the manifolds and through the spaces between the wafers in a counterflow pattern. In the annular assembly, the manifolds are oriented substantially axially, and the flow channels are oriented substantially radially. The heat exchanger can be formed from a ceramic material, and can be incorporated into an engine assembly or a heat-recirculating combustor.

Owner:UNITED STATES OF AMERICA

Reaction injection molding assembly for manufacturing a golf ball component

InactiveUS20070069424A1Golf ball performance characteristicMix thoroughlyFrozen sweetsConfectioneryEngineeringGolf Ball

A molding assembly and related process are described that eliminate or significantly reduce cosmetic defects otherwise occurring in golf balls. The assembly includes molds with particular runner configurations, gate configurations, and venting characteristics. The assemblies and processes described herein are particularly well suited for reaction injection molding of golf balls.

Owner:CALLAWAY GOLF CO

Heater with an atomizer nozzle

InactiveUS20050079458A1Emission reductionAvoid compressionGaseous fuel burnerCombustorAtomizer nozzle

A heater, especially for mobile applications, is provided which includes a burner for burning a liquid fuel, an atomizer nozzle located on the burner for atomizing the liquid fuel into extremely fine fuel droplets, and a fuel supply for feeding the liquid fuel to the atomizer nozzle. A heating means is provided on the atomizer nozzle with which the liquid fuel can be vaporized before and / or during its emergence from the atomizer nozzle.

Owner:WEBASTO AG

Exhaust gas muffler

ActiveUS7357221B2Achieve heatingExtended retention timeExhaust apparatusCombustion-air/fuel-air treatmentExternal combustion engineExhaust fumes

An exhaust gas muffler is provided for an internal combustion engine, especially for an internal combustion engine in a manually-guided implement such as a power saw, a cut-off machine, or the like. The muffler has a housing having an inlet for exhaust gases and an outlet out of the housing. To achieve an after burning of exhaust gas in a straightforward manner, the exhaust gases in the housing flow through a reaction zone in which the exhaust gases circulate at least partially.

Owner:ANDREAS STIHL AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com