Method for refining catalytic liquefied petroleum gas

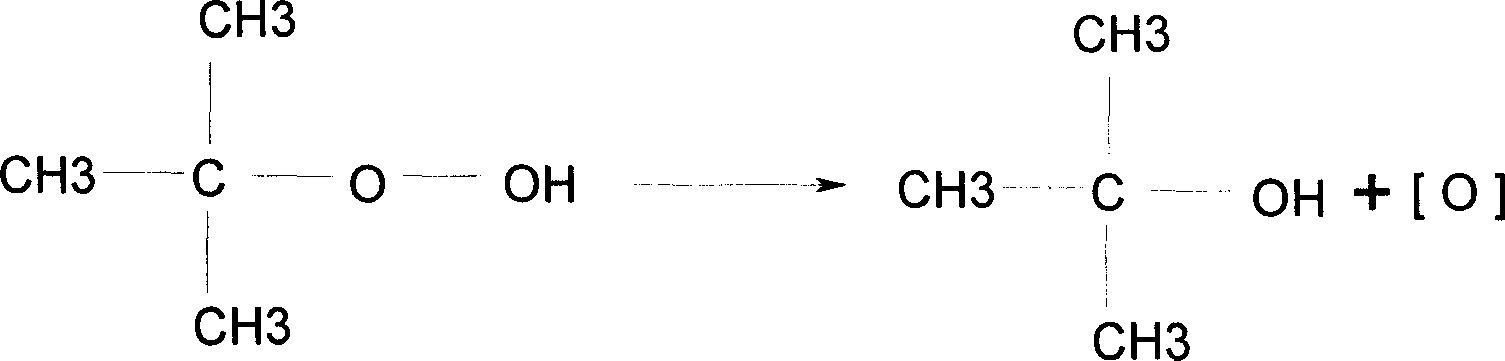

A catalytic liquefaction and petroleum gas technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve problems such as inability to convert, incomplete conversion of mercaptans, and failure to remove carbonyl sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

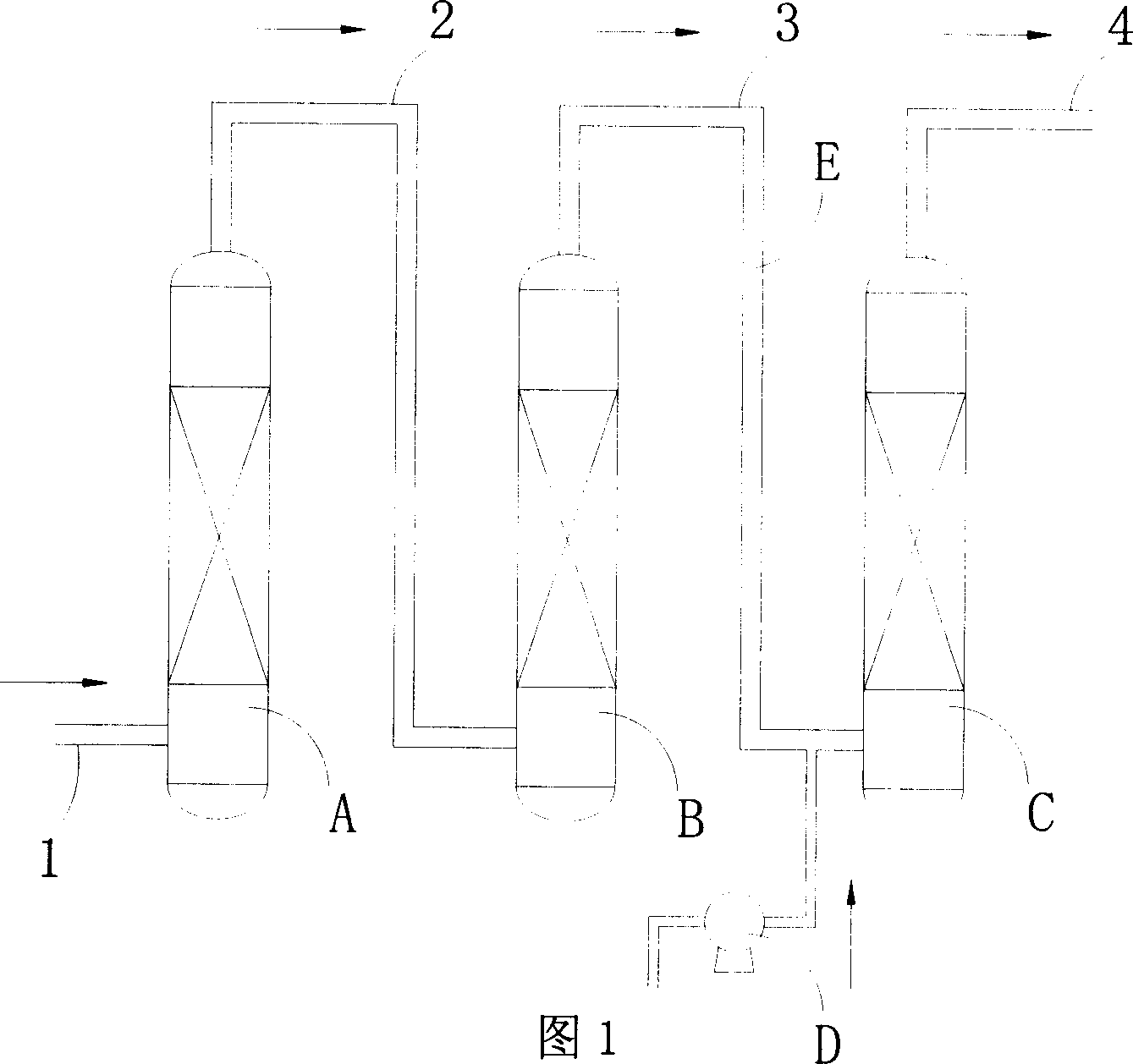

Method used

Image

Examples

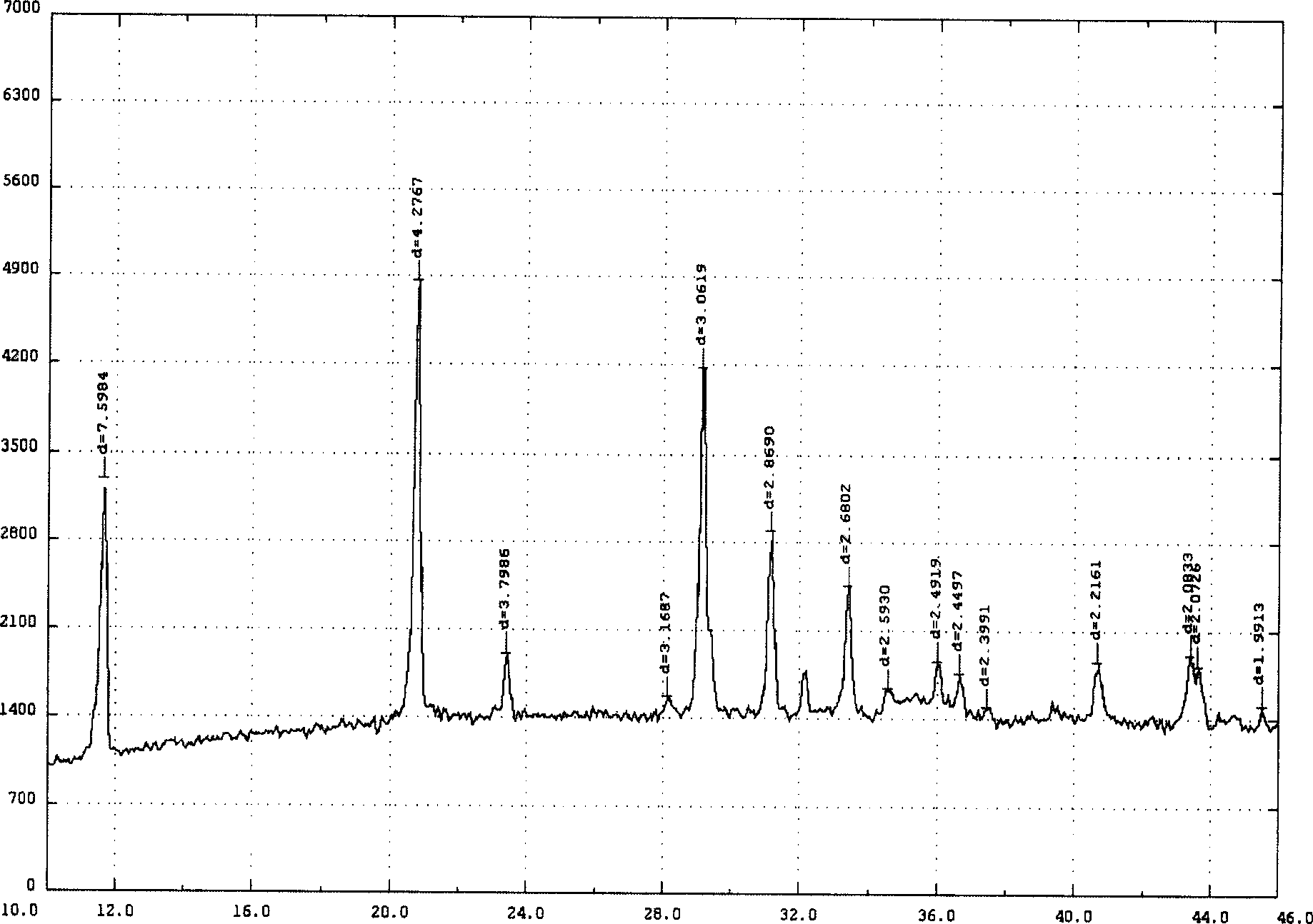

manufacture example 1 to manufacture example 3

[0038] A cylindrical double-effect catalyst A1 whose active component is manganese dioxide, and the double-effect catalyst A1 is entirely composed of manganese dioxide. The manufacturing method is as follows: Each manufacturing example takes a certain weight of powdered manganese dioxide respectively, and uses a tablet machine or a tablet press to press the powdered manganese dioxide under corresponding pressure into a cylindrical shape with a certain lateral pressure strength. The solid moldings of the two-way catalyst finished product A11 of production example 1, the double-way catalyst finished product A12 of production example 2 and the double-way catalyst finished product A13 of production example 3 were respectively obtained. The diameters of these finished double-effect catalysts are all 6.5 mm, and the heights are all 6.2 mm to 6.5 mm. See Table 1 for the relevant parameters of the specifications and properties of the catalysts of each manufacturing example. In Manufa...

manufacture example 4 to manufacture example 6

[0040] A cylindrical double-effect catalyst A2 whose active component is manganese carbonate, and the double-effect catalyst A2 is entirely composed of manganese carbonate. The manufacturing method is as follows: Each manufacturing example weighs a certain weight of powdered manganese carbonate respectively, and presses the powdered manganese carbonate under corresponding pressure into a cylindrical solid with a certain lateral pressure strength by using a tablet machine or a tablet press. The finished double-way catalyst A21 of Production Example 4, the finished double-way catalyst A22 of Production Example 5, and the finished double-way catalyst A23 of Production Example 6 were obtained respectively. The diameters of these finished double-effect catalysts are all 6.5 mm, and the heights are all 6.2 mm to 6.5 mm. See Table 1 for the relevant parameters of the specifications and properties of the catalysts of each manufacturing example. In manufacturing example 4 to manufactu...

manufacture example 7 to manufacture example 9

[0042] The active component is a cylindrical double-effect catalyst A3 whose active component is trimanganese tetraoxide, and the double-effect catalyst A3 is entirely composed of trimanganese tetraoxide. The manufacturing method is as follows: Each manufacturing example weighs a certain weight of powdered trimanganese tetroxide, respectively, and presses the powdered trimanganese tetraoxide under corresponding pressure with a tablet machine or a tablet press to form a tablet with a certain lateral pressure strength. Cylindrical solid moldings were used to obtain the finished double-effect catalyst A31 of Production Example 7, the finished double-effect catalyst A32 of Production Example 8, and the finished double-effect catalyst A33 of Production Example 9. The diameters of these finished double-effect catalysts are all 6.5 mm, and the heights are all 6.2 mm to 6.5 mm. See Table 1 for the relevant parameters of the specifications and properties of the catalysts of each manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com