Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

737 results about "Animal fat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Animal fats and oils are lipid materials derived from animals. Physically, oils are liquid at room temperature, and fats are solid. Chemically, both fats and oils are composed of triglycerides. Although many animal parts and secretions may yield oil, in commercial practice, oil is extracted primarily from rendered tissue fats obtained from livestock animals like pigs, chickens and cows. Dairy products also yield popular animal fat and oil products such as cheese, butter, and milk.

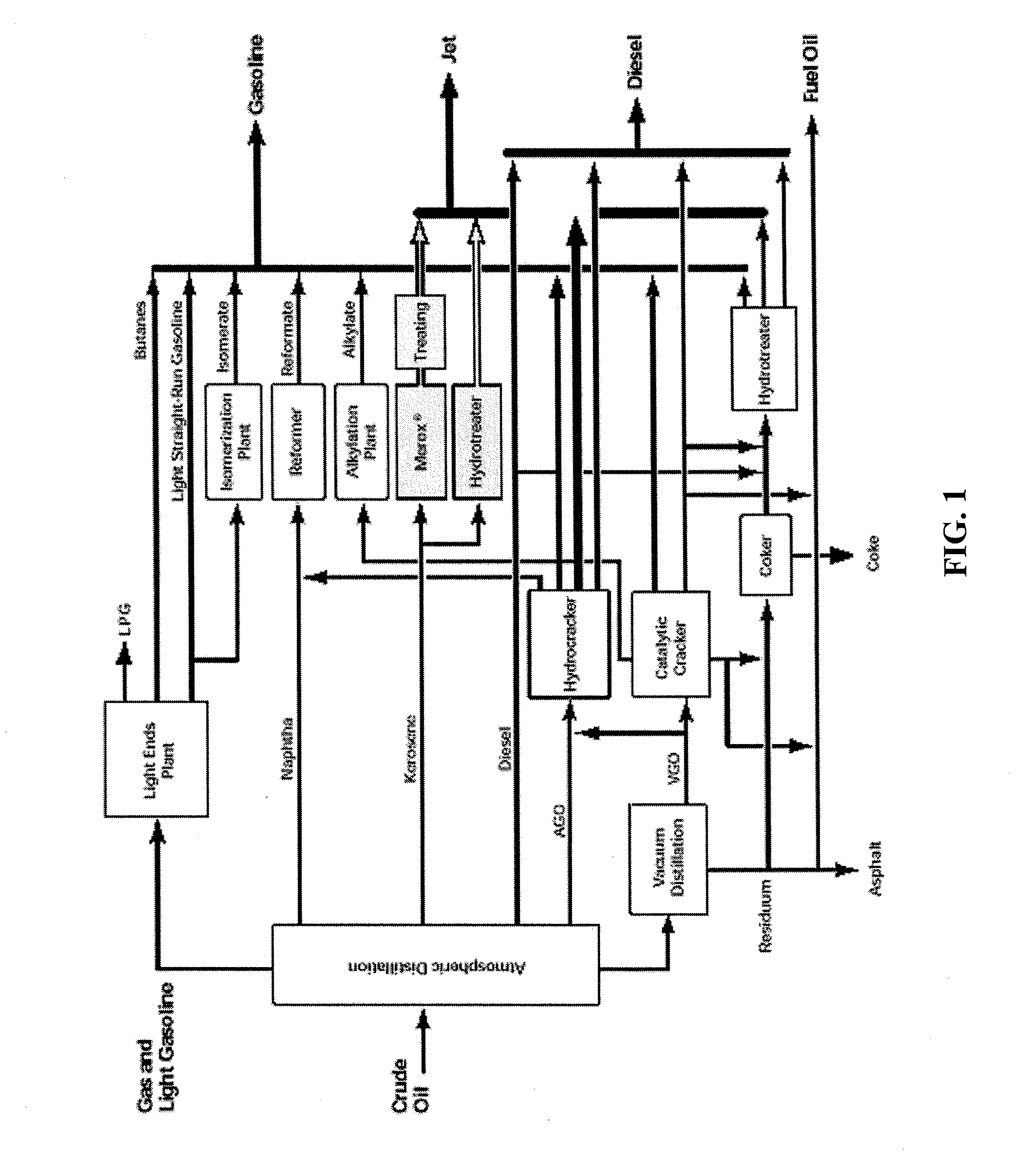

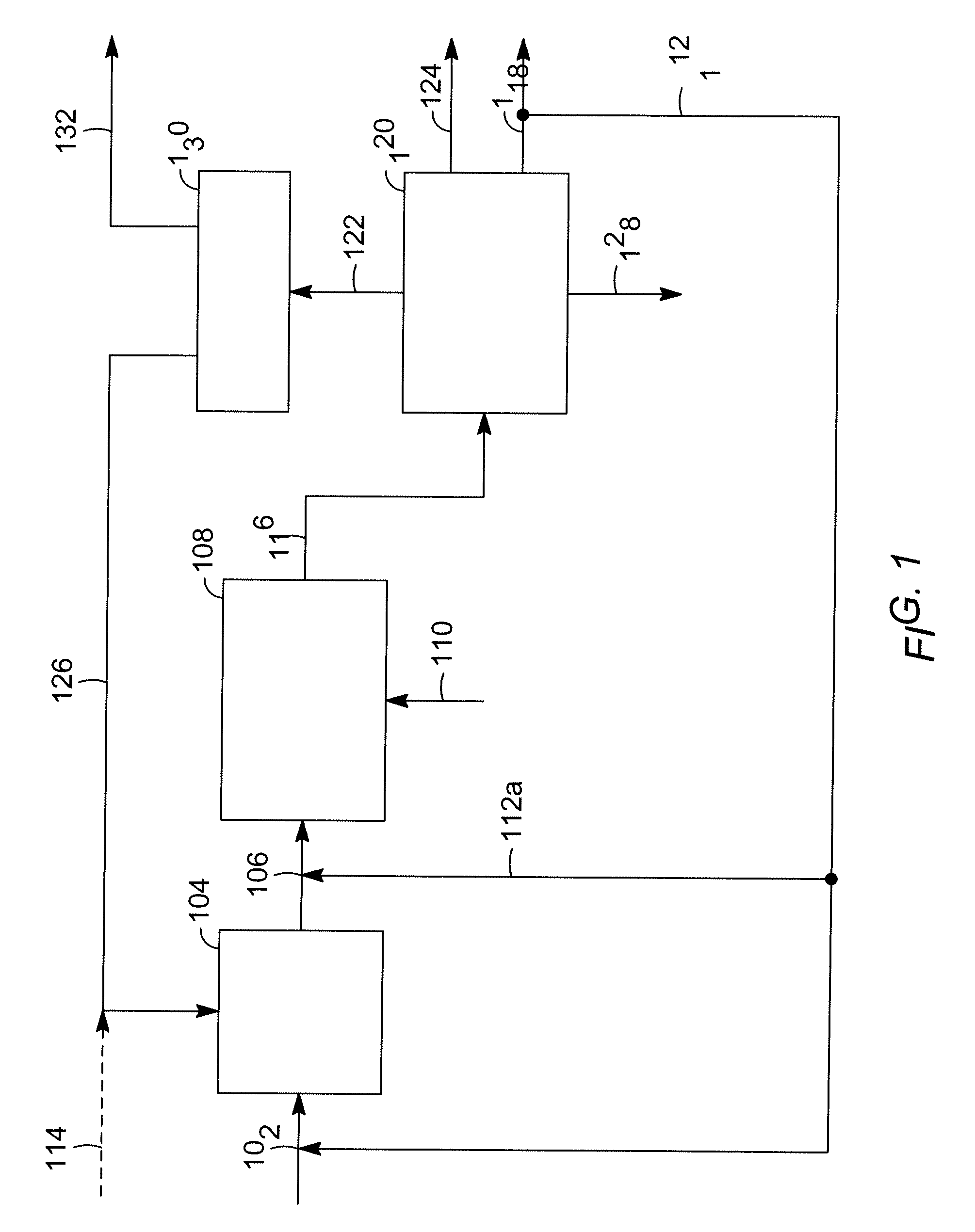

Production of Aviation Fuel from Biorenewable Feedstocks

ActiveUS20090158637A1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAlkaneVegetable oil

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different aviation fuels such as JP-8.

Owner:UOP LLC

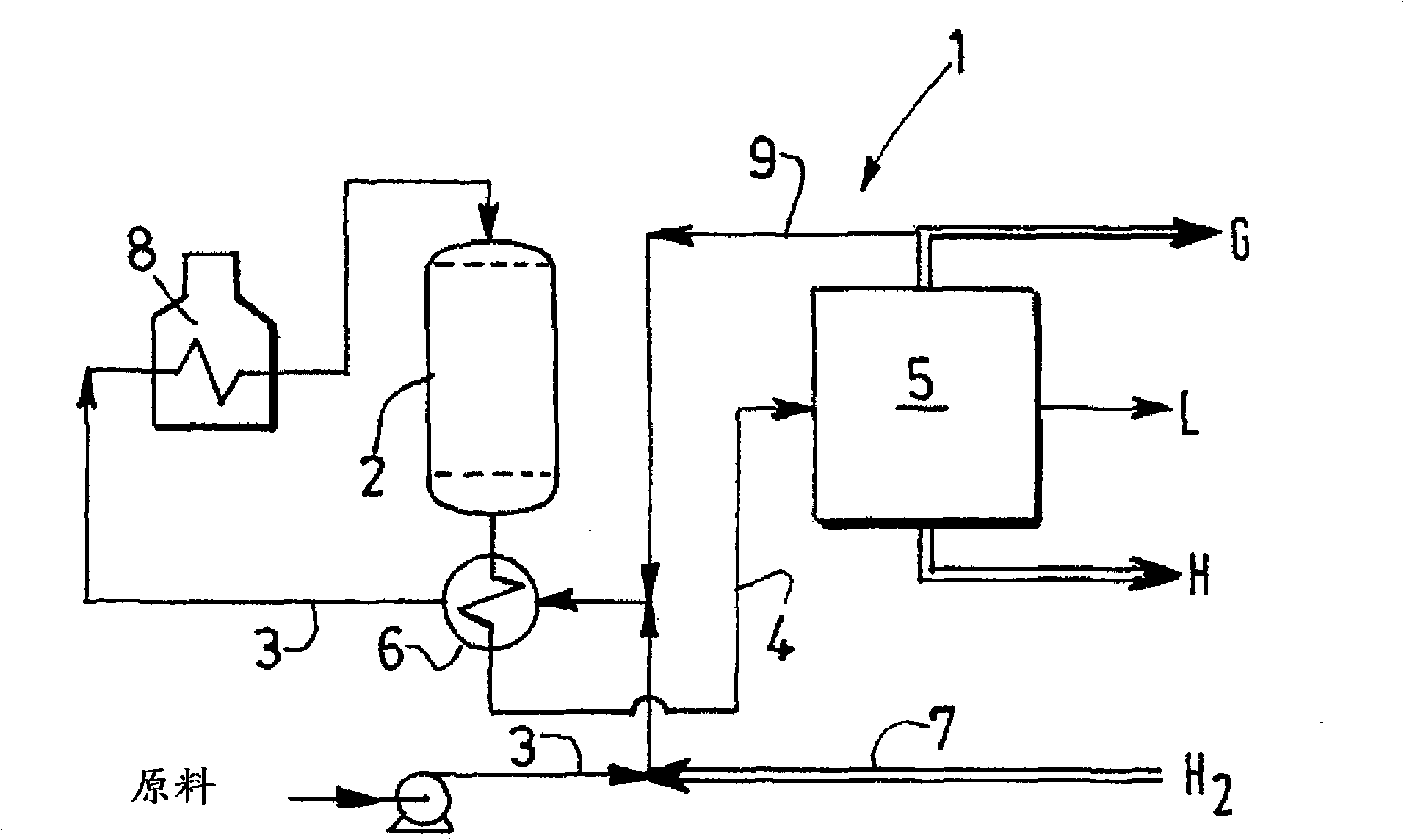

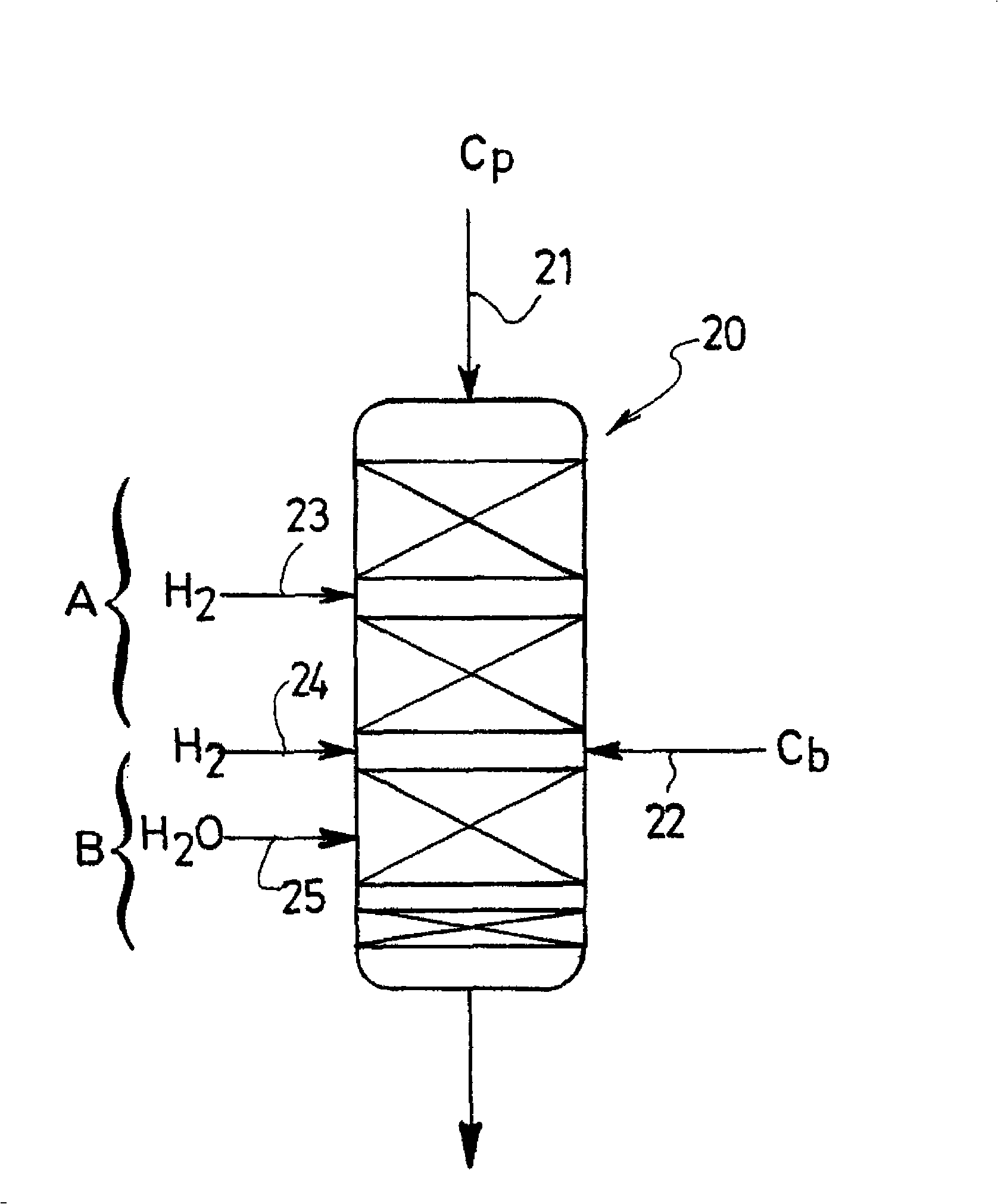

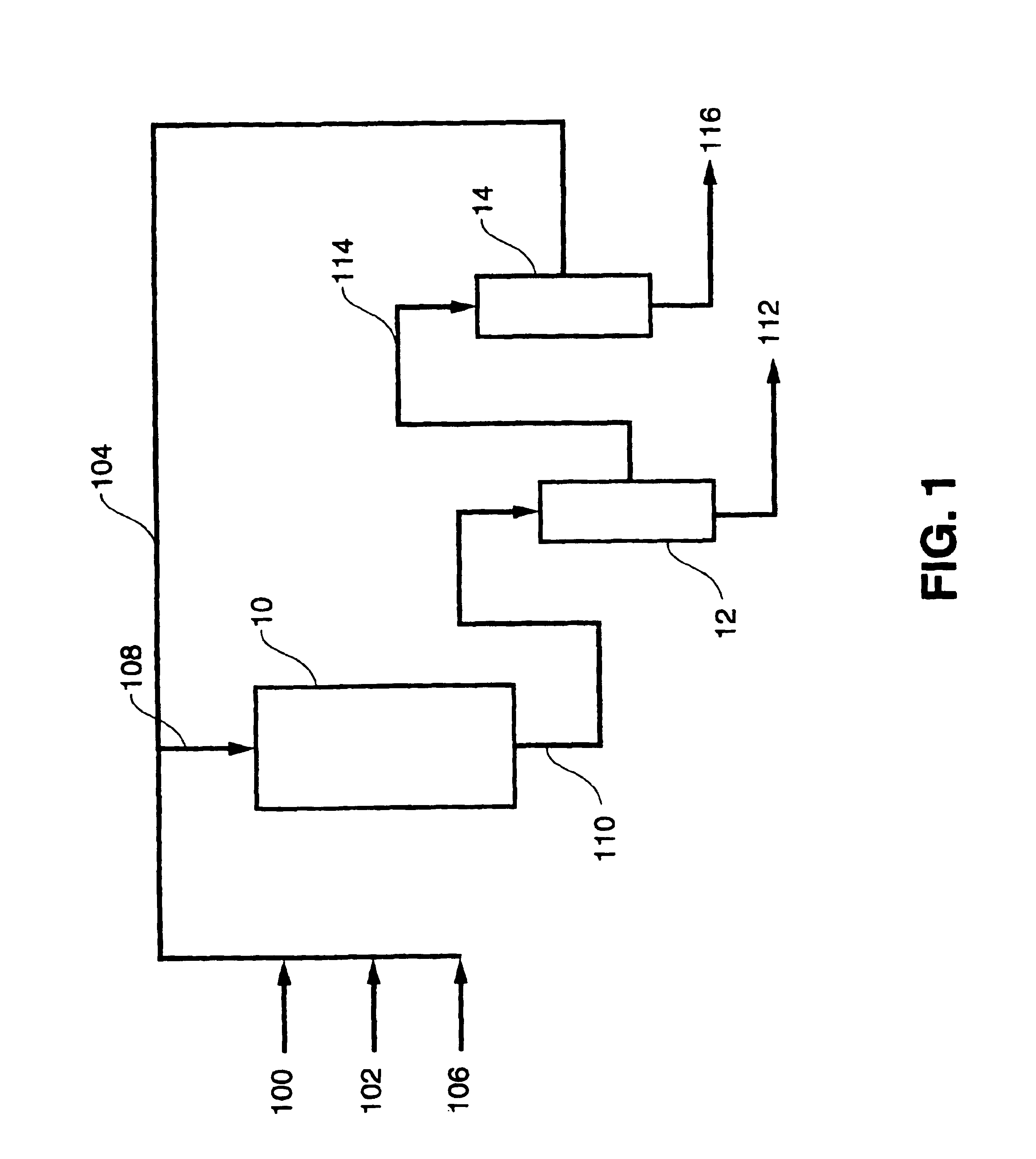

Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

InactiveCN101517038AShort stayReduce volumeLiquid hydrocarbon mixture productionEthylene productionFixed bedPetroleum

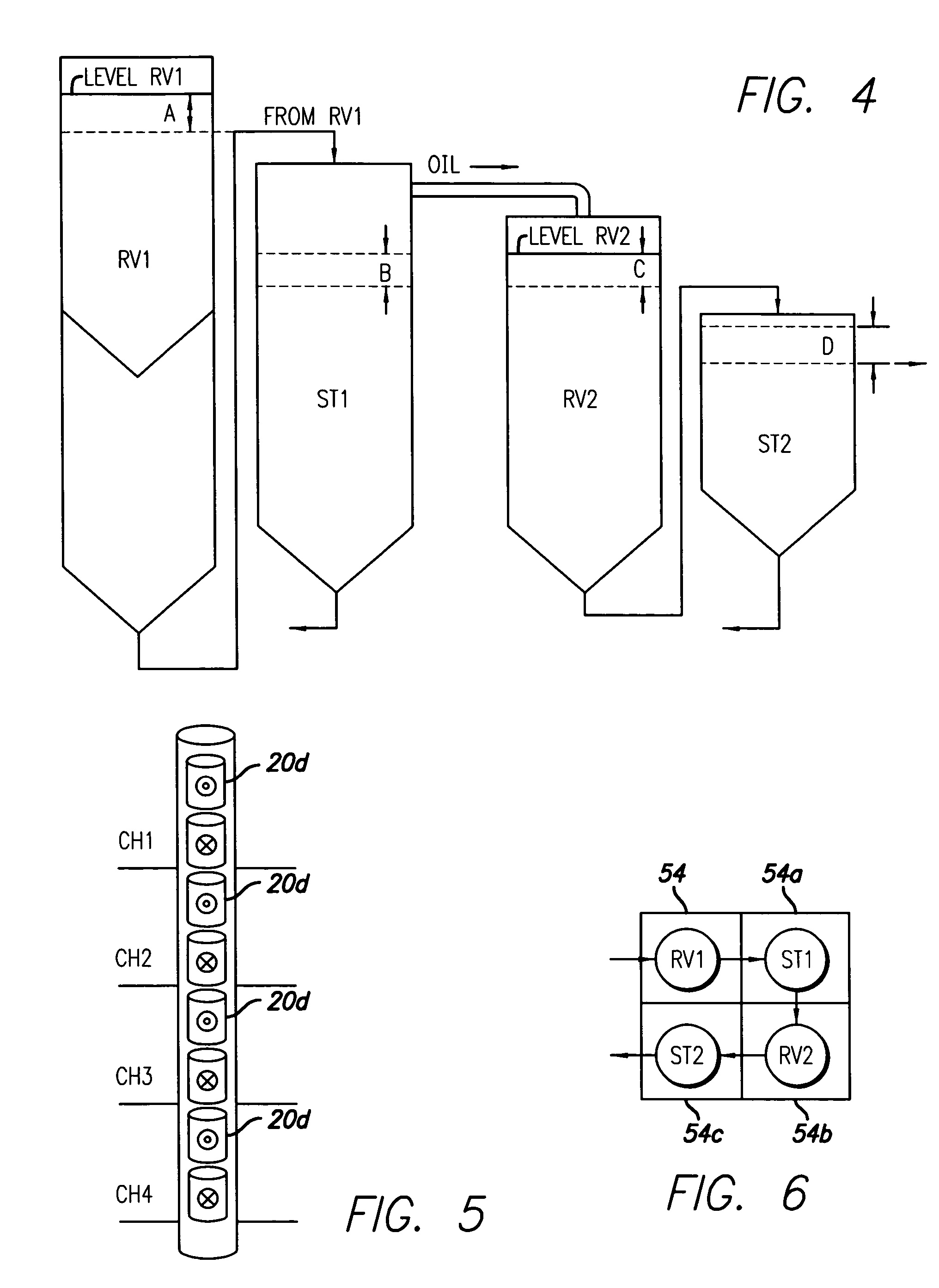

The invention relates to a method for the catalytic hydro-processing of a petroleum feedstock of the gas oil type and of a biological feedstock containing vegetal oils and / or animal fats, in a catalytic fixed-bed hydro-processing unit, said method being characterised in that the petroleum feedstock is introduced into the reactor upstream from the biological feedstock. The invention also relates to a catalytic hydro-processing unit for implementing said method, and to a corresponding hydro-refining unit.

Owner:TOTAL RAFFINAGE MARKETING

Fuel Composition

ActiveUS20080229654A1Maximize product yieldYield maximizationFatty acid isomerisationFatty acid oxidationIsomerizationVegetable oil

Compositions and methods for forming hydrocarbon products from triglycerides are disclosed. In one aspect, the methods involve the thermal decomposition of fatty acids, which can be derived from the hydrolysis of triglycerides. The thermal decomposition products can be combined with low molecular weight olefins, such as Fischer-Tropsch synthesis products, and subjected to molecular averaging reactions. Alternatively, the products can be subjected to hydrocracking reactions, isomerization reactions, and the like. The products can be isolated in the gasoline, jet and / or diesel fuel ranges. Thus, vegetable oils and / or animal fats can be converted using water, catalysts, and heat, into conventional products in the gasoline, jet and / or diesel fuel ranges. These products are virtually indistinguishable from those derived from their petroleum-based analogs, except that they can have virtually no aromatic, sulfur or nitrogen content, they are derived, in whole or in part, from renewable resources, and can also be derived from domestically available coal and / or natural gas.

Owner:BRADIN DAVID

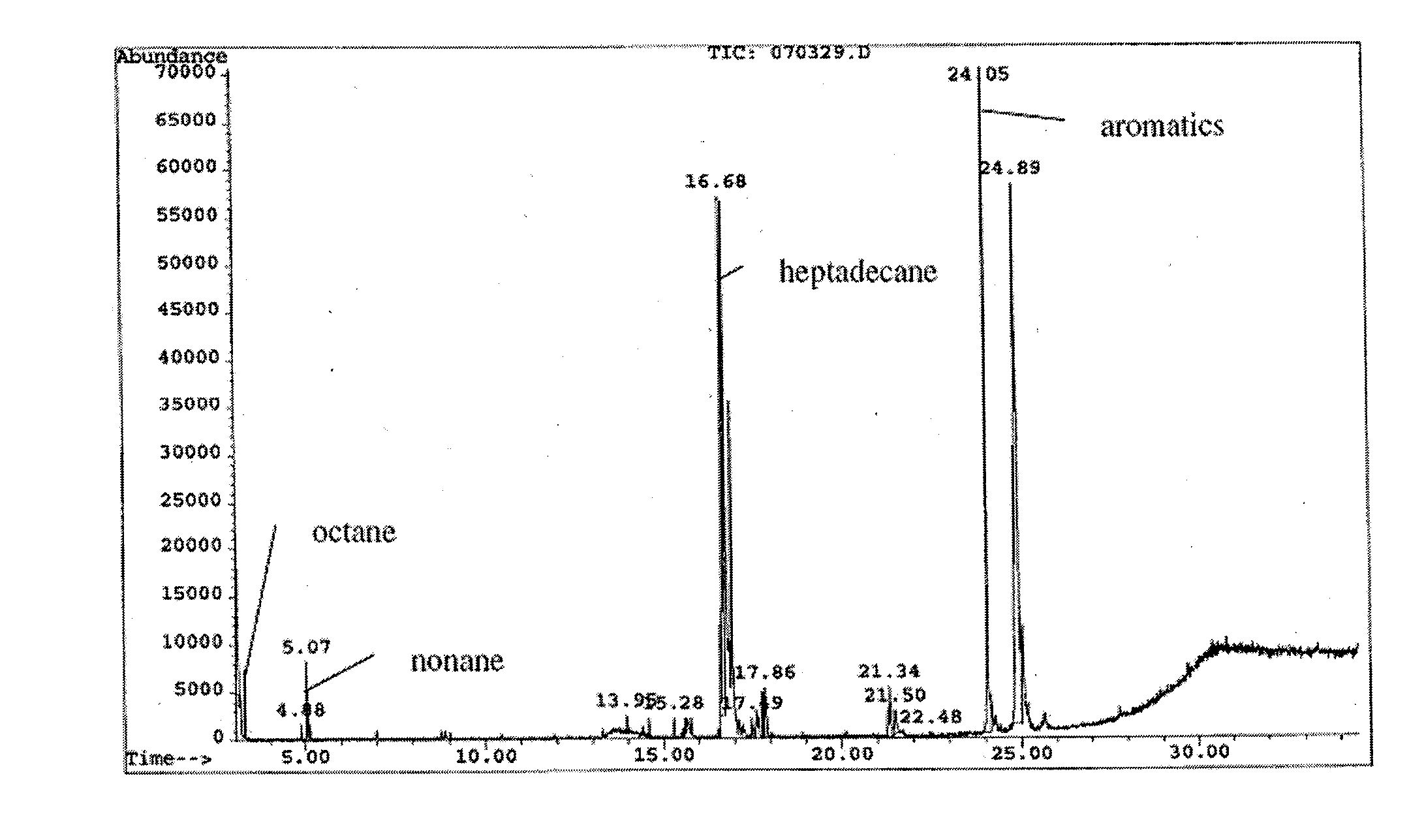

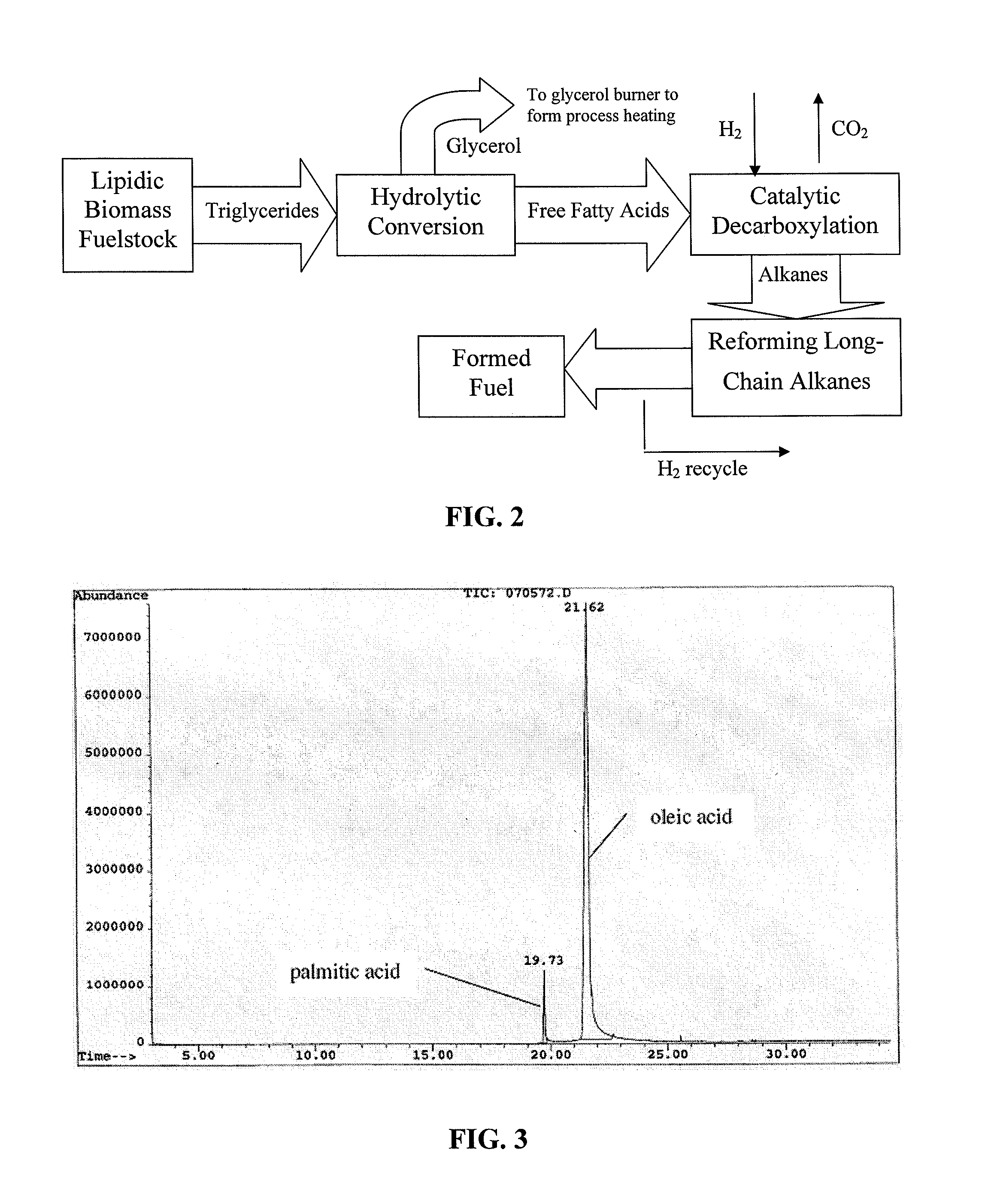

Process for conversion of biomass to fuel

ActiveUS20090069610A1Meet growth needsEasy to processFatty acid esterificationRefining to change hydrocarbon structural skeletonAlkaneChain length

The present invention is directed to processes for the direct conversion of lipidic biomass fuelstock to combustible fuels. In particular, the invention provides a process for the direct conversion of animal fats to transportations fuels suitable as replacement for petroleum-derived transportation fuels. In one embodiment, the method comprises the steps of hydrolyzing a lipidic biomass to form free fatty acids, catalytically deoxygenating the free fatty acids to form n-alkanes, and reforming at least a portion of the n-alkanes into a mixture of compounds in the correct chain length, conformations, and ratio to be useful transportation fuels. Particularly, the product prepared according to the invention comprises mixtures of hydrocarbon compounds selected from the group consisting of n-alkanes, isoalkanes, aromatics, cycloalkanes, and combinations thereof.

Owner:NORTH CAROLINA STATE UNIV

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

Method of converting feedstocks coming from renewable sources into high-quality gas-oil fuel bases

ActiveUS20080161615A1The implementation process is simpleHydrocarbon by hydrogenationSolid fuelsVegetable oilEngineering

Owner:INST FR DU PETROLE

Healthier Baked Goods Containing Microalgae

Provided herein are microalgae-containing baked goods with novel properties compared to preexisting products of the same type. Methods of formulating and manufacturing these foods to deliver reduced fat, reduced cholesterol, and increased fiber content are disclosed herein. Various embodiments include elimination or reduction of eggs, butter, animal fat, and saturated oils in favor of healthy oil-containing microalgae biomass and oils, including the manufacture of foods with lower calories than preexisting products of the same type. Methods of producing raw materials for the manufacture of novel processed baked foods and intermediates such as cake and bead mixes are also provided.

Owner:TERRAVIA HLDG INC

Melting Vegetable Protein Based Substitute Cheese

This invention is directed to a molded, pressed, low animal fat substitute cheese composition, comprising;moisture in an amount that is at least about 50% by weight of the cheese composition, and(A) a vegetable protein material;(B) a vegetable oil triglyceride; and(C) a hydrocolloid.In another embodiment, the molded, pressed, low animal fat substitute cheese compositions further comprises at least one component selected from the group consisting of(D) a cheese flavorant and(E) a starch.

Owner:SOLAE LLC

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

InactiveUS20080312480A1Hydrocarbon from carbon oxidesFatty acid chemical modificationAlkaneVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises molybdenum, a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of even-numbered hydrocarbons to odd-numbered hydrocarbons of at least 2:1.

Owner:EI DU PONT DE NEMOURS & CO

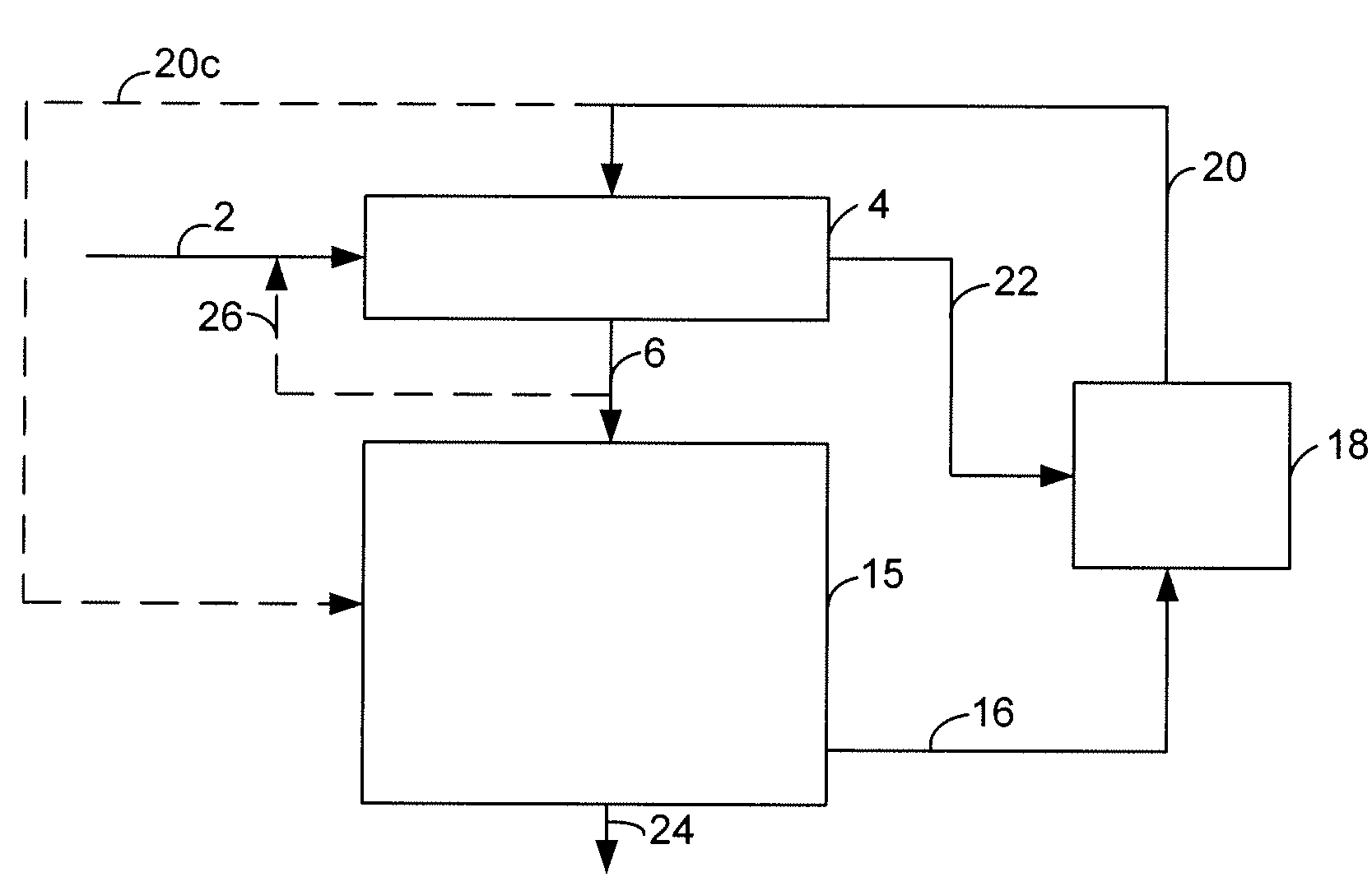

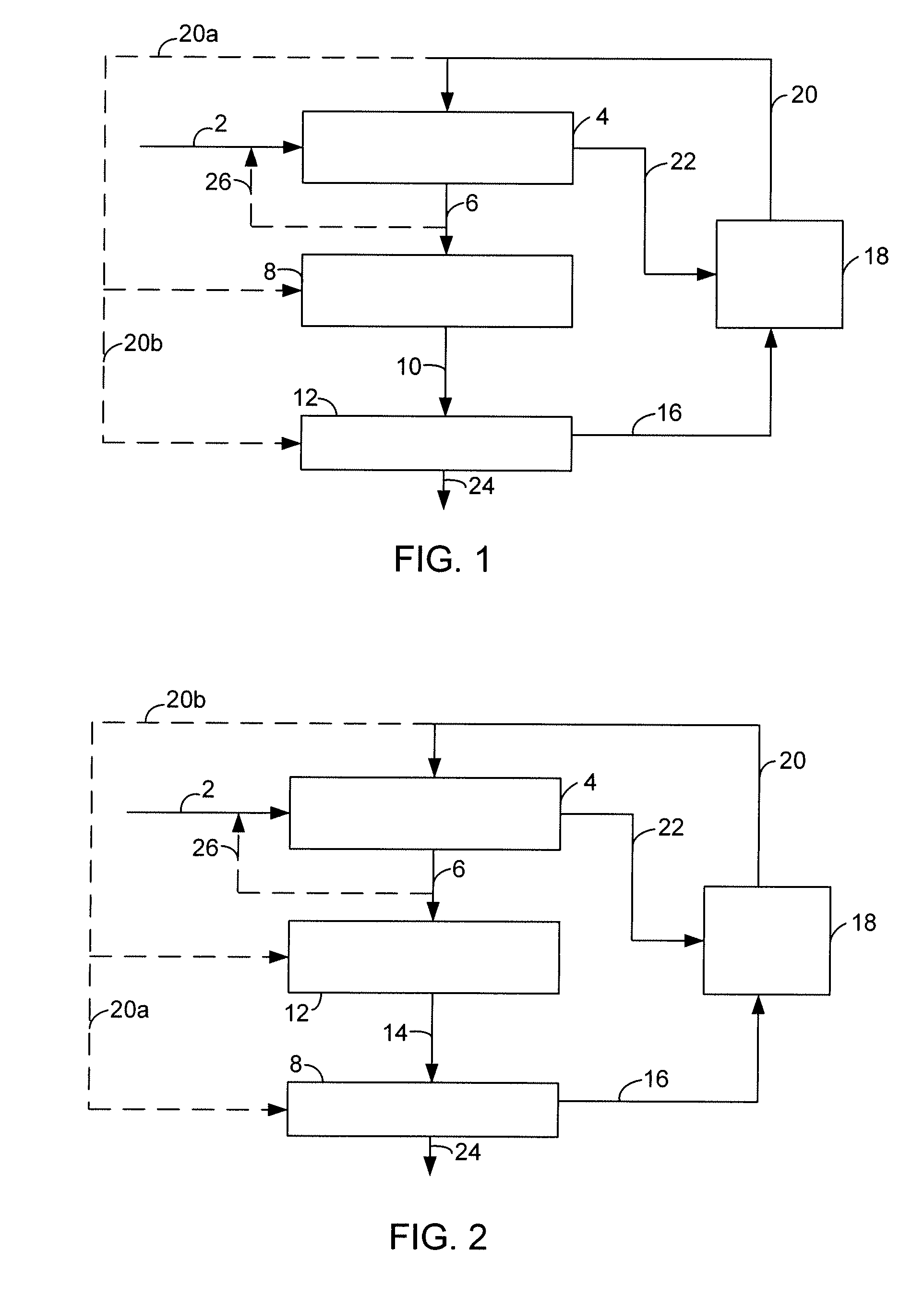

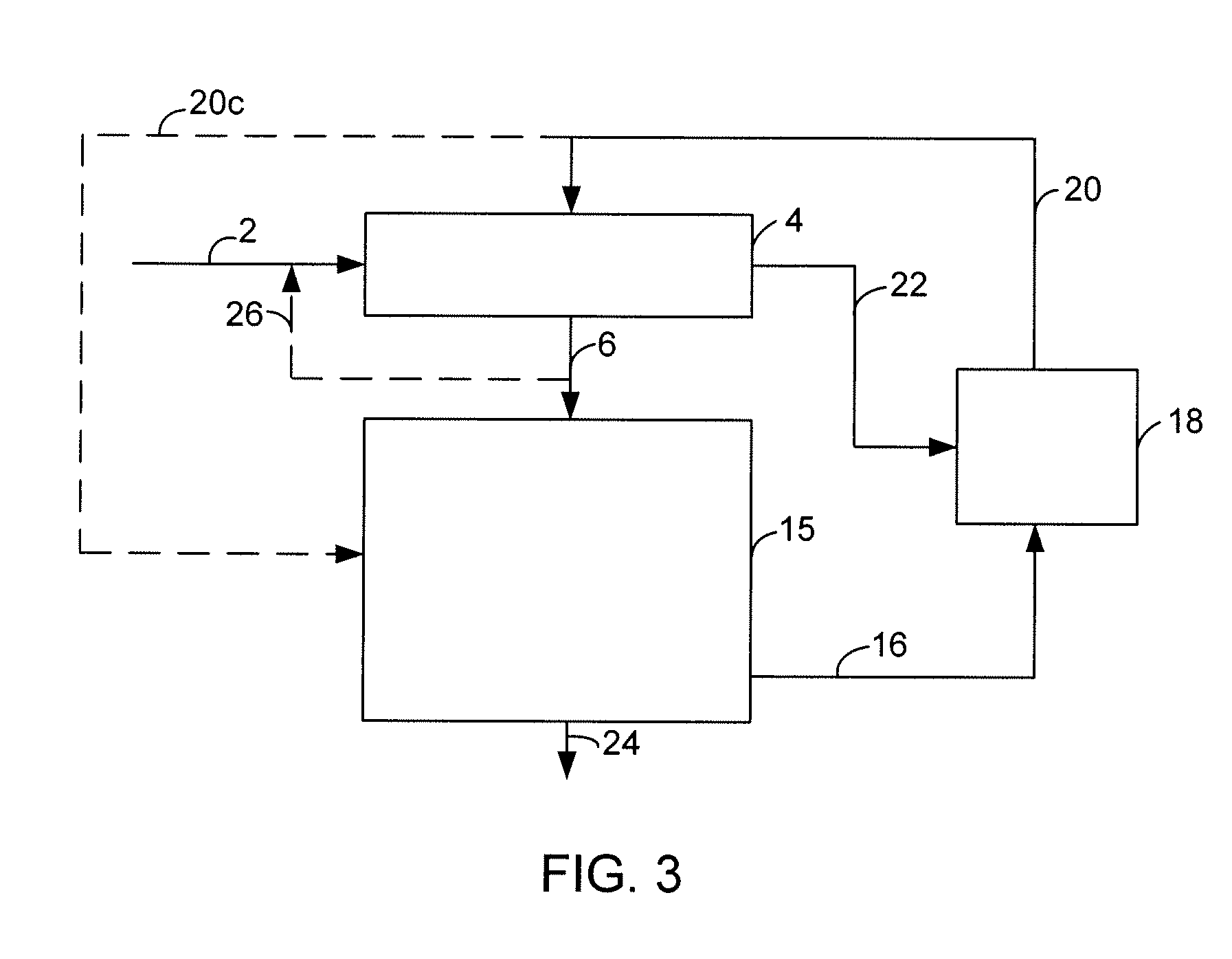

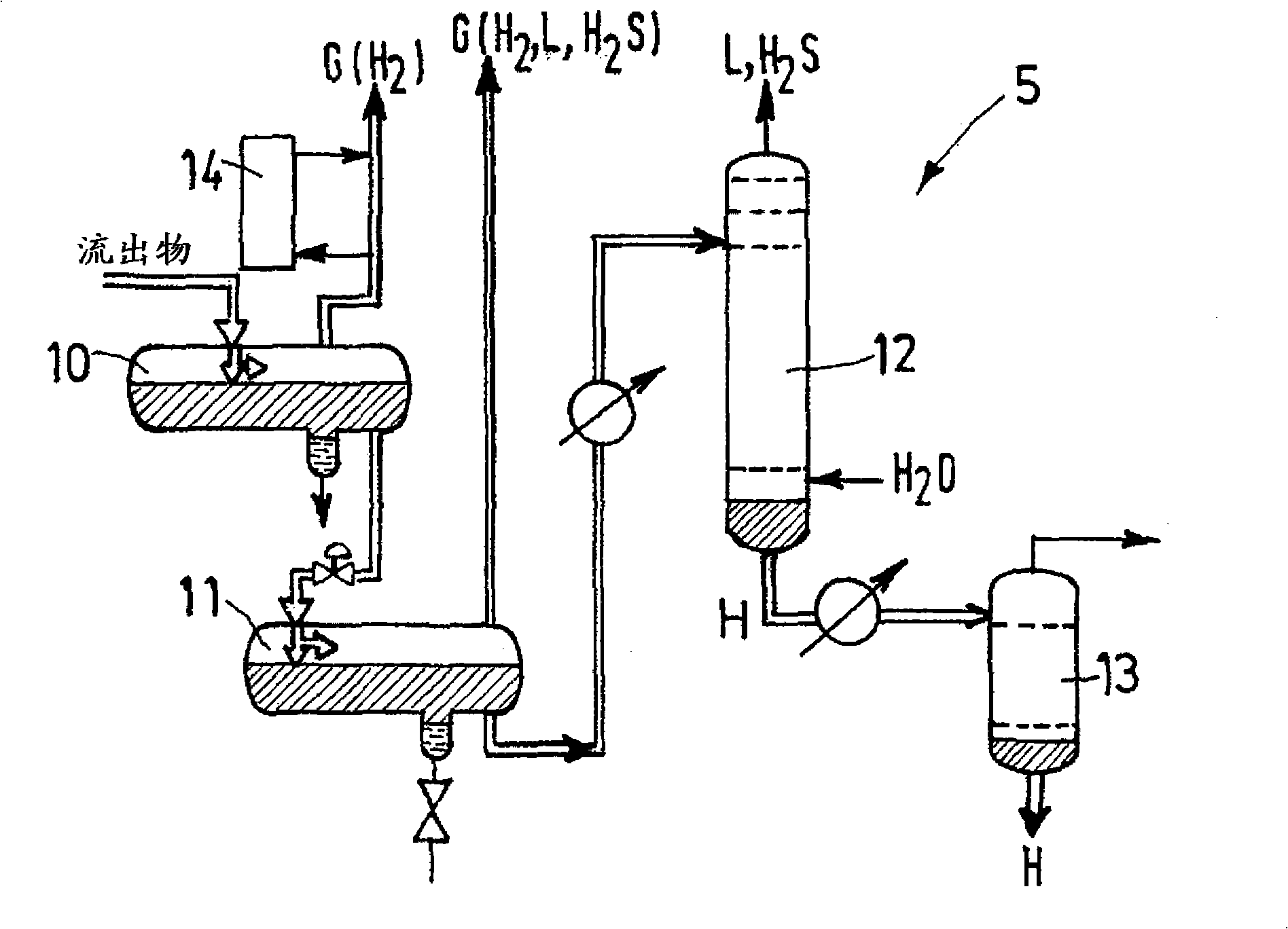

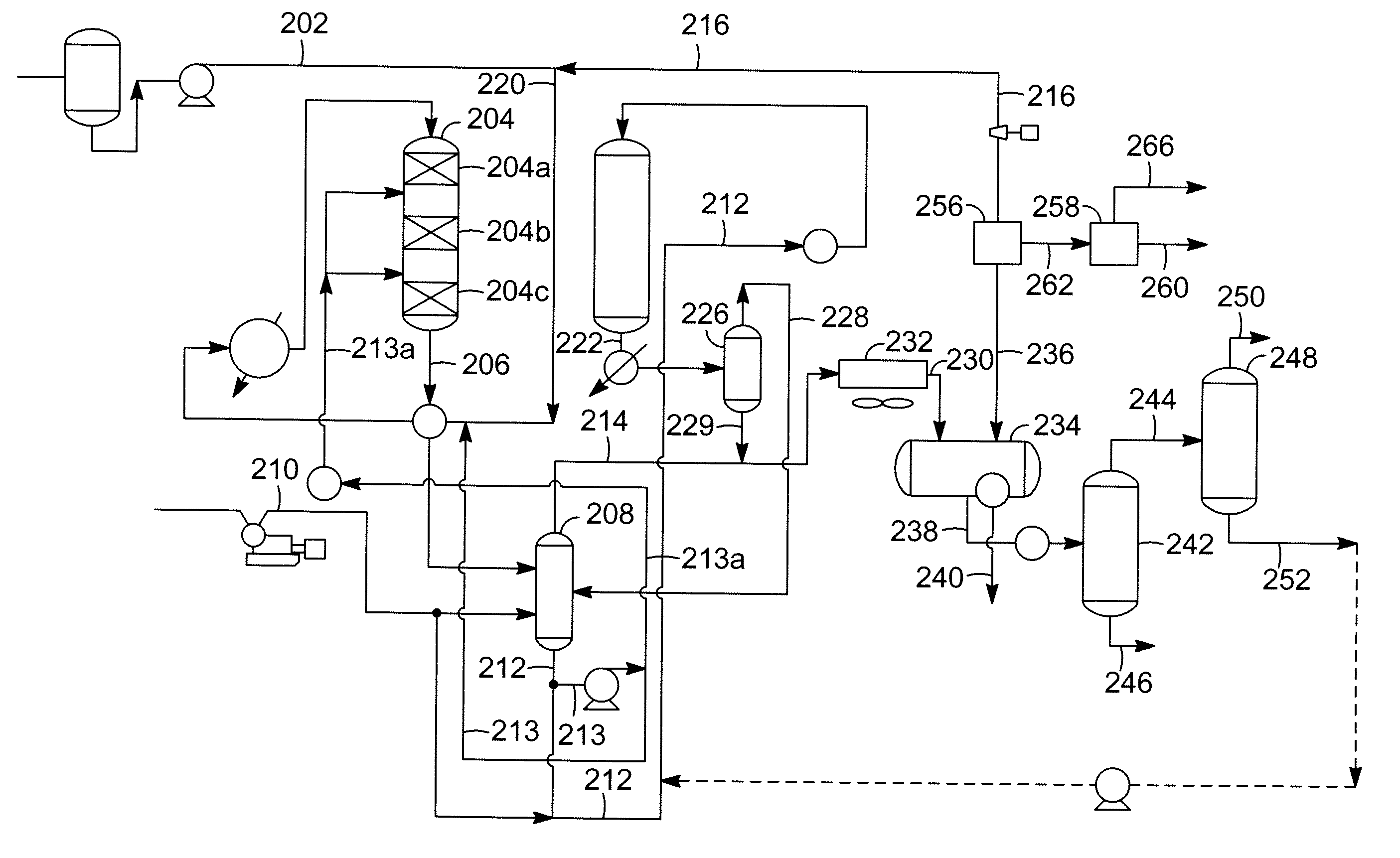

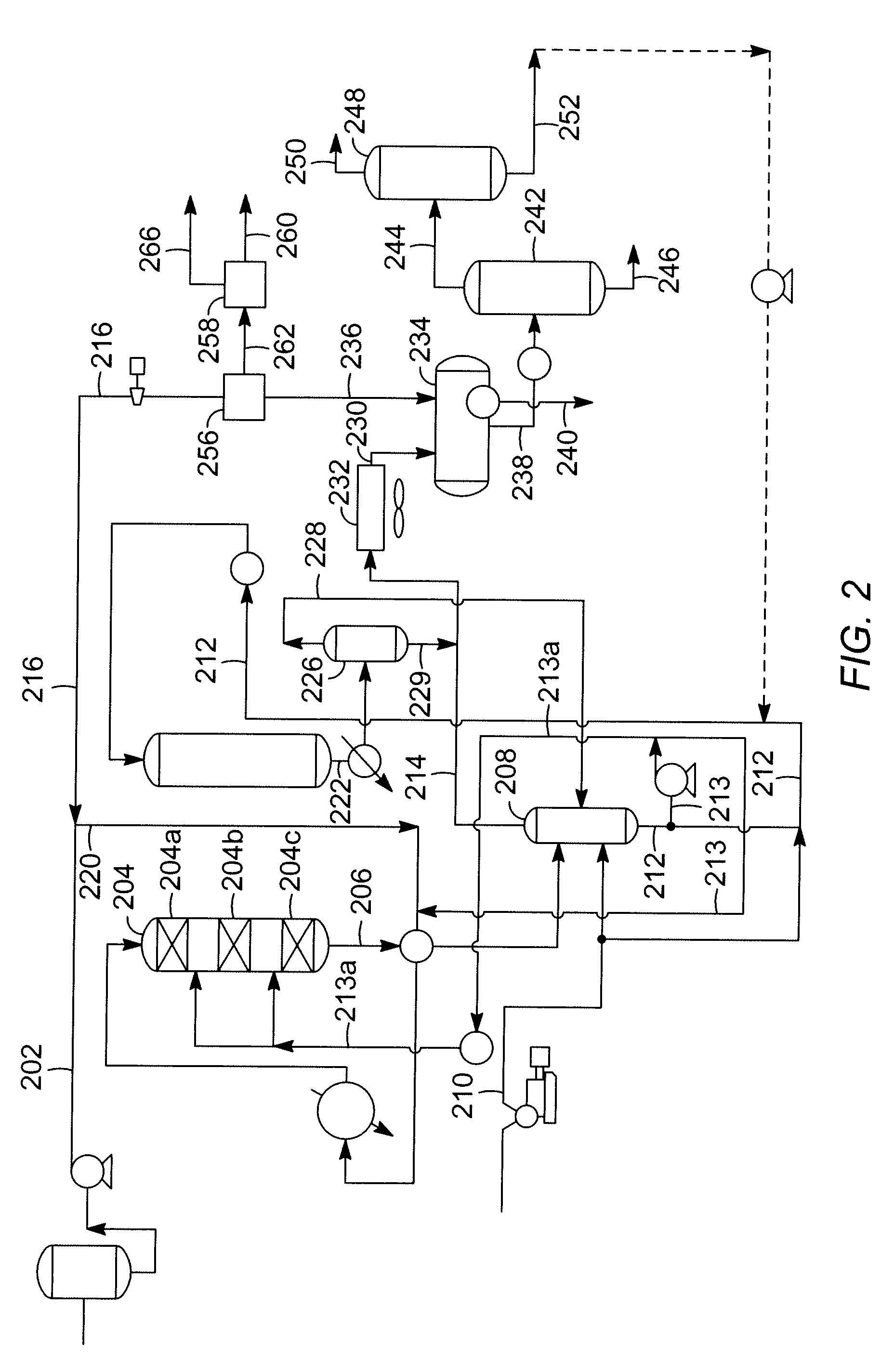

Production of Diesel Fuel from Biorenewable Feedstocks with Selective Separation of Converted Oxygen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils, the process providing for sulfur management. The process involves catalytically treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. The hydrocarbon fraction is isomerized to improve cold flow properties. A selective separation such as a hot high pressure hydrogen stripper is used to remove at least the carbon oxides from the first zone effluent before entering the isomerization zone, and to provide liquid recycle to the treating zone at pressure and temperature. A vapor stream is separated from the isomerization effluent and at least carbon dioxide is removed using at least one selective or flexible amine solution absorber. The resulting hydrogen-rich stream is recycled to the deoxygenation reaction zone

Owner:UOP LLC

Staple food for pets and preparation method thereof

ActiveCN102008026AGood for strong bonesEnhance physical fitnessAnimal feeding stuffVegetable oilAntioxidant

The invention discloses a baked staple food for pets, which is prepared from raw materials comprising animal raw materials, grain powder, microbial protein, plant and animal protein, animal fat, vegetable oil, an antioxidant, a water-retaining agent, calcium acid phosphate and / or a dietary supplement, wherein the animal raw materials are fresh animal raw materials, and may be one or more of beef, chicken, mutton, rabbit meat, duck, goose meat, fish, pork, beef liver, beef lung, chicken liver, rabbit liver, rabbit lung, pork liver and pork lung; the animal raw material content of all the raw materials is 10 to 60 mass percent; and the grain powder content of all the raw materials is 10 to 40 mass percent. The staple food for the pets is prepared completely from the fresh raw materials, is healthy, nutrient, highly palatable, digestible, and more favorable for strengthening bones and enhancing the physique of the pets, and can maximally reduce discomfort caused by diet change and effectively improve the intestinal tract function of dogs.

Owner:WEIFANG PINGHEYUAN PET ARTICLE COMMERCE & TRADECO

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

ActiveUS20080308458A1Fatty acid chemical modificationMolecular sieve catalystsParaffin waxVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal a first oxide and optionally a second oxide wherein at least one of the first oxide or second oxide comprises a zeolite, through hydrodeoxygenation and one or both of hydroisomerization and hydrocracking.

Owner:REFINING TECH SOLUTIONS LLC

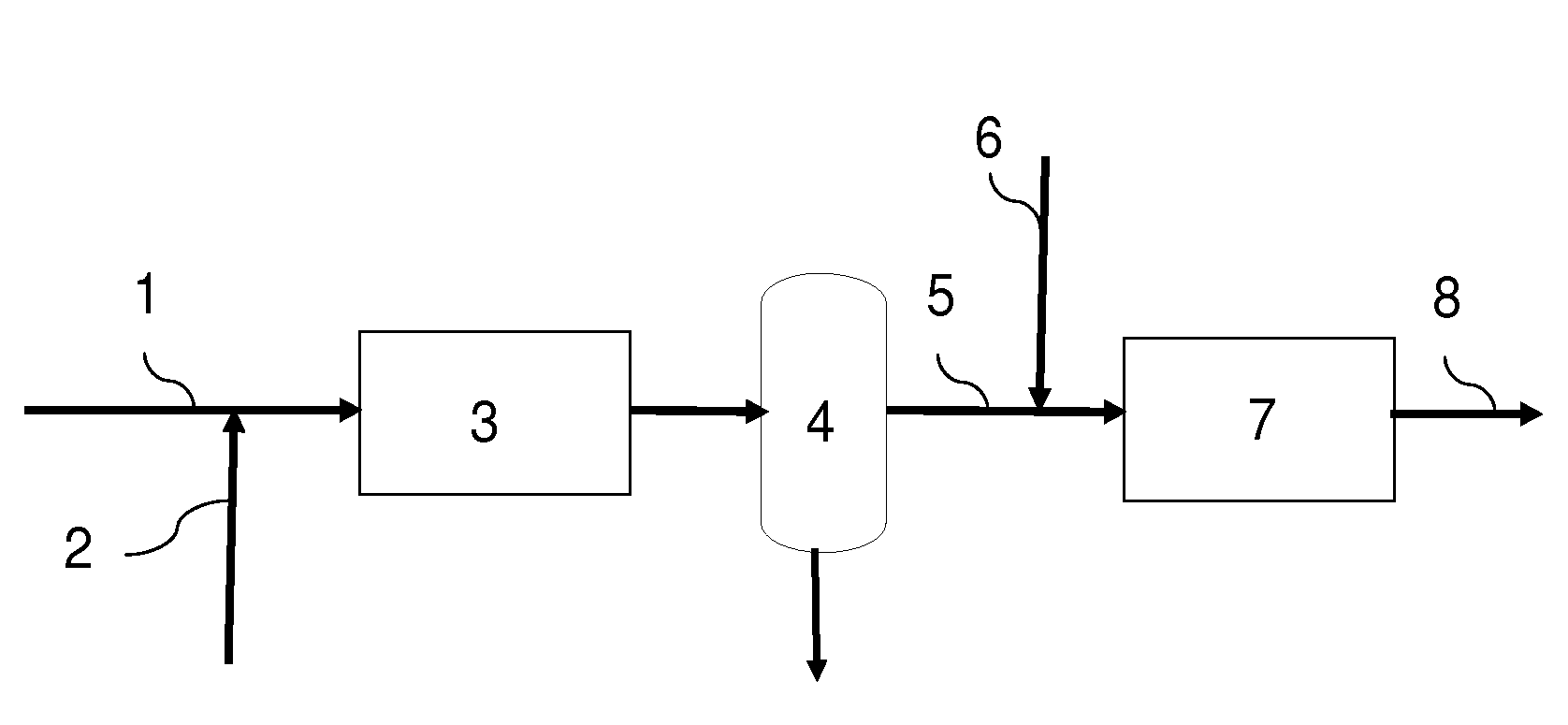

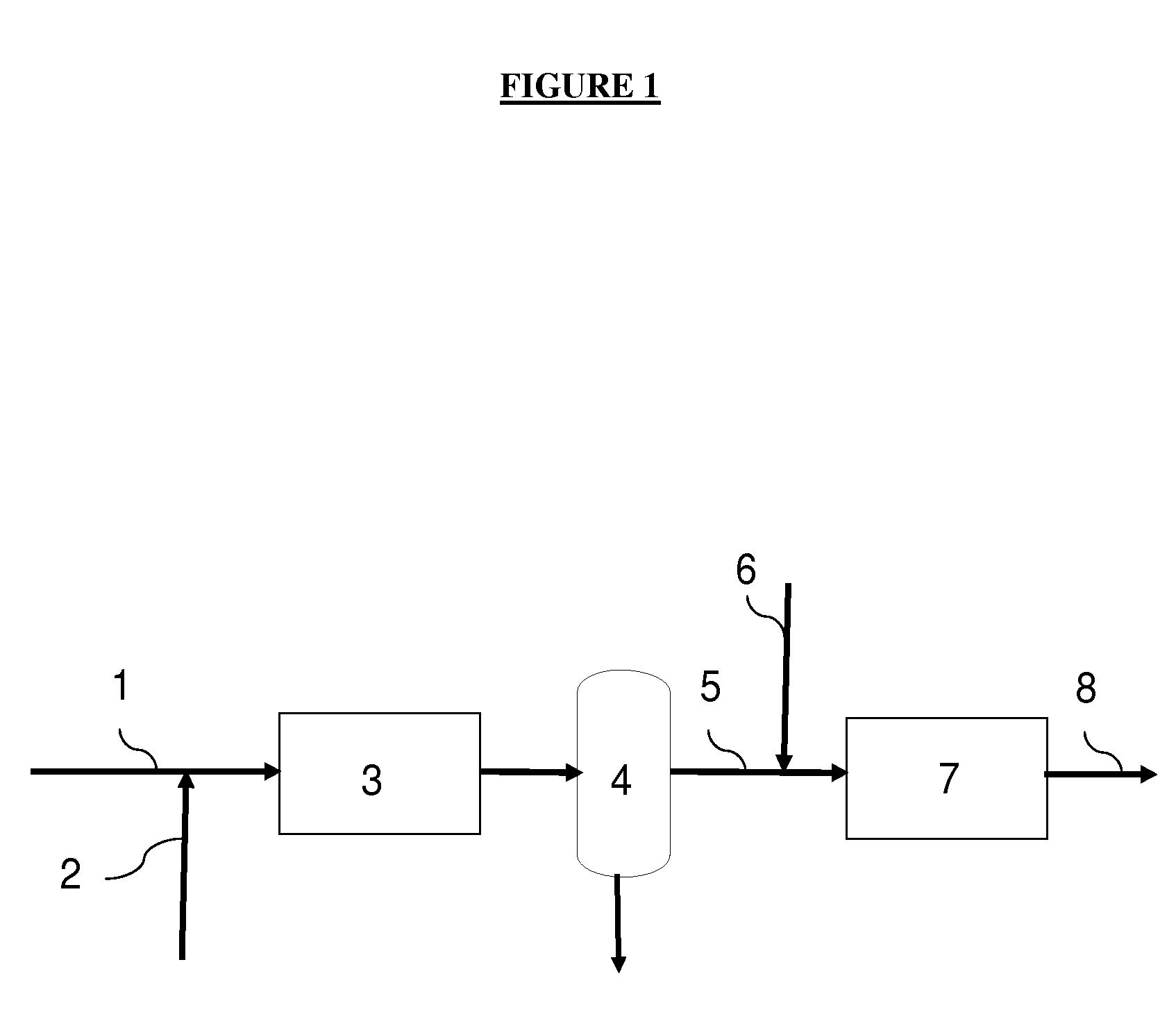

Process for producing a renewable fuel in the gasoline or jet fuel range

ActiveUS7928273B2Yield maximizationFatty acid isomerisationFatty acid oxidationVegetable oilGasoline

Processes for producing hydrocarbons in the gasoline and jet fuel range. The processes involve the thermal decarboxylation of fatty acids, which can be derived from the hydrolysis of triglycerides, which triglycerides can be vegetable oils, animal fats, or combinations thereof. The resulting hydrocarbons can be hydrocracked, and, optionally, isomerized and / or hydrotreated, to yield hydrocarbons in the jet fuel or gasoline range. Where the resulting hydrocarbons include olefinic double bonds, they can alternatively be combined with low molecular weight olefins, and subjected to olefin metathesis to yield hydrocarbons in the jet fuel or gasoline range.

Owner:BRADIN DAVID

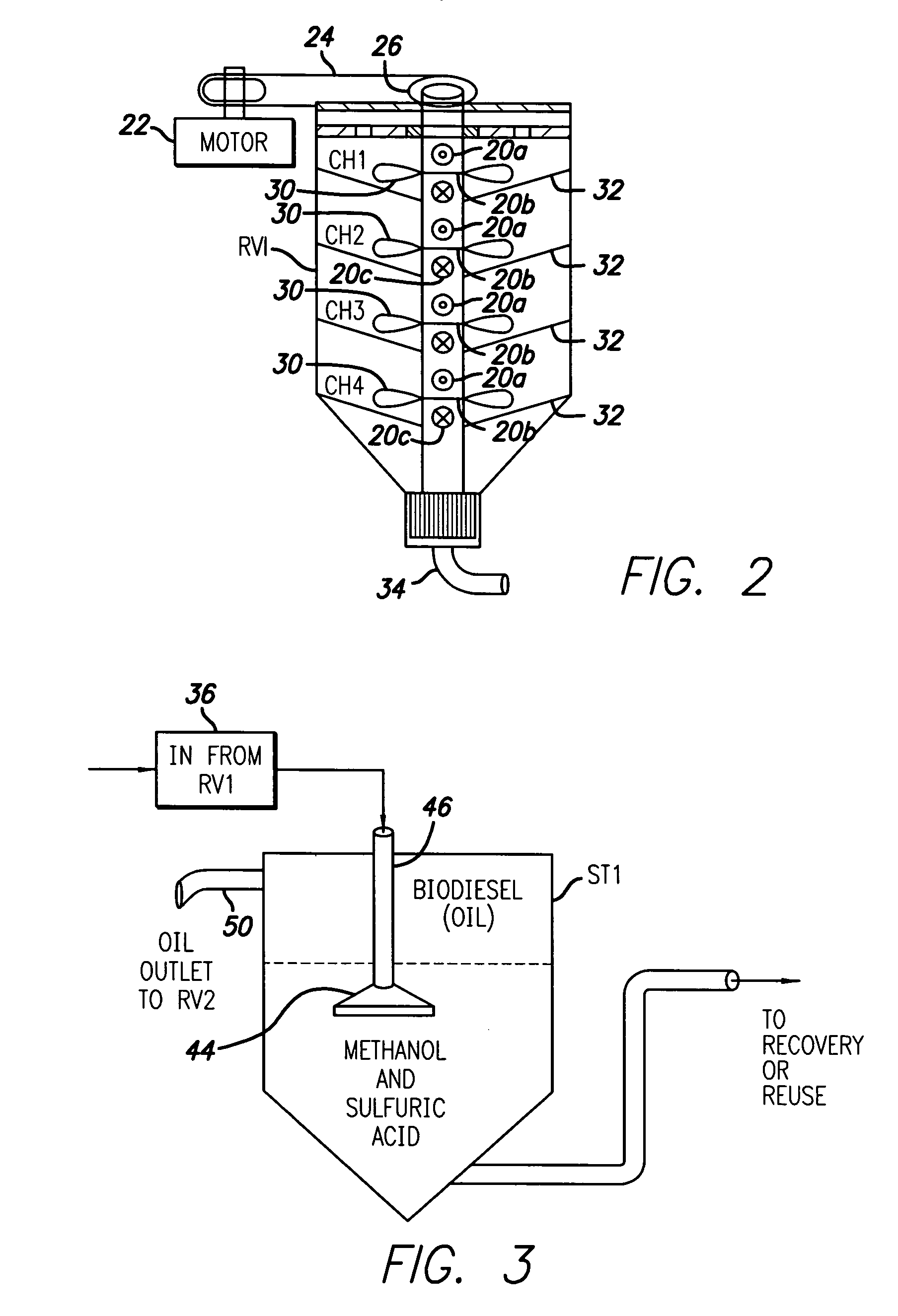

Apparatus and method for the production of fatty acid alkyl ester

InactiveUS20050027137A1Eliminate operationShort possible reaction timeFatty oils/acids recovery from wasteAnalysis using chemical indicatorsAlcoholVegetable oil

An apparatus and method for producing fatty acid alkyl esters from fatty acids derived from vegetable oils and animal fats with an alkaline solution dissolved in stoichiometric or near stoichiometric levels of a monoalkyl alcohol to form a mixture. The method further comprises emulsifying the mixture as a means to reach a completed chemical reaction state in a reactor section, wherein the oils or fats are transesterified into fatty acid alkyl esters. The transesterification occurs when the natural boundary surfaces of the immiscible mixture are enlarged by ultrasonic cavitation in the reaction section and the transesterification is performed at, or near atmospheric pressure. The method finally includes, after reaching the chemical reaction state, separating residues from the fatty acid alkyl ester in a gravitational phase separation section.

Owner:HOOKER JEFFREY D

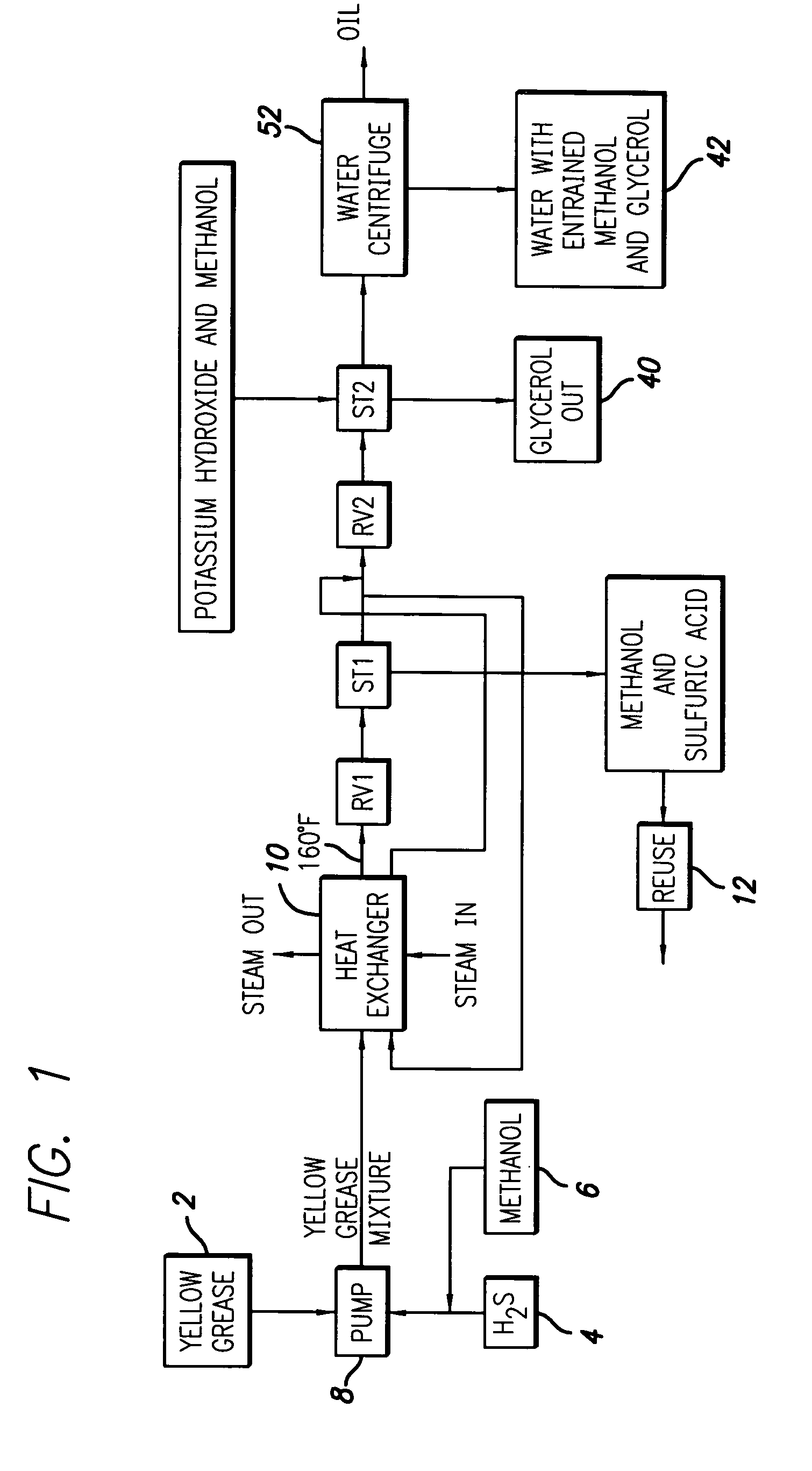

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

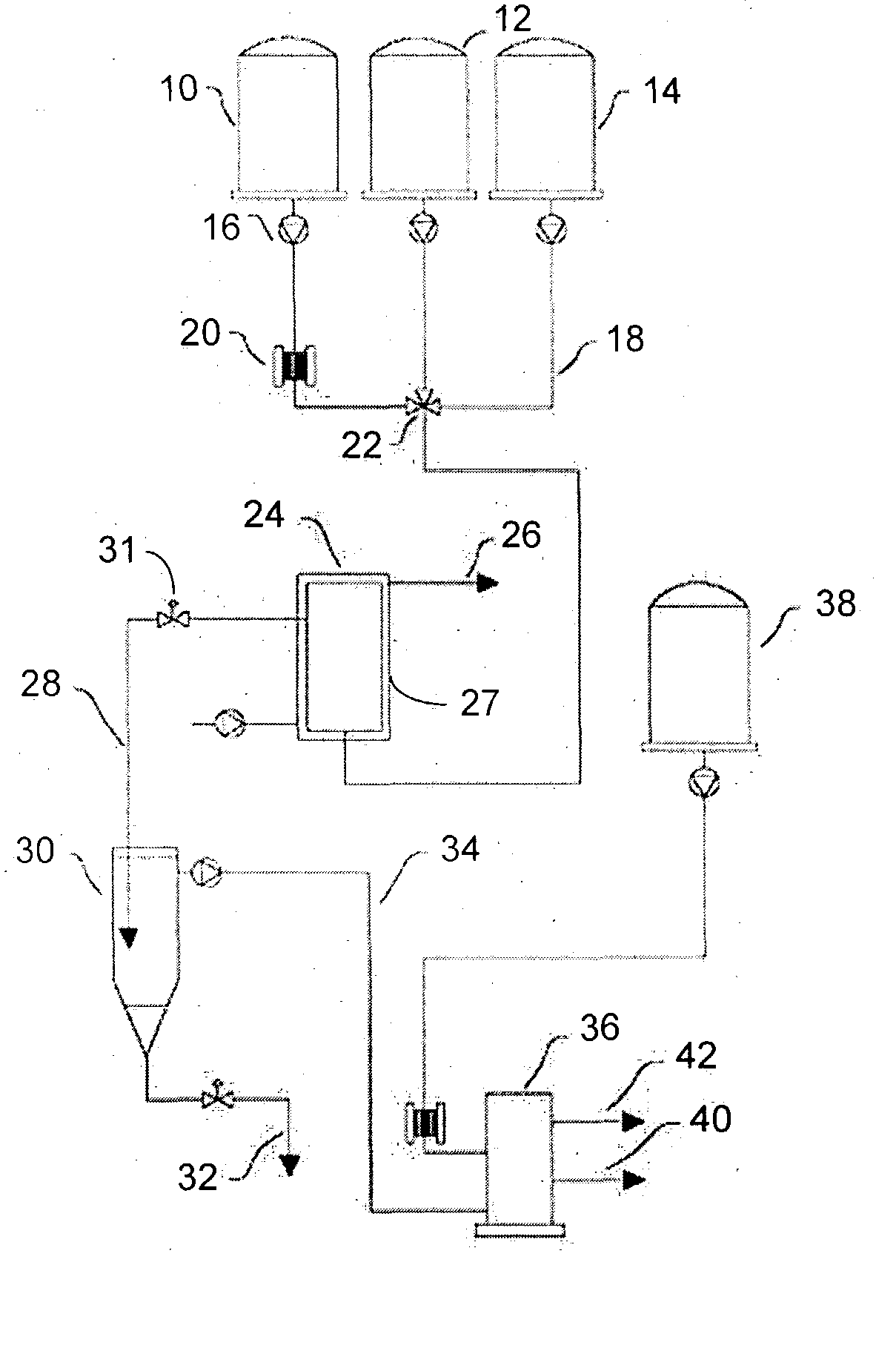

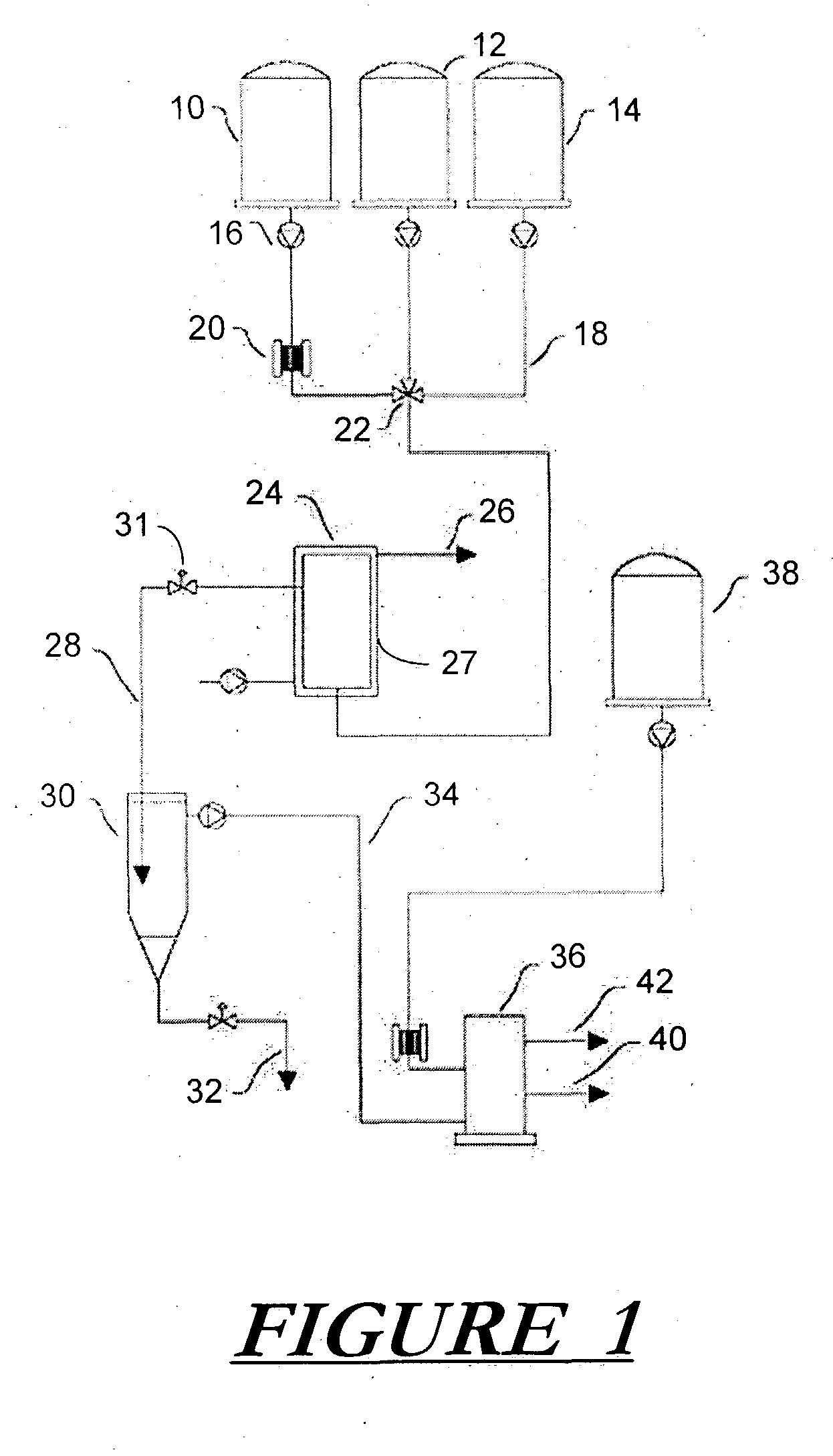

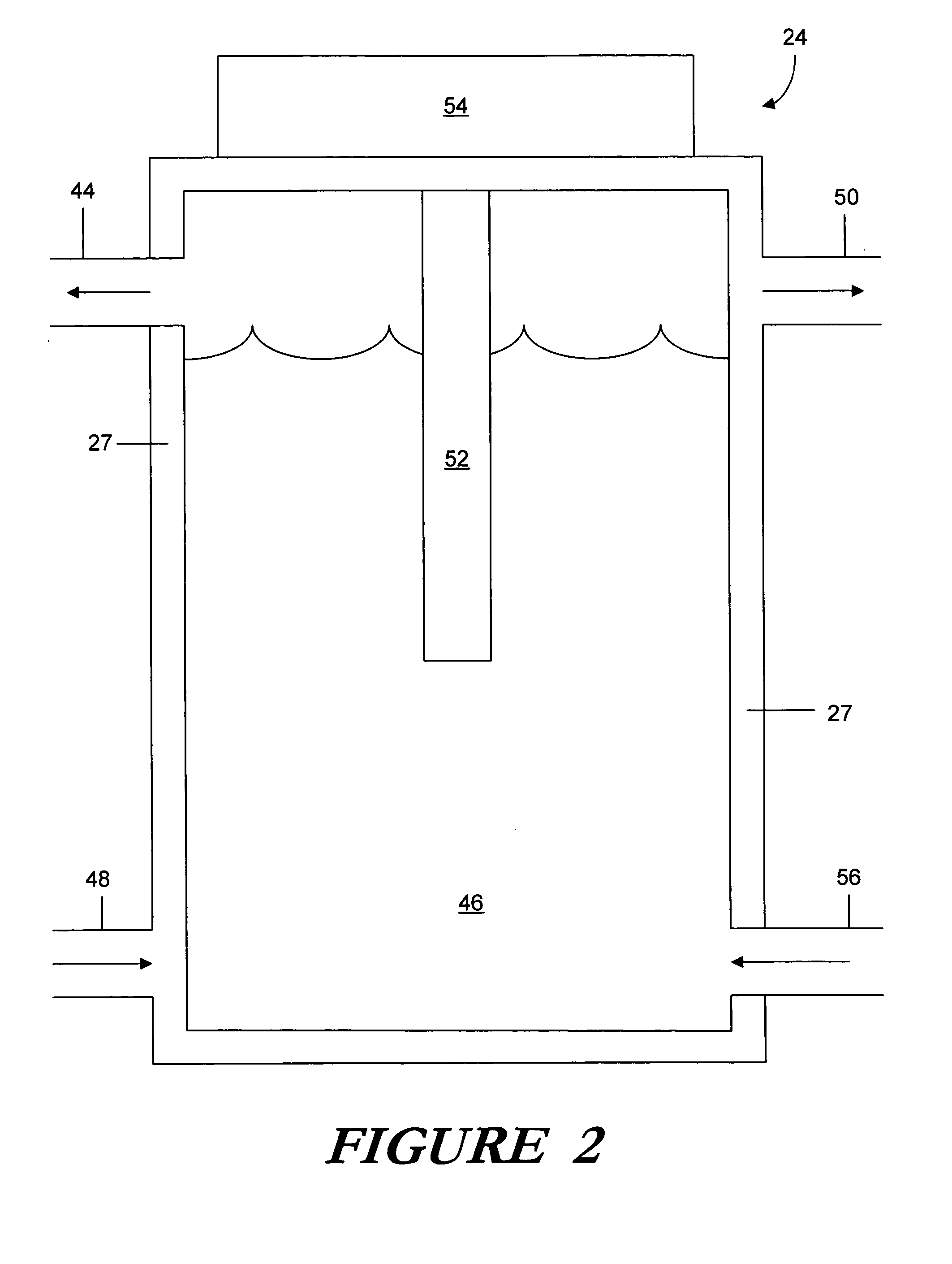

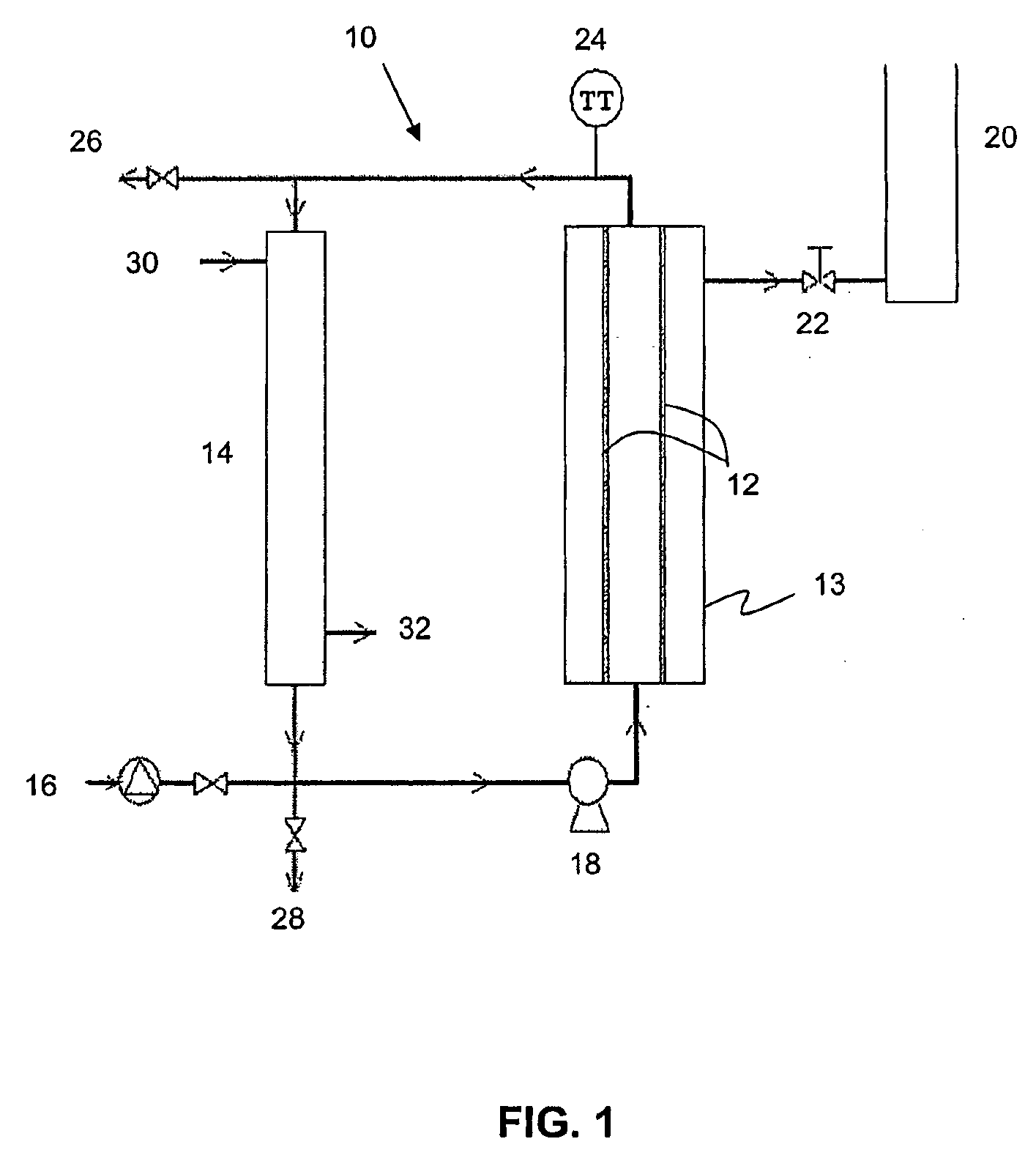

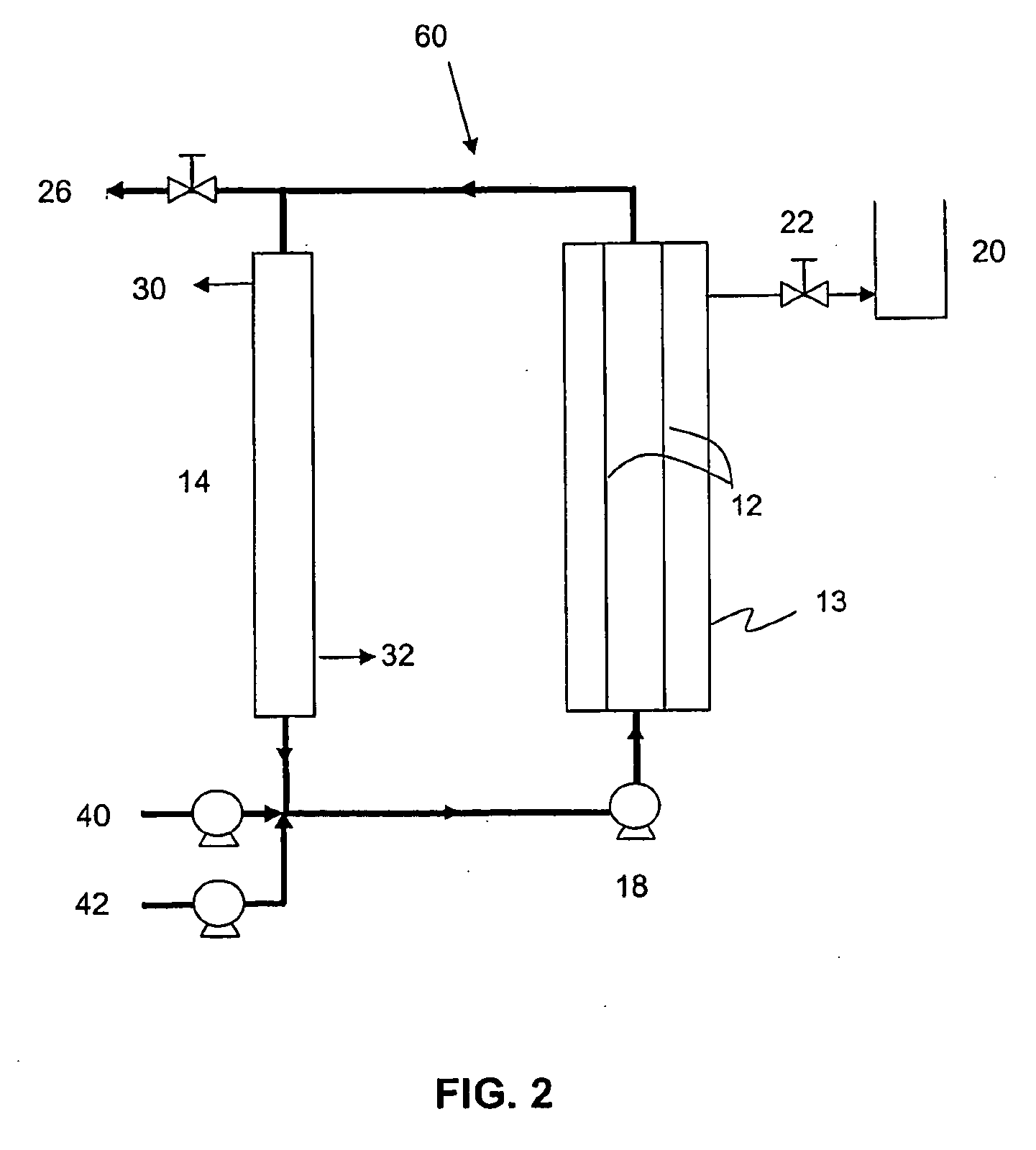

Continuous flow method and apparatus for making biodiesel fuel

InactiveUS20050081435A1Small footprintAvoid small quantitiesTransportation and packagingRotary stirring mixersOil and greaseVegetable oil

In an economical and efficient process and apparatus for producing biofuel from waste oil, such as vegetable oils and animal fats, waste oil is esterified with alcohols to produce alcohol esters and the by-products of the transesterification reaction are recovered. Static pressure may be used as well as continuous flow-through reaction vessels and separation tanks without the need for additional pumps. There may also be specialized reaction tanks that have vertical rotating feed tubes having separators and inlet and outlet openings. The method and device achieves efficient production of biofuel while employing reaction and mixing tanks having a limited size, which in turn permits a smaller plant layout or “footprint”. For example, the largest tank may be in a size of about 36 / 100,000 times the desired plant output in gallons per year. The benefits of the process and apparatus include minimal space for a plant; minimal on-site feedstock needed therefore minimal on-site storage is needed; minimal capital costs to build a plant e.g., reduction by about fifty to sixty five percent (50 to 65%); reduction in construction time from typically over one year to under three months in many plants; minimal energy usage, e.g., reduction by about sixty percent (60%); minimal labor costs due to the automatic continuous flow; minimal pumps needed thereby reducing pump operation and maintenance costs; environmentally friendlier and safer plant design; and due to smaller plant footprint, lower capital cost and minimal construction time enables site selection much nearer to the raw material supplies, thereby minimizing or even eliminating transportation costs for yellow grease or vegetable oil.

Owner:BIO CLEAN FUELS

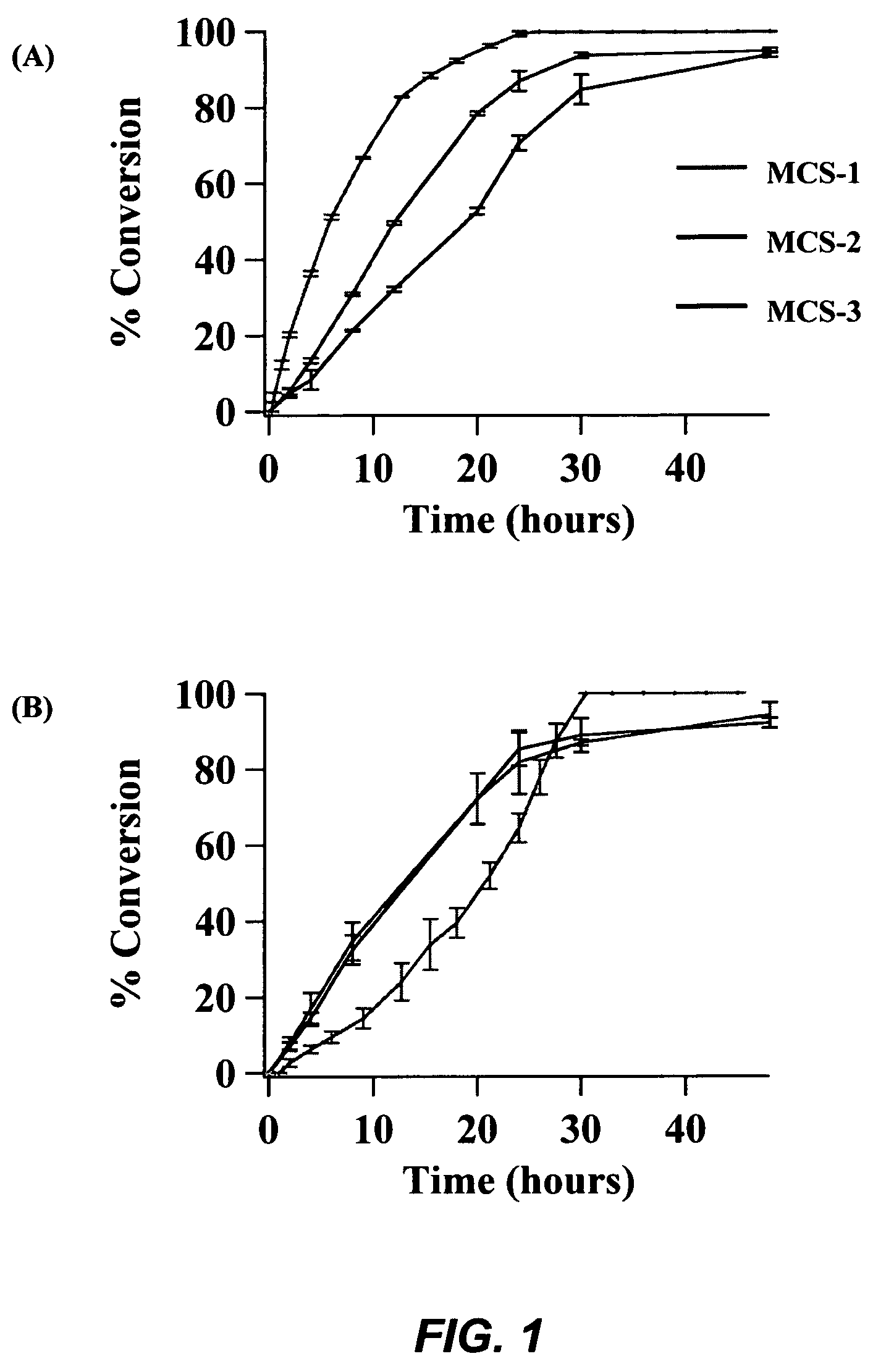

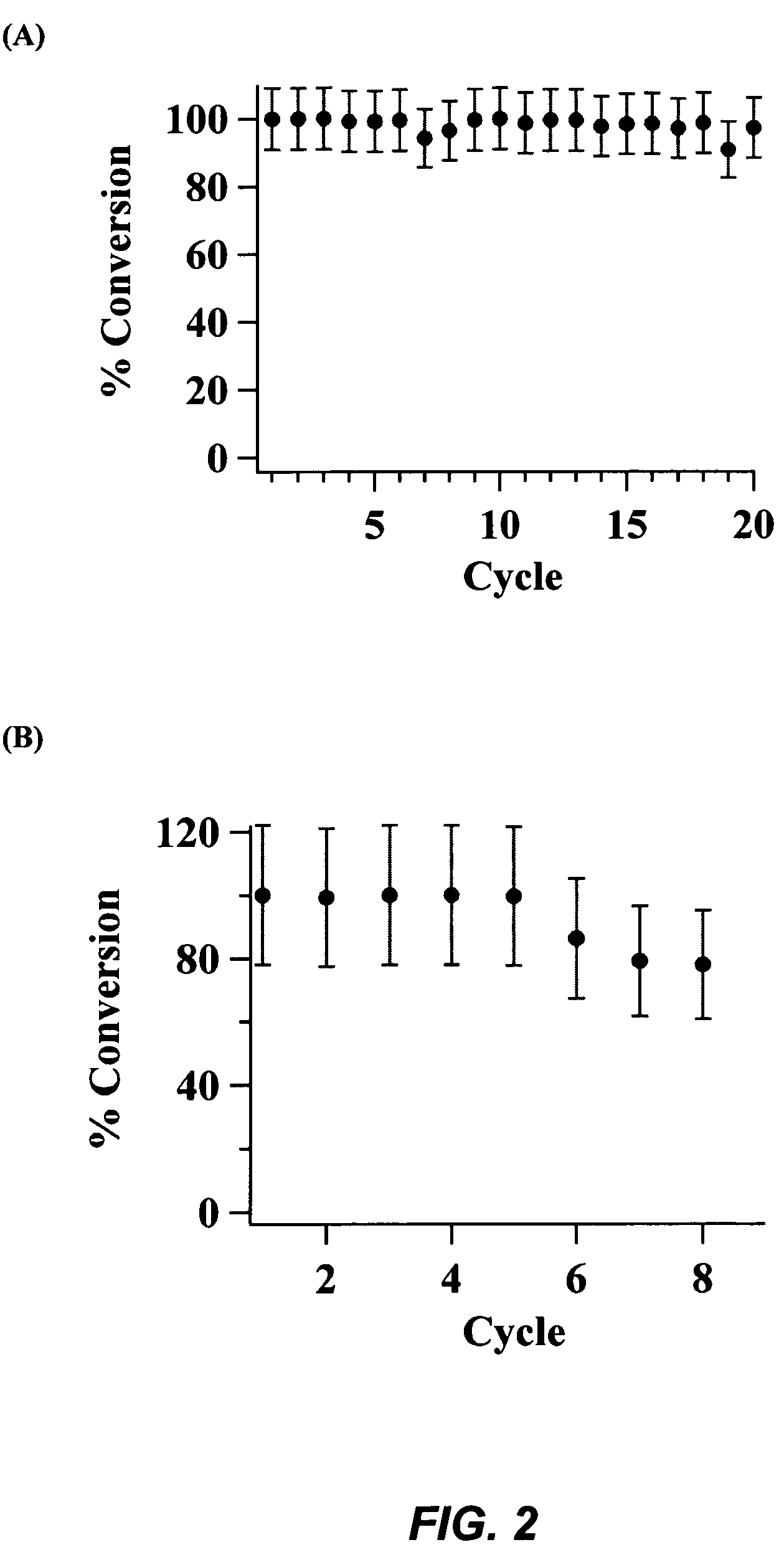

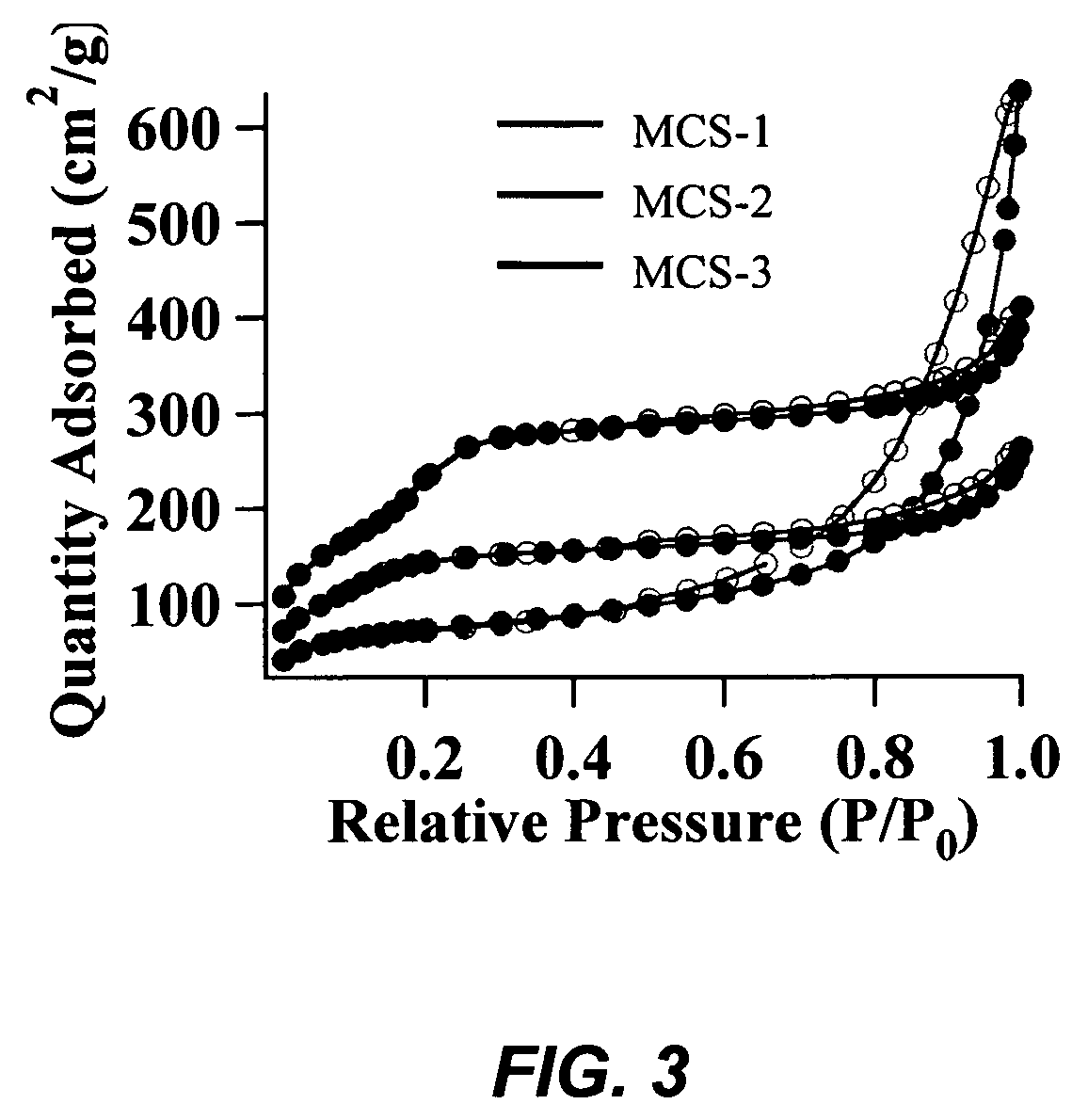

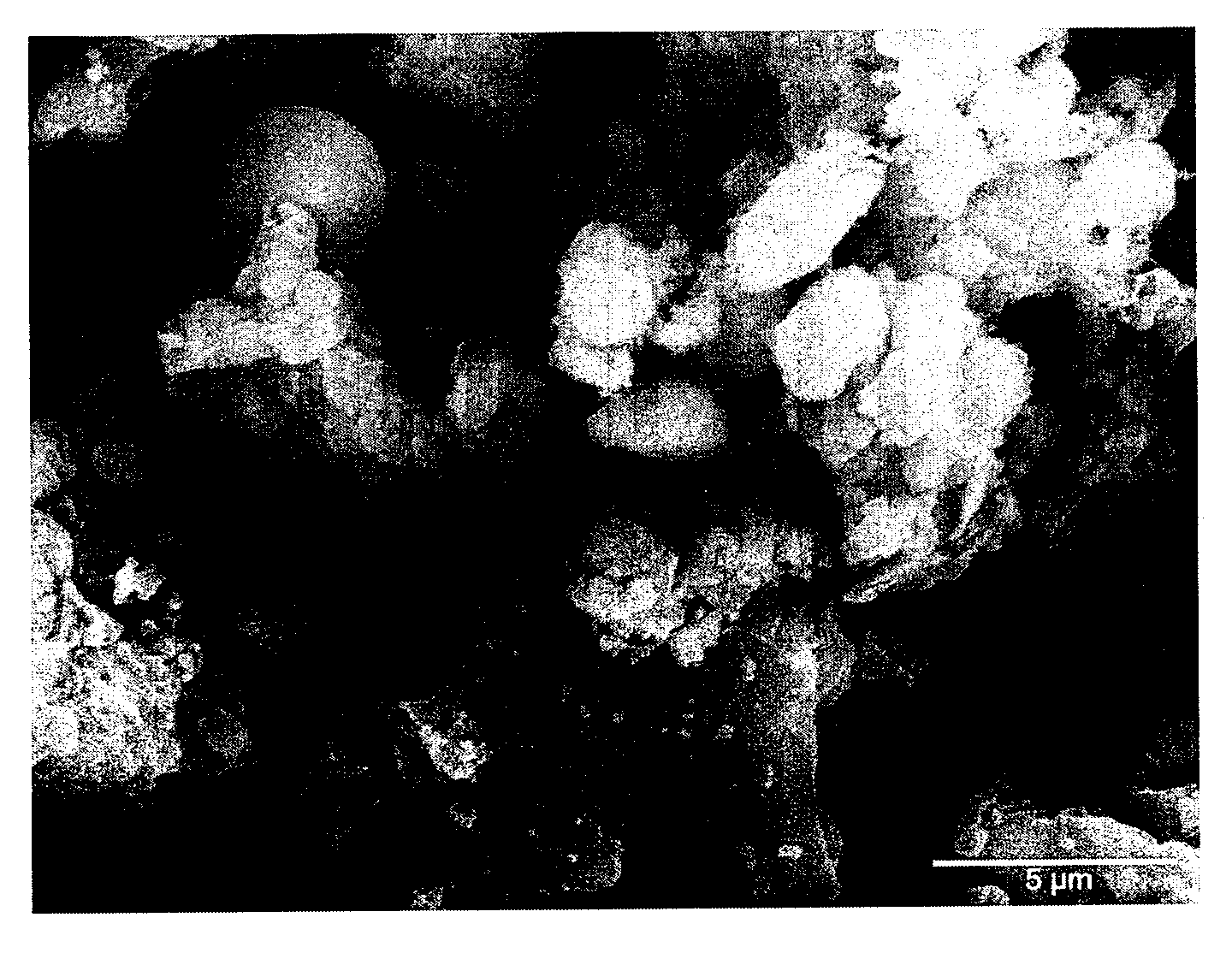

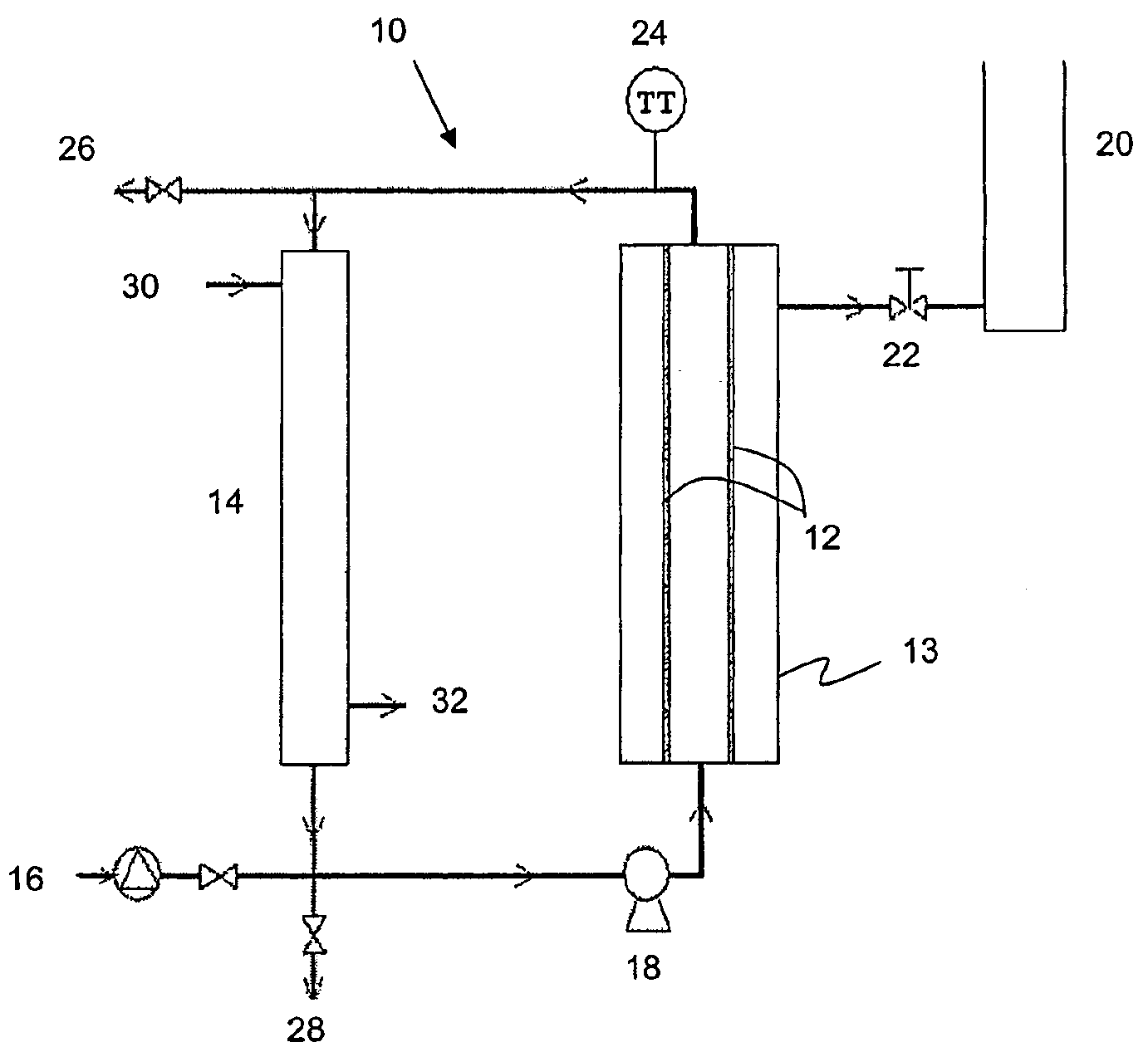

Porous silica and metal oxide composite-based catalysts for conversion of fatty acids and oils to biodiesel

ActiveUS7790651B2Easy to separateEasy to recycleFatty oils/acids recovery from wasteNanotechMETHYL SOYATEVegetable oil

A recyclable esterification or transesterification catalyst and methods for making and using the same are provided herein. The catalyst can be used to prepare biodiesel or methyl soyate from various feedstocks, including vegetable oils and animal fats. The catalyst can both esterify free fatty acids and transesterify mono-, di-, and triglycerides. The catalyst can also be combined with a metal oxide, and optionally calcined, prior to carrying out a catalytic reaction.

Owner:IOWA STATE UNIV RES FOUND

Plant based material useful in adsorbing petroleum products, processes for making these, and uses thereof

ActiveUS20150251156A1Fatty/oily/floating substances removal devicesWater cleaningPetroleum productAnimal fat

The invention relates to methods for making completely biodegradable, hydrophobic, oleophilic plant based materials which are useful in adsorption of petroleum products. The materials have an average diameter of from 1 to 5 mm, and an ash content of from 10% to 30%. The non-paraffin coating is an animal fat product, preferably produced by dissolving a pure animal fat and using this as the coating material.

Owner:SAUDI ARABIAN OIL CO

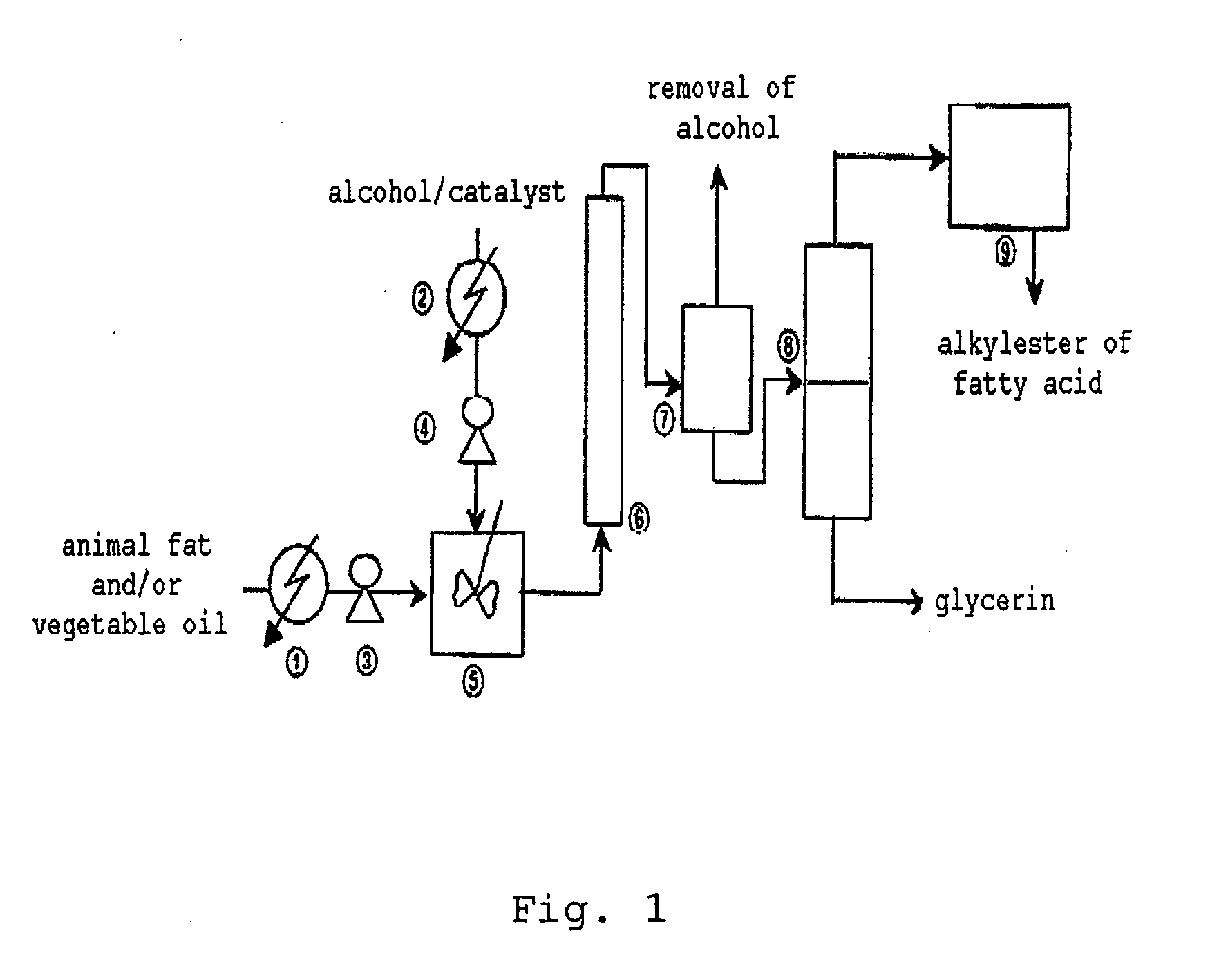

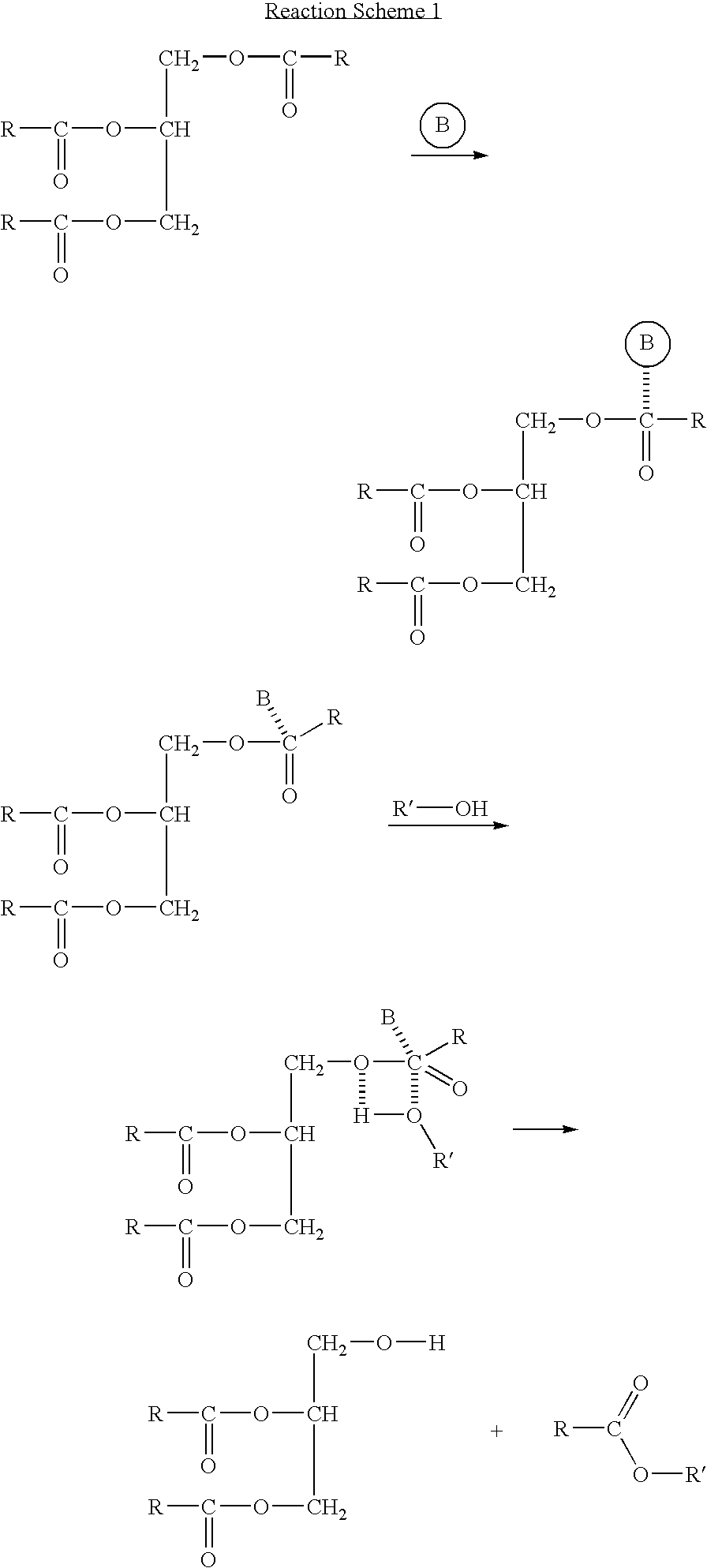

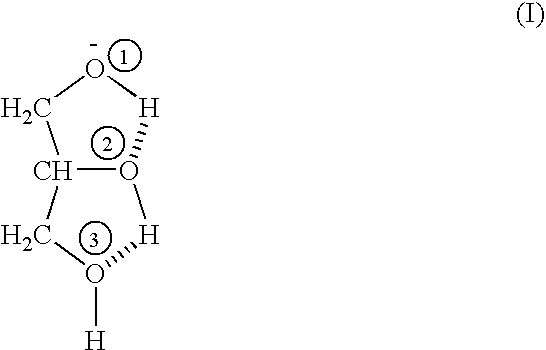

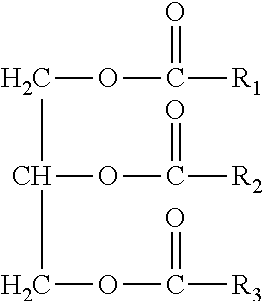

Process for producing alkylester of fatty acid in a single-phase continuous process

InactiveUS20050080280A1Phase separationFatty oils/acids recovery from wasteFatty acid esterificationAlcoholVegetable oil

The present invention relates to a process for preparing an alkylester of fatty acid with high purity via one-step continuous process by reacting an animal fat and / or vegetable oil with a lower alcohol in the presence of alkali catalyst by passing through a continuous tubular reactor while maintaining a single-phase, removing residual lower alcohol from the reaction mixture and removing residual glycerin, catalyst, etc. by phase separation. In accordance with the present invention, an alkylester of fatty acid can be produced with a high yield of 97% or more via one-step continuous process in a continuous tubular reactor without any limitation in flow types by reacting an animal fat and / or vegetable oil with a lower alcohol in the presence of alkali catalyst and carrying out a simple separating process.

Owner:M ENERGY

Simulated fat and method for preparing same

The invention discloses a simulated fat. The base material for preparing the simulated fat comprises konjaku flour and carrageenin of which the compound weight ratio is 1:0.3-0.45, and the auxiliary material comprises egg white protein, a defoamer, alkaline gel and water. The simulated fat is prepared by using compounded vegetable glue as the base material assisted by the egg white protein and vegetable oil through the steps of stirring with the water, molding, precooking, forming, cooling, mould unloading, recooking and secondary cooling under the action of the gel. The simulated fat product has a plurality of physical characteristics similar to natural fat and has no health hazards. The simulated fat can be used as a substitute in meat products processing and is widely applied to the meat products processing. Sausages, hamburger bakemeat and the like processed from the simulated fat are completely same with animal fat from the appearance and the cross section, have quite similar mouthfeel and flavor and low fat, are rich in dietary fiber, and do not contain cholesterol.

Owner:CHINA MEAT RES CENT

Porous silica and metal oxide composite-based catalysts for conversion of fatty acids and oils to biodiesel

ActiveUS20080021232A1Easy to separateEasy to recycleFatty oils/acids recovery from wasteNanotechMETHYL SOYATEVegetable oil

A recyclable esterification or transesterification catalyst and methods for making and using the same are provided herein. The catalyst can be used to prepare biodiesel or methyl soyate from various feedstocks, including vegetable oils and animal fats. The catalyst can both esterify free fatty acids and transesterify mono-, di-, and triglycerides. The catalyst can also be combined with a metal oxide, and optionally calcined, prior to carrying out a catalytic reaction.

Owner:IOWA STATE UNIV RES FOUND

Plant based material useful in adsorbing petroleum products, processes for making these, and uses thereof

InactiveUS20140102987A1Water cleaningFatty/oily/floating substances removal devicesPetroleum productParaffin oils

The invention relates to methods for making completely biodegradable, hydrophobic, oleophilic plant based materials which are useful in adsorption of petroleum products. The materials have an average diameter of from 1 to 5 mm, and an ash content of from 10% to 30%. The non-paraffin coating is an animal fat product, preferably produced by dissolving a pure animal fat and using this as the coating material.

Owner:SAUDI ARABIAN OIL CO

Pretreatment of fats and oils in the production of biofuels

InactiveUS20120167454A1Reduced useful lifeIncrease costBiofuelsFatty-oils/fats refiningTrace elementTriglyceride

Methods are disclosed for the treatment of feedstocks comprising a fatty acid- or triglyceride-containing component to remove contaminants that are detrimental to the conversion of such feedstocks to hydrocarbons, and especially biofuel fractions such as diesel or aviation biofuels. Contaminants contributing to the presence of trace elements in animal fats and / or plant oils, as components of feedstocks, hinder the ability to catalytically convert these feedstocks, for example by hydroprocessing, to biofuels.

Owner:UOP LLC

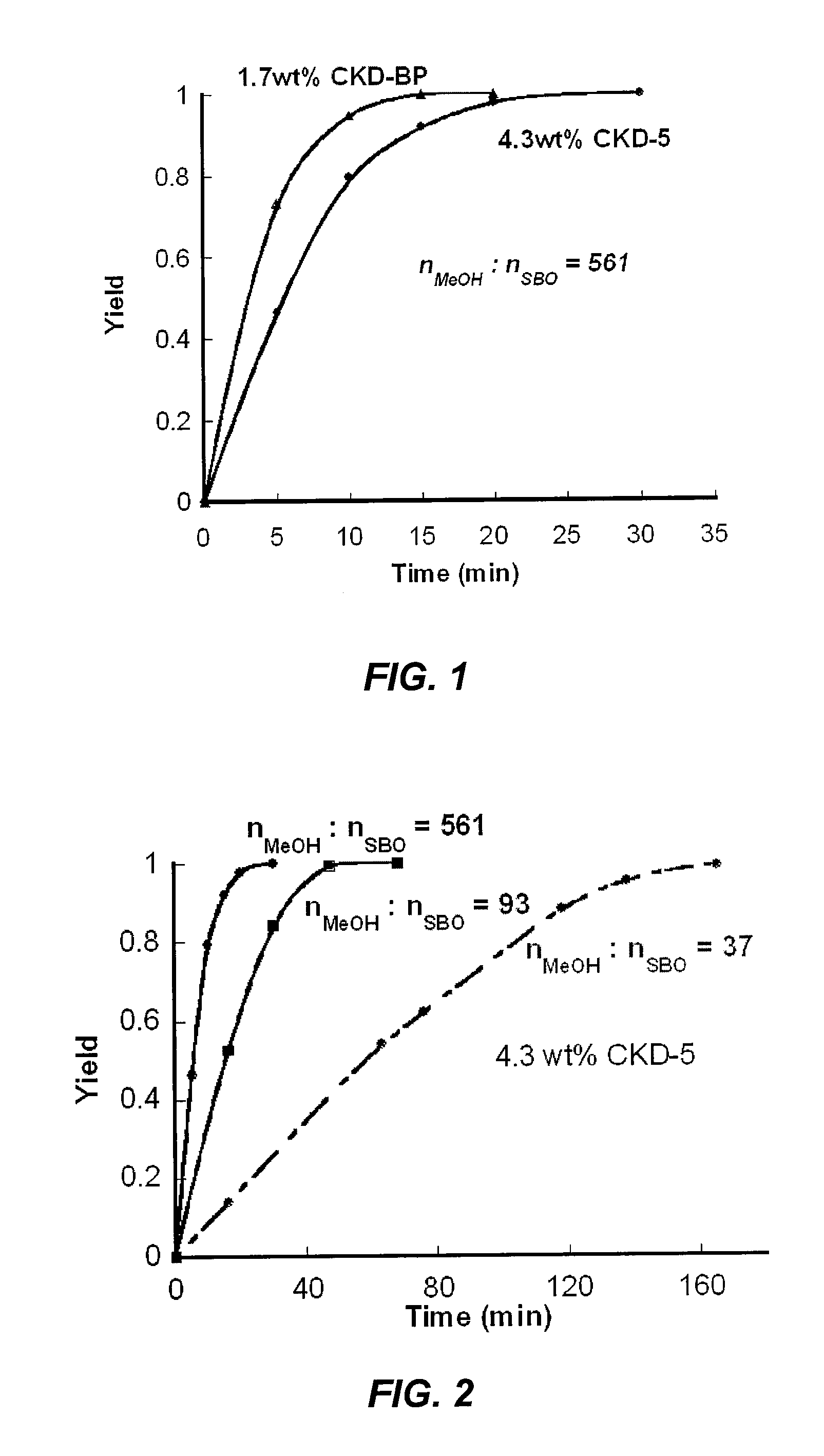

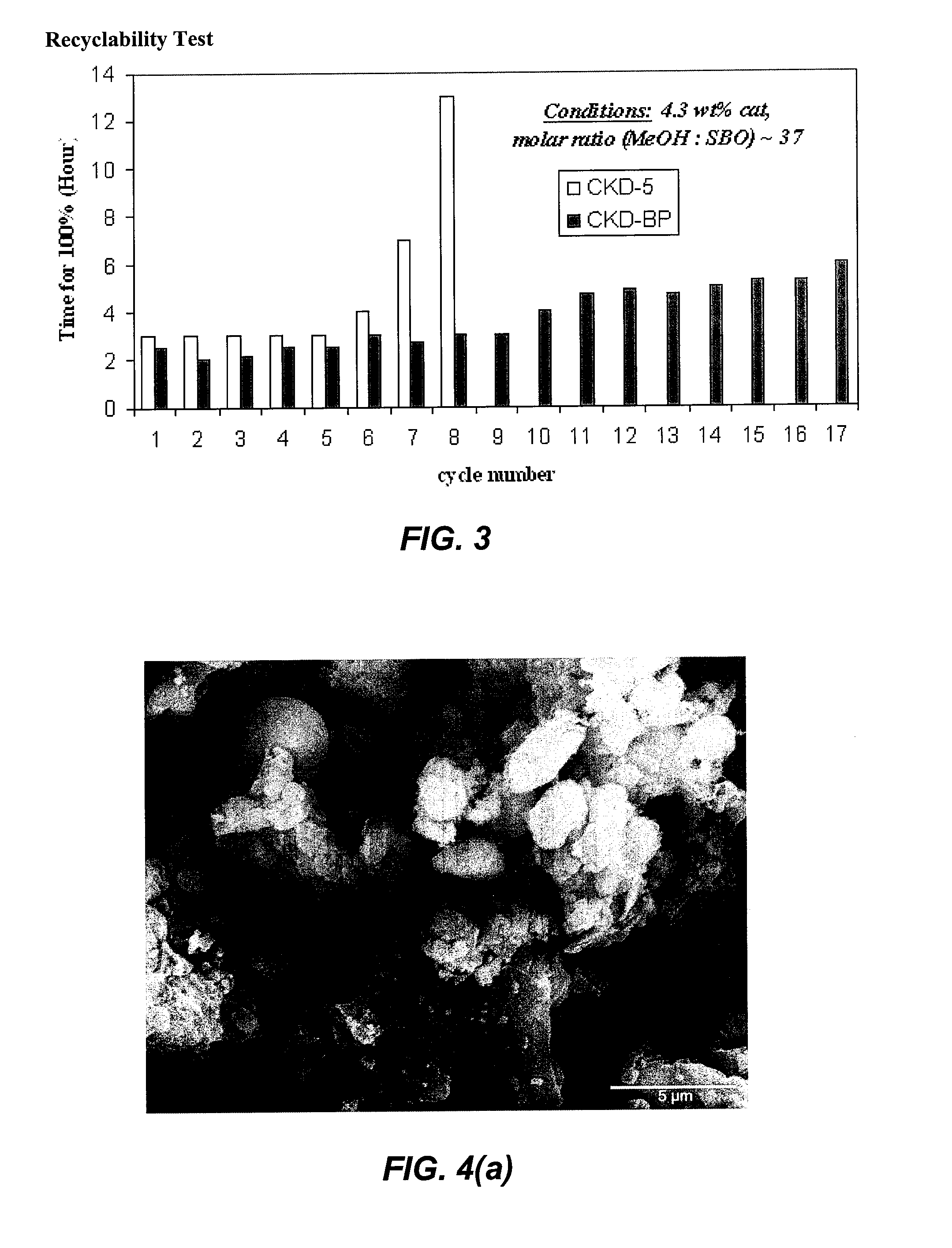

Solid catalyst system for biodiesel production

ActiveUS20090112007A1Increase contact areaRapid responseFatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

Apparatus and Method for Bio-Fuel Production

InactiveUS20080250700A1Easy to separateFatty acid esterificationUltrafiltrationAlcoholPorous membrane

An apparatus for the production of a bio-fuel or a bio-fuel additive from plant-derived oils, animal fats or a mixture thereof, suitable for use in a diesel engine is disclosed. The apparatus comprises a porous membrane for separating a reaction mixture from a permeate, the reaction mixture comprising an alcohol, a feedstock comprising plant-derived oils, animal fats or mixture thereof, and a catalyst for converting said feedstock to a bio-fuel or a bio-fuel additive, wherein said porous membrane is substantially impermeable to the feedstock and substantially permeable to said bio-fuel or bio-fuel additive. A method using said porous membrane in the production of a bio-fuel or a bio-fuel additive is also disclosed

Owner:UNIVERSITY OF OTTAWA

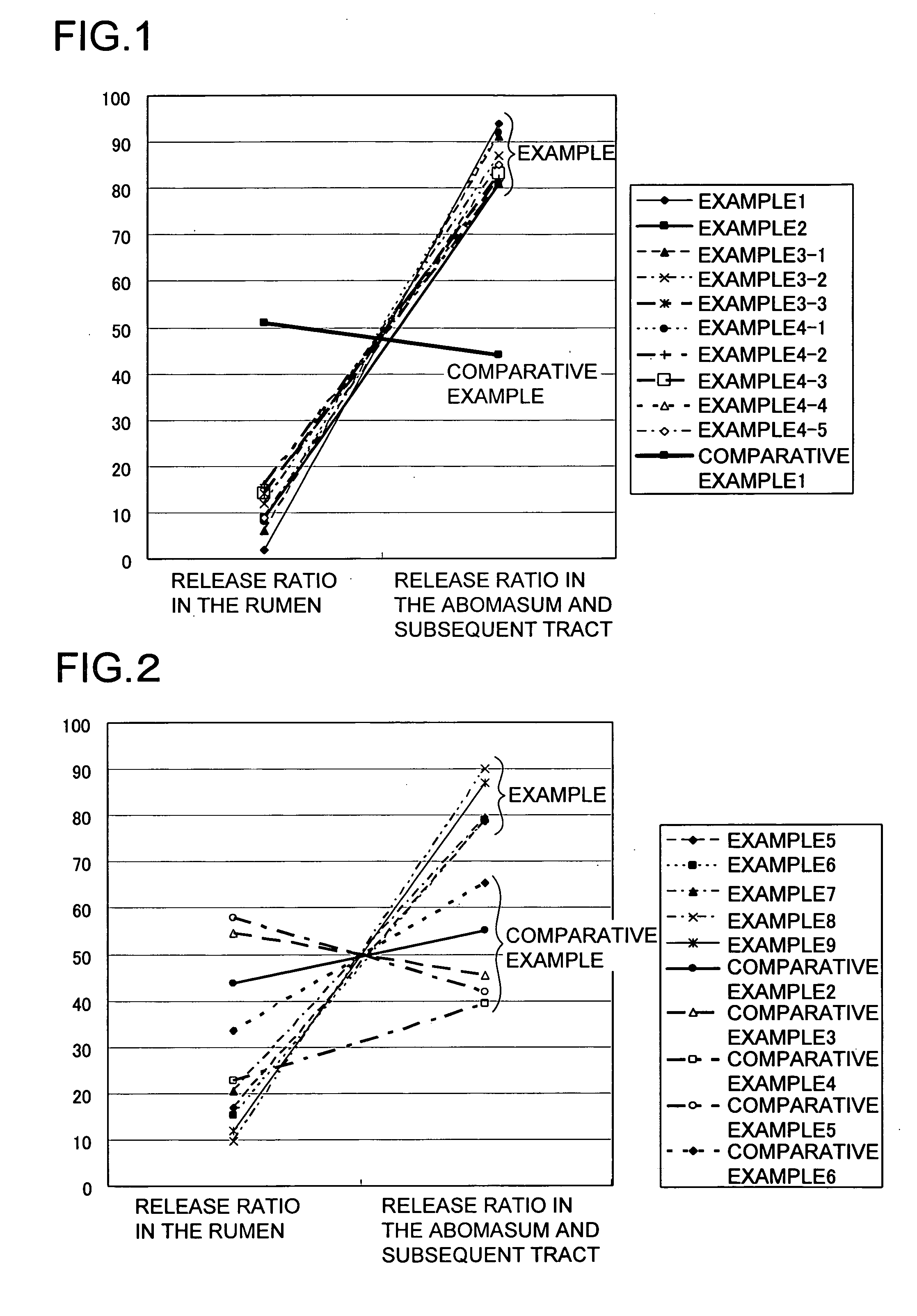

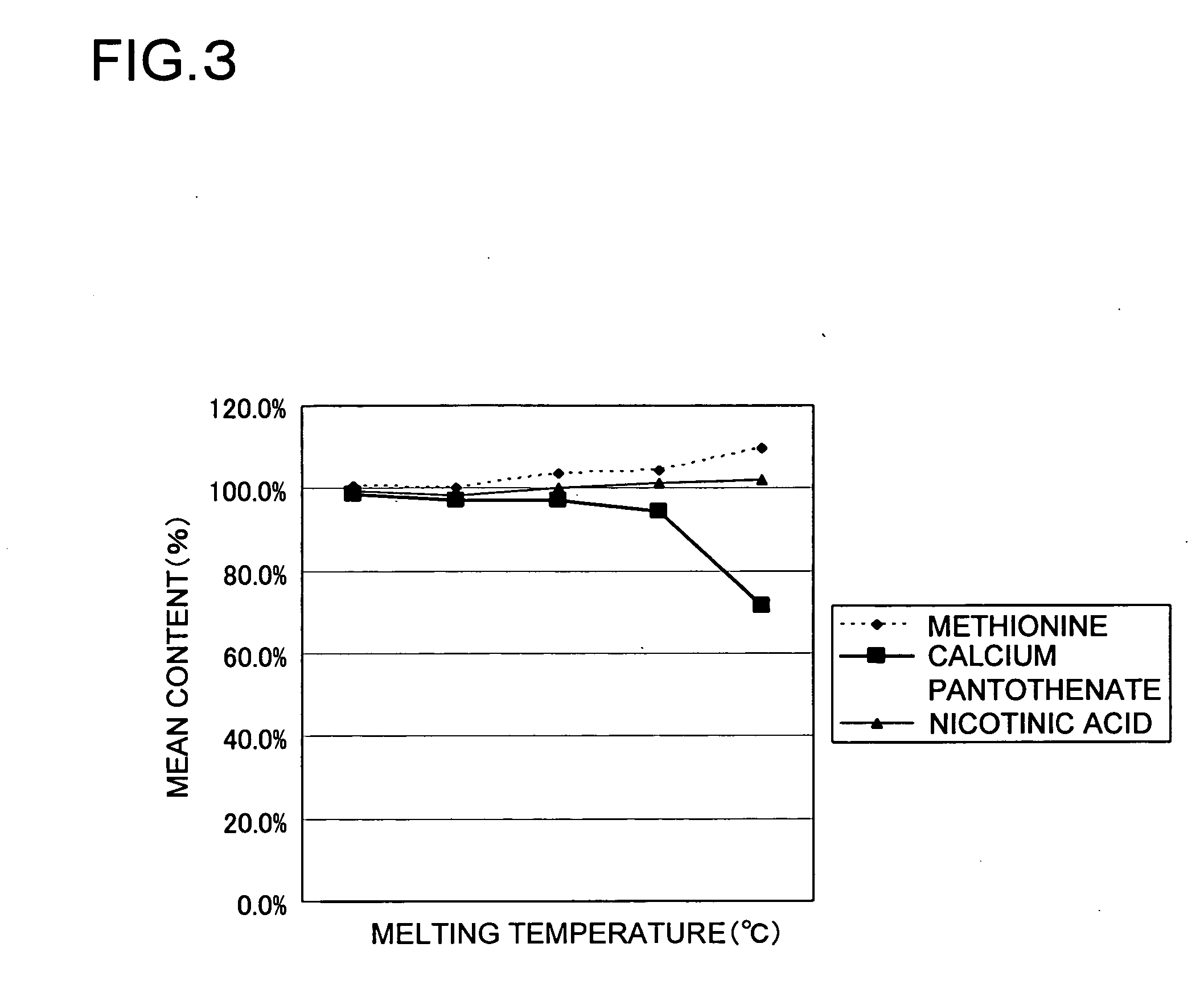

Feed additive composition for ruminants, and feed containing the same, and method of fabricating such feed additive composition for ruminants

ActiveUS20070148212A1Low costImprove protectionBiocideOrganic active ingredientsBenzoic acidDehydroacetic acid

The coating composition which coats the biologically active substance includes at least one protective material selected from the group consisting of a hardened animal fat, a hardened vegetable oil, a linear or branched, saturated or unsaturated aliphatic monocarboxylic acid having 12 to 22 carbon atoms, a fatty acid ester, and a wax group; lecithin; and at least one preservative selected from a propionic acid or its salt, a sorbic acid or its salt, a benzoic acid or its salt, a dehydroacetic acid or its salt, parahydroxybenzoic acid esters, an imazalil, a thiabendazole, an orthophenyl phenol, an orthophenyl phenol natrium, and a diphenyl.

Owner:BIO SCI

Process For Preparing Fatty Acid Alkylesters Using As Biodiesel

InactiveUS20070282118A1Increase concentrationFatty acid esterificationOrganic compound preparationAlcoholVegetable oil

Fatty acid alkyl esters suitable for use as biodiesel are produced by a single step esterification of free fatty acids and transesterification of triglycerides from vegetable oils or animal fats or combinations thereof with a lower alcohol (e.g. methanol) in presence of alkyl Tin oxide as catalyst. The ester thus produced is purified by distillation, treatment with an adsorbent, washing with water or combination thereof to give esters suitable for use as biodiesel.

Owner:COUNCIL OF SCI & IND RES

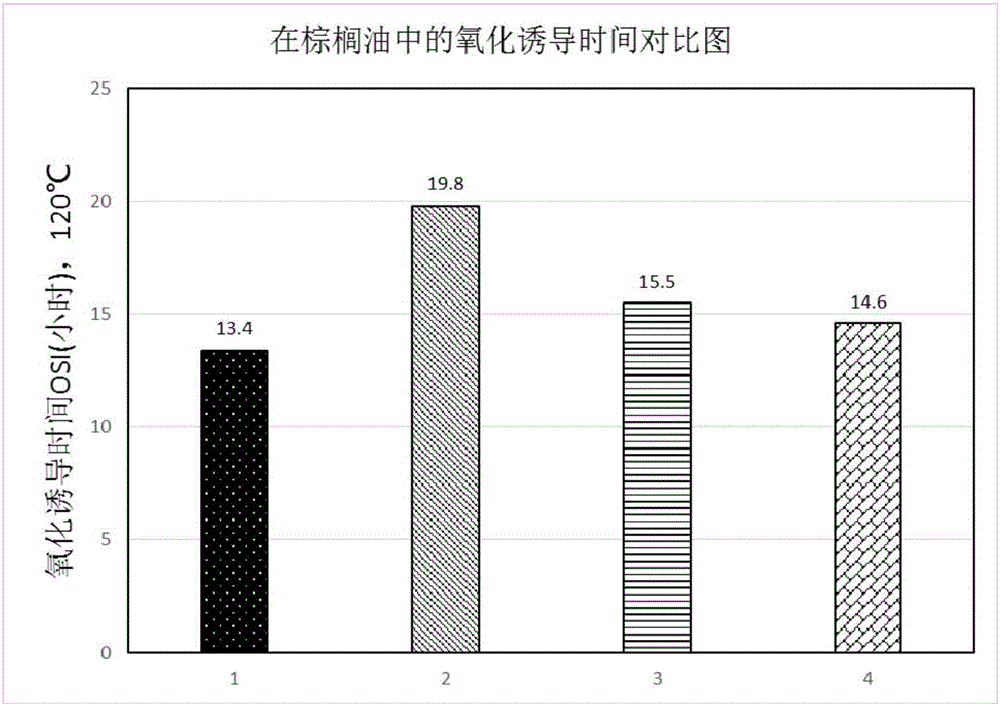

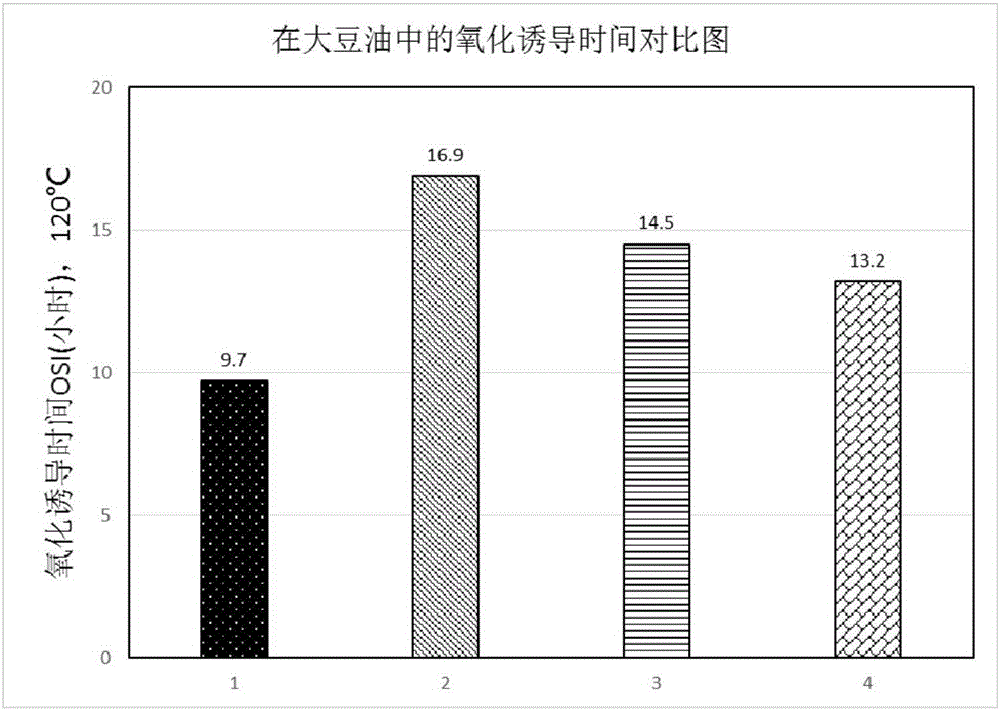

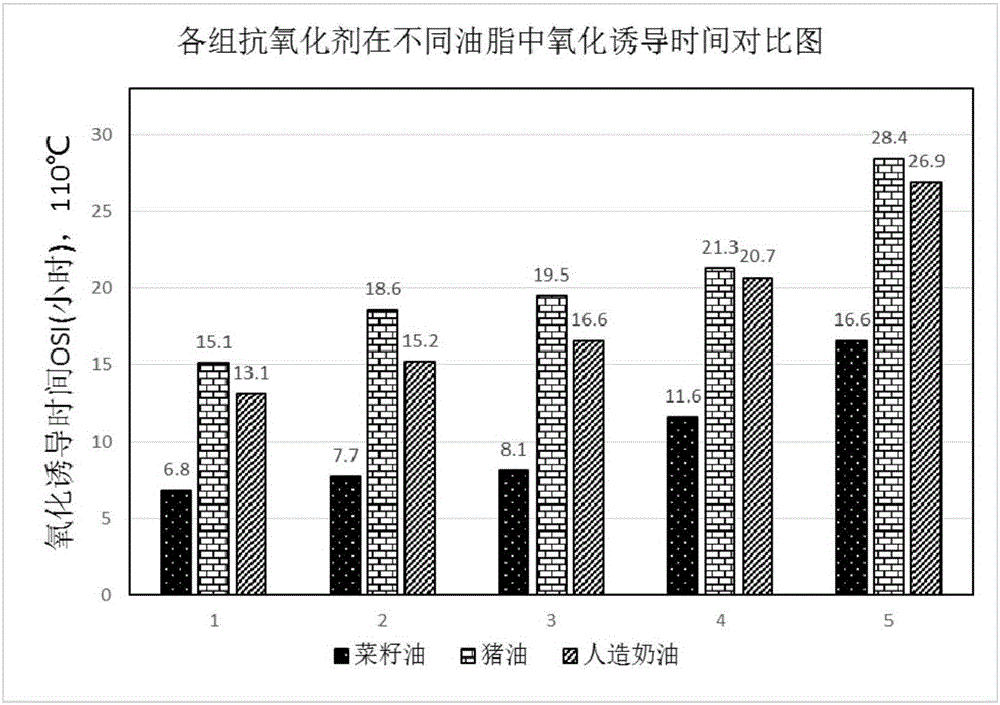

Compound antioxidant and grease containing same

InactiveCN106675780AImprove stabilityCharacteristic flavor retentionEdible oils/fats ingredientsFatty substance preservation using additivesPalmitatesPolyphenol

The invention relates to a compound antioxidant, which is prepared from vitamin E, tea polyphenol-palmitate, ascorbyl palmitate and a rosemary extract. According to the compound antioxidant, the content of the vitamin E is smaller than or equal to 3,000ppm and greater than or equal to 5ppm, the content of the tea polyphenol-palmitate is smaller than or equal to 600ppm and greater than or equal to 5ppm, the content of the ascorbyl palmitate is smaller than or equal to 200ppm and greater than or equal to 5ppm and the content of the rosemary extract is smaller than or equal to 700ppm and greater than or equal to 5ppm; the content of the vitamin E is calculated according to the total content of mixed tocopherol; and the content of the rosemary extract is calculated according to the content of carnosic acid in the rosemary extract. The compound antioxidant is high in stability and high in antioxidant activity, and can be applied to vegetable fat, animal fat, margarine, oleomargarine or shortening.

Owner:天津融信蓝海生物科技有限公司

Apparatus and method for Rapid Biodiesel Fuel Production

InactiveUS20100107474A1Minimizing undesiredReduce energy costsBiofuelsLiquid carbonaceous fuelsVegetable oilBiodiesel

Apparatus and method for rapid production of biodiesel fuel. The apparatus includes a packed column followed by a high pressure kinetic reactor. A homogeneous stream of feed oil (vegetable oil or animal fat), methanol, and a catalyst is metered, mixed, fed into a packed column, and finally into the high pressure kinetic reactor where the conversion into biodiesel fuel is completed. The packed column is packed with rings (either Raschig rings or pall rings or equivalent). The homogeneous stream enters from the bottom with rings kept in a fluidized bed state to allow greatest surface area for reaction to take place. Approximately 40 to 70 percent reaction is typically achieved in the packed column. The high pressure kinetic reactor receives the partially reacted homogeneous stream and breaks fluid molecules into nano molecules with very high instantaneous temperatures and availability of large surface areas which allow complete reaction without external heat.

Owner:TALWAR MAHESH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com