Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

A technology of hydrogenation treatment and treatment method, which is applied in the direction of hydrogenation treatment process, hydrocarbon oil treatment products, biological raw materials, etc., to achieve the effect of shortening residence time and eliminating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

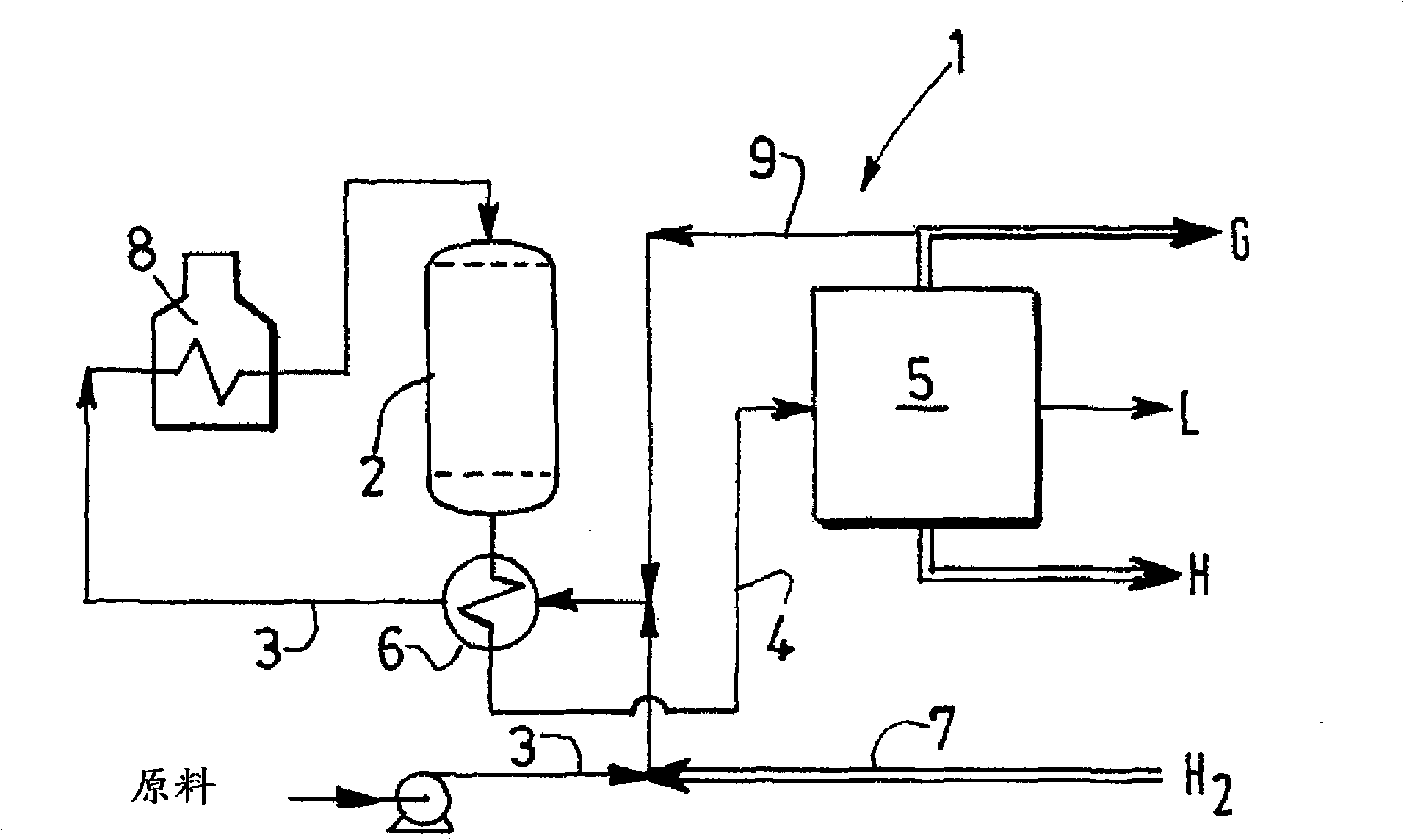

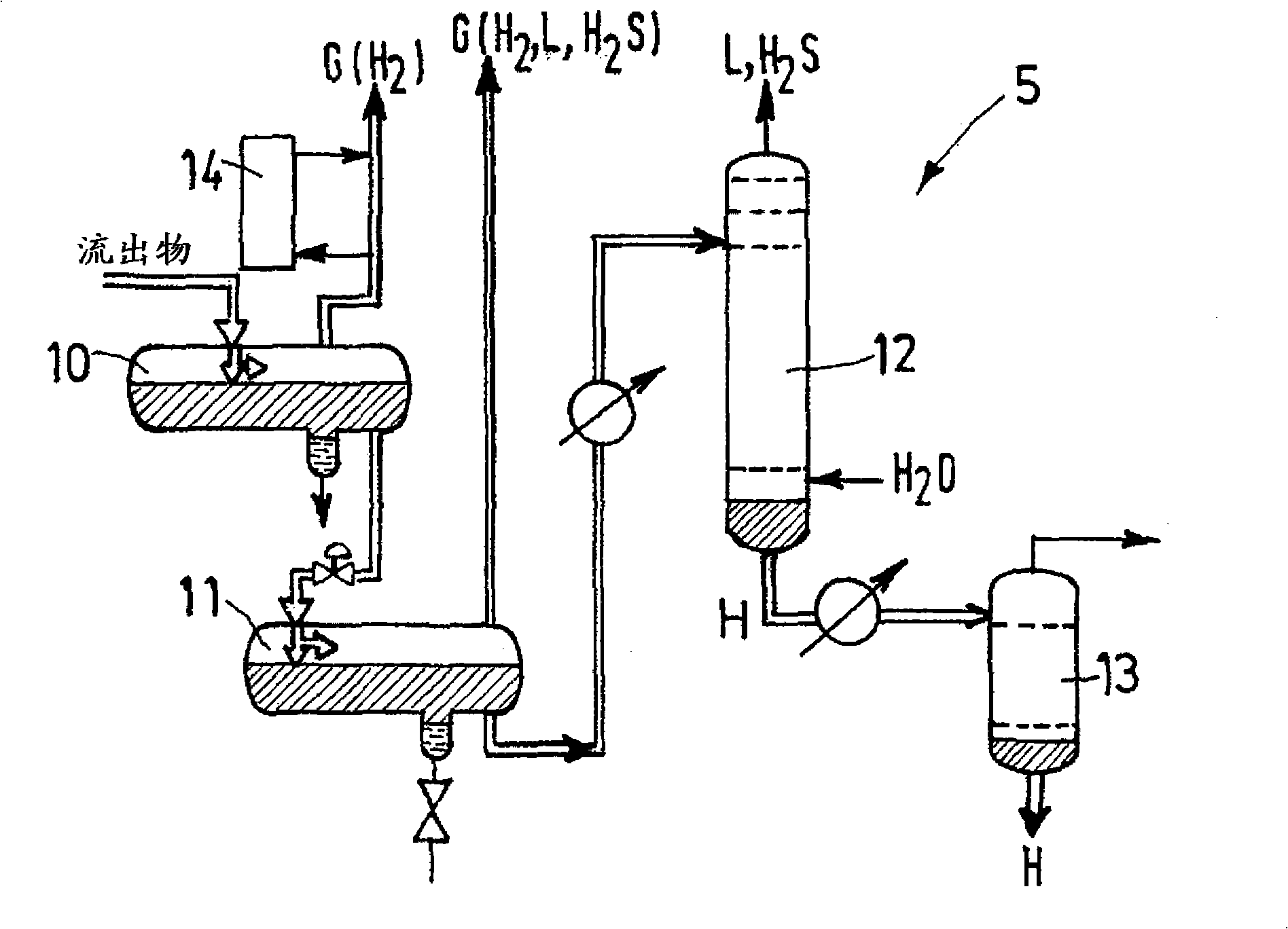

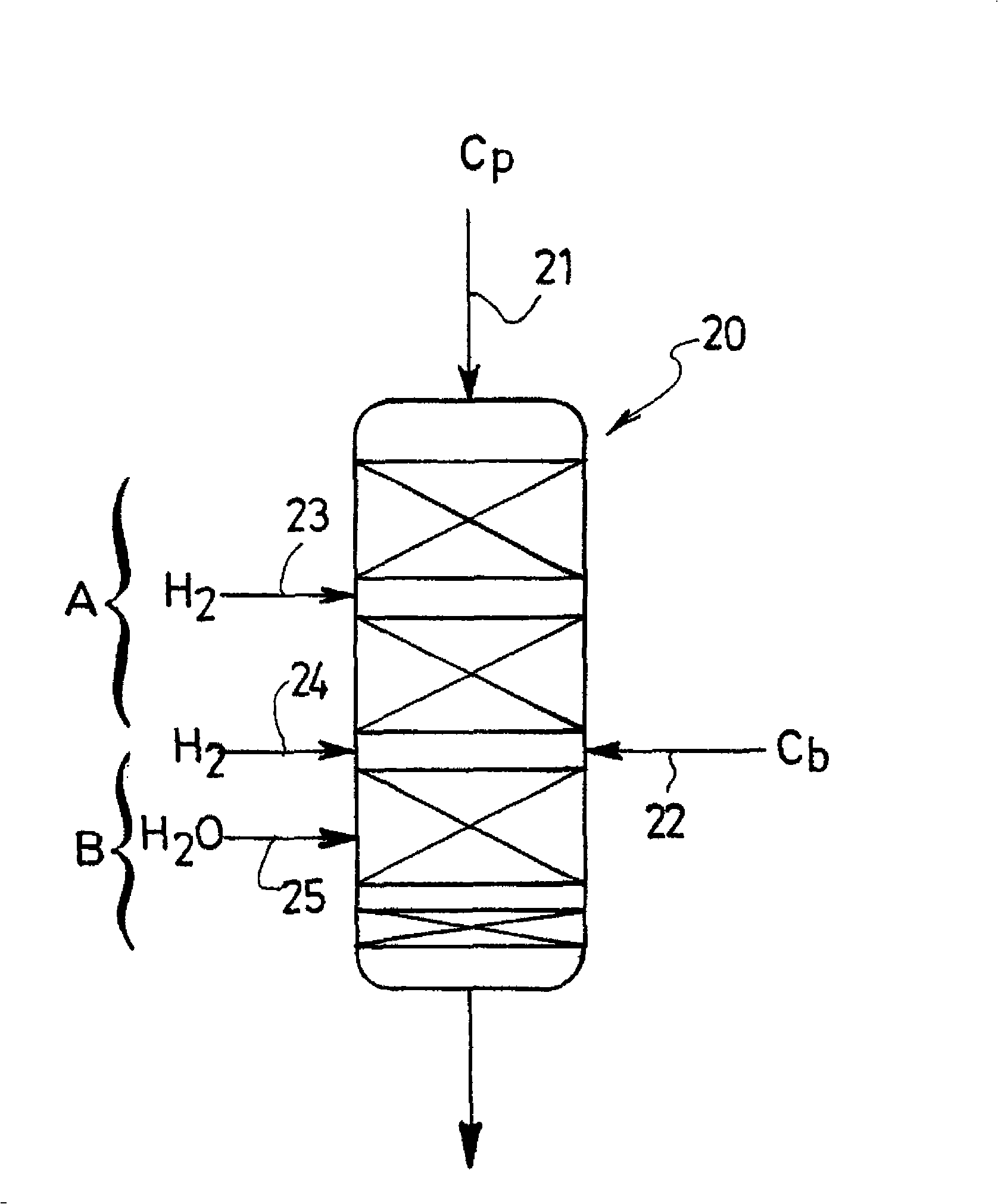

Method used

Image

Examples

Embodiment 1

[0176] A comparison of Examples 1 and 2 shows that using the same catalyst volume (54.6m 3 ), the application of the invention makes it possible to operate the first reactor at 357°C instead of 362°C in the case of Example 1. This 5°C difference has a considerable energy saving effect, and it would be even better if some of the heat was recovered from the effluent from the first reactor. Also, because the conditions are less severe, the operating period is found to be extended. In this case, an extension of at least 5 months to the operating period can be expected. Furthermore, the second reactor in Example 2 is characterized by a very long operating cycle due to the relatively low operating temperature, which is nevertheless sufficient to obtain 10 ppm diesel fuel at the outlet.

[0177] A comparison of Examples 1 and 3 shows that at the same average reaction temperature in the first reactor, the catalyst volume required to obtain 10 ppm diesel fuel at the outlet is lower w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com