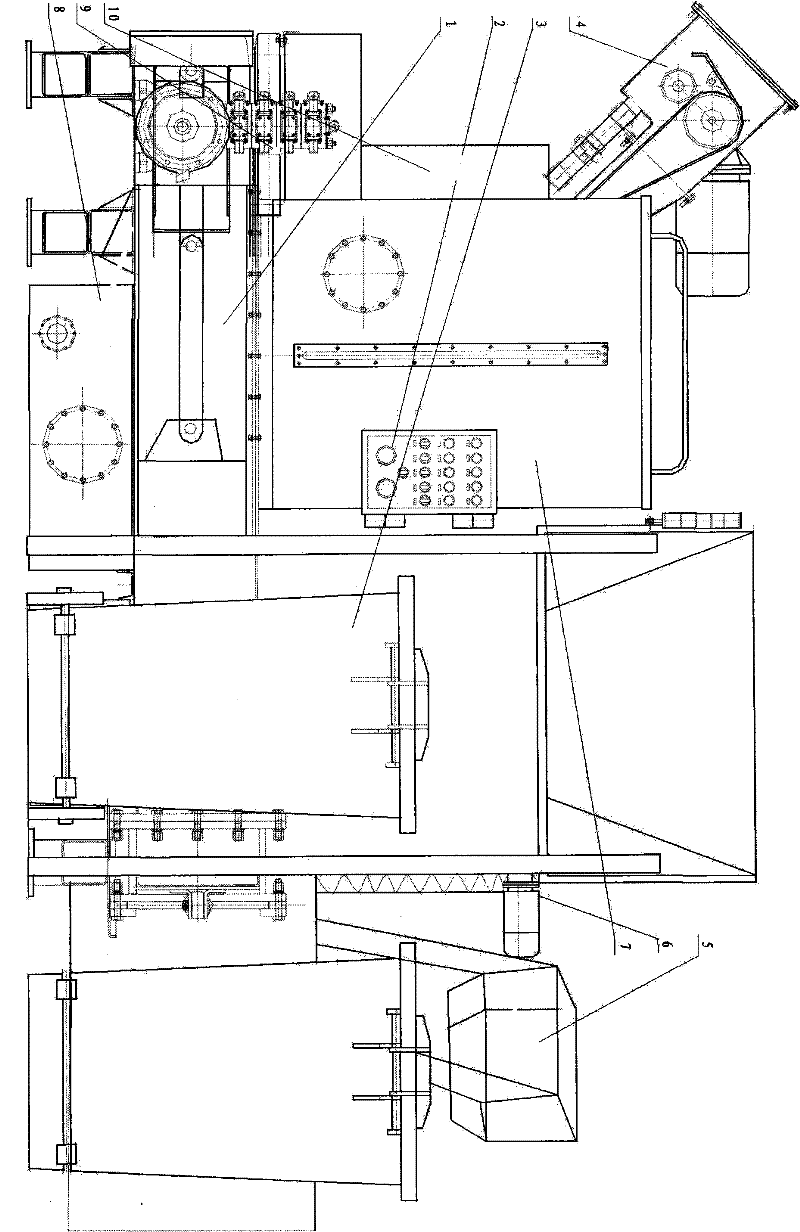

Device for reducing and sorting food waste at the source

A food waste and source technology, applied in the field of municipal environmental protection machinery, can solve the problems of treatment efficiency, water-oil separation quality, and failure to work normally, so as to improve waste treatment capacity and transportation capacity, reduce drying and heating time, The effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] An example of a workflow when using this device is:

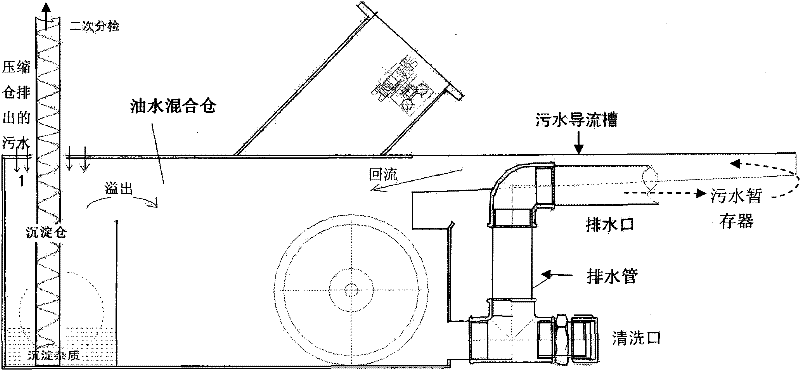

[0062] First put the kitchen waste into the garbage storage bin, and push it to the bracket of the feeding system, fix the garbage storage bin with the clamping mechanism, press the device start button on the control panel, and the transmission mechanism of the feeding system drives the garbage The storage bucket is used to pour the garbage into the hopper of the feeding system. Of course, the garbage can also be manually poured into the hopper. After 3 seconds, the dehydration system will automatically start. Dehydration work; at this time, the sewage enters the sedimentation bin of the sewage tank through the high-strength filter of the compression bin. The sewage tank includes the sedimentation bin and the oil-water mixing bin. When the liquid level in the sedimentation bin reaches the connection position with the oil-water mixing bin, the The liquid overflows and flows into the oil-water mixing chamber, which is ...

Embodiment 2

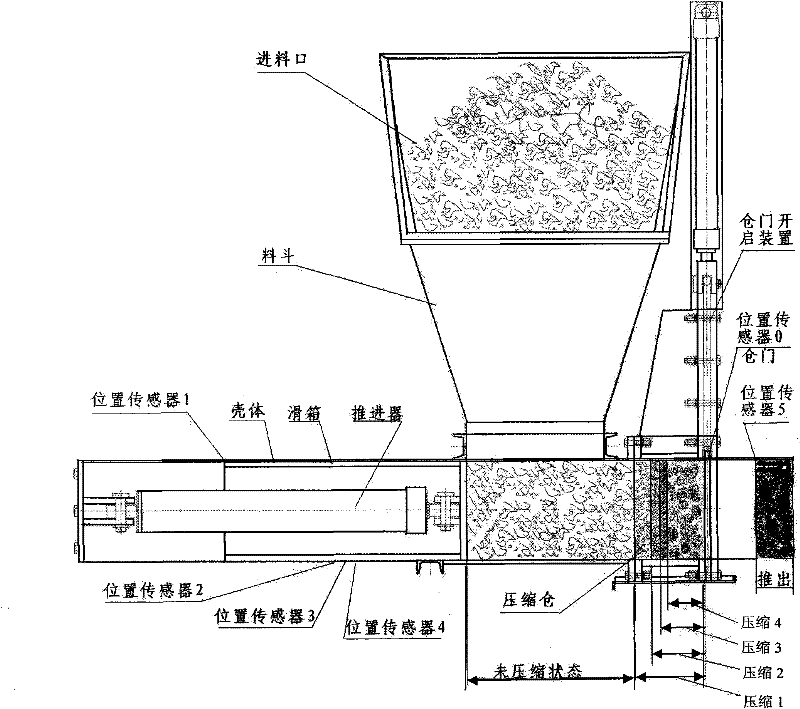

[0068] The work process of described dehydration system and implementation scheme embodiment are as follows (see attached figure 2 ):

[0069] The position sensor 1 is used to detect whether the sliding box is in the initial position; when the food waste in the feeding system enters the shell of the dehydration system, the propeller pushes the sliding box to squeeze the garbage to compression position 1, and when the pressure reaches the set value a, The propeller stops moving to keep the pressure on the door of the compression chamber for 3 seconds, and then drives the sliding box back. When the sliding box touches the position sensor 2, start the propeller to drive the sliding box forward again. When the garbage is squeezed to the compression 2 position, the pressure reaches the set value. After setting the value b, the propeller stops moving so that the pressure on the door of the compression chamber is maintained for 3 seconds, and then drives the sliding box to move back...

Embodiment 2

[0073] The working process and implementation embodiment 2 of the dehydration system are as follows:

[0074] The position sensor 1 is used to detect whether the sliding box is in the initial position; when the food waste in the feeding system enters the shell of the dehydration system, the propeller pushes the sliding box to squeeze the garbage to the door of the compression chamber, and when the pressure sensor installed on the door After the pressure value reaches the set value a, the propeller stops moving to keep the pressure on the door of the compression chamber for 3 seconds, then drives the sliding box back about 100mm, and then pushes the sliding box forward again to squeeze the garbage to the door of the compression chamber. After the door pressure value reaches the set value b, the propeller stops moving to keep the pressure on the door of the compression chamber for 3 seconds, then drives the sliding box back about 100mm again, and then pushes the sliding box forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com