Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Eliminate splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

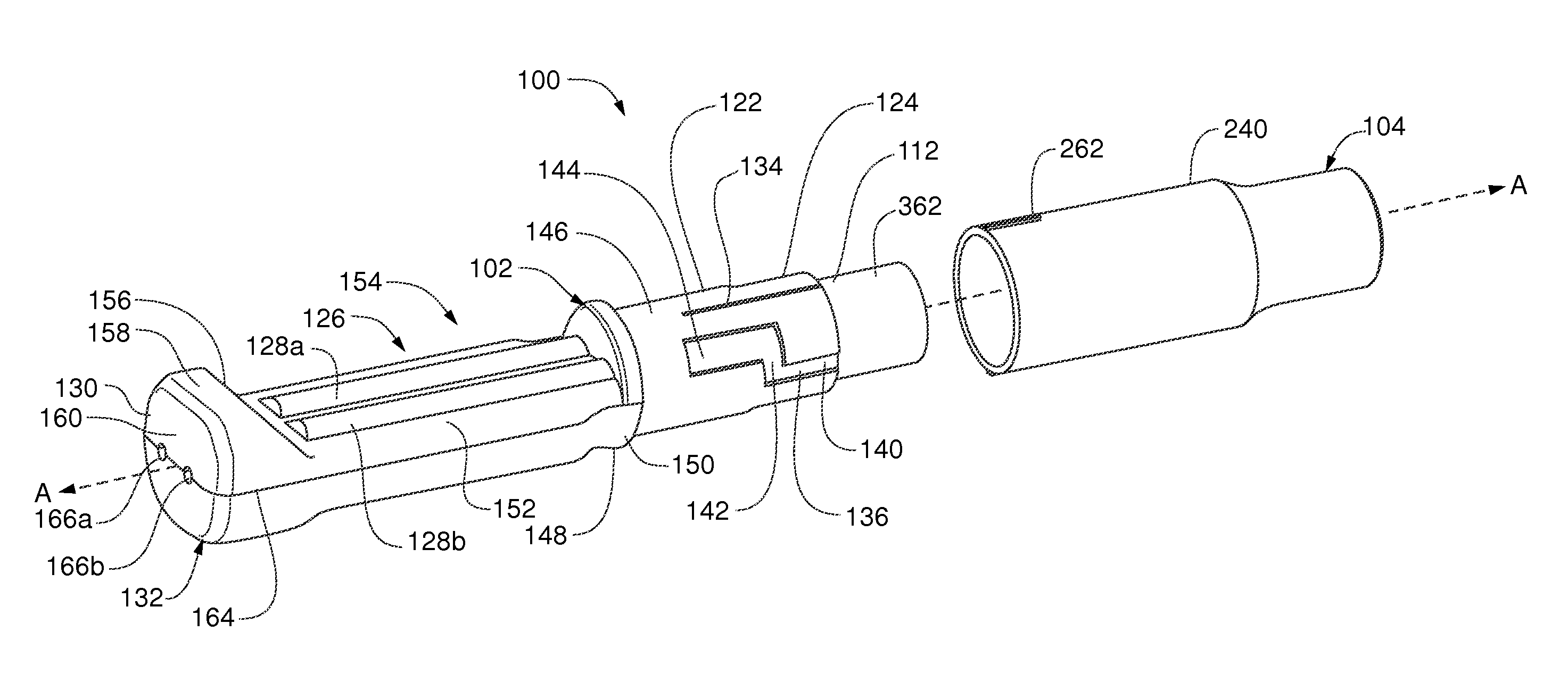

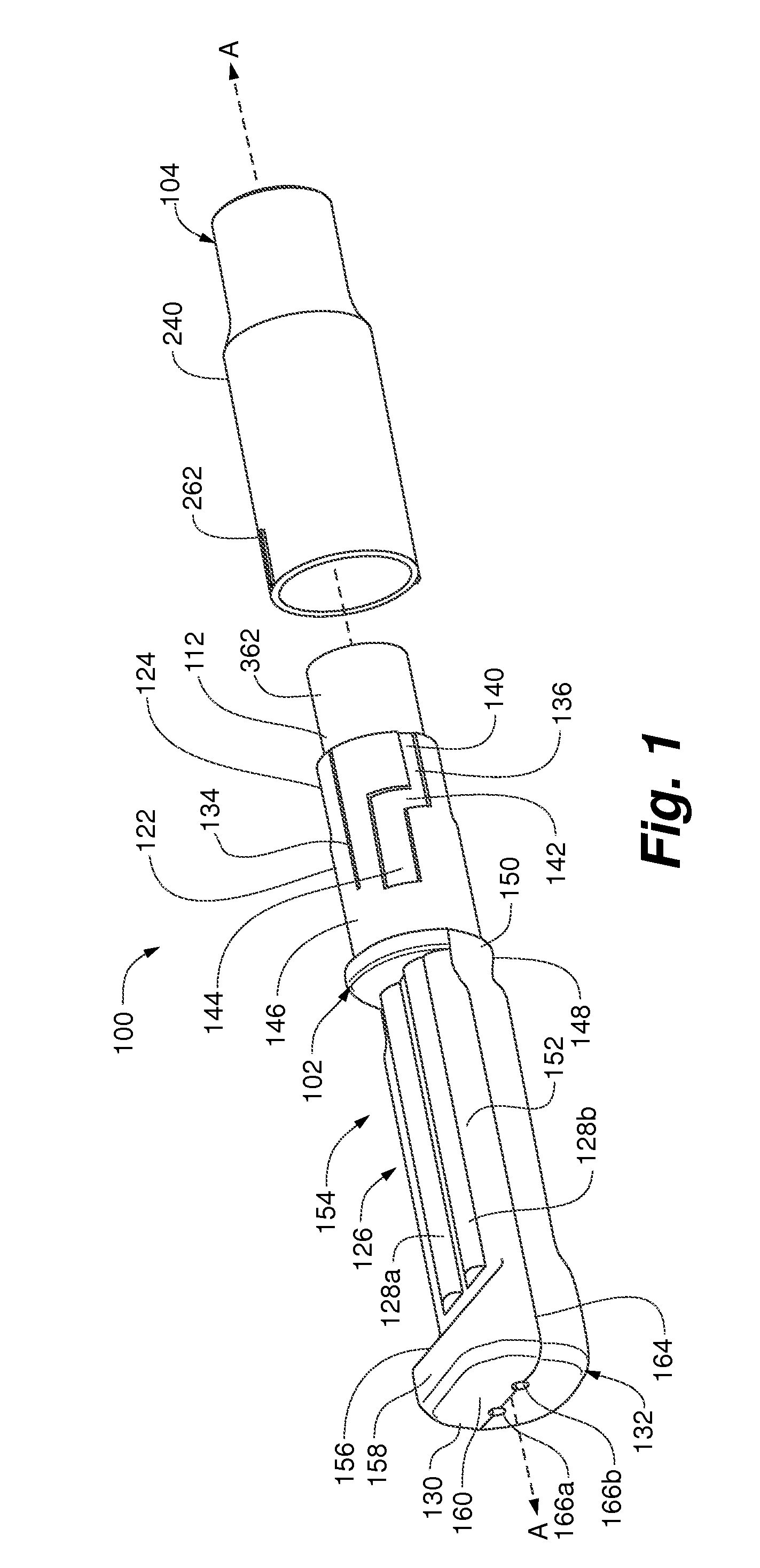

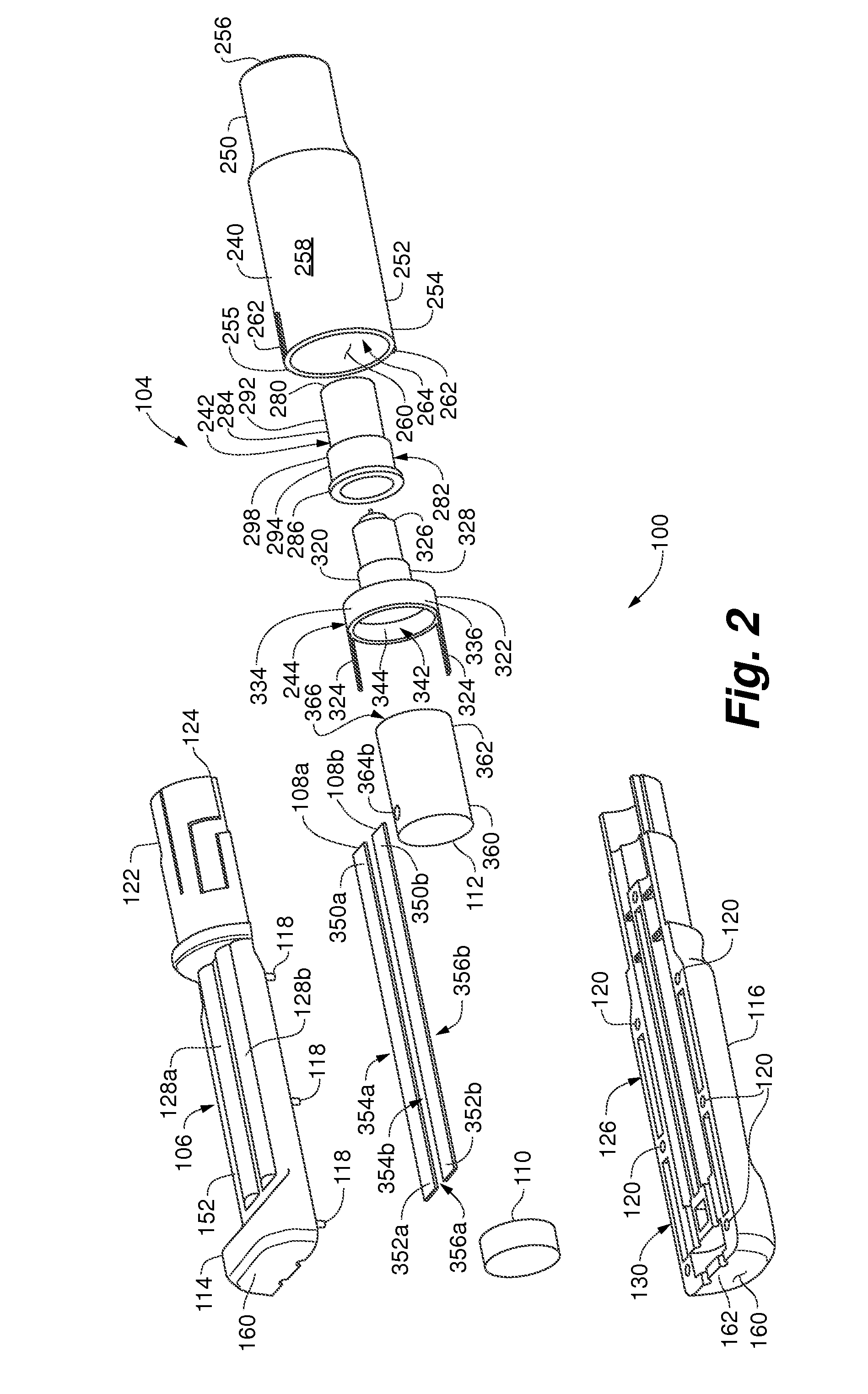

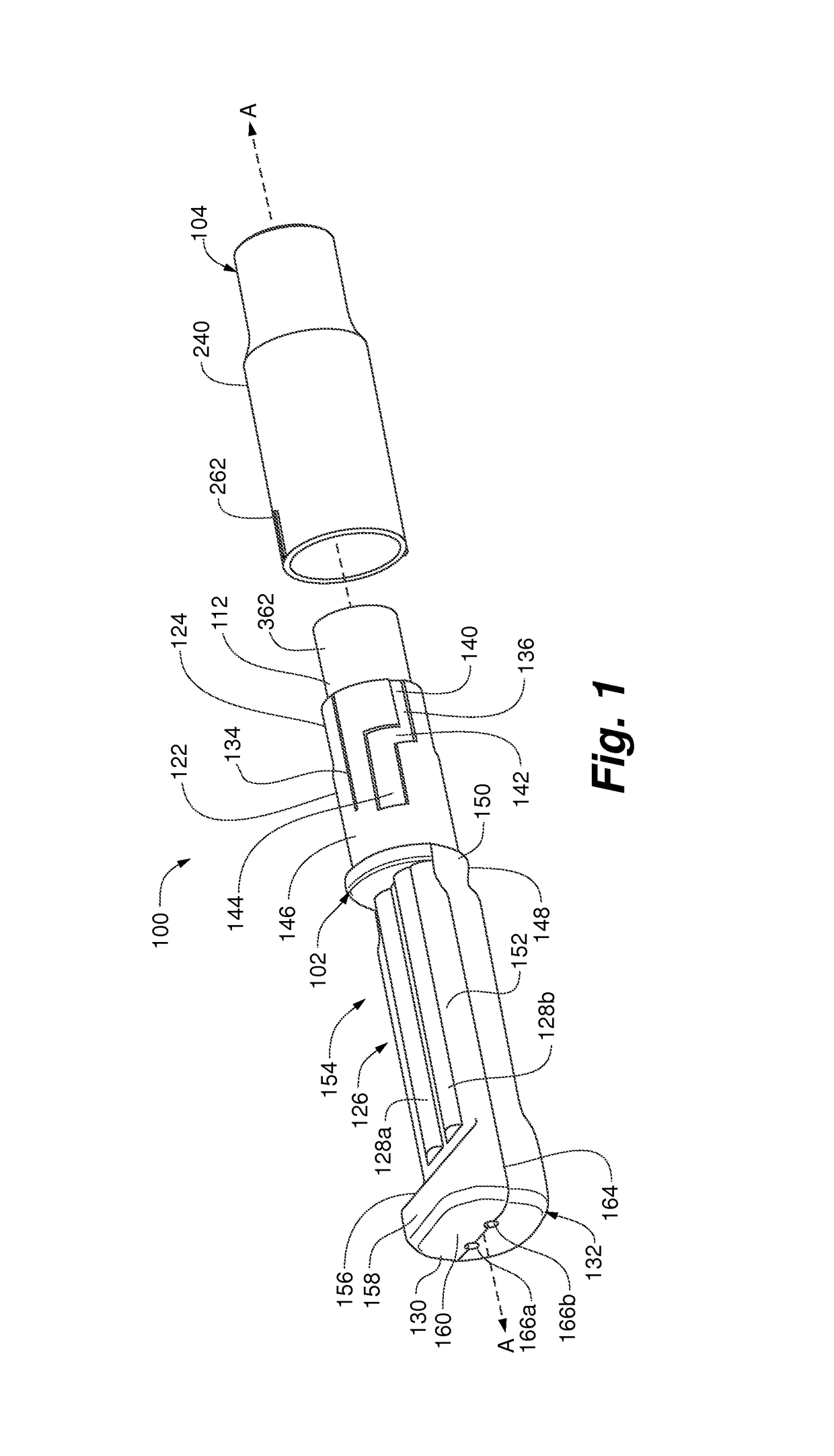

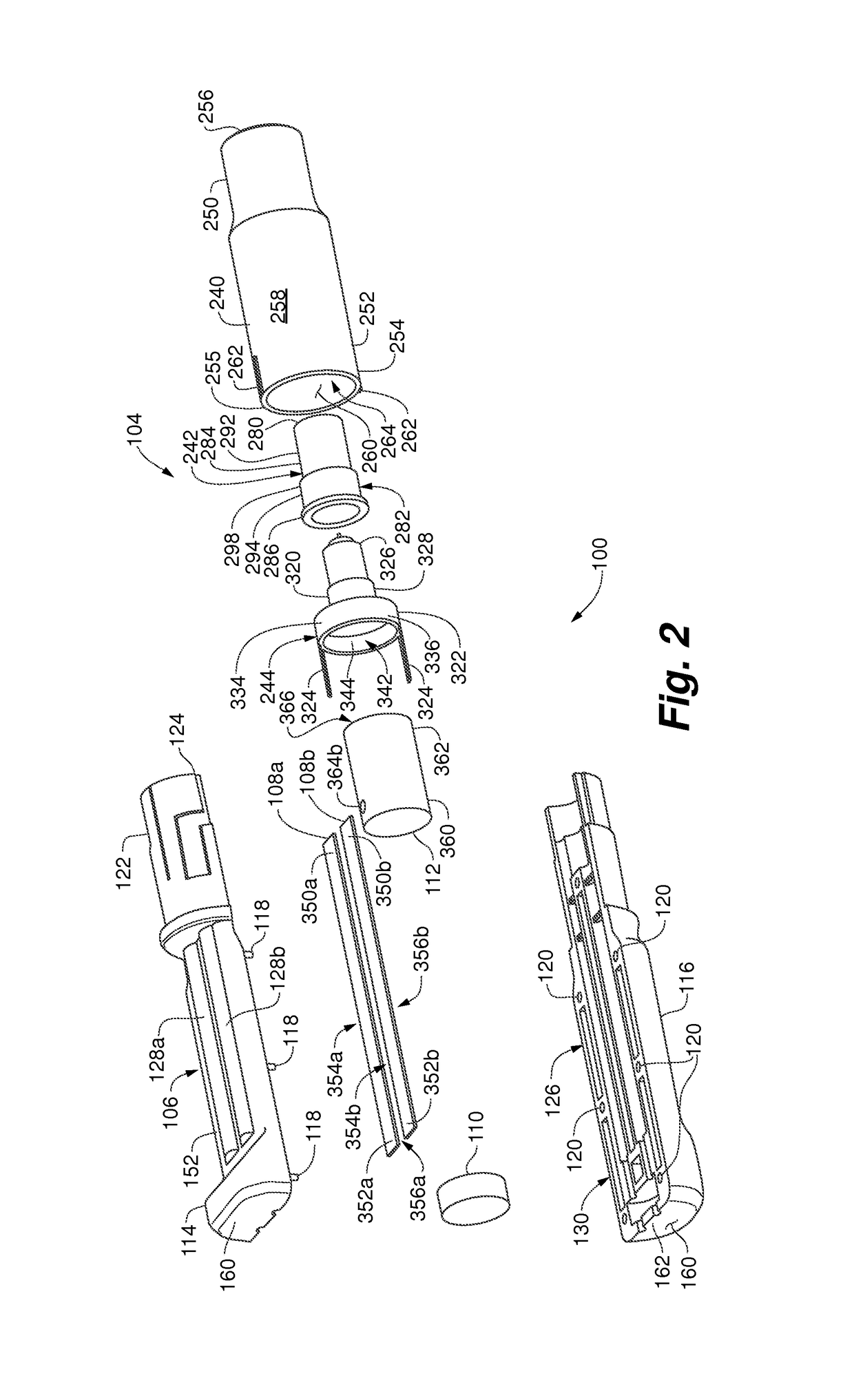

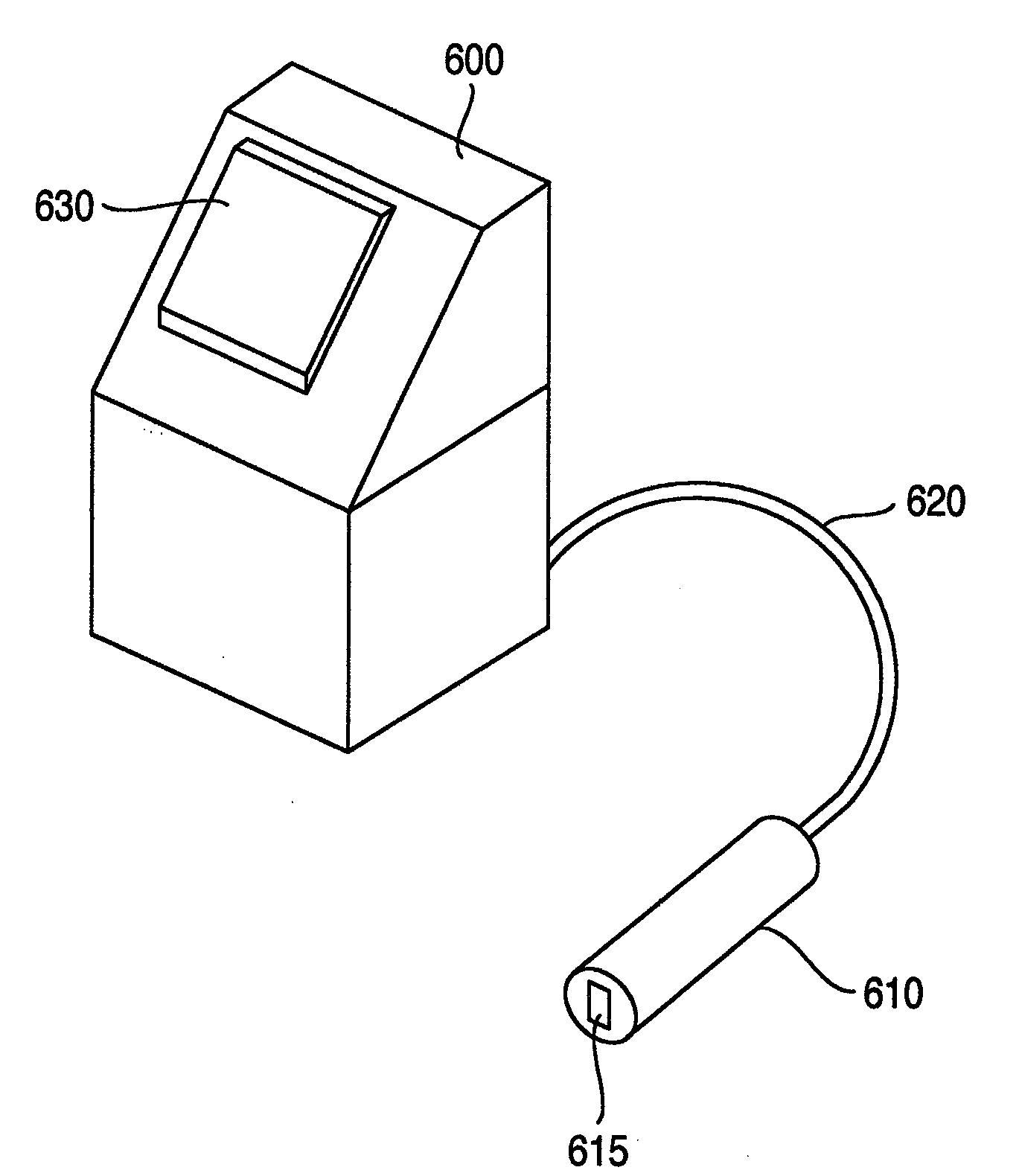

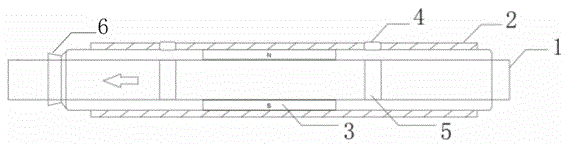

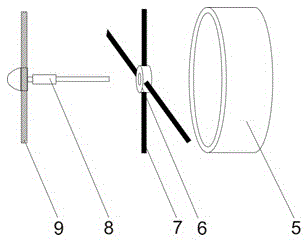

Multi-stage oral-fluid testing device

ActiveUS20160121322A1Easy to useTest accurateAnalysis using chemical indicatorsVaccination/ovulation diagnosticsEngineeringOral fluid

In an embodiment, the claimed invention includes an oral-fluid collection and testing device that. is simple to operate. The device includes a body assembly and a cap assembly that are easy to handle by a user. A collection sponge projects from an end of the body assembly for absorbing the oral fluid of a donor, A cap assembly is easily aligned with the body assembly by way of visual alignment indicators on both the body and the cap. Once the cap is aligned with the body, a user simply pushes the cap onto the 'body, which causes a first stage fluid, flow. More specifically, a buffer fluid is released from the cap and mixes with the oral fluid collected on the sponge—After waiting a short time* the cap is rotated, then pushed again, causing a second-stage fluid flow in which the sponge is compressed such that the buffer fluid / oral fluid exits the sponge and flows toward a. pair of test strips. A user can then easily view the test results by observing a visual indication, such as a color change of the test strips through a viewing window.

Owner:PREMIER BIOTECH LLC

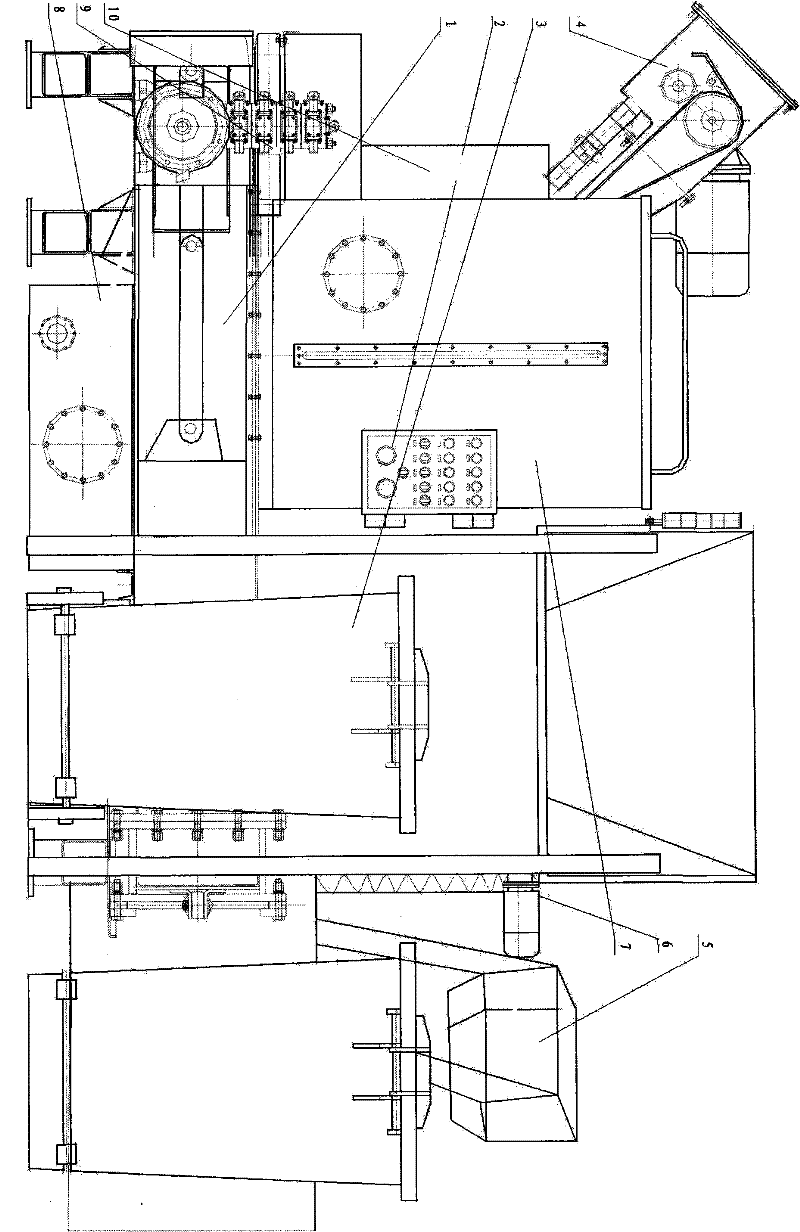

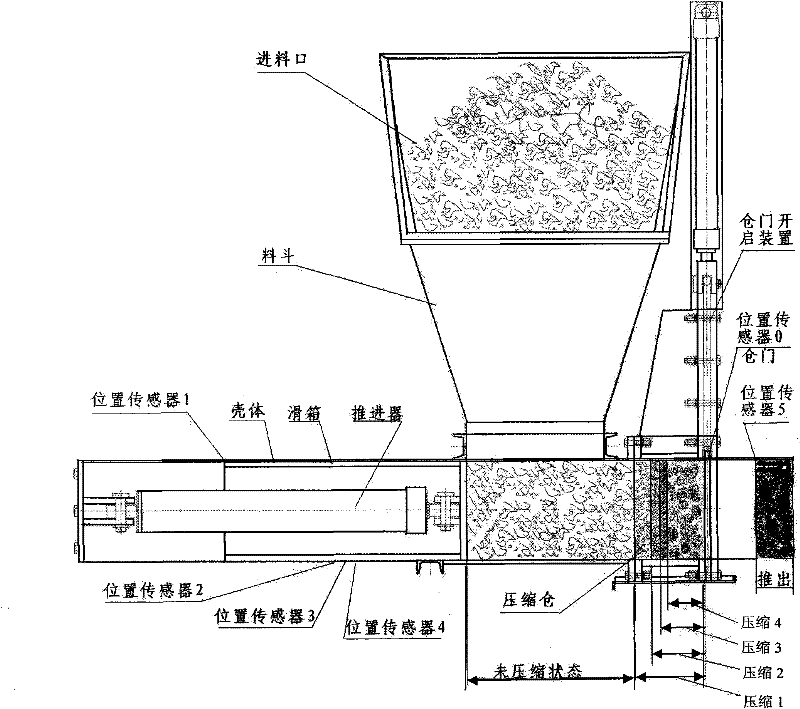

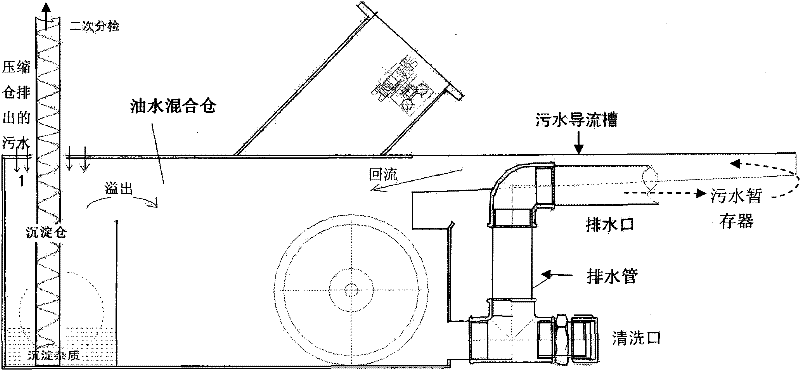

Device for reducing and sorting food waste at the source

InactiveCN102240658AEasy to handleImprove transportation capacitySolid waste disposalDrying solid materials without heatOil and greaseFailure rate

The invention discloses a device for reducing and sorting food waste at the source, and belongs to the technical field of municipal environmental protection machinery. The device is characterized in that: food waste is poured into a feed system and is conveyed into a dehydration system, a sliding box is driven to slide in a housing through a propeller of the dehydration system, a extruding way or a beating way is adopted to complete the food waste dehydrating; the resulting sewage from the dehydration step enters a sewage box from a compression bin to enable a oil and water separation system to extract greases; the solid materials after completing the dehydration are pushed out from the compression bin and enter into a material discharge system; the solid materials are output through the material discharge system and wait for centralized processing. After being processed by the device provided by the present invention, the food waste is divided into three portions comprising the water, the greases and the solid materials so as to conveniently carry out post-treatments such as reuse production of the greases and the solid materials, regeneration treatment of the water source and the like. The device has characteristics of strong processing ability, low failure rate, high automaticity, simple and easy operation and maintenance, no requirement of chemical additives, high dehydration rate, short retention time of the food waste in the device, and the like, and is benefit for improving efficiency of resource reutilization production so as to achieve effect of energy saving and emission reduction.

Owner:曹泽民

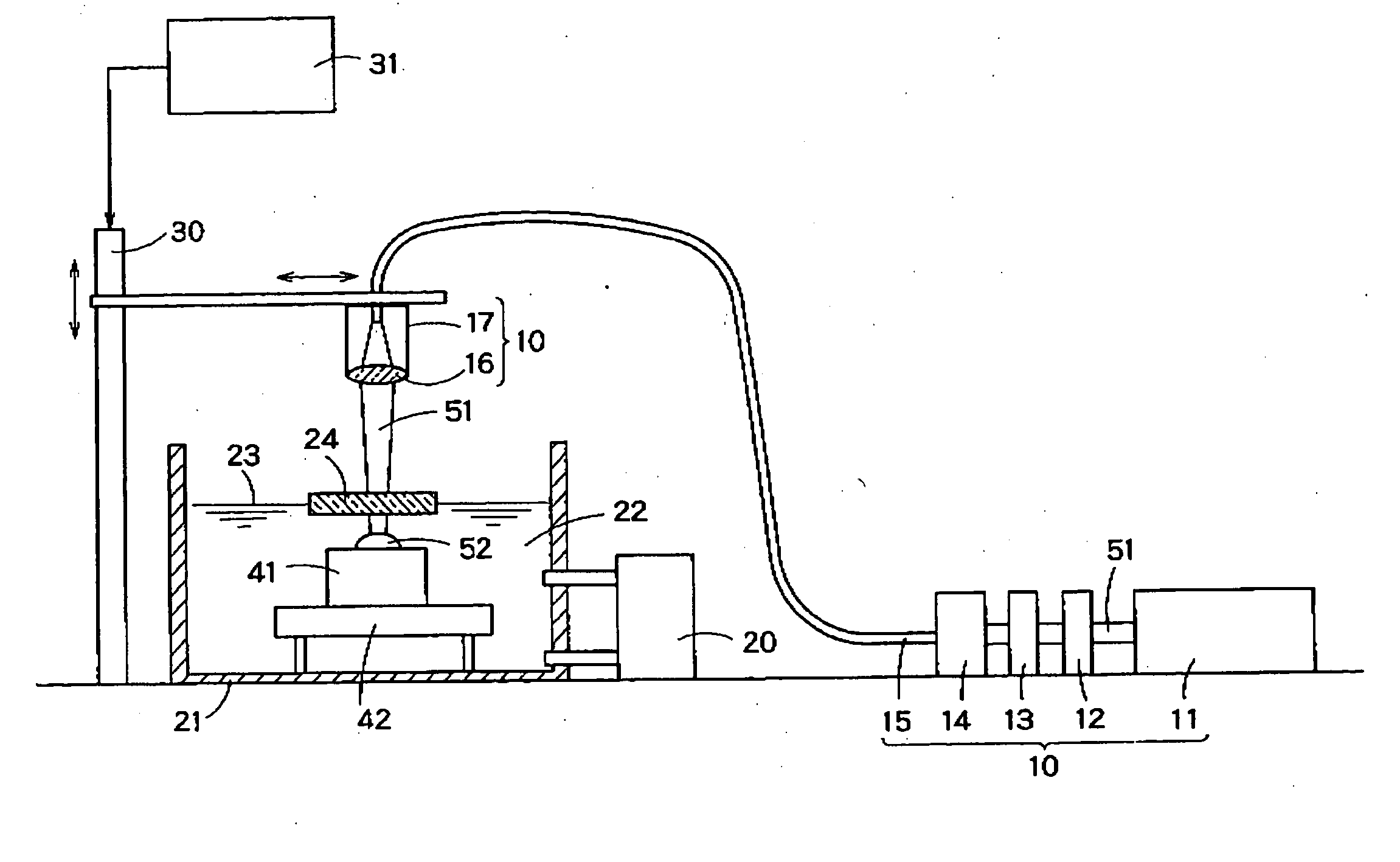

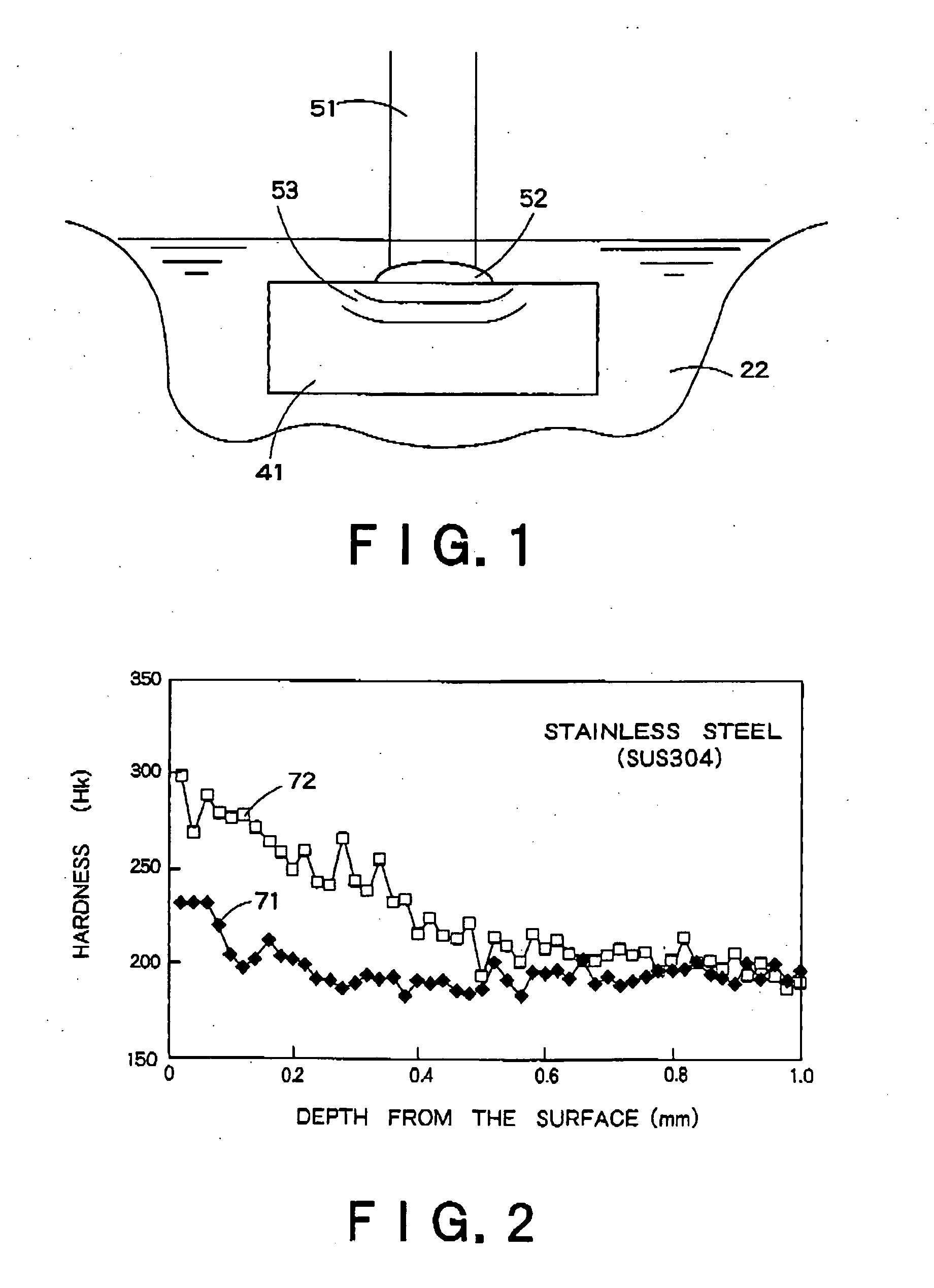

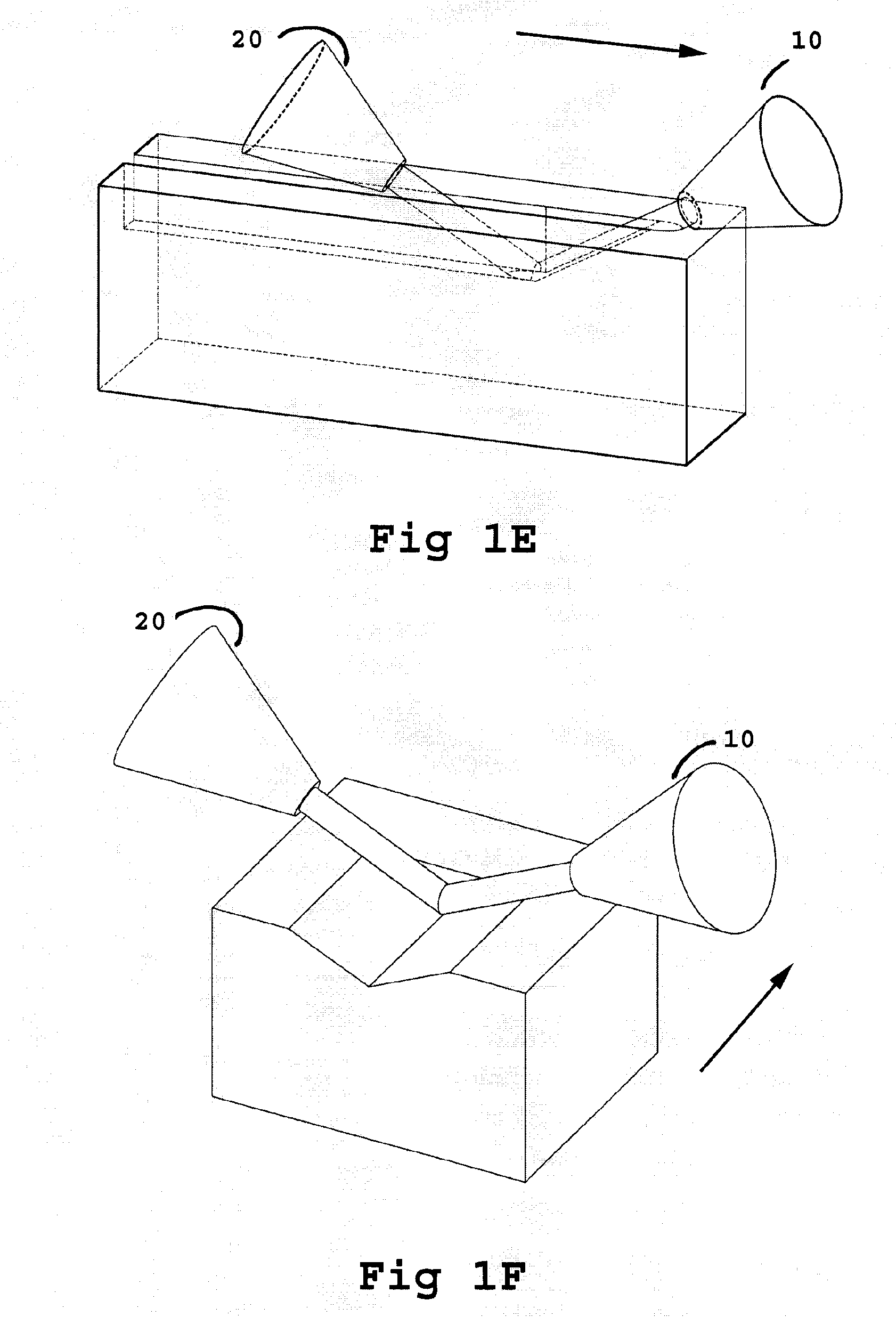

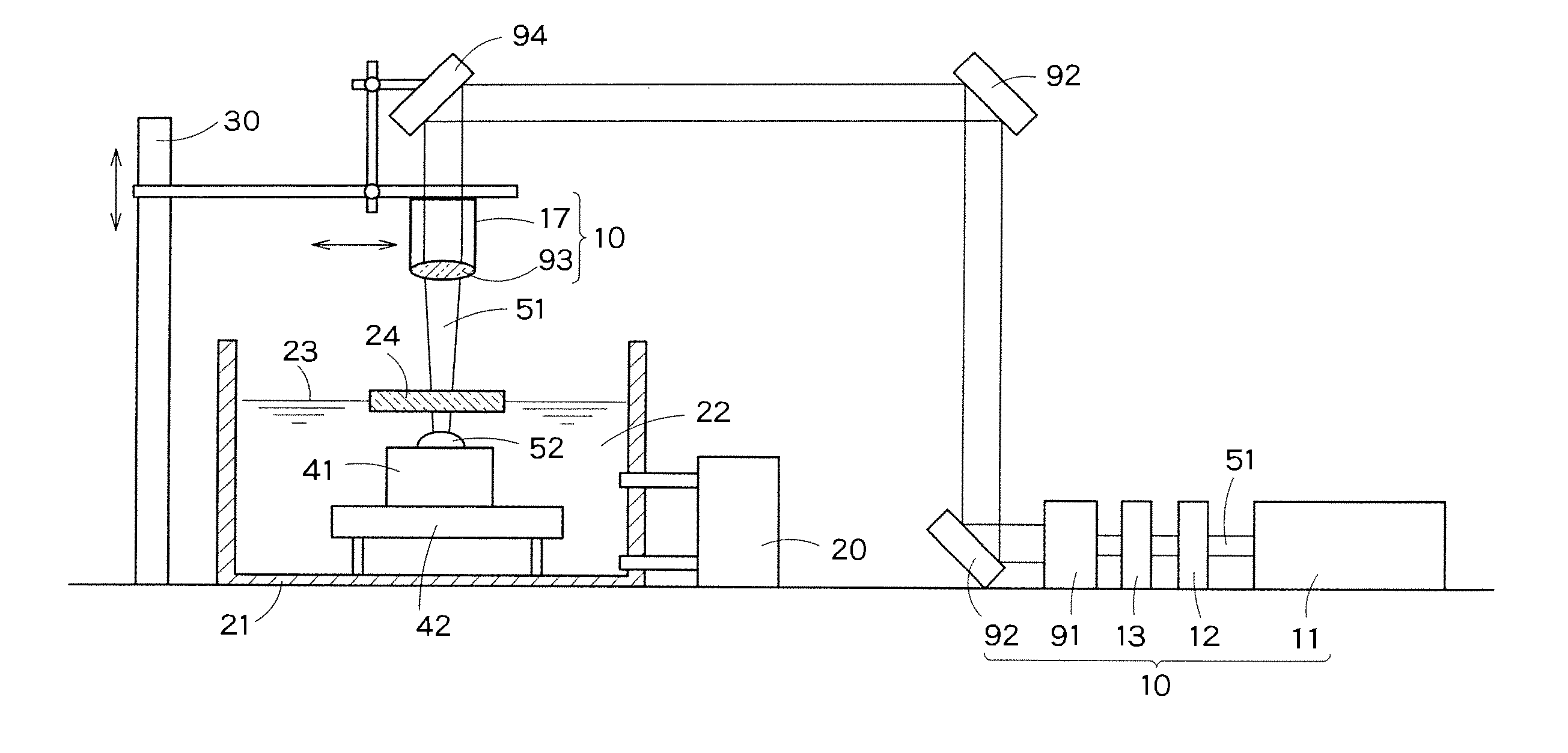

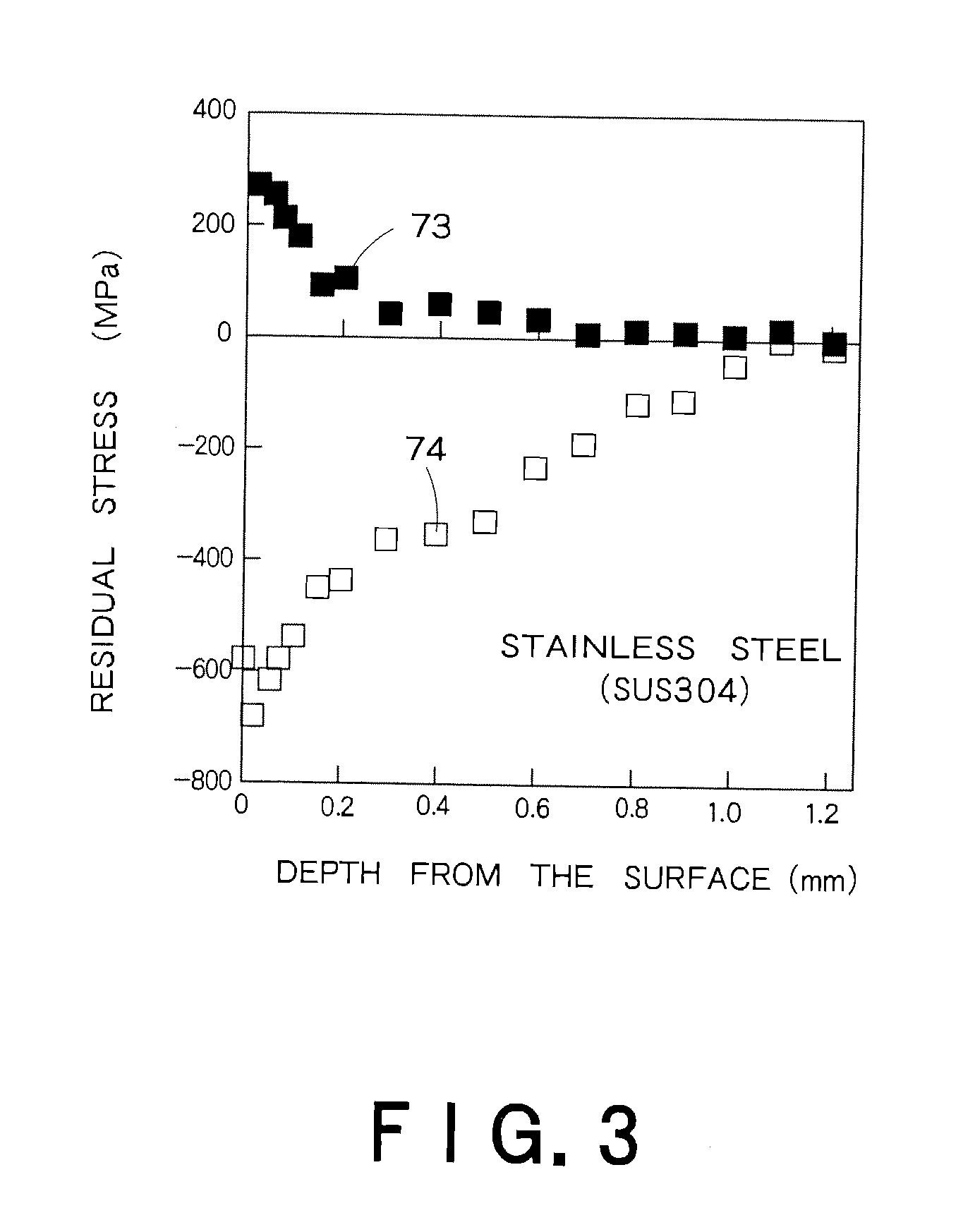

Laser shock hardening method and apparatus

ActiveUS20070262063A1Increase processing speedReduce burdenWelding/soldering/cutting articlesLaser beam welding apparatusOptical pathShock hardening

There is provided an improved laser shock hardening method and apparatus which can eliminate spattering of a liquid and waving of the liquid surface upon laser irradiation, and can stably irradiate a workpiece with a laser beam. Thus, the present invention provides in a laser shock hardening method for carrying out surface processing of a workpiece in contact with a liquid by irradiating through the liquid the surface of the workpiece with a pulsed laser beam intermittently emitted from a laser irradiation device, the improvement comprising: providing a solid transparent to the wavelength of the laser, serving as an entrance window to the surface of the liquid; allowing the liquid to be present in the light path of the laser beam between the solid and the surface of the workpiece; and allowing the laser beam to enter through the solid and irradiating through the liquid the surface of the workpiece with the laser beam, thereby shock-hardening the surface of the workpiece.

Owner:KK TOSHIBA

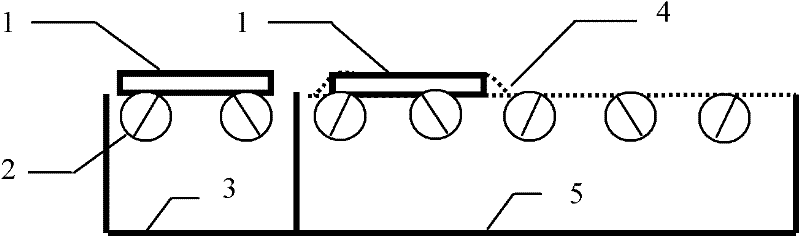

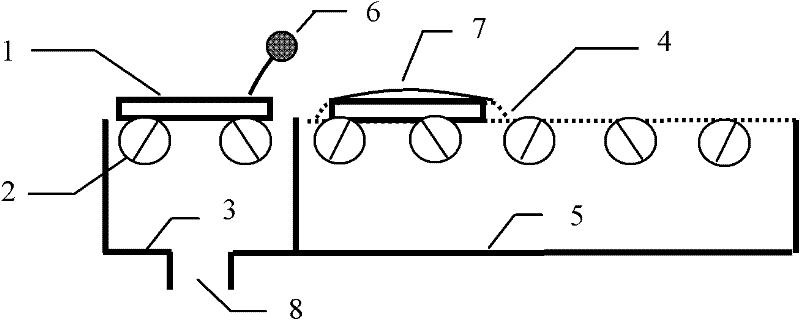

Water film protection wet etching process for diffusing surface

InactiveCN102214732AIncrease the effective light-receiving areaEliminate splashFinal product manufactureSemiconductor devicesEtchingP–n junction

The invention relates to a chained wet etching process during manufacturing of solar batteries, in particular to a water film protection wet etching process for a diffusing surface. The process comprises the following steps of: firstly, forming a water film protection layer on the diffusing surface of a silicon slice to be etched, wherein the water film protection layer is used for protecting the diffusing surface of the silicon slice during subsequent etching; and performing the conventional wet etching on the silicon slice floating on an etching liquid medicine. In the process, the water film protection layer is formed on the surface of the silicon slice by using surface tension of the liquid, so residual etching regions produced in the conventional wet etching process can be removed, effective light-receiving areas of a P node and an N node are increased and the photoelectric conversion efficiency can be improved; furthermore, the damage of the etching liquid medicine to the diffusing surface, which is caused by the problems of the splashing of the etching liquid medicine due to the rupture of bubbles in an etching slot, the drippage of etching liquid medicine drops coagulated above a slot body, unstable air exhaust, abnormal flow rate and the like, can be eliminated, so that the production proportion of various appearance unqualified slices to electric performance ineffective slices of the solar battery can be finally reduced.

Owner:TRINA SOLAR CO LTD

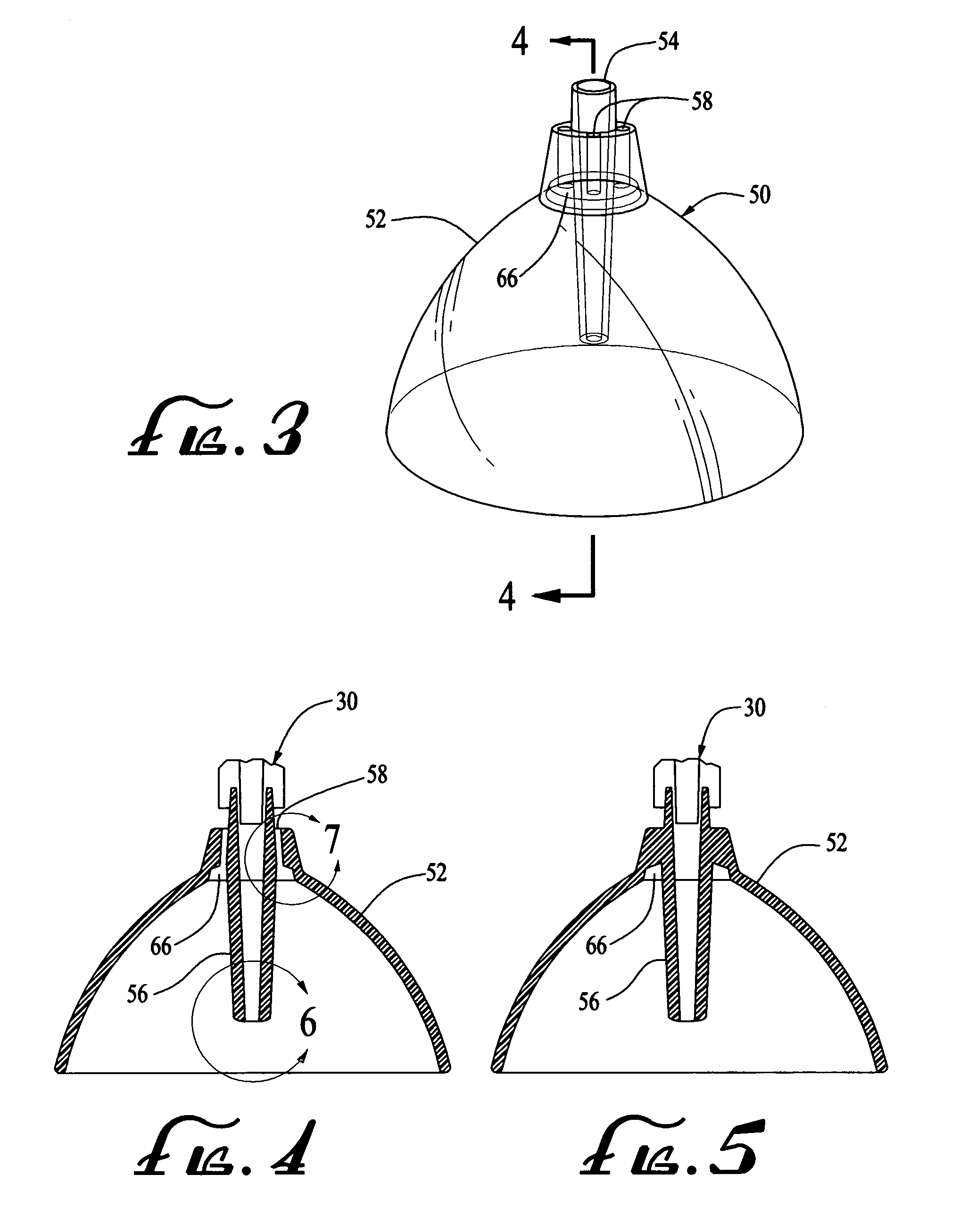

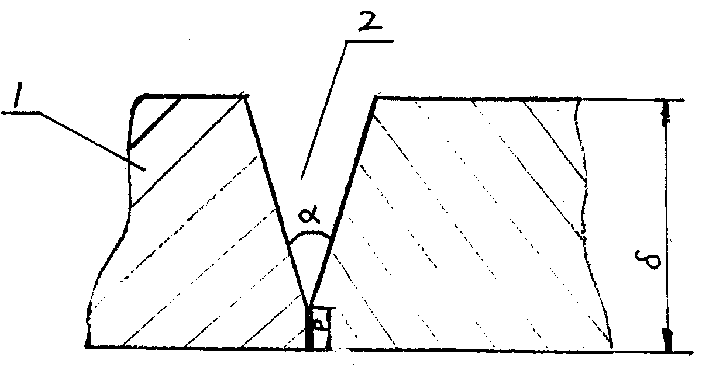

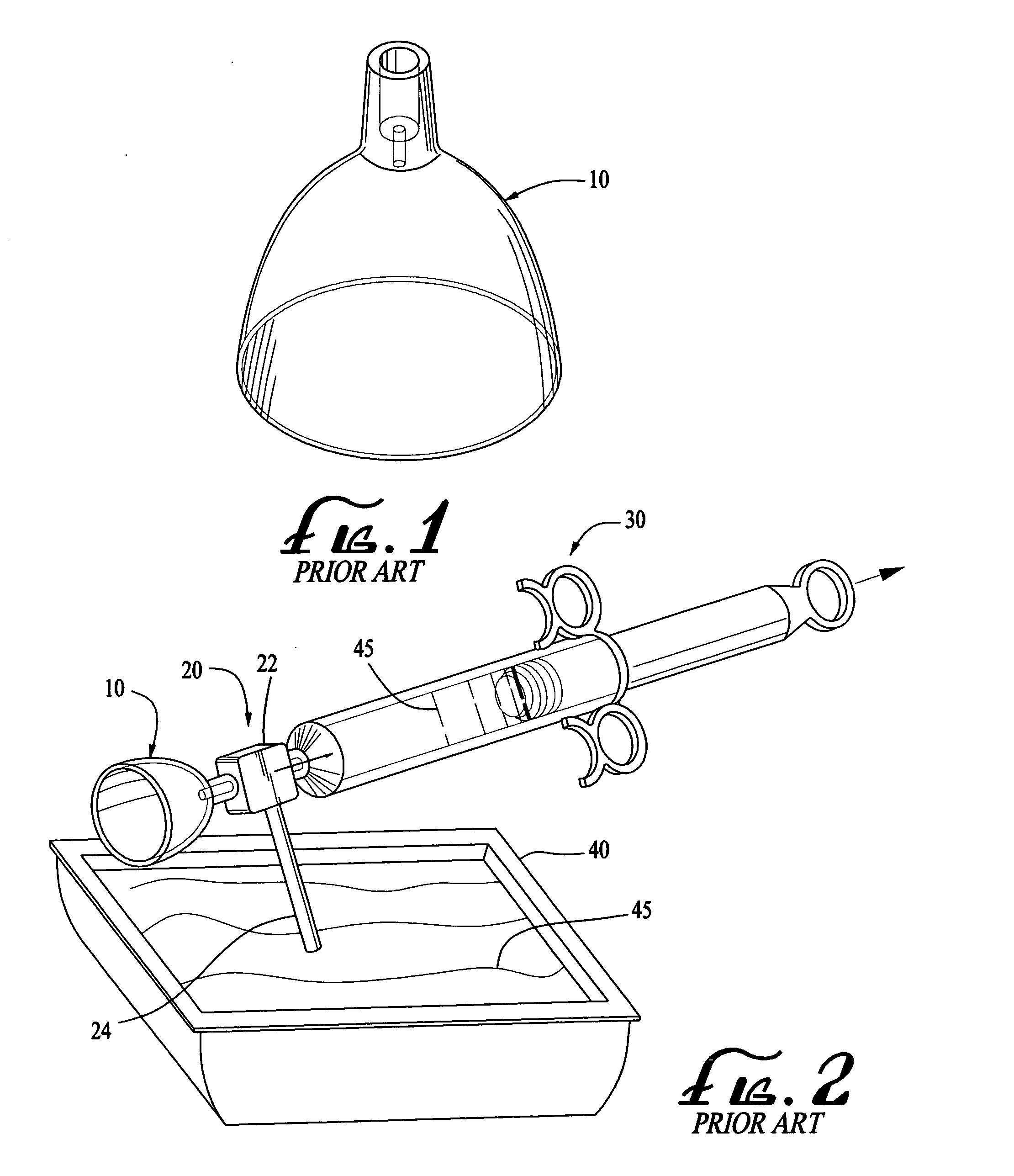

Wound irrigation splashback shield

Owner:STAMLER KEITH

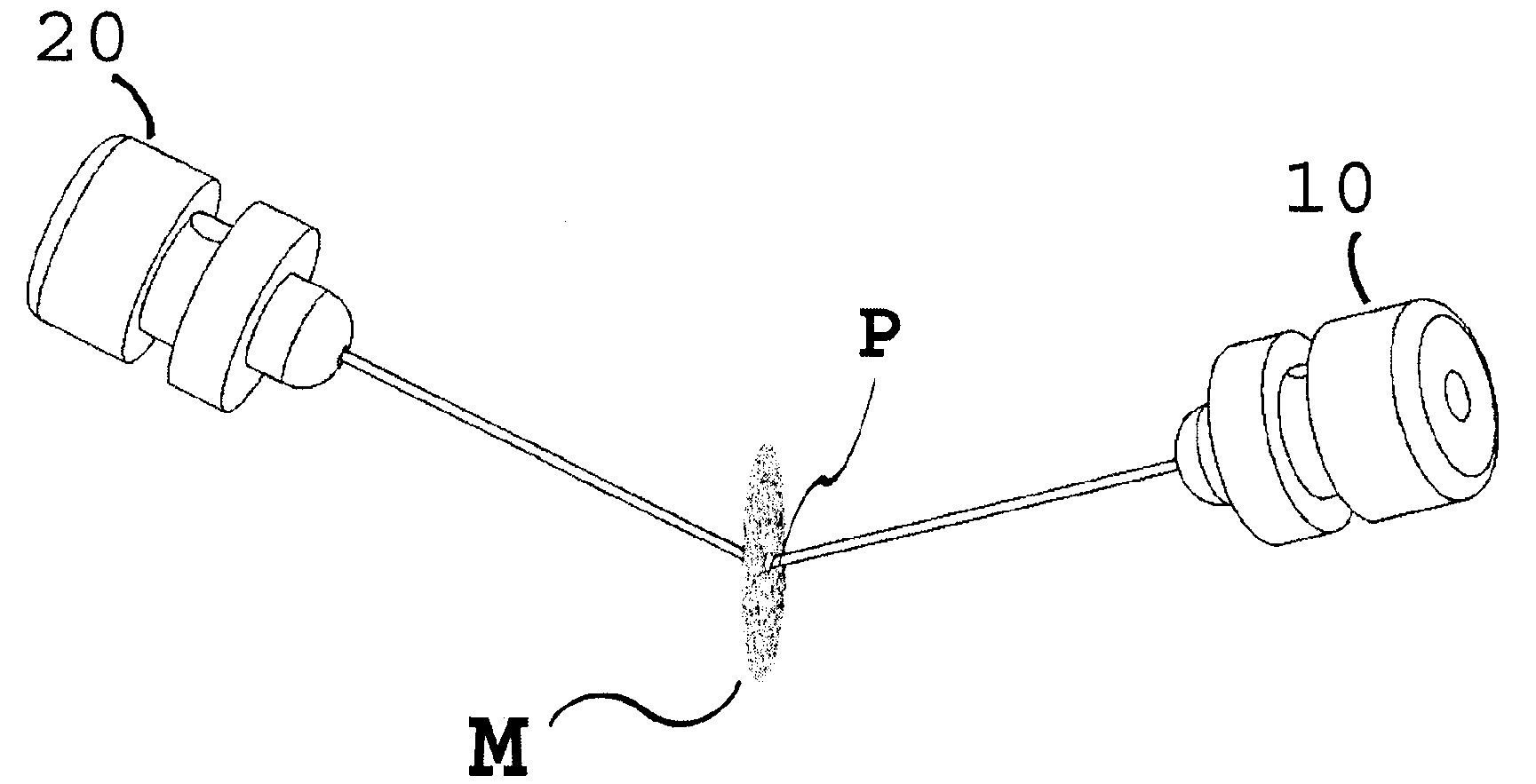

Liquid cutting device

InactiveUS20100180738A1Easy three-dimensional cuttingEasy to controlAbrasive feedersAbrasive machine appurtenancesLiquid jetEngineering

A liquid cutting device employing pressurized working liquid which includes a nozzle assembly. The assembly includes a plurality of liquid jet nozzles, each nozzle of which has a nozzle axis. The plurality of nozzles are arranged so that their nozzle axes intersect at an intersection point located at a predetermined distance downstream from the nozzles. The device also includes an apparatus for delivering the pressurized working liquid to the nozzles. Each of the nozzles is configured to selectably emit a liquid jet operative to cut through a target material. The liquid jets emitted from the nozzles interfere and disperse each other when meeting at the intersection point and the liquid jets are atomized. The device includes a spacer element adjustably mounted onto the nozzle assembly, which increases or decreases the cutting depth of the device. A method for employing the liquid cutting device is also discussed.

Owner:TAVGER MICHAEL

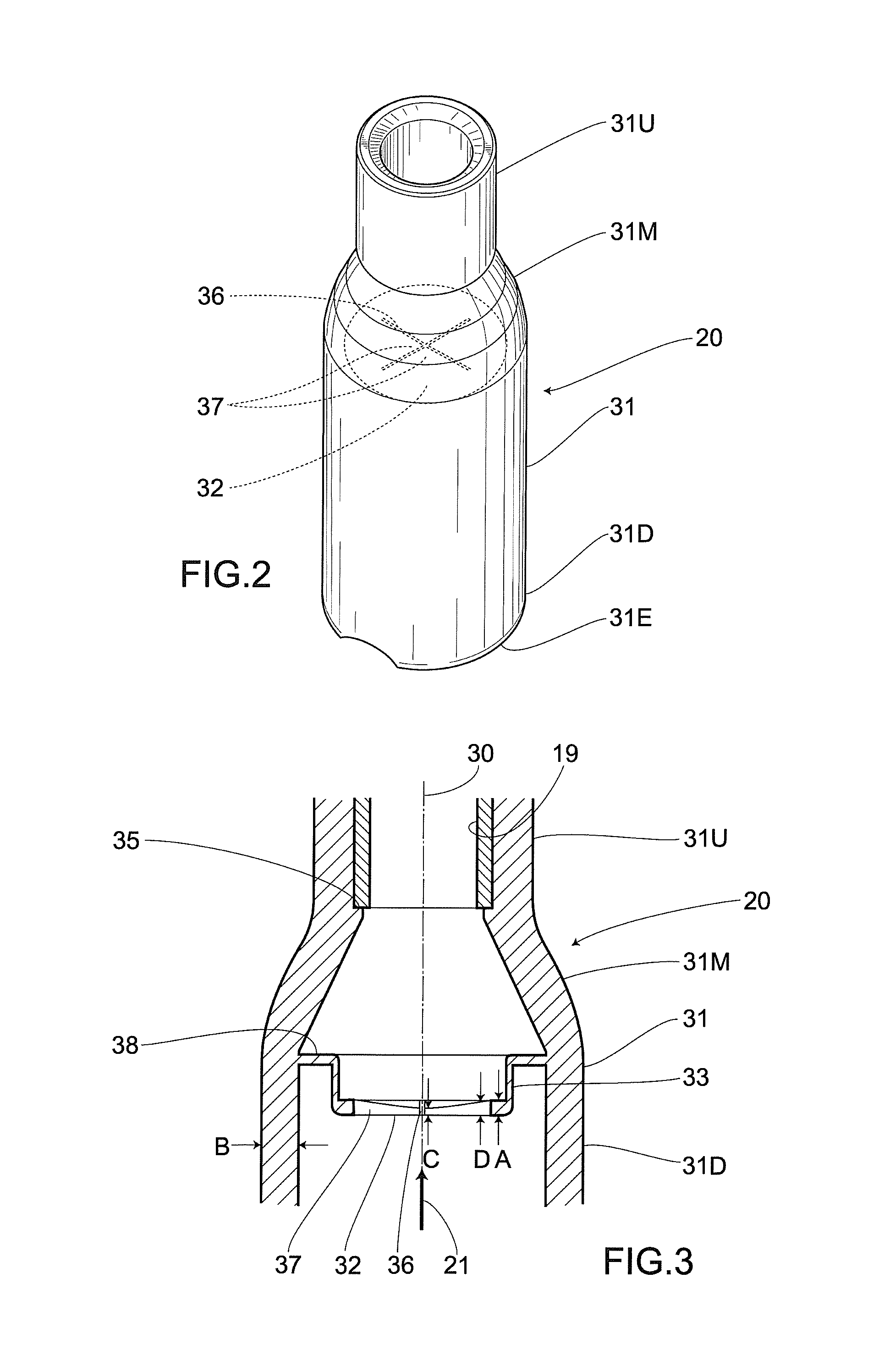

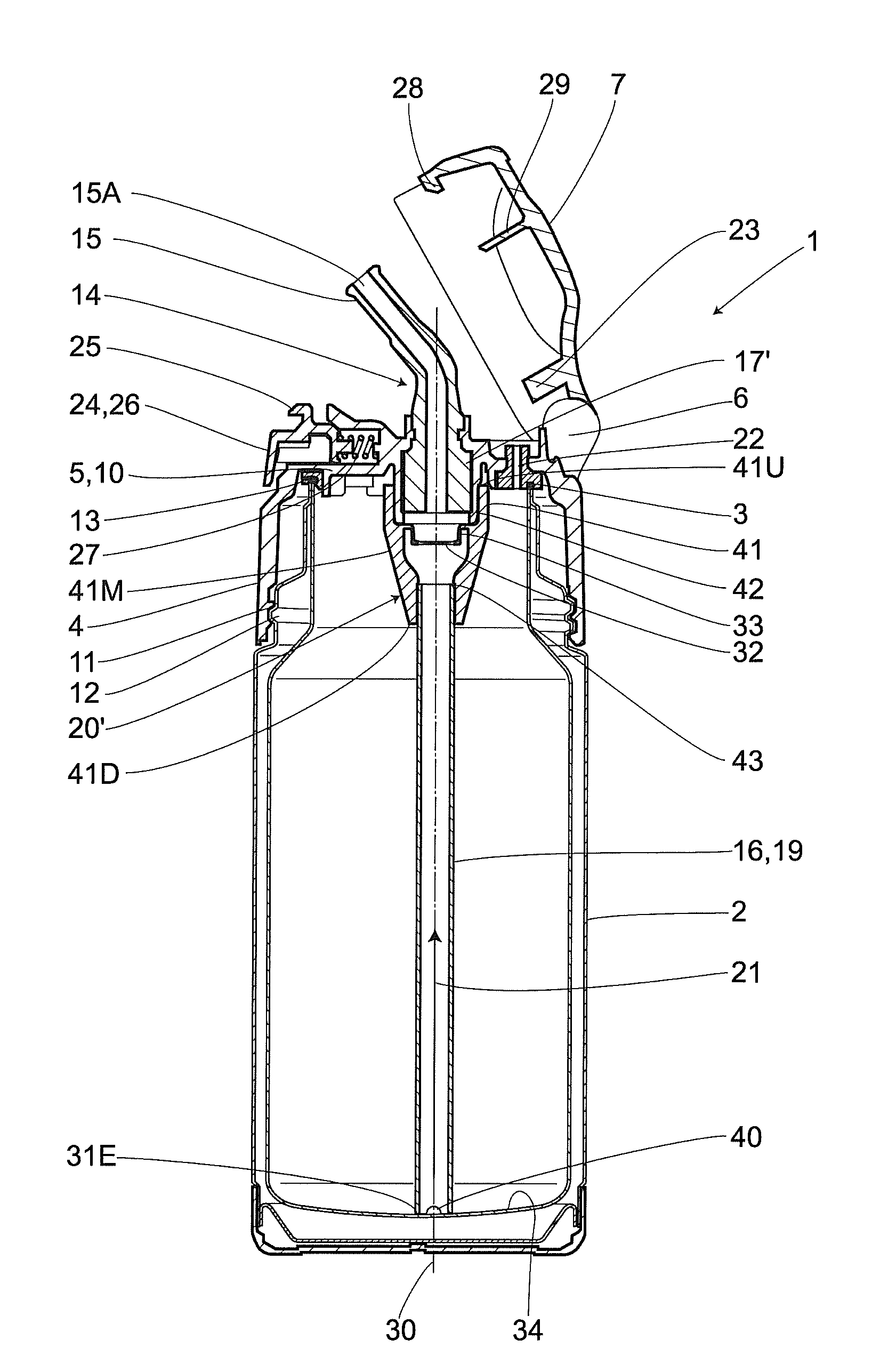

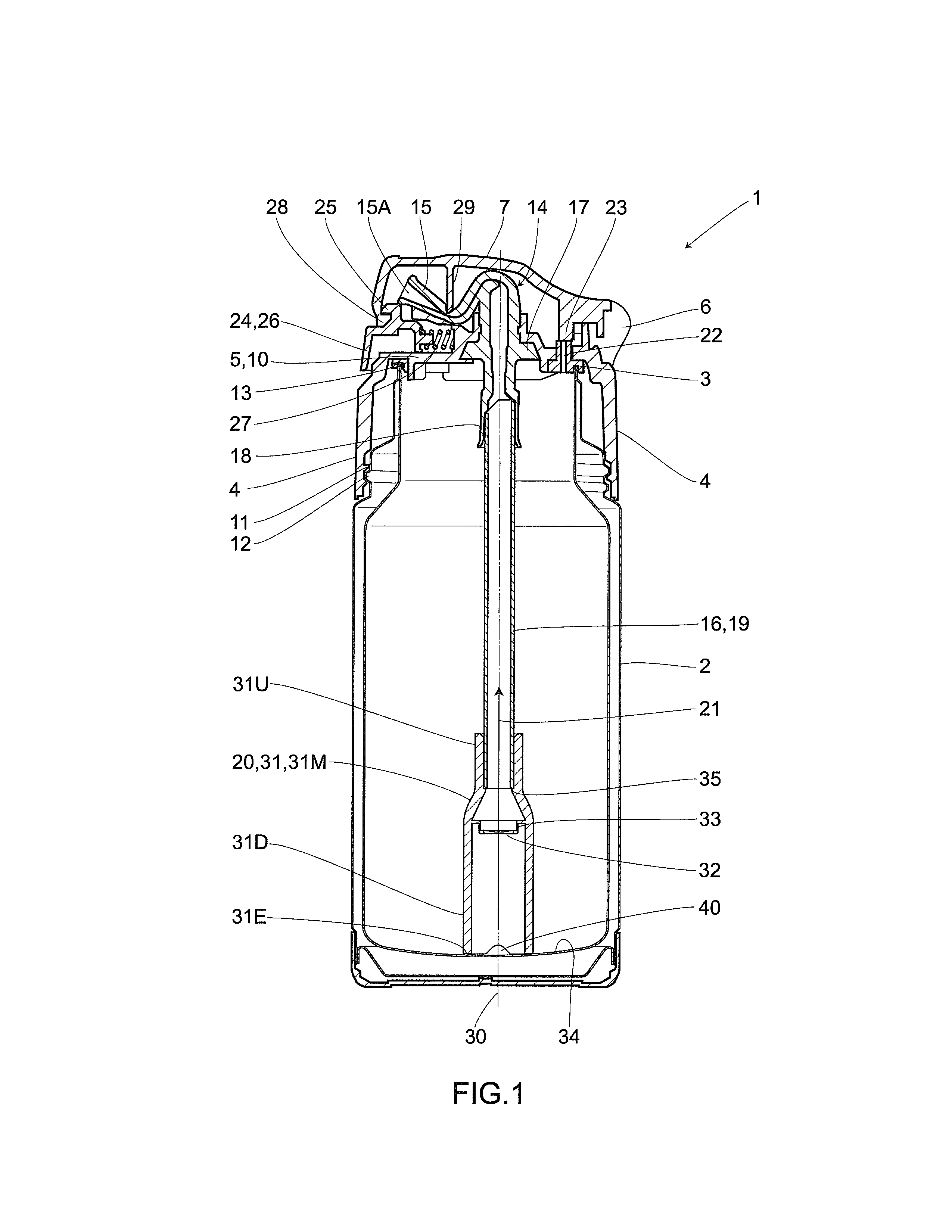

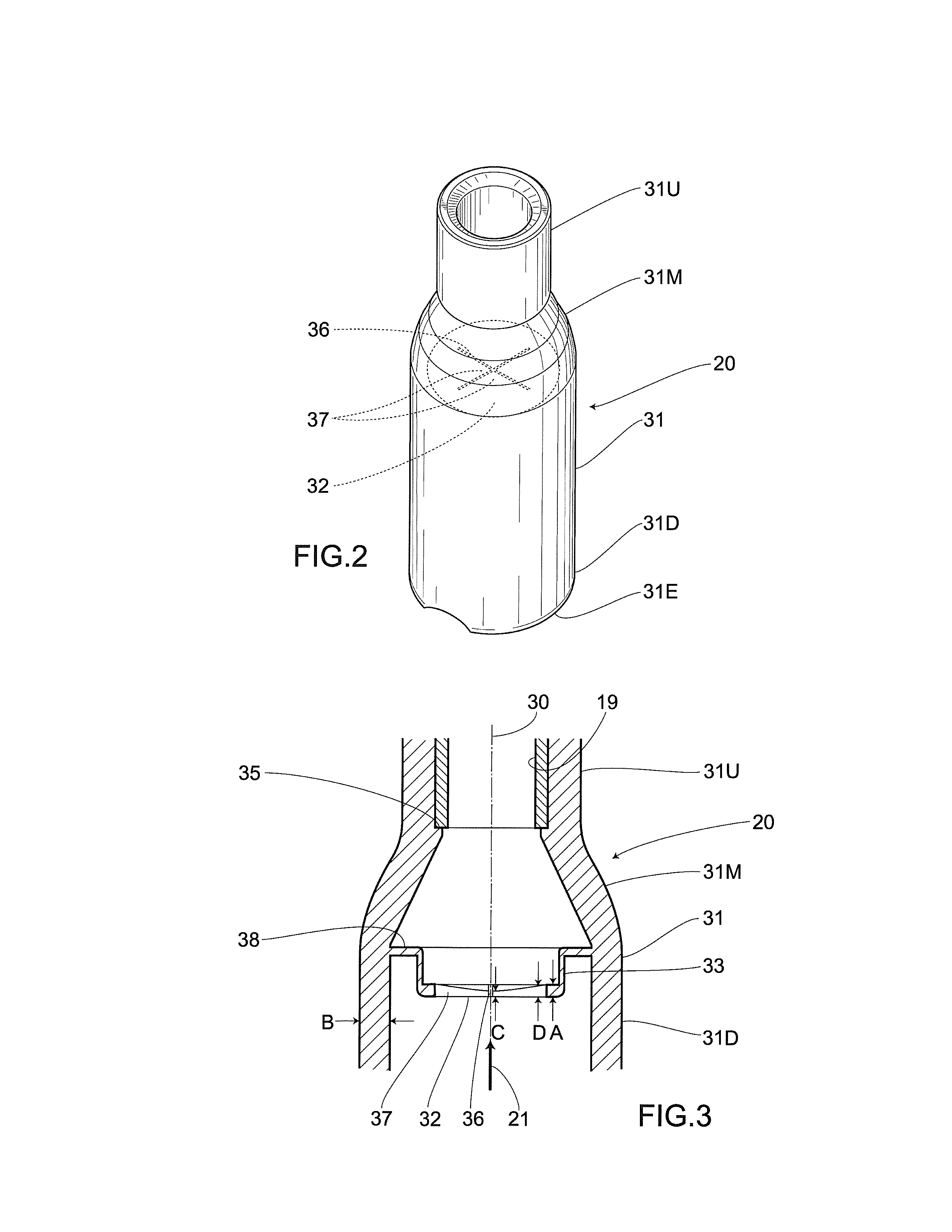

Beverage container

ActiveUS8844742B2Eliminate splashImprove washabilityClosuresDispensing apparatusSuction forceFront edge

Owner:THERMOS LLC

Beverage container

ActiveUS20130175270A1Improve washabilityPrecise positioningClosuresDrinking vesselsSuction forceEngineering

A drinking mouth portion pointing upward is provided on a plug body of a container main body having a sealed structure. A down-pointing beverage cylindrical member is built into the container main body and has a front edge side thereof communicated with the drinking mouth portion. Provided inside a fluid passage of the beverage cylindrical member is a valve movable in accordance with a pressure difference therein. The valve is not manually opened and closed, but reacts to a suction force in the fluid passage. An up-pointing cut-out section is provided on a lower edge of the beverage cylindrical member, thus allowing one to drink up a content fluid remaining in an inner bottom section. Therefore, a relatively small number of additional parts are needed to address the spewing of a content fluid and the occurrence of a residual liquid at the time of opening the drinking mouth portion.

Owner:THERMOS LLC

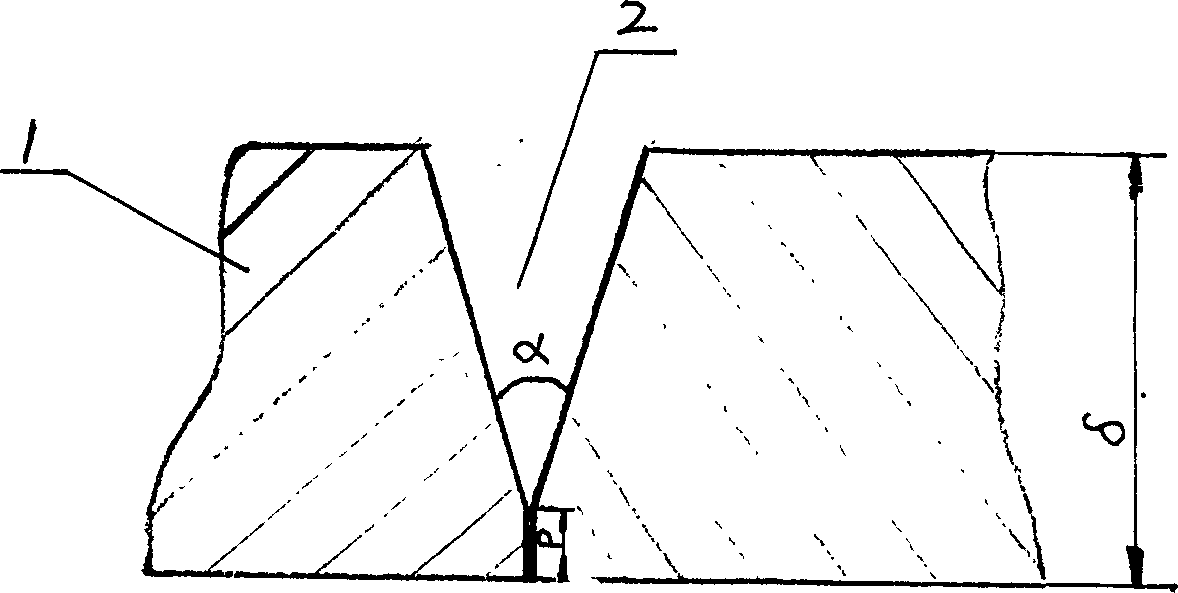

Technique for welding car axle housing made by punching medium heavy steel plates

InactiveCN1431080AImprove welding strengthEliminate generationWelding apparatusMelting tankSheet steel

A technology for welding the punched bridge shell of car includes punching on (12-20)-mm steel plate to form bridge shell, making, Y-shape bevels by 6-20 deg. of angle, fixing by dot welding, and gasprotected welding with consumable electrode. Its advantages are high welding strength and quality, and no splash.

Owner:重汽(济南)车桥有限公司

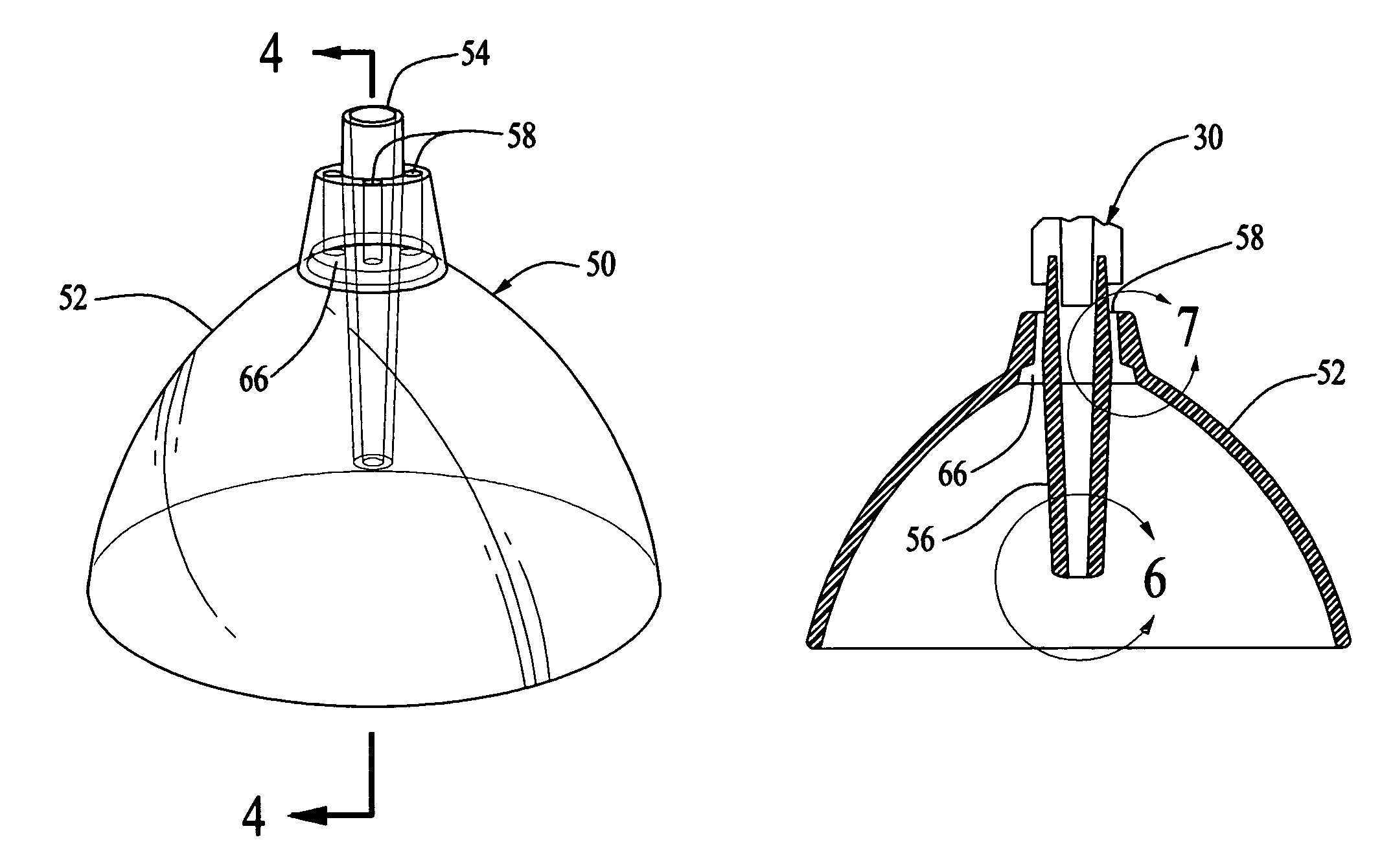

Wound irrigation splashback shield

A splashback shield for attachment to a syringe for wound irrigation includes a generally dome-shaped shield with a conduit or tunnel through the top that narrows to form a nozzle as it extends substantially inside the shield. A number of air vents or passageways surround the conduit so when submerging and re-filling the syringe with irrigant with the shield attached any air trapped inside the shield escapes rather than drawn into the syringe. The air vents are preferably elongate tubular passageways that narrow exiting the shield, facilitating air escaping but the irrigant mixed with any blood and contamination tends not to pass through the vents. The device is an improvement over the conventional Zerowet® Splashield® product.

Owner:STAMLER KEITH

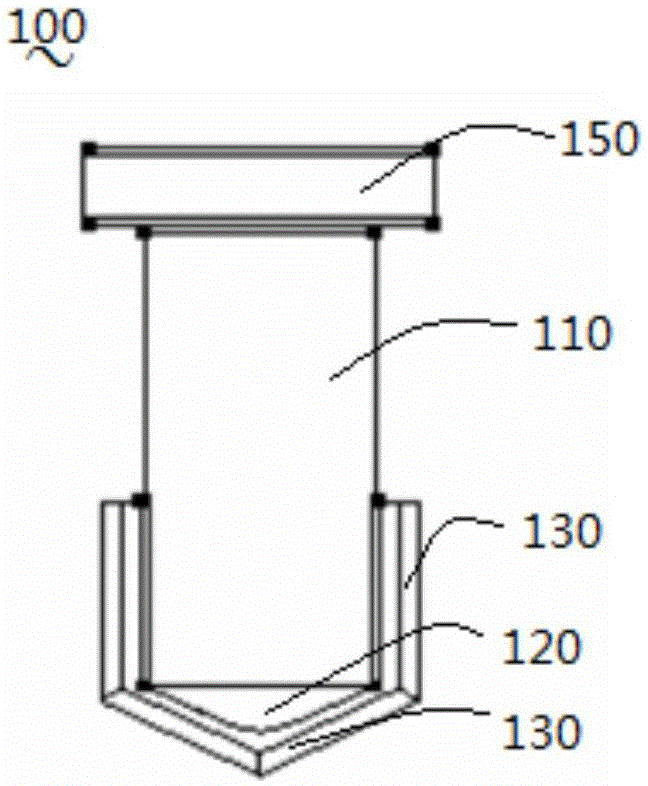

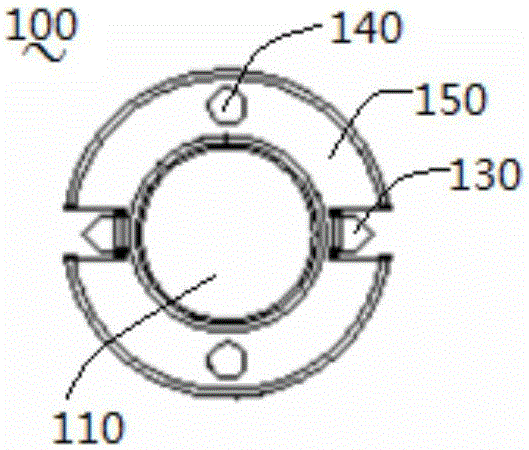

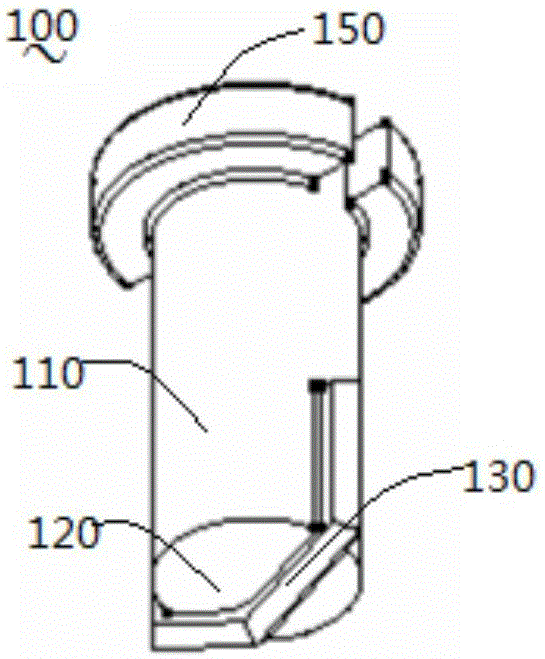

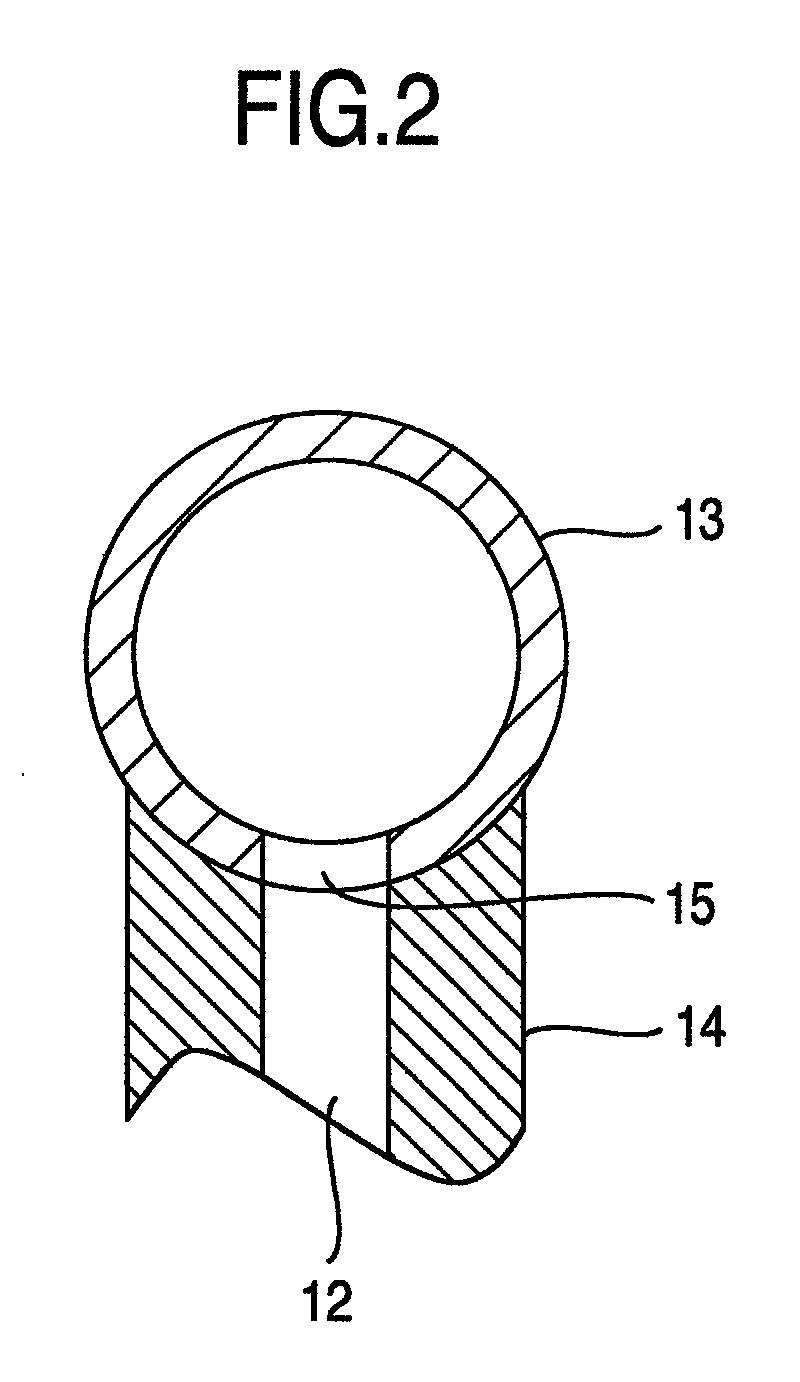

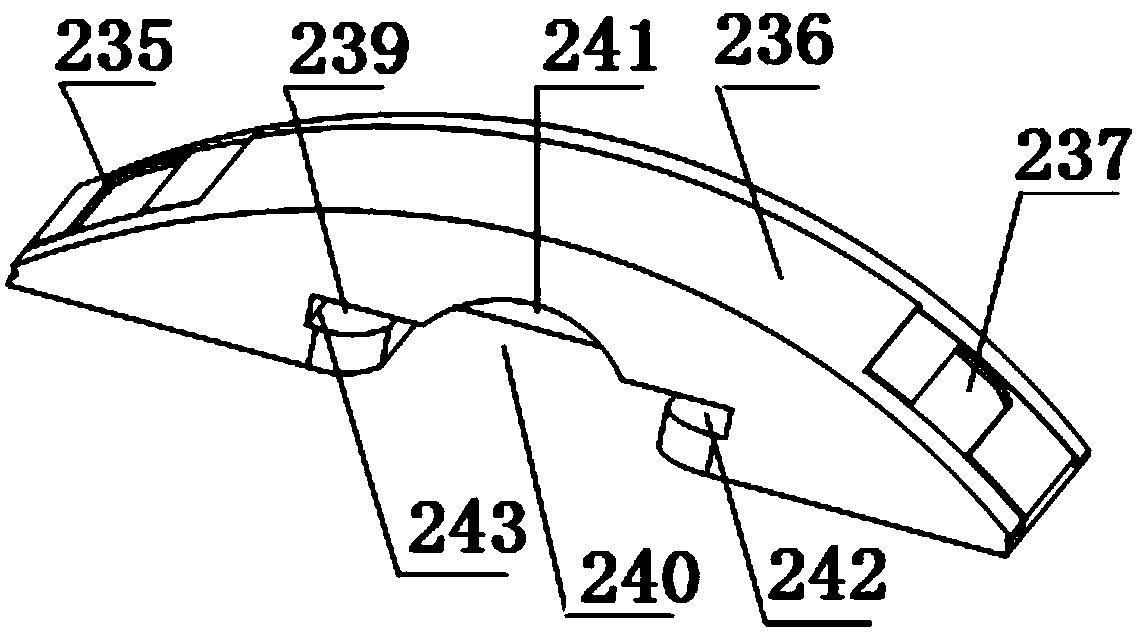

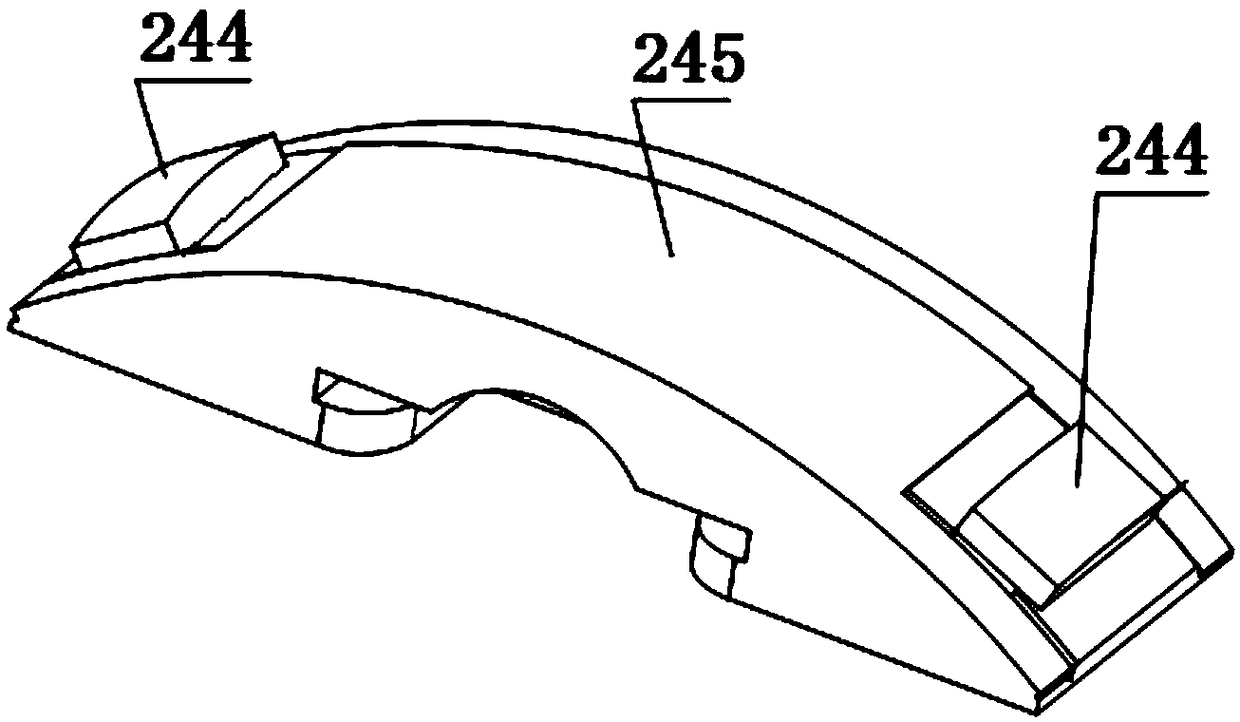

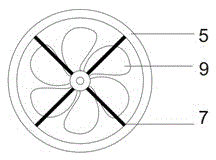

Magnetic rod pipe sleeves, multi-link assembly and nucleic acid extraction instrument

ActiveCN105062888AHigh yieldReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadRotation velocity

The invention relates to magnetic rod pipe sleeves, a multi-link assembly and a nucleic acid extraction instrument. The nucleic acid extraction instrument comprises the multi-link assembly, a fixing device and a power mechanism, wherein the power mechanism drives the magnetic rod pipe sleeves to rotate and is connected with the fixing device. The magnetic rod pipe sleeves, the multi-link assembly and the nucleic acid extraction instrument have the beneficial effects that the magnetic rod pipe sleeves on the multi-link assembly are driven by the power mechanism to rotate at high speed relative to a support plate; the rotation speeds of the magnetic rod pipe sleeves can be adjusted by adjusting the speed of the power mechanism, so that the requirement of flow of high-viscosity magnetic beads can be met; stirring structures stir reagent liquid at high speed by driving the magnetic rod pipe sleeves to rotate at high speed, thus eliminating the phenomenon of splash of the reagent liquid, widening the uniformly mixed area, fully adsorbing, washing and eluting the magnetic beads, greatly increasing the nucleic acid yield and also reducing the nucleic acid extraction instrument production cost.

Owner:苏州东胜兴业科学仪器有限公司

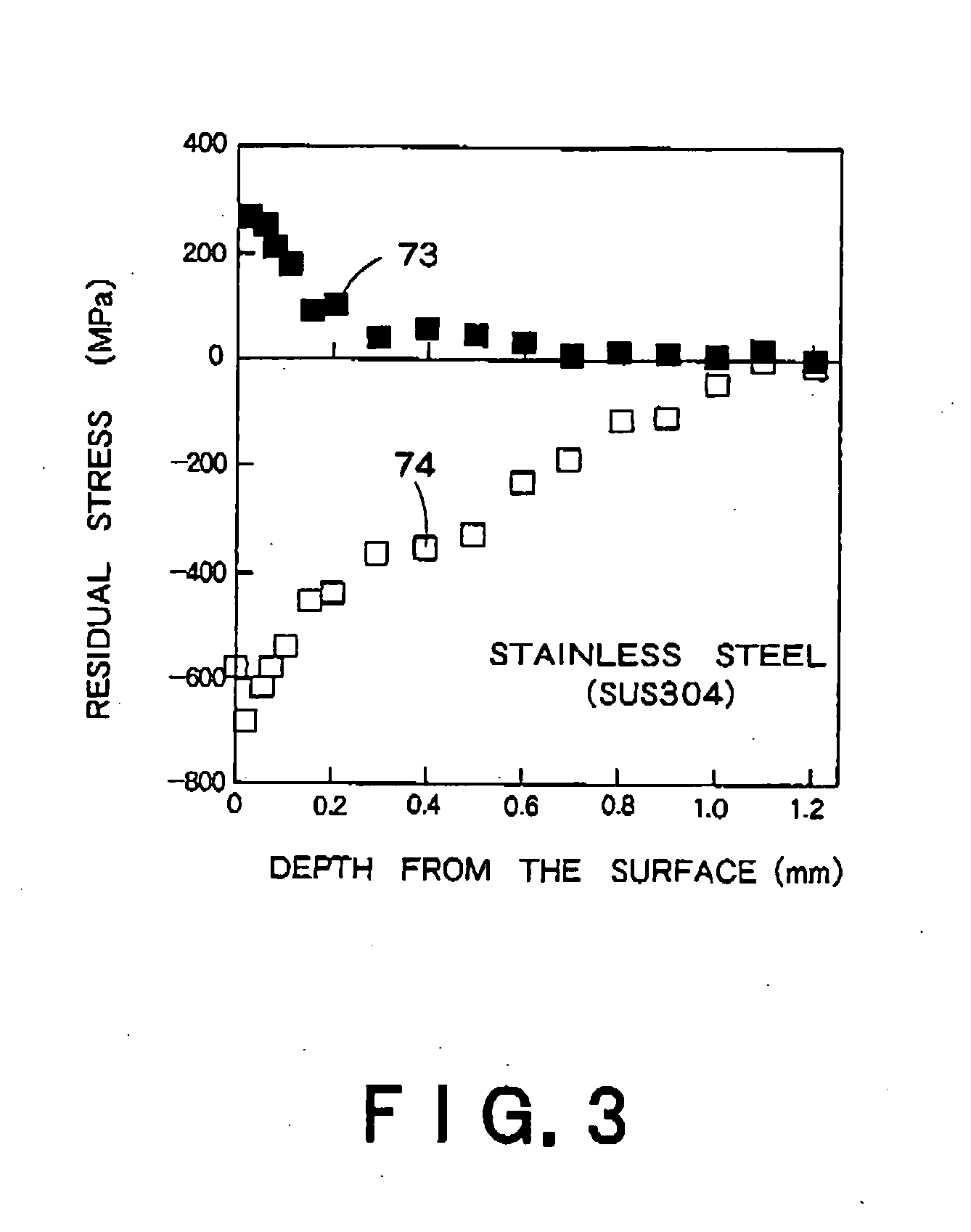

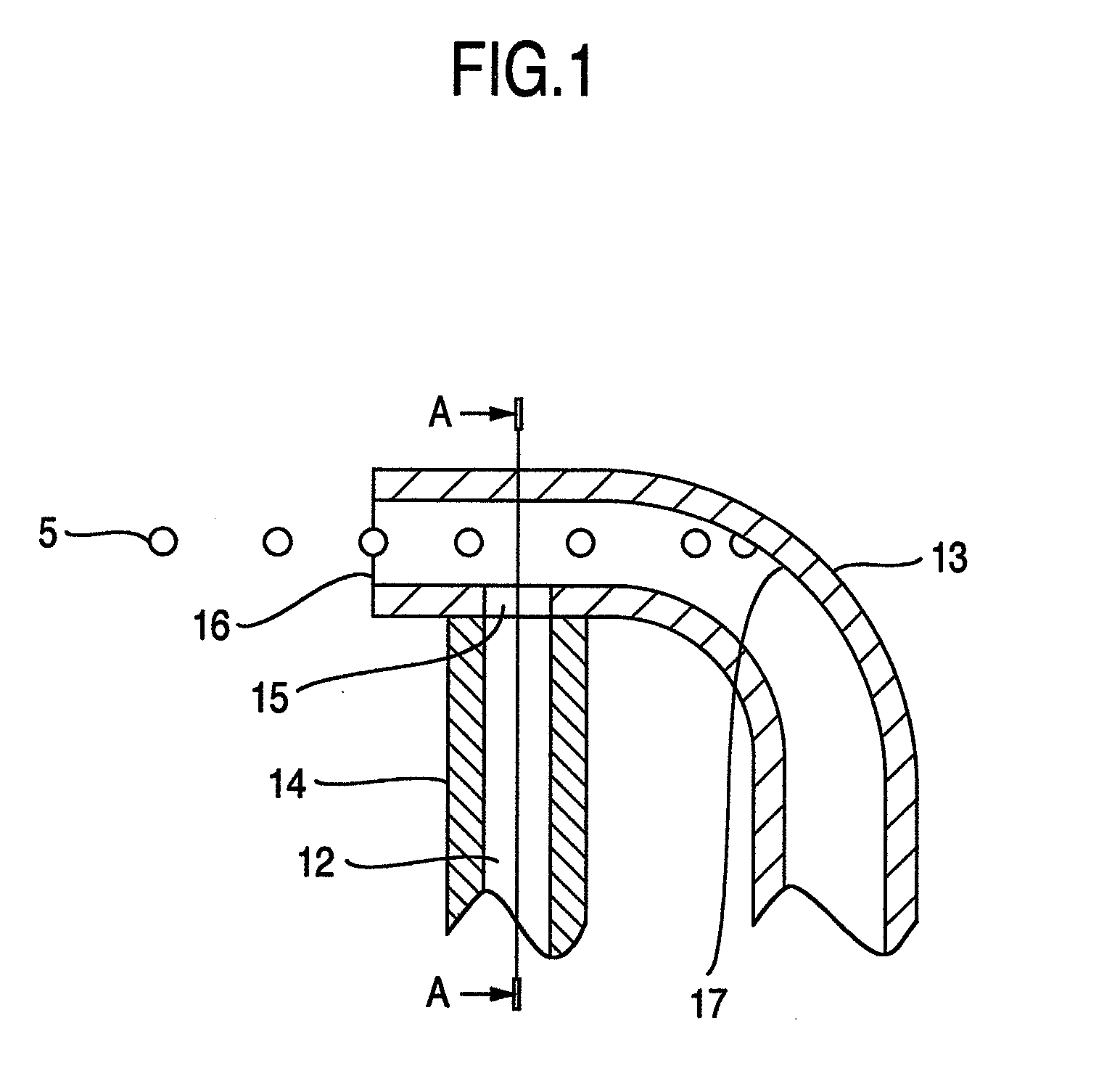

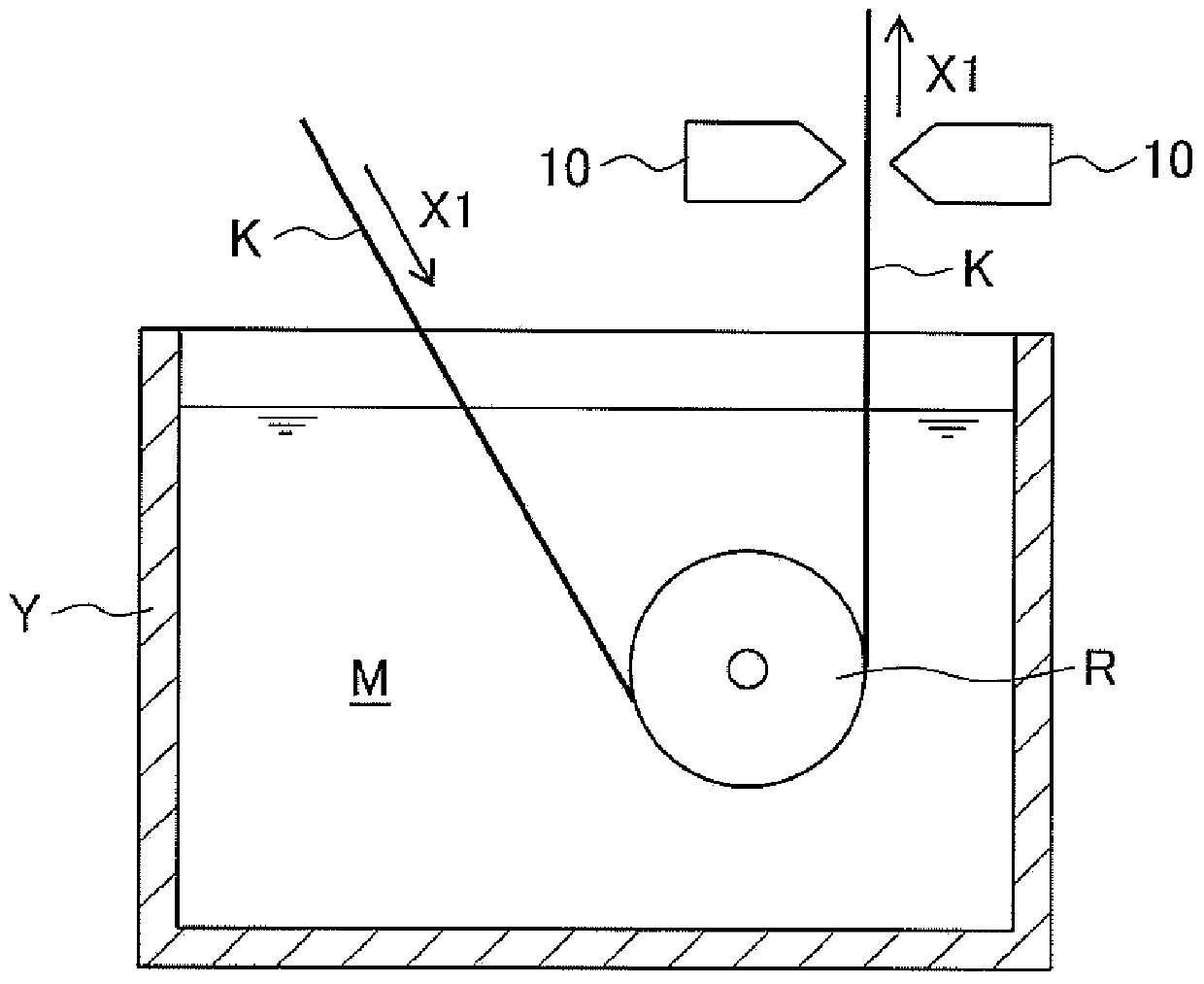

Laser shock hardening method and apparatus

ActiveUS20100170877A1High hardnessImprove residual stressArc welding apparatusHigh frequency current welding apparatusShock hardeningLight beam

There is provided an improved laser shock hardening method and apparatus which can eliminate spattering of a liquid and waving of the liquid surface upon laser irradiation, and can stably irradiate a workpiece with a laser beam. Thus, the present invention provides in a laser shock hardening method for carrying out surface processing of a workpiece in contact with a liquid by irradiating through the liquid the surface of the workpiece with a pulsed laser beam intermittently emitted from a laser irradiation device, the improvement comprising: providing a solid transparent to the wavelength of the laser, serving as an entrance window to the surface of the liquid; allowing the liquid to be present in the light path of the laser beam between the solid and the surface of the workpiece; and allowing the laser beam to enter through the solid and irradiating through the liquid the surface of the workpiece with the laser beam, thereby shock-hardening the surface of the workpiece.

Owner:KK TOSHIBA

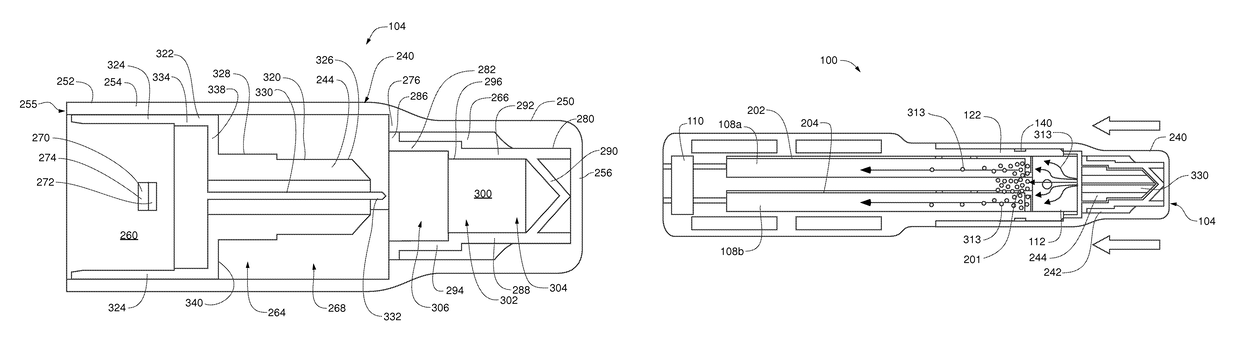

Multi-stage oral-fluid testing device

ActiveUS10035146B2Easy to useTest accurateSurgeryVaccination/ovulation diagnosticsColor changesVisual perception

In an embodiment, the claimed invention includes an oral-fluid collection and testing device that. is simple to operate. The device includes a body assembly and a cap assembly that are easy to handle by a user. A collection sponge projects from an end of the body assembly for absorbing the oral fluid of a donor, A cap assembly is easily aligned with the body assembly by way of visual alignment indicators on both the body and the cap. Once the cap is aligned with the body, a user simply pushes the cap onto the ‘body, which causes a first stage fluid, flow. More specifically, a buffer fluid is released from the cap and mixes with the oral fluid collected on the sponge—After waiting a short time* the cap is rotated, then pushed again, causing a second-stage fluid flow in which the sponge is compressed such that the buffer fluid / oral fluid exits the sponge and flows toward a. pair of test strips. A user can then easily view the test results by observing a visual indication, such as a color change of the test strips through a viewing window.

Owner:PREMIER BIOTECH LLC

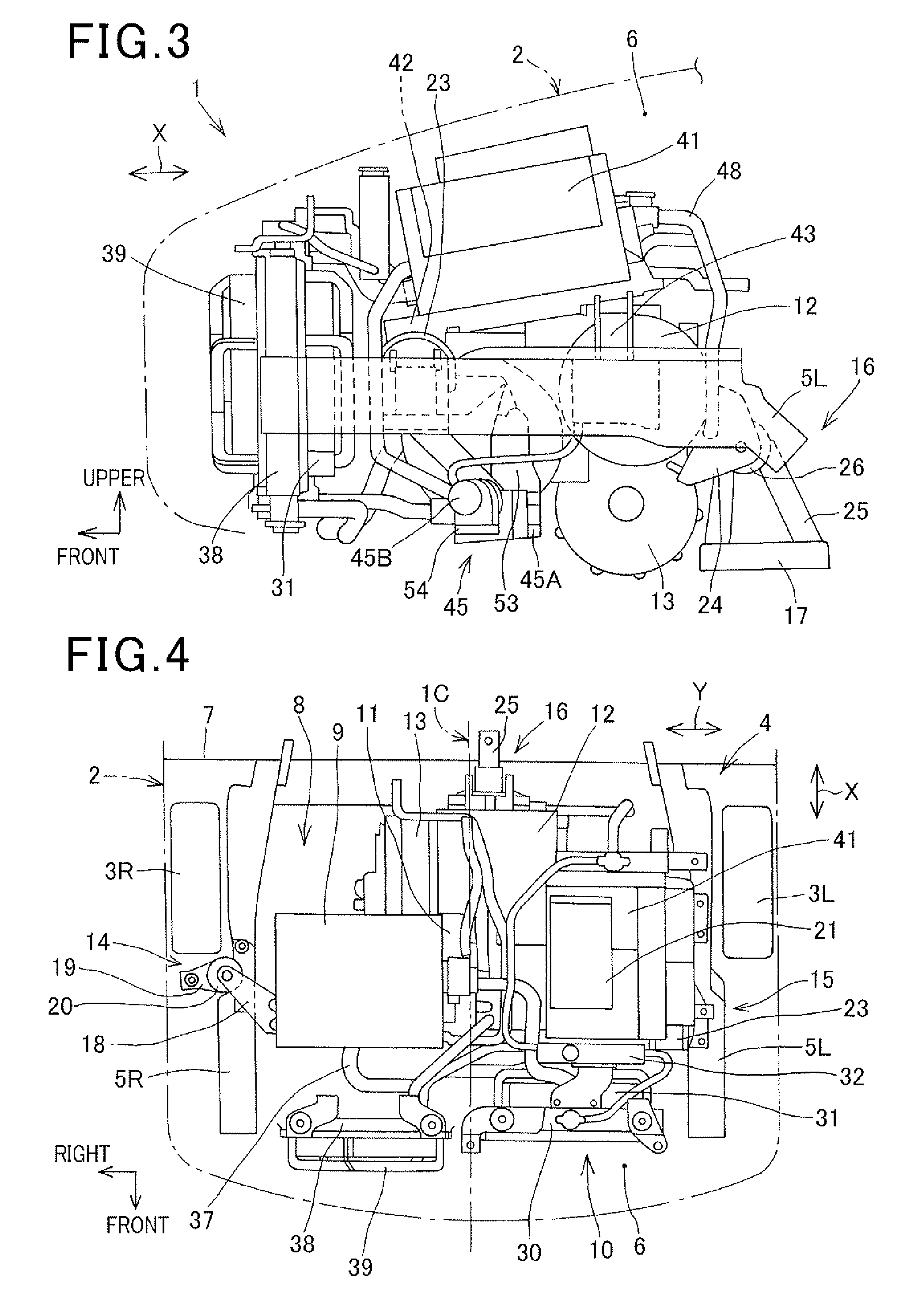

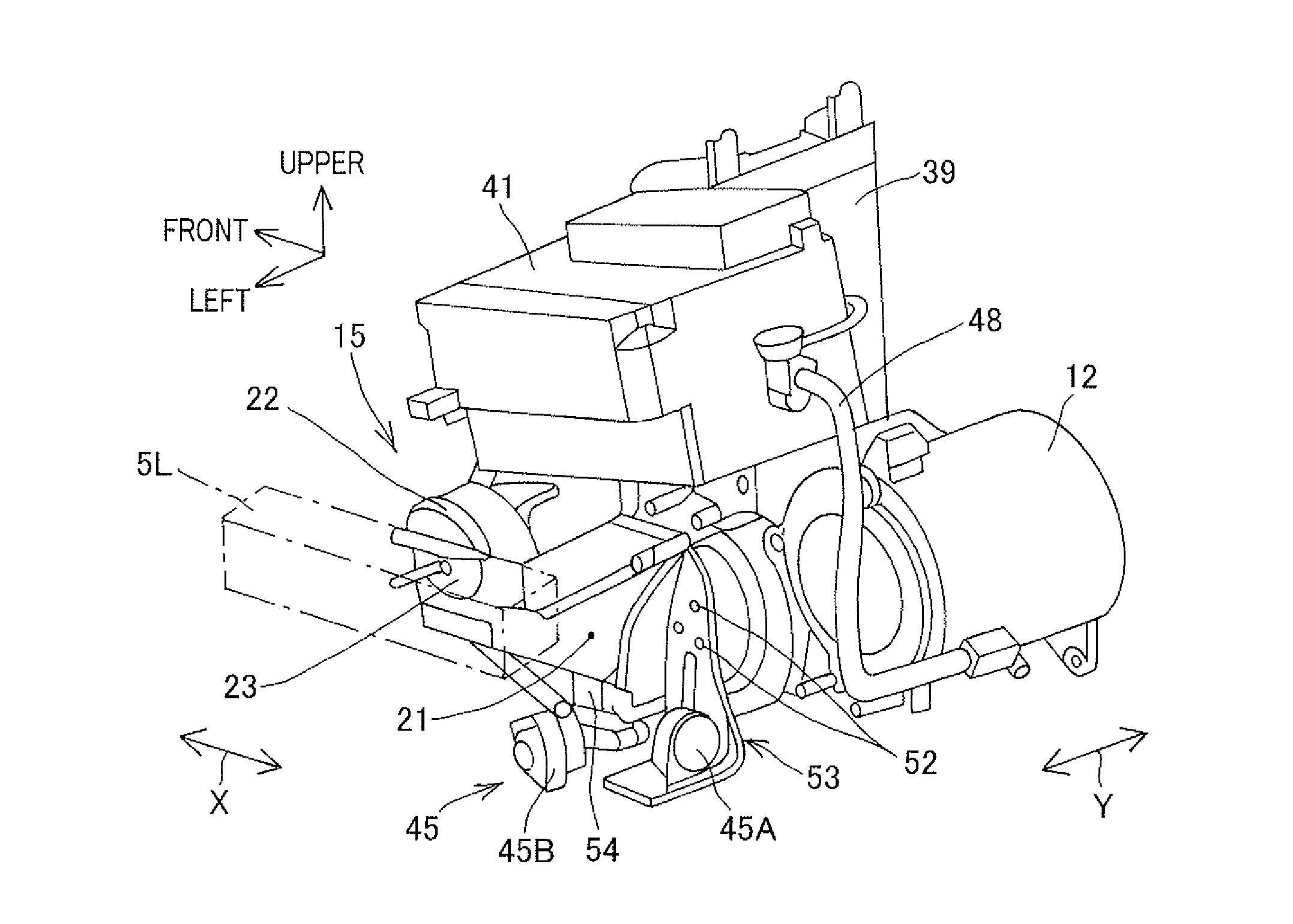

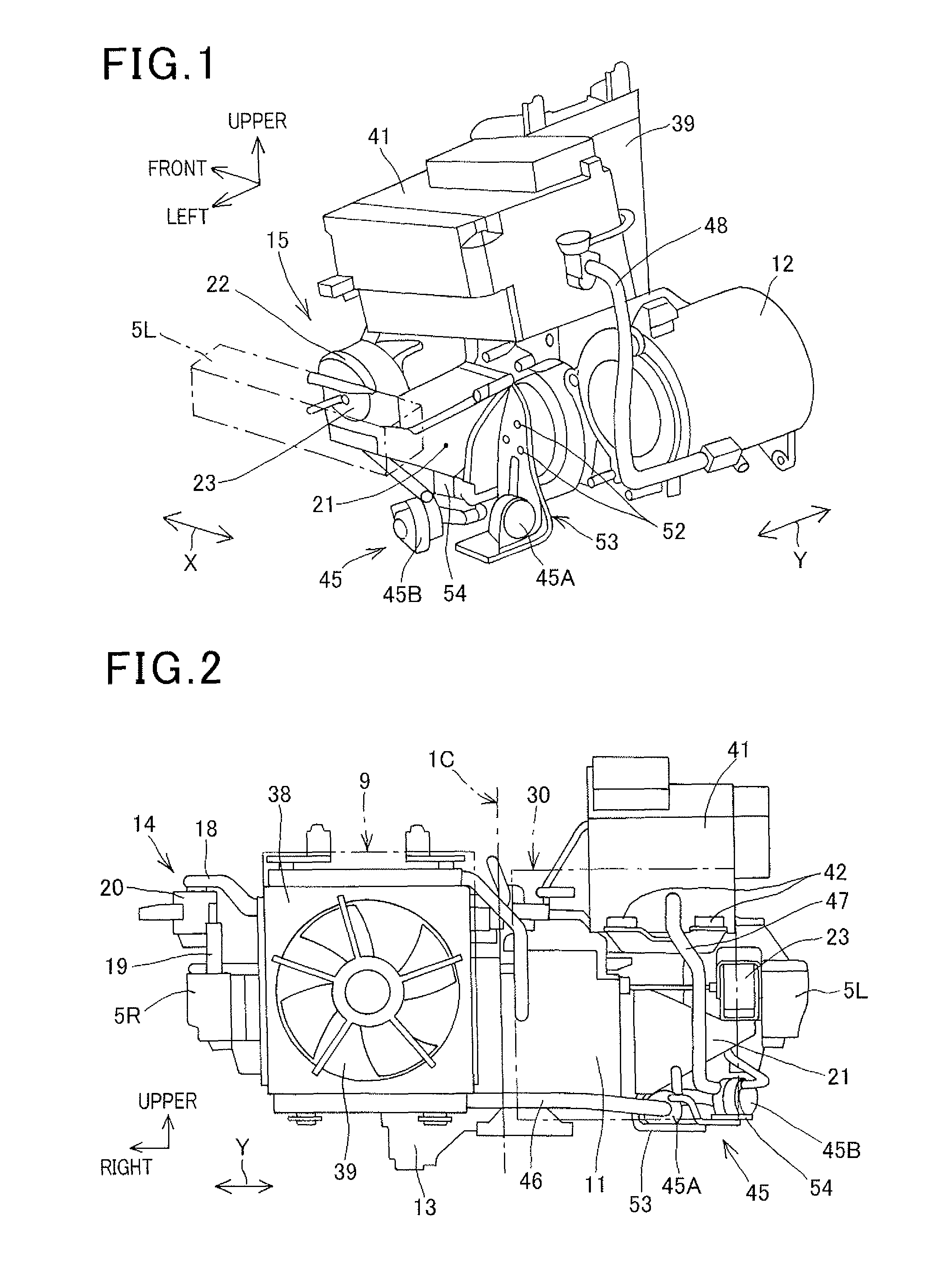

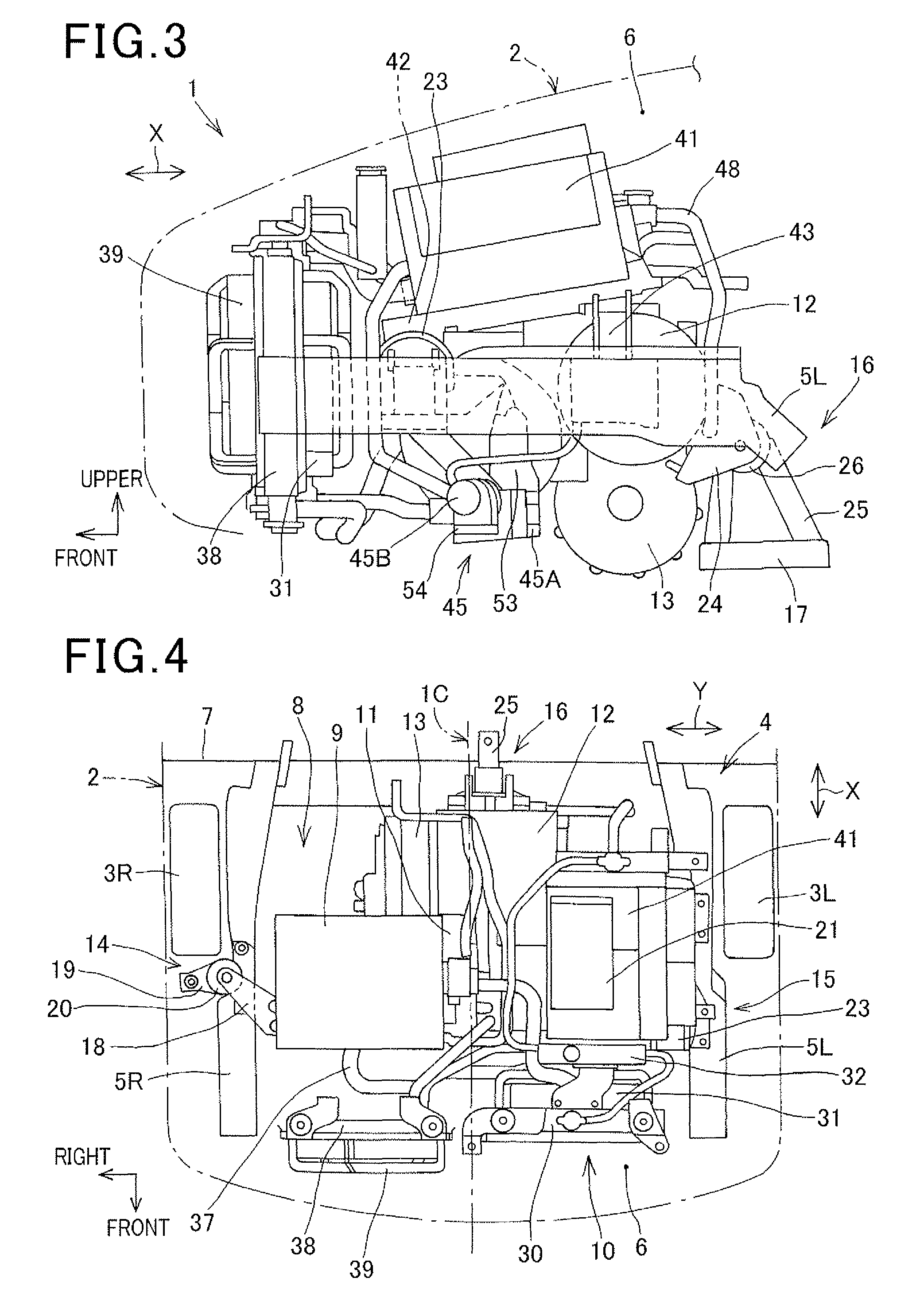

Hybrid vehicle cooling apparatus

InactiveUS20110073394A1Eliminate splashElectric propulsion mountingPropulsion using engine-driven generatorsHybrid vehicleDynamo

In cooling apparatus for a hybrid vehicle having driving apparatus including a generator driven by an engine and an electric motor (12) for driving the vehicle, the driving apparatus, a radiator arranged in a front portion of an engine compartment and an inverter (41) are coupled by a cooling circuit for the motor equipment. An electric water pump (45) for circulating cooling water is arranged in the cooling circuit. Mounting apparatus (15) for supporting the driving apparatus to the vehicle body is arranged laterally in the vehicle width direction of the driving apparatus. The electric water pump (45) is arranged under the mounting apparatus (15). By the use of such a structure, a situation in which the electric water pump (45) gets sandwiched between the engine radiator which has been shifted backwardly in the presence of an external force acting from the front of the vehicle, and the driving apparatus and gets damaged can be prevented.

Owner:SUZUKI MOTOR CORP

Press-in treatment process method for iron notch sputtering of blast furnace

InactiveCN103114160AImprove the operating environmentImprove smelting safety performanceDischarge devicesBrickControl system

The invention relates to a press-in treatment process method for the iron notch sputtering of a blast furnace, which is characterized in that a special refractory material for an iron notch is pressed into the cold surface and the heat surface of a cooling wall, iron notch combined bricks, and the cracks and the defects of iron notch channel brick ladles via a press-in equipment unit and by adopting the process steps of iron notch cleaning, iron notch sealing plate welding, furnace shell pore opening, and pressure and feed quantity control. The highest pressure of construction equipment is controlled to be not greater than 30 MPa, the pressure of furnace shell press-in holes is controlled to be 1-5 MPa, the press-in quantity of the refractory material is adjusted and controlled via a press-in equipment control system, the press-in speed is controlled to be in a range from 10 to 75 kg per minute, and is steplessly adjusted. The invention discloses a press-in treatment process method which is low in cost and short in furnace blowout time, for the iron notch sputtering of a blast furnace, wherein via the press-in treatment process method, coal gas blowby channels are blocked and sealed, so as to achieve prevention for coal gas blowby in an iron notch area, eliminate the phenomenon of iron notch sputtering, ensure the smooth iron tapping of the iron notch, and improve the operating environment and the smelting safety performance of the blast furnace.

Owner:BEIJING RUIPU TONGCHUANG TECH DEV

Hybrid vehicle cooling apparatus

InactiveUS8485292B2Eliminate splashElectric propulsion mountingGas pressure propulsion mountingHybrid vehicleHeat spreader

In cooling apparatus for a hybrid vehicle having driving apparatus including a generator driven by an engine and an electric motor (12) for driving the vehicle, the driving apparatus, a radiator arranged in a front portion of an engine compartment and an inverter (41) are coupled by a cooling circuit for the motor equipment. An electric water pump (45) for circulating cooling water is arranged in the cooling circuit. Mounting apparatus (15) for supporting the driving apparatus to the vehicle body is arranged laterally in the vehicle width direction of the driving apparatus. The electric water pump (45) is arranged under the mounting apparatus (15). By the use of such a structure, a situation in which the electric water pump (45) gets sandwiched between the engine radiator which has been shifted backwardly in the presence of an external force acting from the front of the vehicle, and the driving apparatus and gets damaged can be prevented.

Owner:SUZUKI MOTOR CORP

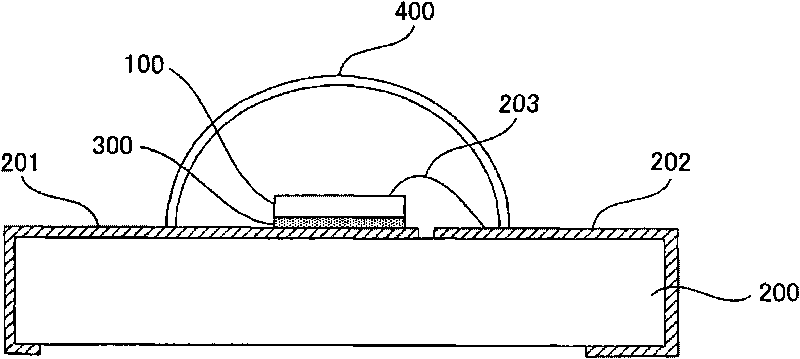

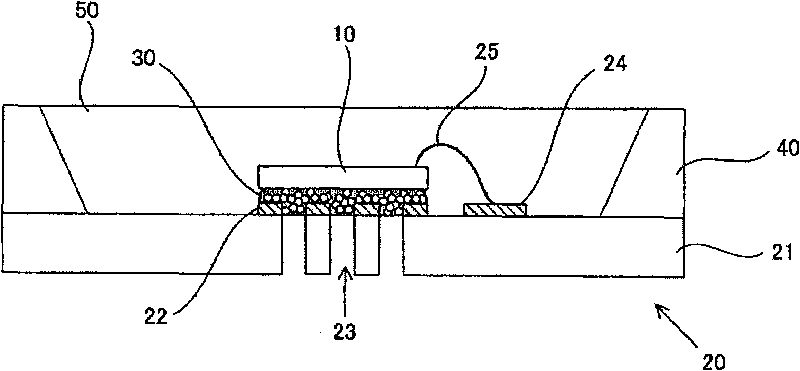

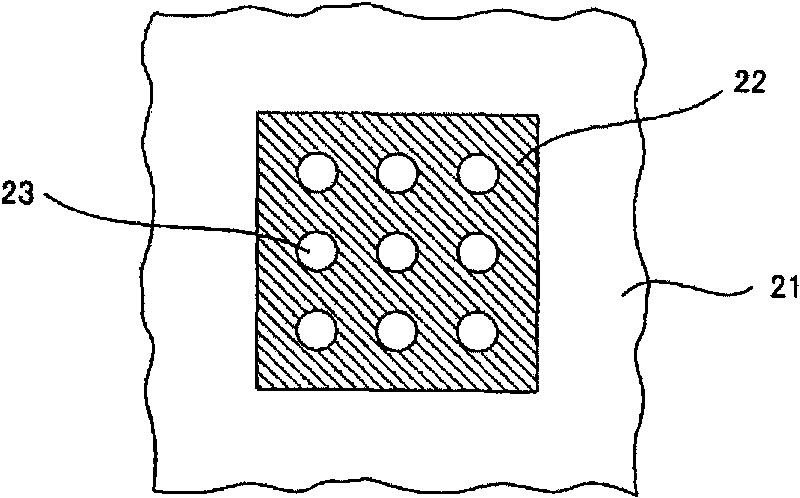

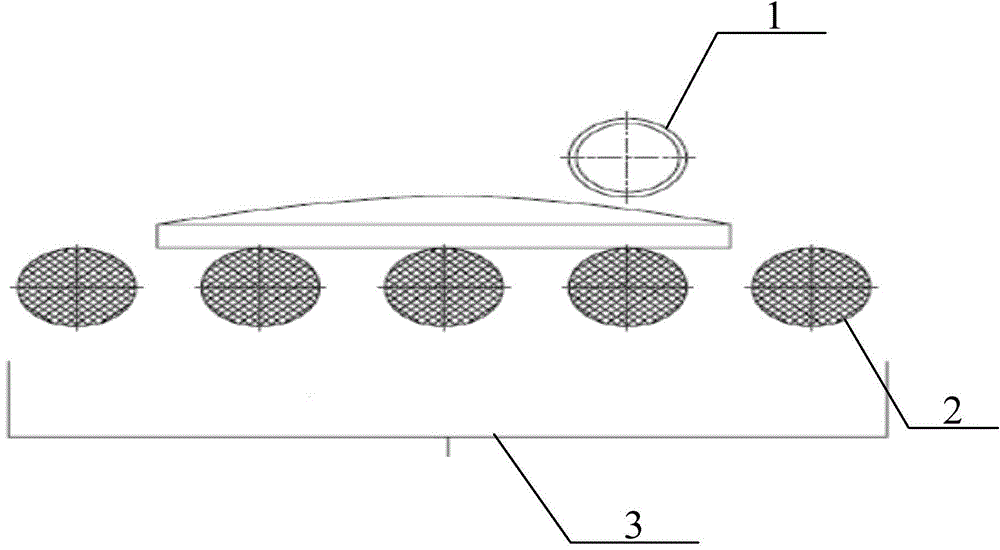

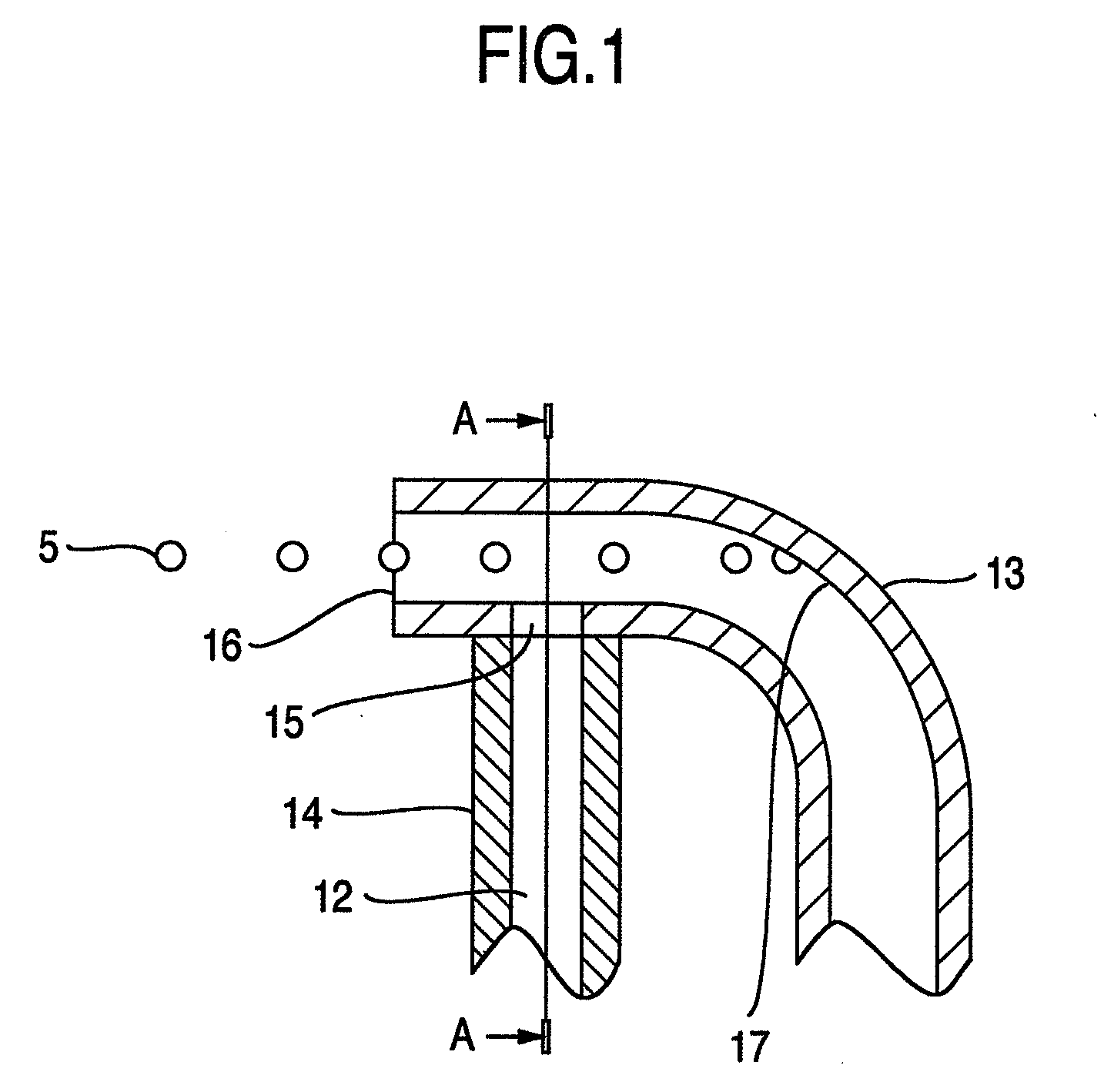

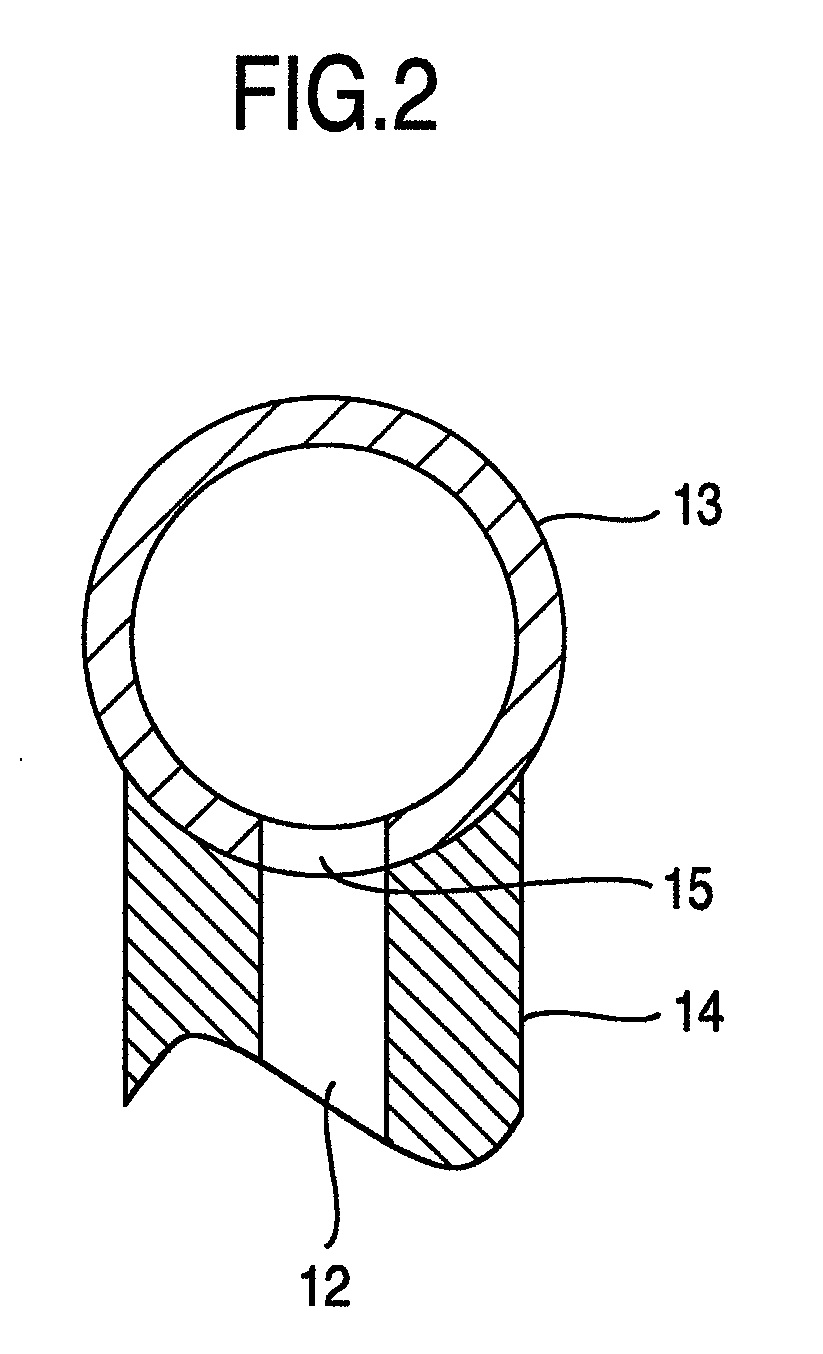

Optical semiconductor apparatus and method for producing the same

ActiveCN101740709AEliminate splashReduce reflow timeSolid-state devicesSemiconductor devicesEngineeringSolder paste

An optical semiconductor apparatus can be configured by mounting an optical semiconductor element on a package substrate using a solder paste. The optical semiconductor apparatus can include a package substrate and a metal die pad formed on the substrate, and an optical semiconductor element bonded to the die pad with a solder material. The substrate can be made of a ceramic base material. A plurality of through holes can be formed in the substrate so that the through holes penetrate both the substrate base material and the die pad. Each of the through holes can have an inner surface where the ceramic base material is exposed. Each through hole can have an opening diameter greater than or equal to 40 [mu]m and less than or equal to 100 [mu]m. The plurality of through holes can be formed such that the total area of the openings of the through holes is 50% or less of the bonded area between the optical semiconductor element and the die pad including the through holes covered with the solder material. The through holes can be covered with the solder material at the upper end thereof where the optical semiconductor element and the die pad are bonded to each other.

Owner:STANLEY ELECTRIC CO LTD

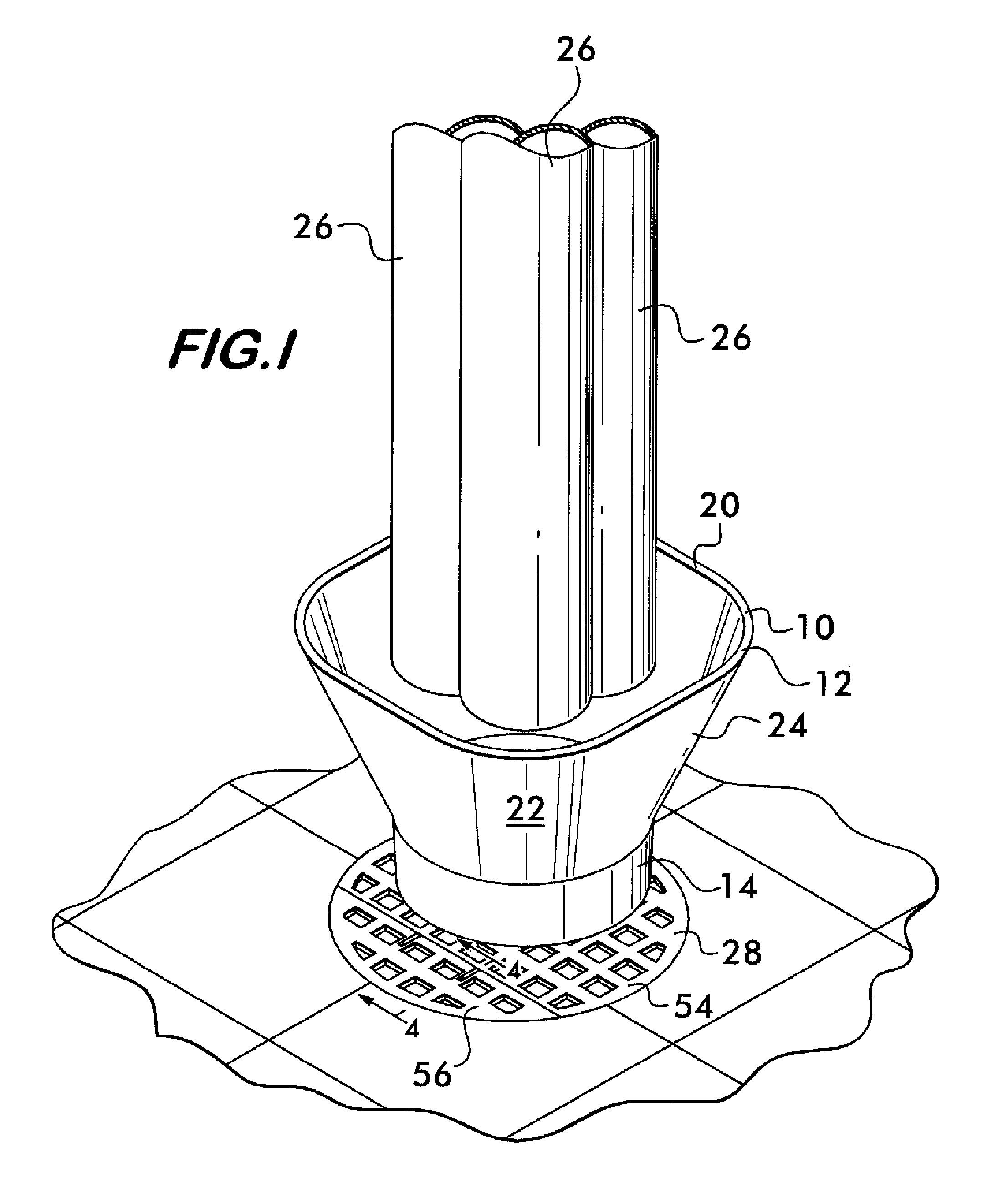

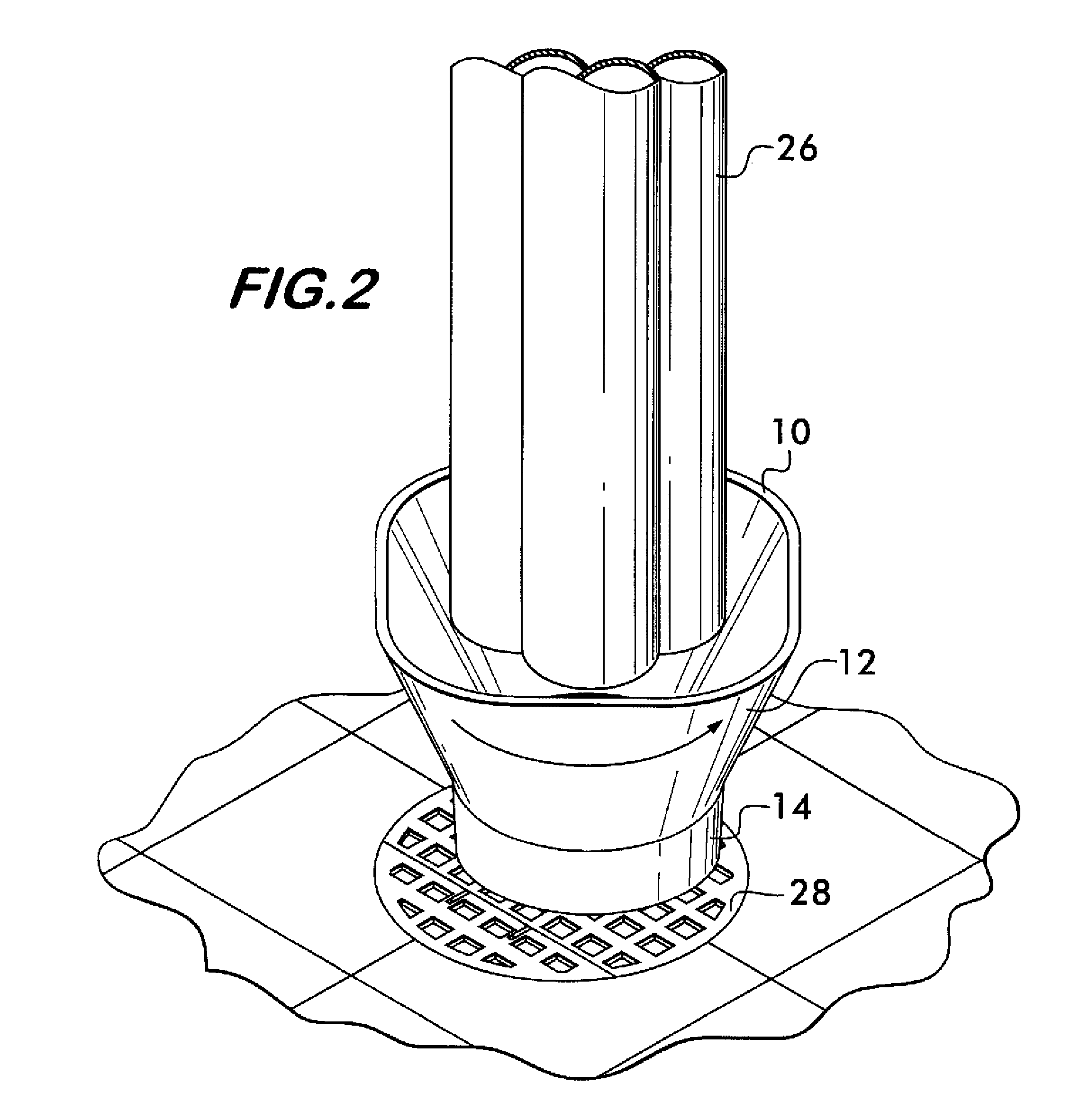

Removable drain funnel

InactiveUS8857481B2Easy to engageEasy to disassembleFatty/oily/floating substances removal devicesTableware washing/rinsing machine detailsEngineeringTube drain

Owner:FRANKLIN MACHINE PRODS

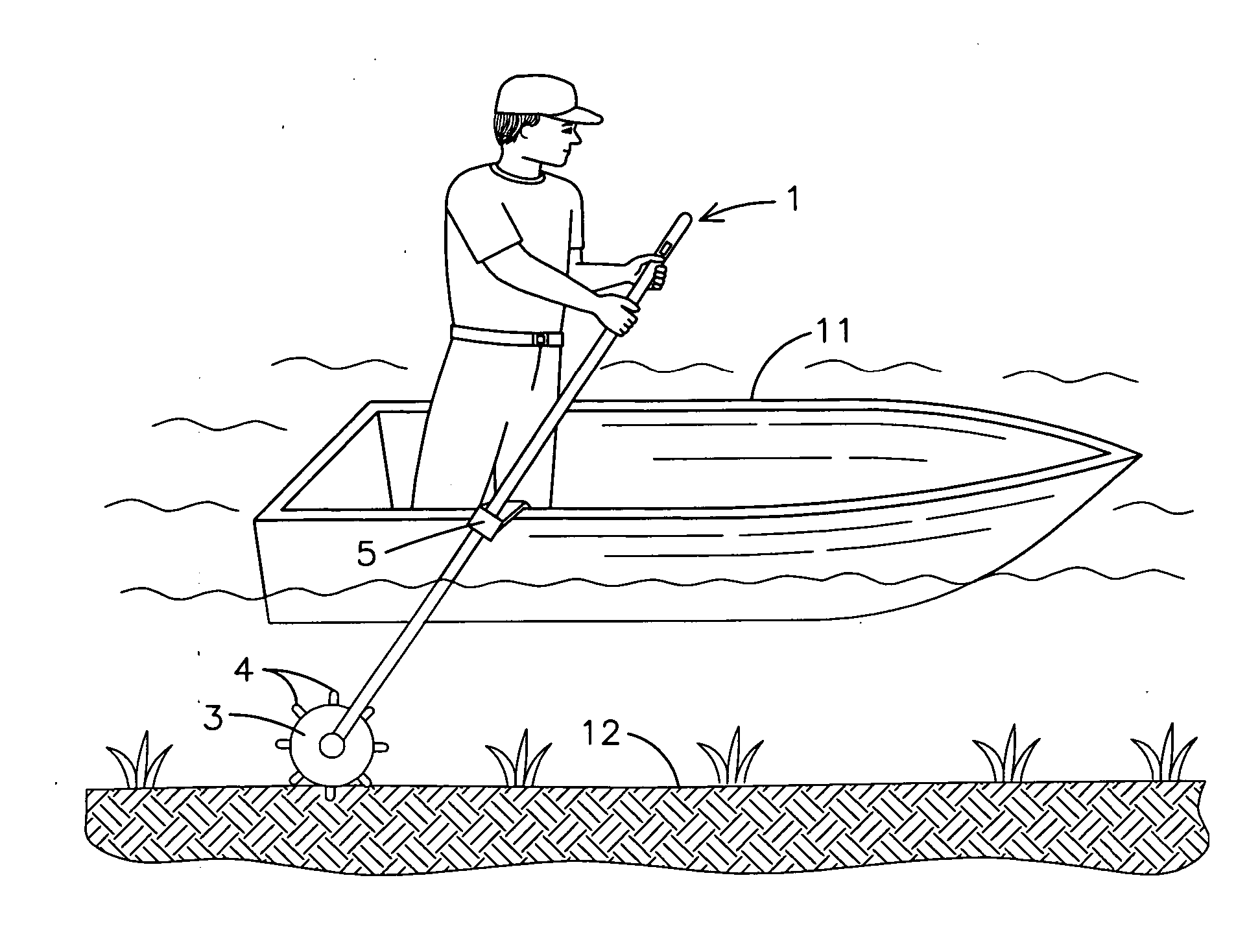

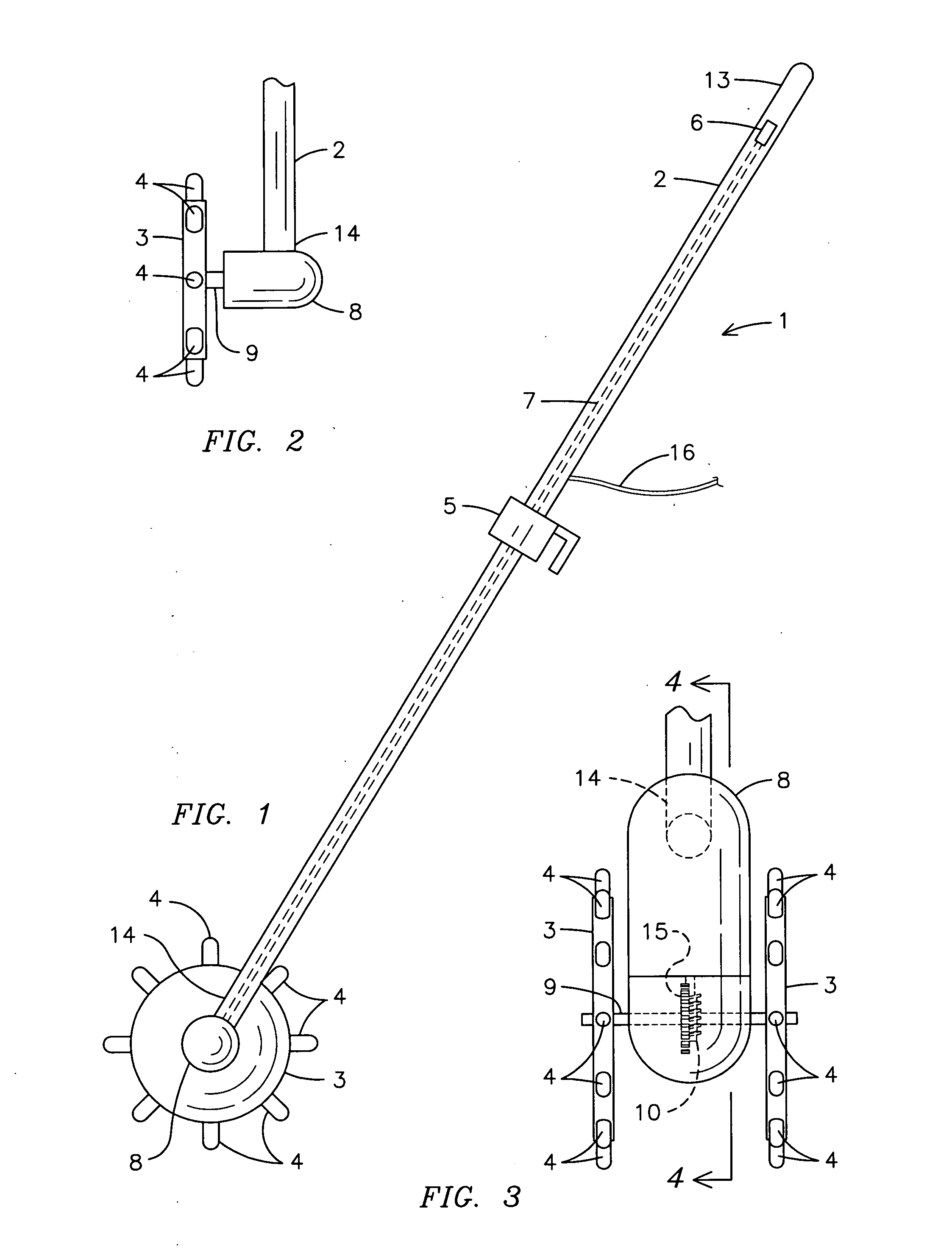

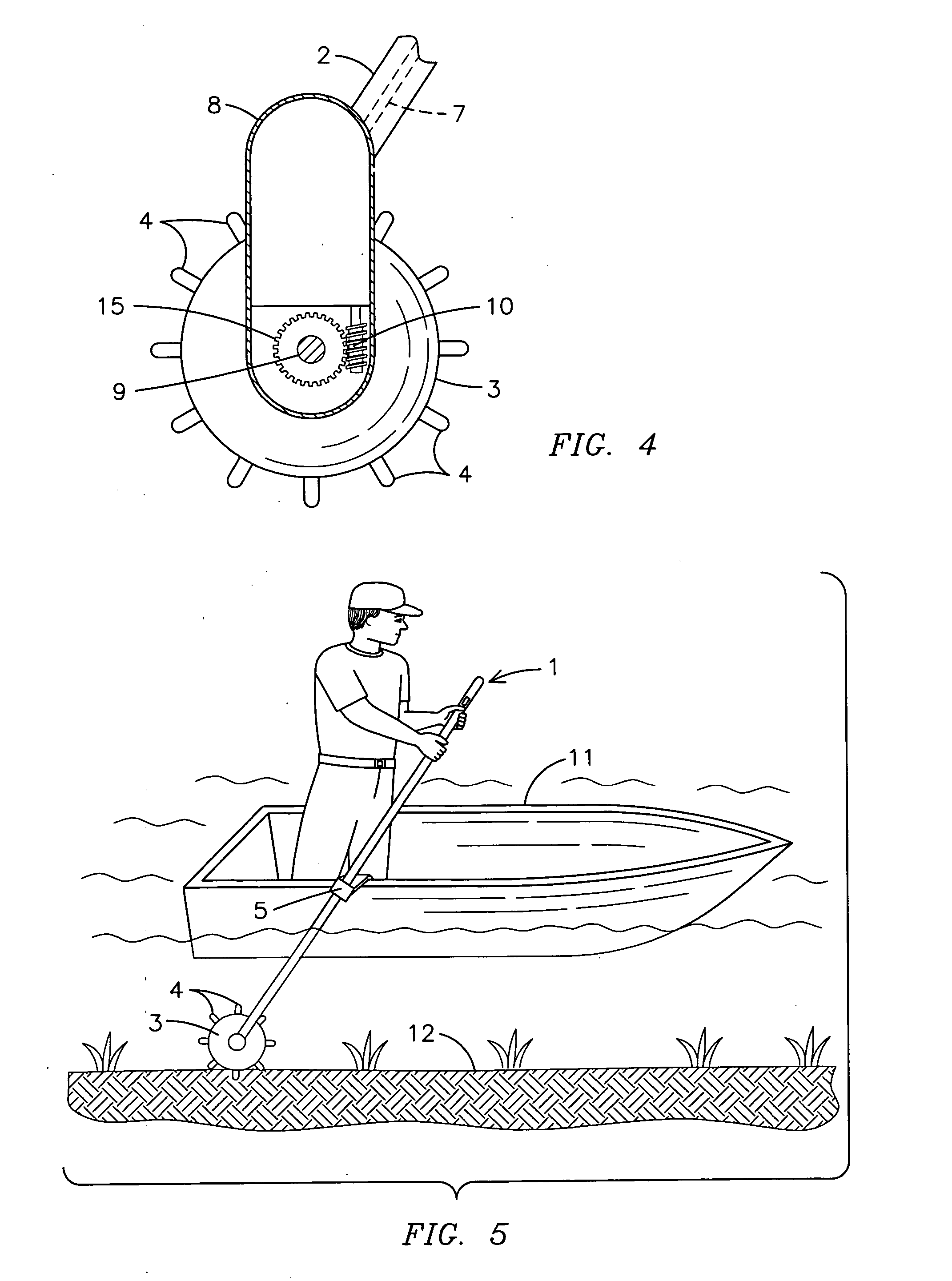

Power push pole

InactiveUS20070202756A1Easily push a boatEasy to useMuscle power acting propulsive elementsDrive wheelEngineering

A power push pole (1) having an elongated pole with a proximal end (13) and a distal end (14) wherein at least one drive wheel (3) with extending members (4) is located at the distal end (14) of the pole (1). An electric motor (8) is preferably located adjacent to the wheel (3) and is operable via at least one control (6) located on the proximal end (13) of the pole (1). Alternate embodiments of the invention include the use of dual wheels (3) for added stability, interchangeable extending members (4) and drive wheels (3) to accommodate varying ground textures, speed controls and forward / reverse controls. In addition, the power push pole (1) may be secured to a boat (11) via a fastener, such as a bracket (5).

Owner:HARDWICK CHARLES W

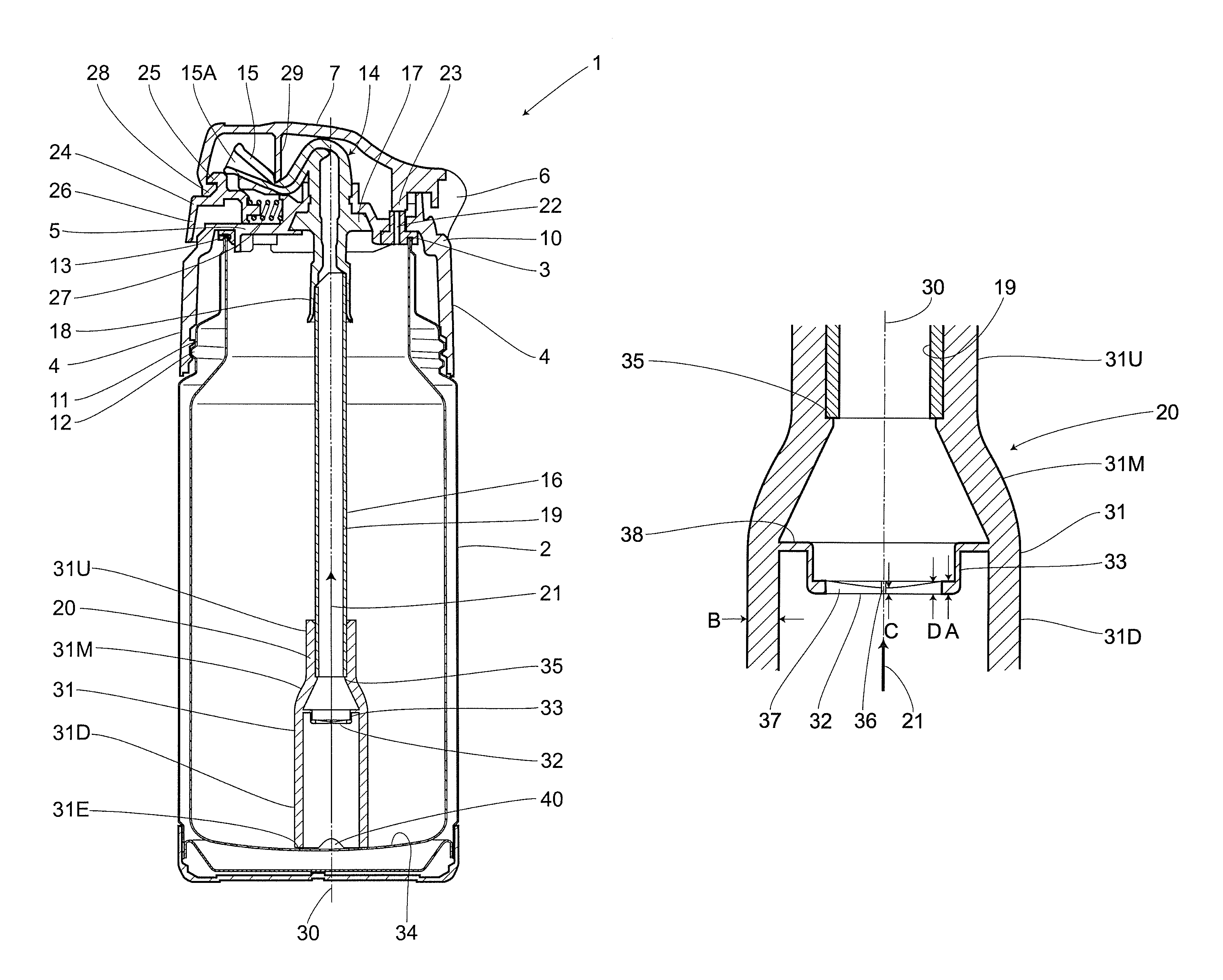

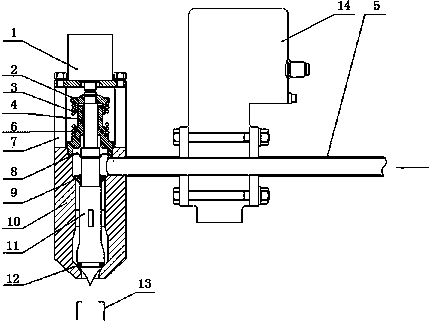

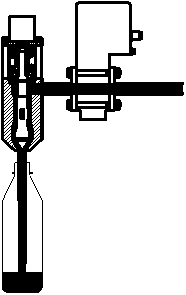

Liquid filling valve and operating method thereof

The invention provides a liquid filling valve and an operating method thereof. The liquid filling valve comprises a valve body, wherein a valve core is arranged in the valve body, the top of the valve body is sealed by a sealing diaphragm of the valve core, a discharge opening which is aligned with a container is formed in the bottom of the valve body, a filling channel is formed between the inner wall of the valve body and the valve core, the filling channel is connected to a feed pipe by virtue of a flowmeter, and a push device which is used for pushing the sealing diaphragm of the valve core to move is arranged on the top of the valve body. The liquid filling valve is characterized in that a pre-closed valve clack sleeves the upper part of the valve core, a clearance is left between the valve core and the pre-closed valve clack, the pre-closed valve clack can freely move up and down along the valve core, and a valve port sealing ring is arranged between the bottom of the valve core and the discharge opening in the lower end of the valve body. The liquid filling valve has the advantages of sanitation, no cleaning dead angle and low cost, and the splashing phenomenon is fully eliminated when the filling valve is closed.

Owner:南京保立隆包装机械有限公司

Ink Jet Recording Device

An ink jet recording device comprises a main body equipped with an ink container, an ink supply pump ink, an ink recovery pump, and a control unit. A printing head equipped with a nozzle emits ink supplied from the main body as ink particles. An electrification electrode electrifies the ink particles and a deflection electrode deflects the electrified ink particles. A gutter collects ink particles which are not used for printing. An exhaust circulation path connects the ink container and the gutter. The gutter comprises two members of an ink flow path block in which ink flows and an exhaust flow path block in which exhaust solvent vapor flows.

Owner:HITACHI IND EQUIP SYST CO LTD

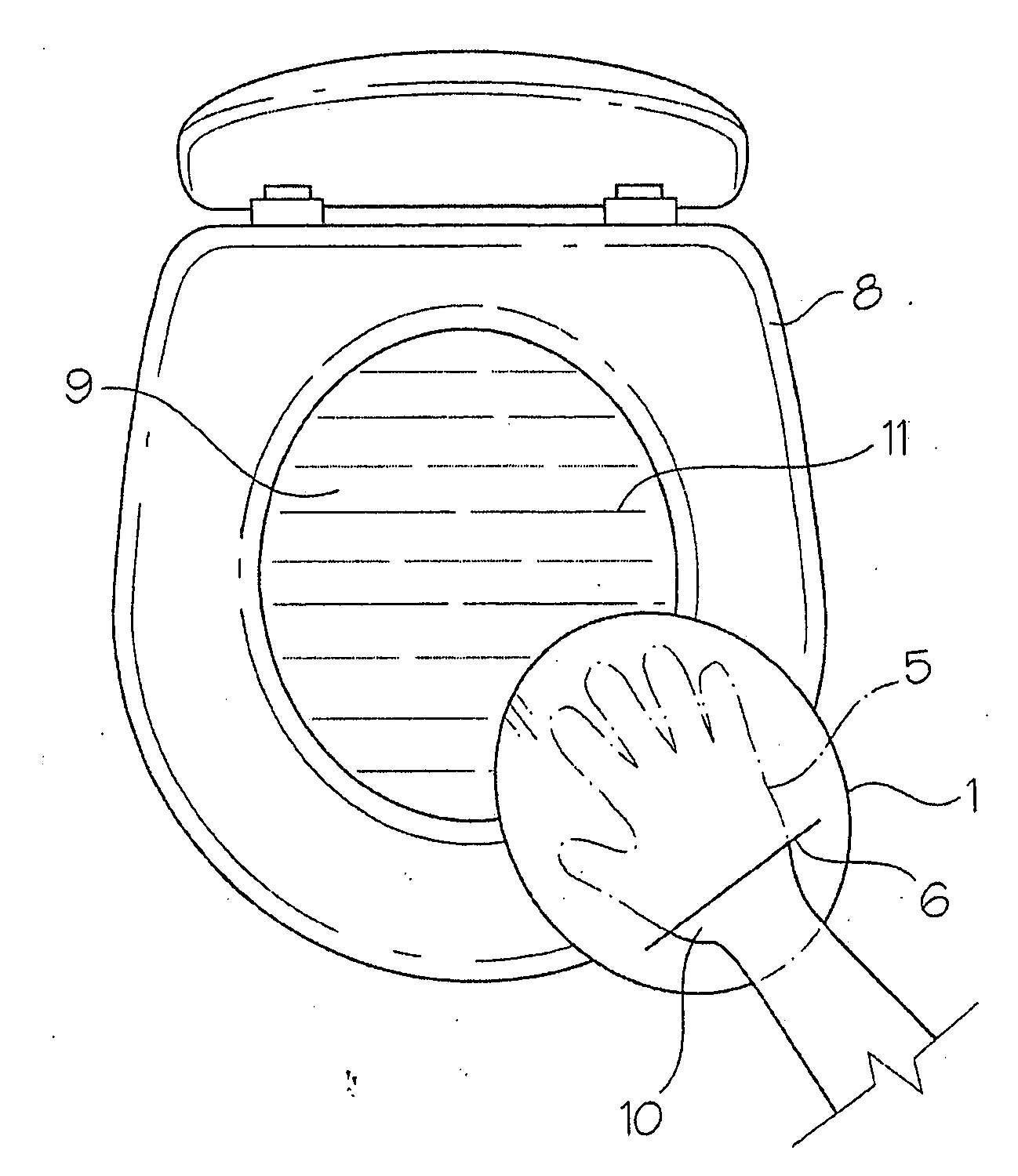

Toilet cleaning pad and splash guard

A combination toilet cleaning and splash preventing device includes a sheet of biodegradable material which may be laminated for floating at least temporarily on the surface of the water in a toilet bowl and a pocket in the sheet of material for receiving a portion of the hand of a user, whereby the device can be used to wipe a toilet and / or seat before being placed on the water in the bowl to reduce or prevent splashing.

Owner:FIELD GEORGE RAYMOND

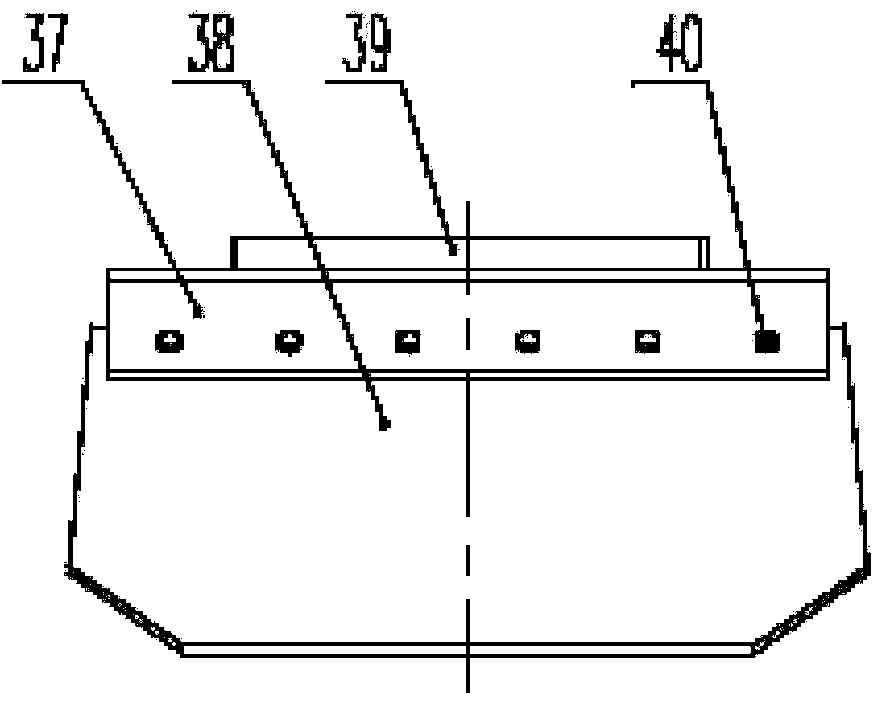

Silicon wafer and wet etching system

InactiveCN104409390AEliminate splashEliminate drippingFinal product manufactureSemiconductor/solid-state device manufacturingEtchingP–n junction

The invention provides a silicon wafer, comprising a to-be-etched silicon wafer and a water film protecting layer compounded on the diffusion surface of the to-be-etched silicon wafer. The water film protecting layer formed on the diffusion surface of the to-be-etched silicon wafer is used for protecting the silicon wafer in the subsequent etching, so that chemical liquids cannot enter the diffusion surface of the silicon wafer in the subsequent wet etching process and excessive etching regions generated in the wet etching process can be removed; the effective light interception area of PN junctions can be increased and the photoelectric conversion efficiency can be improved. The invention further provides a wet etching system, comprising a water film spraying system arranged at the feeding end of wet etching equipment.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

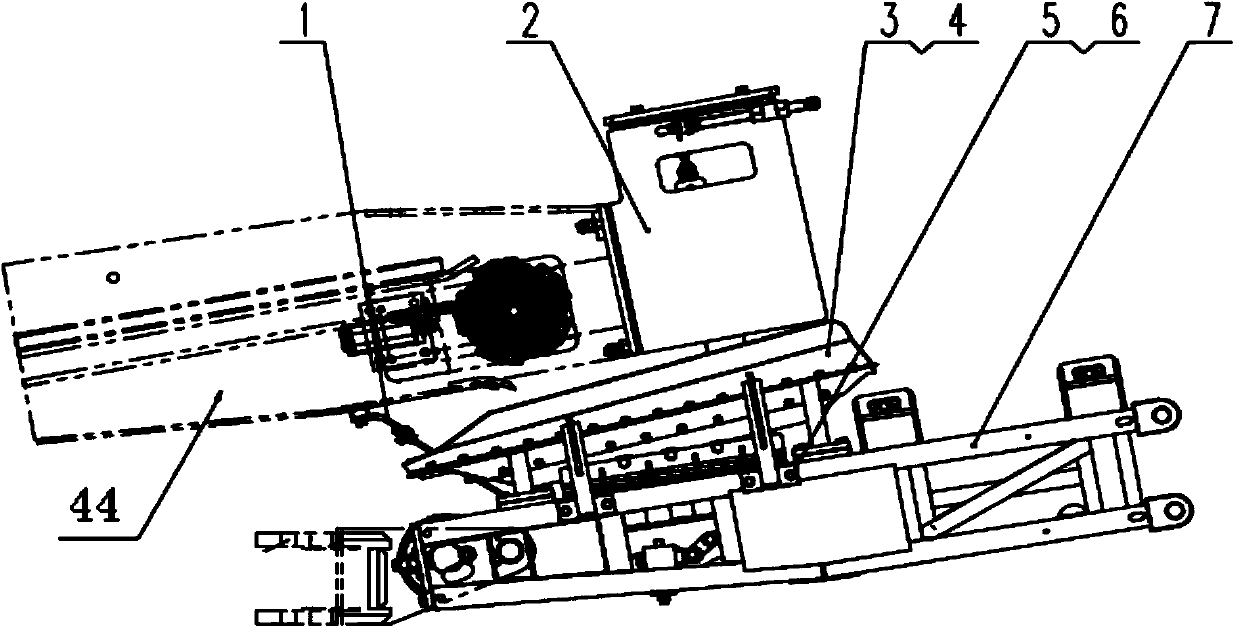

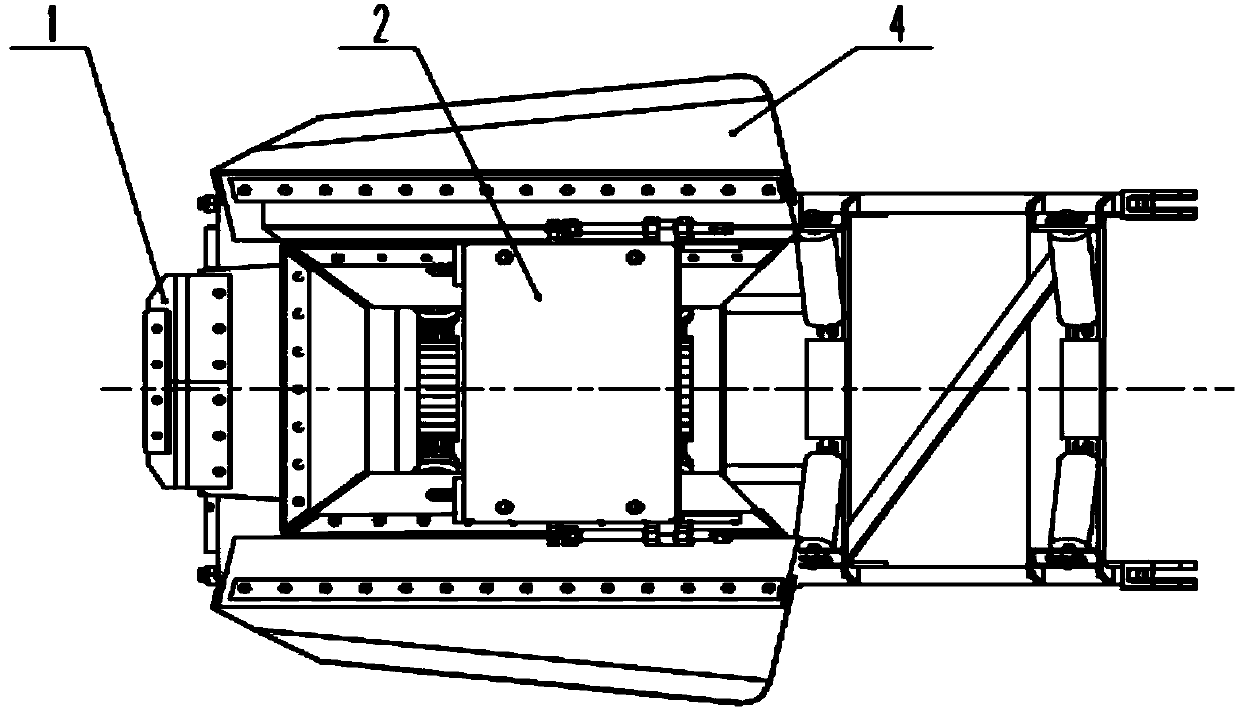

Buffering material-receiving device for coal mine

The invention discloses a buffering material-receiving device for a coal mine. The discharging end of a first conveyer (44) is connected with a buffering device (2), a buffering carrying roller (10) is arranged at the position, aligned to the outlet of the buffering device (2), of a second-conveyer tail portion (7), a rear stopping device is arranged at the rear end of the second-conveyer tail portion (7), a left stopping device (3) is arranged on the left side of the second-conveyer tail portion (7), a right stopping device (4) is arranged on the right side of the second-conveyer tail portion (7), a hopper-shaped structure is formed by the rear stopping device (1), the left stopping device (3) and the right stopping device (4), one surface of the hopper-shaped structure is open, and the open direction consists with the moving direction of a conveying belt. The buffering material-receiving device for the coal mine is simple in operation, practical, low in maintenance cost, long in service life, and ideal in buffering effect, and prevents material leakage; by means of combination of the buffering device, the stopping devices and the second-conveyer tail portion, materials are effectively buffered, and the problems of leakage and scattering of materials are solved.

Owner:ANHUI SHANHE MINING EQUIP

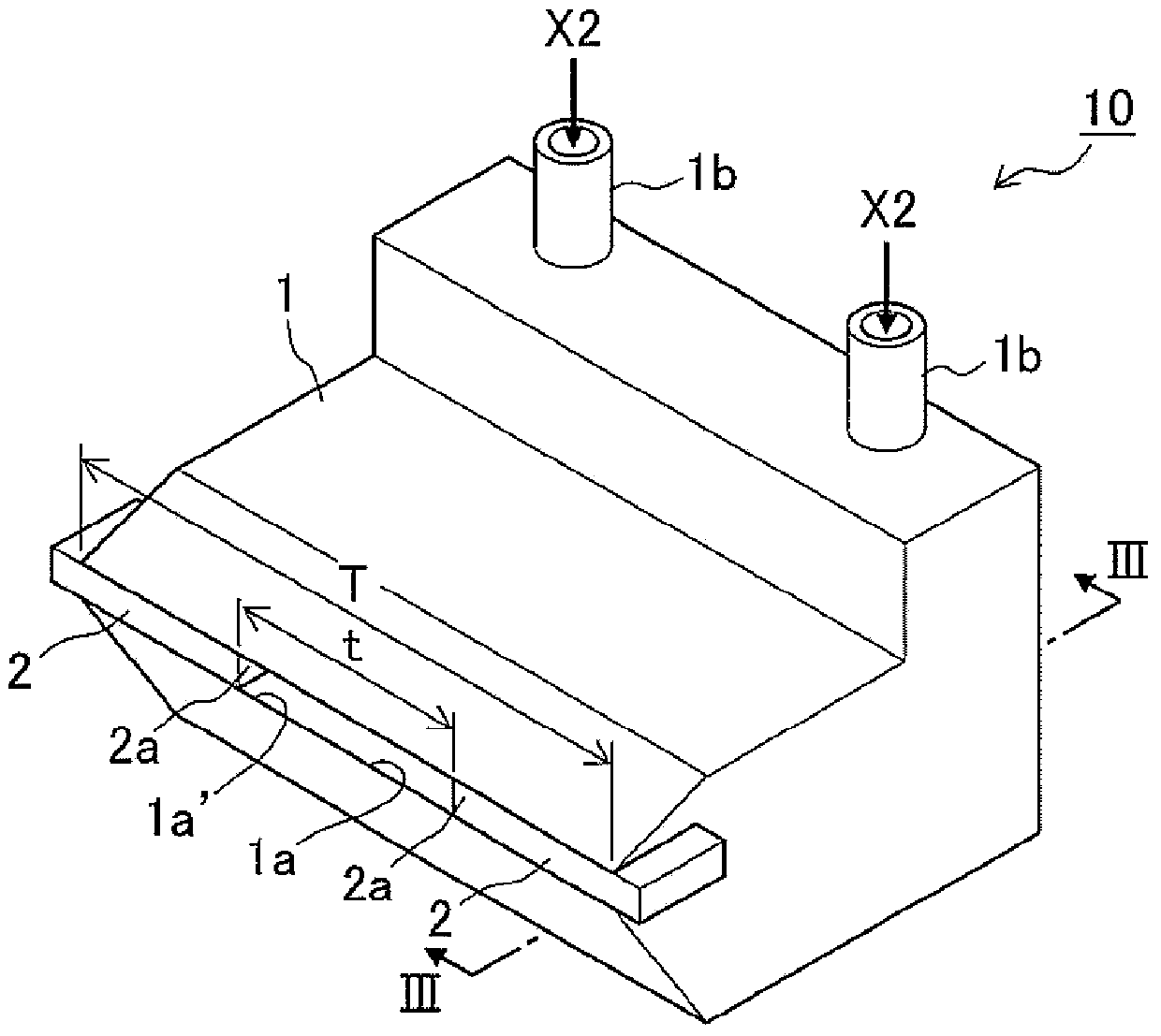

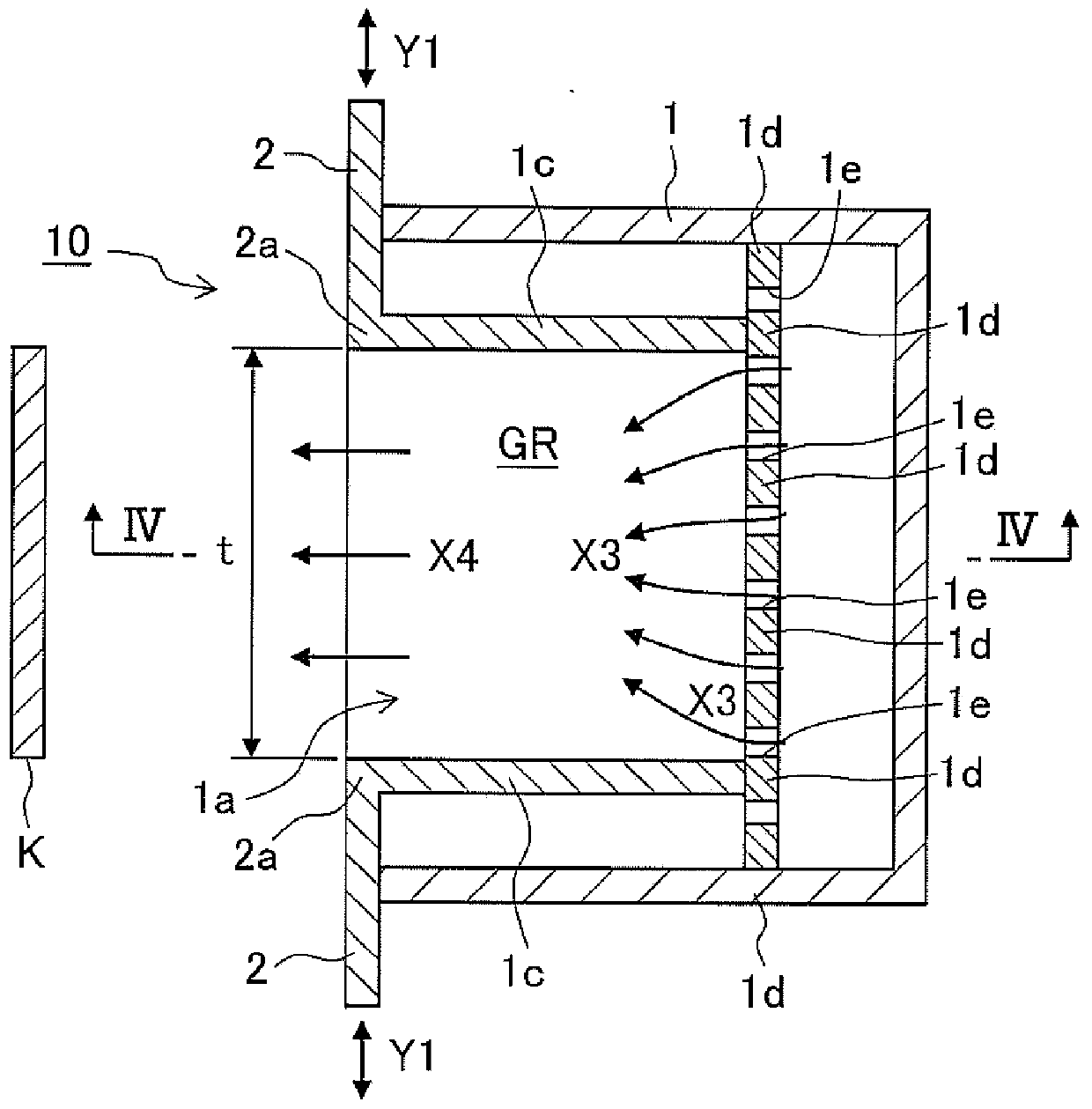

Gas wiping device

This invention relates to a gas wiping device provided with a gas wiping nozzle which sprays a gas onto the surface of the steel strip to adjust the amount of a molten metal for plating which adheres to said surface, said gas wiping device having excellent overcoat and splash suppression at the ends of the steel strip in the width direction. This gas wiping device (10) is provided in a gas wiping nozzle (1) with a slit (1a') which extends in the width direction of a steel strip (K) and sprays a gas from a hollow space, and with gas inlets (1e) for introducing the gas into the hollow space; in the slit (1a') are provided left and right blocking members (2, 2) which freely slide and block the left and right regions of said slit, and a gas outlet port (1a) is formed between the left and right blocking members (2, 2); in the hollow space are provided left and right rectifier pieces (1c, 1c) which extend from the outlet port-side ends (2a, 2a) of the left and right blocking members (2, 2) to a partition wall (1d), forming a gas flow path (GR) between the left and right rectifier pieces (1c, 1c), wherein the width of the gas outlet port (1a) and the width of the gas flow path (GR) are the same.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

Ink Jet Recording Device

An ink jet recording device comprises a main body equipped with an ink container, an ink supply pump ink, an ink recovery pump, and a control unit. A printing head equipped with a nozzle emits ink supplied from the main body as ink particles. An electrification electrode electrifies the ink particles and a deflection electrode deflects the electrified ink particles. A gutter collects ink particles which are not used for printing. An exhaust circulation path connects the ink container and the gutter. The gutter comprises two members of an ink flow path block in which ink flows and an exhaust flow path block in which exhaust solvent vapor flows.

Owner:HITACHI IND EQUIP SYST CO LTD

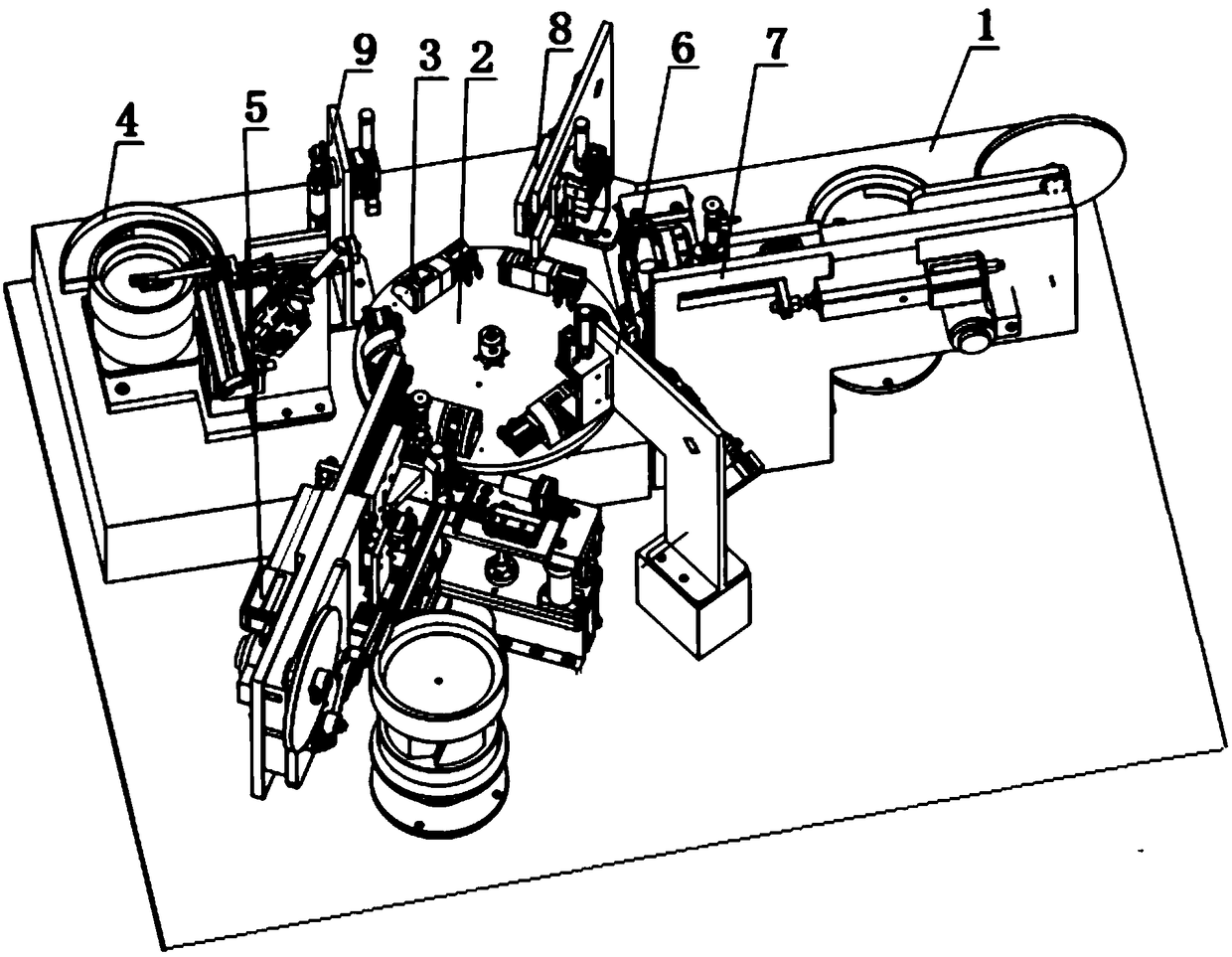

Fully-automatic welding equipment for double-breaking-point electrical system

ActiveCN108907530AExtend your lifeEliminate positioningWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentWeld strength

The invention discloses fully-automatic welding equipment for a double-breaking-point electrical system. The fully-automatic welding equipment comprises a rotary plate which is arranged on a table board, wherein six locking clamps are uniformly and fixedly mounted on the upper surface of the rotary plate along the periphery; the outer sides of the periphery of the rotary plate is equipped with sixstations; the stations are equipped with mechanisms with different functions, i.e., the outer side of the station I is equipped with a double-breaking-point rack loading mechanism, the outer side ofthe station II is equipped with a loading mechanism I, the outer side of the station III is equipped with a welding mechanism I, the outer side of the station IV is equipped with a loading mechanism II, the outer side of the station V is equipped with a welding mechanism II, and the outer side of the station VI is equipped with a discharge mechanical hand; and a qualified product output rail and an unqualified product output rail are arranged beside the discharge mechanical hand. The device is compatible with automatic production of various contacts and the double-breaking-point rack, improvesthe production efficiency by 25-40 times, prolongs the service life of an electrode, improves the welding strength to be 100%, has a qualification rate of 100%, and greatly reduces the cost.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

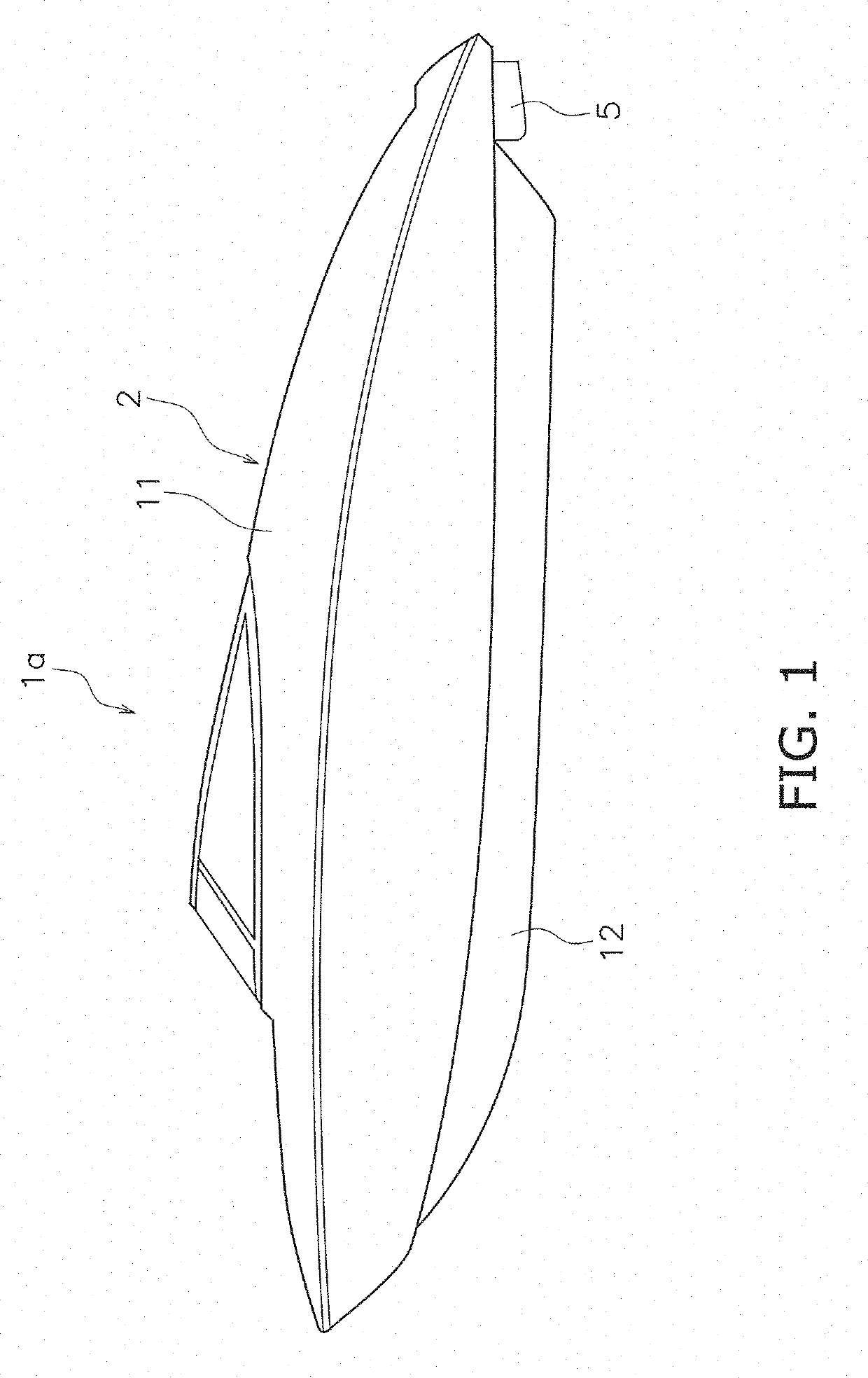

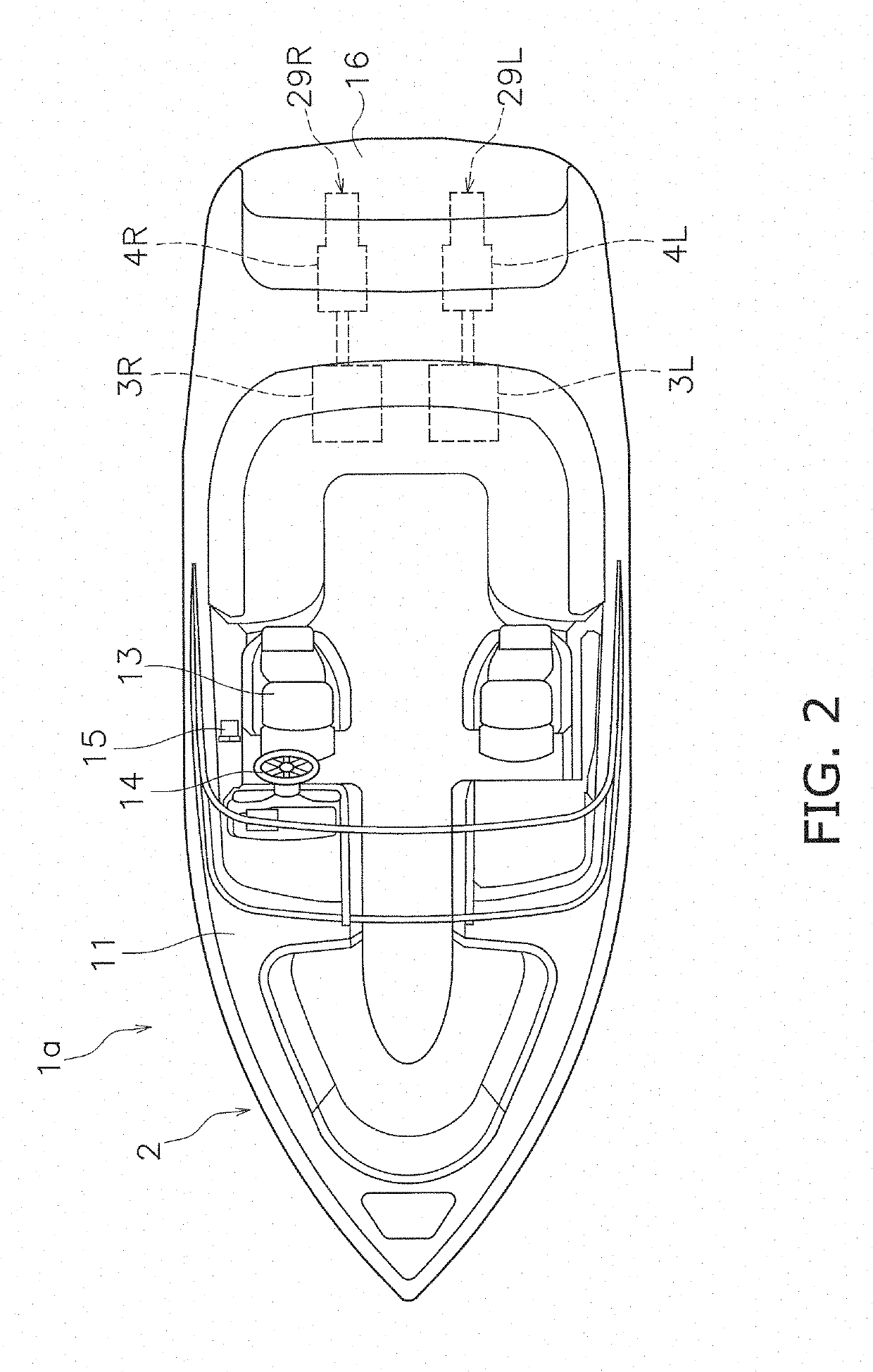

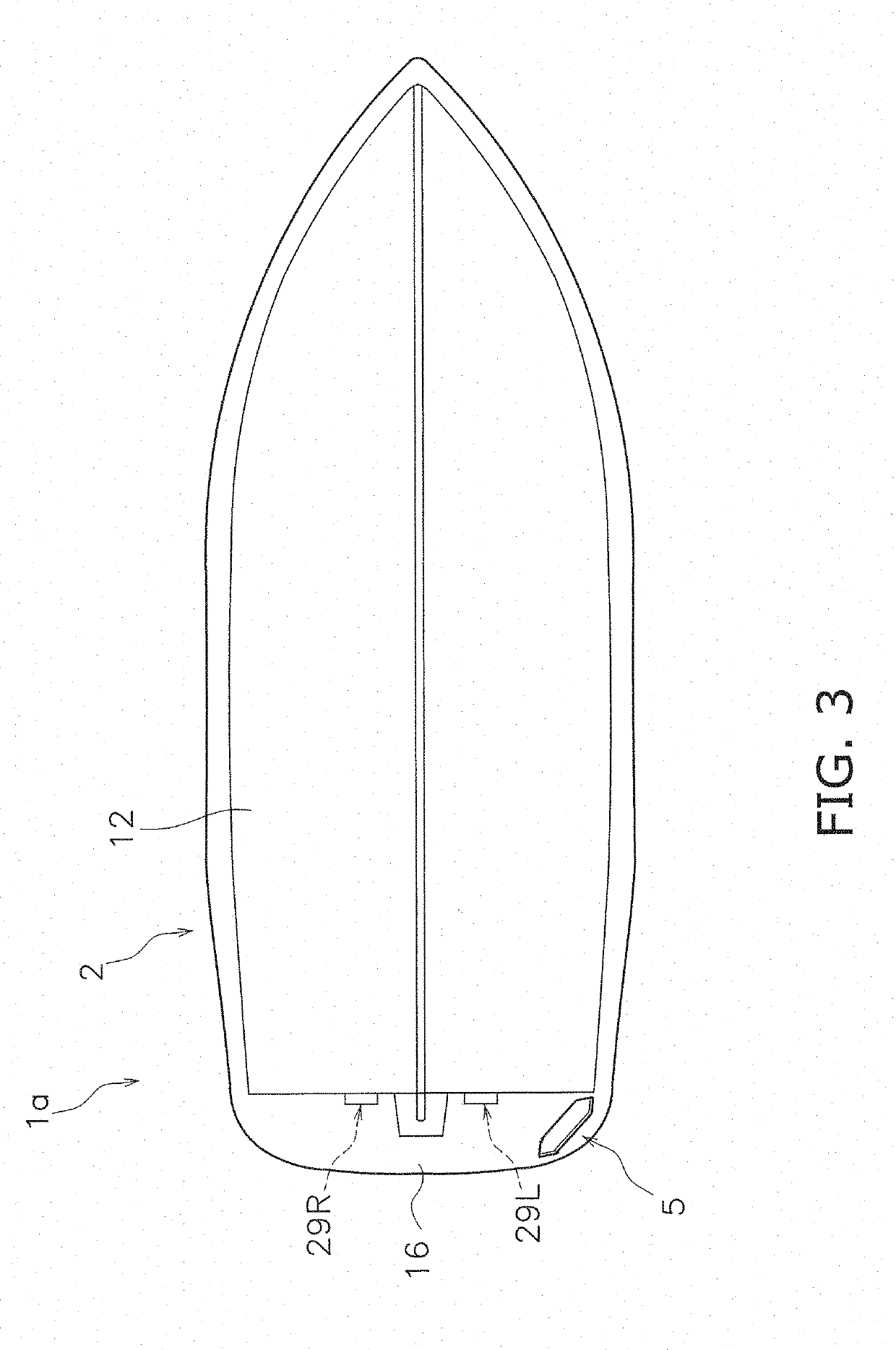

Watercraft and guide

ActiveUS20190217921A1Inhibition effectEliminate splashWave generating vesselsWater sport boardsMarine propulsionWater flow

A watercraft includes a vessel body, a marine propulsion device and a guide. The marine propulsion device is attached to the vessel body and includes a water stream generator that propels the vessel body. The guide is provided on the vessel body and extends astern of the vessel body and toward a center of the vessel body in a width direction of the vessel body from a position located sideward of the water stream generator. The guide inwardly directs water flowing on one lateral side of the vessel body such that confluent timing of the water flowing on the one lateral side of the vessel body and water flowing on the other lateral side of the vessel body is caused to occur earlier than when the guide is not provided on the vessel body.

Owner:YAMAHA MOTOR CO LTD

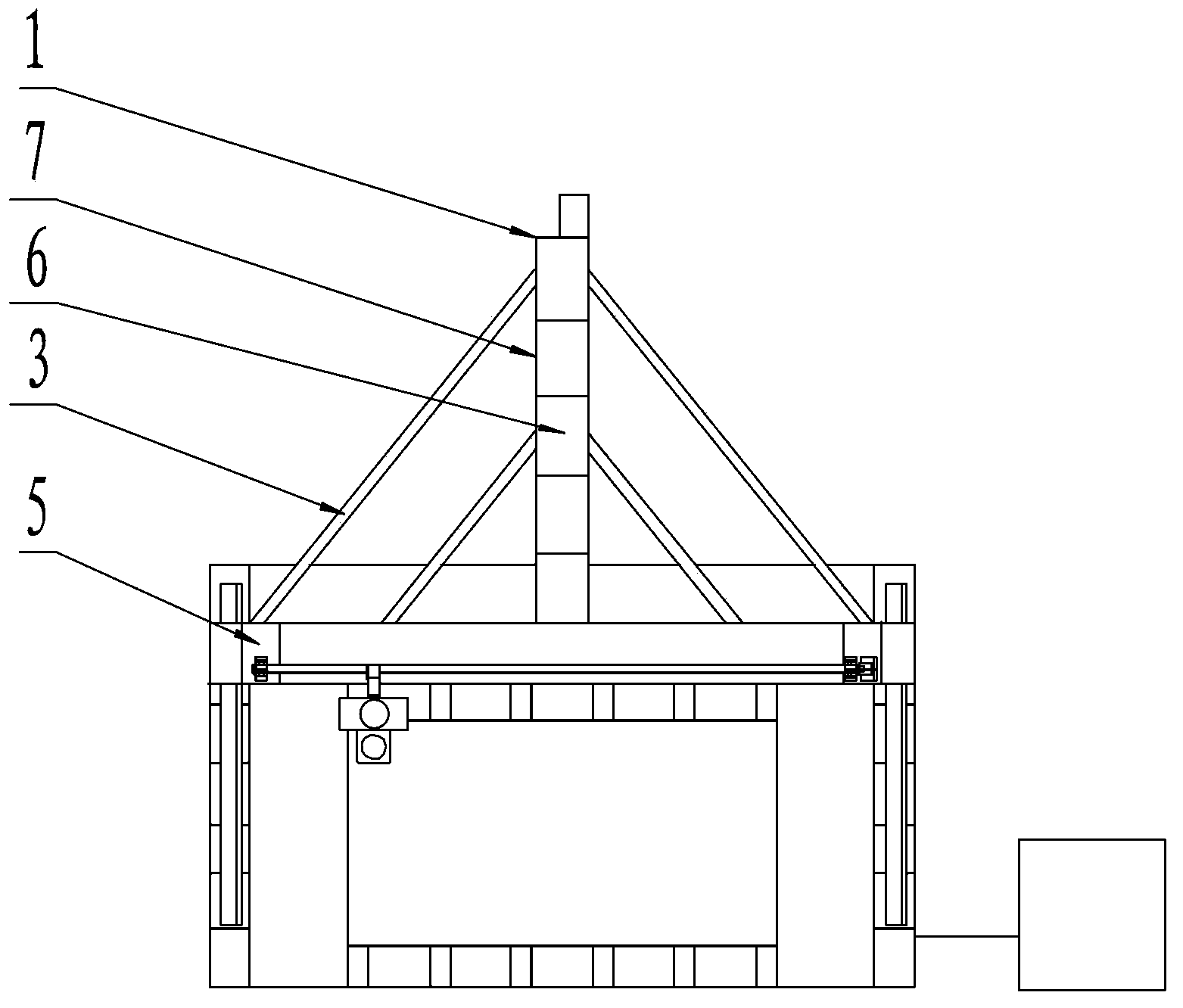

Energy-saving power generation device capable of being additionally arranged on water pipe

ActiveCN105626357APure tap waterExtended rotor lifeHydro energy generationMachines/enginesWater pipeThrough transmission

An energy-saving power generation device capable of being additionally arranged on a water pipe comprises an insulation layer arranged outside the water pipe, a pair of semi-annular magnets is arranged between the insulation layer and the water pipe, and a micro power generation device body is arranged in the water pipe; a transmission shaft of the power generation device body is in threaded connection with fan blades, the transmission shaft is connected with a rotor through a shaft sleeve, an electric brush is arranged on the rotor, and the rotor and the electric brush are connected with a rotor supporting shaft sleeve through a connecting fixed support; the rotor supporting shaft sleeve is in threaded connection with a copper sheet contact, two wires are connected to the copper sheet contact, and the other ends of the two wires are connected with a storage battery through transmission openings; the shaft sleeve is in threaded connection with a shaft sleeve fixing support, and the shaft sleeve fixing support is connected with turbofan sleeves through pins; and water drives the fan blades to rotate while the water flows out, and the fan blades transmit power to a transmission shaft, so that the electric brush cuts a magnetic induction line generated by a large external magnet, and currents are generated; and the currents are stored in the storage battery through the wires, and the device has the beneficial effects of being simple in structure, environment-friendly, convenient to use and user-friendly in operation.

Owner:SHAANXI UNIV OF SCI & TECH

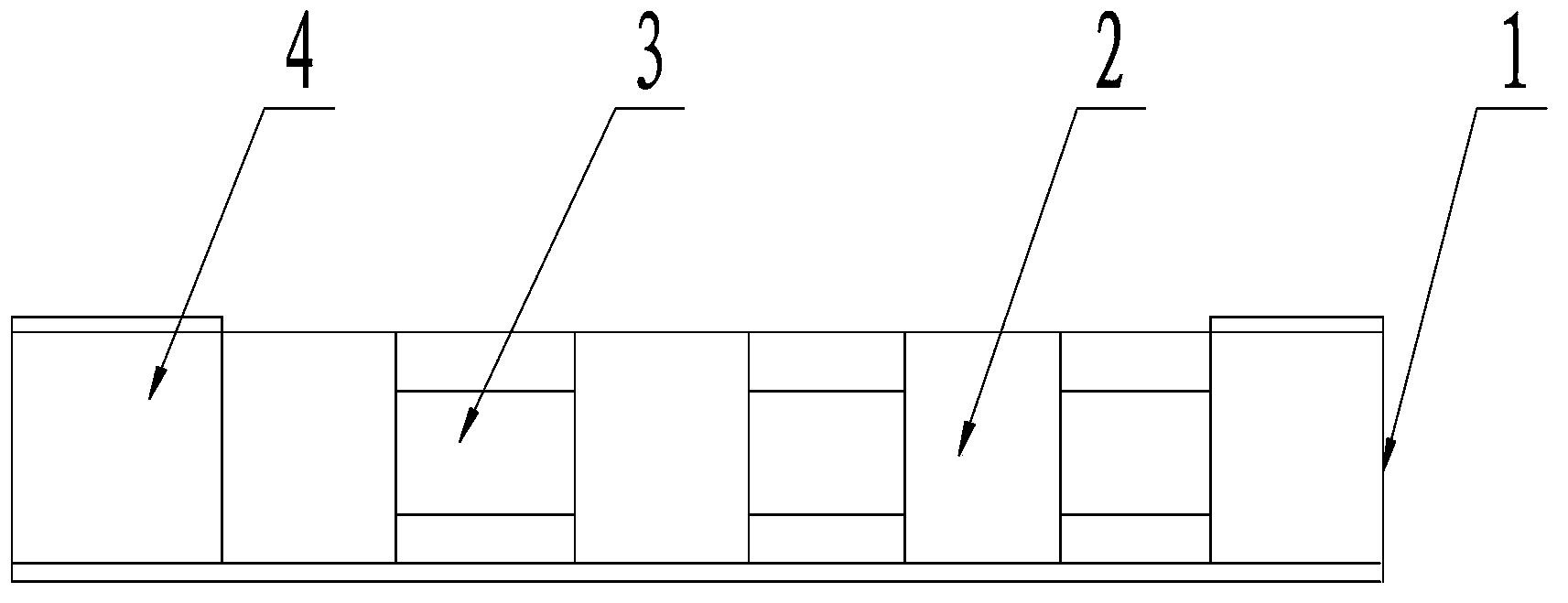

Method for welding T-shaped movable beam for deformed glass machining system

InactiveCN103358037AGuaranteed uptimeGood synchronizationWelding apparatusElectrical resistance and conductanceEngineering

The invention discloses a method for welding a T-shaped movable beam for a deformed glass machining system. The T-shaped movable beam consists of a longitudinal stepping / servo mechanism longitudinal beam, a rib plate, channel steel, a square pipe, a longitudinal stepping / servo mechanism transverse beam, a bottom plate and a vertical plate, and is characterized in that the rib plate, the channel steel, the square pipe, the bottom plate and the vertical plate are 10-15 millimeters in thickness. Automatic rotary welding equipment is adopted, electric resistance welding and carbon dioxide gas protection dual-gun balanced welding are adopted for welding, the welding way of the electric resistance welding includes point welding and backing welding, and the welding way of the carbon dioxide gas protection dual-gun balanced welding includes transverse welding and flat welding, so that the T-shaped movable beam has the advantages of high welding speed, no air hole in welding lines, small bevel angle, high quality, reliable performance and high mechanical performance of joints, and horizontal accuracies of upper and lower horizontal planes are ensured; and when the deformed glass machining system runs, the T-shaped movable beam has ideal synchronizing performance, is firm and highly rigid in structure, runs more stably, and can bear large-torque grinding without being deformed.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com