Gas wiping device

A gas and gas flow path technology, which is applied in metal material coating process, hot-dip plating process, coating, etc., can solve problems such as disturbing gas flow, achieve the effect of eliminating over-coating or splashing, and simple structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

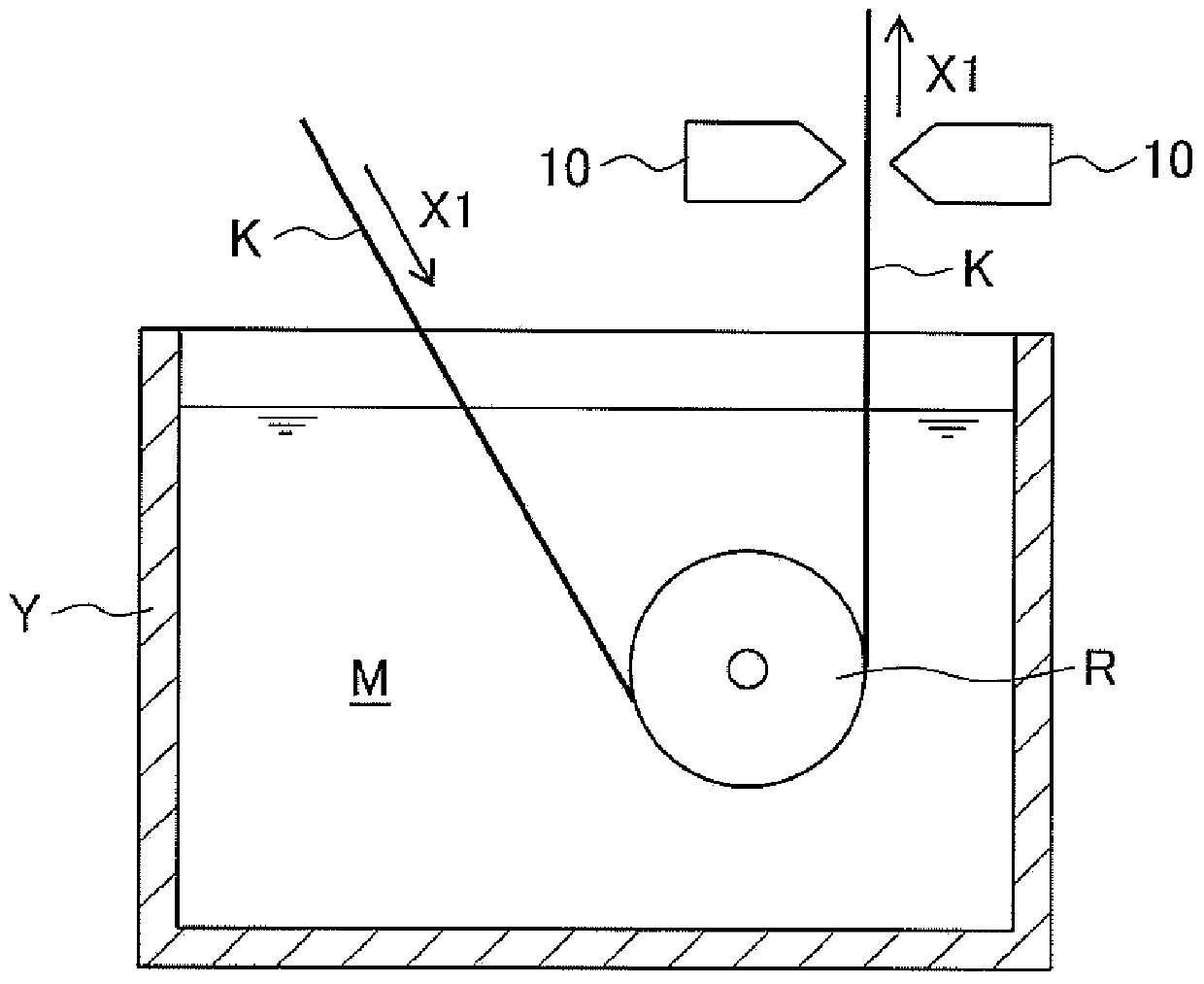

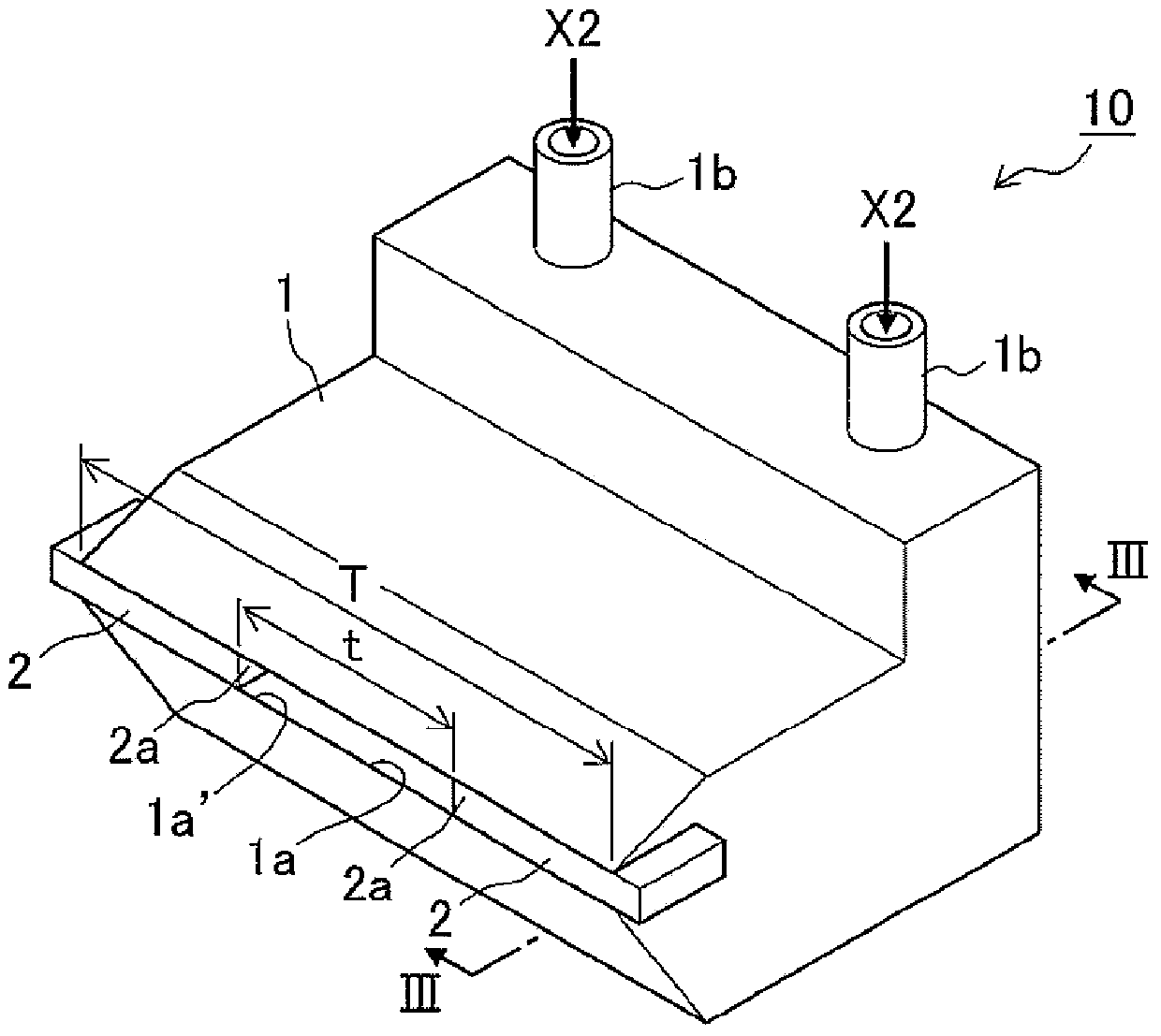

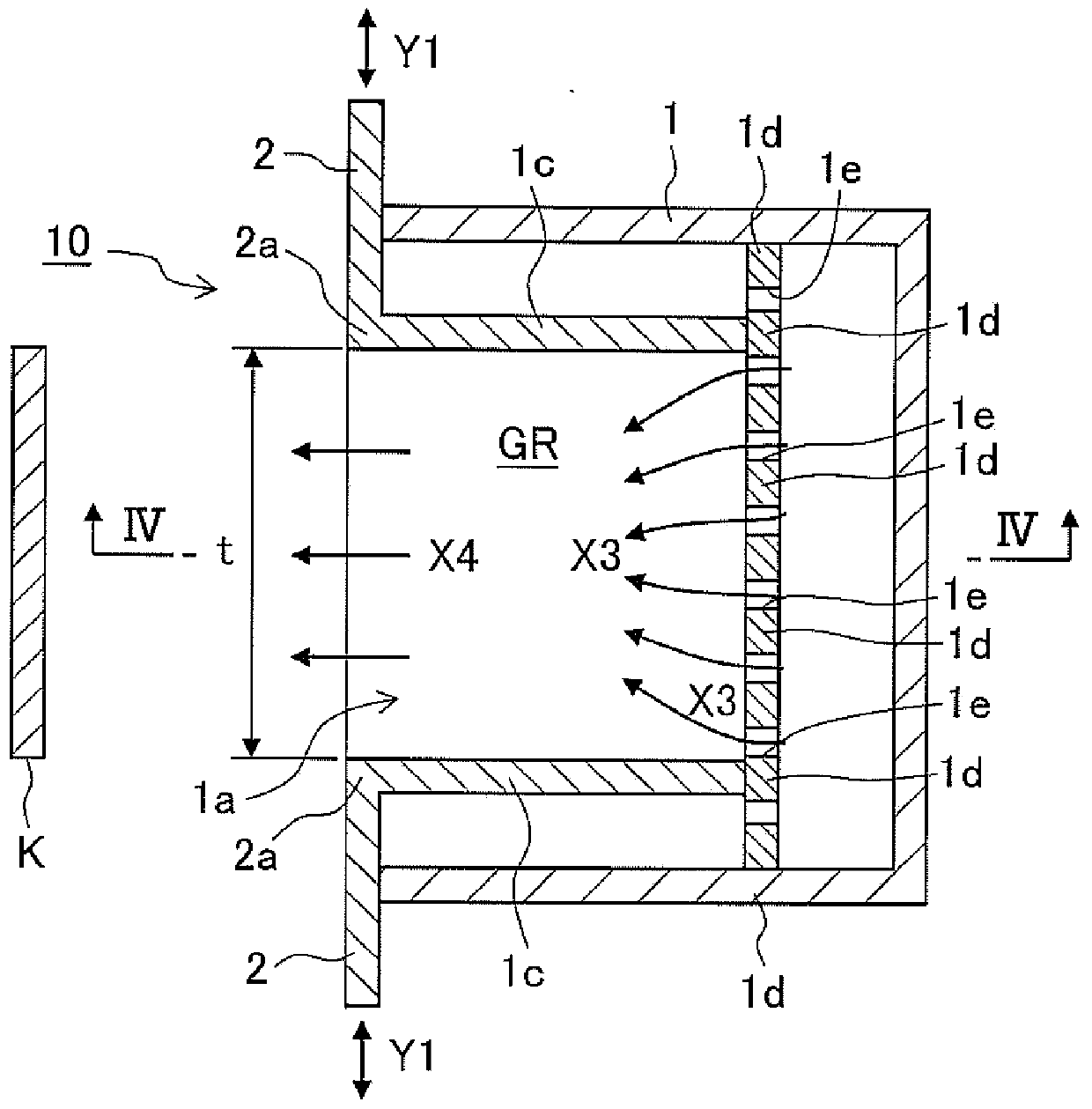

[0053] figure 2 It is a three-dimensional representation of the composition figure 1 A diagram of an embodiment of the gas wiping device of the electroplating device, image 3 yes figure 2 III-III direction view, Figure 4 yes image 3 IV-IV direction view.

[0054] Figure 2 ~ Figure 4 The gas wiping device 10 shown in is roughly composed of a gas wiping nozzle 1 having a cavity, and a gas (not shown) that is provided behind and supplies gas to a gas inflow pipe 1b that supplies gas to the cavity of the gas wiping nozzle 1. Supply device (gas supply source) configuration.

[0055] Furthermore, the gas wiping nozzle 1 has a slit 1a' (its overall width is T) extending along the width direction of the steel strip K and blowing gas from its cavity. And the left and right closing members 2, 2 are slidable (Y1 direction) along the gap 1a', and the gas outlet 1a is formed in the gap region between the separated left and right closing members 2, 2.

[0056] A gas inflow pi...

Embodiment approach 2)

[0064] Figure 5 is a cross-sectional view of another embodiment of the gas wiping device, based on the image 3 The graph corresponding to the representation of the form, Figure 6 yes Figure 5 The VI-VI direction view.

[0065] In the gas wiping device 10A shown in the figure, in the gas flow path GR, a hanging piece 3a that does not reach the lower surface is fixed on the upper surface of the cavity, and a hanging piece 3a that does not reach the upper surface is fixed on the lower surface of the cavity at a position away from the hanging piece 3a. The gas introduced into the gas channel GR from the gas inlet 1e is rectified during the process (X3') of flowing through these hanging pieces 3a and the vertical pieces 3b.

[0066] The other ends of the left and right rectifying pieces 1c, 1c are located in front of the standing piece 3b or the hanging piece 3a, and slide in front of the standing piece 3b and the hanging piece 3a according to the width change of the gas out...

Embodiment approach 1)

[0070] Next, refer to Figure 7 , Embodiment 1 of the sliding mechanism of the left and right blocking members will be described by taking the gas wiping device 10 as an example.

[0071]In the sliding mechanism shown in the figure, the left and right blocking members 2, 2 are slidable to the left and right by the inherent left sliding mechanism 5A and right sliding mechanism 5B, respectively, and the left sliding mechanism 5A and the right sliding mechanism 5B are mounted on the common base 6. , the common base 6 is connected with the base sliding mechanism 7 so as to slide freely.

[0072] The left blocking member 2 and the electric slider constituting the left sliding mechanism 5A are connected by two wires W1, W1 via a pulley 9 to form a roughly ring shape, whereby when the left sliding mechanism 5A slides left and right (Z1 direction), the left blocking member 2 also slides freely to the left and right synchronously (Z1' direction). Similarly, the right blocking part 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com