Silicon wafer and wet etching system

A wet etching, silicon wafer technology, used in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as poor appearance of solar cells, damage to diffusion surfaces, and unstable exhaust air, achieving increased Effective light-receiving area, improving photoelectric conversion rate, and eliminating redundant etched areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Install a constant pressure tank on the RENA equipment, and connect a separate water pipe to the constant pressure tank on the original pure water main road;

[0031] 2. Install eight drip boxes above the etching section of the RENA equipment, connect the eight water outlets of the constant pressure tank to the drip boxes, and the eight drip boxes are divided into eight channels; install sensors in charge of eight channels above the driving roller of the feeding table, Add an encoder to the equipment transmission system to measure the transmission speed;

[0032] 3. Install a PP electrical box near the feeding end on the side of the equipment, and install an independent PLC inside the electrical box to form a water film spray system.

[0033] The above water film sprinkler system is a control system independent of RENA equipment. When the sensor detects that the silicon wafer to be etched enters the loading table, it sends a signal to the PLC, and the PLC performs d...

Embodiment 2

[0035] 1. Install a constant pressure tank on the RENA equipment, and connect a separate water pipe to the constant pressure tank on the original pure water main road;

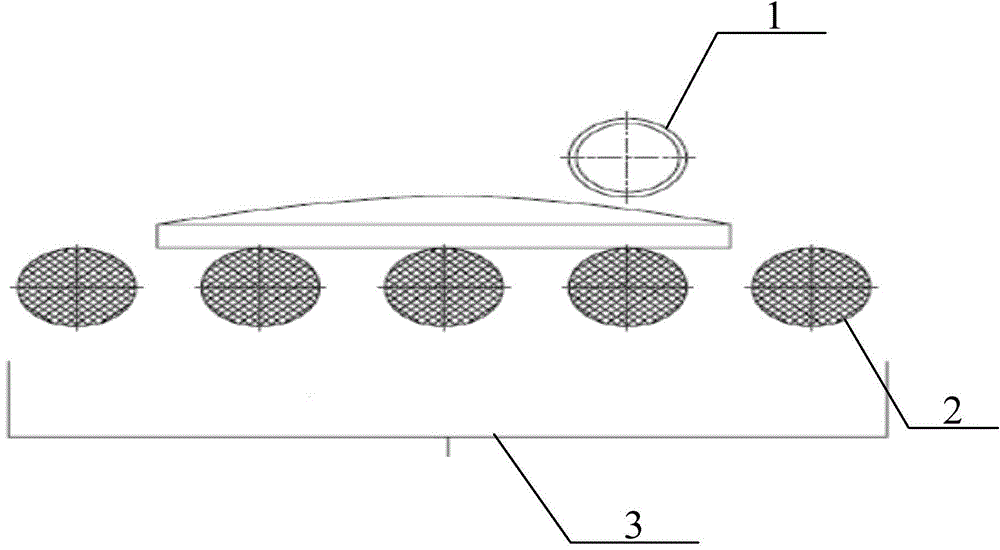

[0036] 2. Install eight drip boxes above the etching section of the RENA equipment, connect the eight water outlets of the constant pressure tank to the drip boxes, and the eight drip boxes are divided into eight channels; install sensors in charge of eight channels above the driving roller of the feeding table, An encoder is added to the equipment transmission system to measure the transmission speed; a pressure roller is installed on the feeding table corresponding to the drip box to make it roll the water film dripping on the surface of the silicon wafer to make it more uniform, and at the same time A diversion box is added to the lower part of the pressure water roller to discharge the squeezed water film; figure 2 as shown, figure 2 Schematic diagram of the structure of the pressurized rollers added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com